Preparation and application of ammonia oxidizing bacteria immobilized bioactive filler based on polyurethane carrier

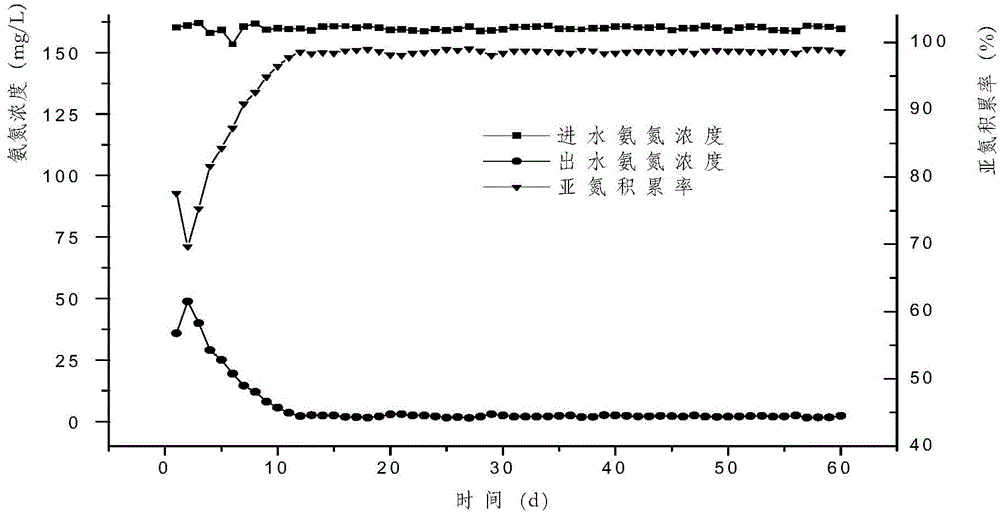

A technology of ammonia oxidizing bacteria and biological activity, applied in the direction of immobilization on/in organic carriers, sustainable biological treatment, biological water/sewage treatment, etc., can solve the difficulties in making spherical polyurethane, high processing costs, and low processing efficiency and other problems, to achieve the effect of saving raw materials, reducing treatment costs, and high nitrosation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Treatment of ammonia oxidizing bacteria

[0026] Using the residual sludge in the secondary sedimentation tank of the urban sewage plant as the bacterial source, the ammonia-oxidizing bacteria suspension after screening and enrichment culture was centrifuged and concentrated to obtain 3.5×10 9 Ammonia oxidizing bacteria concentrate per mL.

[0027] 2. Acquisition of embedding solution

[0028] Weigh 200g of polyvinyl alcohol, add 2500ml of ultrapure water and heat to 90°C to dissolve for 15min, take it out and stir evenly, then heat to 90°C and dissolve for 5min, take it out, stir evenly and cool to 30°C, mix 2500ml of polyvinyl alcohol solution with preparation The 2500ml concentrated solution was mixed, and 50g calcium carbonate was added, stirred evenly to make 5000ml embedding solution.

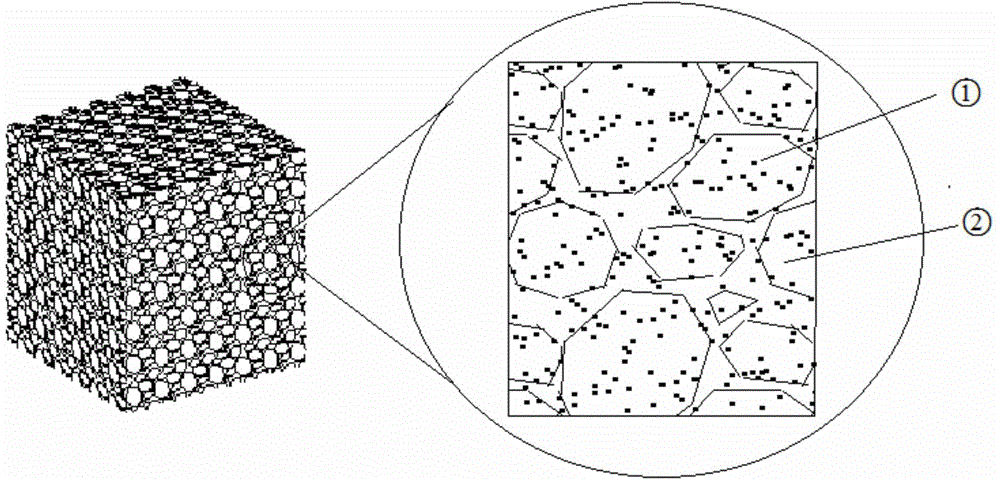

[0029] 3. Combination of embedding solution and polyurethane carrier

[0030] Pour the embedding solution into the entire polyurethane foam material (1m*1m*9mm), and squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com