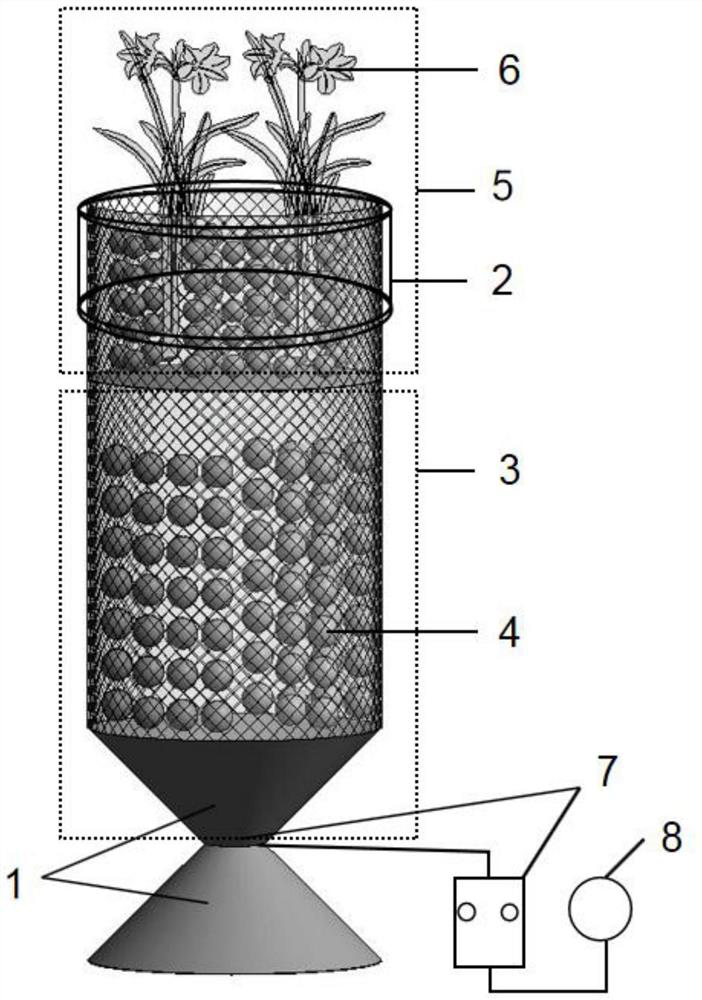

Garden type ecological floating island for in-situ upgrading and reconstruction

An ecological floating island, garden-like technology, applied in floating buildings, special treatment targets, biological treatment devices, etc., can solve the problems of uneven distribution of dissolved oxygen, reduced microbial activity, and uneven oxygen dispersion in the aerobic section. Optimizing the effect of low utilization, increasing concentration, and increasing microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The simulated oxidation ditch sewage is treated by using the ecological floating island and filler of the present invention, and the porous filler is made of nylon, coconut shell activated carbon and starch according to the mass ratio of 50:8:3, and the filling ratio is 30%. Put the ecological floating island into a simulated small-scale oxidation ditch device. The diameter of the gas collection and release device is 5cm, and the diameter of the opening is 60cm. The inoculation sludge was taken from the oxidation ditch, and the influent water was taken from the oxidation ditch of a sewage treatment plant in Shanxi. The residence time was 1 hour, the effluent water quality was stable, the removal rate of ammonia nitrogen increased by 17%, the removal rate of TN increased by 24.9%, and the removal rate of COD It has increased by 15.4% and reached the standard of the fourth category of surface water. The monitoring data are shown in Table 1.

[0025] Table 1 is the monitor...

Embodiment 2

[0028] Adopt the ecological floating island and filler of the present invention to process simulated oxidation ditch sewage, make porous filler according to the mass ratio of nylon, coconut shell activated carbon, and starch according to the ratio of 40:5:5, and the filling ratio is 40%. Put the ecological floating island into a simulated small-scale oxidation ditch device. The diameter of the gas collection and release device is 10cm, and the diameter of the opening is 100cm. The inoculum sludge was taken from the oxidation ditch, and the influent water was taken from the oxidation ditch of a sewage treatment plant in Jiyuan. The residence time was 50 minutes, the effluent water quality was stable, the removal rate of ammonia nitrogen increased by 17.9%, the removal rate of TN increased by 29.1%, and the removal rate of COD It has increased by 19.4% and reached the standard of the fourth category of surface water. The monitoring data are shown in Table 2.

[0029] Table 2 is ...

Embodiment 3

[0032] The simulated oxidation ditch sewage is treated by using the ecological floating island and filler of the present invention, and the porous filler is made of nylon, coconut shell activated carbon and starch according to the mass ratio of 35:6:5, and the filling ratio is 50%. Put the ecological floating island into the simulated small-scale oxidation ditch device. The diameter of the gas collection and release device is 8cm, and the diameter of the opening is 70cm. The inoculation sludge was taken from the oxidation ditch, and the influent water was taken from the oxidation ditch of a sewage treatment plant in Luohe. The residence time was 50 minutes, and the effluent water quality was stable. The removal rate of ammonia nitrogen increased by 16%, the removal rate of TN increased by 30.4%, and the removal rate of COD It has increased by 22.1% and reached the standard of the fourth category of surface water. The monitoring data are shown in Table 3.

[0033] Table 3 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com