Wood sandwich board

A sandwich panel and wood technology, which is applied in the field of building decoration materials, can solve the problems of low decorative effect and heavy metal feeling, and achieve the effect of increasing the decorative effect without losing the heavy feeling and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

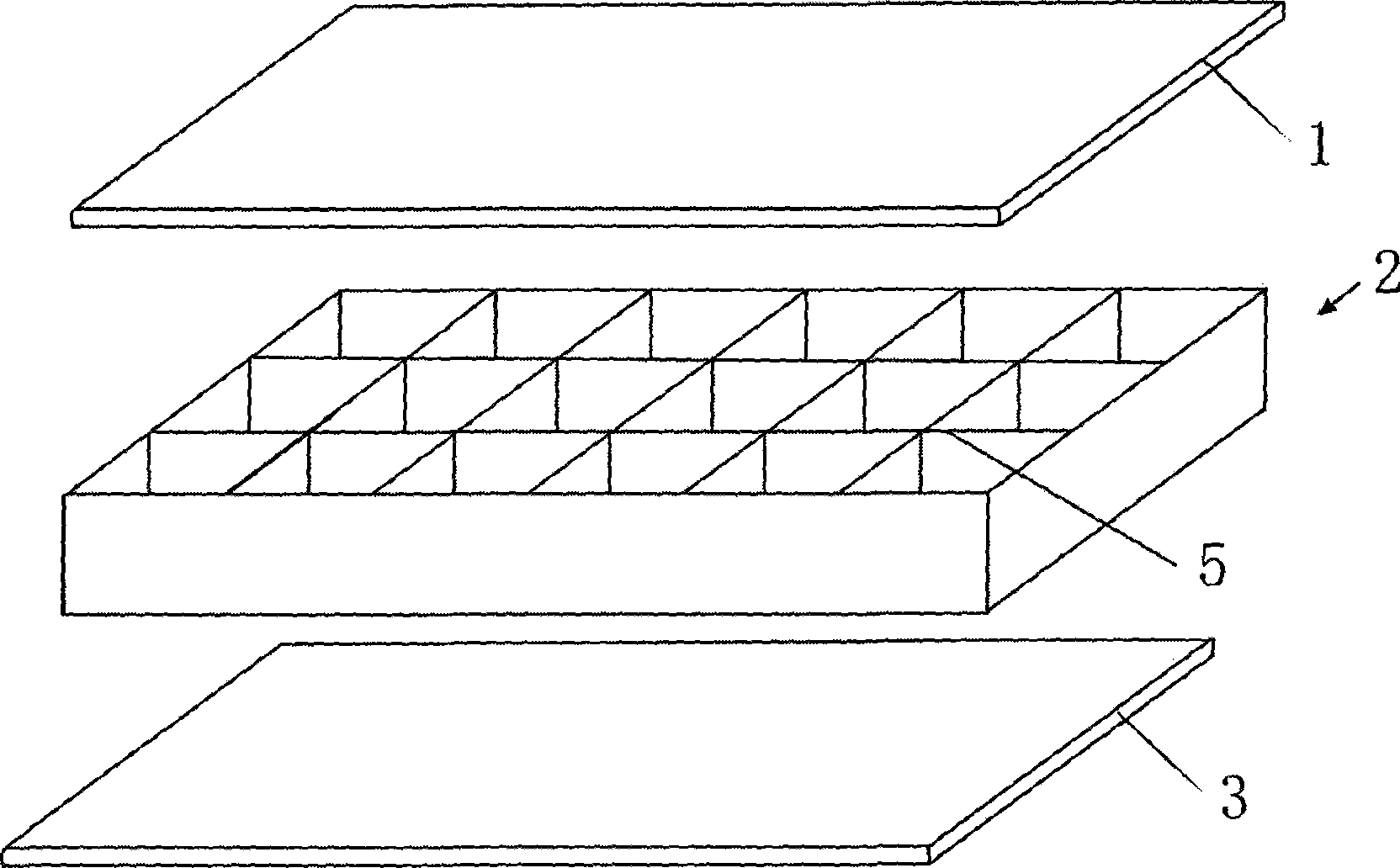

[0028] Such as figure 1 As shown, a wood sandwich panel includes a wood board layer 1, a core layer 2, a wood board layer 2 3, a wood board layer 1, a core layer 2, and a wood board layer 2 3 through interlayer glueing and pressing into a whole.

[0029] The core layer 2 includes a wood structure skeleton 5 and fillers filled in the wood structure skeleton 5. The wooden frame 5 is evenly distributed in the core layer 2 in a crisscross pattern to ensure the structural stability of the core layer 2 and increase the strength and impact resistance. The filler of the core layer 2 is a polystyrene foam board EPS.

[0030] The wood layer 1, wood layer 2 and 3 are all made of reorganized decorative thin wood, and the surface of the wood board 1 and wood layer 2 3 is provided with a paint treatment layer.

Embodiment 2

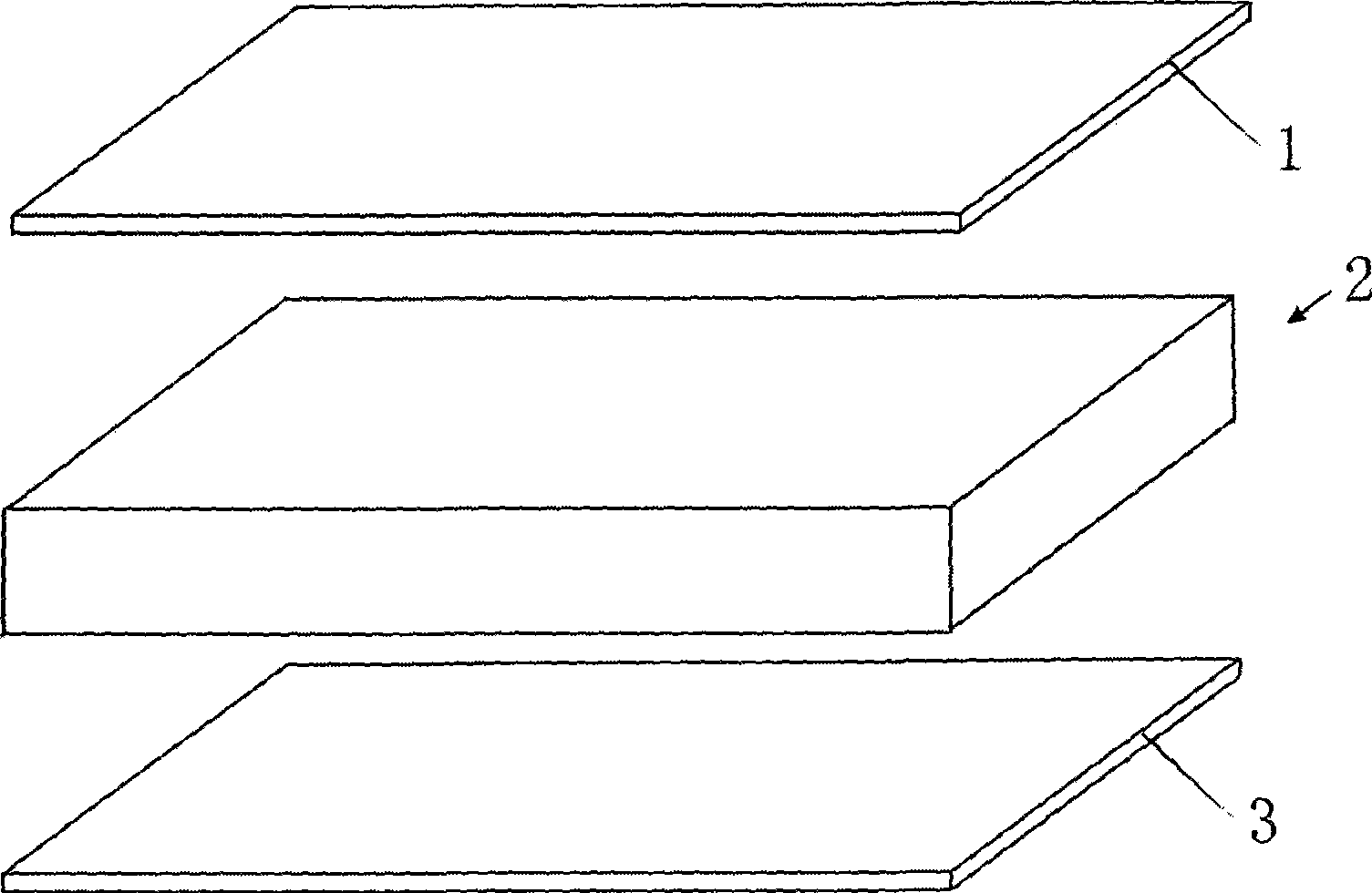

[0032] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that: the core layer 2 only contains fillers and does not contain the wood structure skeleton 5. The filler of the core layer 2 is an extruded polystyrene board XPS.

Embodiment 3

[0034] The difference between this embodiment and the first embodiment is that the wood layer 1 and the wood layer 2 3 are all made of natural decorative thin wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com