Strengthened coating in sandwich-like structure on surface of precipitation hardening stainless steel

A precipitation hardening, stainless steel technology, applied in the direction of coating, metal material coating process, layered products, etc., can solve the problem of no impact stress buffer zone, strengthening layer damage, falling off, etc., to achieve a wide range of applications, improve surface hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Reinforcing material specially used for surface pre-coating, the composition is: mixed metal oxide (Al 2 o 3 : TiO 2 =1:3) 40%, WC15%, Co9%, Cr9%, Ni3%, the rest is binder (502 glue: E-44 type epoxy resin=3:1).

[0032] 2. Laser treatment, laser power 1200W, spot size 12×1mm, scanning speed 0.3m / min, overlap 10%, using Ar gas to protect the laser irradiation area.

[0033] 3. Auxiliary heat treatment: heat treatment temperature is 450°C, holding time is 3 hours, air cooling.

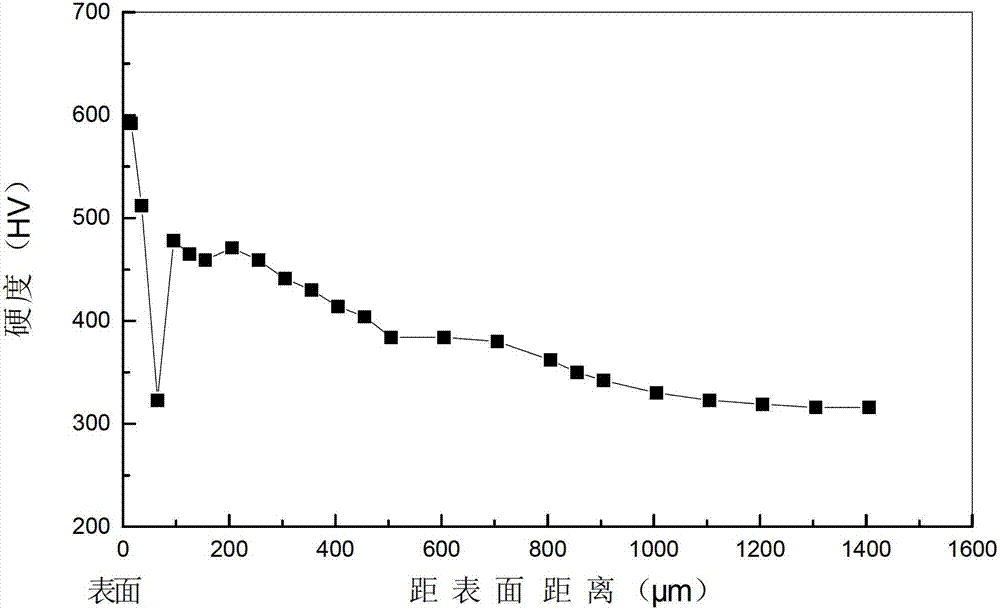

[0034] Such as figure 2 As shown, within 3mm of the surface of the workpiece, a sandwich-like composite reinforced layer with three layers of "hard-soft-hard" can be obtained, in which the maximum surface hardness is greater than 590HV, and the hardness of the base hardened layer is between 350-500HV and shows Gradient descending trend, the total strengthening depth of the composite strengthening layer is greater than 1.2mm.

Embodiment 2

[0036] 1. Reinforcing material specially used for surface pre-coating, the composition is: mixed metal oxide (Al 2 o 3 : TiO 2 =1:3) 26.7%, VC33%, WC10%, Co6%, Cr6%, Ni2%, the rest is binder (502 glue: epoxy resin=3:1).

[0037] 2. Laser treatment, laser power 2100W, spot size 9×1mm, scanning speed 500mm / min, overlap 10%, using Ar gas to protect the laser irradiation area.

[0038] 3. Auxiliary heat treatment: heat treatment temperature is 450°C, holding time is 3 hours, air cooling.

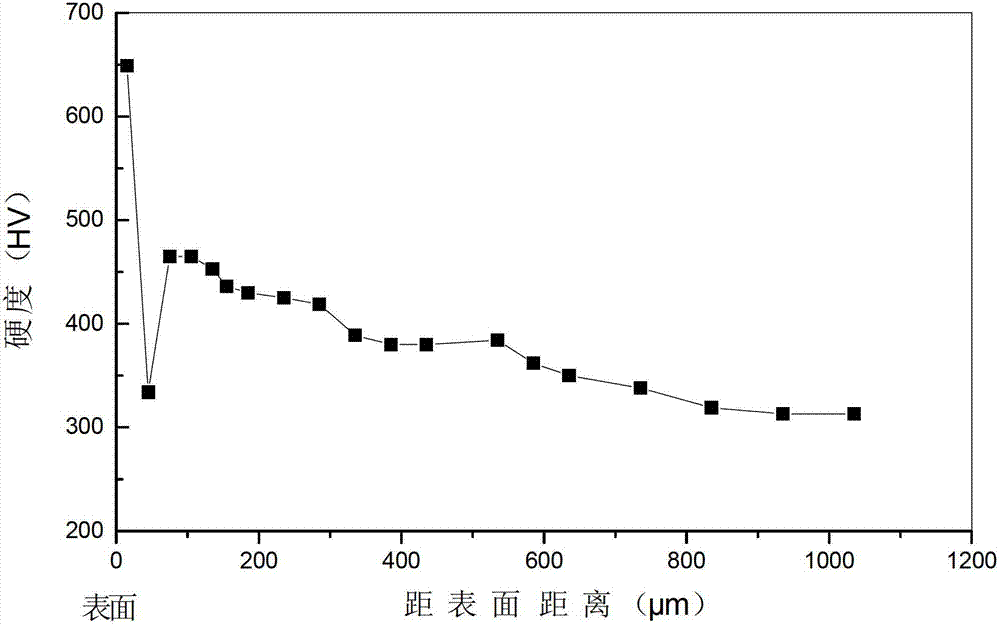

[0039] Such as image 3 As shown, within 3 mm of the surface of the workpiece, a sandwich-like composite strengthening layer with three layers of "hard-soft-hard" can be obtained, in which the maximum surface hardness is greater than 650HV, and the hardness of the base hardened layer is between 350 and 500HV and shows Gradient descending trend, the total strengthening depth of the composite strengthening layer is greater than 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com