Microorganism desulfurizing and sulfur recycling method

A sulfur recovery and microbial technology, which is applied in the field of microbial desulfurization, sulfur recovery and microbial desulfurization, can solve the problems of poor stability of desulfurization efficiency, low desulfurization efficiency, high energy consumption, etc., and achieve the promotion of benign development, low operating cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

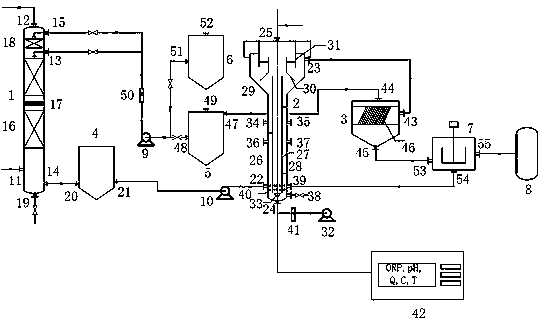

[0034] Example 1: Immobilized Thiobacillus Process

[0035] Take Na 2 S 2 o 3 5~10g / L, KNO 3 5~10g / L, NaHCO 3 2g / L, KH 2 PO 4 Cultivate 0.1g / L medium at 30oC for 2 days, and at the same time moderately aerate every 4 hours to expand the cultivation of the thiobacteria group, and then put 0.5% biological ceramsite as the carrier to make the thiobacteria group adhere and immobilize on the carrier, continue The above culture was carried out for 6-8 days, so that a large number of thiobacteria were attached to the carrier, and the attached biomass was weighed to be 1.263 mg / g, and the immobilization process was completed.

Embodiment 2

[0036] Embodiment 2 gas biological desulfurization process

[0037] Simulated hydrogen sulfide-containing gas content (v / v): 4%H 2 S, 96%N 2 .

[0038] Take Na 2 CO 3 / NaHCO 3 The solution is an absorbing liquid, and Na is added at the same time 2 S 2 o 3 8g / L, KNO 3 5g / L, NaHCO 3 2g / L, KH 2 PO 4 0.1g / L is the nutrient solution, the pH value of the circulating liquid is adjusted to 9.0, and 30ppm sodium dodecylbenzenesulfonate is added as the sulfur modifier. When the reaction temperature is 30oC and the gas-liquid ratio of the absorption tower is 10:1, When the ORP value in the bioreactor is -340mV, the conductivity of the circulating fluid is 40mS / cm, the desulfurization rate is 99.8%, and the sulfur recovery rate is 98.2%.

Embodiment 2-1

[0039] Example 2-1 Gas Biological Desulfurization Process

[0040] Simulated hydrogen sulfide-containing gas content (v / v): 4%H 2 S, 96%N 2 .

[0041] Take Na 2 CO 3 / NaHCO 3 The solution is an absorbing liquid, and Na is added at the same time 2 S 2 o 3 8g / L, KNO 3 5g / L, NaHCO 3 2g / L, KH 2 PO 4 0.1g / L is the nutrient solution, and the pH value of the circulating liquid is adjusted to be 8.0. Adding 10ppm of sodium dodecylbenzenesulfonate is the sulfur modifier. When the reaction temperature is 25oC and the gas-liquid ratio of the absorption tower is 50:1, When the ORP value in the bioreactor is -300mV, the conductivity of the circulating fluid is 30mS / cm, the desulfurization rate is 92.1%, and the sulfur recovery rate is 93.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com