Patents

Literature

69results about How to "Improve fluidization state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

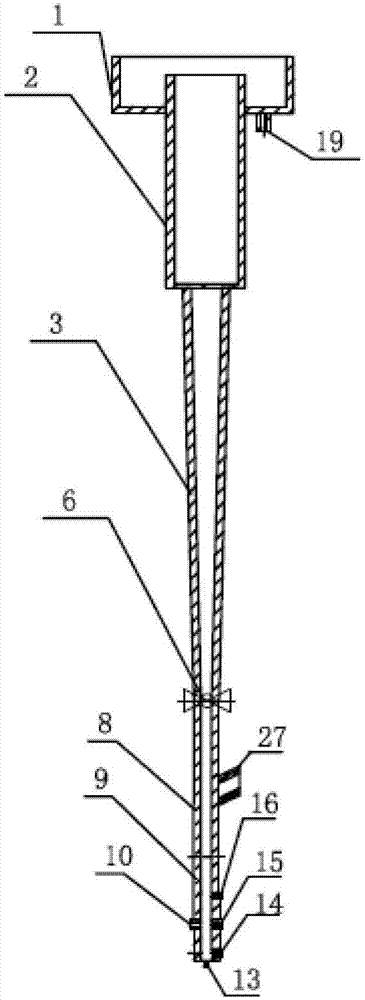

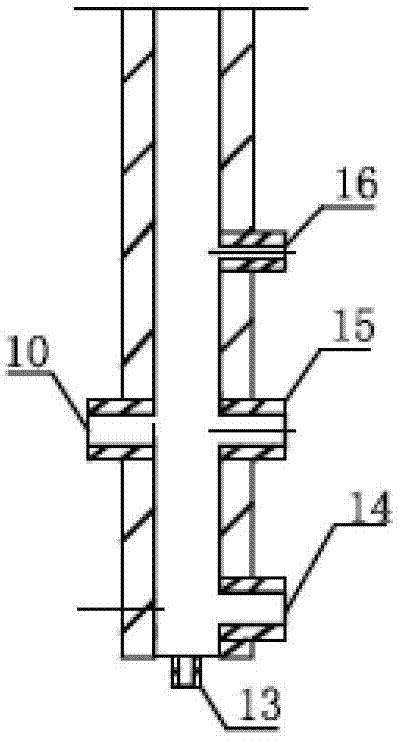

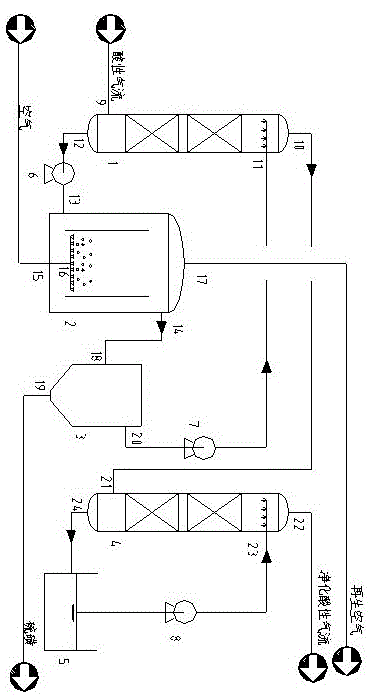

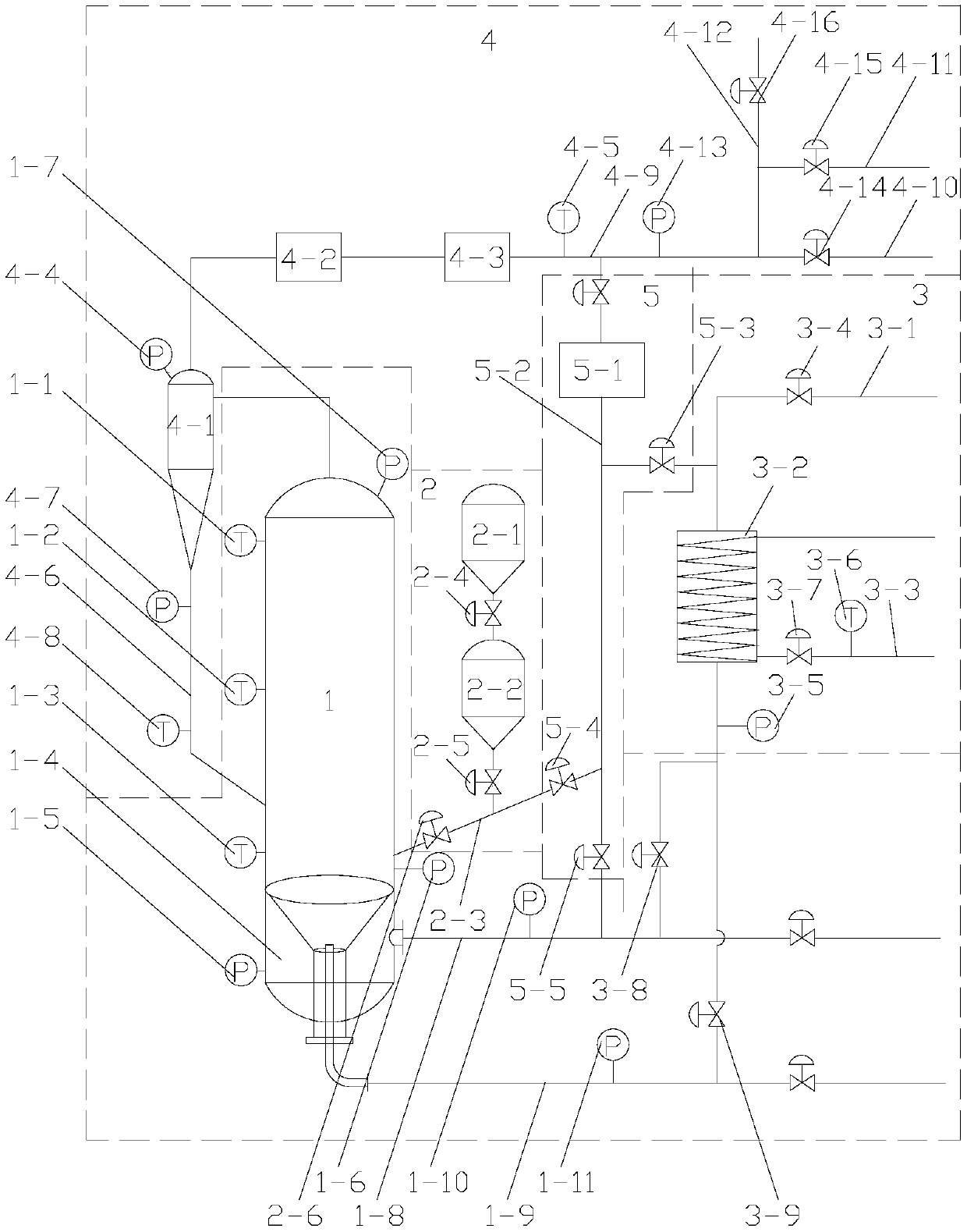

Microorganism desulfurizing and sulfur recycling method

InactiveCN105498470AAvoid cloggingReduce energy consumptionChemical industryDispersed particle separationMicroorganismAbsorption column

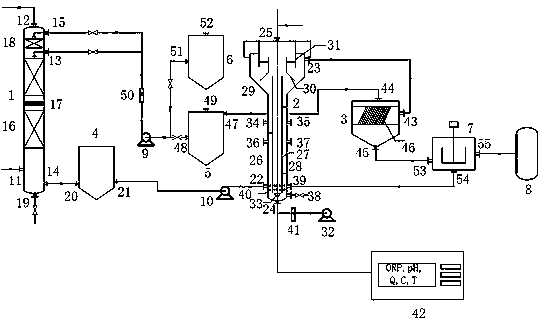

A microorganism desulfurizing and sulfur recycling method. A gas material flow containing hydrogen sulfide is fed into an absorption column and then is subjected to chemical absorption with an alkali solution sprayed from the top of the column in a counter-contact manner, wherein treated purified gas is discharged out from the top of the absorption column. A back-washing apparatus is arranged in the absorption column to wash the sulfur attached to a filling material. A rich solution, in which the hydrogen sulfide is dissolved, is fed into a rich solution tank from the bottom of the absorption column and then is fed into a bio-reactor for aeration, so that a carrier, on which desulfurization bacteria is immobilized, is fluidized and the sulfide in the absorption solution is biologically oxidized to generate elementary sulfur. The regenerated solution containing the sulfur then is fed into a settling tank through an overflow weir of the bio-reactor and a supernatant liquid is fed into a barren solution tank. The supernatant liquid then is fed back to the absorption column for being recycled through a barren solution pump. Sulfur slurry in the bottom layer is discharged through the bottom of the settling tank and then is subjected to solid-liquid separation in a centrifugal machine to obtain biological sulfur. A separated filtrate is fed back to the bio-reactor for being recycled. The bio-desulfurization technology is green and environment-friendly, is energy-saving and emission-reducing and can recycle resources, and has social, economical and environmental benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application of nitrifying bacteria immobilized bioactive filler based on polyurethane carrier

InactiveCN103951039AImprove the living environmentStable living environmentSustainable biological treatmentBiological water/sewage treatmentMicroorganismStart up time

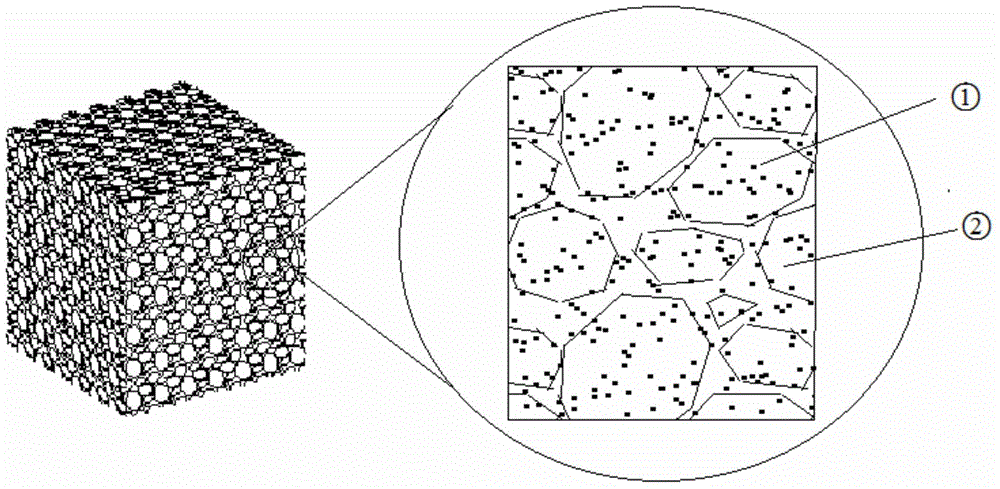

The invention discloses preparation and an application of a nitrifying bacteria immobilized bioactive filler based on a polyurethane carrier, and belongs to the technical field of water treatment. The bioactive filler comprises two parts: an embedding body and the polyurethane carrier; a porous structure of the polyurethane foam carrier can provide a quite good and relatively stable living environment for microorganisms, and is beneficial for attachment and reproduction of the microorganisms. An embedding liquid is prepared by mixing a nitrifying bacteria concentrated solution and a polyvinyl alcohol solution; a whole sheet of polyurethane foam is used as the embedding carrier, the embedding liquid is immersed to the interior of the polyurethane foam by squeezing and other ways, the embedding body is formed after boric acid secondary cross-linking and is combined with the polyurethane carrier to obtain a filler shape meeting requirements, and thus the nitrifying bacteria bioactive filler is obtained. The prepared nitrifying bacteria immobilized bioactive filler not only solves the problems that nitrifying bacteria are difficult in advantage establishment, easy to lose and the like, but also improves the processing ability of a reactor, shortens the start-up time, and has broad application prospects.

Owner:BEIJING UNIV OF TECH

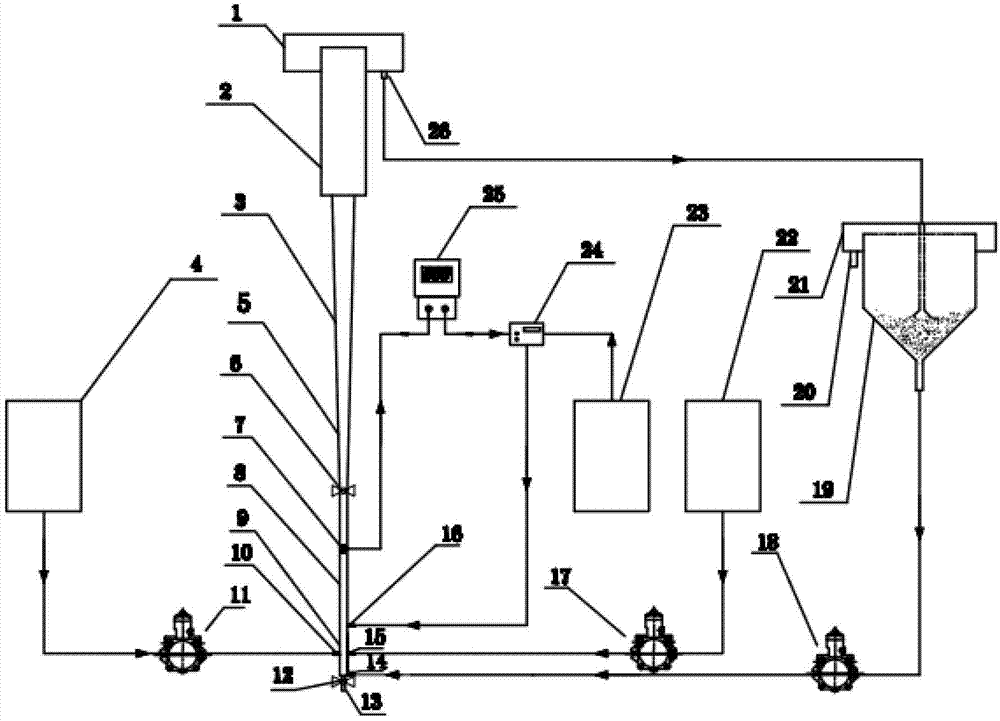

Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

InactiveCN102963970AIncreased turbulence intensityCompact structureWater/sewage treatment by flocculation/precipitationPhosphorus compoundsStruvite CrystalsSmall footprint

The invention relates to a device and a process for preparing struvite crystals from nitrogen and phosphorus in sewage. The device comprises a reactor (5), a pH (potential of Hydrogen) controller (25), a pH regulating pump (24), an alkali liquor tank (23), a nitrogen and phosphorus containing waste water tank (22) and a secondary sedimentation tank (19), wherein the reactor (5) is composed of a reactor feed pipe (9), a reactor crystal collecting pipe (8), a reactor growth tube (3) and a reactor sediment tube (2) from bottom to top. The process comprises the steps of pumping nitrogen and phosphorus containing wastewater into the reactor (5) and pumping a magnesium chloride solution into the reactor (5) to ensure that the molar ratio of NH3-N to PO43-P to Mg <2+> in the reactor (5) is (1:1:1)-(1:1:1.3); controlling the reflux ratio between 14 and 28 and the pH equal to 6.4-9.2; and forming the struvite crystals in the reactor (5) by using the nitrogen, phosphorus and magnesium containing solution. The device disclosed by the invention has the advantages of simple structure and small floor space, is simple and easy to operate and difficult to scale, can be widely applied to preparation of the struvite crystals from the nitrogen and phosphorus containing wastewater such as coking wastewater, pig manure wastewater or sludge fermentation liquor, and is capable of realizing the resource recycling of nitrogen and phosphorus.

Owner:TONGJI UNIV

Method for removing acidic gases through biological technology

ActiveCN106310890AAchieve co-removalAchieve recyclingDispersed particle separationWaste water treatment from gaseous effluentsCarbonyl sulfidePollution

The invention belongs to the field of environmentally-friendly purification, and relates to a method for removing acidic gases through a biological technology. The method is mainly used to remove acidic gas flow containing carbon dioxide, hydrogen sulfide, carbonyl sulfide, carbon disulfide and mercaptan. A chemical absorption, microbial oxidation regeneration and biotrickling filter three-tower technology is adopted, and the chemical absorption characterized in that an alkaline solution is used to absorb carbon dioxide, hydrogen sulfide and a small amount of organic sulfur which are introduced to the alkaline solution; the microbial oxidation regeneration realizes biological oxidation of sulfides into biological sulfur under aeration conditions and alkaline solution regeneration; and biotrickling filter purification of organic sulfur is used for removing carbonyl sulfide, carbon disulfide, mercaptan and other organic sulfurs. The method adopting carbon dioxide fixation, sulfur resource recovery, absorption liquid recycling and organic sulfur deodorizing purification realizes acidic gas integral treatment, and solves the environmental protection problem of acidic gas pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

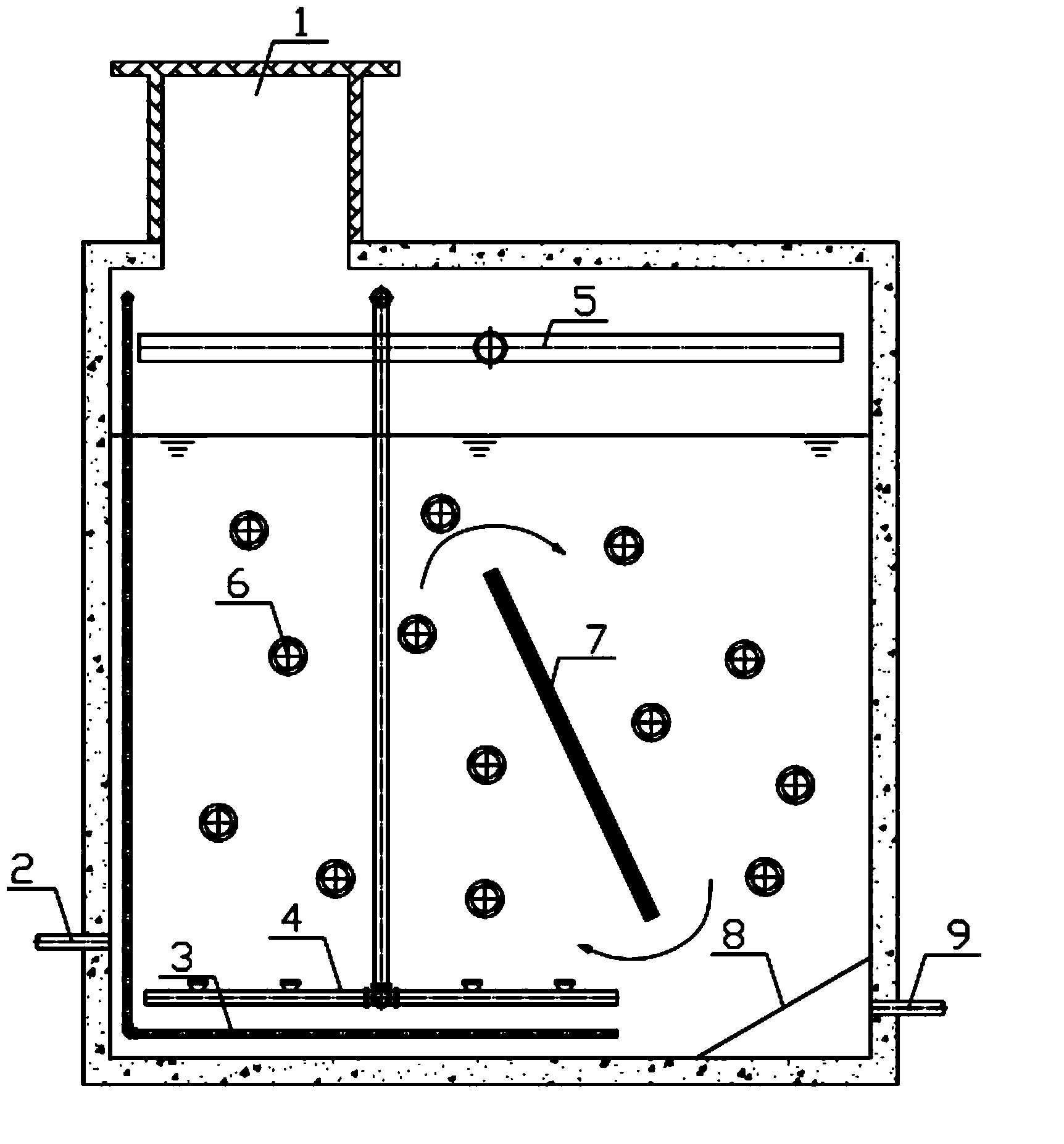

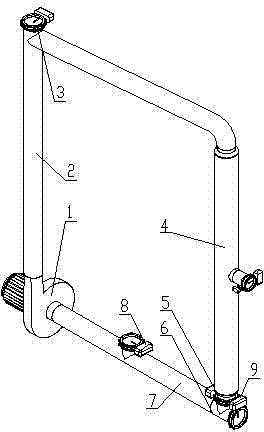

Combined aeration moving bed bio-membrane reactor

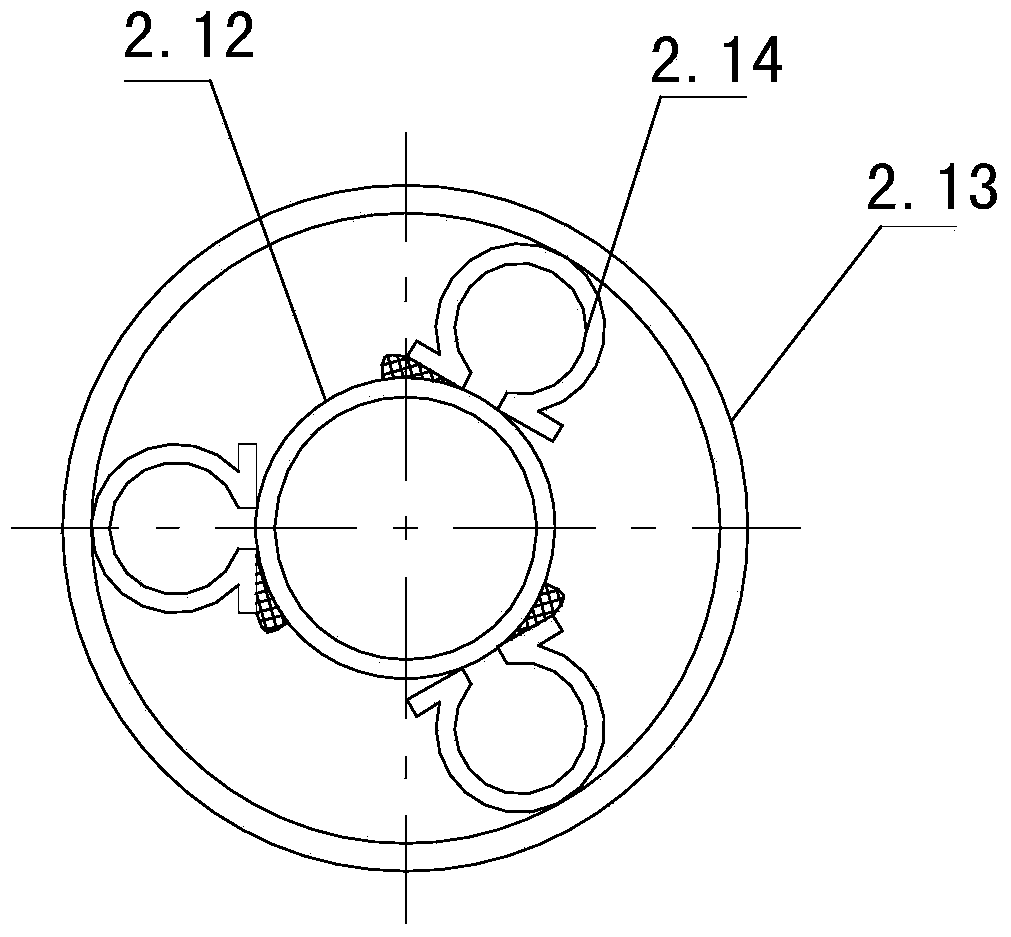

InactiveCN103466787AImprove fluidization statePrevent floatingTreatment using aerobic processesSustainable biological treatmentMoving bed biofilm reactorAeration system

The invention discloses a combined aeration moving bed bio-membrane reactor. The combined aeration moving bed bio-membrane reactor comprises a reactor main body with a manhole in one side of the top end, the side wall of the reactor main body is provided with a water inlet pipe and a water outlet pipe which are communicated with an inner cavity of the reactor main body, a circulating guide plate is arranged in the reactor main body, a perforated pipe aeration system is arranged at one side, close to the bottom end in the reactor main body, of the circulating guide plate, a micropore aeration system is arranged above the perforated pipe aeration system, and a back flush system for preventing suspended filler from floating above a liquid level in the reactor is arranged at the top in the reactor main body. On the basis of a traditional moving bio-membrane reactor, the aeration system is improved and upgraded, and the back flush system is added. By virtue of a simple pipeline system, the problems that suspended filler in a traditional moving bed bio-membrane reactor is deposited on the bottom of a pool and float upwards along a wall and that dissolved oxygen is not enough are solved, and the actual application of the moving bed bio-membrane reactor is further perfected.

Owner:西安绿标水环境科技有限公司

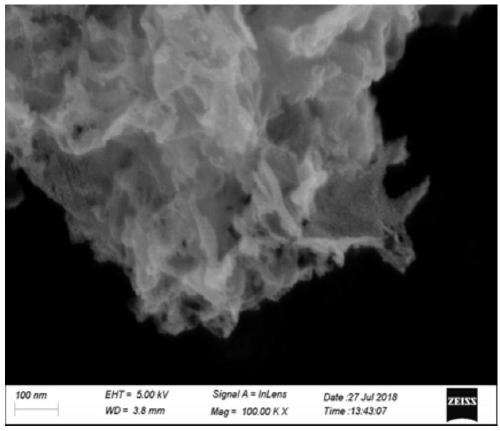

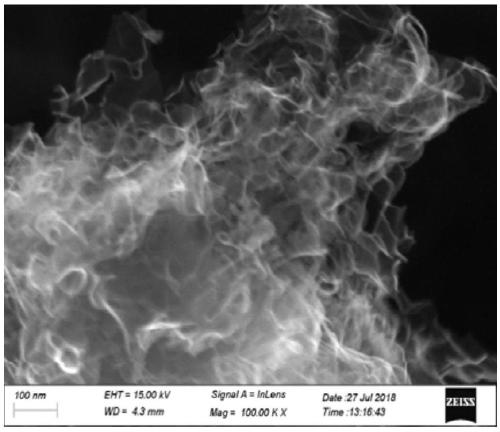

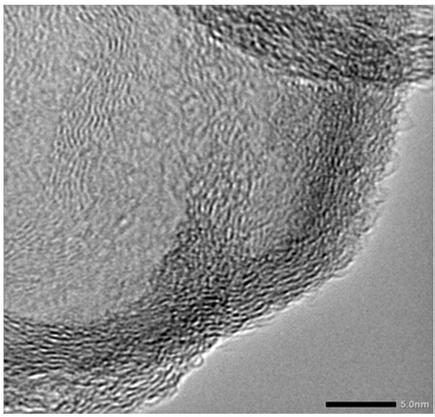

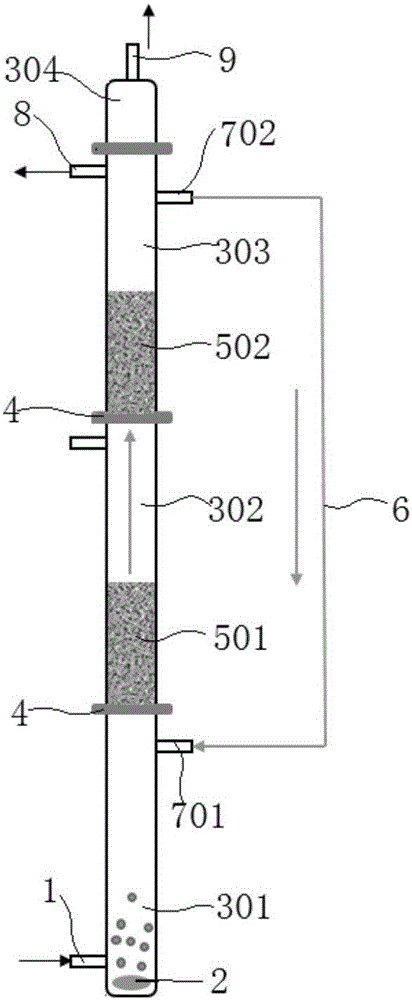

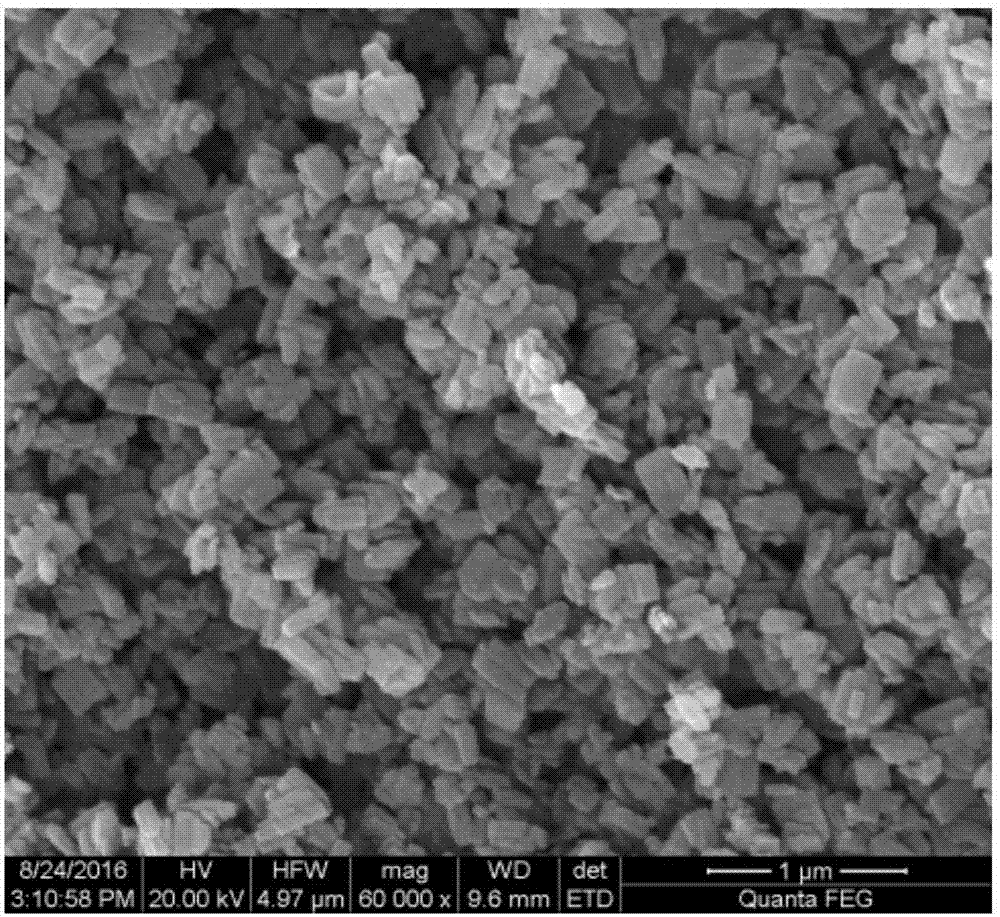

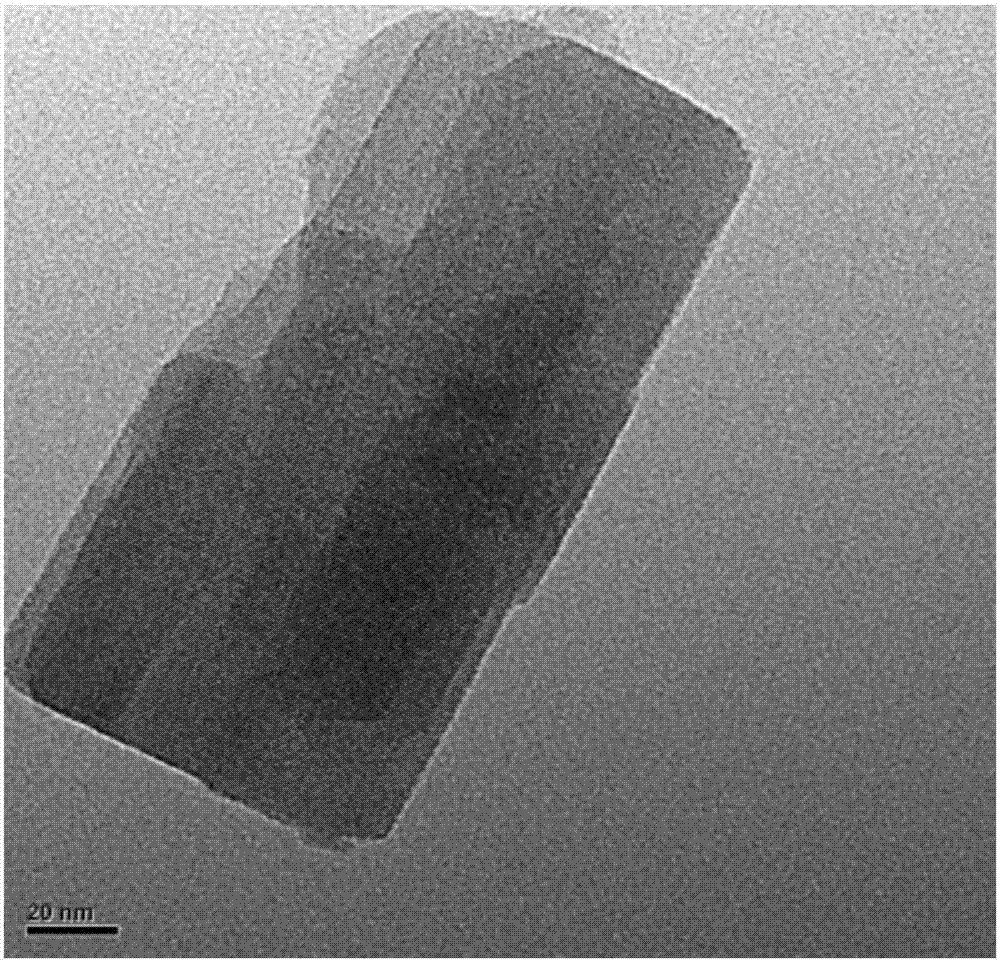

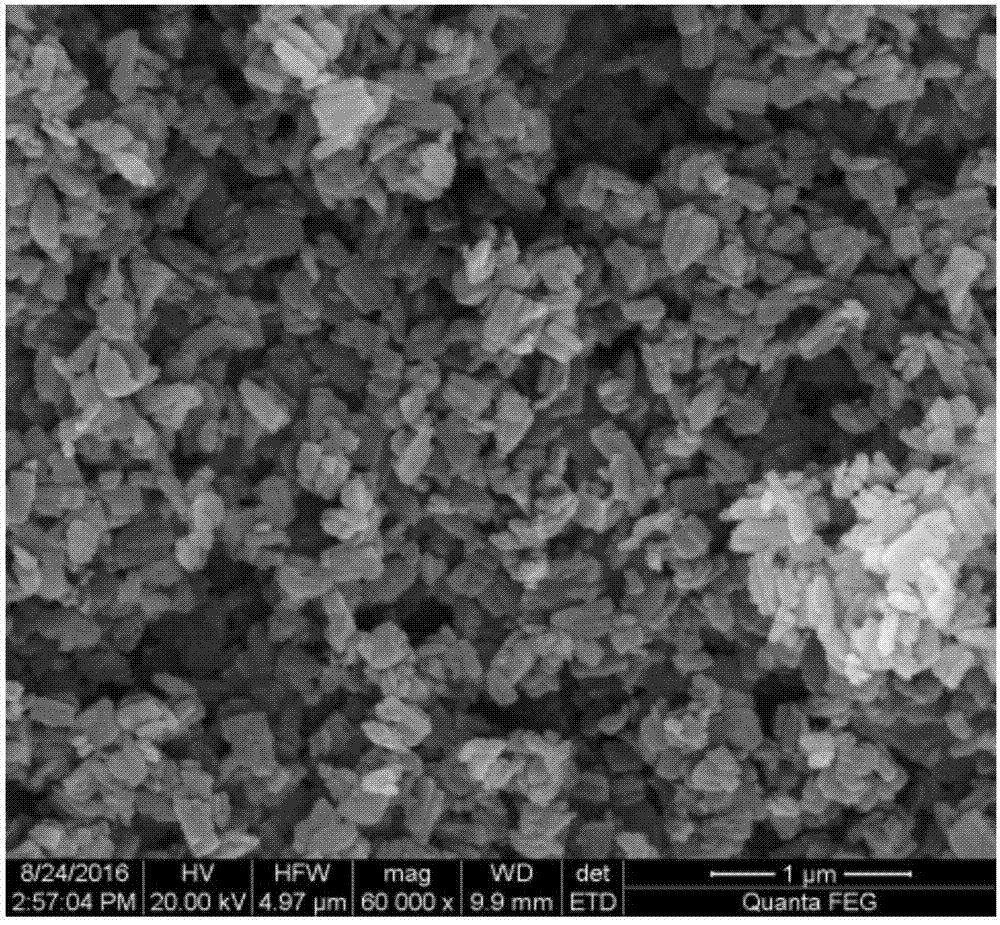

Method for controllably preparing three-dimensional nanometer porous graphene powder by chemical vapor deposition method

ActiveCN109264706AEliminate soft and hard agglomerationsImprove fluidization stateGraphenePorous grapheneGas phase

The invention discloses a method for controllably preparing a three-dimensional nanometer porous graphene powder by a chemical vapor deposition method. The method comprises the following steps of treating a solid catalyst by salt, and activating at high temperature; coating the surface of the solid powder, subjected to high-temperature activating, with a polymer, leading the solid powder, coated with the polymer, into a carbon source at high temperature, performing the chemical vapor deposition, and growing graphene; pickling, filtering, and drying, so as to obtain the three-dimensional nanometer porous graphene powder. The method has the advantages that the common core problem of particle agglomeration of a solid catalyst in a large-scale preparation process of graphene powder by the chemical vapor deposition method is solved by the surface coating of the catalyst; by adjusting the amount of the carbon source, the particle size of the solid catalyst and the amount of salt, the high-quality three-dimensional nanometer porous graphene powder can be controllably prepared; the technology process is simplified, the higher requirement preparation conditions on equipment is decreased, and the large-scale controllable preparation of the three-dimensional nanometer porous graphene powder is easy to implement.

Owner:陕西兴汉澜墨科技有限公司

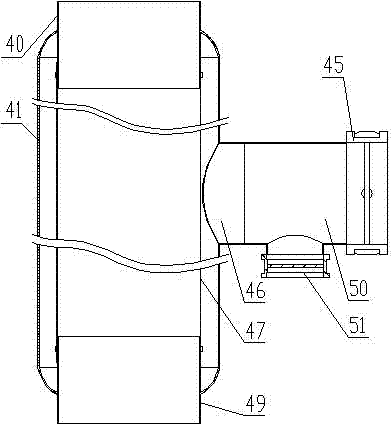

Integrated fluidized bed device for gradient ozone catalyzing and application of integrated fluidized bed device

PendingCN106630110AEasy to handleGuaranteed treatment effectWater treatment compoundsWater contaminantsRefluxFluidized bed

The invention discloses an integrated fluidized bed device for gradient ozone catalyzing and application of the integrated fluidized bed device. The integrated fluidized bed device comprises a primary reactor, a secondary reactor, a tertiary reactor and a quaternary reactor from bottom to top, a water inlet and an ozone aerating apparatus are arranged at the bottom of the primary reactor, a recycling water inlet is arranged on an upper portion of the primary reactor, a catalyzer layer and a second catalyzer layer are respectively arranged in the secondary reactor and the tertiary reactor, a water outlet and a recycling water outlet are arranged on an upper portion of the tertiary reactor, the recycling water inlet is connected with the recycling water outlet through a reflux pump and a circulating tube, and an upper cut angle is reserved between the recycling water inlet and a main reactor body. The integrated fluidized bed device for gradient ozone catalyzing has the advantages that a usage rate and a catalytic oxidation efficiency of ozone are increased, a catalytic oxidation reaction is more efficient and more thorough, a compact reaction mechanism is adopted to enable the reaction to be finished in one device, and small floor area is occupied.

Owner:NANJING UNIV +1

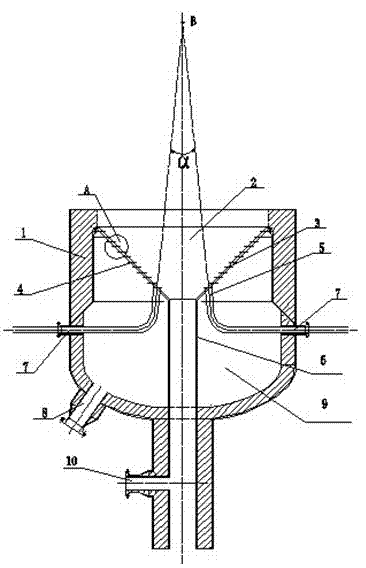

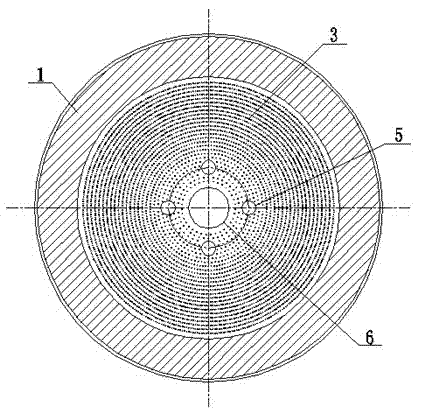

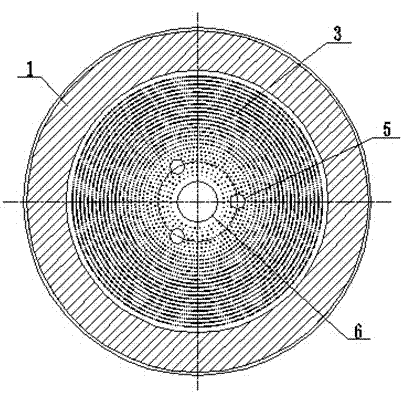

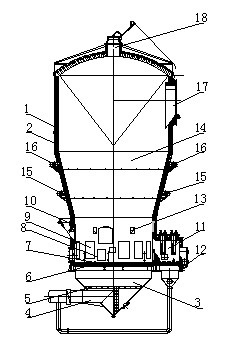

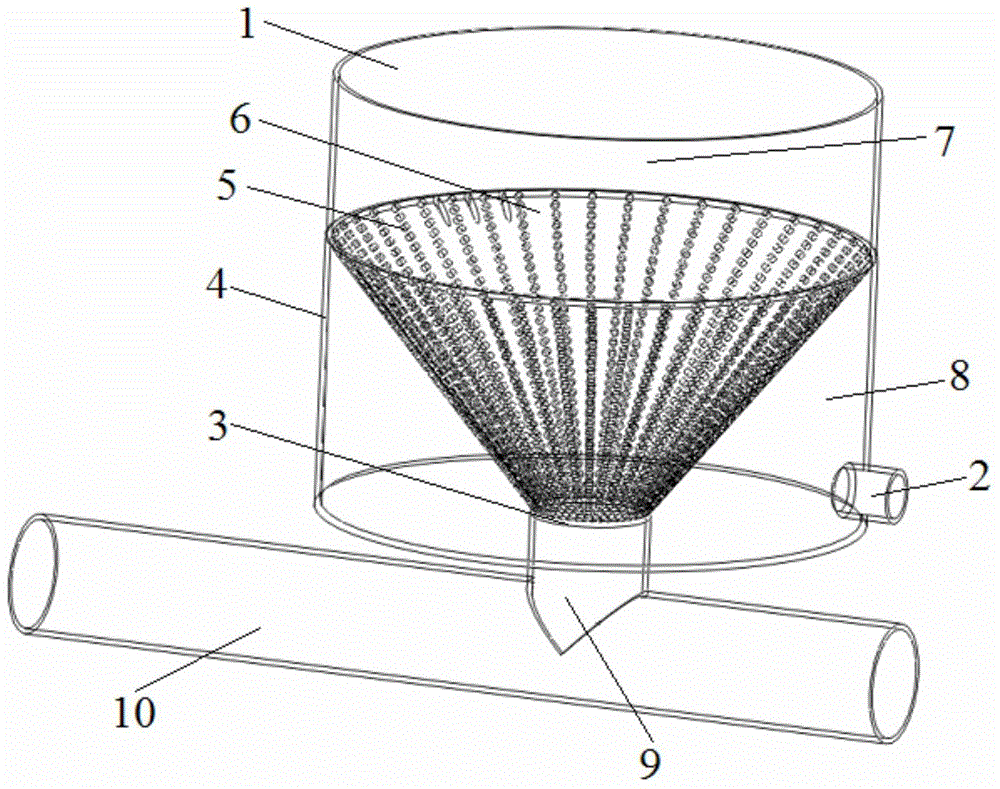

Gas distributor for ash agglomerating fluidized-bed gasification furnace

InactiveCN102827644AAvoid scour wearAvoid Vibration FractureGranular/pulverulent flues gasificationFluidized bed gasifierEngineering

The invention provides a gas distributor for an ash agglomerating fluidized-bed gasification furnace. The gas distributor comprises a gasification furnace shell, a tapered distribution plate, at least three distributed injection pipes, a slagging pipe and a gas inlet pipe of a gas chamber, wherein one end of the slagging pipe is connected to the bottom of the tapered distribution plate, and is open, and the other end of the slagging pipe penetrates through the gasification furnace shell, and is connected with a gasification agent gas source. The gas distributor is characterized in that one end of each distributed injection pipe is connected to the lower part of the tapered distribution plate, and is open, and the other end of each distributed injection pipe penetrates through the gasification furnace shell, and is connected with the gasification agent gas source; and openings of the distributed injection pipes in the tapered distribution plate are symmetrically and uniformly distributed about the center of the slagging pipe. The gas distributor is high in fluidization performance, adapted to long-cycle running, simple in structure and applicable to a large-sized fluidized-bed gasification furnace.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

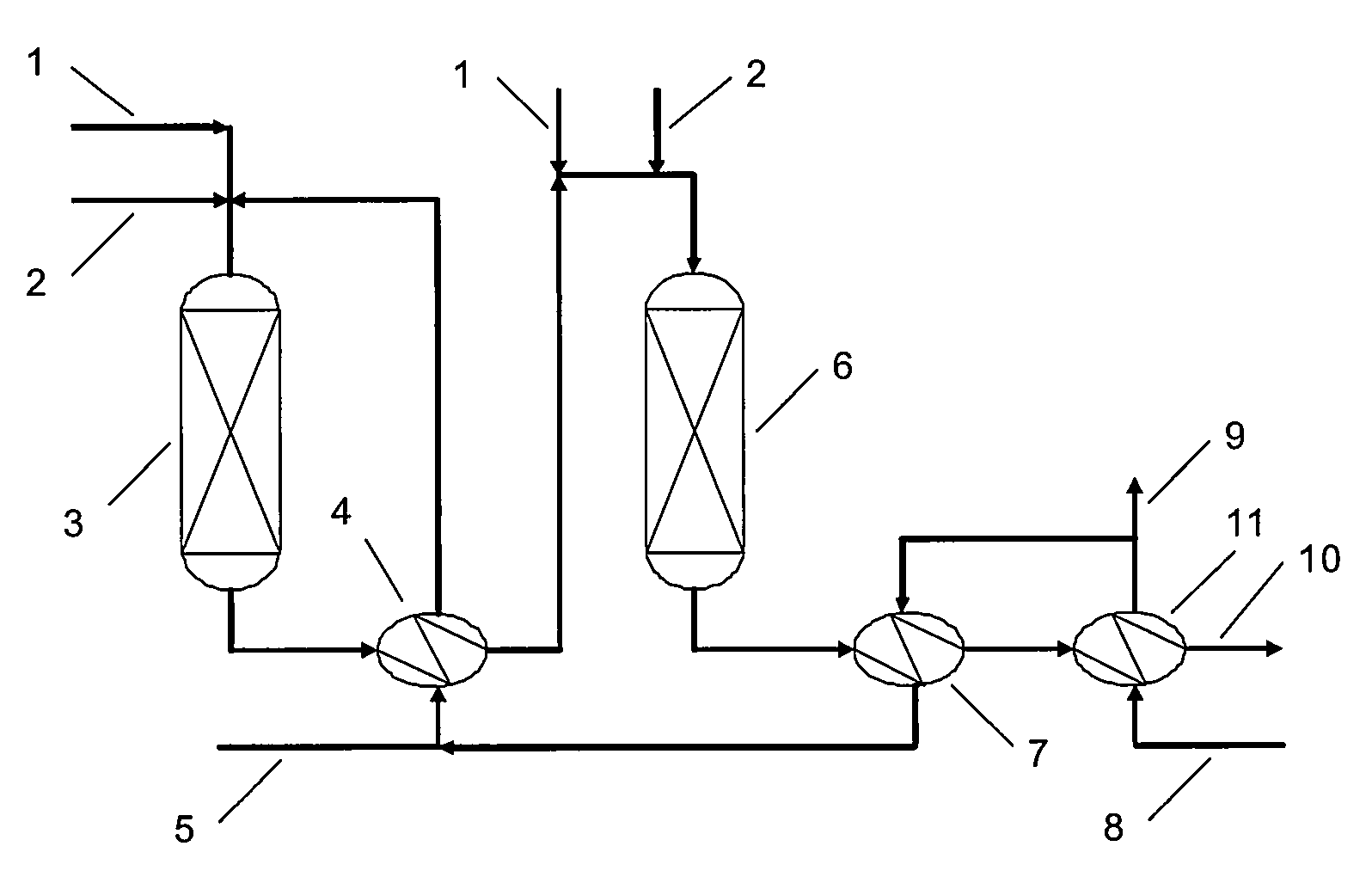

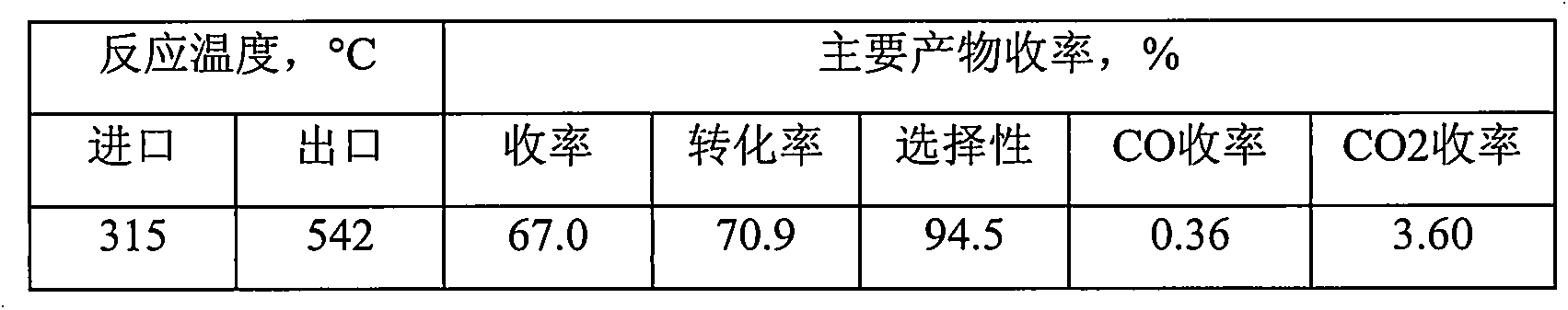

Method for producing butadiene through mixing carbon C

InactiveCN103304359AImprove fluidization stateUniform temperature distributionHydrocarbonsHydrocarbon preparationButeneSeparation technology

The invention discloses a method for producing butadiene through mixing carbon C, mainly solving the problems of poor butene conversion per pass, low butadiene once through yield and large device energy consumption in the prior art. The following main technical schemes are adopted to realize the purposes: adopting a ferrite catalyst and a fluidized bed reactor reaction technology to carry out oxidative dehydrogenation on butene in a mixed carbon C so as to generate butadiene; exchanging heat with a desalted water by utilizing a gas generated after the reaction and generating a byproduct-steam, further cooling the gas to be about 110 DEG C, and filling the gas into a quench tower to remove impurities such as water, oxides and solid powder; condensing the quenched gas to be about 1.2MPa, absorbing and resolving to obtain crude butadiene; and treating the crude butadiene through utilizing a conventional butadiene extraction and separation technology so as to obtain a polymer grade butadiene product. By utilizing the method, the conversion per pass of the butene in the mixed carbon C is more than 90%, the butadiene selectivity is more than 95%, the device energy consumption is reduced by about 40%, and the device investment is saved about 20%, and the method can be applied to the field of butadiene industrial production.

Owner:王伟跃

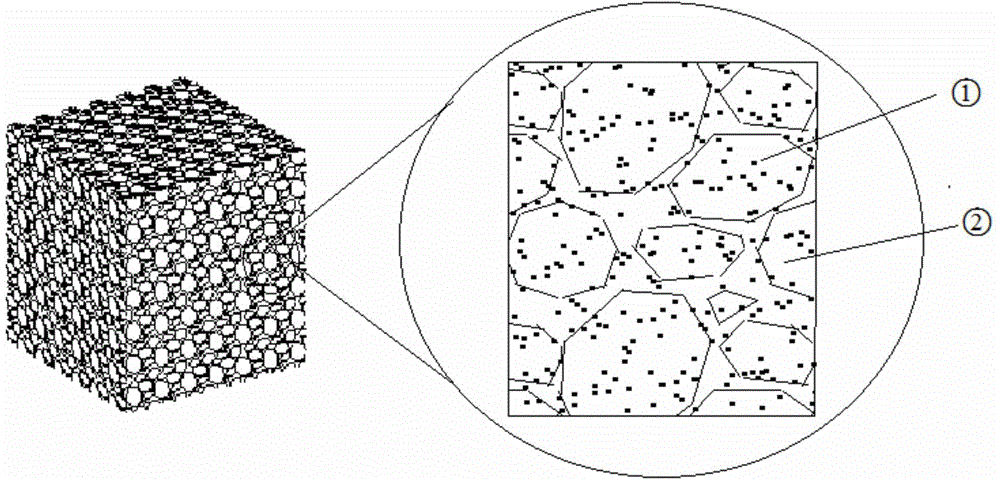

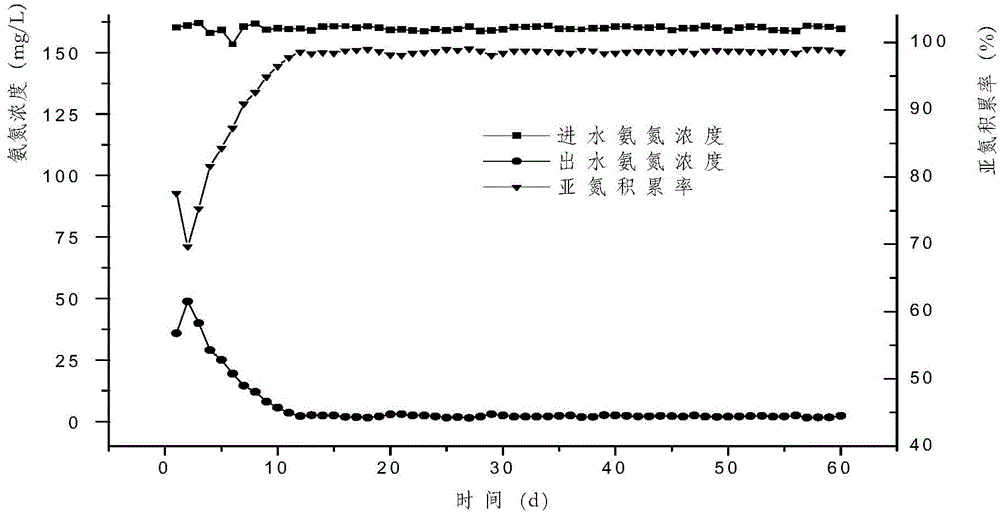

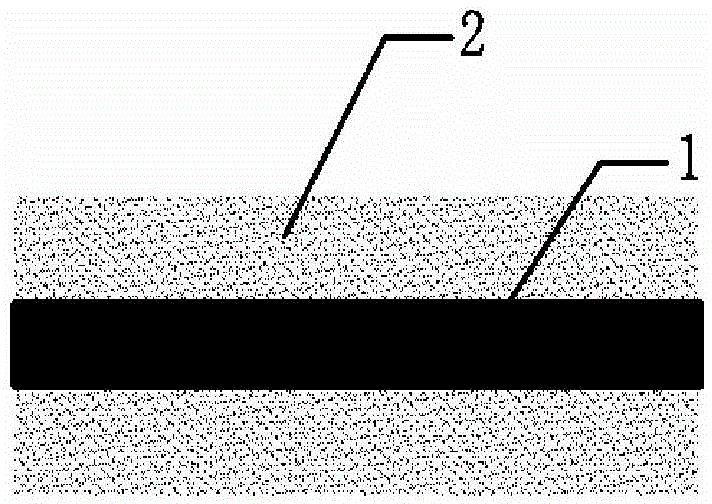

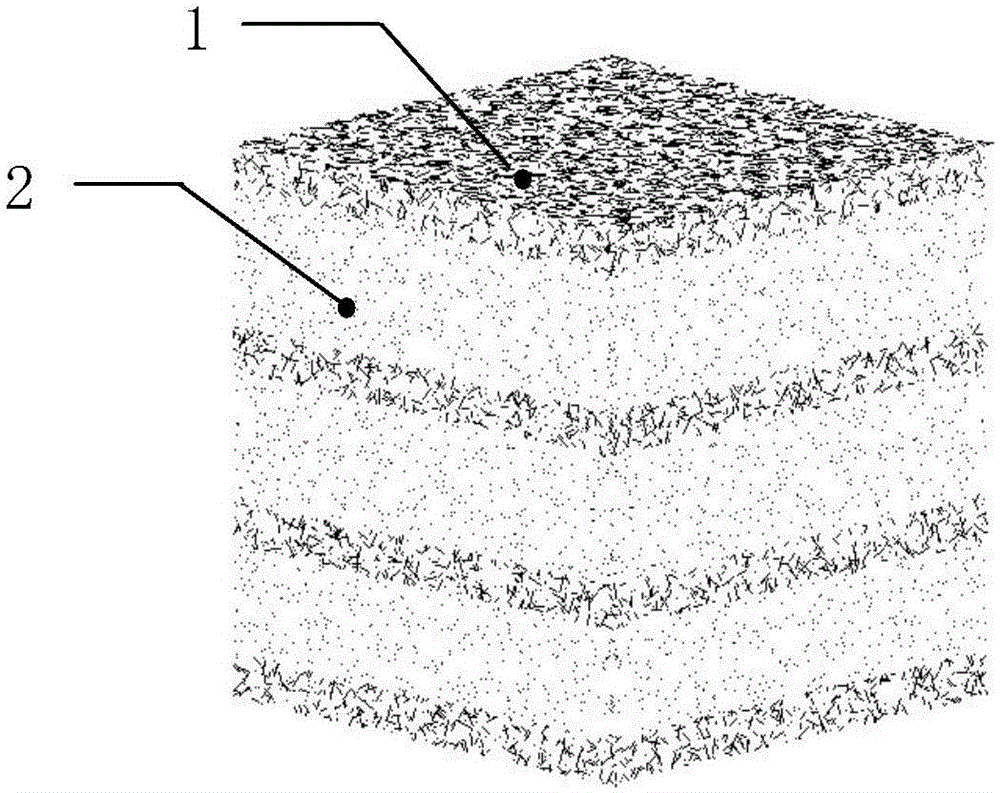

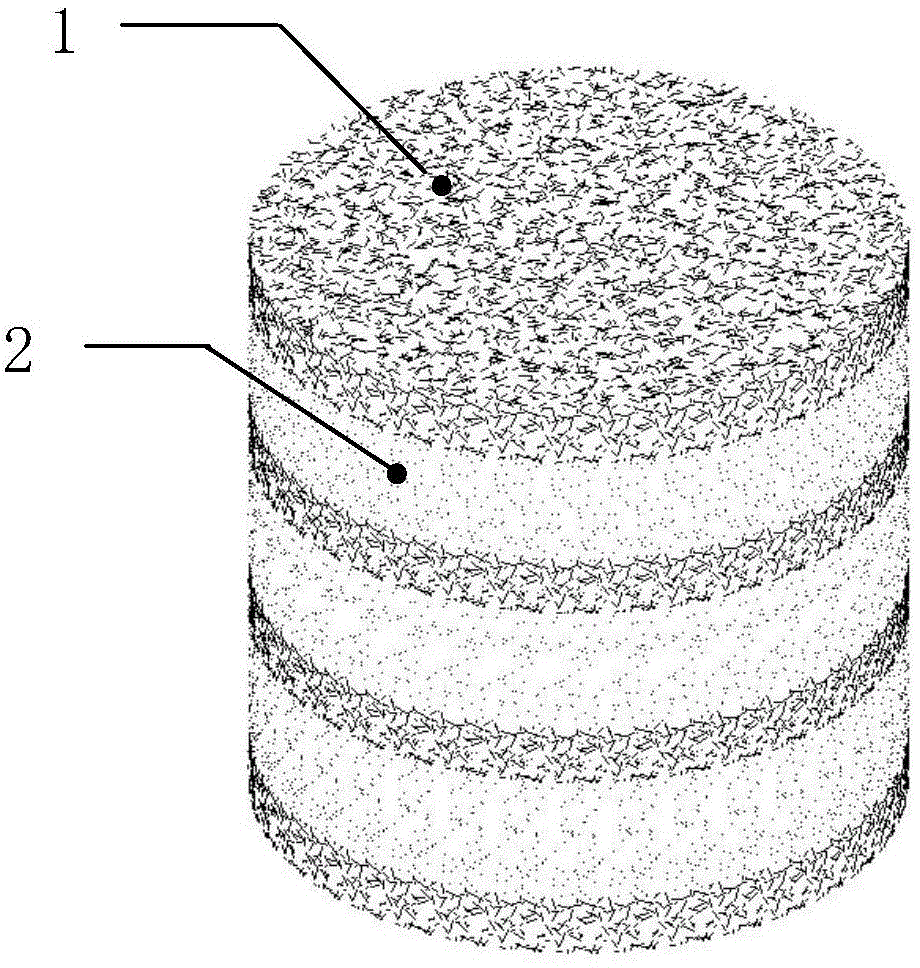

Preparation and application of ammonia oxidizing bacteria immobilized bioactive filler based on polyurethane carrier

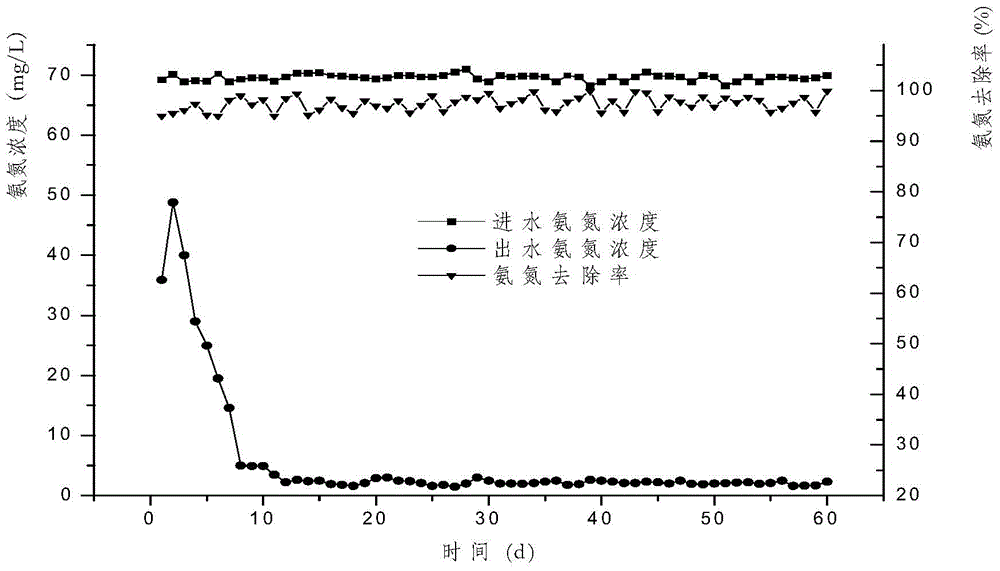

InactiveCN103951040AAchieve short-cut nitrificationNitrosation efficiency is highSustainable biological treatmentOn/in organic carrierPolyvinyl alcoholAmmonia-oxidizing bacteria

The invention discloses preparation and an application of an ammonia oxidizing bacteria immobilized bioactive filler based on a polyurethane carrier, and belongs to the technical field of water treatment. The bioactive filler comprises two parts: an embedding body and the polyurethane carrier; a porous structure of the polyurethane foam carrier adsorbs a bacteria-containing embedding liquid, wherein the embedding liquid is prepared by mixing an ammonia oxidizing bacteria concentrated solution and a polyvinyl alcohol solution; a whole sheet of polyurethane foam is used as the embedding carrier, the embedding liquid is immersed to the interior of the polyurethane foam by a squeezing way, the embedding body is formed after boric acid secondary cross-linking and is combined with the polyurethane carrier to obtain a filler shape meeting requirements, and thus the ammonia oxidizing bacteria bioactive filler is obtained. The prepared ammonia oxidizing bacteria immobilized bioactive filler not only solves the problems that ammonia oxidizing bacteria are difficult in advantage establishment, easy to lose and the like, but also improves the processing ability of a reactor, shortens the start-up time, and has broad application prospects.

Owner:BEIJING UNIV OF TECH

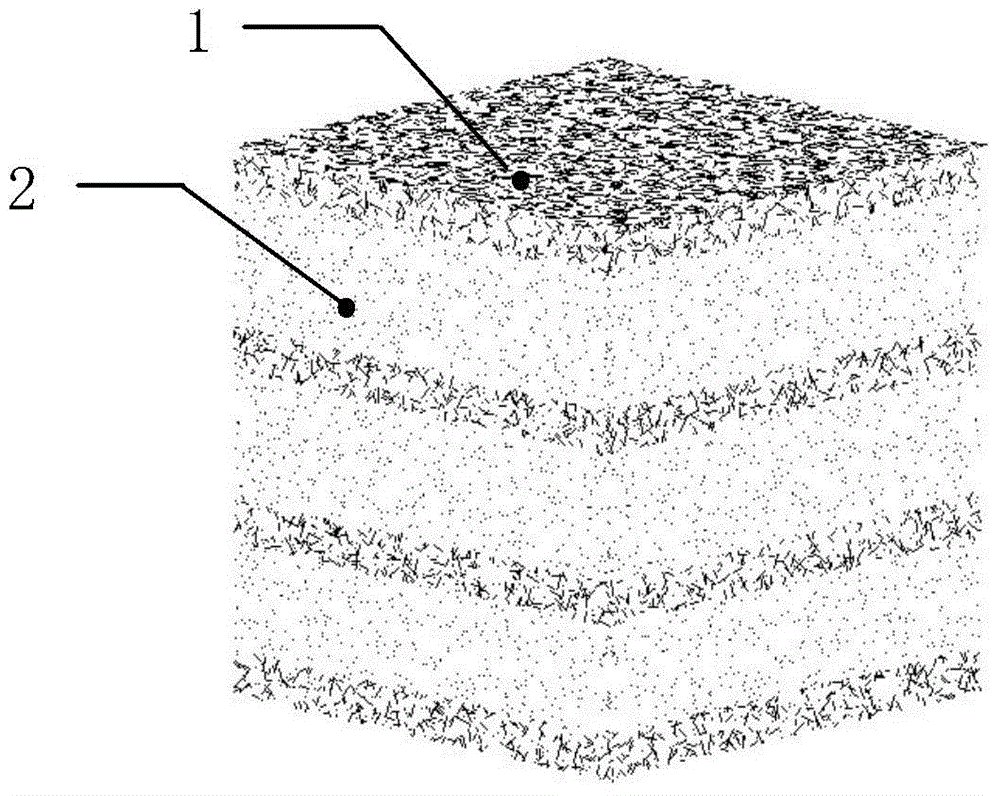

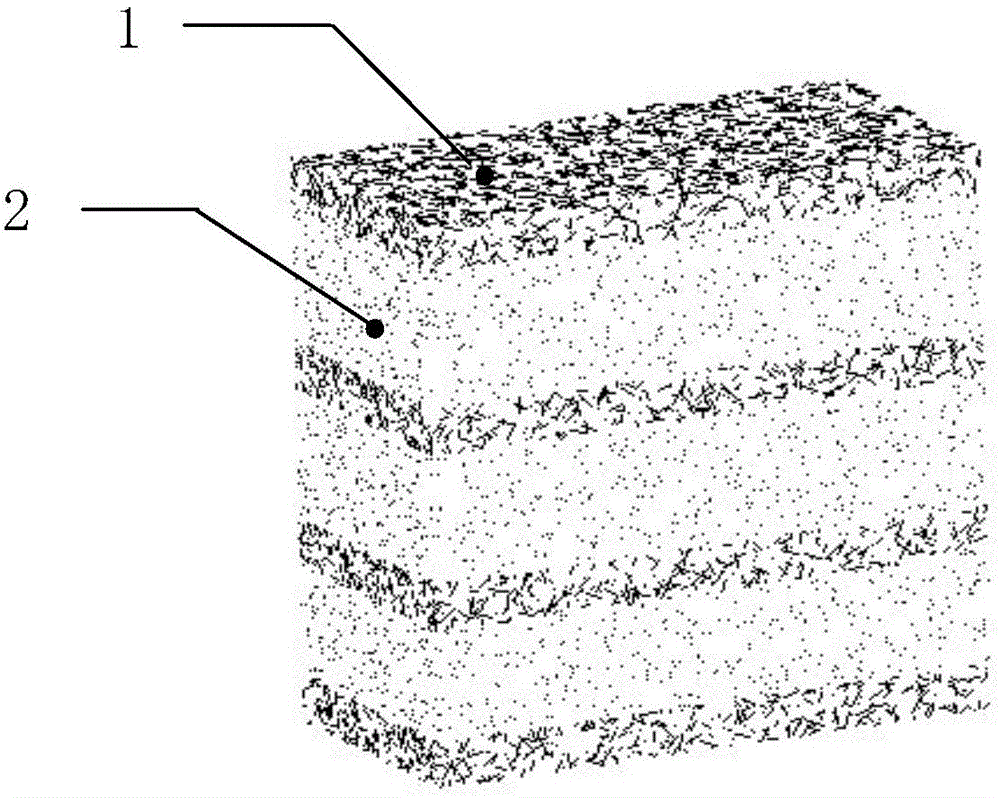

Preparation and application of sandwich-type multilayer immobilized bioactive filler

ActiveCN103951041AStable structureGuaranteed uptimeSustainable biological treatmentOn/in organic carrierSandwich likeYarn

The invention discloses preparation and an application of a sandwich-type multilayer immobilized bioactive filler, and belongs to the technical field of water treatment. The bioactive filler is composed of two parts: embedding bodies and non-woven carriers; the embedding bodies are obtained by boric acid secondary cross-linking curing of an embedding liquid; the embedding bodies and the non-woven carriers are in alternative arrangement; fiber yarns of the non-woven carriers and the embedding bodies are combined into a stable organic whole; the embedding liquid formed by mixing a bacteria concentrated solution and a polyvinyl alcohol solution evenly coats the non-woven carriers, multiple layers of carriers are overlaid together, a layered filler having a sandwich-like structure is formed after boric acid secondary cross-linking curing, and then the granular bioactive filler is prepared through cutting the layered filler. The problems that bacteria in a traditional biochemical method are low in concentration, easy to lose and the like are solved, and moreover, the sandwich-like layered structure formed by the non-woven fabrics and the embedding bodies improves the stability of the bioactive filler, and the bioactive filler has a good application prospect.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Additive capable of improving utilization rate of silicon power in synthesis of methyl chlorosilane

ActiveCN104151343ALow impurity contentIncrease contact areaGroup 4/14 element organic compoundsSilica fumeOxide

The invention discloses an additive capable of improving utilization rate of silicon power in synthesis of methyl chlorosilane. The additive is characterized by being prepared from the following components in parts by weight through mixing: 30-70 parts of an oxide, 25-50 parts of silicon powder, 4.5-15 parts of copper powder and 0.5-5 parts of zinc powder, wherein the average particle size of the additive is 70-100mm and the weight ratio of silicon oxide to aluminum oxide to calcium oxide in the oxides is (82-87) to (7-13) to (3-7). At the later stage of a reaction between silicon powder and chloromethane in a fluidized bed, by adopting the reaction additive disclosed by the invention, the intensity of the reaction in the fluidized bed is effectively controlled and thus the quality of the reaction product can be ensured, and meanwhile, since silicon powder is in full contact with chloromethane, the conversion rate of silicon powder is improved, the generation of waste silicon powder is reduced and therefore the production benefits are further increased.

Owner:LUXI CHEM GRP

Method for preparing rubber powder by desulfurizing waste tires at low temperature through ammonia method

The invention relates to the technical field of low-temperature desulfurization for waste tires, in particular to a method for preparing rubber powder by desulfurizing the waste tires at low temperature through an ammonia method. The method includes the steps that after the waste tires are cut into blocks, magnetic separation, grinding, magnetic separation and grinding are carried out on the blocks to obtain powder of 80-100 meshes; the powder is treated through a circulating fluidized bed treater, ammonia gas is introduced, ammonia gas introducing speed and time are controlled, the catalytic action of microwave radiation is combined, S-S bonds and S-C bonds in the waste tires are activated by the ammonia gas, bond energy is reduced, the fracture rate is increased, and the sulfur component in the waste tires is removed. As the method for recovering and preparing the waste tires into the rubber powder is low in cost and energy consumption, the desulfurizing step can be carried out in a low-temperature environment, the high quality of the rubber powder is ensured, and the quality of rubber powder prepared by recovering the waste tires is improved.

Owner:贵州华宇橡胶科技有限公司

Mesoporous selective molecular sieve and preparation method thereof

InactiveCN107324356AImprove fluidization stateNot easy to deposit carbonCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a mesoporous selective molecular sieve and a preparation method thereof. The mesoporous selective molecular sieve is obtained by performing alkali treatment on IM-5 zeolite with the silica-alumina ratio being 10 to 14. The preparation method comprises the following steps that the IM-5 zeolite is added into an alkali treatment solution for alkali treatment; after filtering, washing and drying, the mesoporous selective molecular sieve is obtained, wherein the alkali treatment solution comprises one or a combination of several of a NaOH solution, a KOH solution, a TPAOH solution and a TBAOH solution. The mesoporous IM-5 molecular sieve can be applied to cracking reaction; the mesoporous IM-5 molecular sieve has rich mesopores, so that in the reaction process, the catalyst fluidizing state is better; heavy oil macromolecules can easily approach to the active center; cracked products can be easily diffused; the yield of ethylene and propylene is relatively high; catalysts cannot generate carbon deposition, so that the catalysts have good catalytic activity and long service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

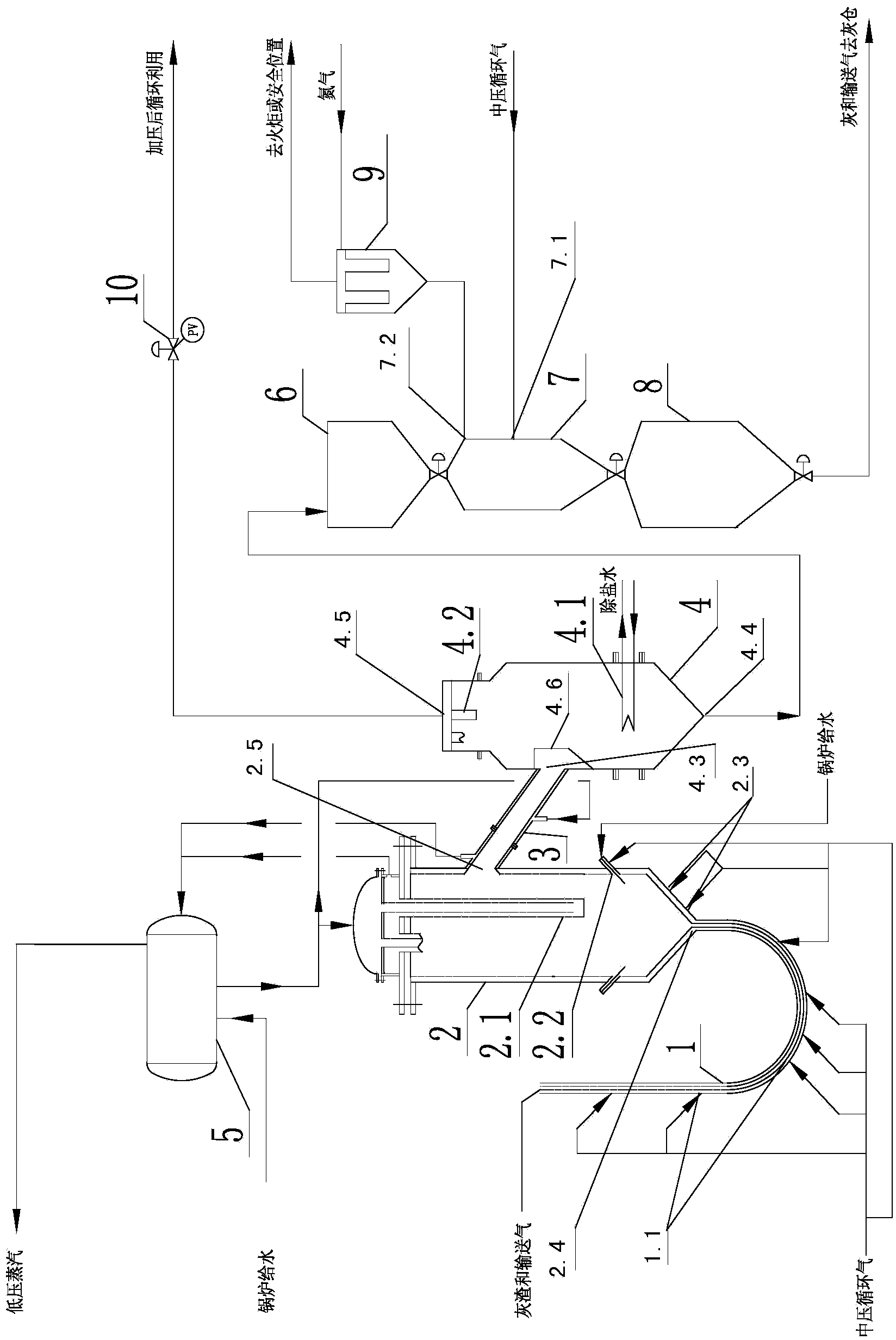

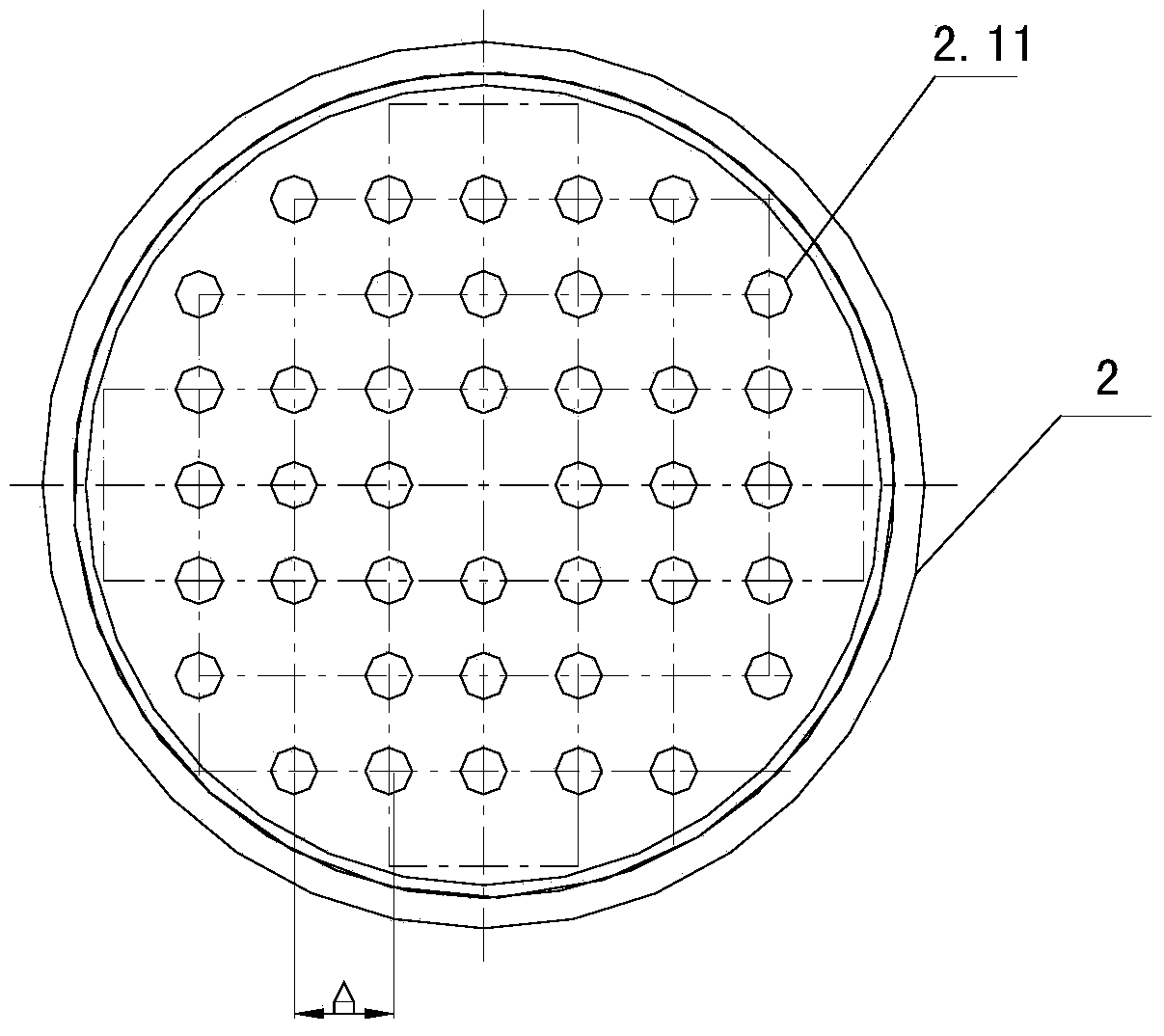

Pressurized ash residue treatment technology and system

ActiveCN103528055AIncrease throughputImprove recycling efficiencyFluidized bed combustionApparatus for fluidised bed combustionFluidized bedProcess engineering

The invention discloses a pressurized ash residue treatment technology and a system thereof, and solves the problems of non-operability of ash residue under pressure, severe pipeline abrasion and low thermal energy recovery efficiency in existing gasification furnaces. The technological method consists of: subjecting high-temperature ash residue to a first stage fluidized bed cooler and a second stage cooler in order to undergo two stage cooling by means of pneumatic conveying, then conducting further depressurization by an ash residue depressurization device and conducting discharge, adopting water cooling heat exchange, and recovering steam by a steam drum. The method involved in the invention has a simple process, the system running cost is low, the investment cost is low, the heat recovery efficiency is high, the water-cooled pipe is not easy to wear, and the ash residue particle size has a wide range of application.

Owner:江苏晟宜环保科技有限公司

Marine sewage treatment integrated device on basis of biological moving beds

InactiveCN102329056AImprove hydrophilicityImprove adhesionMultistage water/sewage treatmentGratingUv disinfection

The invention relates to a marine sewage treatment integrated device on the basis of biological moving beds, which comprises a grating, a regulating basin, two stages of biological moving beds, a sedimentation tank, a backwashing water tank, an external membrane module, a reagent bucket and an ultraviolet disinfector. Sewage sequentially enters the regulating basin, the two stages of biological moving beds and the sedimentation through the grating. Supernatant fluid can be disinfected by ultraviolet rays and be directly discharged and can also be disinfected to be reused as recycled water after entering the membrane module. The external membrane module is connected with the backwashing water tank and can be used for effectively preventing a membrane from being blocked. The ultraviolet disinfector not only can be arranged behind the sedimentation tank, but also can be arranged behind the membrane module so as to meet different drainage requirements. The membrane module is kept working normally by regular backwashing and medicine washing. Due to the adoption of the marine sewage treatment integrated device on the basis of biological moving beds, the biodegrability of organic matter is effectively strengthened, effluent can directly reach the standard to be discharged after passing through the sedimentation tank, and the high efficiency degradation on marine domestic wastewater is realized. The marine sewage treatment integrated device has simple and reasonable structure and good working performance. The defect of short service life of the membrane module is overcome. Compared with a like reactor, the marine sewage treatment integrated device has obviously improved sewage treatment capability.

Owner:DALIAN UNIV OF TECH

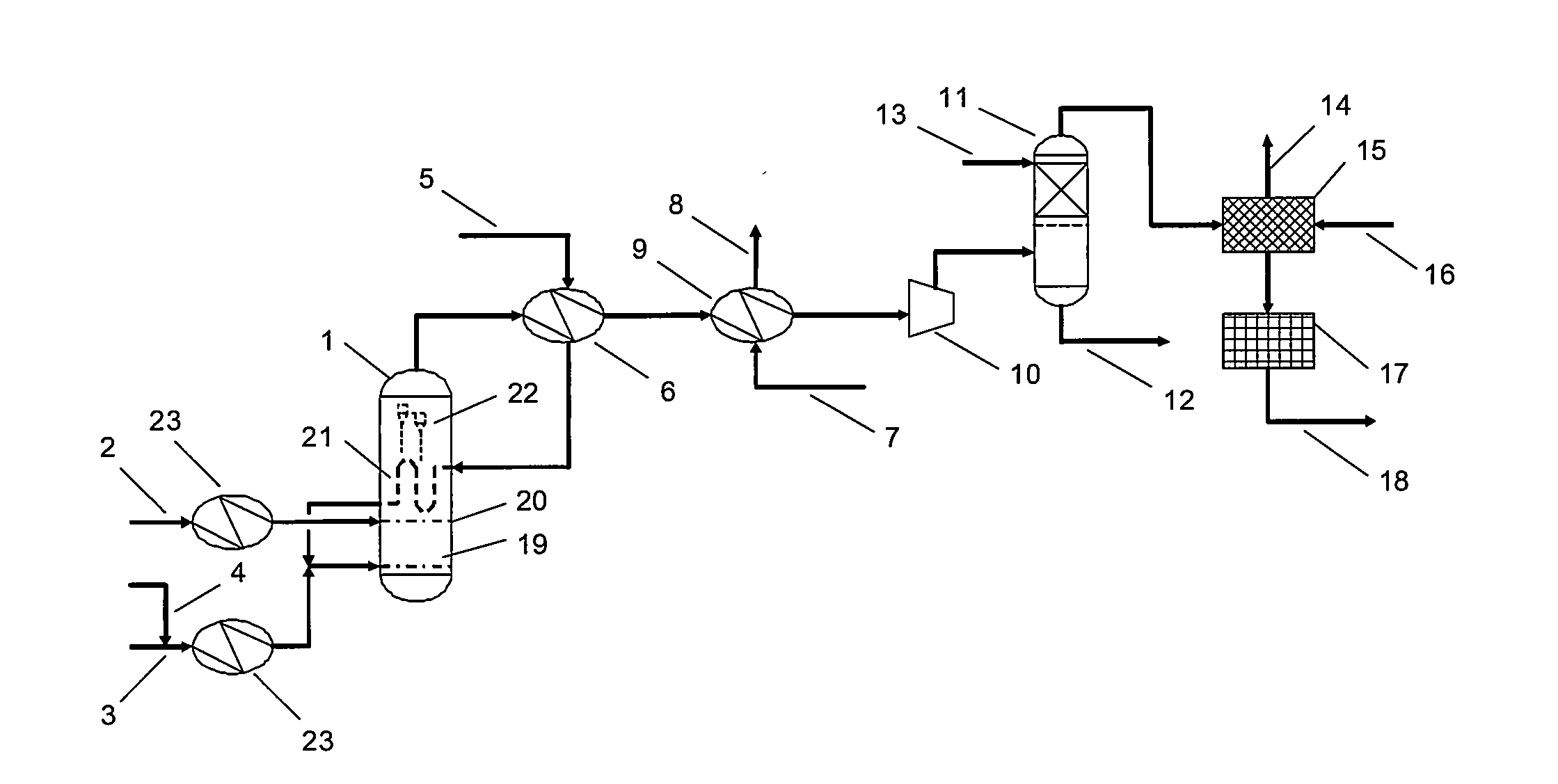

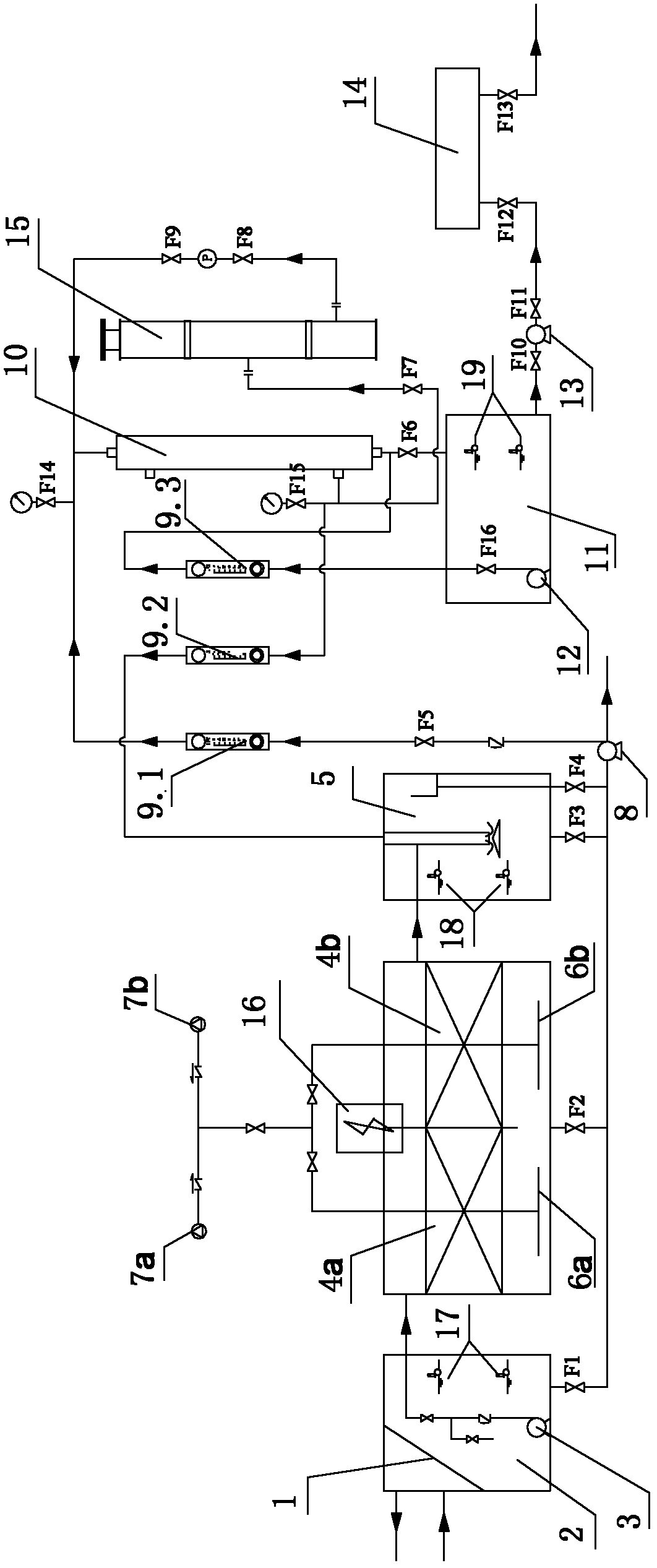

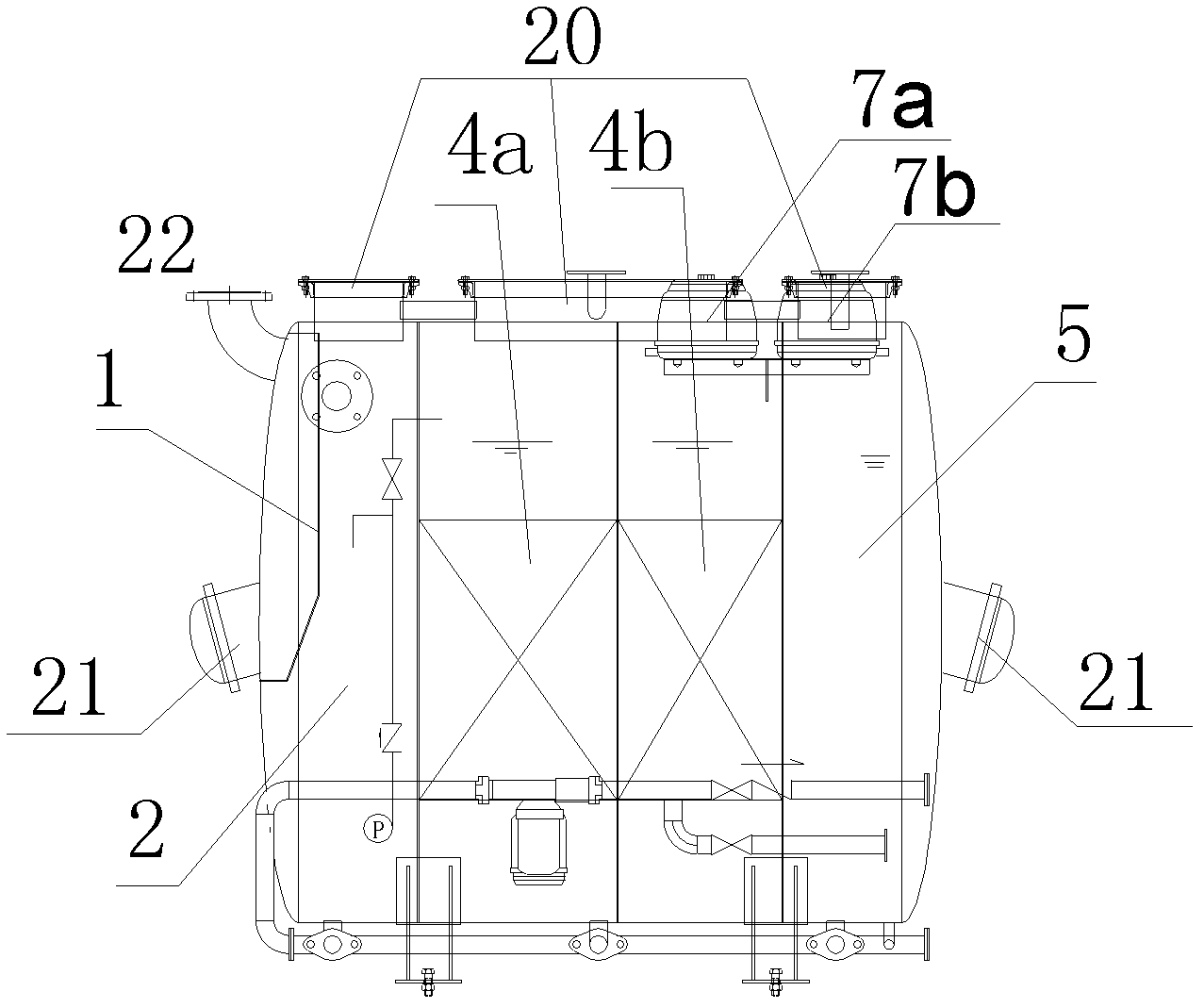

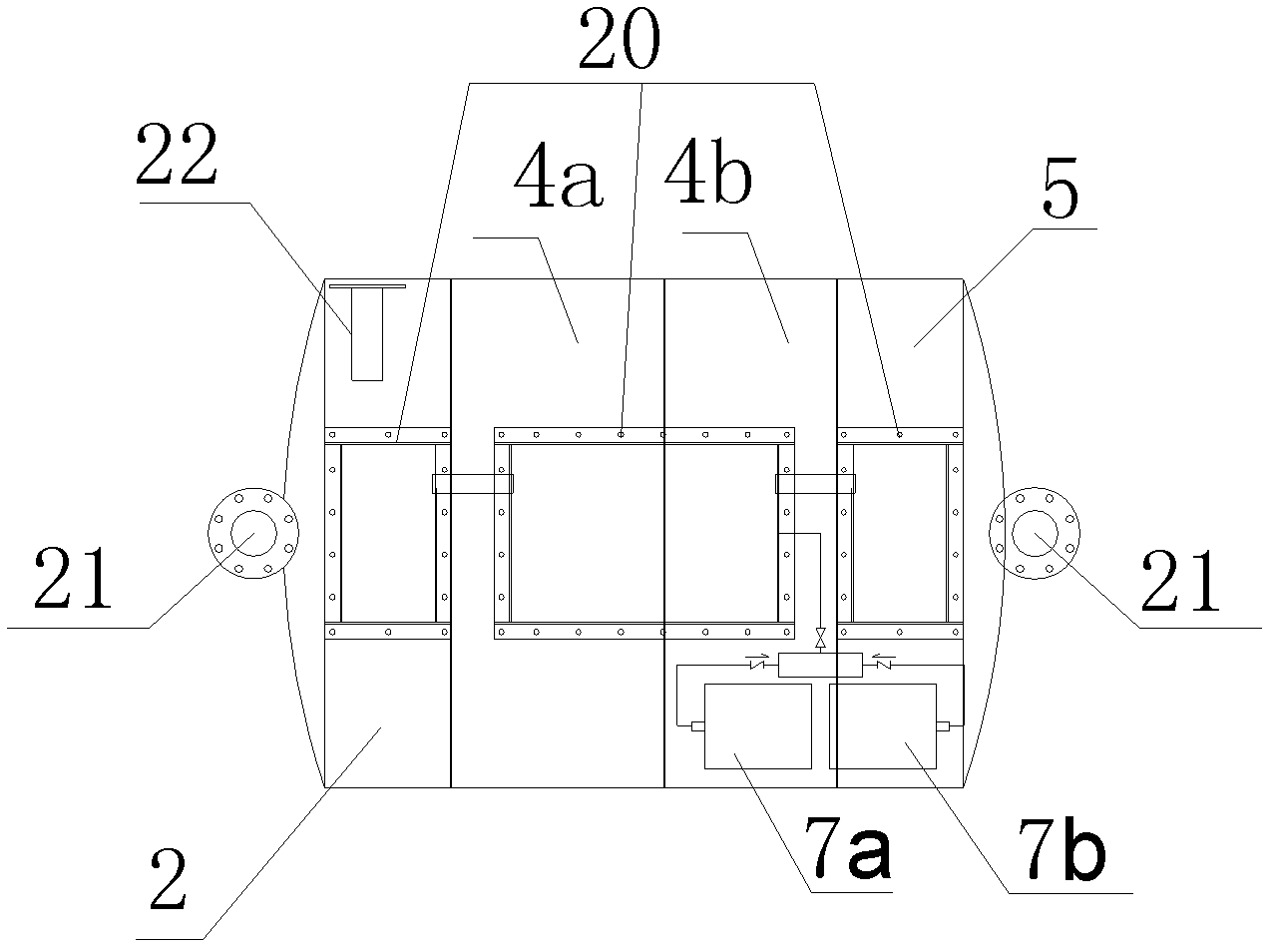

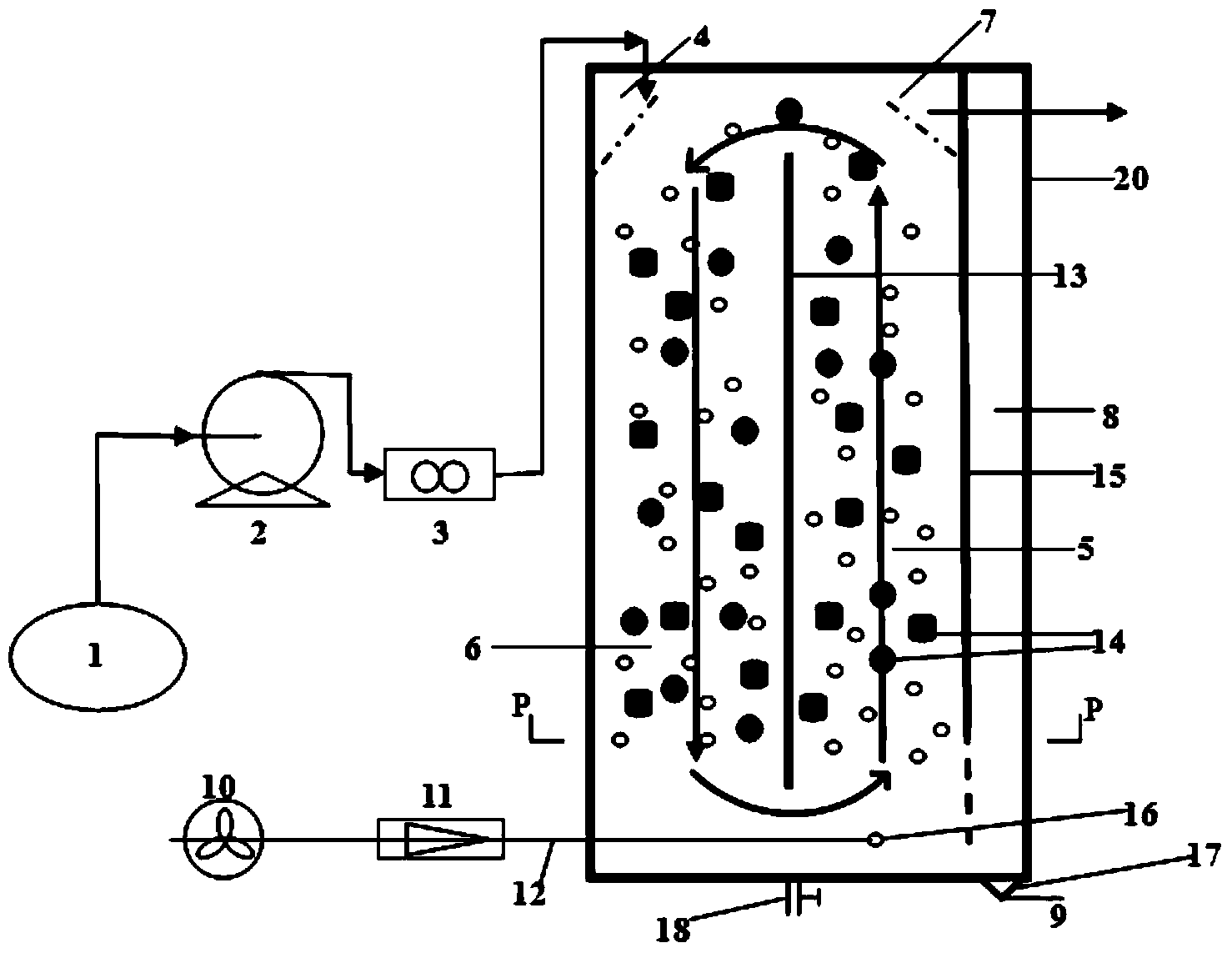

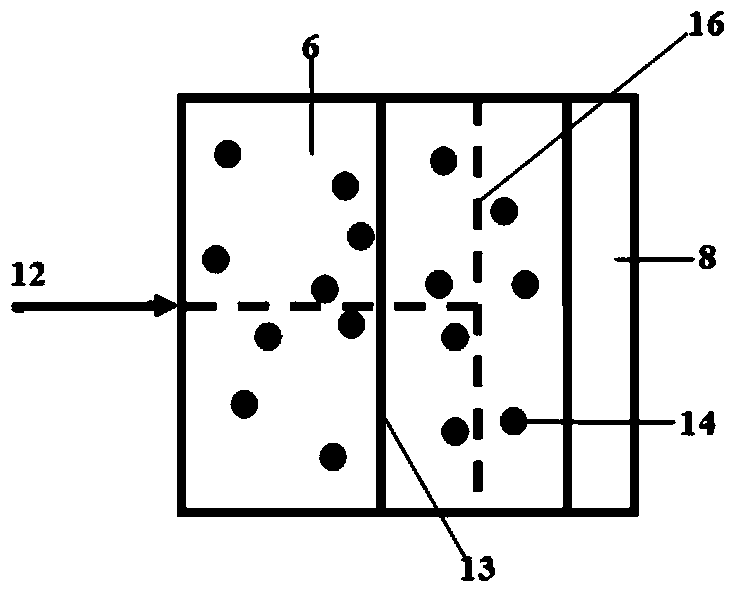

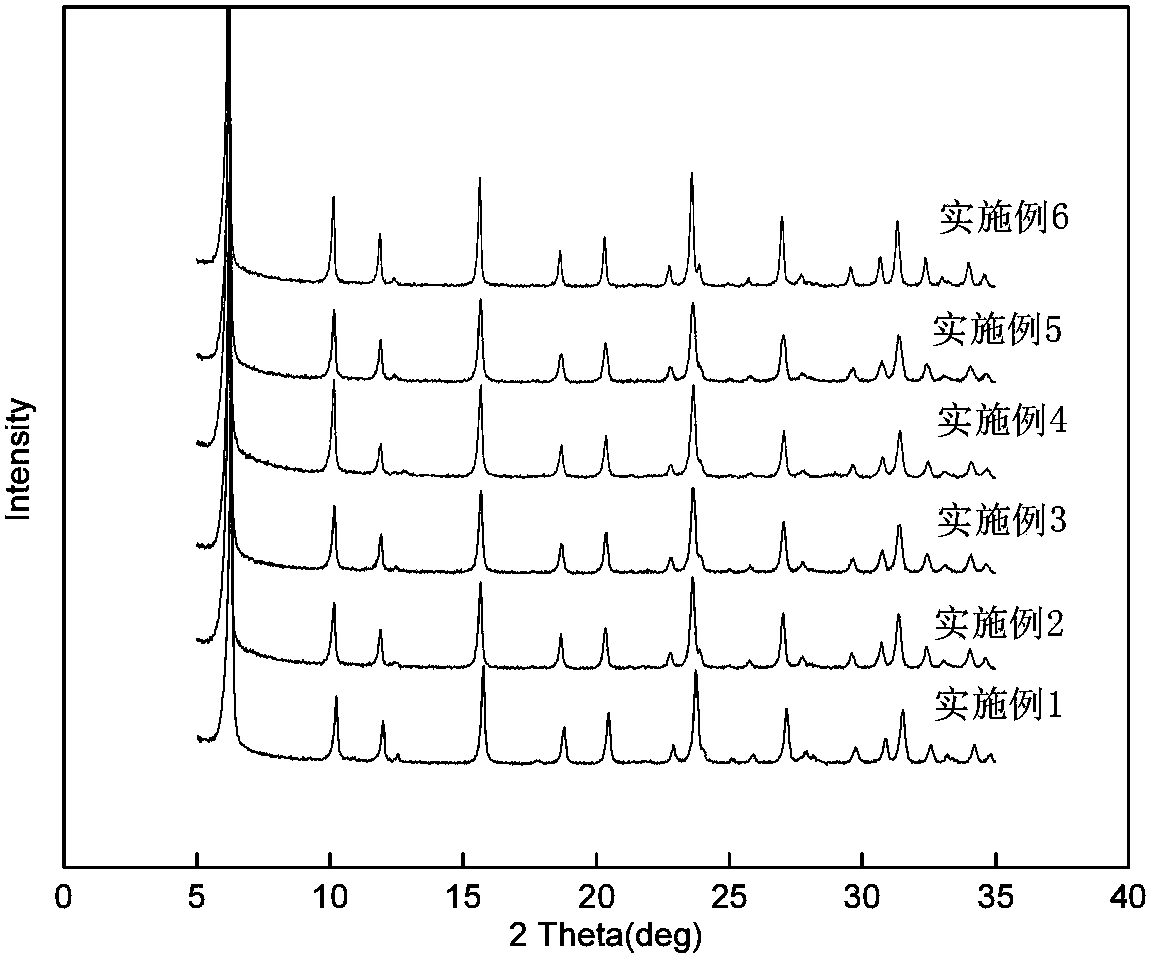

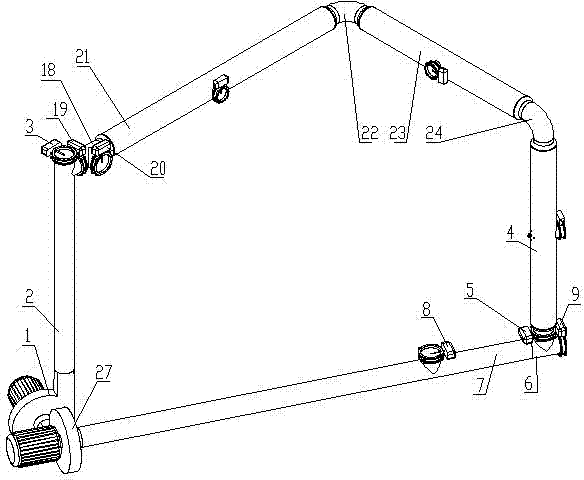

MBBR pretreatment method and system for high-ammonia nitrogen micro-polluted raw water

InactiveCN103936140ALarge specific surface areaGood removal effectTreatment using aerobic processesSustainable biological treatmentPretreatment methodSludge

The invention belongs to the technical field of drinking water treatment, and relates to a moving bed biofilm reactor pretreatment method and system for high-ammonia nitrogen micro-polluted raw water. The system comprises a feed pump (2), a moving bed biofilm reactor (20) and an air blower (10), wherein a separation baffle (13) and a guide wall (15) are arranged in the moving bed biofilm reactor (20). The system has the advantages that separation baffle is arranged in the moving bed biofilm reactor, so that the state of fluidization in a whole tank is intensified, and microorganisms are facilitated to purity raw water; the system is also provided with a yielding water settling zone so as to facilitate the discharge of excess sludge; a reaction tank is compact in structure, the occupied area is small, the energy consumption is low, the system is easy to operate, maintain and manage, and the investment and operating cost are reduced.

Owner:TONGJI UNIV

NaY compound and preparation method thereof

ActiveCN103693657AWell-developed microporous structureImprove structural stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveActive site

The invention relates to a NaY compound and a preparation method thereof. The NaY compound is composed of NaY molecular sieve and expanded perlite, the NaY molecular sieve grows on the expanded perlite in an overgrowth manner, and the NaY compound has a bulk density of 0.25g / cm<3> or less, a BET specific surface area of 600m<2> / g or more and a molar ratio of SiO2 / Al2O3 of 4.0-6.0. The preparation method of the NaY compound comprises the following steps: mixing a silicon source, a crystallization directing agent, the expanded perlite, NaOH and water to obtain a reaction mixture; and crystallizing the reaction mixture at 70-120DEG C for 5-72h, filtering, washing, and drying to prepare the NaY compound. The NaY compound can be used in a cracking reaction, allows the flowing state of a catalyst to be good, heavy oil macromolecules to easily approach active sites and cracking products to be easily dispersed, can improve the heavy oil conversion rate, and allows the catalyst to have a good catalytic activity. The preparation method of the NaY compound has the advantages of cheap and easily available raw materials, low cost, no environmental pollution, and good application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-efficiency magnetic roasting boiling furnace

InactiveCN102679732AImprove fluidization stateResidual sulfur content decreasedFluidised-bed furnacesSlagSulfur content

The invention relates to a high-efficiency magnetic roasting boiling furnace of a sulfurous iron ore calcination acid making device. The boiling furnace provided by the invention is characterized in that the whole section in an air chamber is provided with a gas pre-sparger, the tilt angle of the charging opening is of a 35-degree groove type structure, and the distance from the bottom of the charging opening to air caps is greater than or equal to 2600 mm; a deslagging heat recovery unit is arranged for deslagging cooling and heat recovery; the air caps are arranged at high density of 80-100 / m<2>, and the fluidized state of a boiling bead is optimized; and a tertiary air device is arranged along the tangential direction of a furnace body. According to the invention, the air chamber is provided with the pre-sparger and the gas distribution plate is provided with the air caps at high density, the fluidization condition is effectively improved and a boiling layer is guaranteed to be a weak oxygen state, and the flow distribution is uniform; and the tilt angle of the charging opening is improved as the 35-degree groove type structure, the charging material height is improved, the mineral aggregate is not stacked, the roasting temperature is improved, the slag disabled sulfur content is reduced, meanwhile, the inlet air is supplementally added, the sublimed sulfur is not generated, and the magnetic firing condition is met.

Owner:JIANYE QINGSONG GROUP

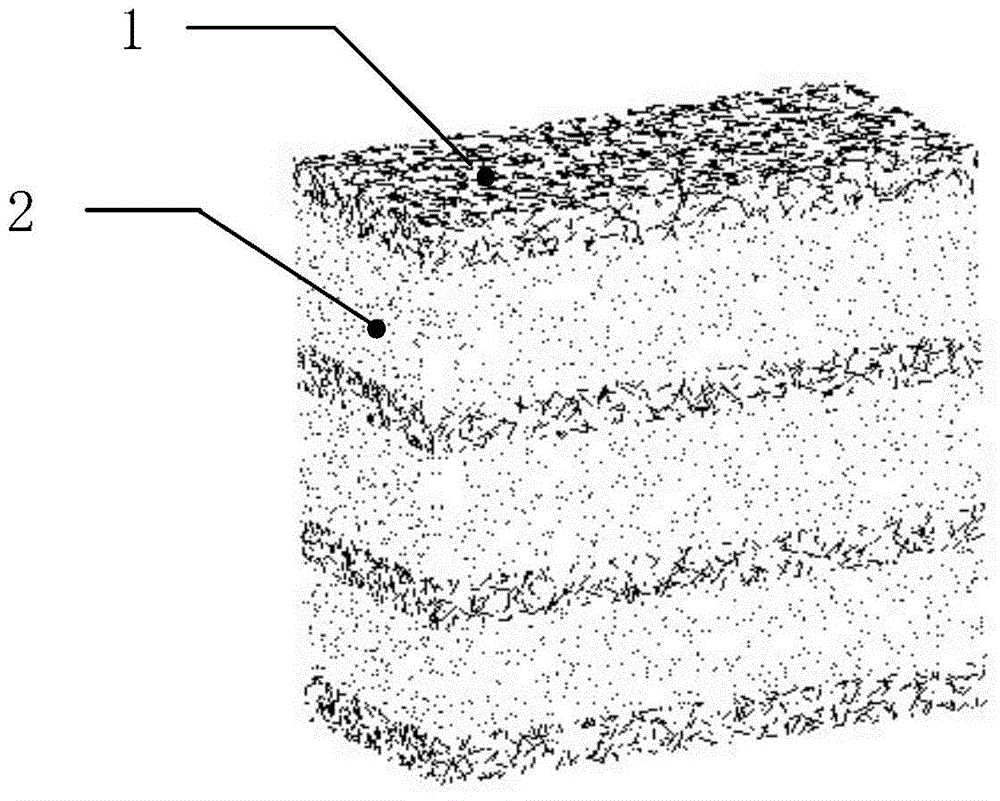

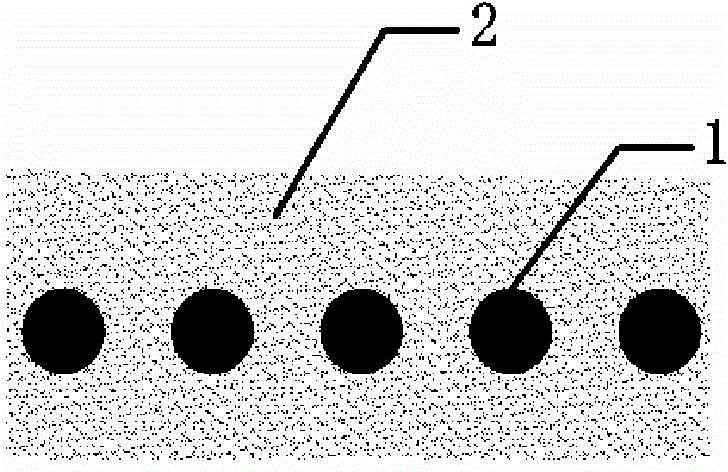

Preparation and application of ammonia oxidizing bacteria immobilized star-shaped bioactive filler based on reticulate carrier

ActiveCN103951073AIncrease concentrationNot easy to fall offSustainable biological treatmentBiological water/sewage treatmentPolyvinyl alcoholAmmonia-oxidizing bacteria

The invention discloses an ammonia oxidizing bacteria immobilized star-shaped bioactive filler based on a reticulate carrier, and preparation and an application thereof, and belongs to the technical field of water treatment. The star-shaped bioactive filler comprises two parts: an embedding body and the carrier; the carrier is a star-shaped reticulate carrier formed by taking polyethylene or polypropylene as a main material, adding a polyvinyl alcohol hydrophilic material and carrying out hot melting or plate hot pressing; with a reticulate structure of the carrier, the embedding body can be allowed to penetrate through meshes to form a riveting fixing structure so as to increase the filler overall stability; an embedding liquid is formed by mixing an ammonia oxidizing bacteria concentrated solution and a polyvinyl alcohol solution; the reticulate carrier is evenly coated with the embedding liquid, and the embedding body is formed after boric acid secondary cross-linking and is combined with the reticulate carrier to obtain the ammonia oxidizing bacteria bioactive filler. The prepared ammonia oxidizing bacteria immobilized star-shaped bioactive filler not only solves the problems that ammonia oxidizing bacteria are difficult in advantage establishment, easy to lose and the like, but also improves the processing ability of a reactor, shortens the start-up time, and has broad application prospects.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

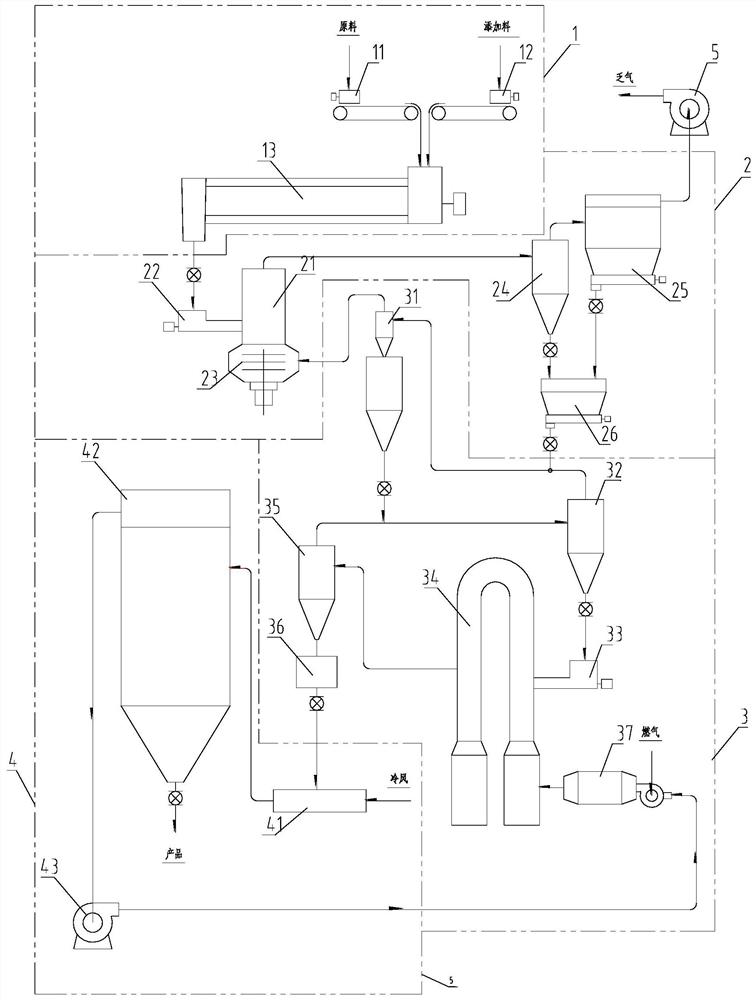

Device and method for producing self-excited II type anhydrous gypsum by utilizing industrial byproduct gypsum

The invention discloses a device and method for producing self-excited II type anhydrous gypsum by utilizing industrial byproduct gypsum. The process device comprises a two-stage dynamic cyclone calcining system, a rotary flash evaporation drying system, an industrial byproduct gypsum pretreatment system, a II type anhydrous gypsum cooling system, a system high-pressure induced draft fan, a pipeline system and the like. The process method comprises the step of continuously and sequentially performing operations according to the type and property of an industrial by-product gypsum material; performing raw material selective dehydration, performing pretreatment, performing drying dehydration, performing two-stage dynamic calcination and performing II type anhydrous gypsum product cooling process treatment. A process device system is totally closed, negative pressure state operation is achieved, echelon utilization of system heat is achieved, and energy conservation and consumption reduction are achieved. A high-quality II-type anhydrous gypsum product which is excellent in mechanical property and capable of realizing self-excitation subsequently can be prepared from the industrial by-product gypsum, so that the resource utilization of the industrial by-product gypsum is expanded, and the method and the production device can realize large-scale industrial production.

Owner:辽宁东大粉体工程技术有限公司 +1

Blowing desulfurization fluidized chamber

InactiveCN104419797AStable feeding speedReduce processing timeCharge manipulationGas supplyProcess time

The invention discloses a blowing desulfurization fluidized chamber. The blowing desulfurization fluidized chamber comprises a shell (4) which comprises a desulfurizer inlet (1) and a desulfurizer outlet (3) formed in the height direction, an air supply duct (2) and an air distributing plate (6) provided with a plurality of air outlet holes (5) densely, wherein the upper edge of the air distributing plate (6) is attached to the inner wall of the shell (4) and the lower edge is connected with the desulfurizer outlet (3) so as to divide the shell (4) into a fluidized chamber (7) above the air distributing plate (6) and an air inlet chamber (8) below the air distributing plate (6); the air supply duct (2) is communicated with the air inlet chamber (8); and gas supplied from the air inlet chamber (8) enters into the air inlet chamber (8) and is sprayed into the fluidized chamber (7) through the plurality of air outlet holes (5) of the air distributing plate (6). According to the blowing desulfurization fluidized chamber disclosed by the invention, the desulfurizer is uniformly fluidized in the process of discharging the desulfurizer with a relatively good fluidizing effect, so that the desulfurizer is stable in discharging speed, the blowing process time is shortened, the spattering is reduced, and the iron loss is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

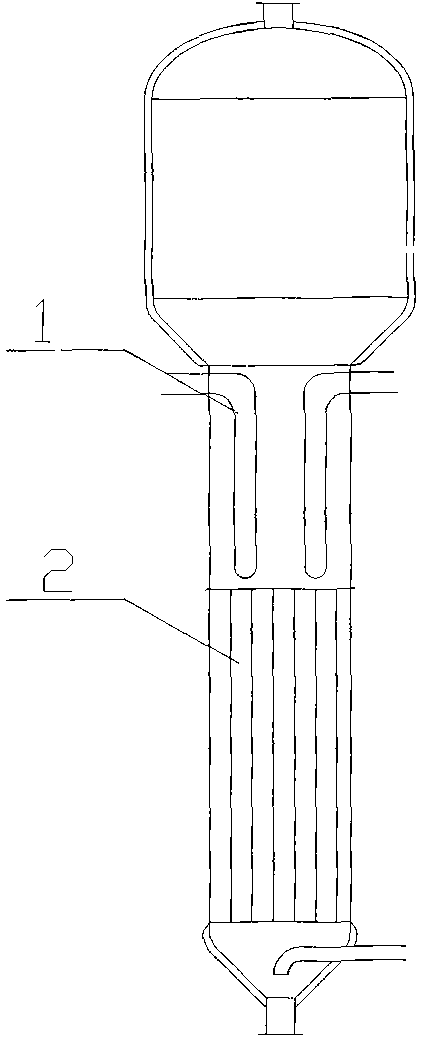

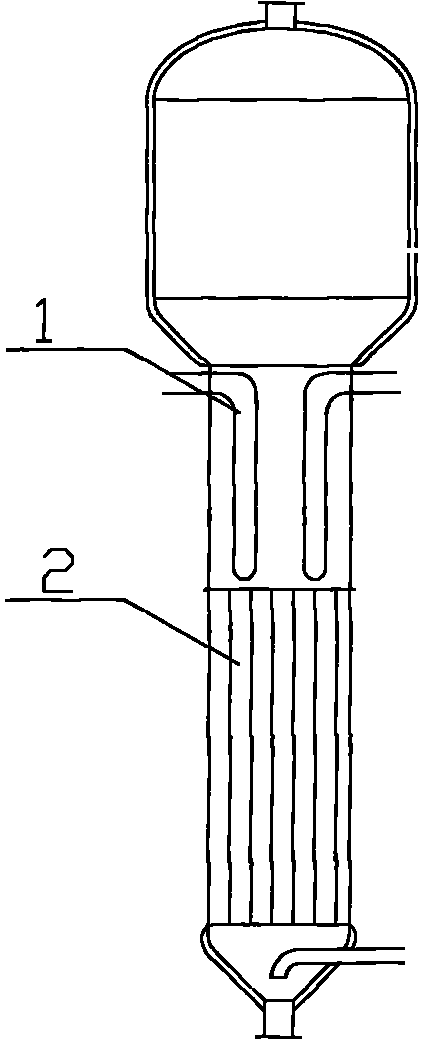

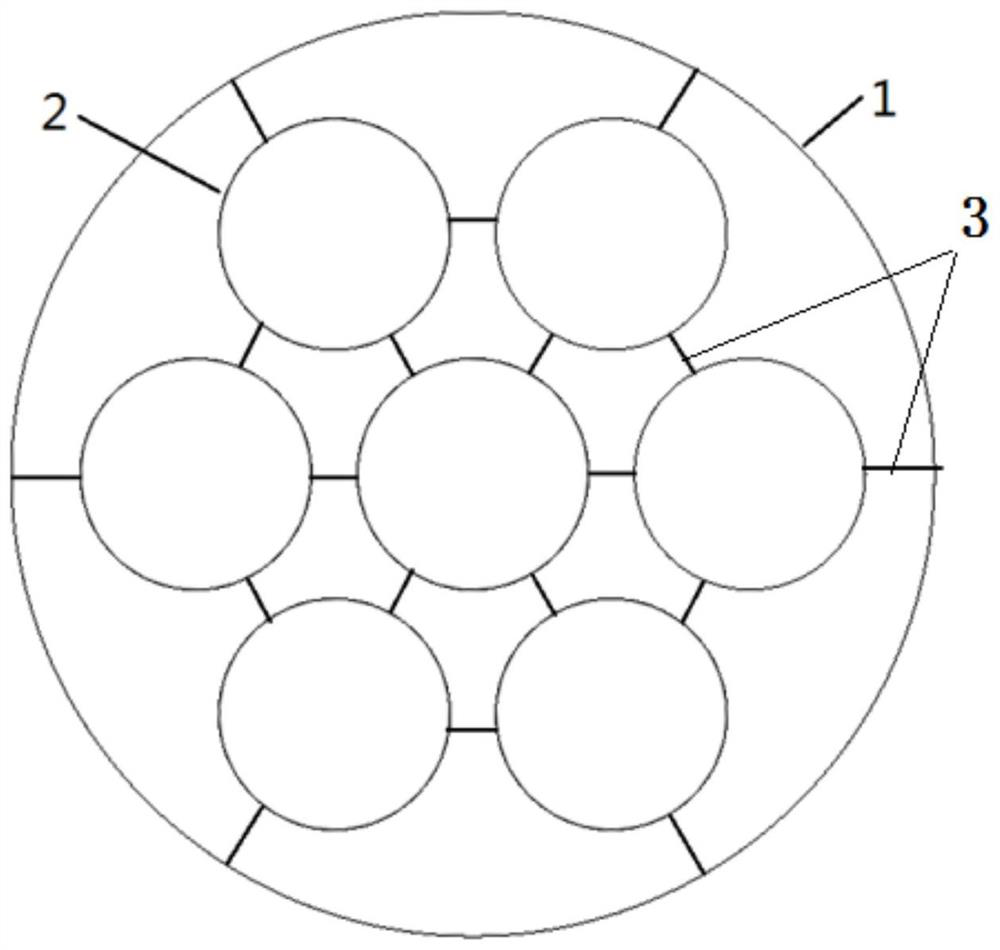

Tube-type fluid bed reactor in production of chlorothalonil

ActiveCN101985089BIncrease the heat exchange areaImprove fluidization stateChemical/physical processesCarboxylic acid nitrile purification/separationFluidized bedProcess engineering

Owner:JIANGSU XINHE AGROCHEM

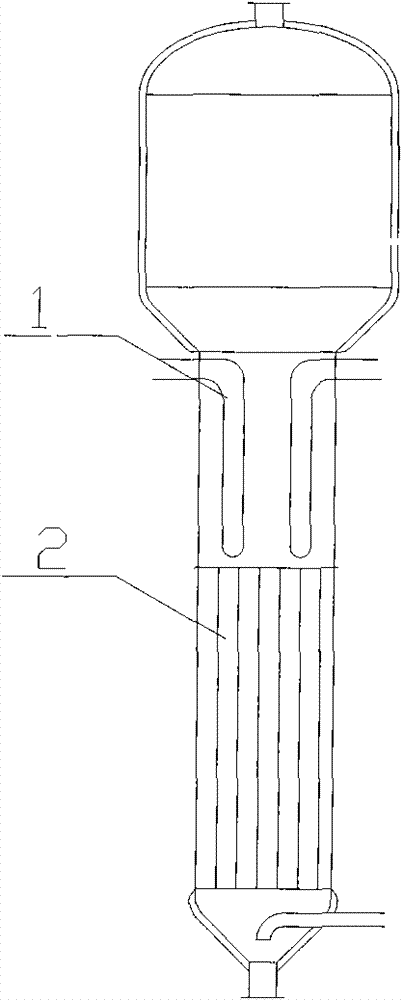

Pneumatic drying device of circulating fluidized bed

ActiveCN103673514APromote circulationImprove fluidization stateDrying solid materials with heatHearth type furnacesEngineeringMoisture

The invention discloses a pneumatic drying device of a circulating fluidized bed. According to the pneumatic drying device, a draught fan (1), a circulation pipe I (2), a dust remover (4), a regulating valve (5), an air inlet tee joint (6) and a circulation pipe II (7) form a circulation passage. The draught fan (1) sucks airflow in through the air inlet tee joint (6). Under the action of the airflow, materials are in a fluidization state and flow in the circulation passage at a high speed, heat exchange and water exchange are rapidly carried out between the fluidized materials and the air, and then moisture is discharged out through an exhaust port of the dust remover (4). The process is carried out repeatedly until the moisture content of the materials meets the requirement.

Owner:云南彝医药开发有限公司

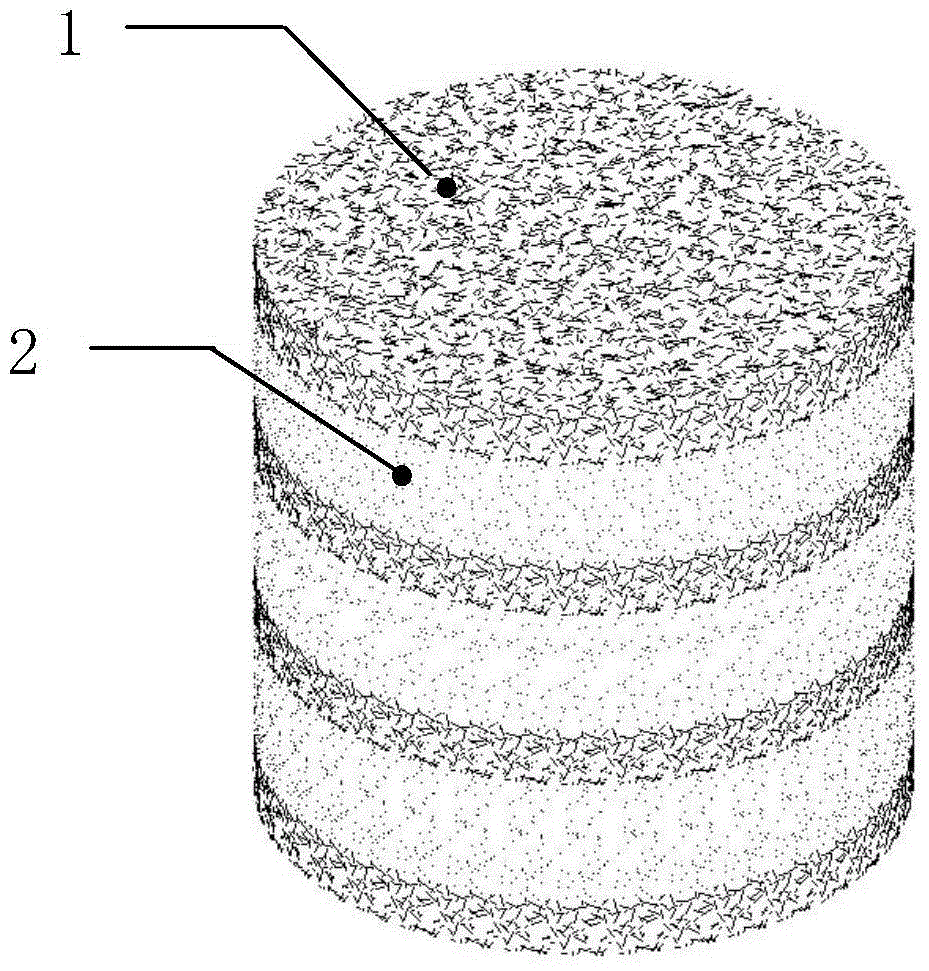

Preparation and application of ammonia oxidizing bacteria sandwich-type multilayer immobilized bioactive filler

InactiveCN103951038AStable structureGuaranteed uptimeSustainable biological treatmentOn/in organic carrierFiberSandwich like

The invention discloses preparation and an application of an ammonia oxidizing bacteria sandwich-type multilayer immobilized bioactive filler, and belongs to the technical field of water treatment. The ammonia oxidizing bacteria bioactive filler is composed of two parts: embedding bodies loaded with ammonia oxidizing bacteria and non-woven carriers; the embedding bodies and the non-woven carriers are alternatively arranged; fiber yarns of the non-woven carriers and the embedding bodies are combined into a stable organic whole, an embedding liquid prepared by mixing an ammonia oxidizing bacteria concentrated solution and a polyvinyl alcohol solution evenly coats the non-woven carriers, and multiple layers of carriers are overlaid together, after boric acid secondary cross-linking, the embedding liquid is cured to form the embedding bodies, and the embedding bodies are combined with the non-woven carriers to form a layered filler having a sandwich-like structure, and then the ammonia oxidizing bacteria granular bioactive filler is prepared through cutting the layered filler. The problems that the ammonia oxidizing bacteria are difficult in advantage establishment and are easy to lose are solved, the processing ability of a reactor is improved, and moreover, the sandwich-like layered structure formed by the non-woven fabrics and the embedding bodies improves the stability of the bioactive filler.

Owner:BEIJING UNIV OF TECH

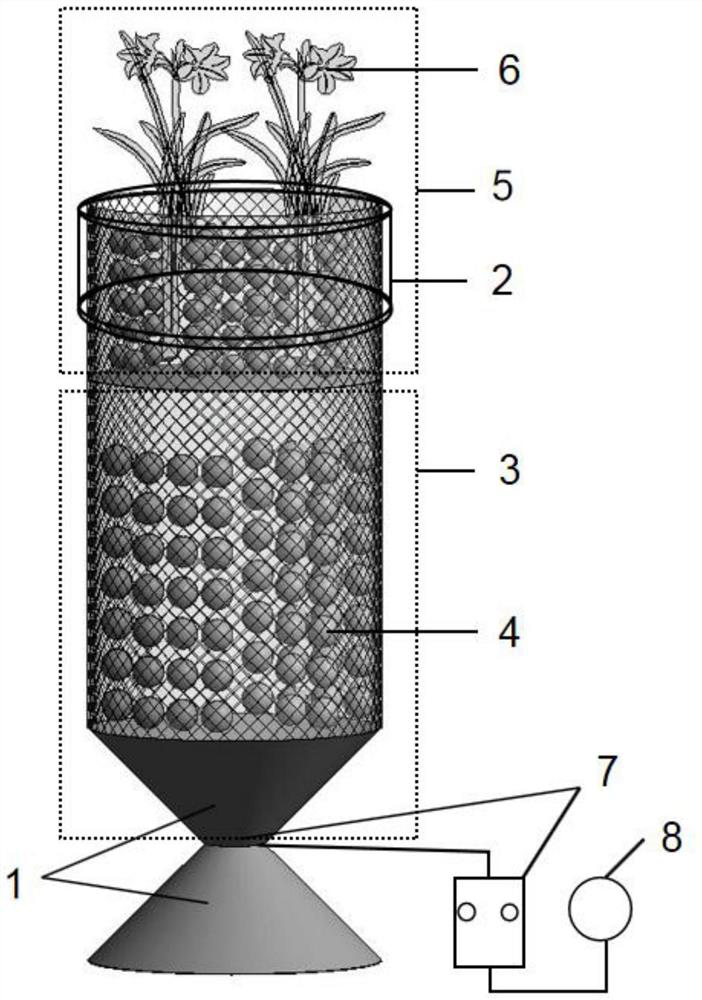

Garden type ecological floating island for in-situ upgrading and reconstruction

ActiveCN113800633AIncrease profitImprove low utilizationWaterborne vesselsSpecific water treatment objectivesEnvironmental engineeringOrganic matter

The invention particularly relates to a garden type ecological floating island for in-situ upgrading and reconstruction. The garden type ecological floating island comprises a gas collecting and releasing device, a floating island frame, a filler area, filler, a plant planting area, emergent aquatic plants, a self-control rotation control system and a motor. The ecological floating island is provided with the gas collecting and releasing device, so that the loss of dissolved oxygen is reduced; the ecological floating island is provided with the filler area, so that the sludge concentration of the system is increased, the utilization rate of dissolved oxygen is increased, and the removal rate of organic matters and nitrogen is increased; the automatic rotation control system of the ecological floating island can relieve the blockage problem; and the upper part of the floating island is the emergent aquatic plant planting area for absorbing organic matters and nitrogen in sewage, and meanwhile, the effects of beautifying and deodorizing the oxidation ditch are achieved.

Owner:ZHENGZHOU UNIV +2

Circulating fluidized bed gasification furnace starting system

PendingCN110358583ASolve the problems of excessive waste, serious environmental pollution and low thermal efficiencySolve the problem of serious pollution and low thermal efficiencyChemical industryGasification processes detailsStart timeFlue gas

The invention discloses a circulating fluidized bed gasification furnace starting system, which comprises a gasification furnace, a coal inlet system, a furnace baking gas system, a flue gas purification system and a flue gas circulation system. According to the present invention, when the furnace is started by using the method, the temperature rising and the pressure increasing of the gasification furnace are simultaneously performed, such that the condition that the temperature rising and the pressure increasing cannot be simultaneously performed in the conventional gasification furnace starting method is solved; by using the un-heated mixed gas as the coal powder conveying gas and the fluidizing agent, the coal powder in the gasification furnace can maintain a good fluidization state, the occurrence of the slagging accident in the gasification furnace can be avoided, the temperature rising and pressure increasing process can be shortened, the furnace starting time can be short, theunqualified synthesis gas volume is low, the waste of resources is reduced, and the environmental protection load of the enterprise is reduced; and the heating process mainly relies on the furnace baking gas, and the furnace baking gas has high heat efficiency, such that the coal powder consumption for ignition is reduced, and the production cost of the enterprise is lowered.

Owner:XINNENG ENERGY CO LTD

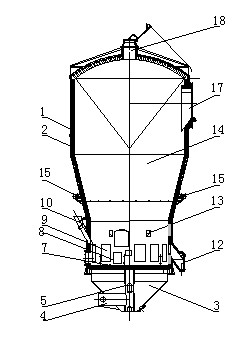

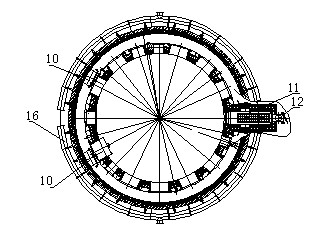

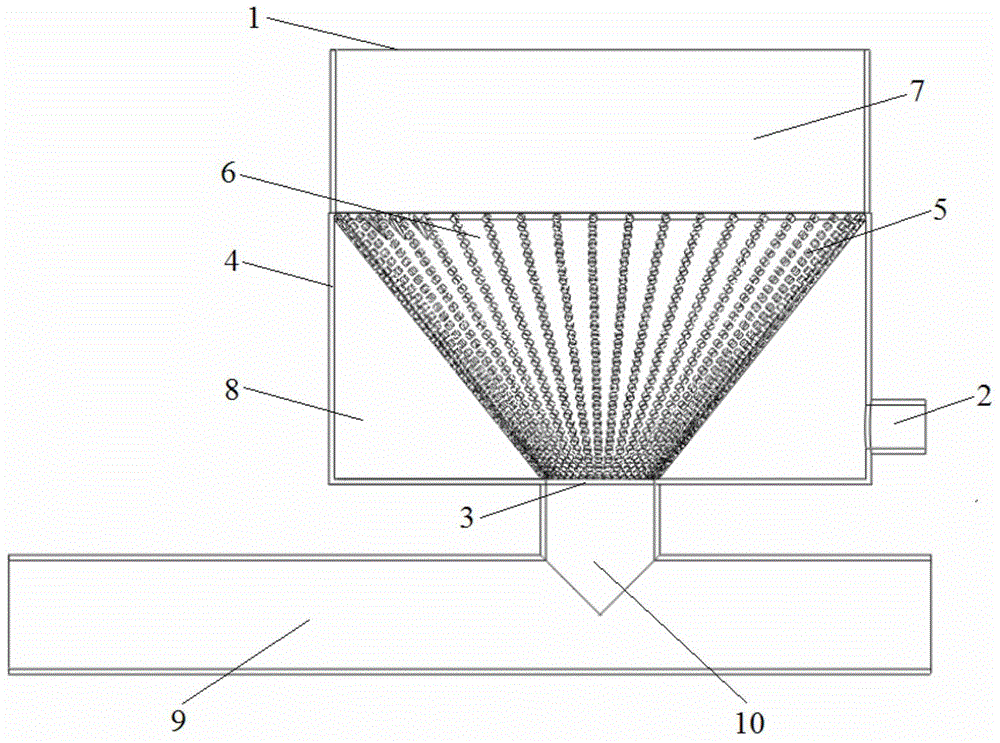

Tube-type fluid bed reactor in production of chlorothalonil

ActiveCN101985089AIncrease the heat exchange areaImprove fluidization stateChemical/physical processesCarboxylic acid nitrile purification/separationFluidized bedProcess engineering

The invention relates to a tube-type fluid bed reactor in the production of chlorothalonil. The fluid bed of the reactor comprises a coil heat exchanger and a tube-type heat exchanger. The coil heat exchanger is arranged below the lower end socket of the fluid bed, and the tube-type heat exchanger is arranged between the coil heat exchanger and the barrel body of the fluid bed. Compared with the prior art, the tube-type fluid bed reactor has the advantages of high temperature, high yield, low cost and the like.

Owner:JIANGSU XINHE AGROCHEM

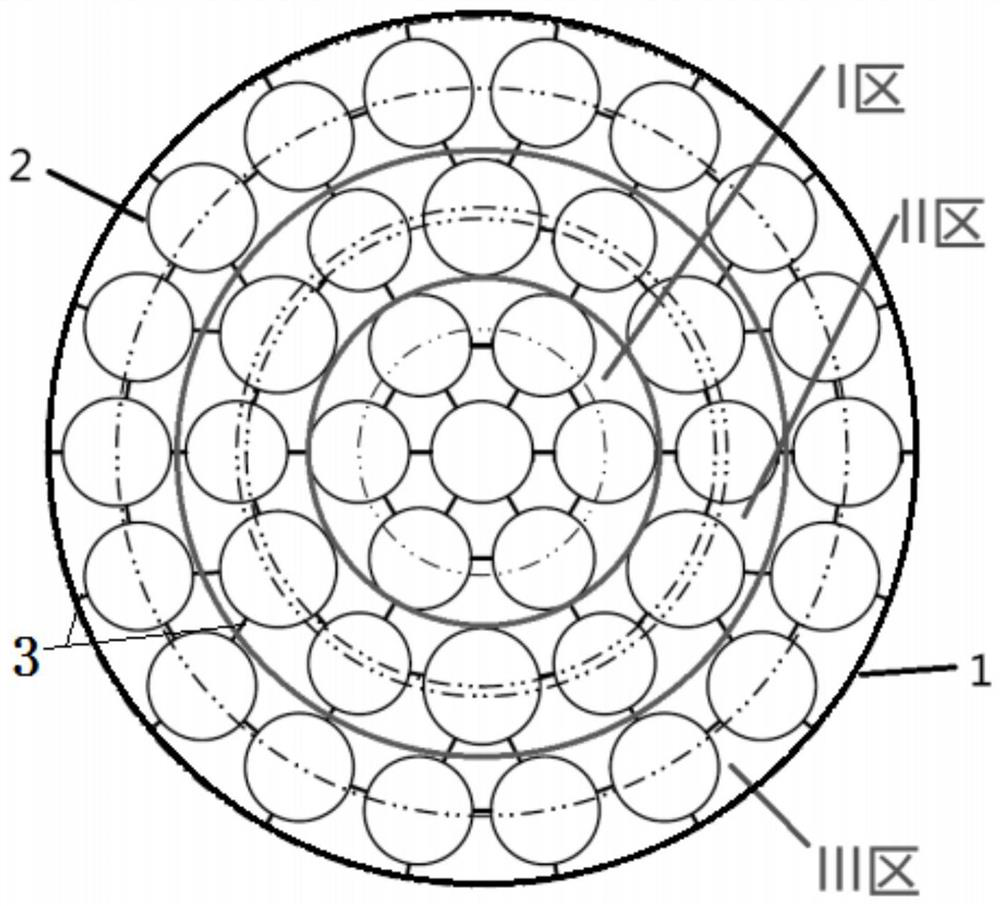

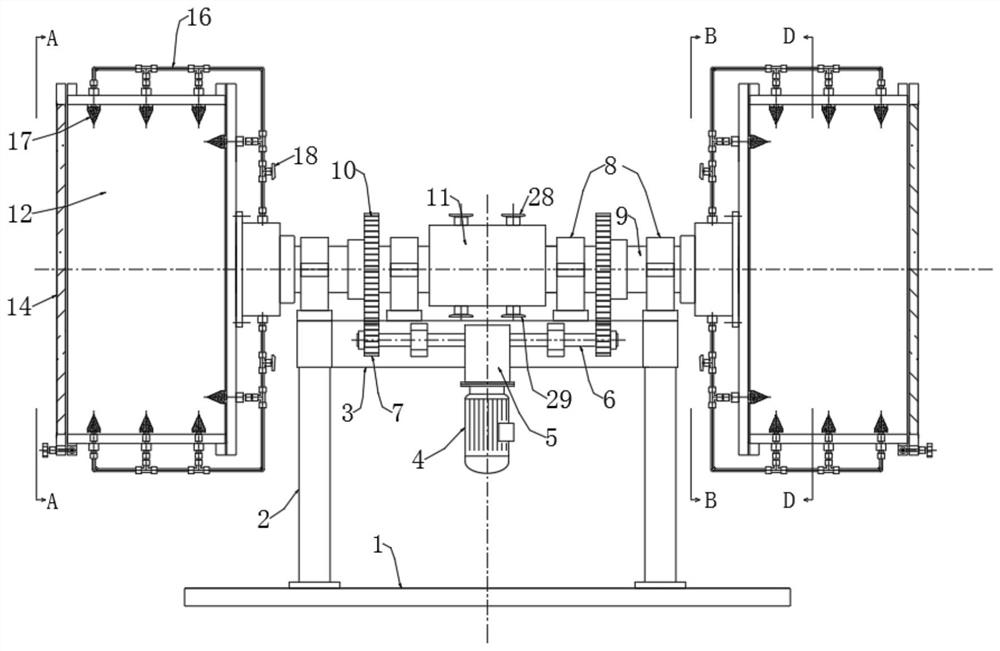

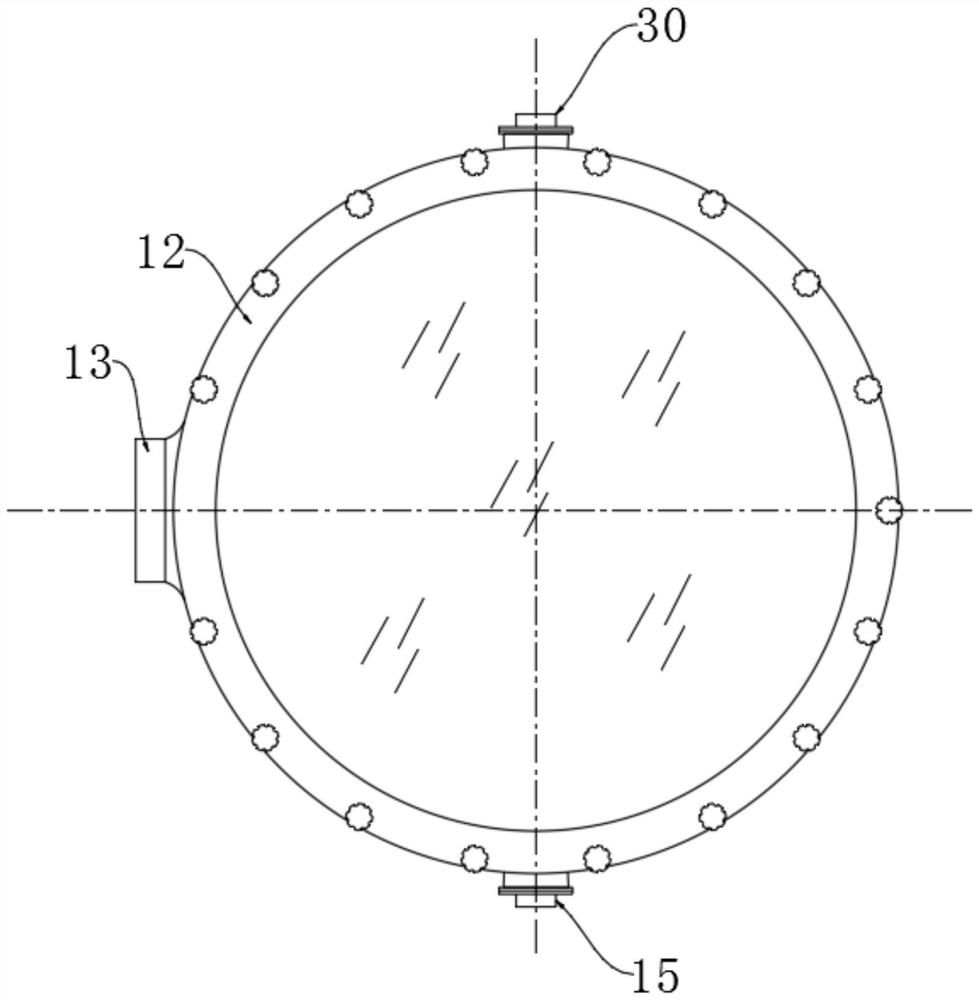

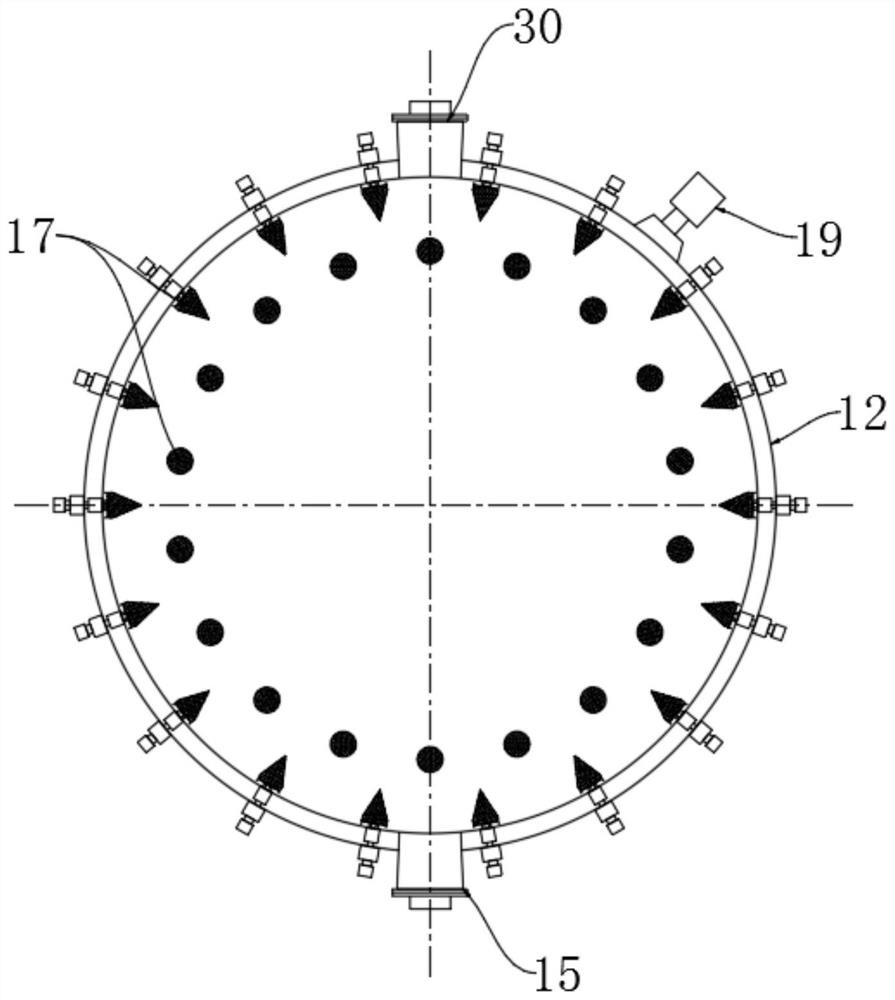

Industrial fluidized bed reactor

PendingCN114426328AImprove mass transfer efficiencyImprove fluidization stateWater treatment parameter controlTreatment using aerobic processesMicroorganismOxygen utilization rate

The invention discloses an industrial fluidized bed reactor which comprises a reactor shell, a plurality of guide cylinders and a plurality of gas distributors arranged at the bottoms of the guide cylinders, the axes of the guide cylinders are parallel, and the guide cylinders are arranged in the reactor shell at intervals. And the guide cylinders as well as the guide cylinders and the reactor shell are connected by adopting support plates through welding or bolts. By reasonably designing the arrangement mode of the guide cylinders, the oxygen utilization rate is improved, the fluidization state in the reactor is improved under the condition that the overall height of the reactor is not changed, the optimal matching of oxygen and air inflow required by aerobic biochemistry of microorganisms is met, the air consumption is reduced, and the mass transfer efficiency of the reactor is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel roller dryer

ActiveCN112325585AAvoid cloggingAvoid easy cloggingDrying gas arrangementsDrying solid materialsDrum dryingProcess engineering

The invention discloses a novel roller dryer. The novel roller dryer is composed of a roller, a gas distributor, a rotary joint and a roller driving mechanism. The working principle of the novel roller dryer is as follows: dry gas is introduced into the roller through the rotary joint and the distributor to realize lower semicircular gas inlet and upper semicircular gas outlet in the roller, and agas inlet and a gas outlet in the roller are sequentially changed along with the rotation of the roller to form gas flow from bottom to top in the roller, so that a dried material is in an approximate fluidized state, and drying of the material is further achieved. The novel roller dryer has the advantages of being high in drying efficiency, wide in material application range, capable of meetingthe GMP standard, high in automation degree and the like, and is an ideal substitute product for traditional stirring dryers, rotary dryers, helical ribbon dryers, rake dryers, box dryers and the like.

Owner:上海迪化科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com