Patents

Literature

142 results about "Sandwich like" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

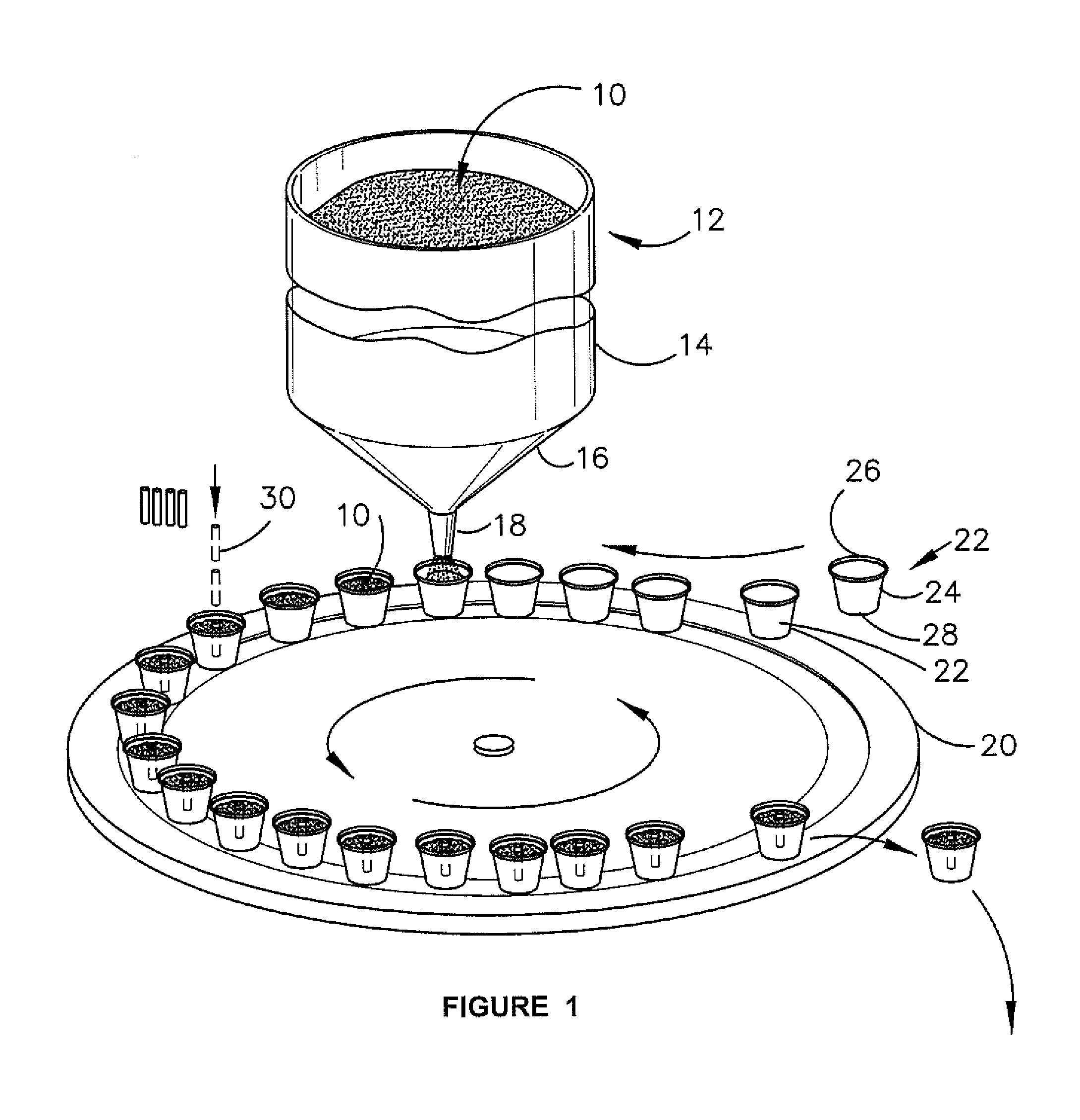

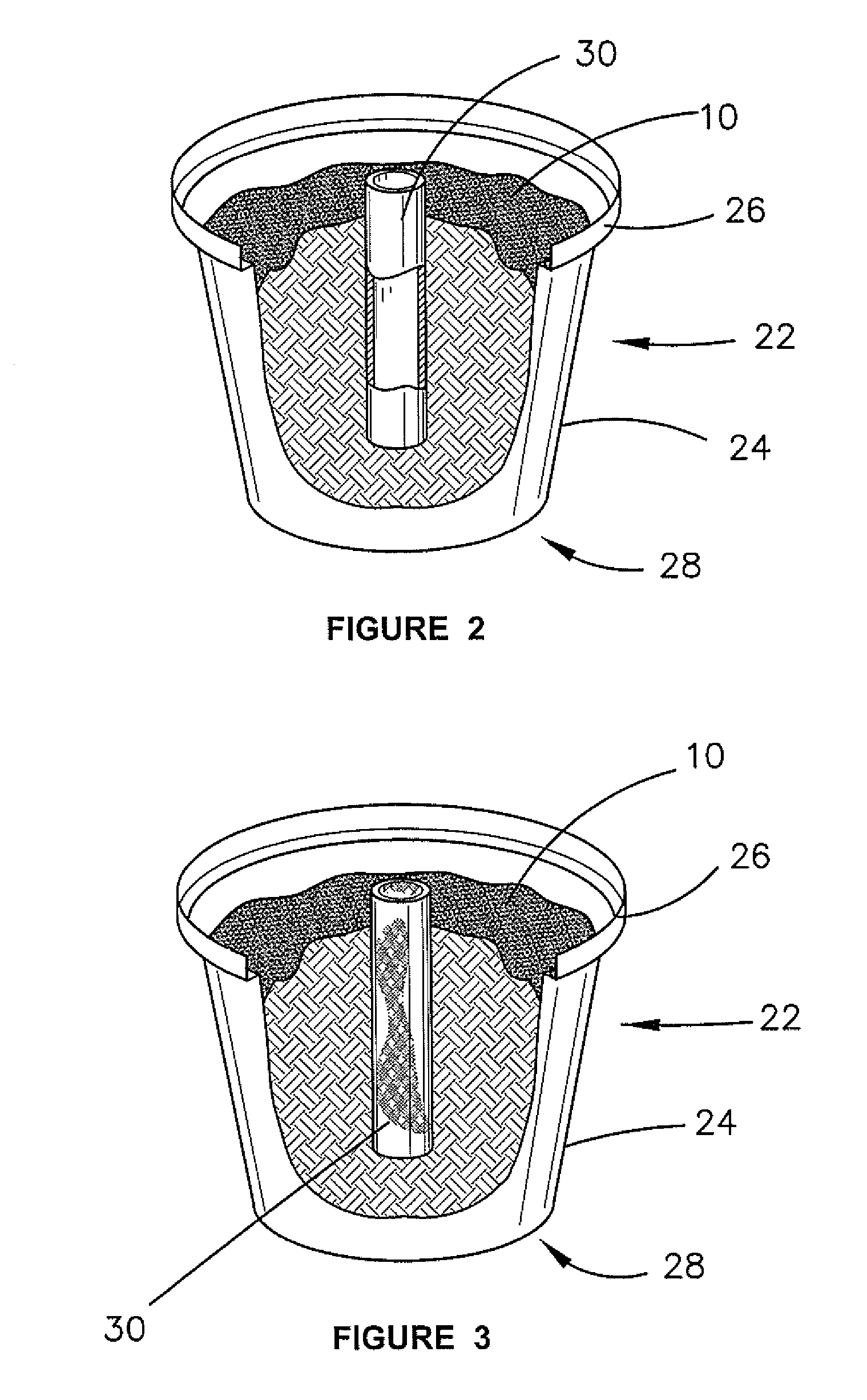

Systems and methods for topical treatment with nitric oxide

InactiveUS7048951B1Reduce skin irritationBiocideInorganic active ingredientsSandwich likeTransdermal patch

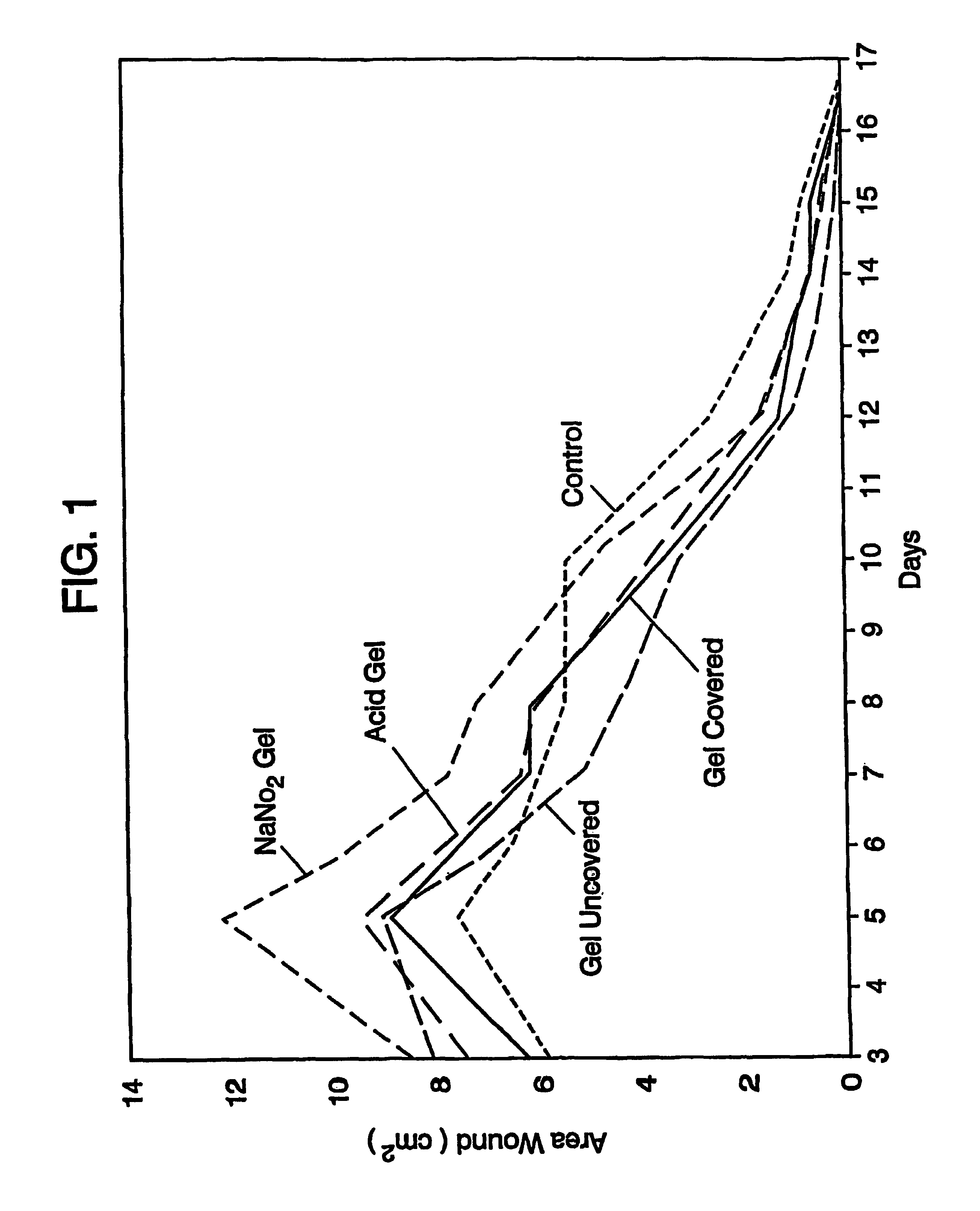

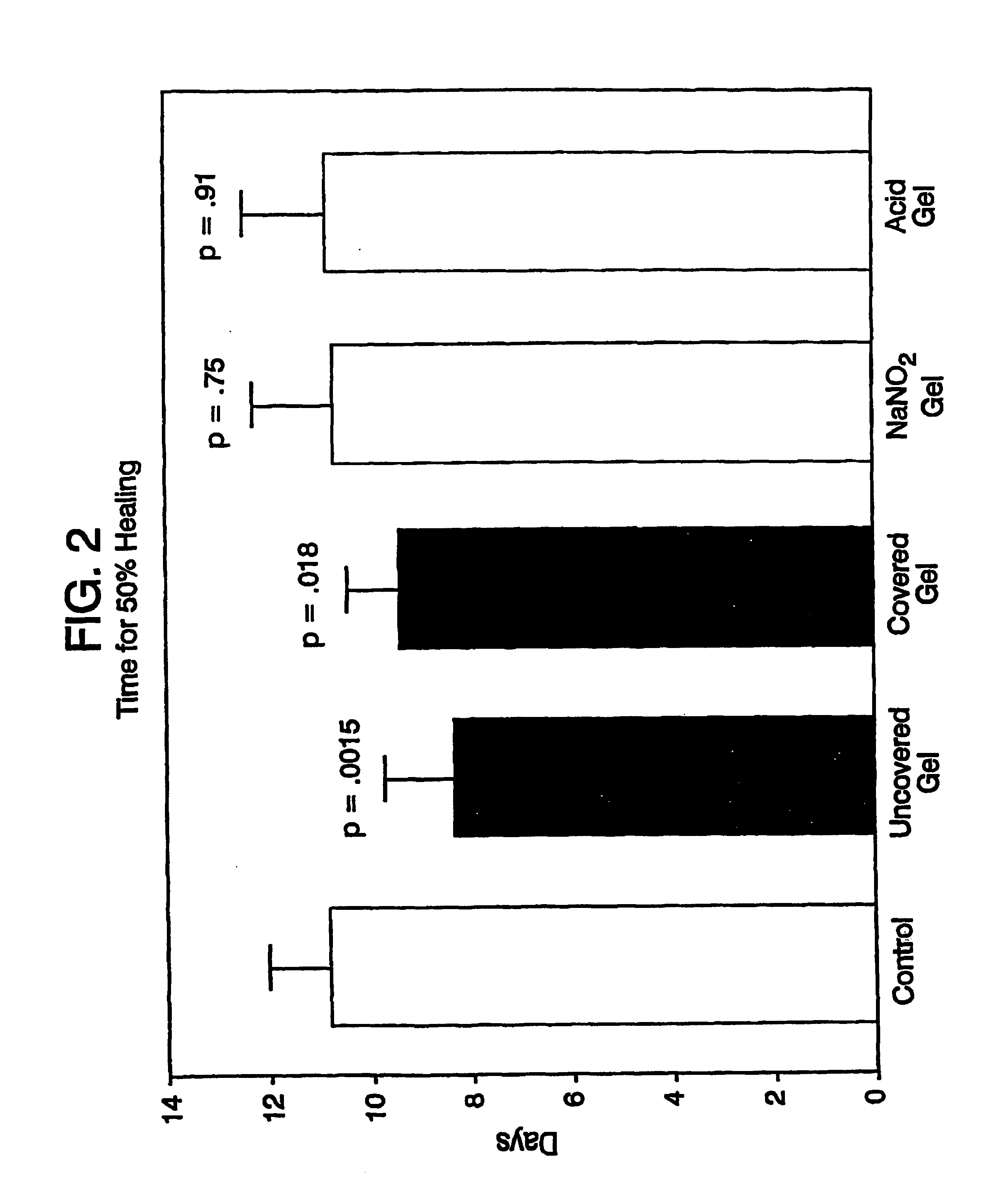

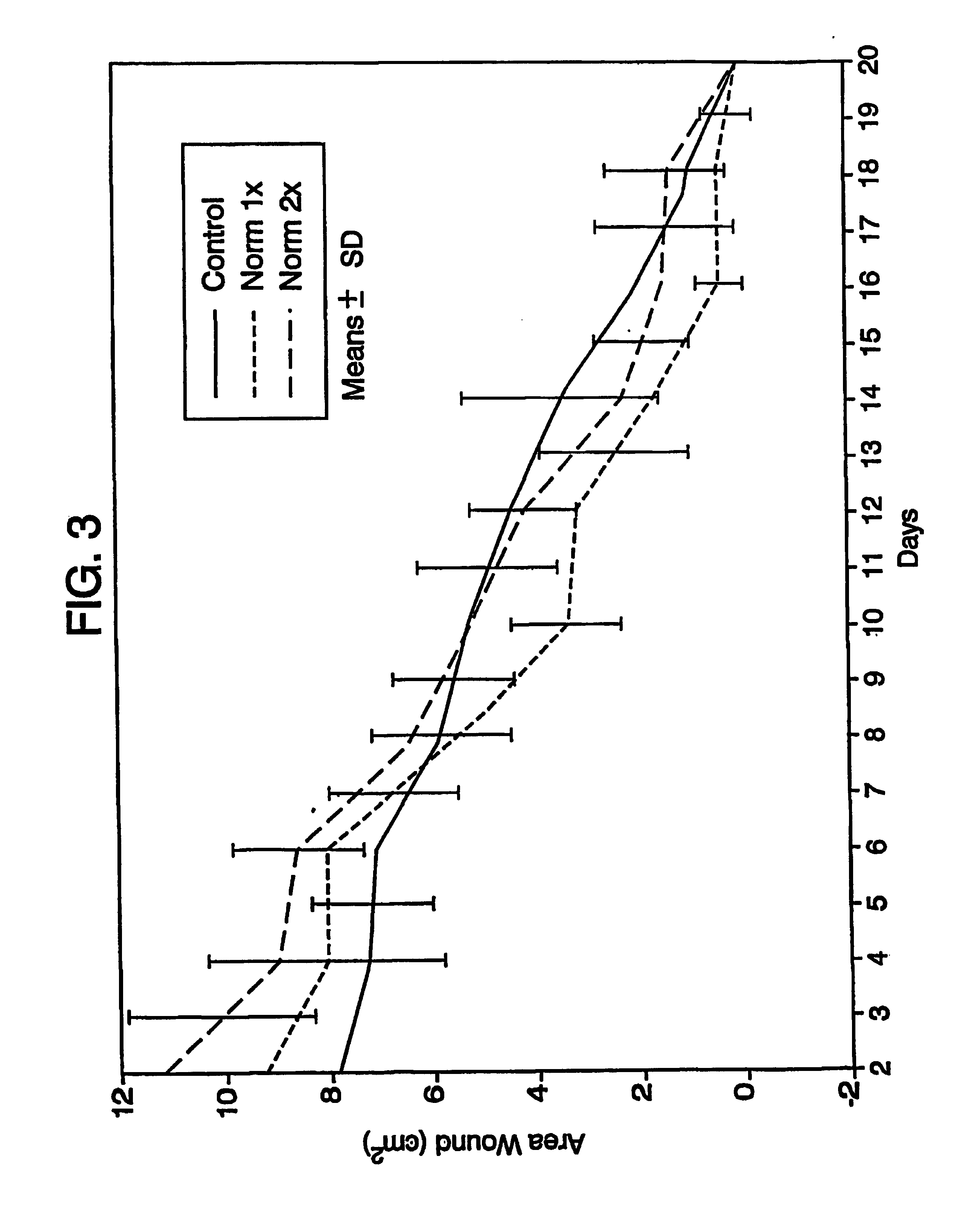

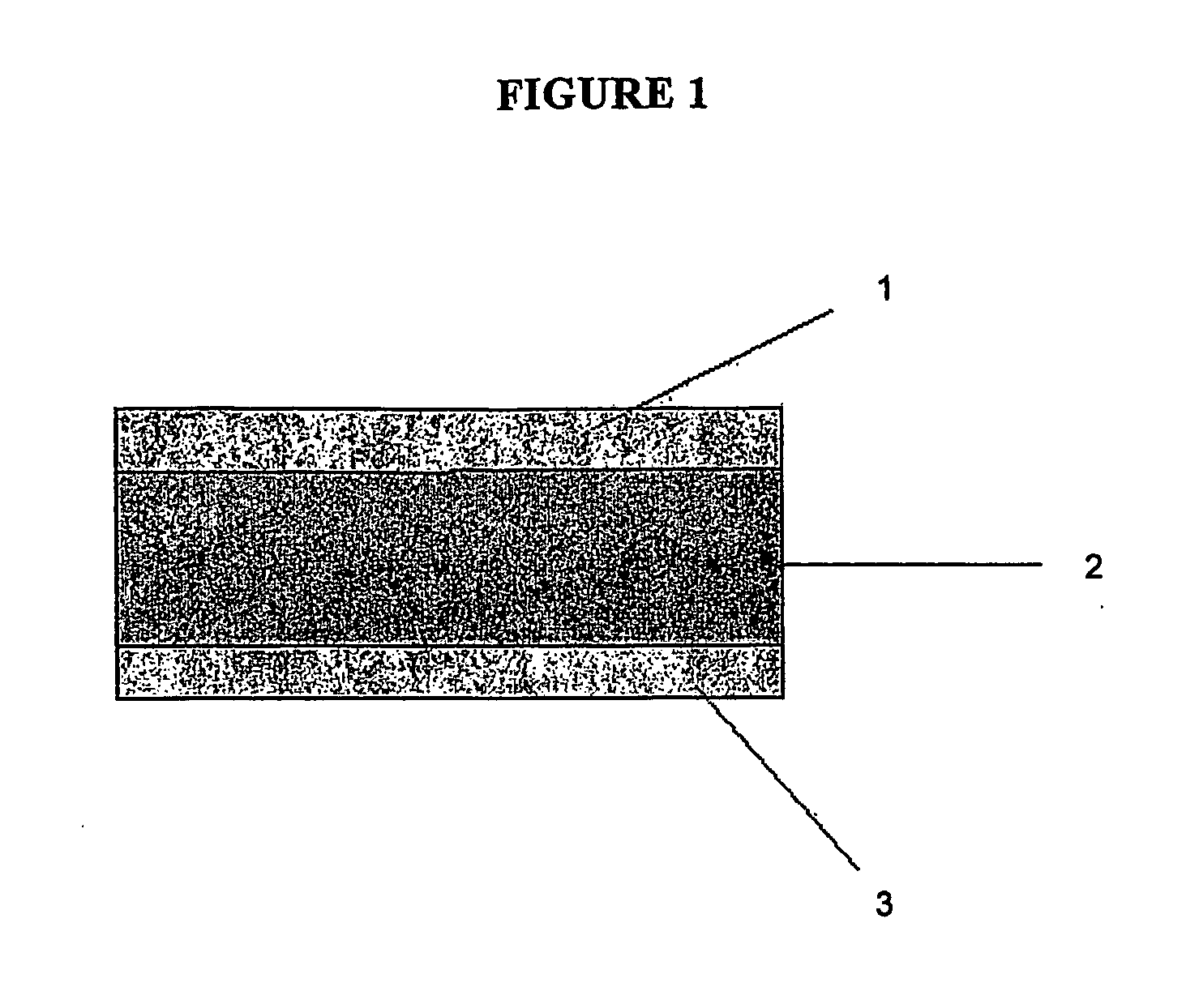

A simple, biocompatible system and procedure for generating nitric oxide (NO) is described. A mixture of powdered sodium nitrite, ascorbic acid, and maleic acid (or another organic acid of adequate strength) immediately generates nitric oxide (NO) on treatment with water. To slow down the NO generation, one may prepare an ointment from a nonaqueous medium (petrolatum, Vaseline™) and the three powdered ingredients, which on being applied topically on the skin will release NO as water permeates through this medium; alternatively, one may convert the aqueous sodium nitrite solution into a gel with hydroxyethylcellulose (or other gel-forming compound) and combine this gel with another gel obtained from aqueous ascorbic and maleic acids with hydroxyethylcellulose for topical application (on intact skin, burns intra-cavity, burns, intra-cavity, etc.). The two gels may be admixed immediately before use (possibly from a single container with separate chambers and dual nozzle, via pushing or squeezing the two gels through the nozzle), or may be applied in sandwich-like fashion (possibly as a transdermal patch) for further slowing down the delivery of NO.

Owner:NITRIC SOLUTIONS

Chewing gum in the form of multi-layer tablets

ActiveUS20060204451A1Improve featuresOvercome difficultiesBiocidePeptide/protein ingredientsSandwich likeAdjuvant

Disclosed are tablets having a sandwich-like structure comprising at least one inner layer of gum base containing one or more active pharmaceutical, dietetic or nutritional ingredients and two non-contigous outer layers comprising antiadhesion excipients and compression adjuvants preventing the adhesion to the punches of the tabletting machine and possibly active ingredients which are the same as or different from those present in the inner layer. Said tablets are obtainable by direct compression of mixtures or granulates of the various components of each layer.

Owner:JAGOTEC AG

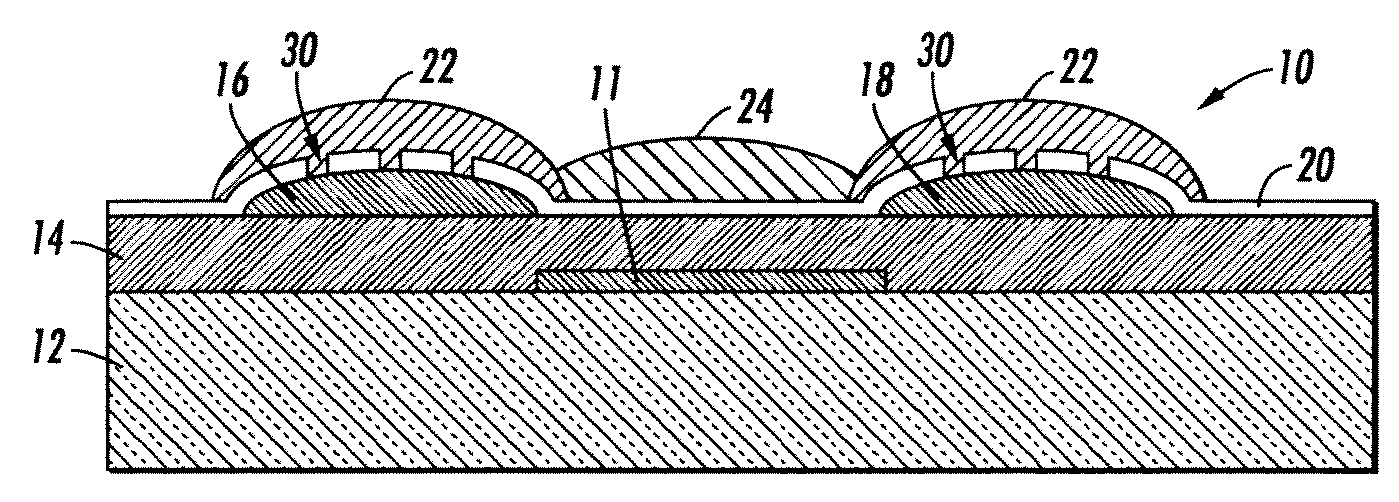

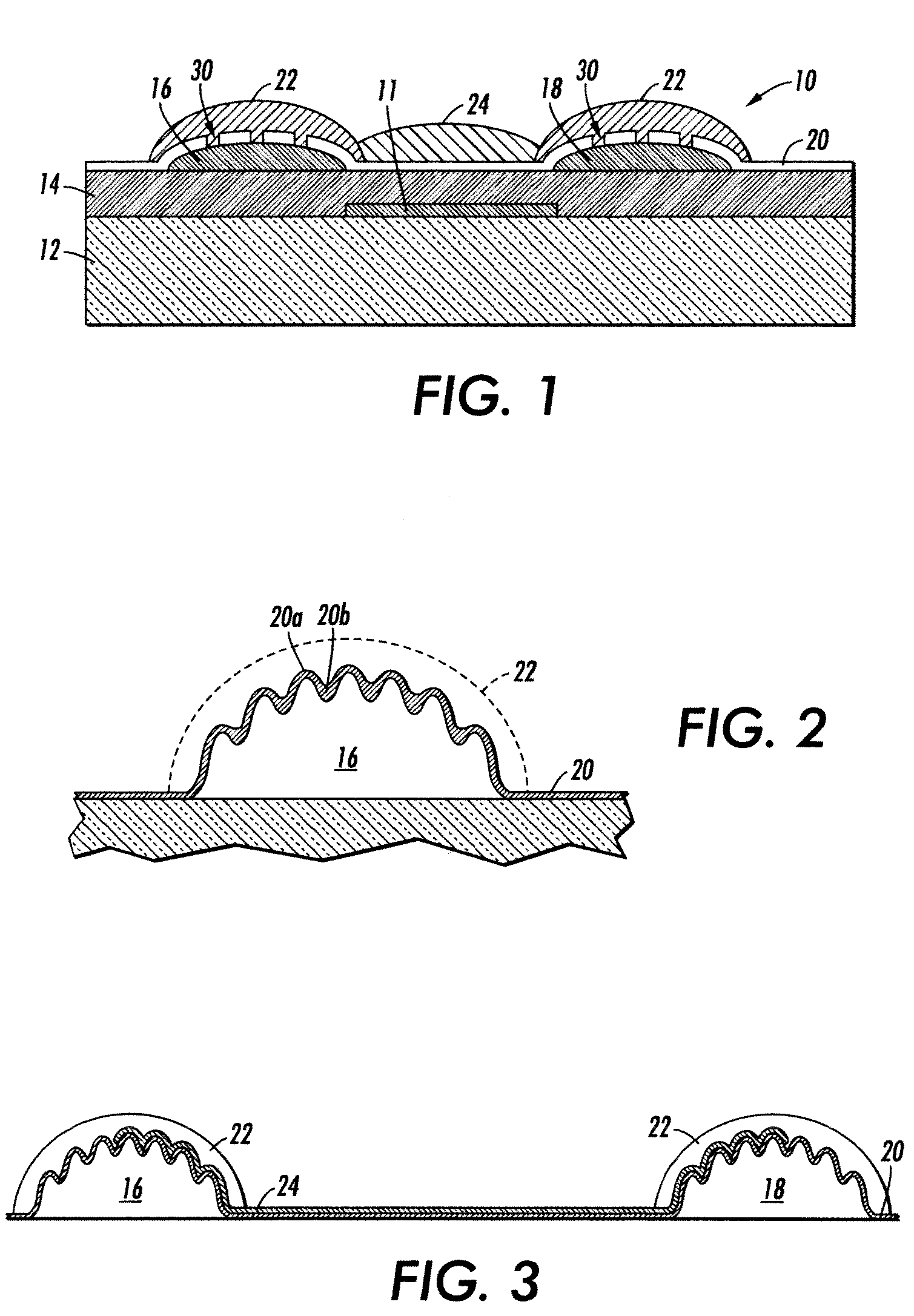

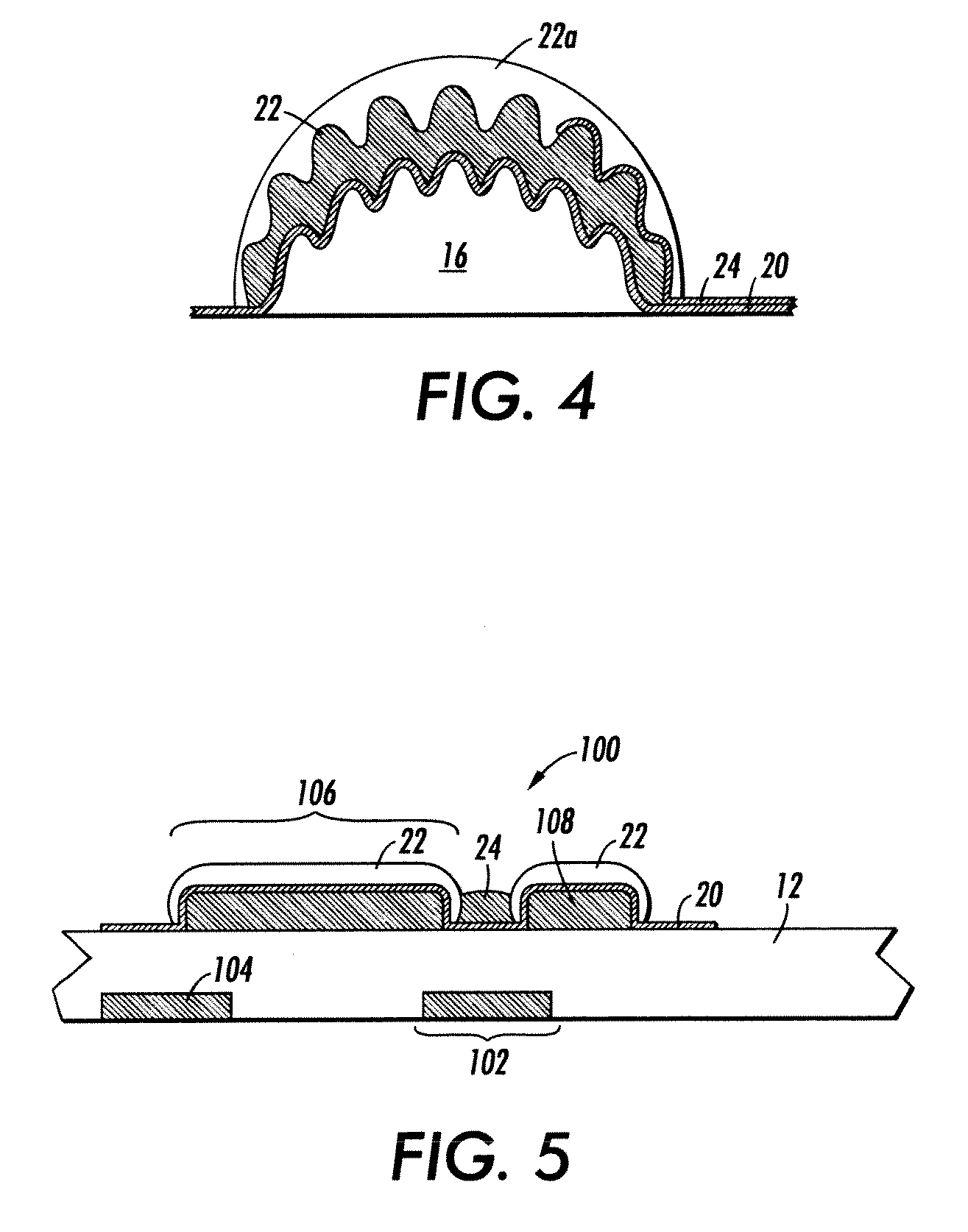

Method and structure for establishing contacts in thin film transistor devices

ActiveUS20100127269A1Surface energy be lowTransistorSolid-state devicesSandwich likeHydrophobic polymer

The roughness and structural height of printed metal lines is used to pin a fluid. This fluid deposits a top contact material which is connected to the bottom printed contacts through pinholes in the hydrophobic polymer layer. This results in a sandwich-like contact structure achieved in a self-aligned deposition process and having improved source-drain contact for all-additive printed circuits. In one form, the present technique is used for thin film transistor applications, but it may be applied to electrodes in general.

Owner:XEROX CORP

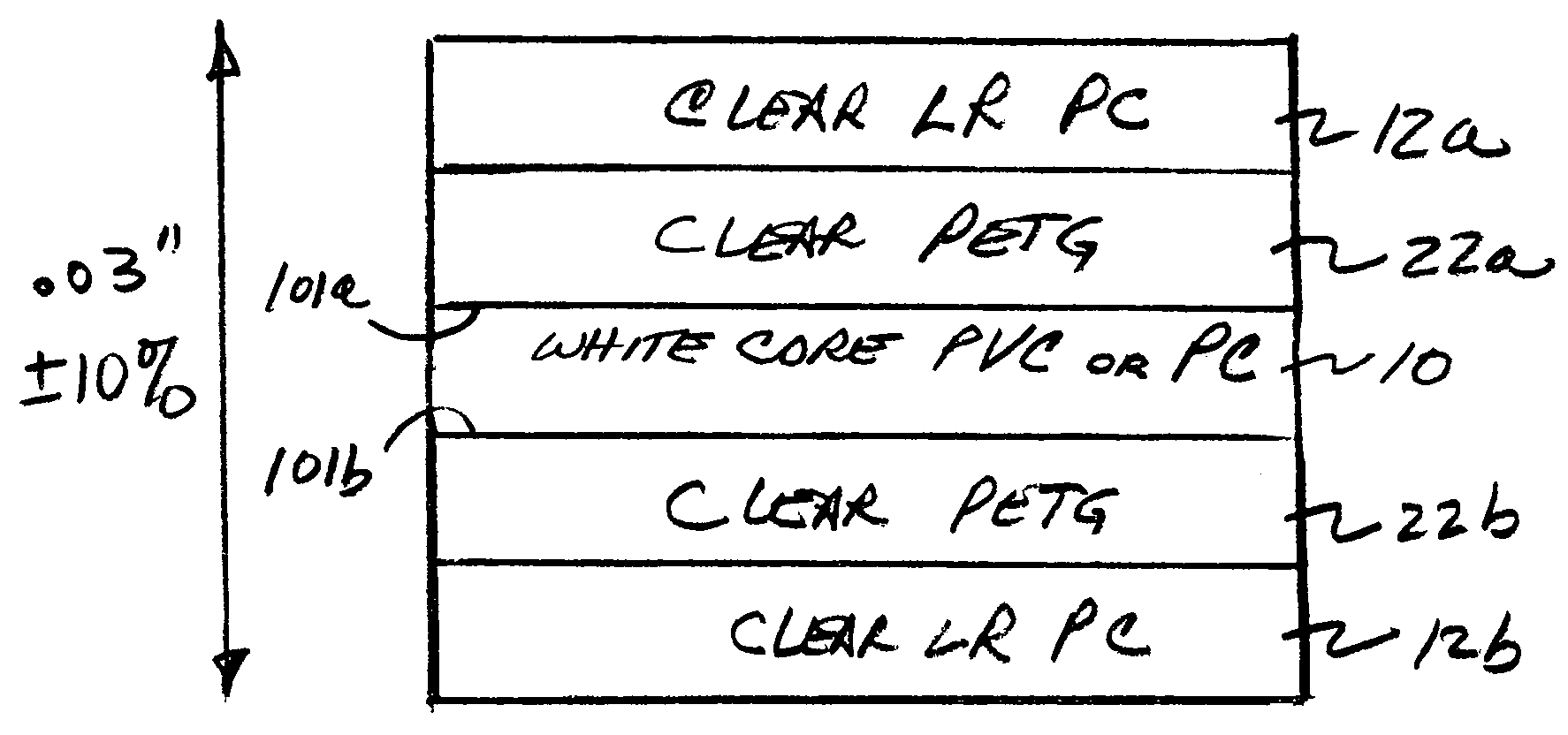

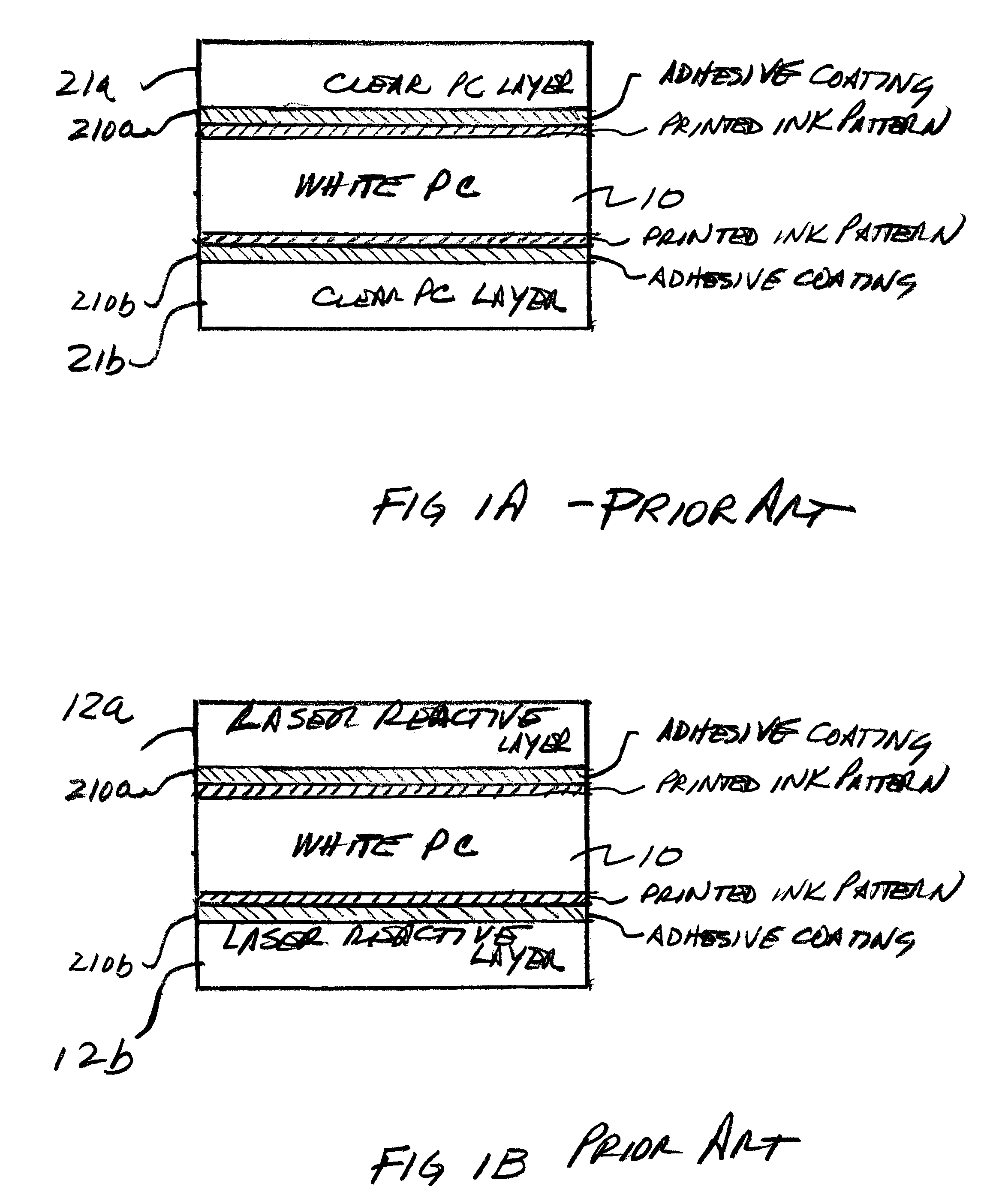

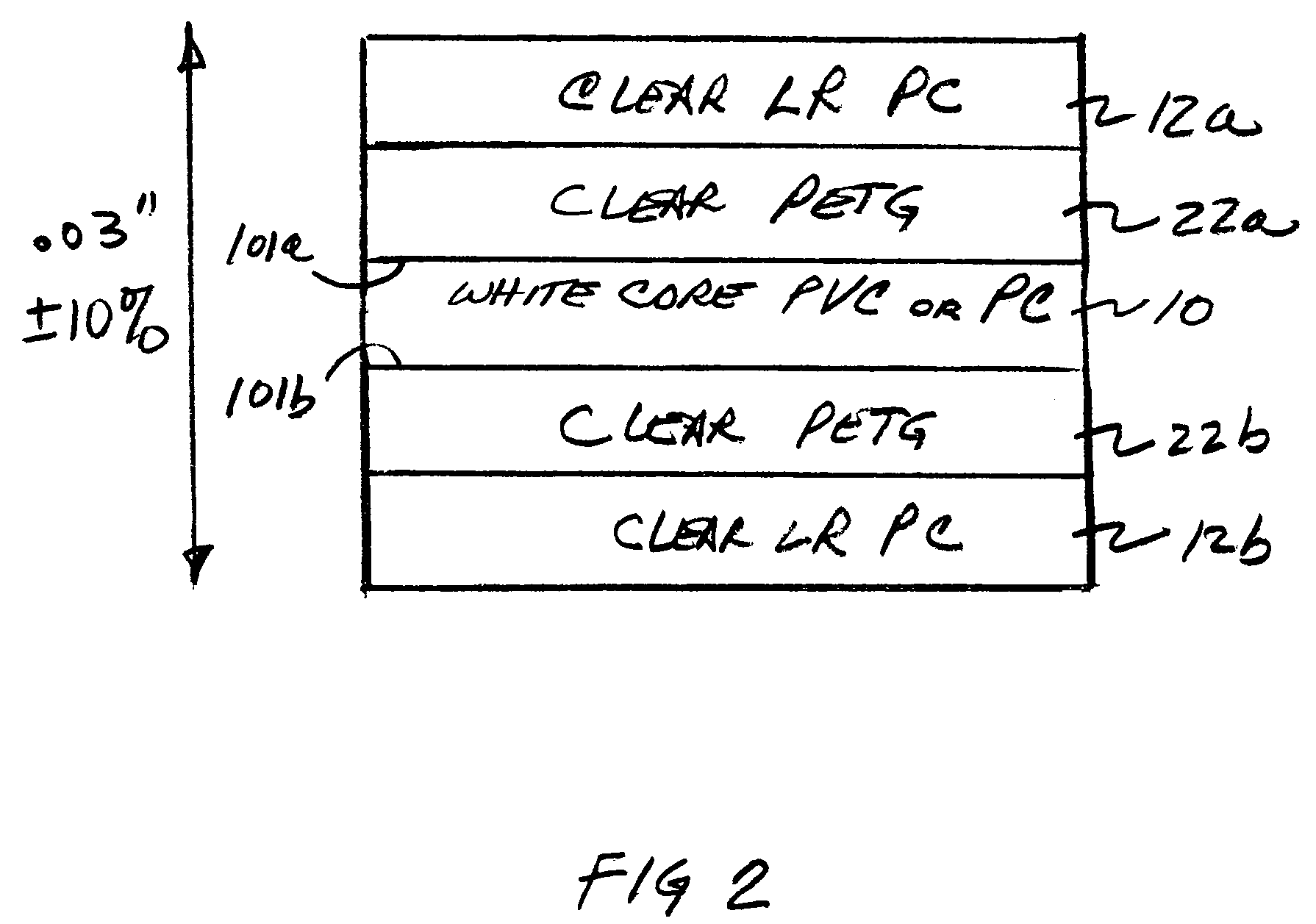

Laser markable secure documents

ActiveUS7287704B2Reduce heatAvoid problemsSynthetic resin layered productsCardsSandwich likePolyester

Owner:COMPOSECURE LLC

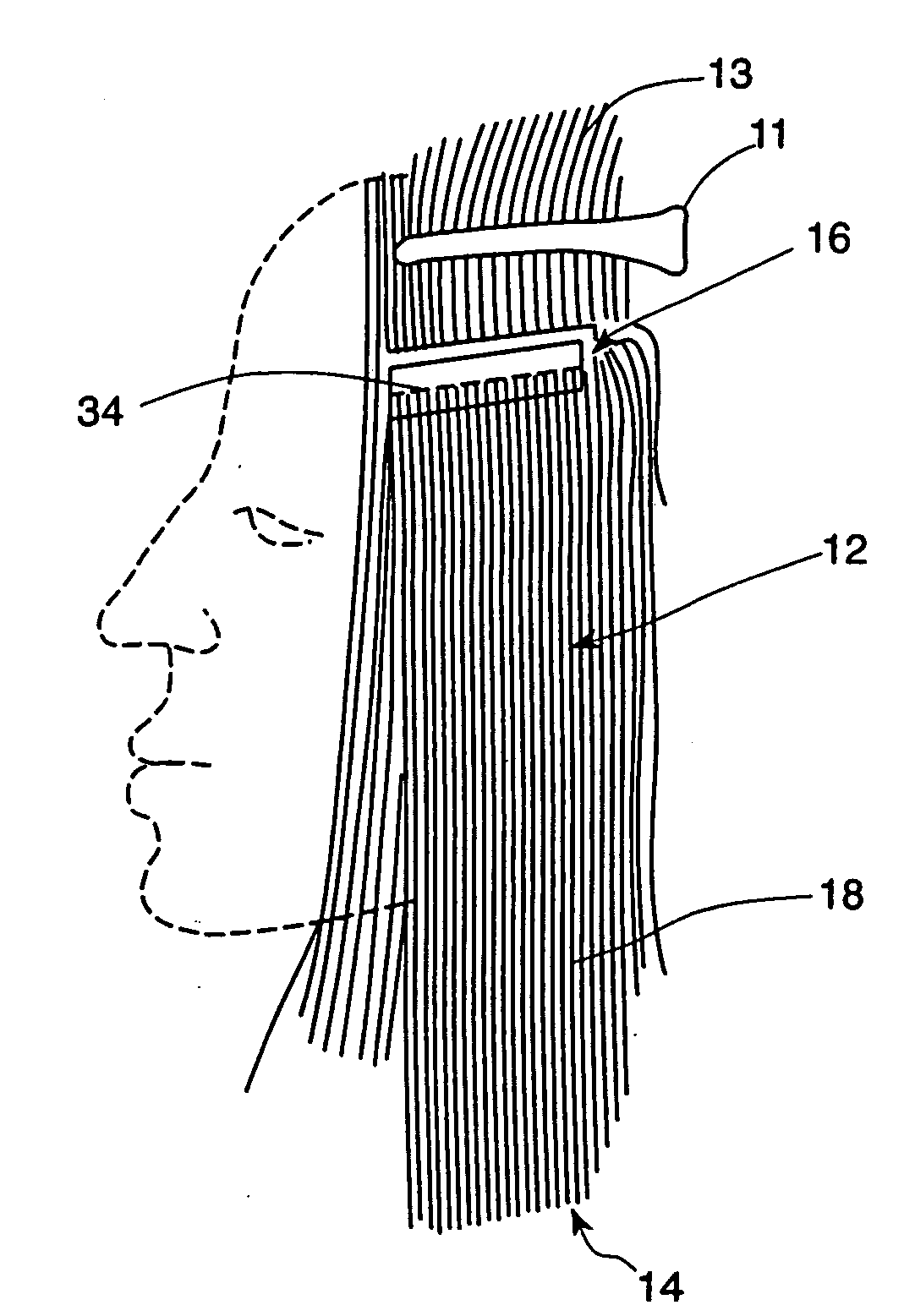

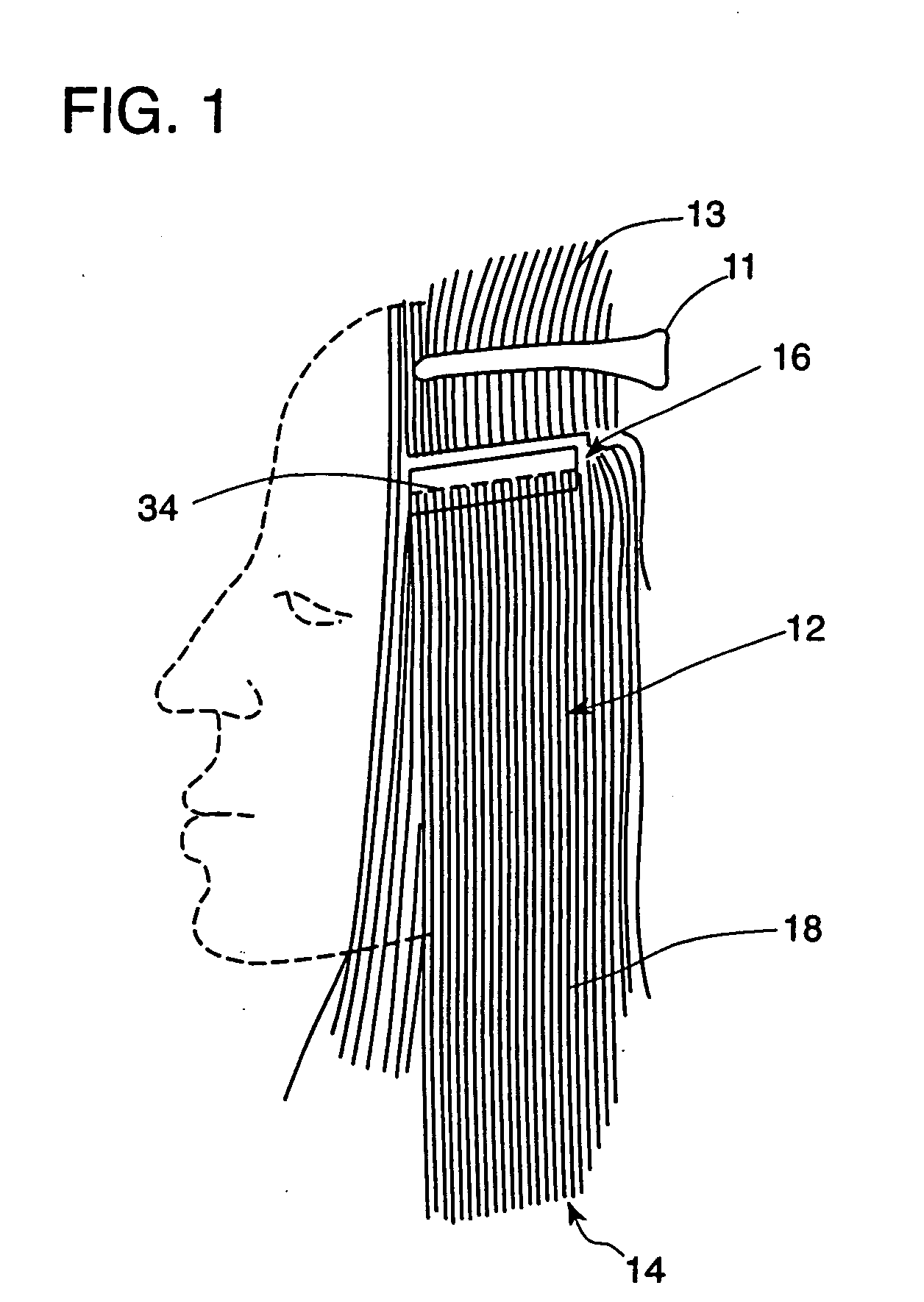

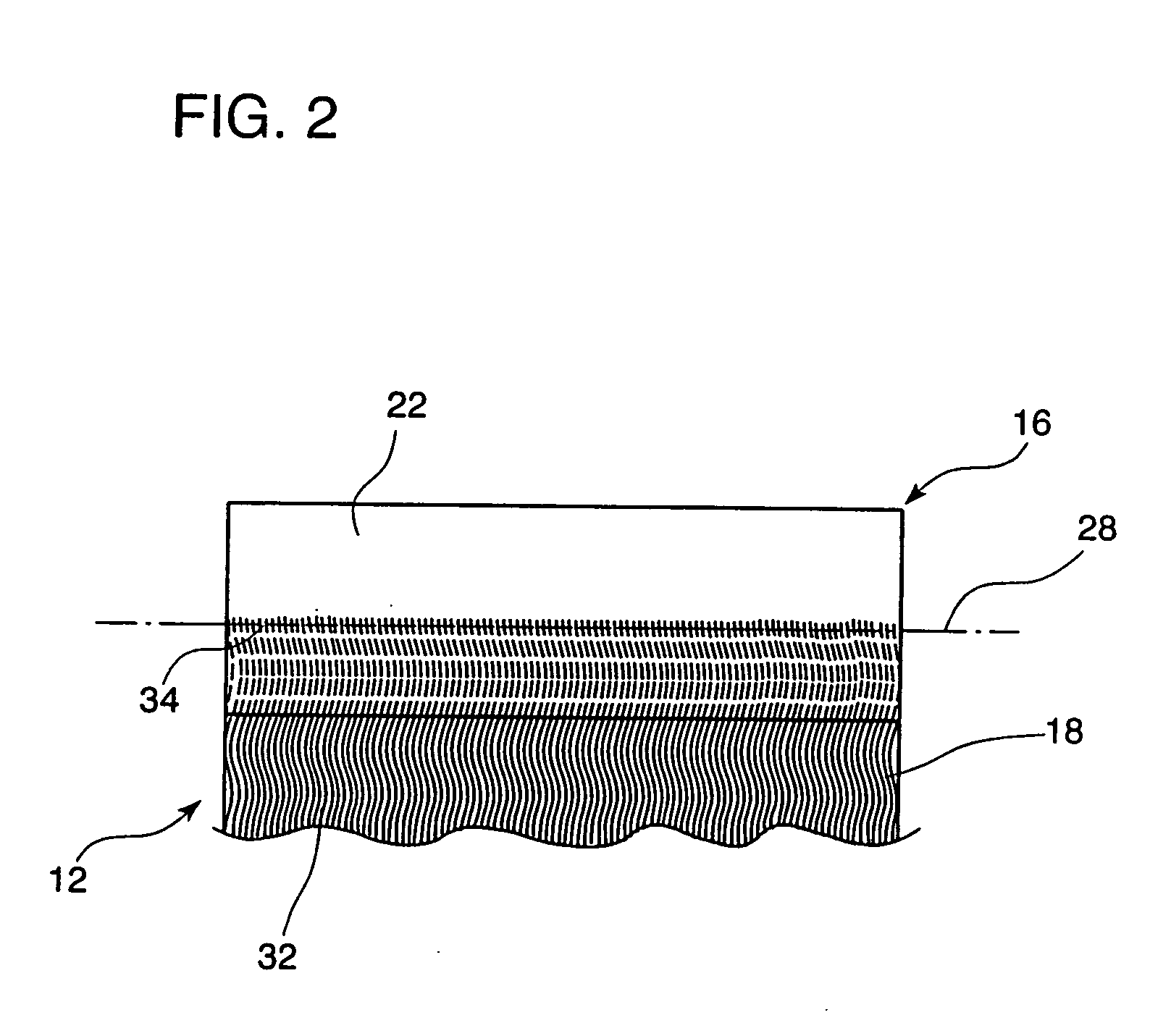

Hair extensions and method of attachment

A unique human or synthetic fibre hair extension and method are disclosed. One embodiment of the human or synthetic fibre hair extensions come packaged with double sided tape attached to both sides of the hair extension, with the weft and human or synthetic fibre hair attached between the two pieces of tape. The double sided tape is covered with a tape cover or liner on both sides of the extensions. First, the human or synthetic fibre hair extension is positioned for correct placement below the horizontal part line, the liner is removed form the bottom side of the hair extension and the human or synthetic fibre hair extension is secured by pressing into place. The second piece of double sided tape which is attached to the second side of he human or synthetic fibre hair extension and facing up has the liner removed and is then covered with a layer of the users's natural hair, which taken from the clipped area above the part. This creates a sandwich-like effect attachment of the human or synthetic fibre hair with the user's hair. Also shown is a flow chart and various application methods aiding the stylist in analyzing and applying extensions to the users head.

Owner:KENNA LISA

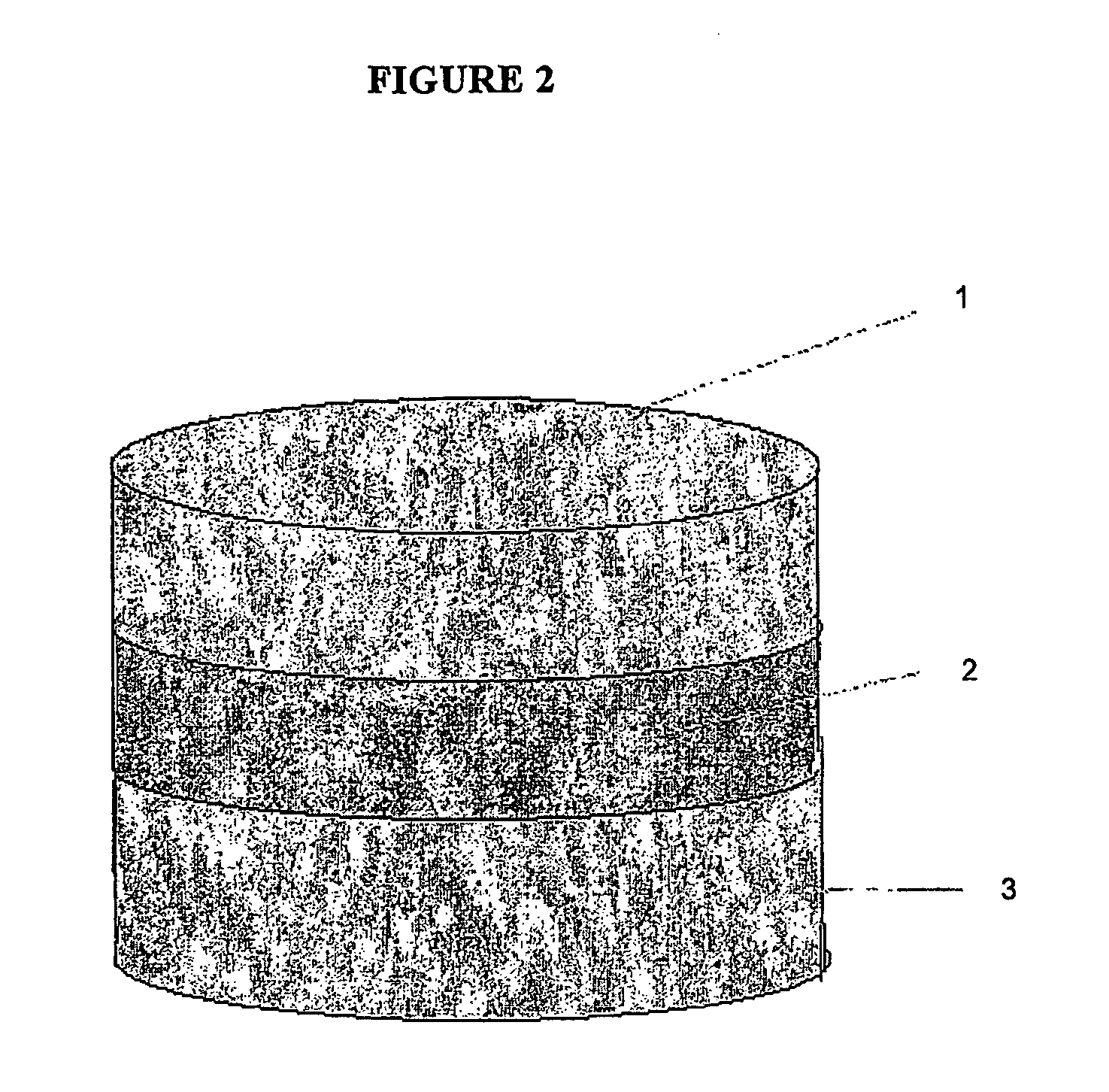

Sandwich-like hollow structure metallic oxide @ noble metal nanoparticles @ metallic oxide catalyst as well as preparation method and use thereof

ActiveCN104001505AReduce pollutionAvoid local damageMaterial nanotechnologyCarbon compoundsSandwich likeSpherical shaped

The invention discloses a sandwich-like hollow structure metallic oxide @ noble metal nanoparticles @ metallic oxide catalyst as well as a preparation method and the use of the sandwich-like hollow structure metallic oxide @ noble metal nanoparticle @ metallic oxide catalyst. The method combines a sol-gel method and a hydrothermal method, and comprises the steps of preparing a spherical SO2 template with uniform size by the sol-gel method; then, coating a metallic oxide shell layer on the surface of the spherical SO2 template, adsorbing noble metal nanoparticles to the surface of the shell layer by electrostatic action, and further coating another metallic oxide shell layer on the surface of the spherical SO2 template by the sol-gel method; finally, carrying out crystallization on the amorphous metallic oxide shell layers and removing the SO2 template by adopting the hydrothermal method to obtain the sandwich-like hollow structure catalyst. The existing 'high-temperature calcination and alkali etching' method is replaced by the hydrothermal method; the method has the characteristics of being simple in operation, high in yield and good in monodispersity; the prepared sandwich-like hollow structure material is excellent in activity and stability in a catalytic reaction.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

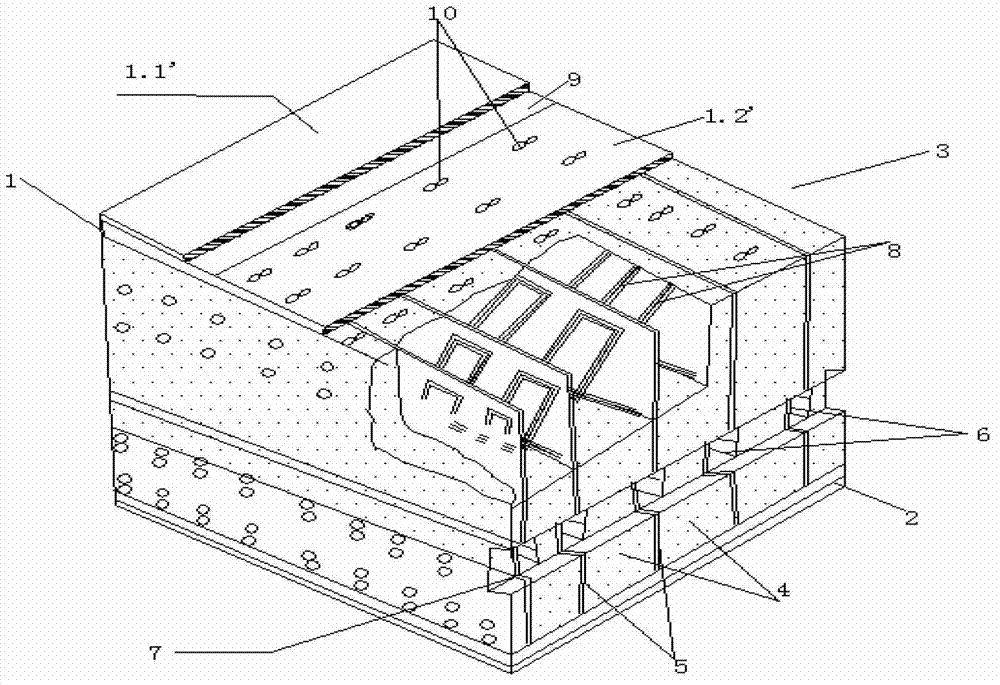

Container and platform floor with bamboo oriented structure shaving board as sandwich layer and manufacturing method thereof

InactiveCN101214669AMeet performance requirementsImprove pressure resistanceWood veneer joiningFlat articlesSandwich likeWood veneer

Belonging to the field of composite boards and production methods thereof, the present invention relates to a oriented structural bamboo flakeboard as the sandwich layer of a container and a carriage bottom board and a production method thereof, in particular to a container and a carriage bottom board, which are produced with the oriented structural bamboo flakeboard as the sandwich layer substrate, and a production method thereof. The oriented structural bamboo flakeboard is composed of a surfacial layer, a sandwich layer and a bottom layer which are bonded together, and is characterized in that the sandwich layer is of a structural flakeboard which is formed by more than five layers of crisscross bamboo flakes which are directionally paved and bonded, and the surfacial layer and the bottom layer are of more than one layer of single wood veneer or impregnated paper or phenolic impregnated paper, or the surfacial layer and the bottom layer are the composite layers of the wood veneer and the impregnated paper or the phenolic impregnated paper. The production method includes the production and bonding of the sandwich layer, the surfacial layer and the bottom layer. The present invention resolves the problems of the scarcity and ecological destruction of the materials of the traditional containers and carriage bottom boards, and not only is the cost reduced, but also the mass production of the novel bottom boards which meet the technical requirements of the international container and carriage bottom board industry is satisfied.

Owner:邱天祥

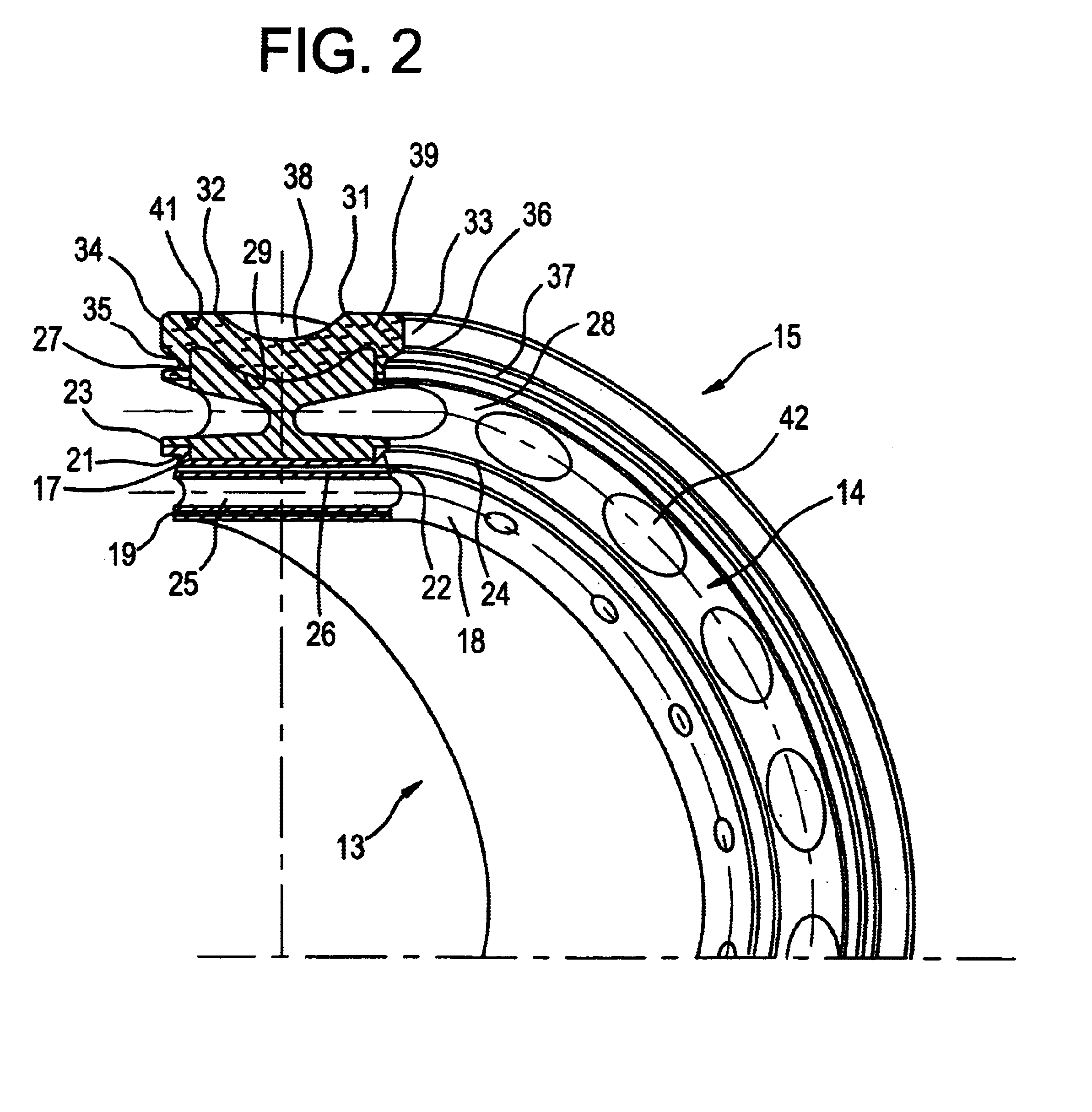

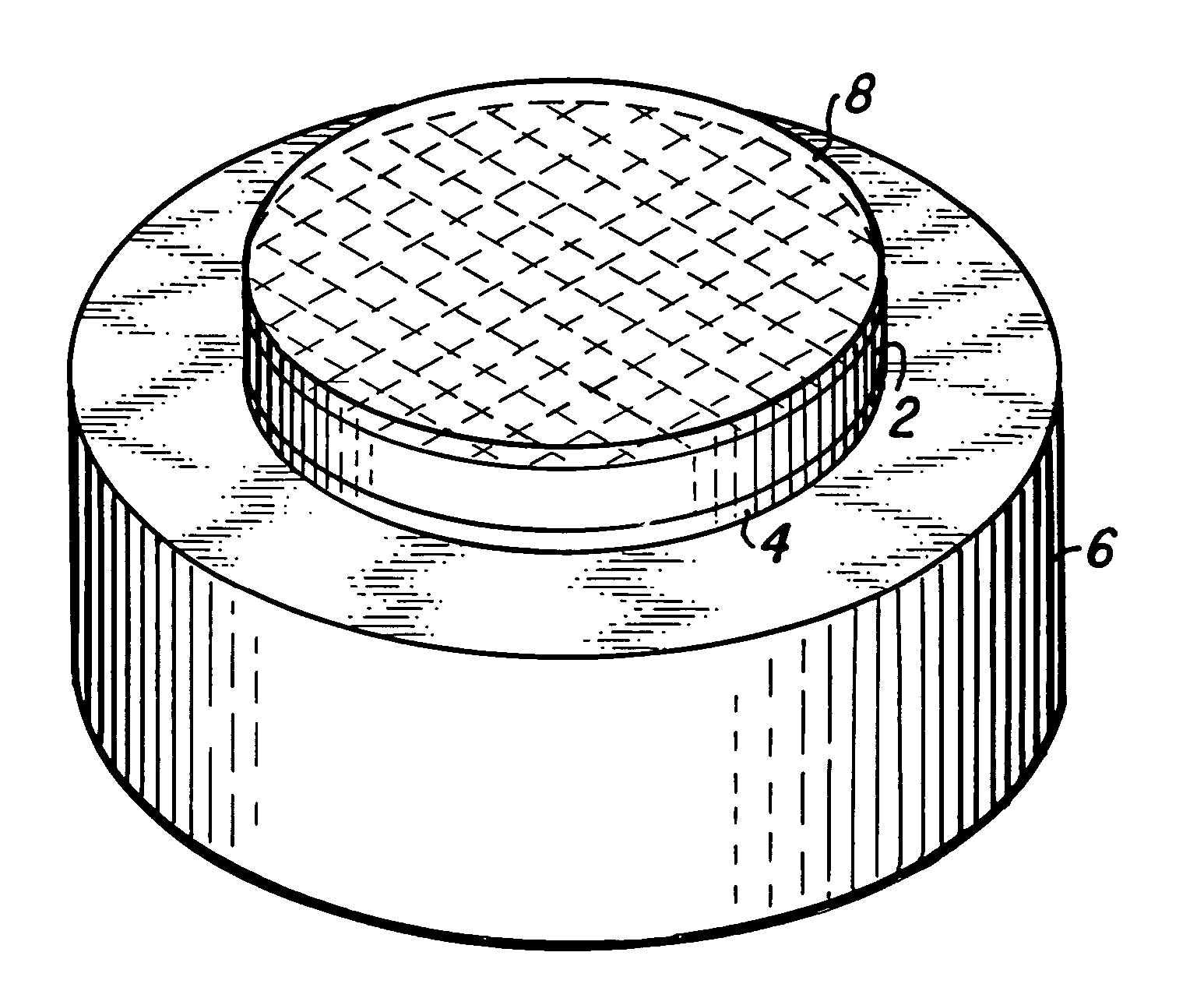

Pulley

A pulley consists of a pulley basic body which has a cylindrical outer circumferential surface. Sitting on this cylindrical outer circumferential surface is a tire which is of sandwich-like design with regard to its radial extent. This results in a plurality of rings concentric to one another. The ring which is furthest on the inside in the radial direction and the ring which is furthest on the outside in the radial direction are in each case elastomeric rings, whereas a reinforcing ring is located between them. The elastomeric outer ring is harder than the elastomeric inner ring, so that a very abrasion-resistant surface is achieved, over which the rope runs, whereas the elastomeric inner ring provides for adequate resilience. The reinforcing ring is provided in order to distribute the rope load as uniformly as possible over the elastomeric inner ring.

Owner:WILHELM KAECHELE ELASTOMERTECHN

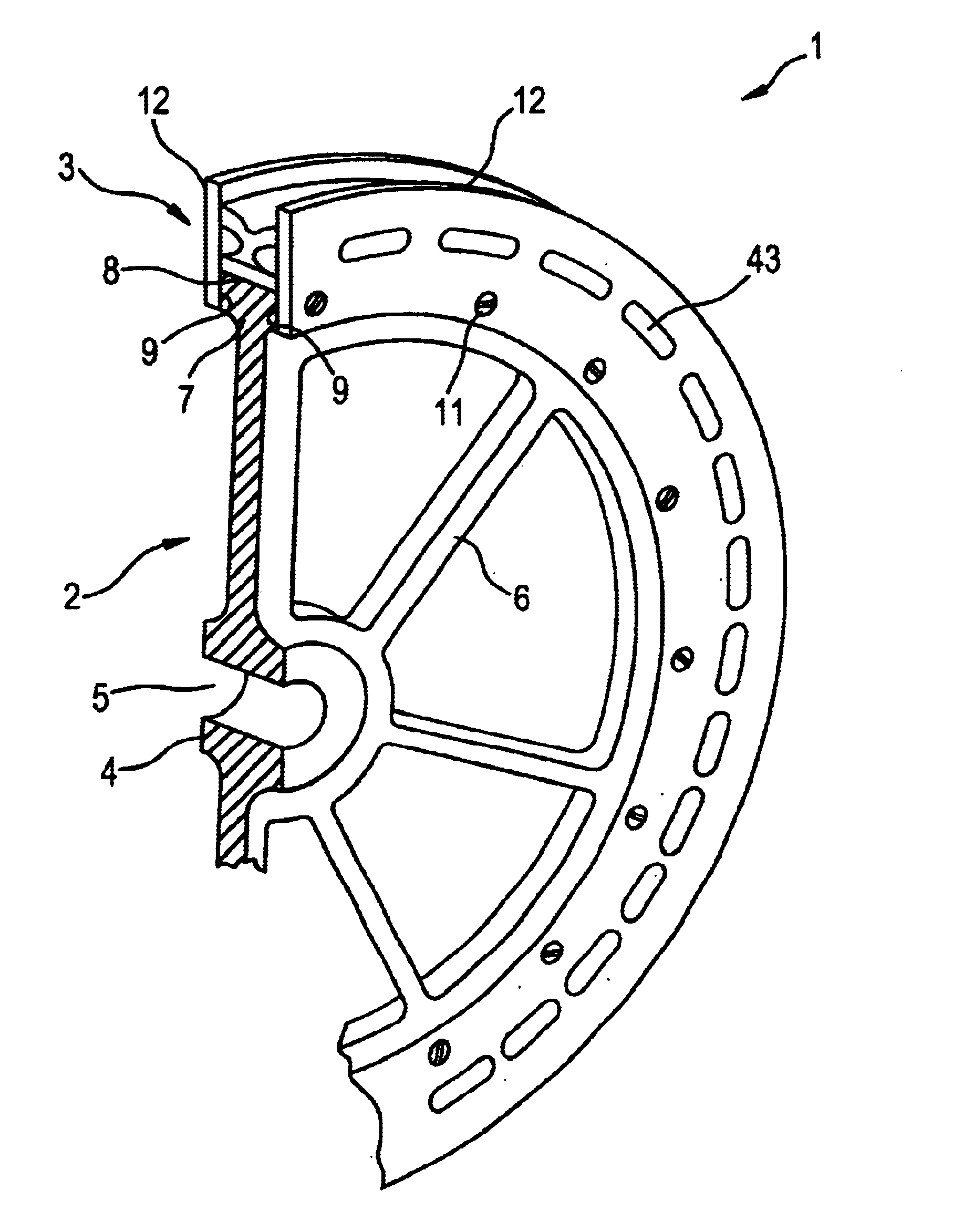

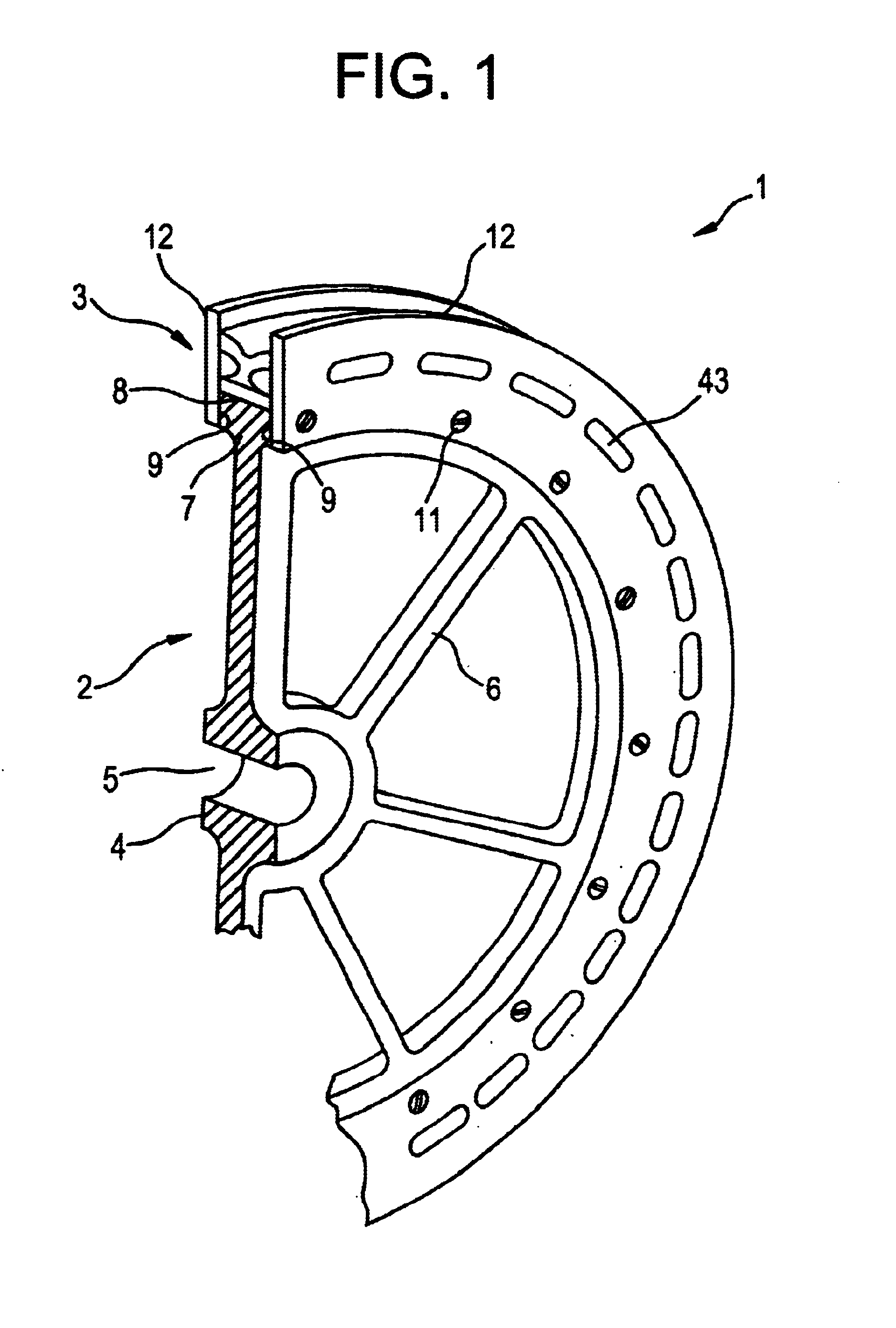

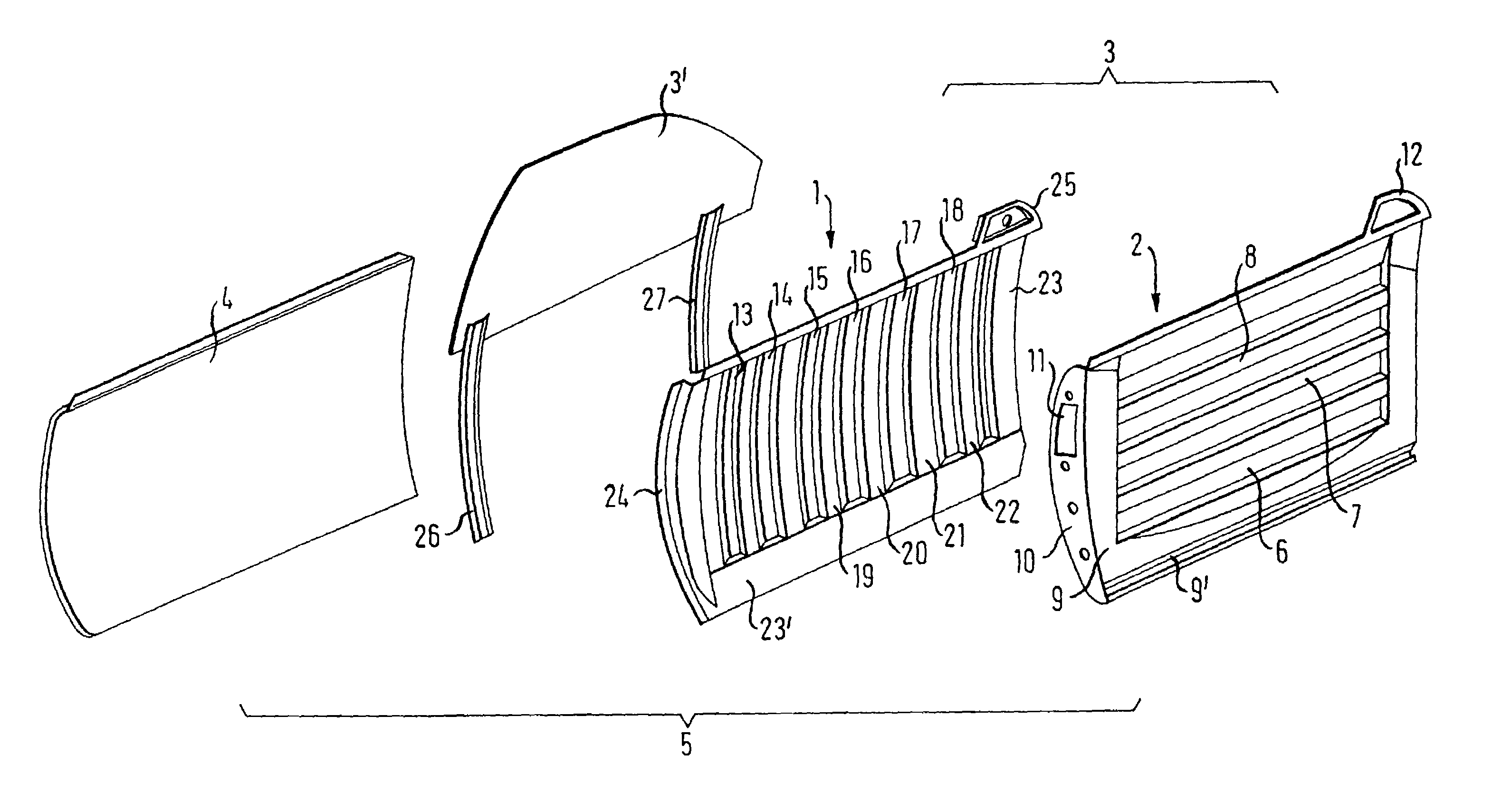

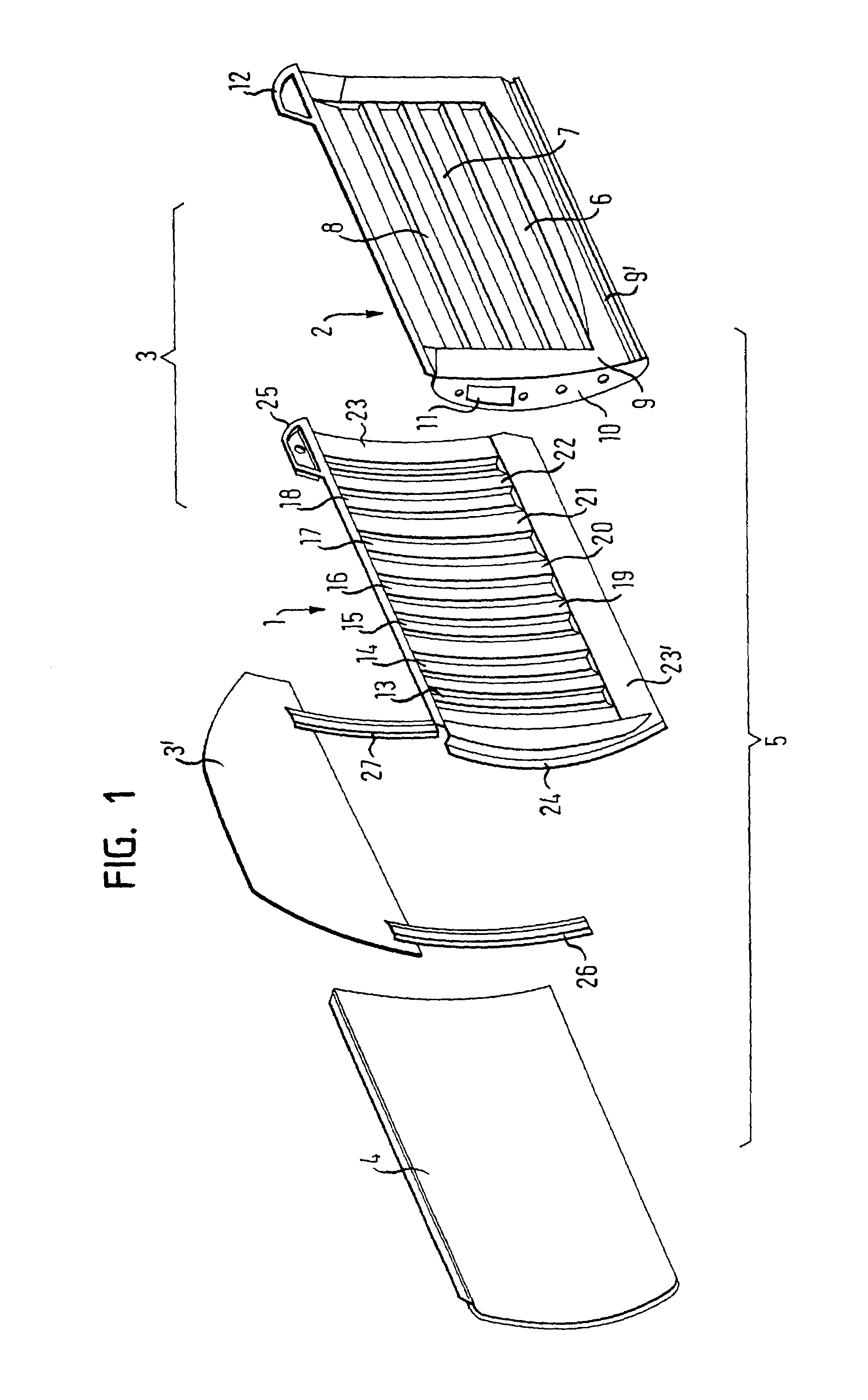

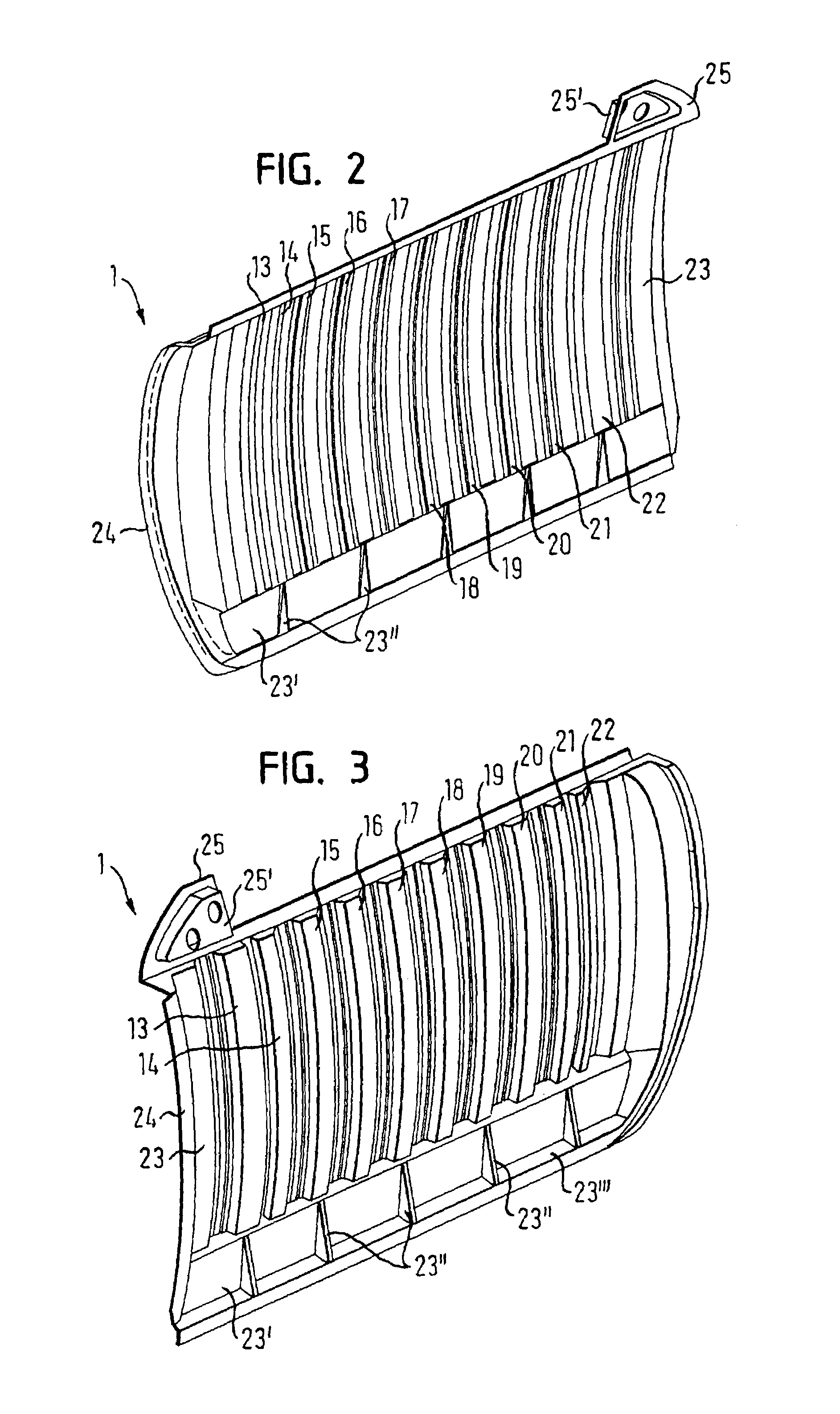

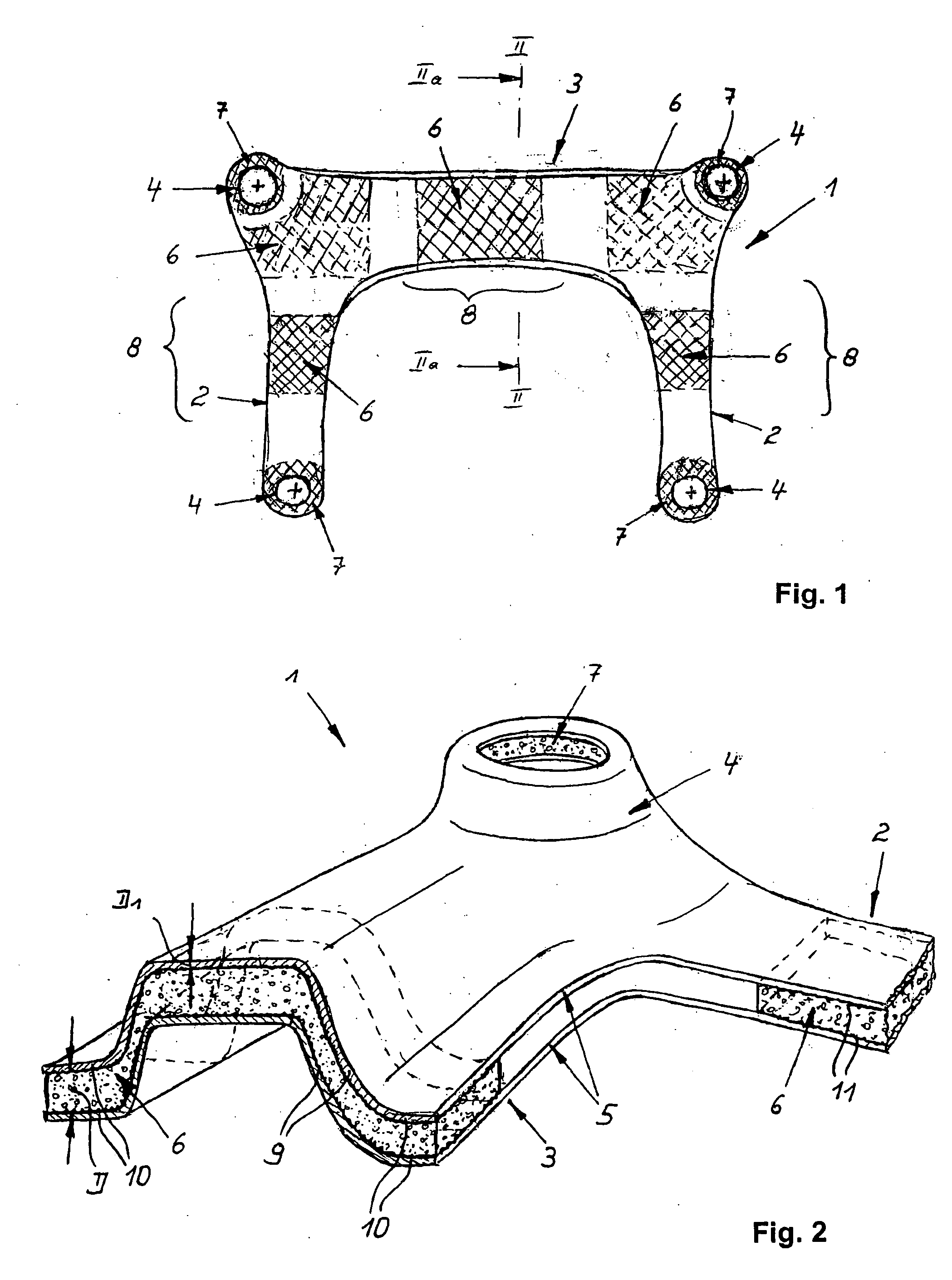

Curved vehicle door having a function carrier providing side impact protection

A curved vehicle door having a correspondingly curved windowpane and a correspondingly curved function carrier on which all of the add-on parts and door coverings are held and which can be used as protection for the occupant in the event of a lateral crash against the door. The function carrier is constructed in a sandwich-like manner from at least two shell bodies each having one of horizontal and vertical stiffening sections, the stiffening sections forming crossing points for fastening the shell bodies to each other so that the shell bodies form together a continuously closed frame of the function carrier. The outer shell body forms the curved outer side of the function carrier having at least two parallel grooves for accommodating a window lifting and lowering device which has a curvature matched to the curvature of the vehicle door.

Owner:FELLNER GERALD

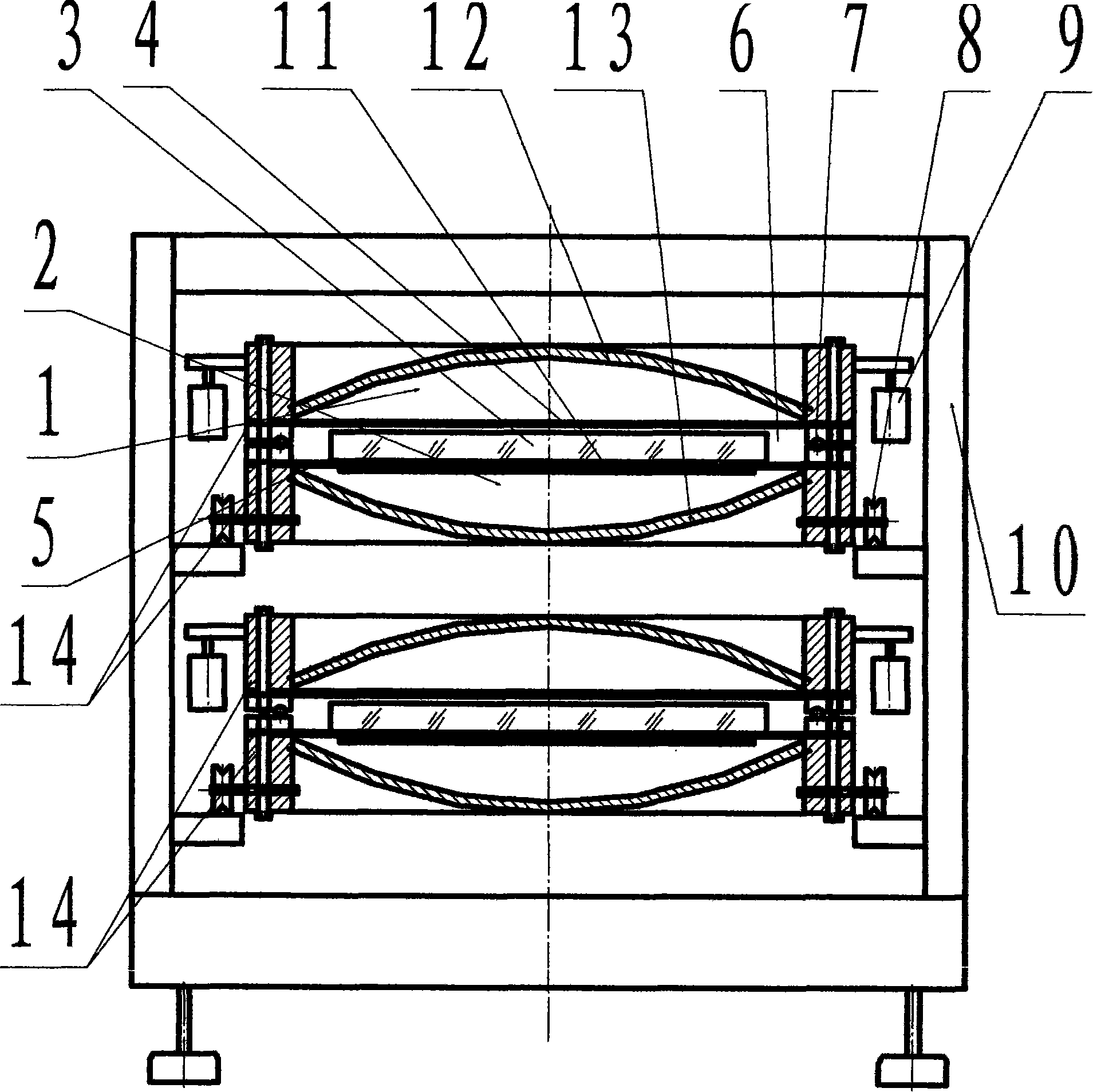

Sandwich plate forming machine

InactiveCN101249739ALess investmentReduce manufacturing costLaminationLamination apparatusSandwich likeEngineering

The invention relates to a sandwich sheet material forming machine, which is composed of an upper vacuum chamber, a middle vacuum chamber and a lower vacuum chamber. The sheet material to be processed is put inside the middle vacuum chamber 6; the middle vacuum chamber 6 is composed of an upper vacuum chamber baffle plate 4, a lower vacuum chamber baffle plate 5 and a sealing joint strip 7; the upper vacuum chamber 1 can be moved vertically; the lower vacuum chamber 2 can be horizontally pulled out and pulled in; the three vacuum chamber can simultaneously perform the vacuum pumping; when a sheet electric hot plate 11 is heated to a certain temperature, the upper vacuum chamber 1 and the lower vacuum chamber 2 simultaneously release gas, and the middle vacuum chamber 6 maintains vacuum, the sheet material 3 to be processed is pressed by an isostatic atmospheric pressure, and therefore a vacuum hot press composite sheet material finished product is obtained. The sandwich sheet material forming machine can be used for processing PVB film laminated glass, so as to reduce equipment investment, save electric energy for more than 50 percent, and reduce production cost.

Owner:刘苏海

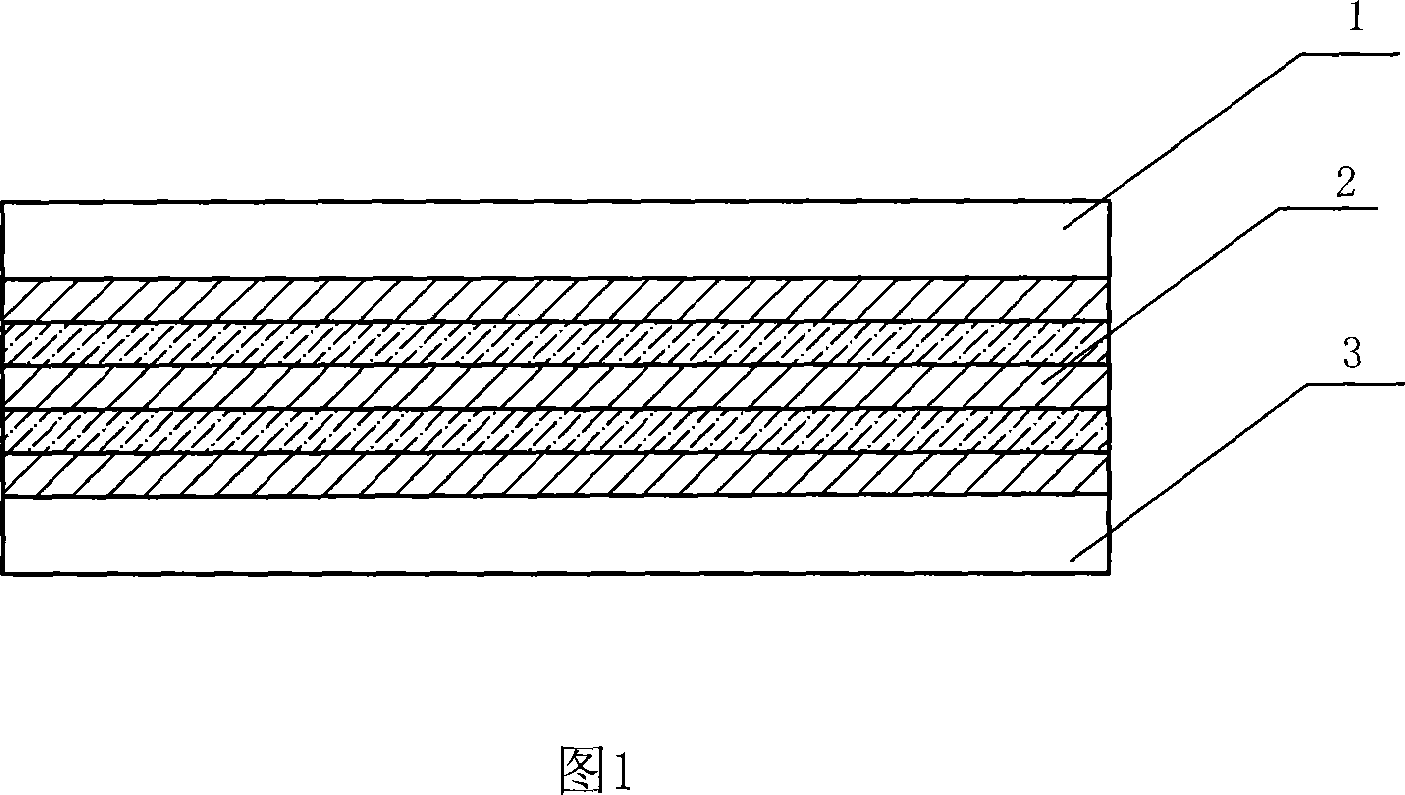

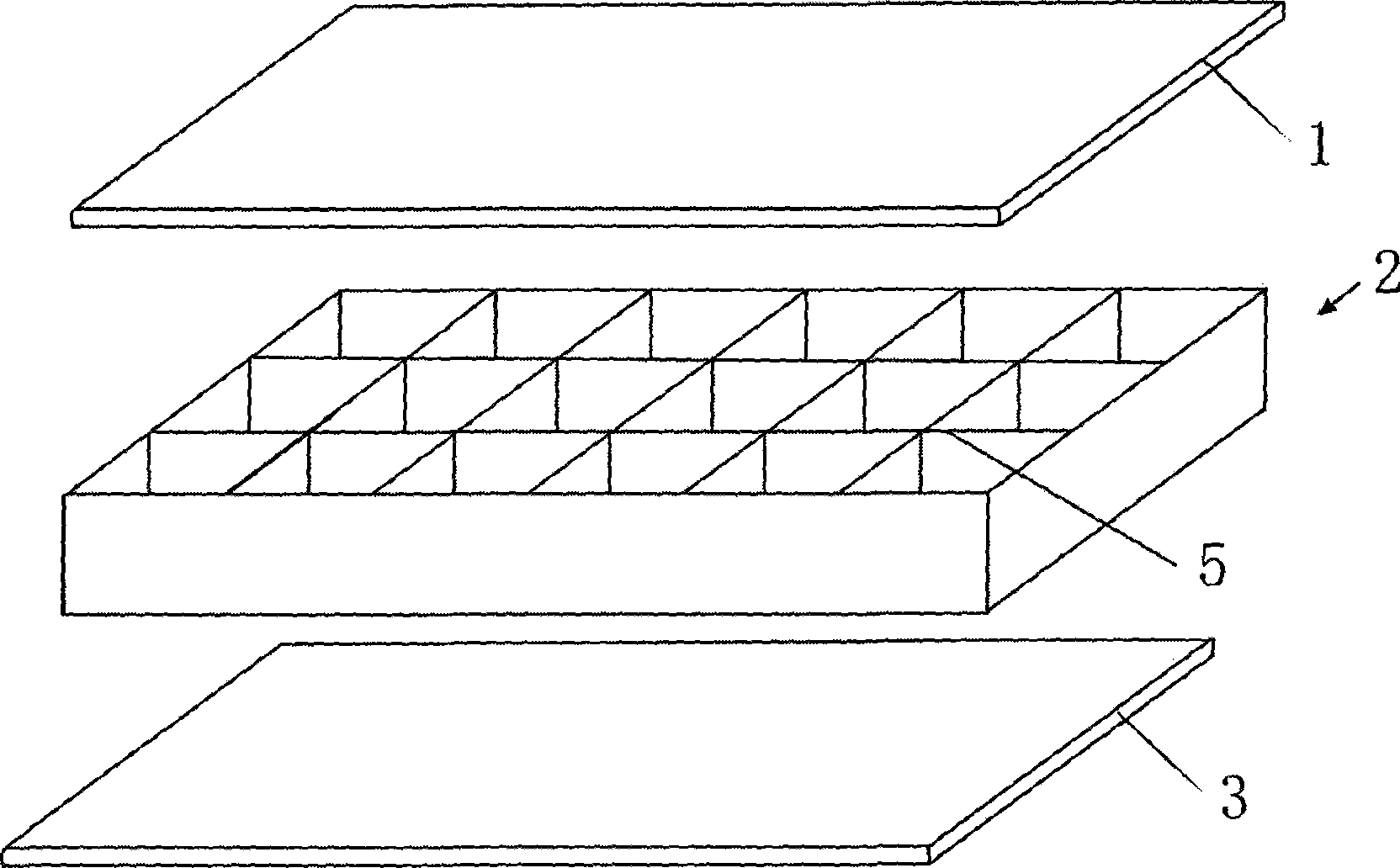

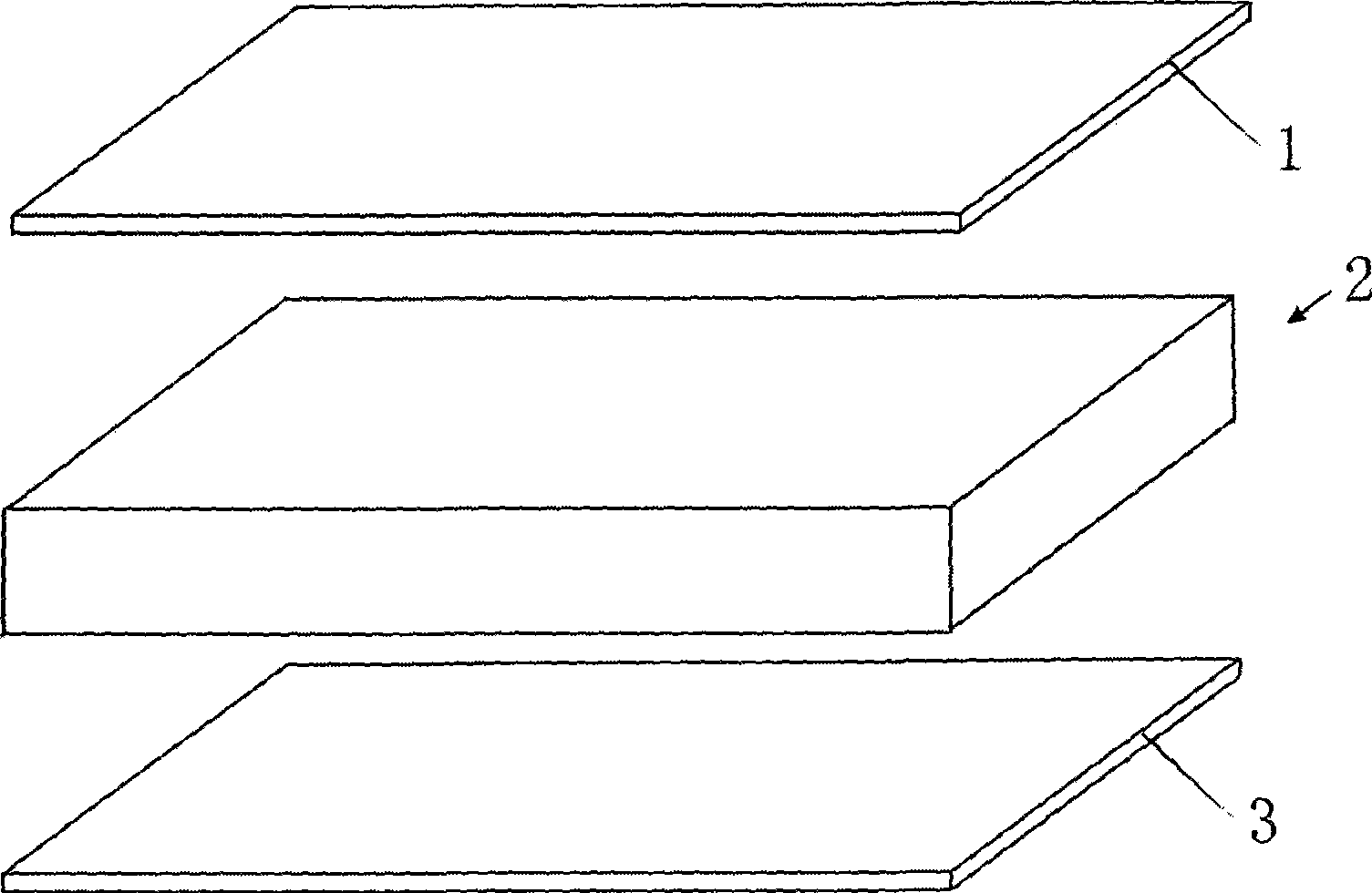

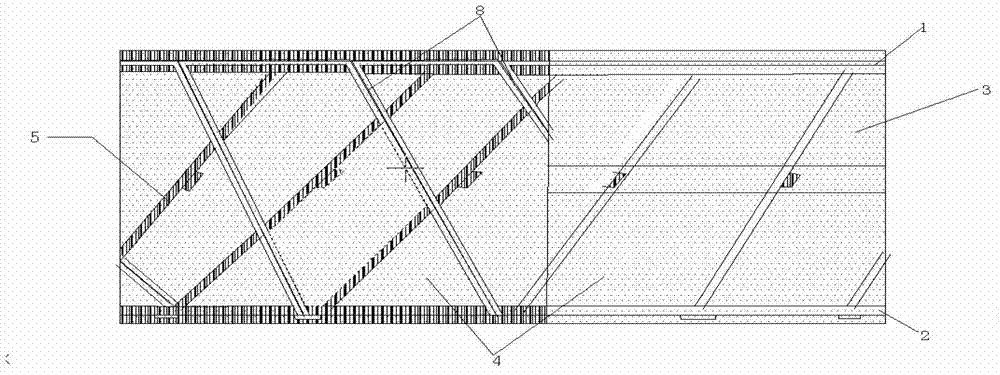

Wood sandwich board

InactiveCN101417450AImprove insulation effectReduce usageWood veneer joiningWood layered productsSandwich likeInter layer

The invention discloses a wood sandwich panel, comprising a board layer one (1), a sandwich layer (2) and a board layer two (3) which are inter-layer stuck and laminated into a whole; the sandwich layer (2) comprises a wood structure framework (5) and filling agents filled in the wood structure framework (5); the wood structure framework (5) is crisscross and uniformly distributed in the sandwich layer; the board layer one (1) and the board layer two (3) can adopt reconstituted decorative veneer or other boards. By introducing the wood elements to the production of the sandwich panels, the invention increases the decorative effect, expands the use ranges of the sandwich panel to meet the requirements of high-grade decoration; in addition, the panel is high in strength, stable, solid, good in sound insulation effect, light as well as massive and has good thermal insulation performance, so the panel can be widely applied for partition, floors, doors, interior wall decoration and repairs of ceilings and roofs and is suitable for high-grade places such as hotels, airports, exhibition centers, villas, and the like.

Owner:庄启程 +2

Hair extensions and method of attachment

ActiveUS9339072B2Good adhesionEasy to removeHair accessoriesToupeesSandwich likeBiomedical engineering

A unique human or synthetic fiber hair extension and method are disclosed. One embodiment of the human or synthetic fiber hair extensions come packaged with double sided tape attached to both sides of the hair extension, with the weft and human or synthetic fiber hair attached between the two pieces of tape. The double sided tape is covered with a tape cover or liner on both sides of the extensions. First, the human or synthetic fiber hair extension is positioned for correct placement below the horizontal part line, the liner is removed form the bottom side of the hair extension and the human or synthetic fiber hair extension is secured by pressing into place. The second piece of double sided tape which is attached to the second side of the human or synthetic fiber hair extension and facing up has the liner removed and is then covered with a layer of the users's natural hair, which taken from the clipped area above the part. This creates a sandwich-like effect attachment of the human or synthetic fiber hair with the user's hair. Also shown is a flow chart and various application methods aiding the stylist in analyzing and applying extensions to the users head.

Owner:KENNA LISA

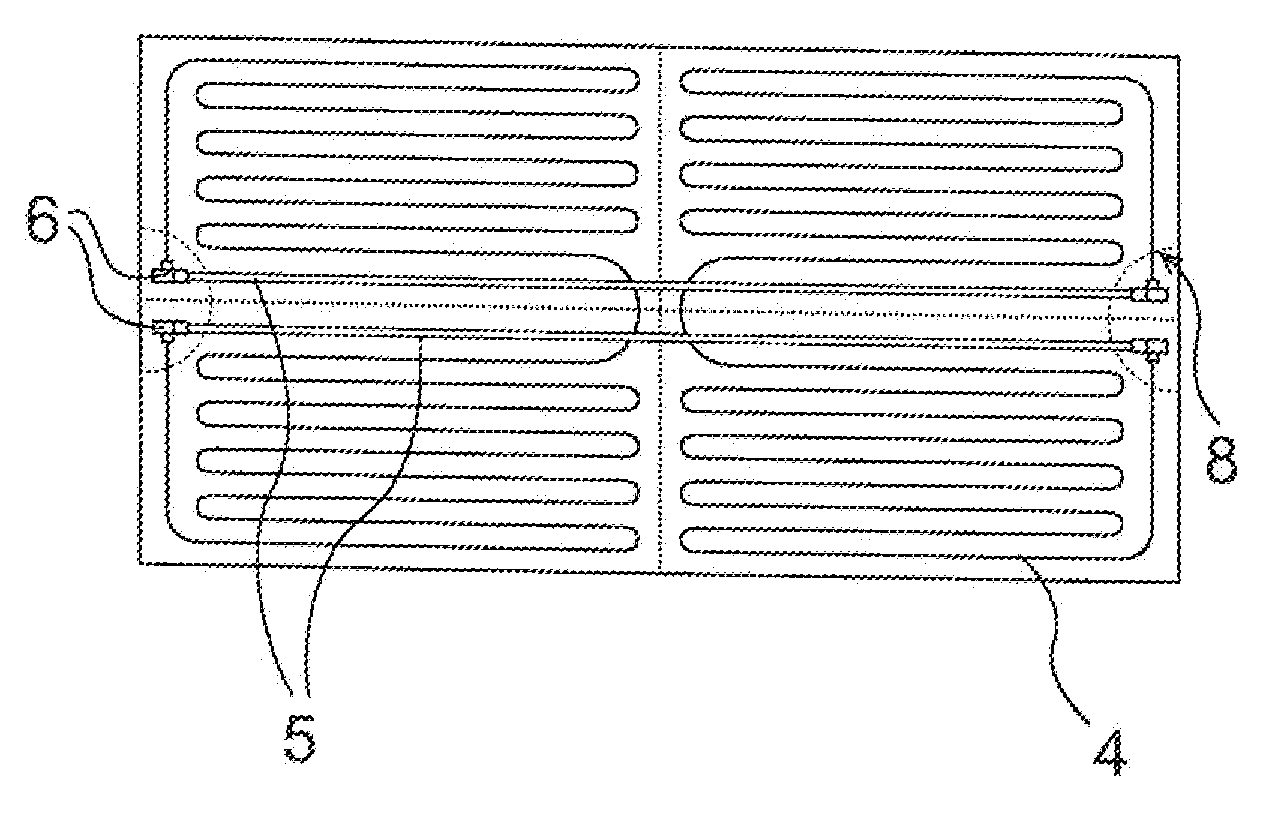

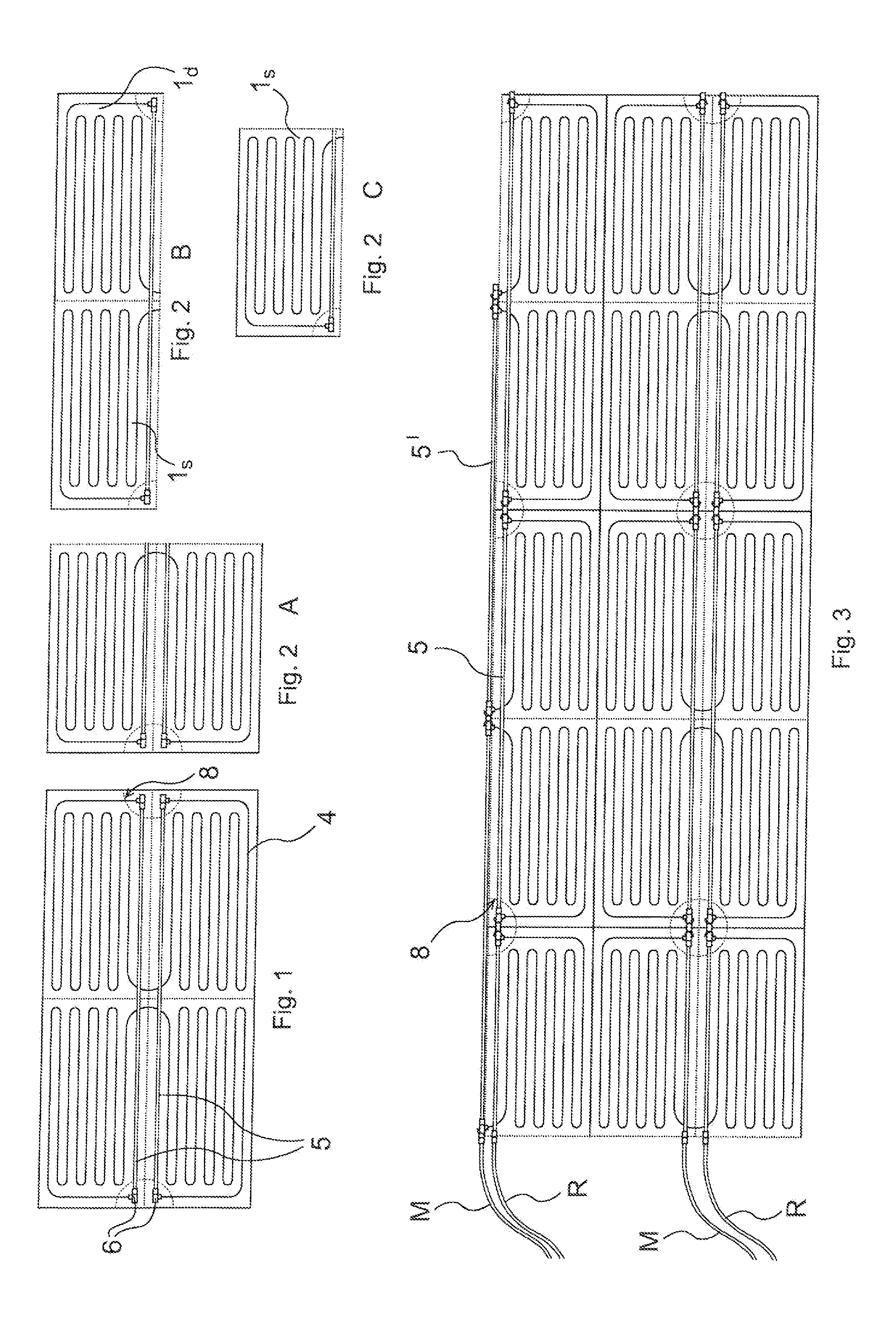

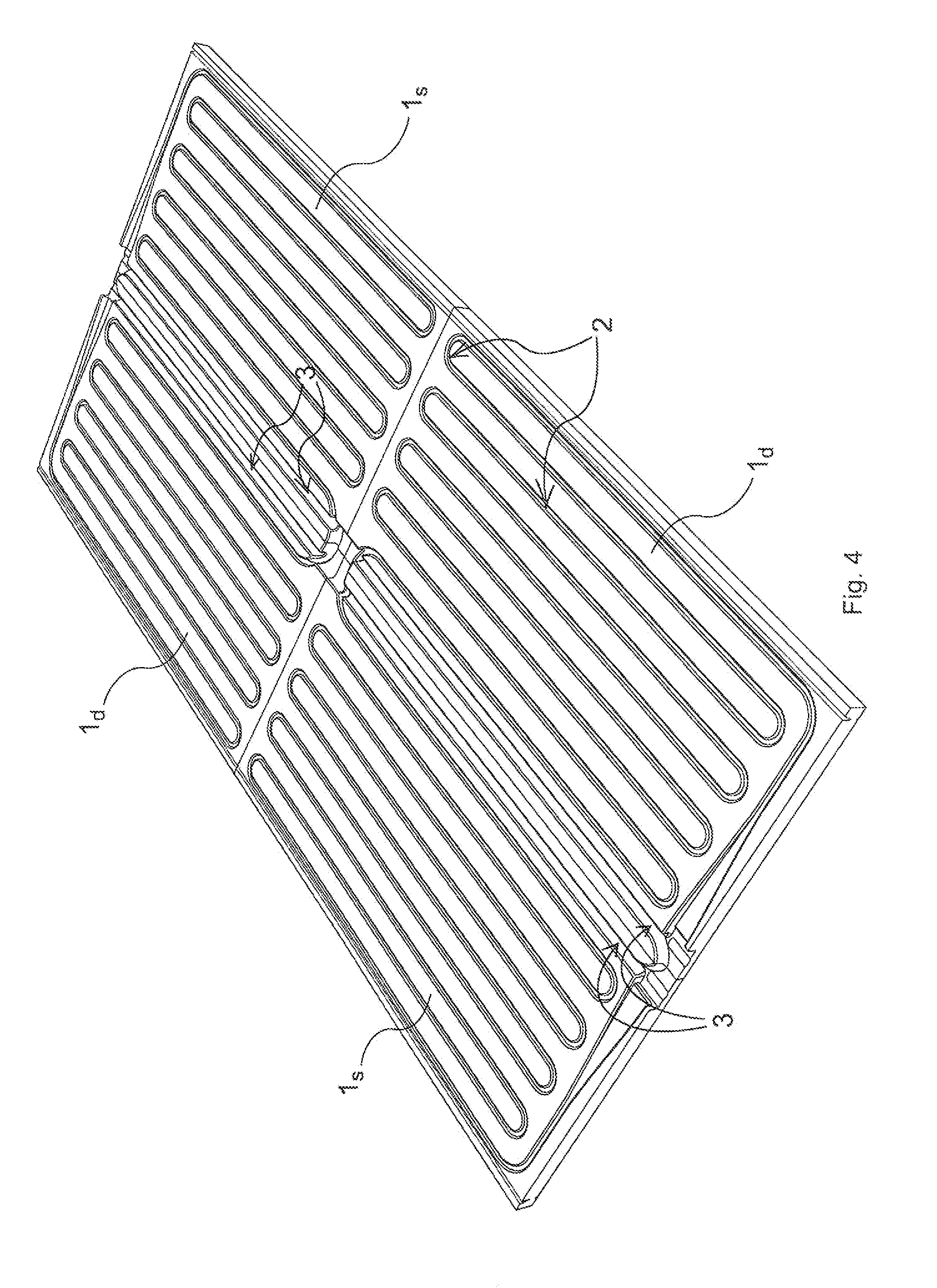

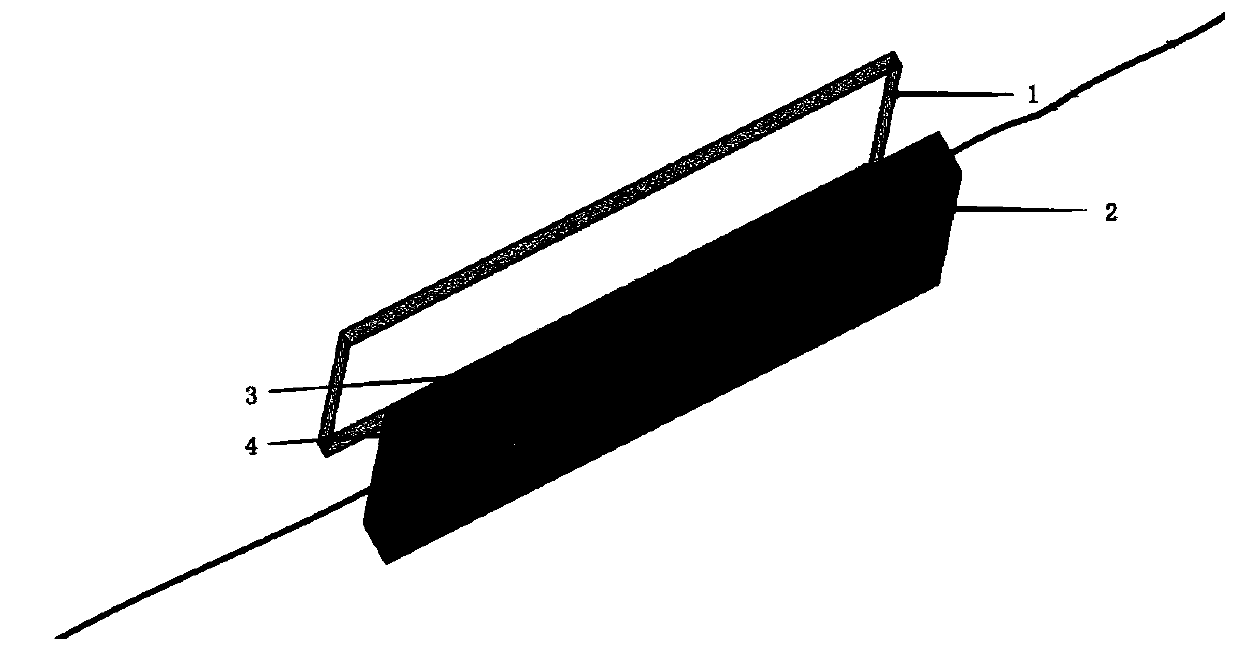

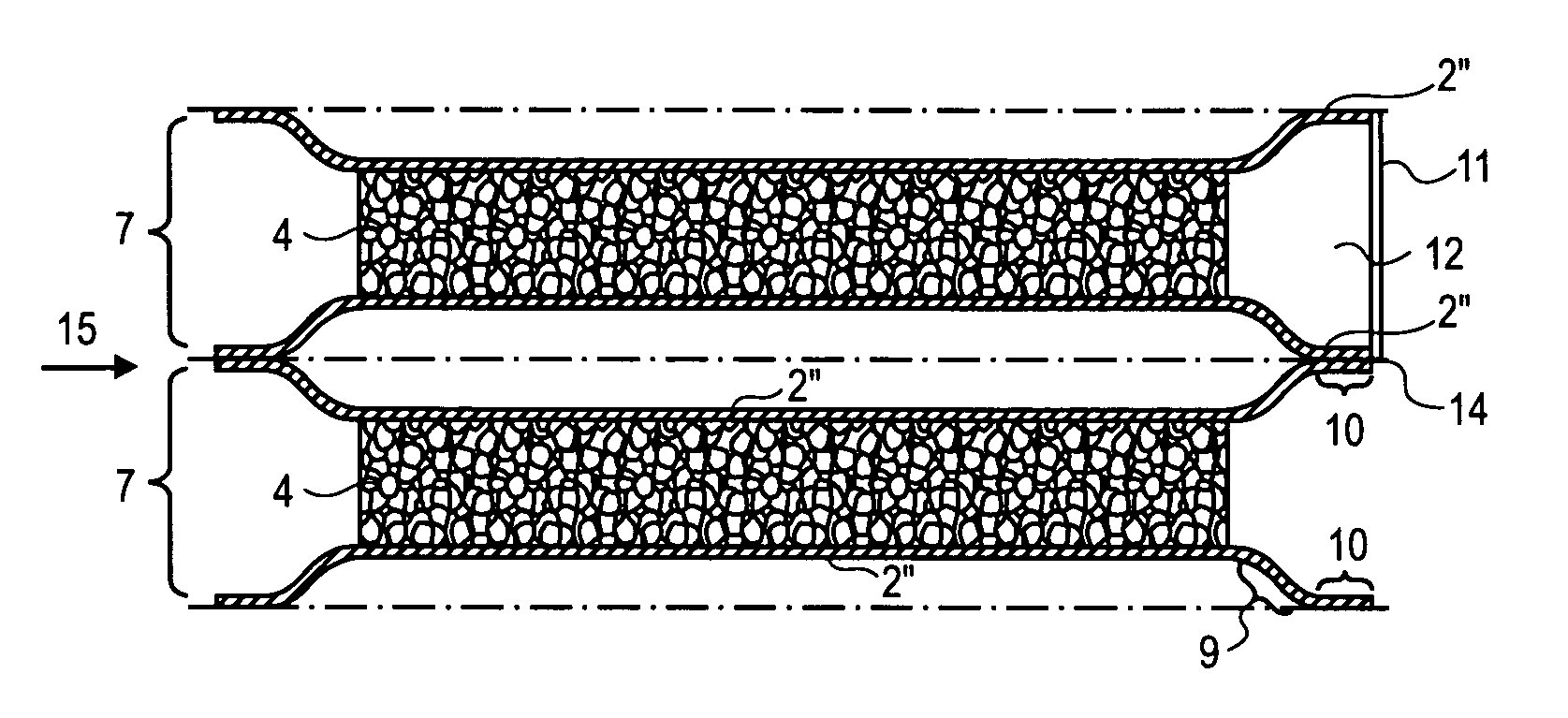

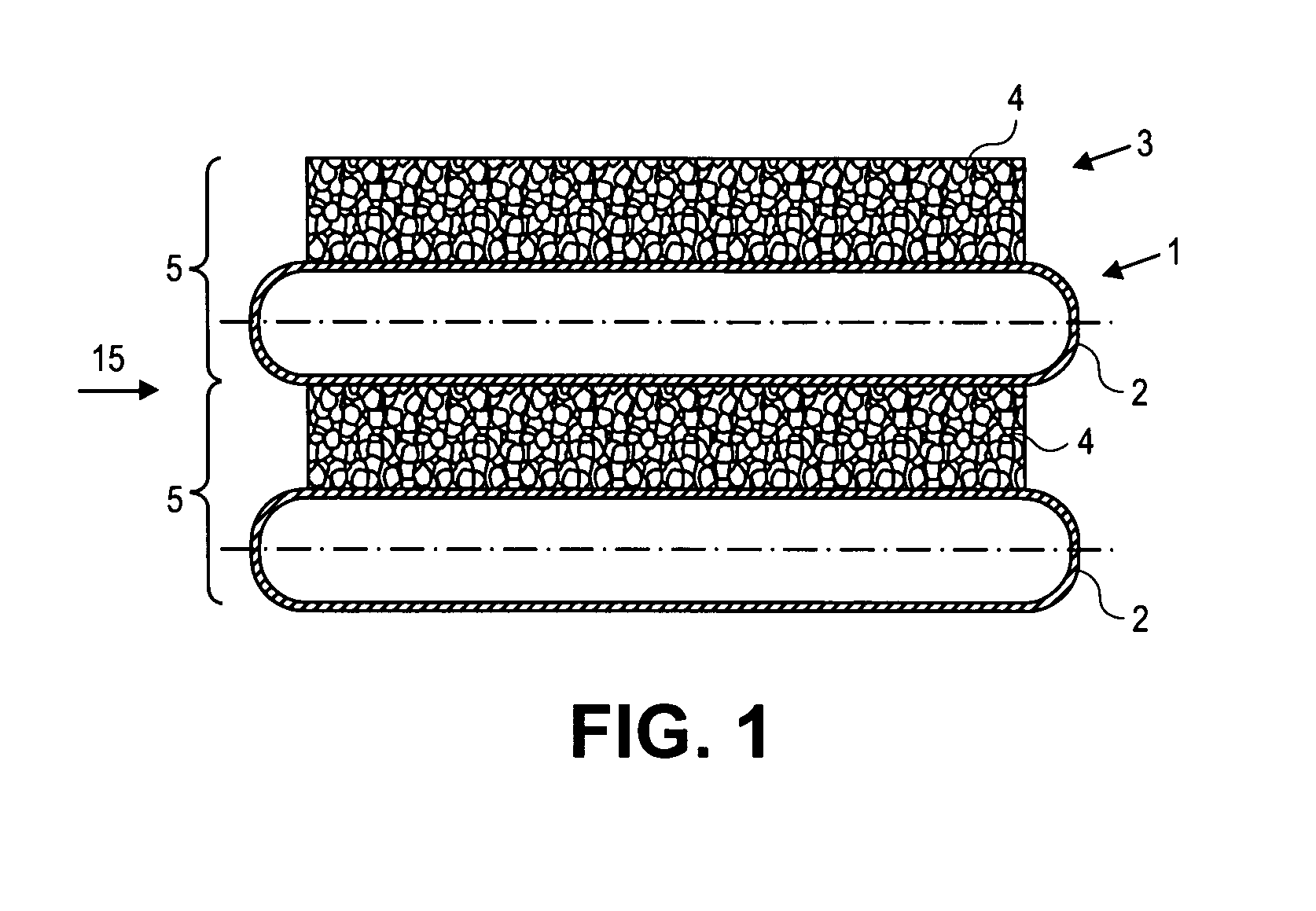

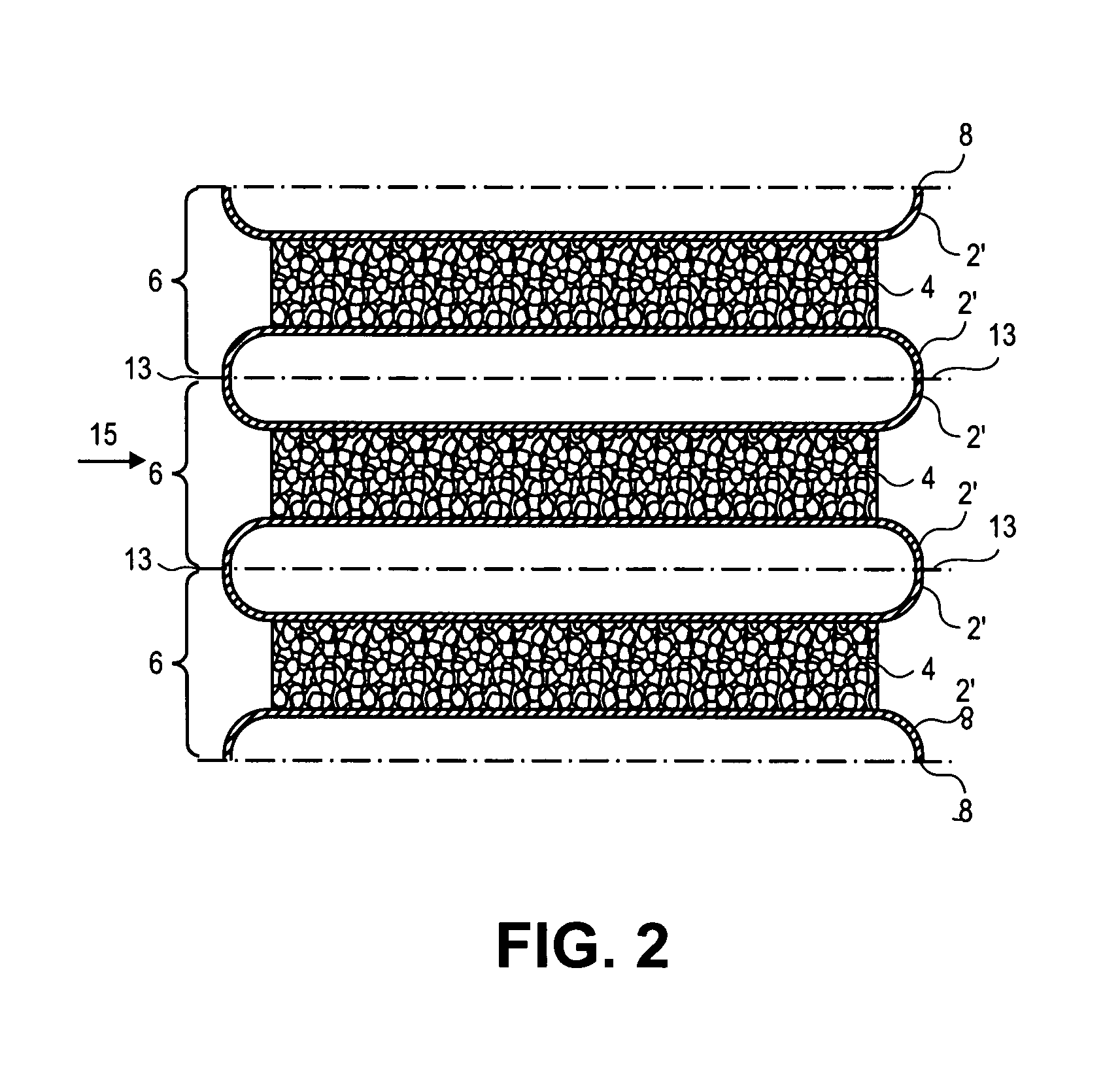

Modular, prefabricated radiant panel with integrated headers

ActiveUS20120103580A1Improved submodularity performanceQuick installationHeat exhanger conduitsHeat exchanger casingsSurface finishSandwich like

Modular, prefabricated radiant panel, of the type having a sandwich-like structure including a thermally insulating rear layer (1), a front layer acting as mechanical support and outer surface finish, and two radiant pipes (4) integrated in the panel for the flow of a heat-carrying fluid. The radiant pipes (4) are housed in preformed grooves (2) in the thermally insulating rear layer. In the same layer there are further provided two parallel, longitudinal grooves (3) for the housing of a pair of headers (5) which supply the radiant pipes (4). The headers (5) housed in the grooves (3) cross the entire panel and end in correspondence of the opposite short sides thereof, where they are connected to the radiant pipes (4) via T-junctions (6), a free mouth of which faces outwards for connection via sleeves (7) to T-junctions (6) of other panels, both directly and through connection pipes.

Owner:MESSANA ROBERTO

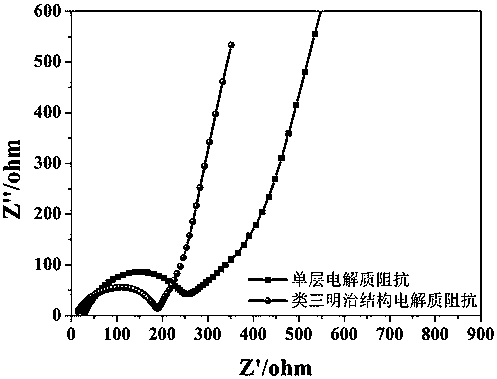

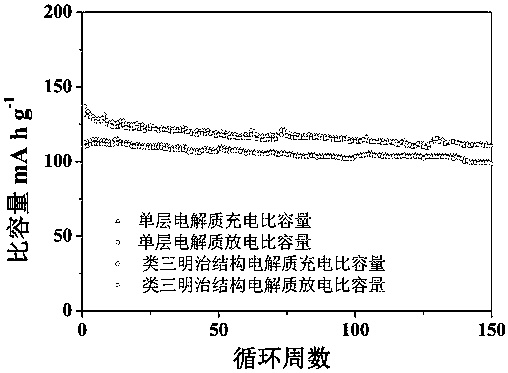

Production method of sandwich-like structure solid polymer electrolyte membrane, and application of sandwich-like structure solid polymer electrolyte membrane in solid-state lithium ion battery

ActiveCN107732293AImprove cycle stabilityImprove mechanical propertiesSecondary cellsElectrolytesSandwich likeMass ratio

The invention discloses a production method of a sandwich-like structure solid polymer electrolyte membrane, and an application of the sandwich-like structure solid polymer electrolyte membrane in a solid-state lithium ion battery, and belongs to the technical field of solid-state lithium ion batteries. The production method comprises the following steps: taking a polymer and an alkali metal saltaccording to a mass ratio of (2-6):1, dissolving the polymer and the alkali metal salt in acetonitrile, and performing stirring and uniform mixing to obtain a solution A; taking half of the solution A, adding a plasticizer, and performing full stirring and uniform mixing to obtain a solution B; and respectively coating two sides of a support membrane with the solution A and the solution B, and drying the coated support membrane in a vacuum drying box for 12-24 h to produce the sandwich-like structure solid polymer electrolyte membrane. The invention also discloses a production method of a solid-state lithium ion battery using the sandwich-like structure solid polymer electrolyte membrane. The produced sandwich-like structure solid polymer electrolyte membrane has the advantages of high ionconductivity, good mechanical strength, low interface impedance, good interfacial stability, and effective improvement of the cycling stability of the solid-state lithium ion battery.

Owner:HENAN NORMAL UNIV +1

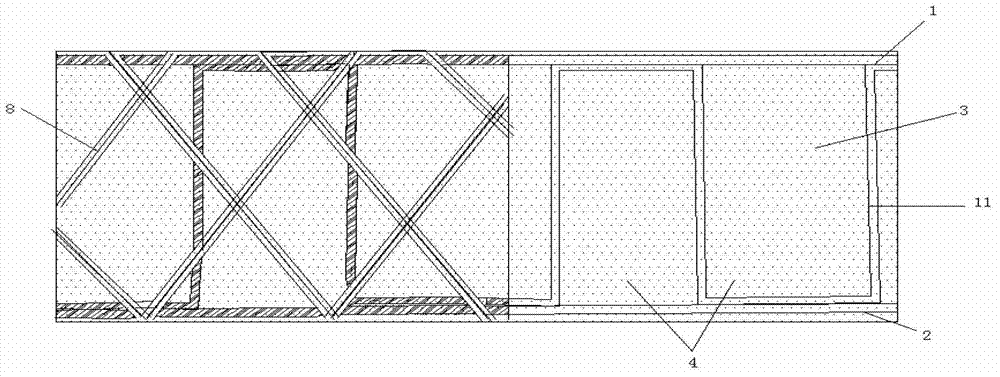

Composite material with foam sandwich structure and preparation method of composite material

InactiveCN102825879AImprove bending strengthHigh compressive strengthSynthetic resin layered productsLaminationSandwich likeYarn

The invention discloses a composite material with a foam sandwich structure and a preparation method of the composite material. The composite material comprises an upper surface layer, a lower surface layer and a foam sandwich layer which is located between the upper surface layer and the lower surface layer; the upper surface layer and the lower surface are formed by overlapping layered fiber fabrics; the foam sandwich layer is formed by arranging a plurality of foam strips, foam plates or foam blocks; parallel sheet-like fiber fabrics are clamped between two adjacent foam strips or adjacent foam plates of the foam sandwich layer; the surfaces on the middle positions of each two foam strips are provided with resin grooves which are parallel with the surface layers; and the resin grooves are crossed with a resin make-up groove which is penetrated in the complete foam sandwich layer in the longitudinal direction; the upper surface layer, the lower surface layer and the sandwich layer are sewn into a complete structure by a sewing rough yarn. The composite material provided by the invention is light in weight and has high strength; the preparation process is simple and the composite material can be molded in one step; and moreover, resin can be injected from the middle layer of the sandwich layer and the injection speed is improved.

Owner:SOUTH CHINA UNIV OF TECH

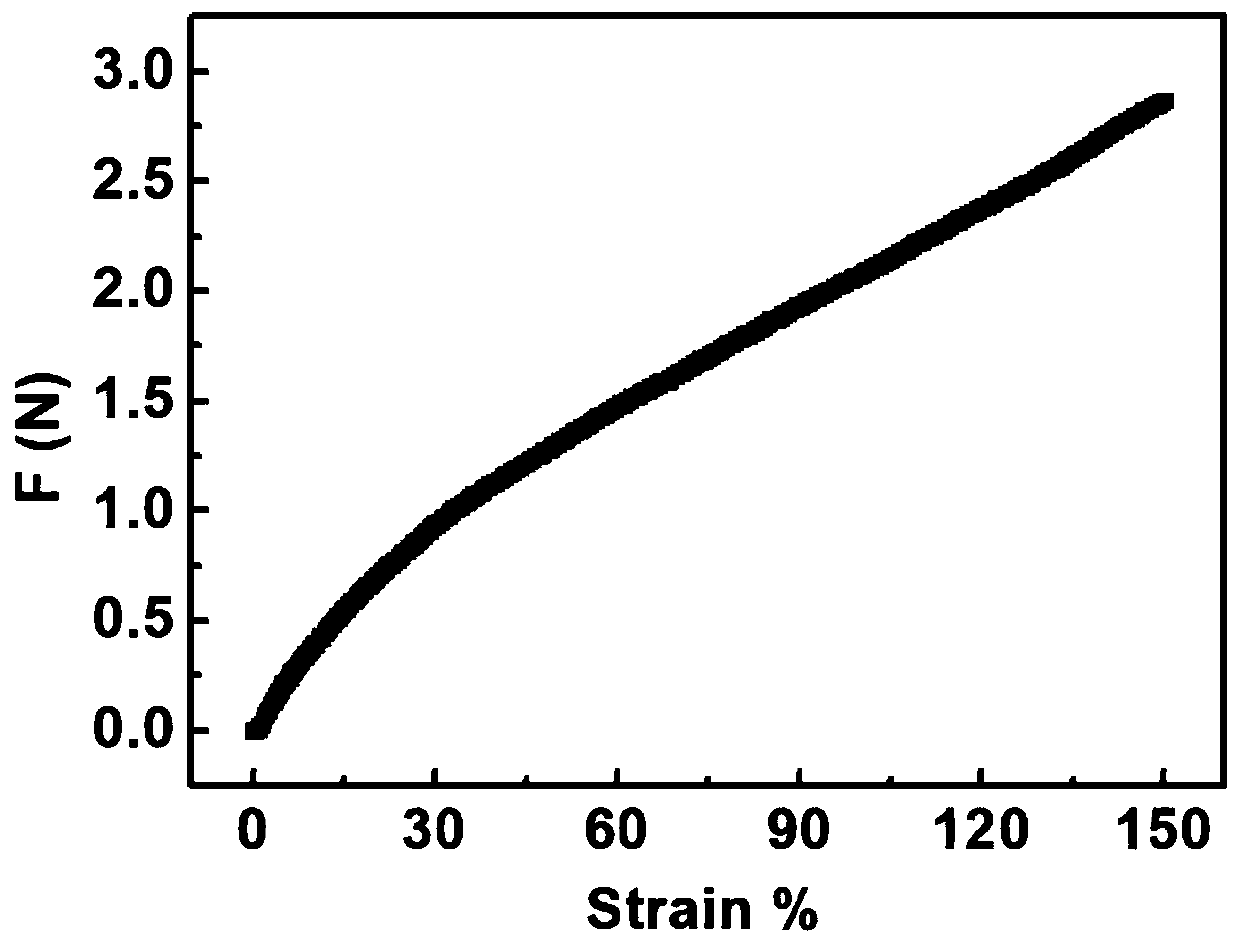

Tensile stress/strain sensor applied to knuckle joint and preparation method thereof

InactiveCN110243276ACause uneven thicknessAvoid wastingForce measurementElectrical/magnetic solid deformation measurementSandwich likeCopper foil

The invention belongs to the field of flexible stress sensors, and relates to a tensile stress / strain sensor applied to a large deformation such as a knuckle joint and a preparation method thereof. The sensor device has a sandwich-like three-layer structure; a flexible substrate made of Ecoflex silicone rubber is arranged at the bottom; a CNTS conductive layer with a dry abrasive paper patterned microstructure is arranged at the middle layer, and the two ends of the CNTS conductive layer are led out by copper foils as electrodes; and a layer of silicone rubber is laid to the top as a protective layer. The Ecoflex silicone rubber has an elasticity modulus similar to that of the skin, which provides a possible for the wearable property of the device; the nanometer material CNTS with excellent conductivity is used as a microstructure sensing material; and the tensile stress / strain sensor is prepared by combining the Ecoflex silicone rubber and the nanometer material CNTS.

Owner:JIANGSU UNIV

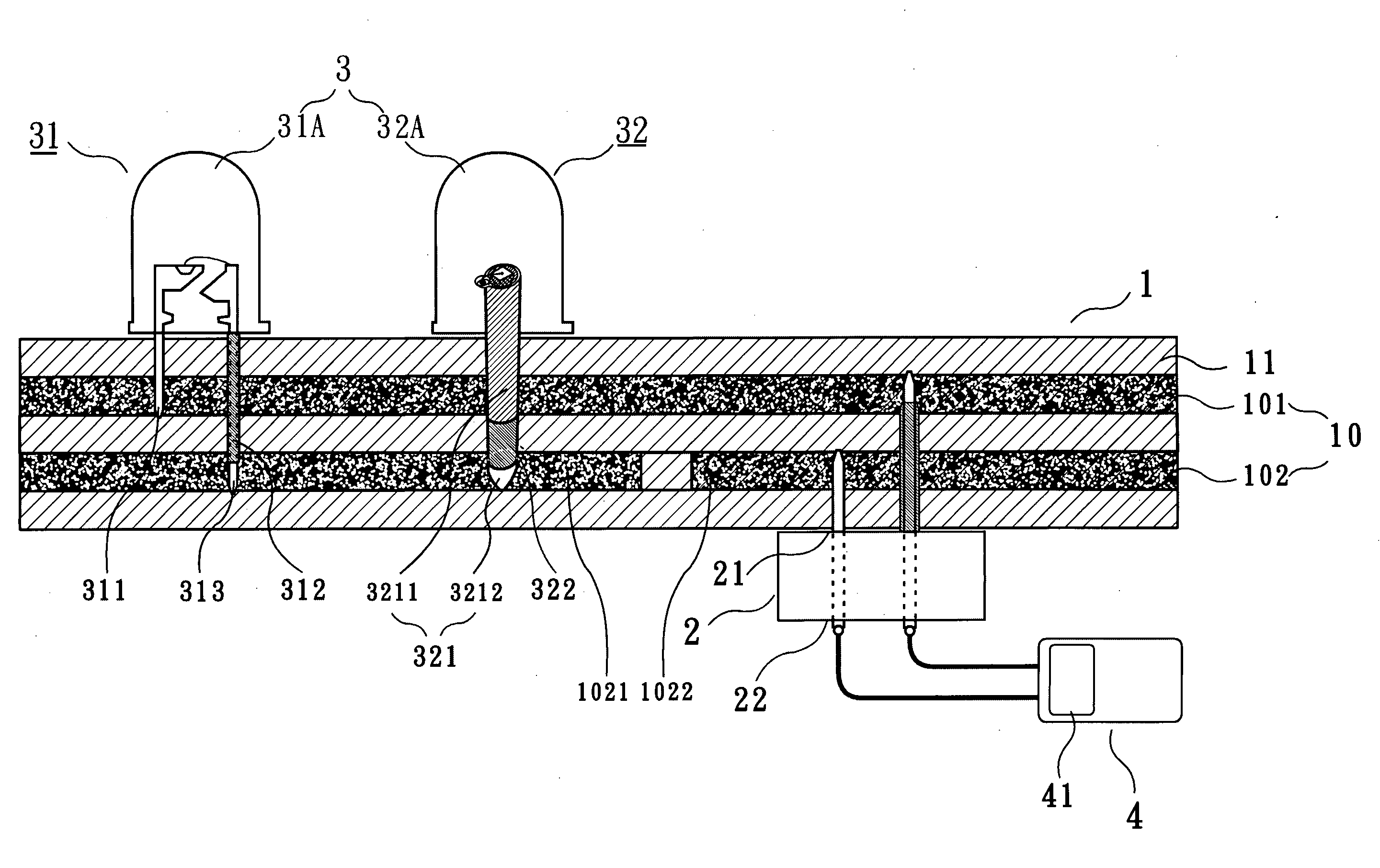

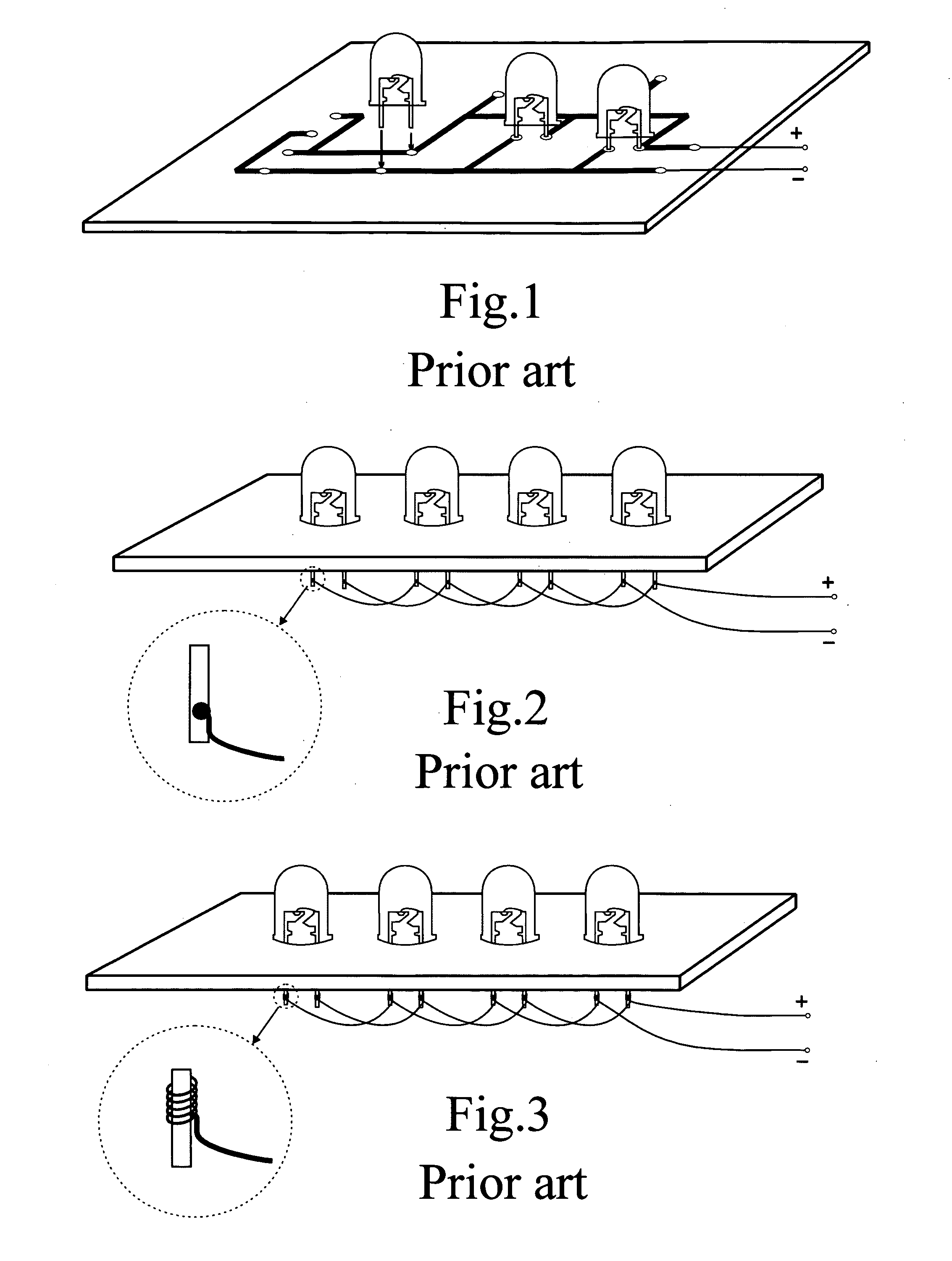

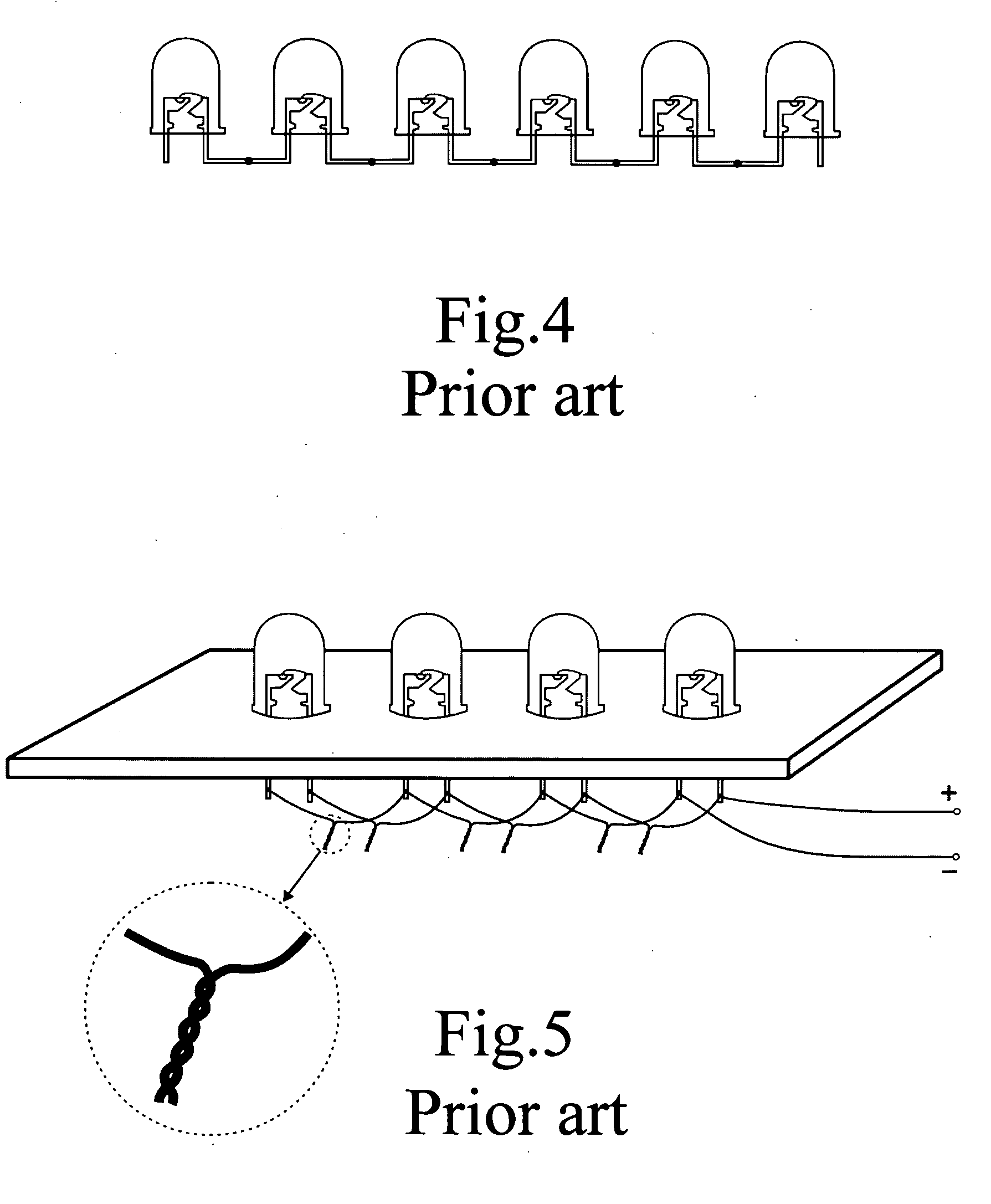

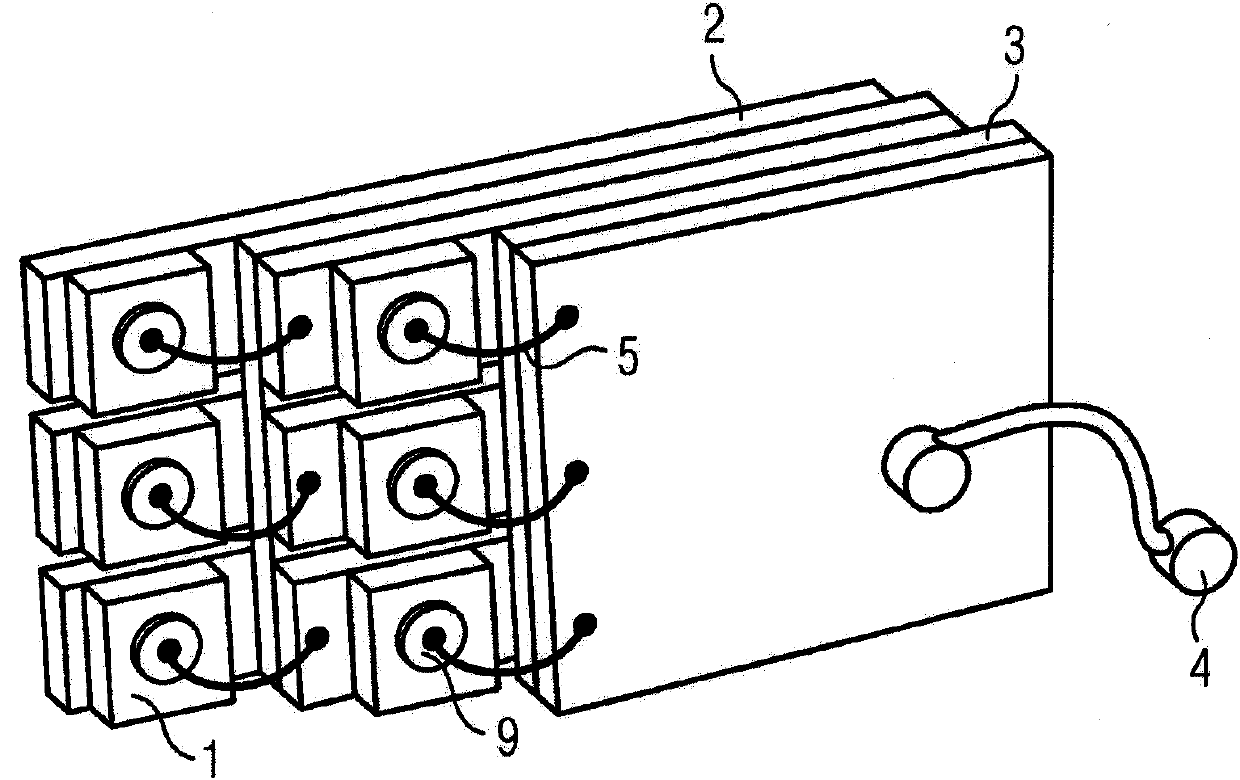

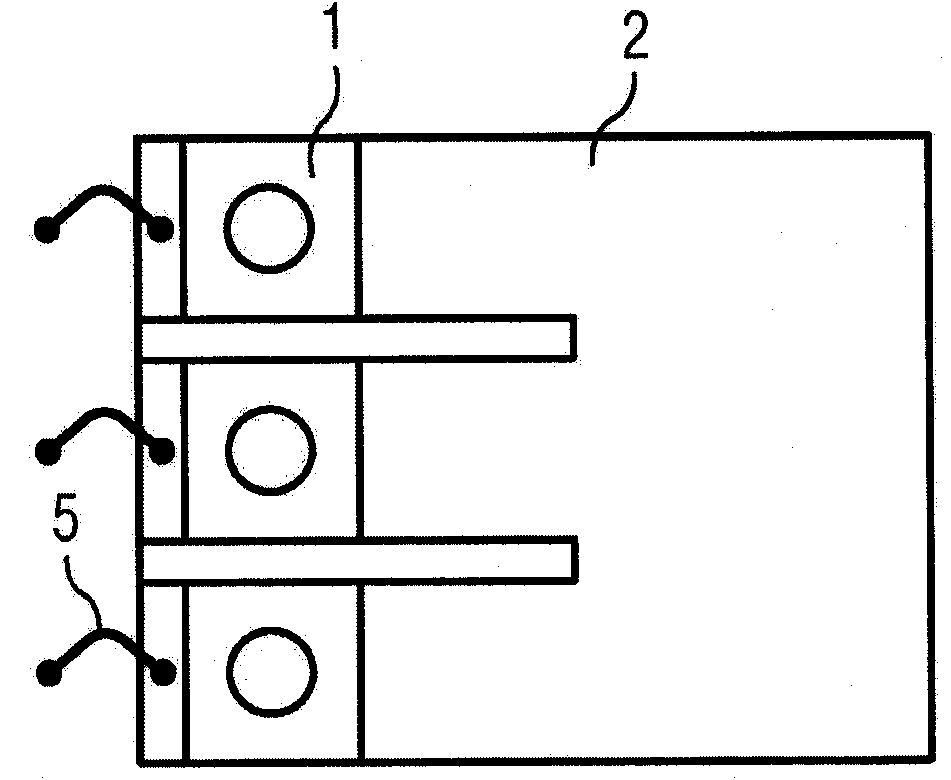

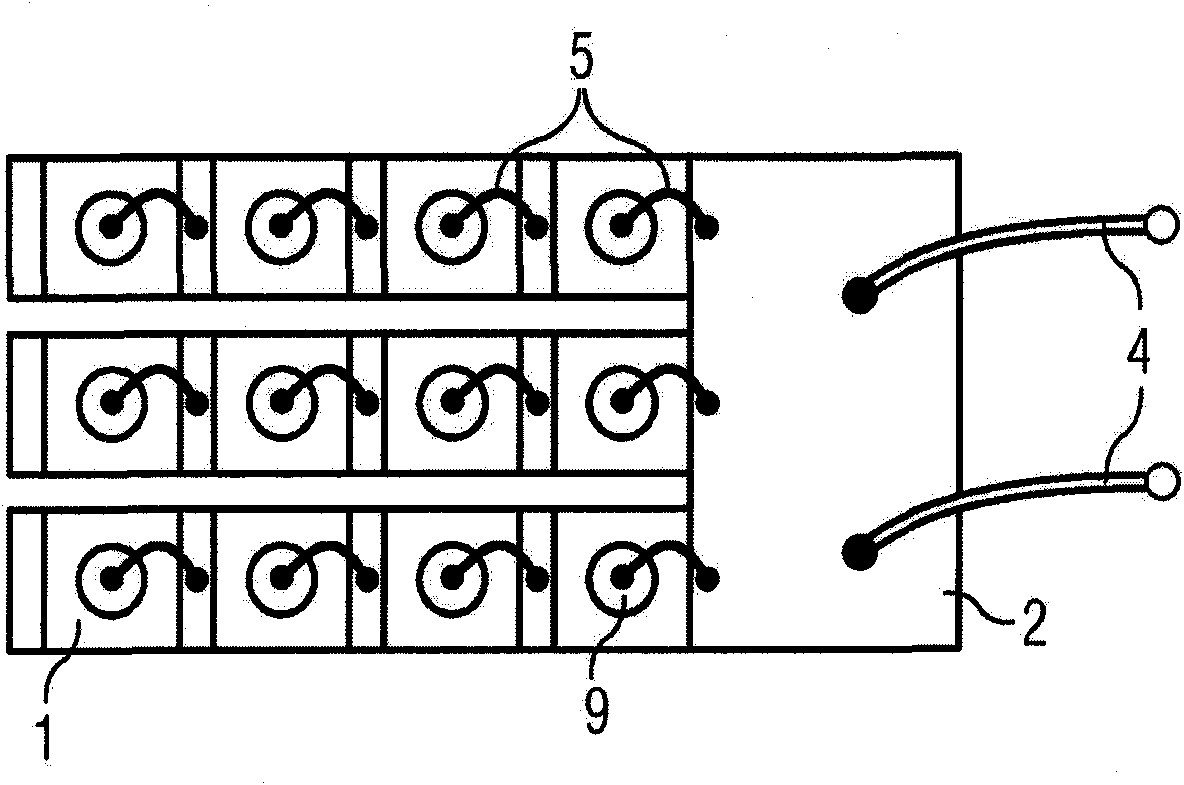

LED and the promptly fabricating material structure and the connect method thereof

InactiveUS20090201680A1Quick changeQuick installationElectrically conductive connectionsLighting support devicesSandwich likeEngineering

An easy-to-assembly LED and substrate providing fast assembling, simple replacement and maintenance, exchangeable arrangement of LED (3) without wiring or welding process comprises:an assembling substrate (1) having sandwich-like structure, consists essentially of a plurality of conductive layers (10) and a plurality of non-conductive layers (11);a plurality of LED (3) having at least one lead partially insulated, all conductive sections and insulated sections of said LED (3) will correspond to the arrangement of conductive layers (10) and non-conductive layers (11) of said assembling substrate (1); anda power source (4).

Owner:JOYIN TECH

Heat exchanger for industrial installations

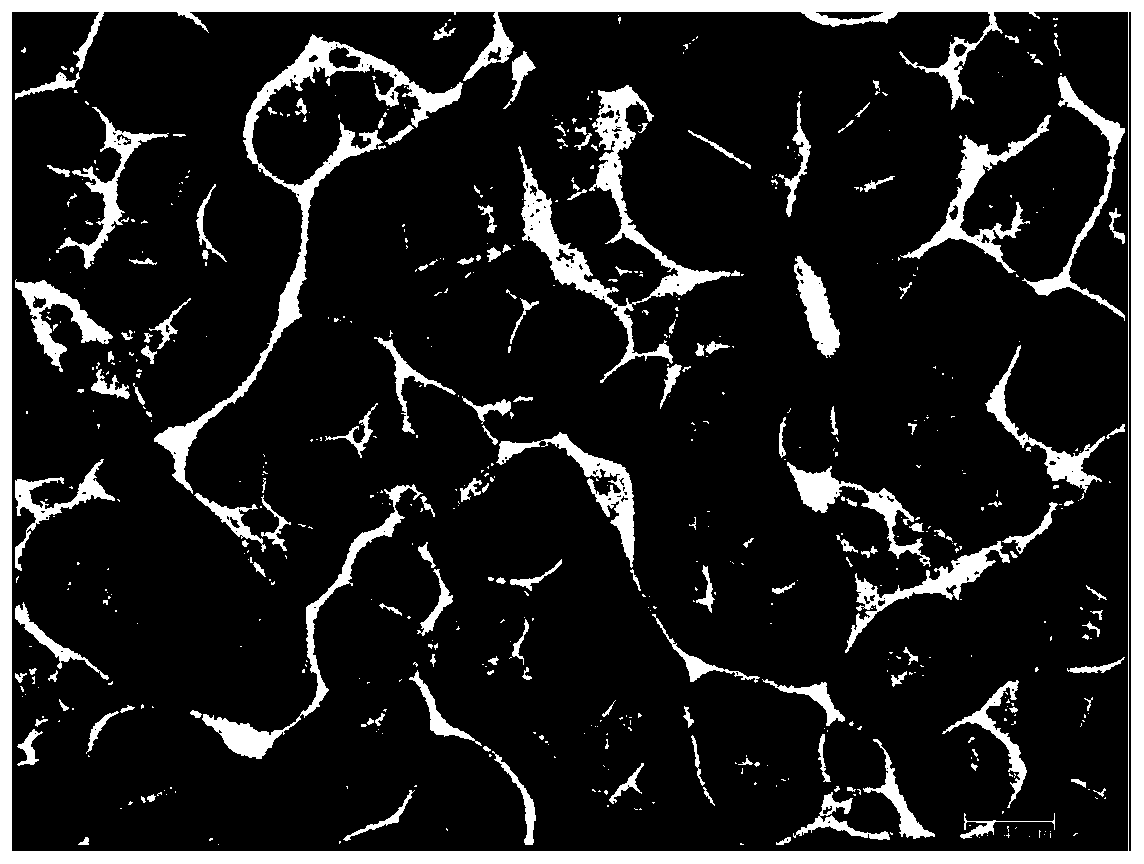

InactiveUS7086457B2Small diameterReduce weightStationary conduit assembliesHeat transfer modificationSandwich likePower station

The invention concerns a heat exchanger for industrial installations, in particular for power plants, with at least one distributor for a fluid medium and at least one heat exchanger element attached to the distributor. The heat exchanger is composed of a sandwich-like configuration of distributors and heat exchanger elements consisting of metal sponges. The distributors are constructed as pipes or at least as semi-pipes connected with each other. Adjacent pipes or semi-pipes are connected with each other through the metal sponge. The sandwich profile of the invention may easily be manufactured in the required dimensions for industrial installations. Herein, particularly the low weight of such a heat exchanger module and the connection between shell and metal sponge, which may simply be made by means of soldering or welding, proves to be particularly advantageous. The metal foam may also be cast onto the shells. The metal sponge should preferably consist of open-pored metal foam and in particular aluminum foam.

Owner:SPG DRY COOLING BELGIUM

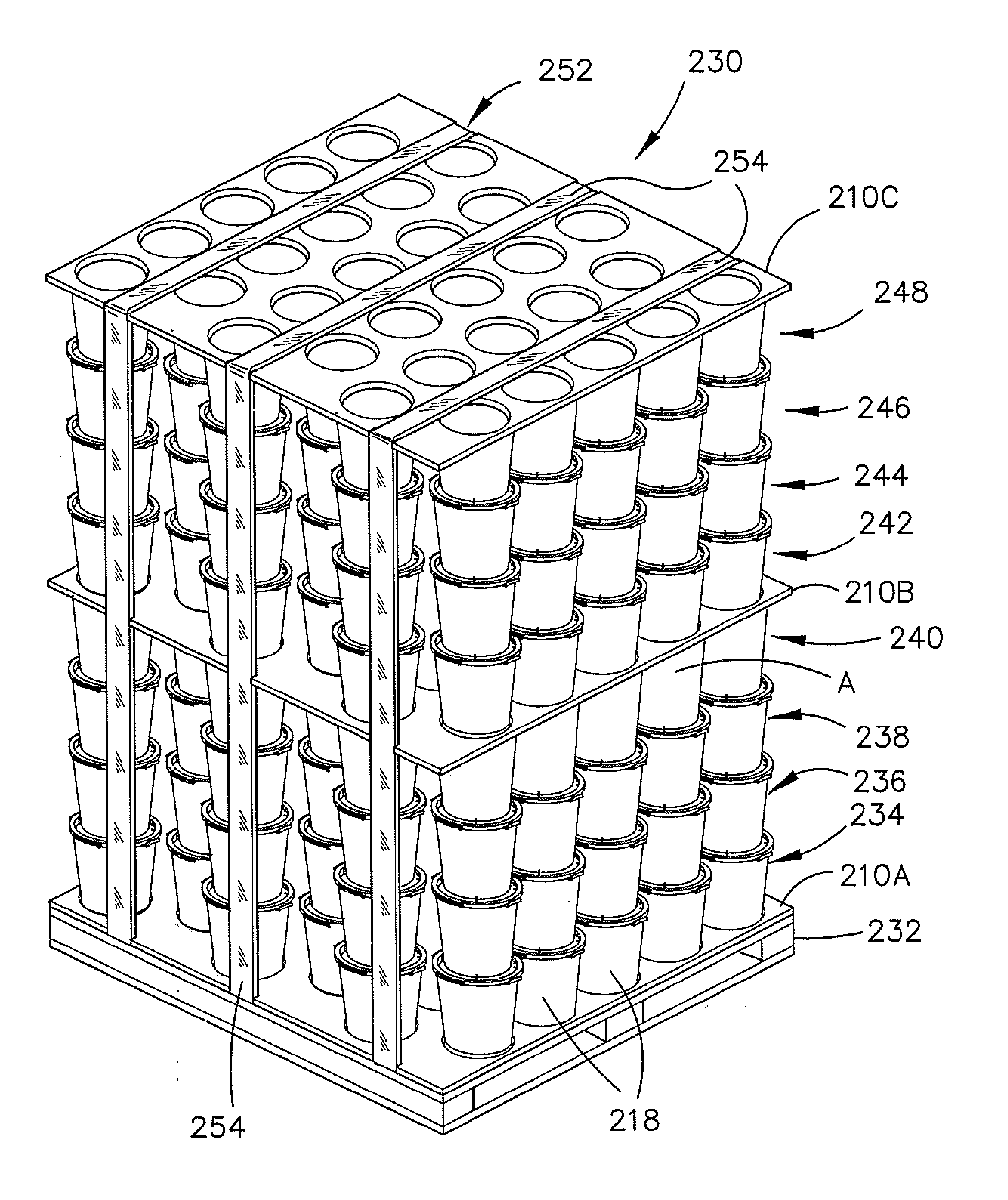

Stackable containers and associated method for the transport of plants

InactiveUS20130213841A1Promote formationEasy to transportLoadersClosure with auxillary devicesSandwich likeTransport system

A filling and transport system is provided in which containers are filled with potting mix or similar growing medium at a first location and transported as a transport module to a second location where plants are planted in the growing medium within the pot. The transport module used to transport the containers and closures containing the growing medium are arranged in a sandwich-like arrangement between two or more stabilising plates having respective retaining elements for engaging with either the base of the containers or the top surface of the closures to retain the containers in stacked relationship to one another during transportation by forming a stable transport module. Each closure is provided with a former for forming and maintaining a void or cavity in the growing medium, particularly during transportation so that the containers arrive at the growers with a preformed bore for receiving the plants. The advantage of the planting and transport system is that growers of plants can plant containers more efficiently since the containers arrive at the growers containing the growing medium ready for planting which obviates the need for the grower to fill the containers on site and form a void before planting.

Owner:DEBCO

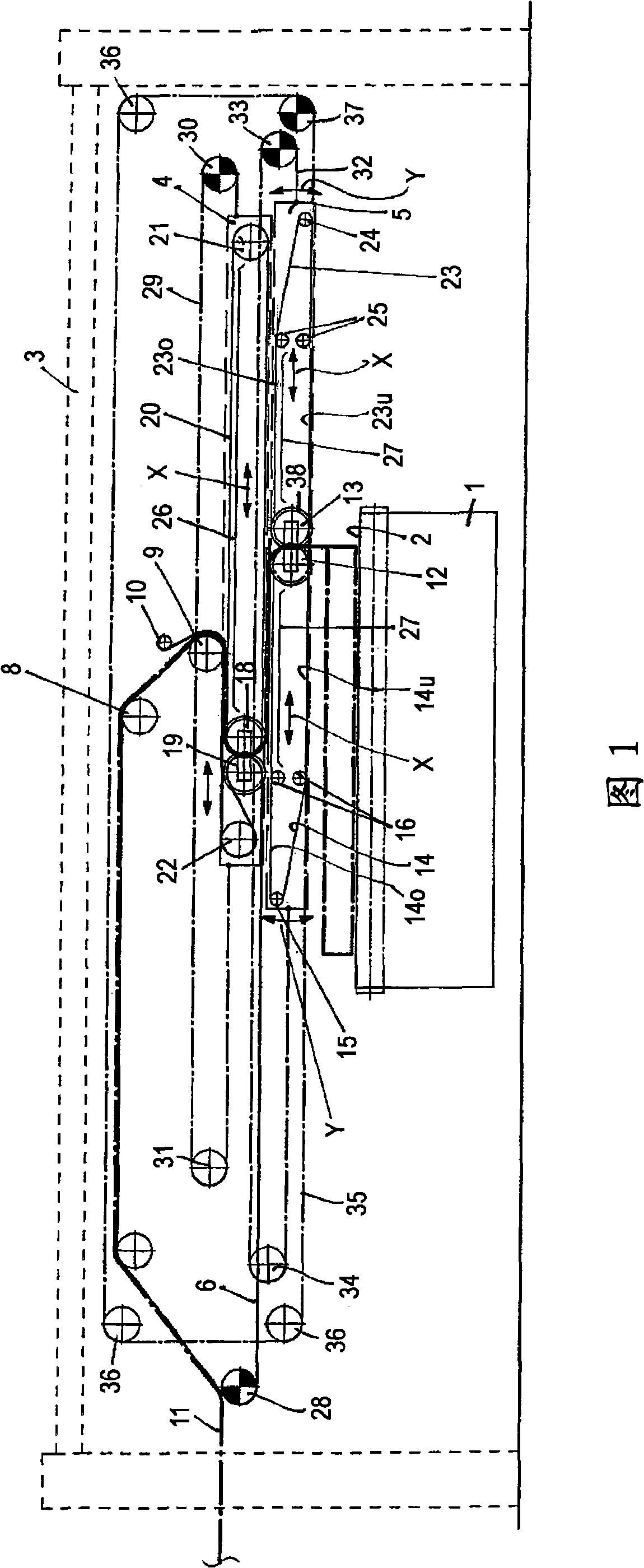

Fleece-laying apparatus

InactiveCN101275313AAvoid aerodynamic effectsAvoid damageLap forming devicesFibre feedersSandwich likeEngineering

In a fleece layer of the carriage cross-lapper type, the laying carriage conveyor belt ( 14 ) wraps around the first laying roller ( 12 ), the upper and lower strands ( 14 o, 14 u) of the belt being parallel to each other as they proceed from the first laying roller ( 12 ). An endless cover belt ( 23 ), which travels around in the laying carriage ( 5 ), wraps around the second laying roller ( 13 ), the cover belt having upper and lower strands ( 23 o, 23 u), which are parallel to each other as they proceed from the second laying roller ( 13 ) in the direction opposite that of the laying carriage conveyor belt ( 14 ). The mutual distances between the web entrance ( 8, 9 ), the upper carriage ( 4 ), the laying carriage ( 5 ), and the output conveyor belt ( 2 ) perpendicular to the transport directions of same are so small that the card web ( 11 ) to be laid is enclosed in a sandwich-like manner between the adjacent strands of the web entrance conveyor belt ( 6 ), of the upper carriage conveyor belt ( 20 ), and of the laying carriage conveyor belt ( 14 ), where the laid fleece on the output conveyor belt ( 2 ) is contacted by the laying carriage conveyor belt ( 14 ) and by the cover belt ( 23 ).

Owner:DILO MASCHF OSKAR

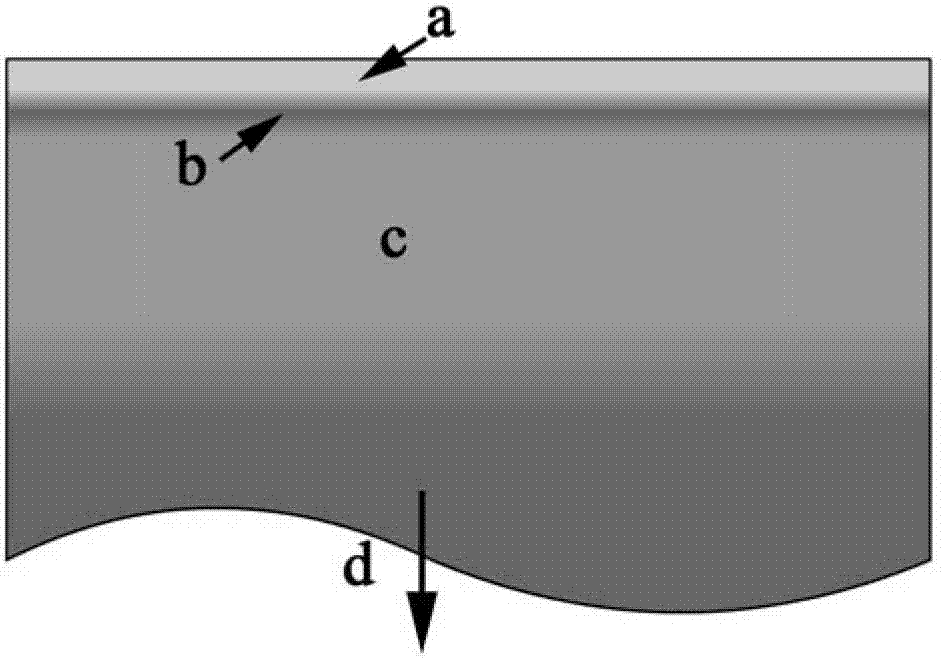

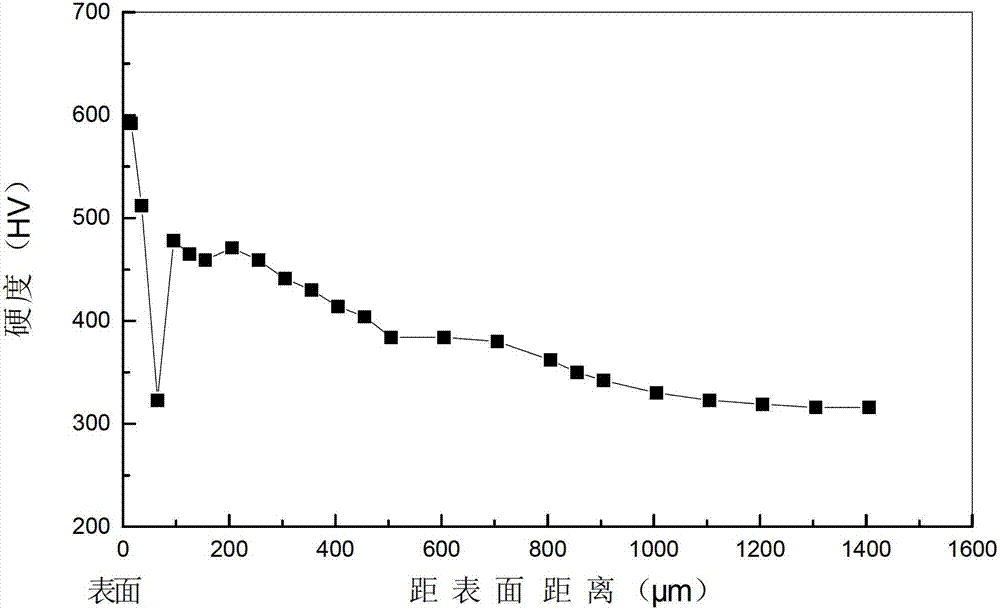

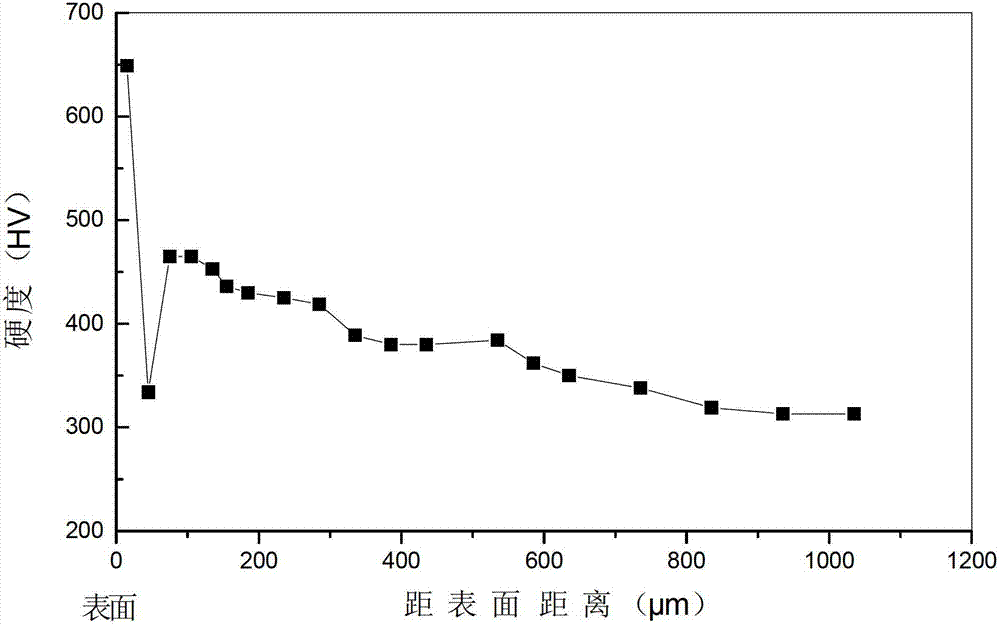

Strengthened coating in sandwich-like structure on surface of precipitation hardening stainless steel

ActiveCN103042759AHigh surface hardnessConvenience to workMetallic material coating processesMetal layered productsSandwich likeSoft layer

The invention discloses a strengthened coating in a sandwich-like structure on the surface of precipitation hardening stainless steel, wherein the strengthened coating comprises a surface high-hard layer, a functional softened layer and a substrate hardened layer, and is characterized by the sandwich-like structure consisting of a hard layer, a soft layer and a hard layer; the surface high-hard layer is 10-80 micrometers in thickness, the functional softened layer is 1-100 micrometers in thickness, and the substrate hardened layer is 10 micrometer to 6mm in thickness; and the substrate hardened layer is combined with the precipitation hardening stainless steel substrate. The strengthened coating in the sandwich-like structure provided by the invention can simultaneously provide thick strengthened layer while improving the surface hardness of the precipitation hardening stainless steel, thus being beneficial to long-term stable operation.

Owner:ZHEJIANG UNIV OF TECH

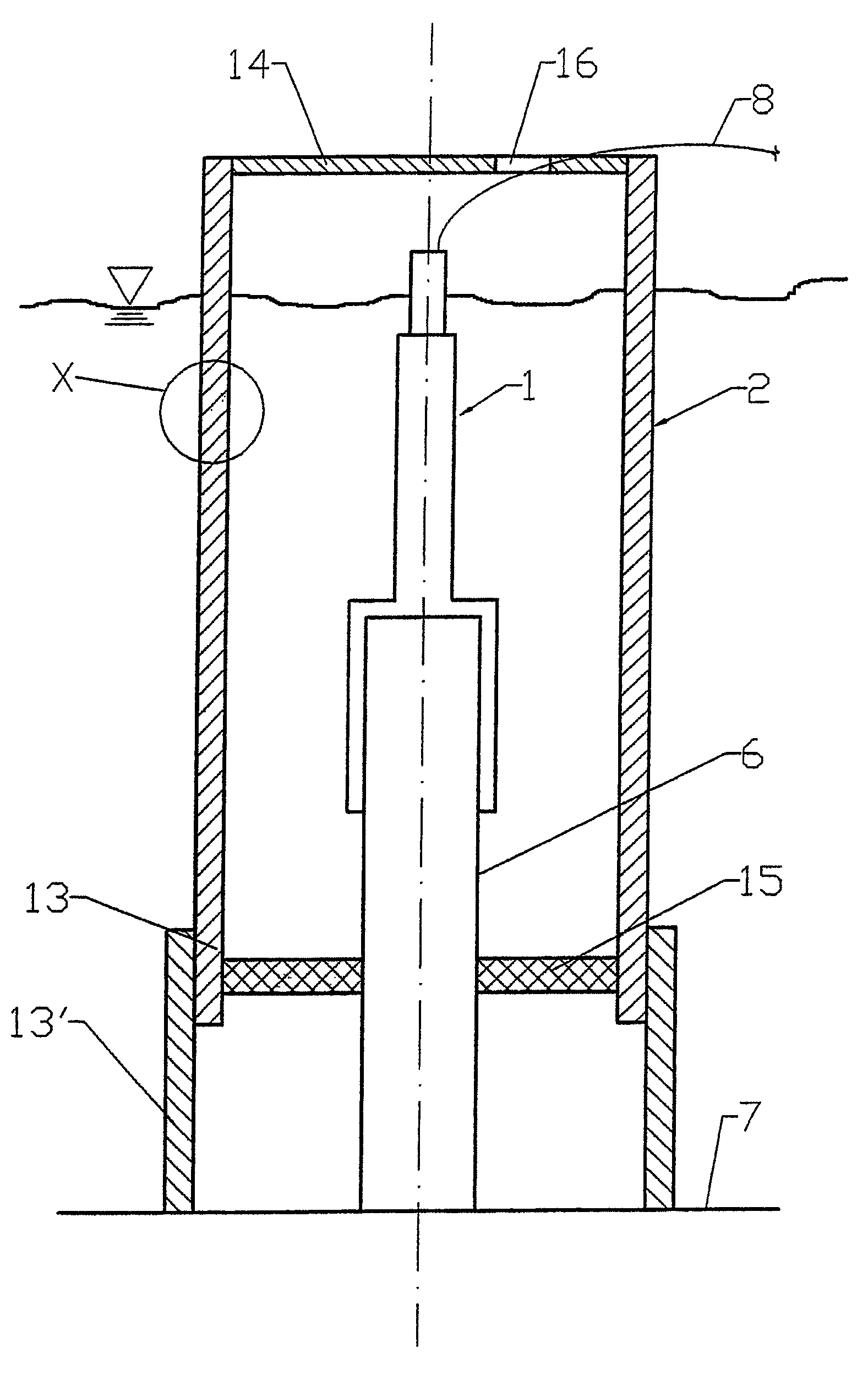

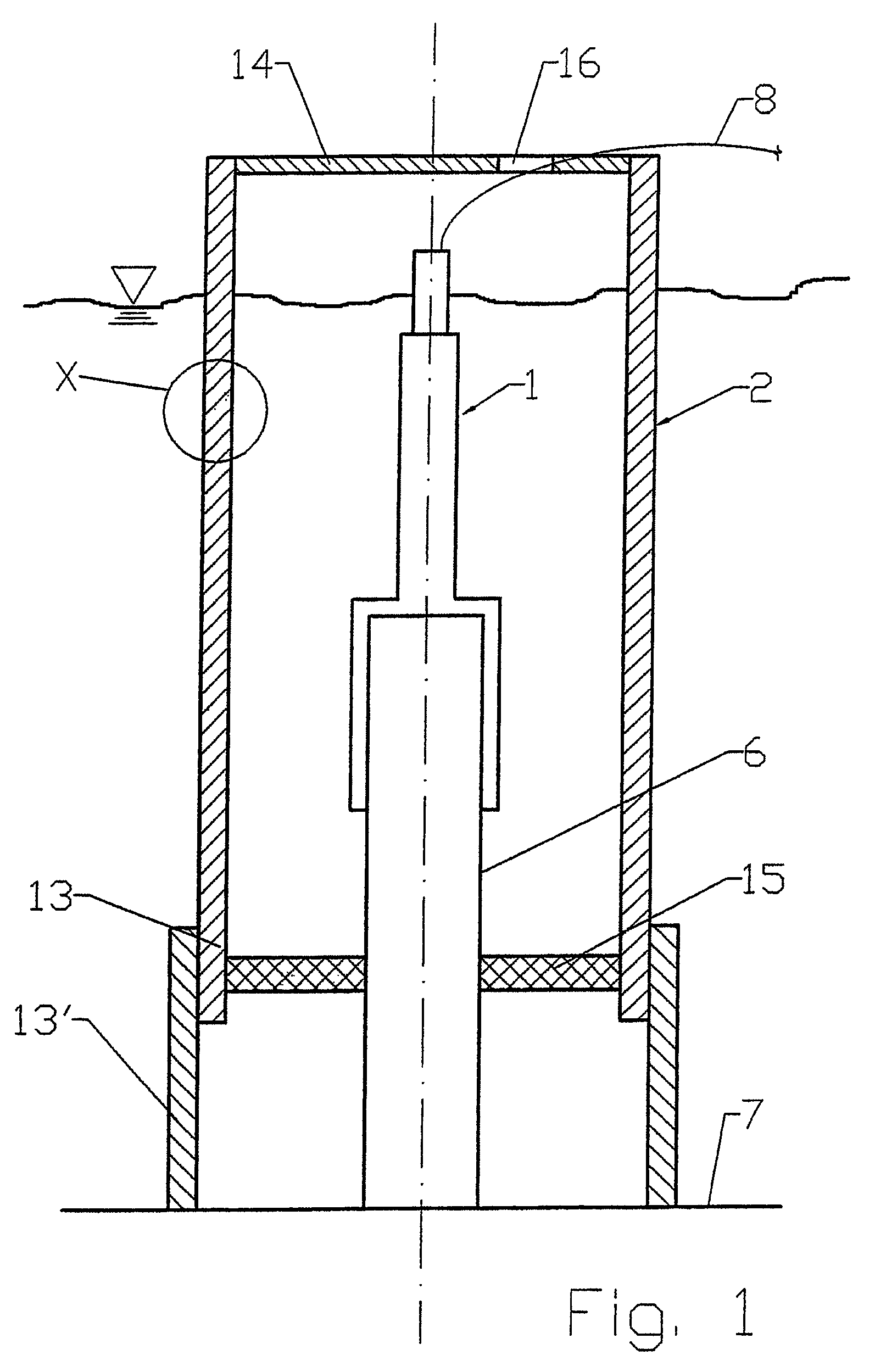

Method and device for environmentally friendly ramming under water

InactiveUS8500369B2Reduce noise inputReduce inputCabinetsBulkheads/pilesSandwich likeEnvironmental engineering

The present invention relates to a method and a device for environmentally friendly ramming under water. To reduce the noise input under water, the machine and the material that is to be rammed are surrounded by a fixed flooded sleeve. The sleeve advantageously has a sandwich-like structure.

Owner:MENCK GMBH

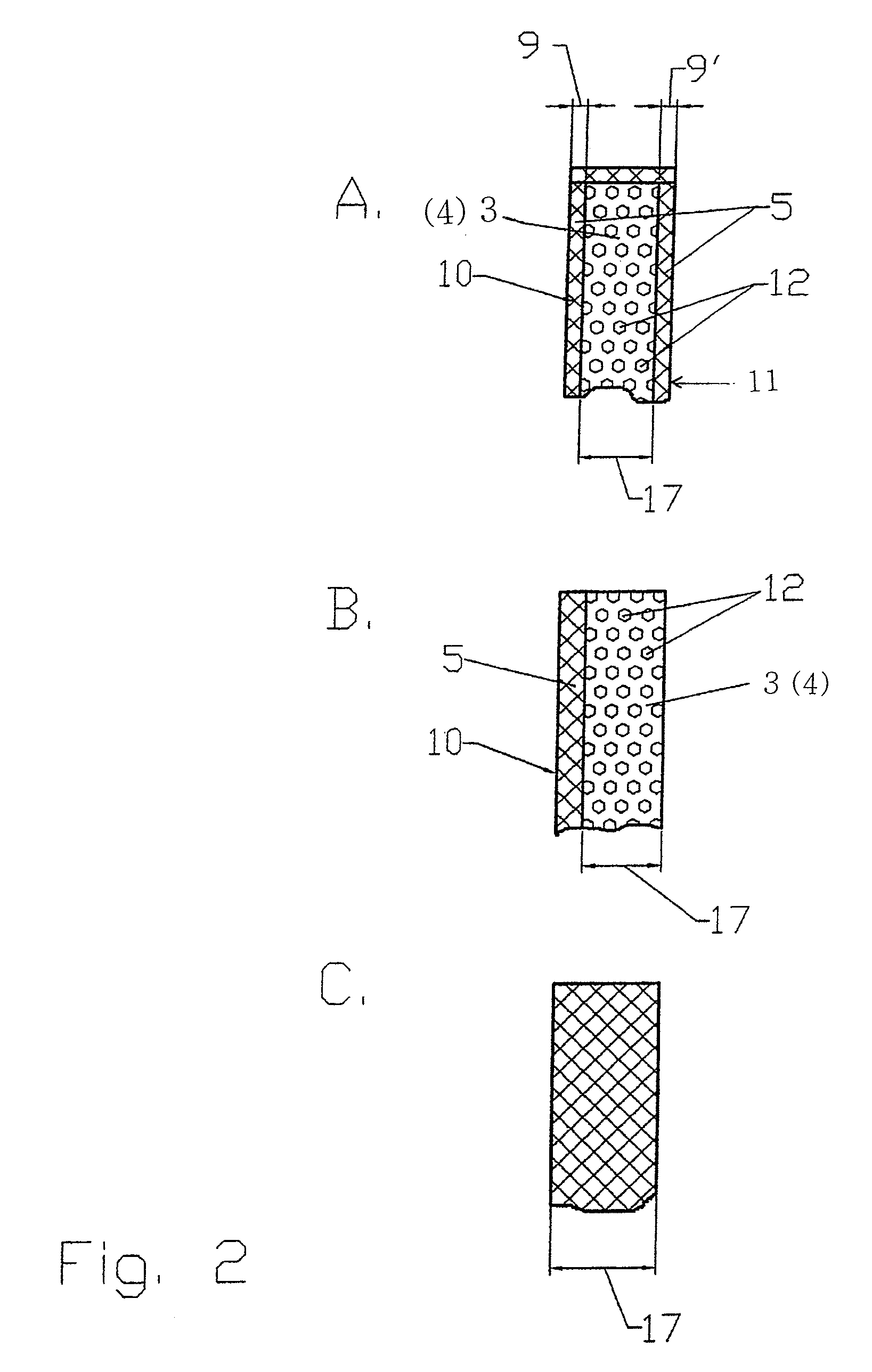

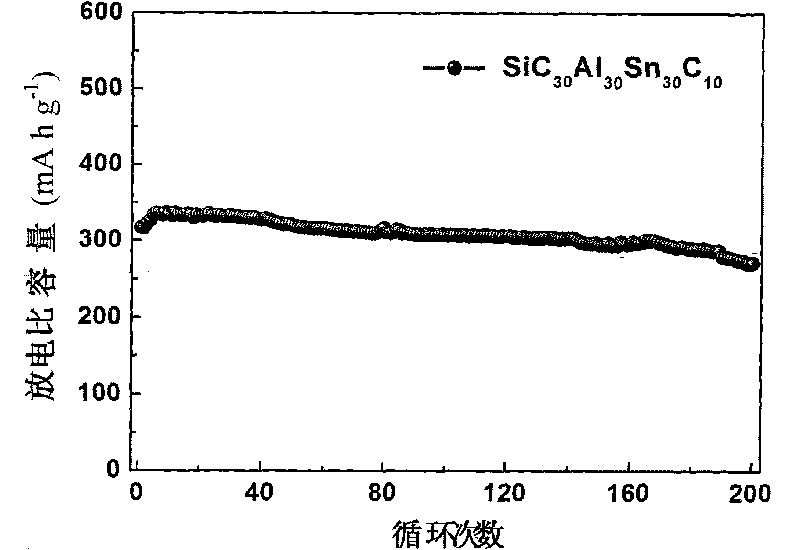

Compound for anode material of lithium ion secondary battery and preparation method thereof

InactiveCN101728513AEvenly distributedImprove cycle performanceNon-aqueous electrolyte accumulator electrodesSandwich likeLithium metal

The invention discloses a compound for an anode material of a lithium ion secondary battery, the compound comprises a sandwich-like structure, an inner layer of the sandwich-like structure uses a hard abrasive, an intermediate layer adopts an embeddable metal or a non-metal or an alloy, and an outer layer adopts a soft conductive material, wherein the embeddable metal or the non-metal or the alloy accounts for 30-90wt% of the total weight of the compound; the hard abrasive accounts for 5-60wt% of the total weight of the compound; and the soft conductive material accounts for 5-60wt% of the total weight of the compound. The prepared anode material compound comprises the sandwich-like nanostructure, and the distribution is even, thereby having excellent cycling performance and rate capability. The preparation method has the advantages of simple process, easy control and abundant raw materials, thereby being a practical technology for preparing the lithium ion metal or alloy anode material.

Owner:WUHAN UNIV

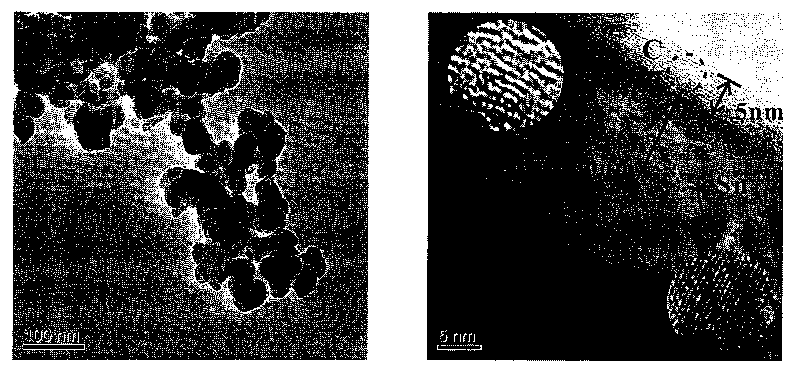

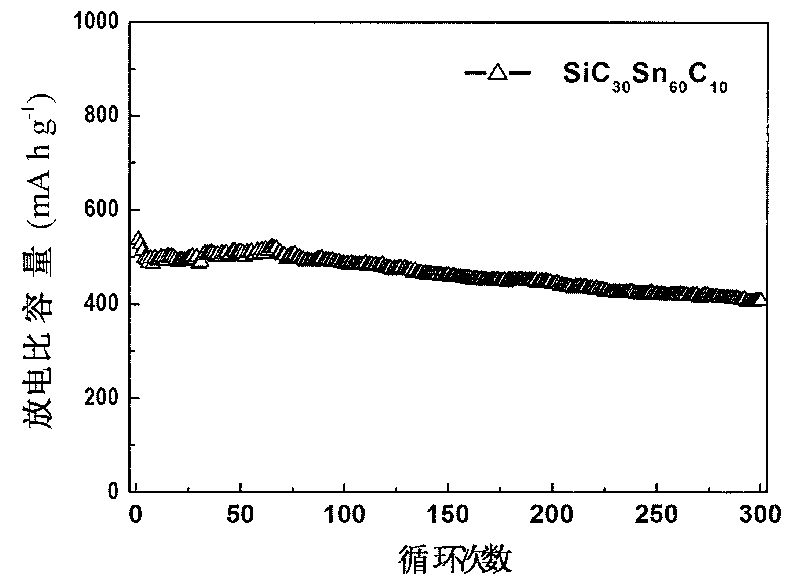

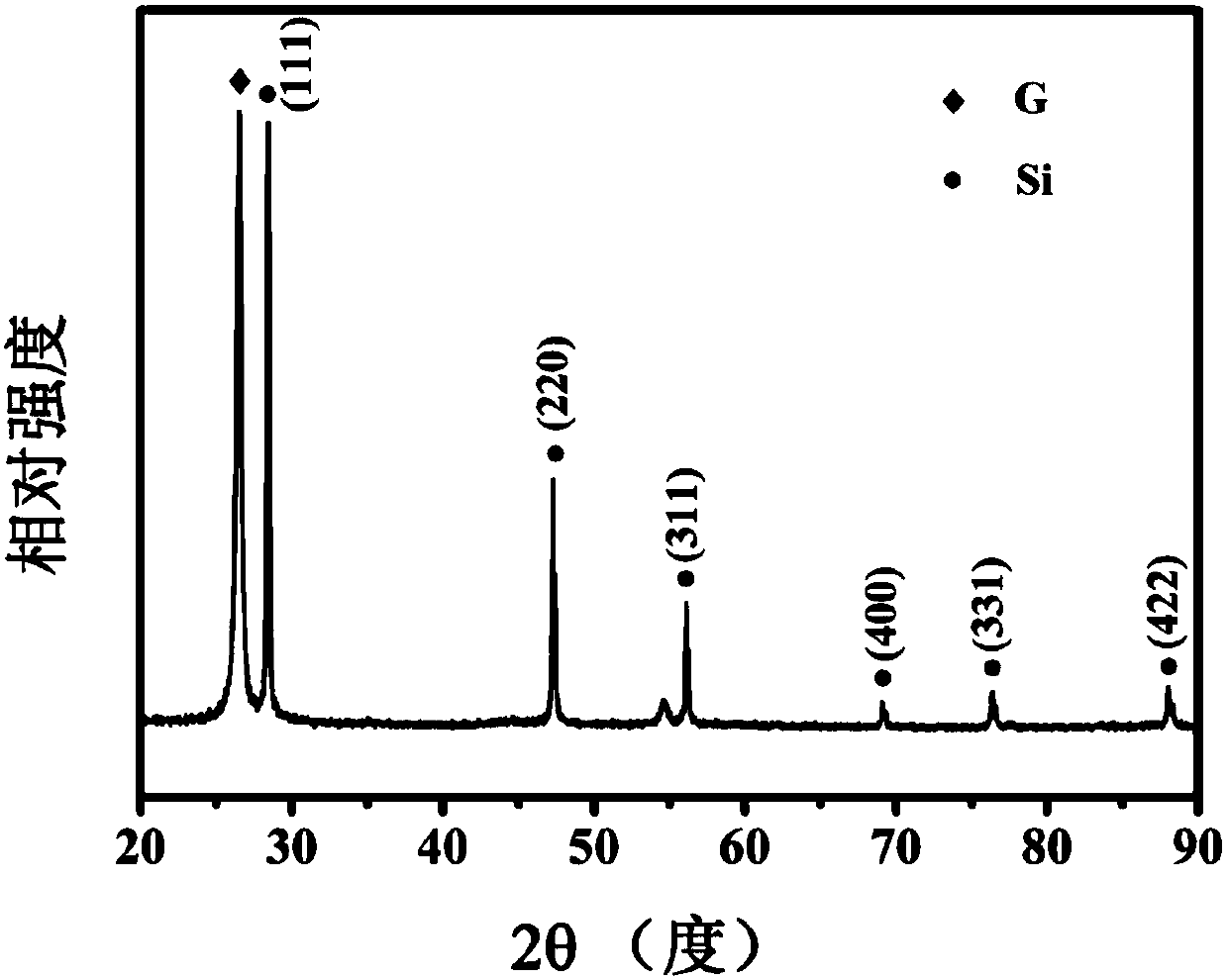

Silicon carbon composite material, and preparation method and application thereof

ActiveCN107611416AHigh tap densityIncrease compaction densityCell electrodesSandwich likeCarbon composites

The invention discloses a silicon carbon composite material, and a preparation method and an application thereof. The preparation method comprises the following steps of performing wet process ball milling on glass powder and a laminated layer carbon material to obtain a uniform mixed product of glass and the carbon material; next, performing uniform mixing and compacting on the product and magnesium powder and fused salt to form an ingot; and then performing a magnesium thermal reaction, and carrying out acid washing on the reaction product to obtain a sandwich layer-shaped porous silicon / graphene-like structured composite material. The preparation method are simple in steps and easy to implement, and the raw materials are wide in resource; more importantly, the mixture is made into the ingot through the compacting process, and then the magnesium thermal reaction is performed, so that the tap density of the silicon carbon negative electrode material is greatly improved, and the volumetric specific capacity of the negative electrode material is improved; meanwhile, by compounding with the graphite and other carbon material to form the sandwich-like structure, the electronic conductivity of the material is improved effectively, and the compatibility between the silicon base material and an electrolyte can be improved, thereby improving cycle performance and rate capability of the material; and therefore, the silicon carbon composite material can be applied to the negative electrode material with high power density and high energy density of the lithium ion battery.

Owner:WUHAN UNIV OF SCI & TECH

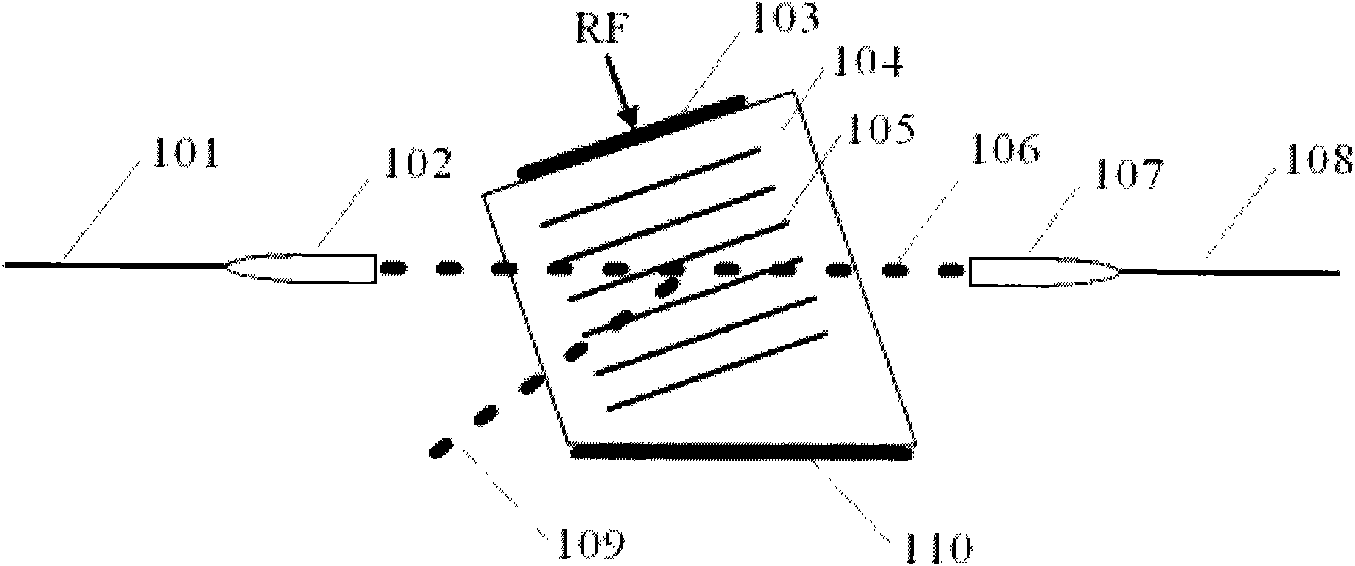

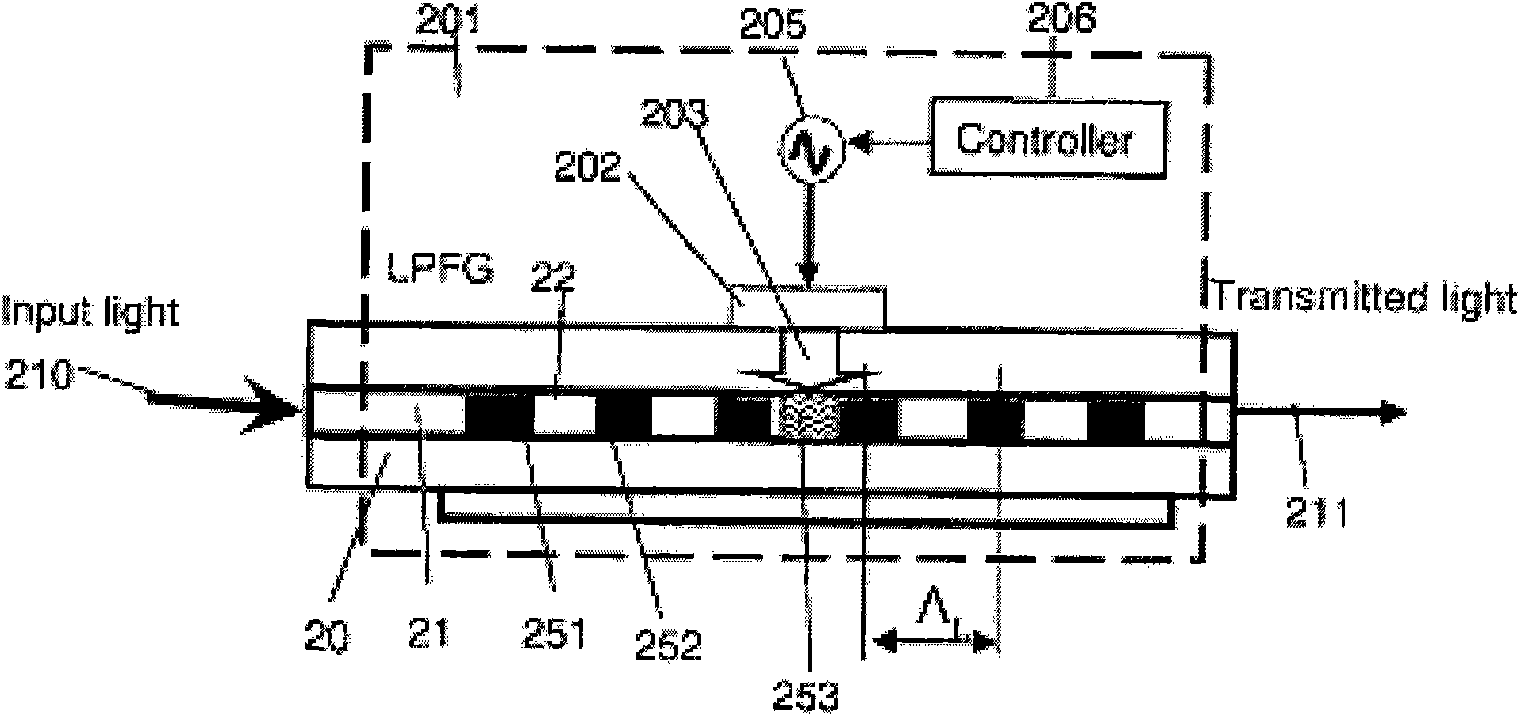

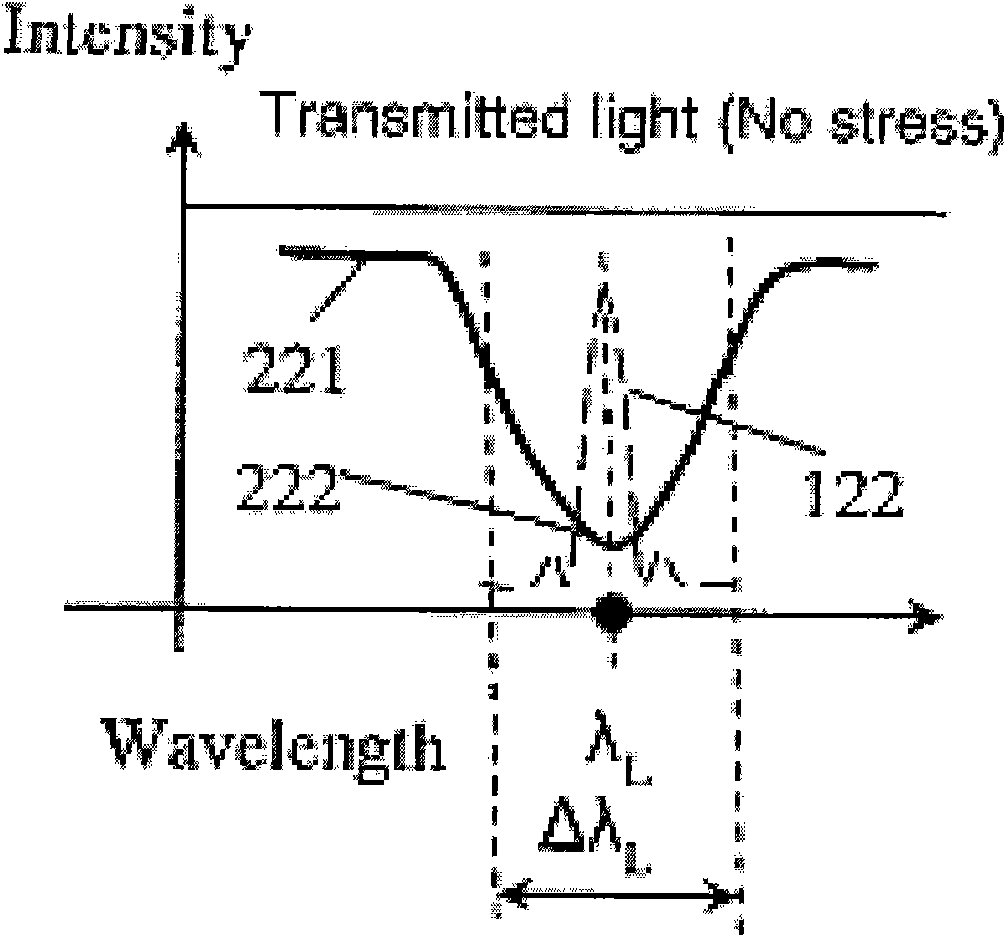

All fiber Q-switch

ActiveCN101854025AChange or stabilize temperatureChanging or stabilizing the center wavelengthActive medium shape and constructionSandwich likeGrating

The invention relates to an all fiber Q-switch, which comprises a fiber, a V-shaped groove, a long-period grating pressed template, piezoelectric ceramics, a semiconductor chilling plate, a thermistor and a metal shell, wherein the fiber passes through the metal shell, and one section of the fiber is a bare fiber; the long-period grating pressed template, the bare fiber and the V-shaped groove are arranged from top to bottom in the metal shell to form a sandwich-like structure; optical cement is coated on the outer surface of the bare fiber; the piezoelectric ceramics is arranged between the inner top of the metal shell and the long-period grating pressed template; the semiconductor chilling plate closely attaches to the outer bottom of the metal shell; and the lateral surface of the V-shaped groove is closely provided with the thermistor for inducing the temperature of the V-shaped groove. The all fiber Q-switch has the characteristic of zero insertion loss. When the all fiber Q-switch is applied to a Q-switched fiber laser, the all fiber Q-switch can improve the output power and efficiency of the laser under the same conditions.

Owner:浙江合波光学科技有限公司

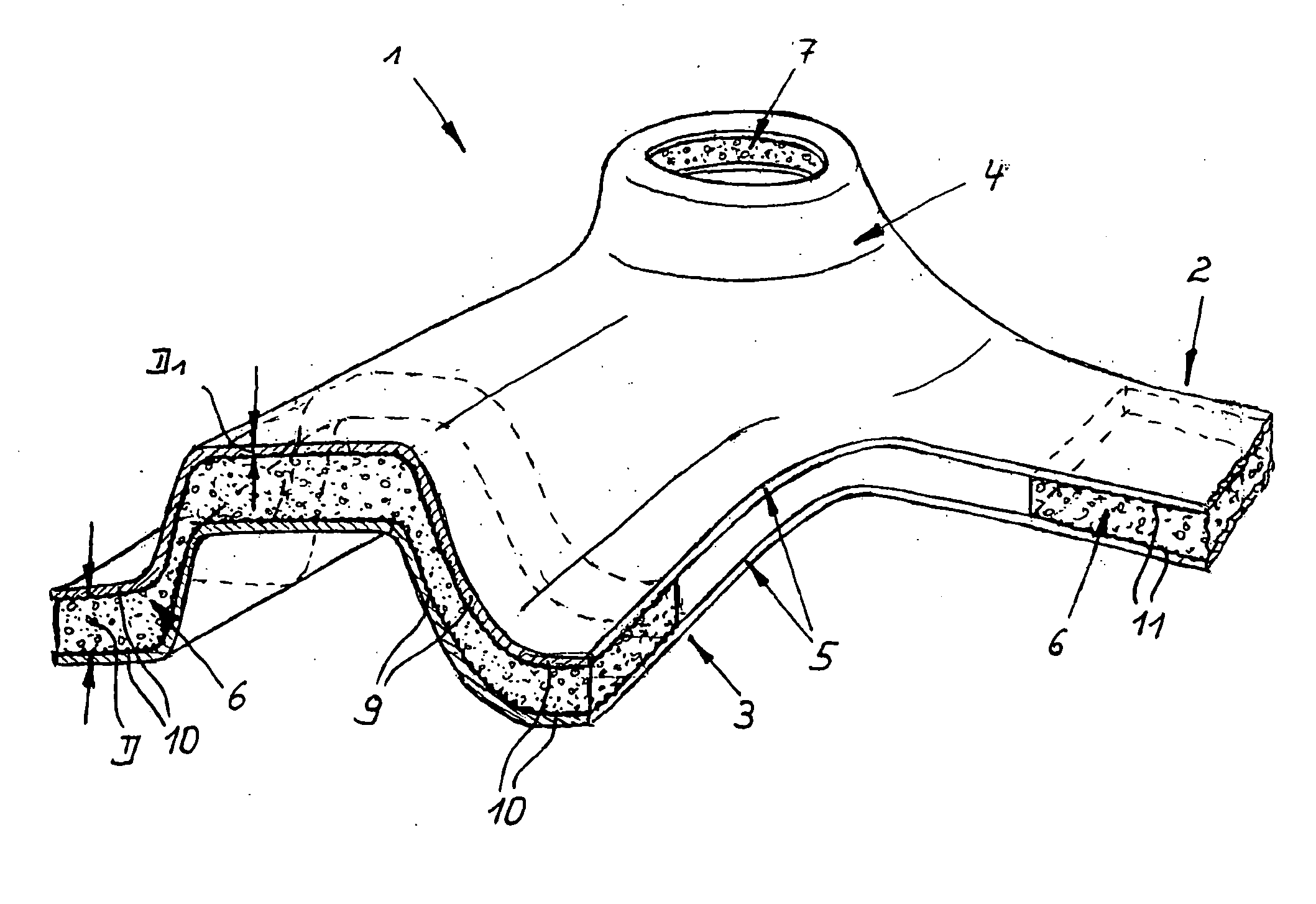

Axle structure for a motor vehicle

InactiveUS20060103099A1Bonded firmlySolve the lack of spaceUnderstructuresInterconnection systemsSandwich likeEngineering

Owner:BENTELER AUTOMOBILTECHNIK GMBH

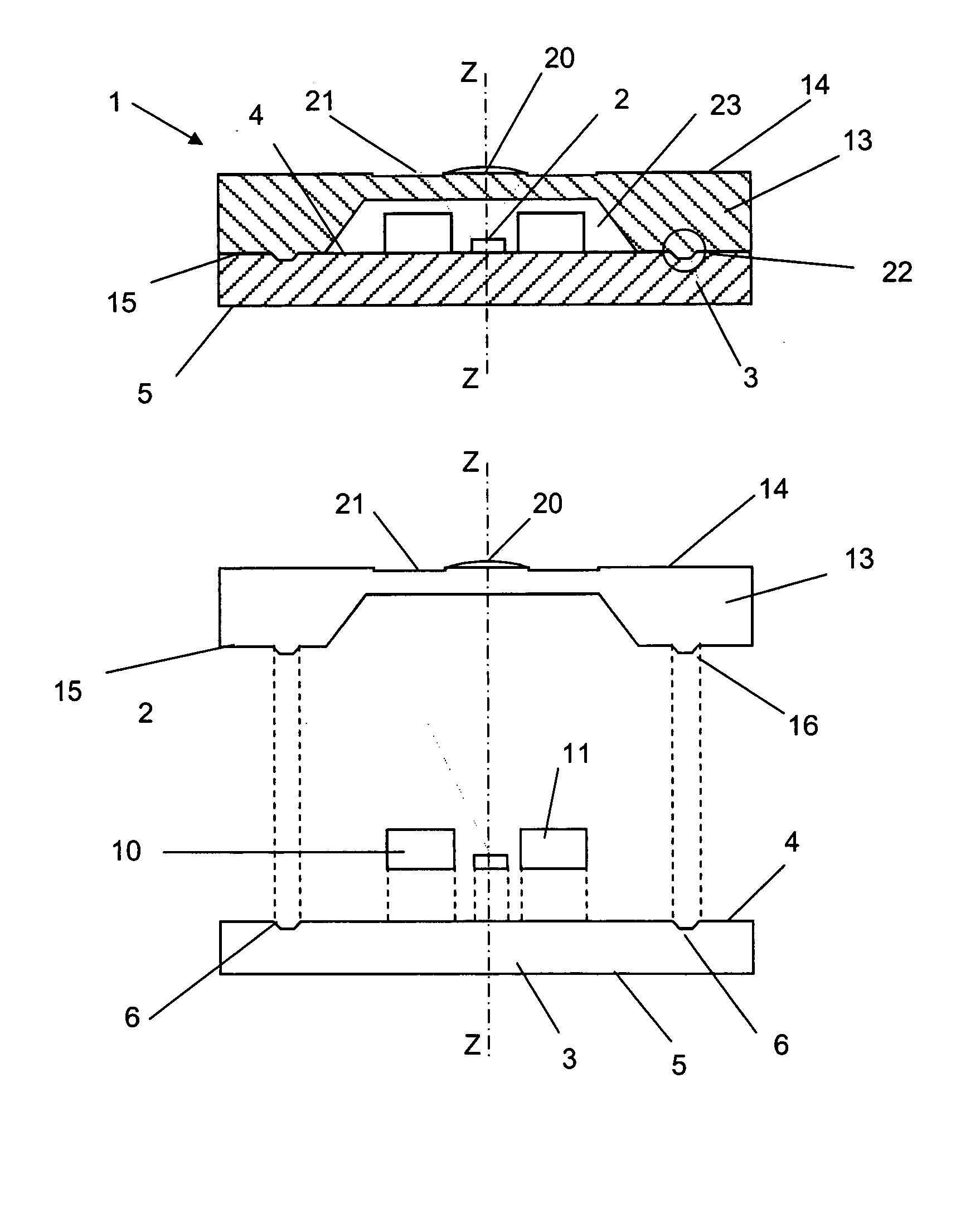

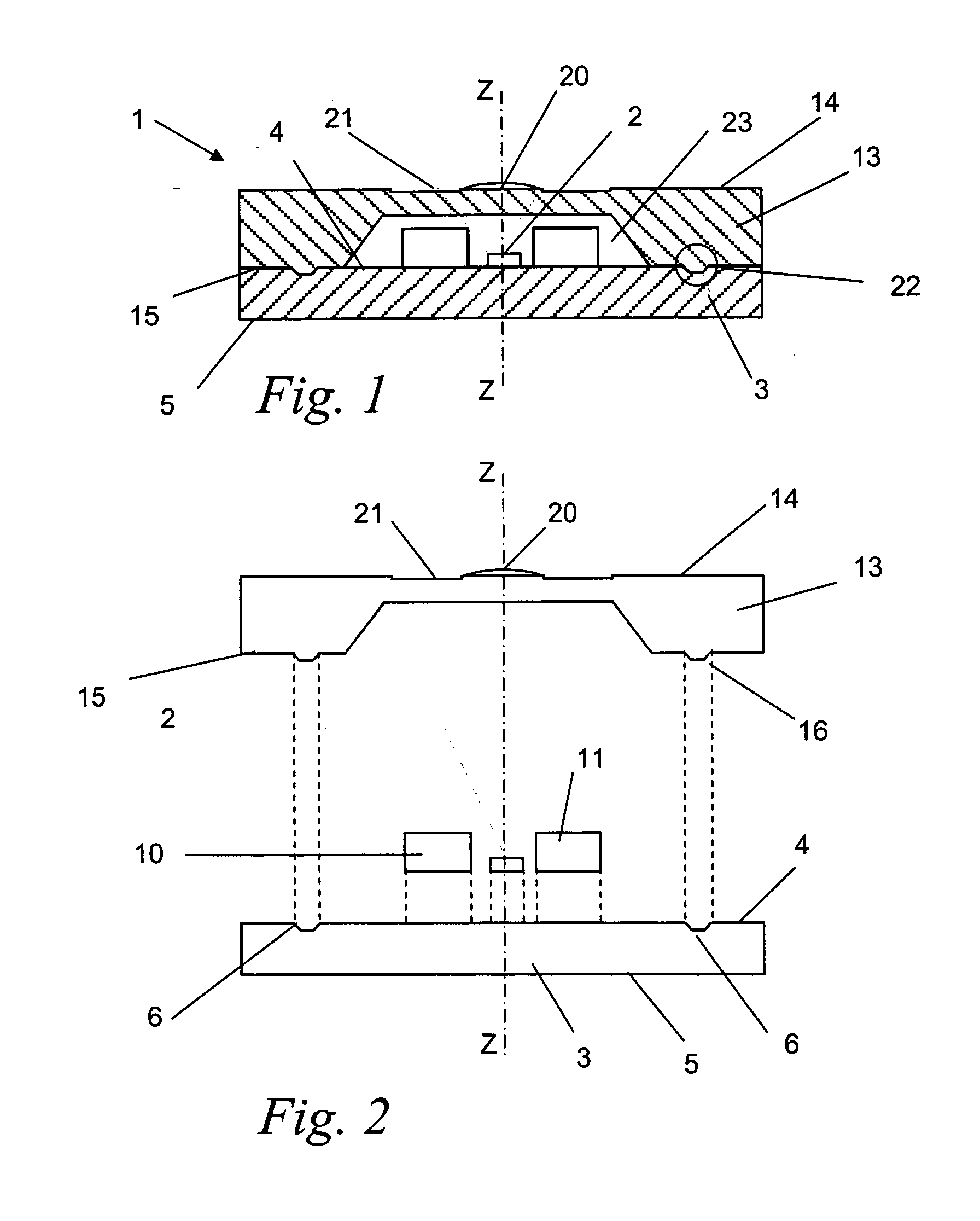

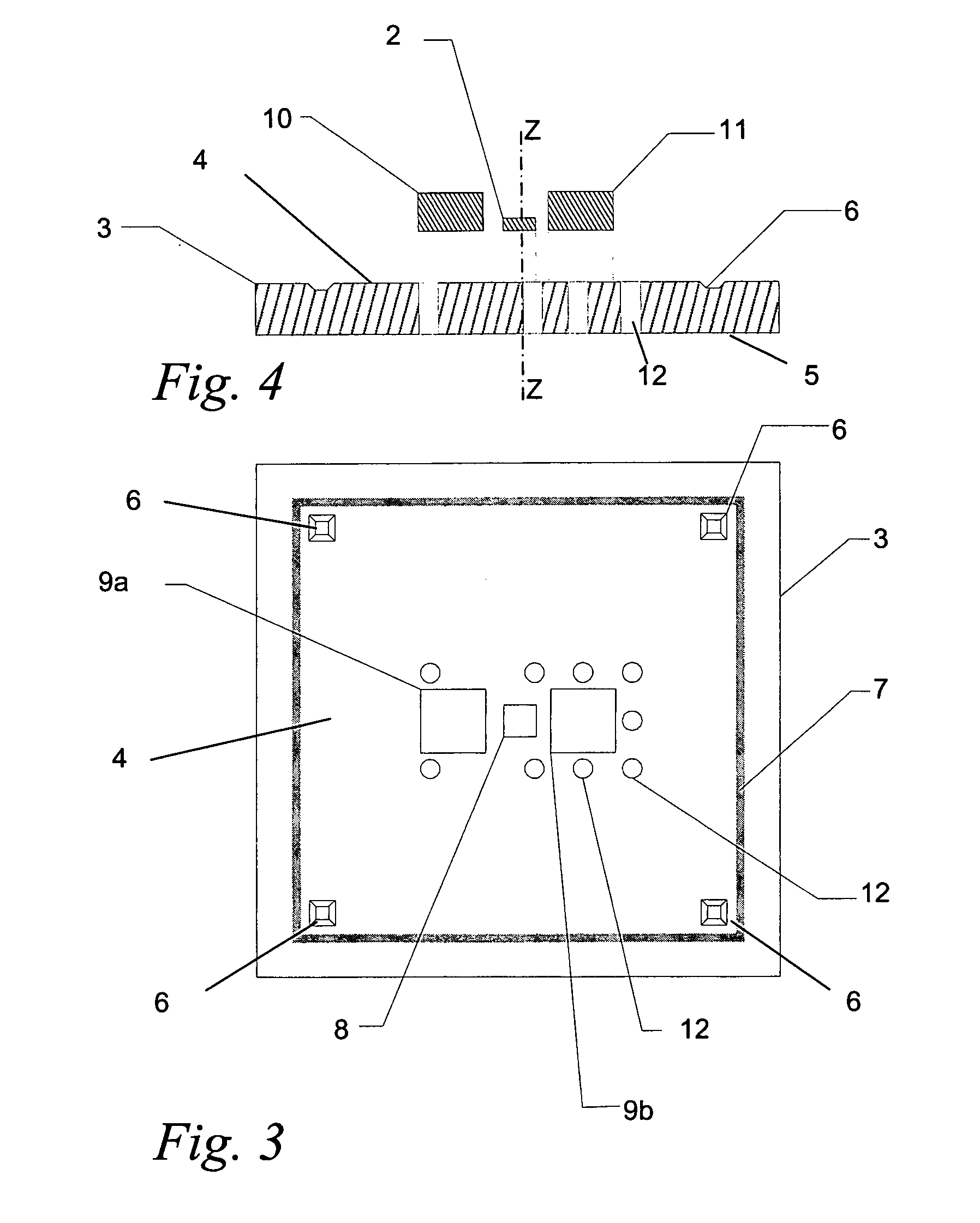

Package for housing at least an electro-optic active element, electro-optic and assembling method

InactiveUS20050263841A1Reliable alignmentCoupling light guidesSemiconductor devicesSandwich likeEngineering

A package houses at least one electro-optic active element for transmission using an optical fiber. The package has a bearing element for the at least one electro-optic active element. Advantageously, the package has a sandwich-like structure and includes a closing element associated with the bearing element using a suitable aligning and coupling device to define a hermetically closed housing seat. Moreover, the closing element houses a lens in axial alignment with the electro-optic active element. An electro-optic module includes the package associated with a casing having a receptacle housing an optical fiber.

Owner:STMICROELECTRONICS SRL

LED arrangement

LED arrangement (light emitting diode), comprising a plurality of adjacent radiating LEDs (1) that are nearly identically aligned for forming an extended area light source, wherein the LEDs are attached to a metallic multi-film support (2) comprising sandwich-like insulating intermediate layers (3) and having at least a step-like structure with at least one step, wherein at least one LED chip (1)is placed on each step on a metal film and the metal layer directly above comprises a corresponding shortening or recess for mounting an LED.

Owner:SIEMENS AG

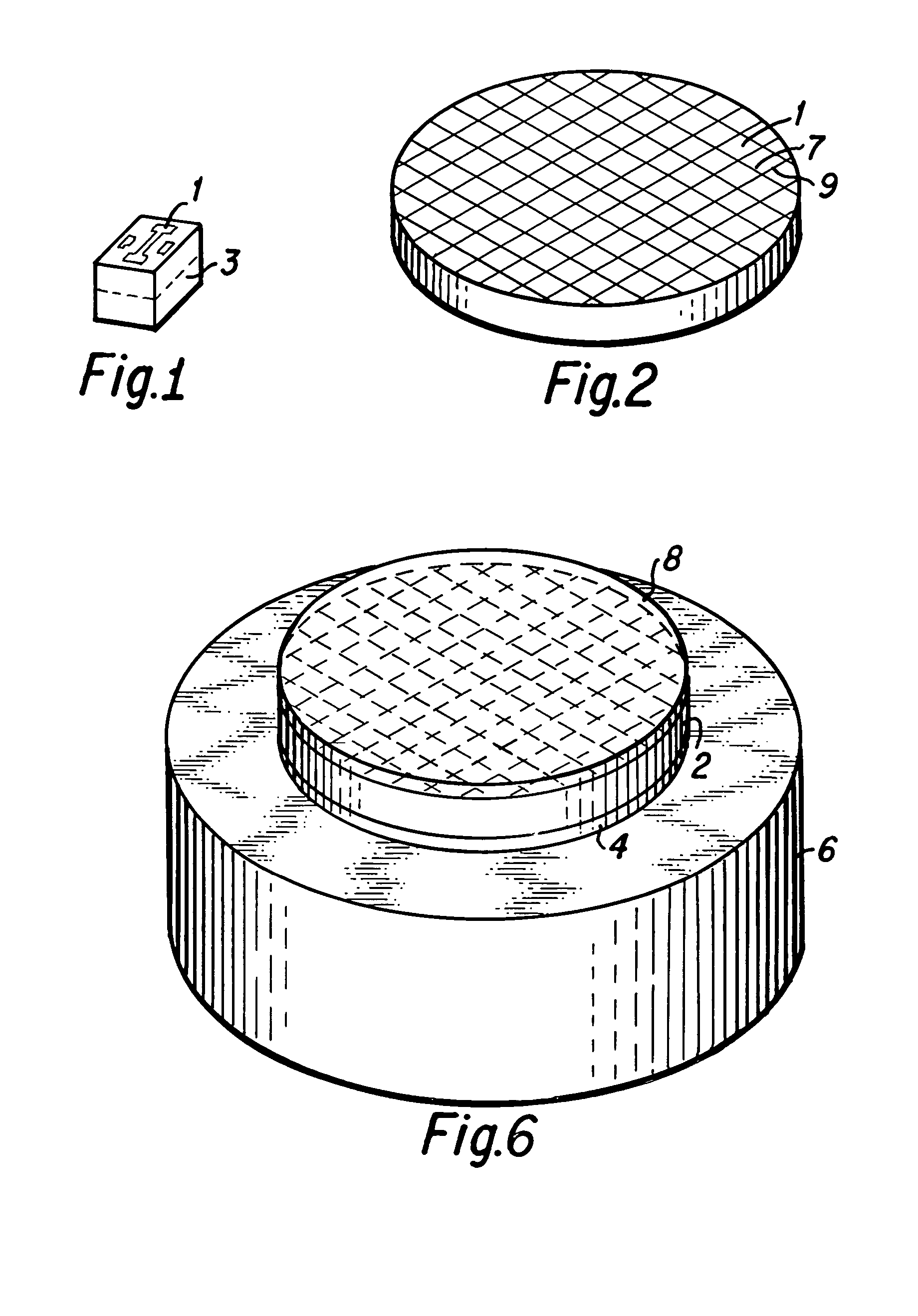

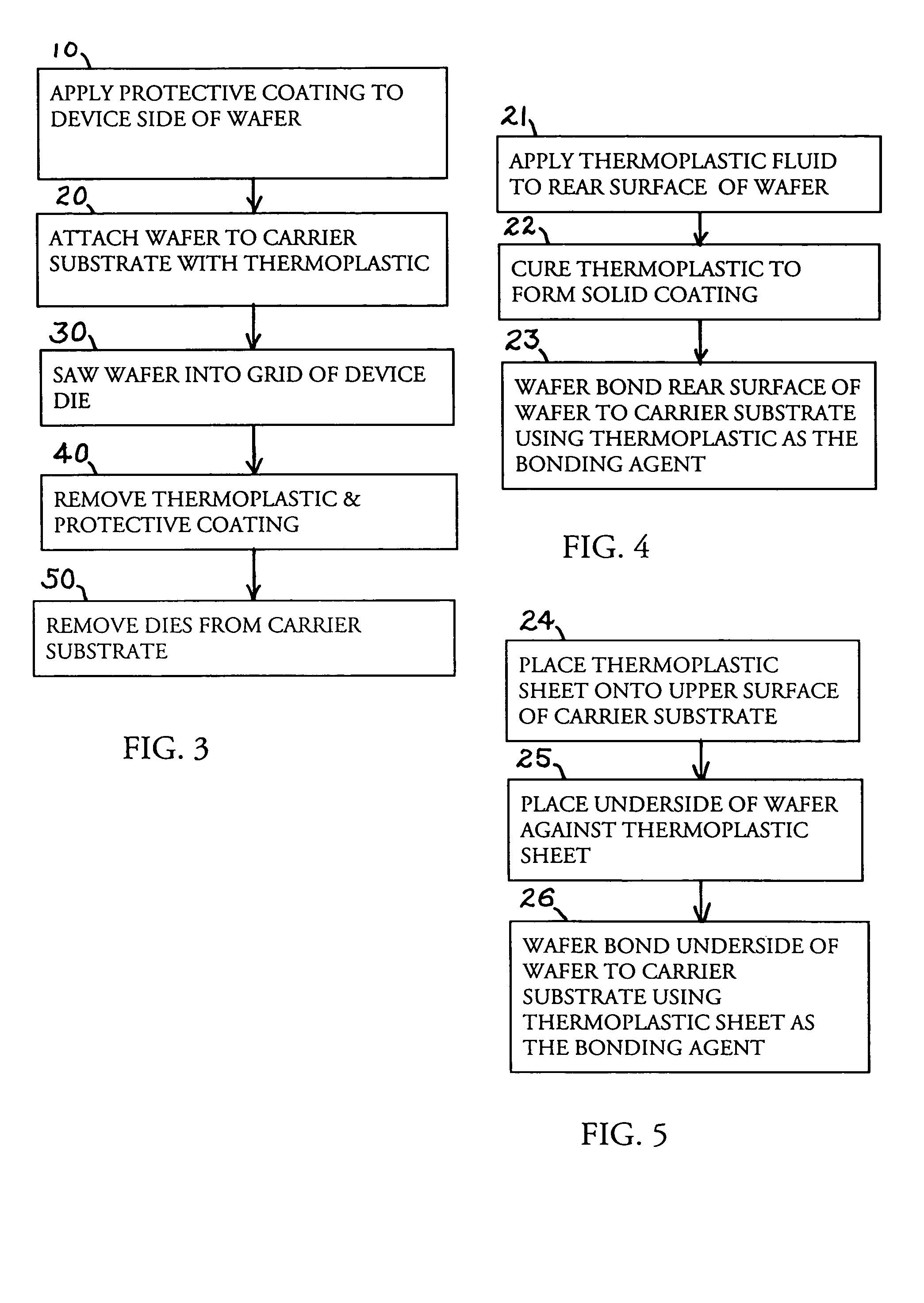

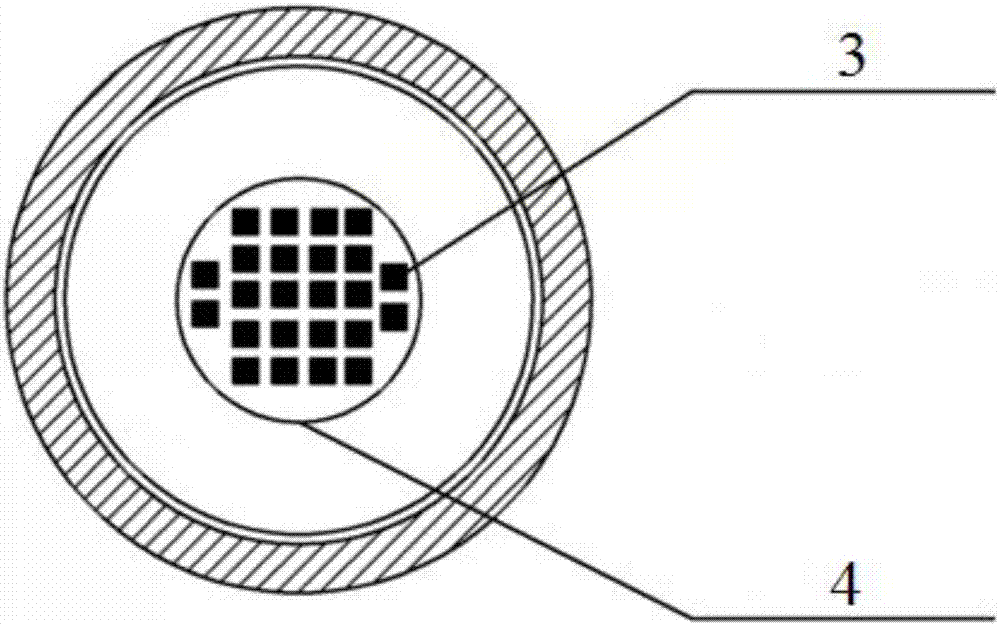

Hard substrate wafer sawing process

ActiveUS7041579B2Solid-state devicesSemiconductor/solid-state device manufacturingSandwich likeThermoplastic

Die of high aspect ratio formed in a hard wafer substrate are sawed out without requiring tape, obtaining high die yields. Preliminary to sawing the semiconductor die (3) from a sapphire wafer (2), the wafer is joined (20) to a silicon carrier substrate (6) by a thermoplastic layer (4) forming a unitary sandwich-like assembly. Sawing the die from the wafer follows. The thermoplastic is removed, and the die may be removed individually (50) from the silicon carrier substrate. Thermoplastic produces a bond that holds the die in place against the shear force exerted by the saw and by the stream of coolant (30).

Owner:NORTHROP GRUMMAN SYST CORP

Method for preparing sandwich-like Ce: YAG glass-ceramic sheet by tape casting method

InactiveCN106892562AGood photoelectric parametersReduce direct contactSemiconductor devicesSandwich likeSlurry

The invention relates to a method for preparing a sandwich-like Ce: YAG glass-ceramic sheet by a tape casting method. The method comprises the following steps: (1) a glass raw material is prepared from the following effective materials by mole fraction: 10 to 20% of ZnO, 5 to 17% of Sb2O3, 25 to 40% of TeO2, 6 to 13% of Li2O, 10 to 15% of K2O, and 5 to 20% of Ce: YAG phosphor; after the glass raw materials are thoroughly mixed and ground, a mixture is mixed with distilled water to obtain a mixed slurry; (2) the mixed slurry is uniformly coated on a white glass sheet having a thickness of 0.1 to 0.5 mm and matched with the size and shape of a light source by a tape casting machine; (3) the coated white glass sheet is dried at a temperature of 200 to 300 DEG C for 6 to 9 hours, the white glass sheet with the same shape and size is covered on the surface layer of the mixture after the water is evaporated, the sandwich-like glass clamping sheet is sintered at a temperature of 600 to 800 DEG C for 1 to 4 hours and then cooled to room temperature to form a sandwich-like Ce: YAG glass-ceramic sheet with a thickness of 0.4 to 1.5 mm. The sandwich-like glass-ceramic sheet with better photoelectric parameters is obtained by firing at a relatively low temperature.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com