Tensile stress/strain sensor applied to knuckle joint and preparation method thereof

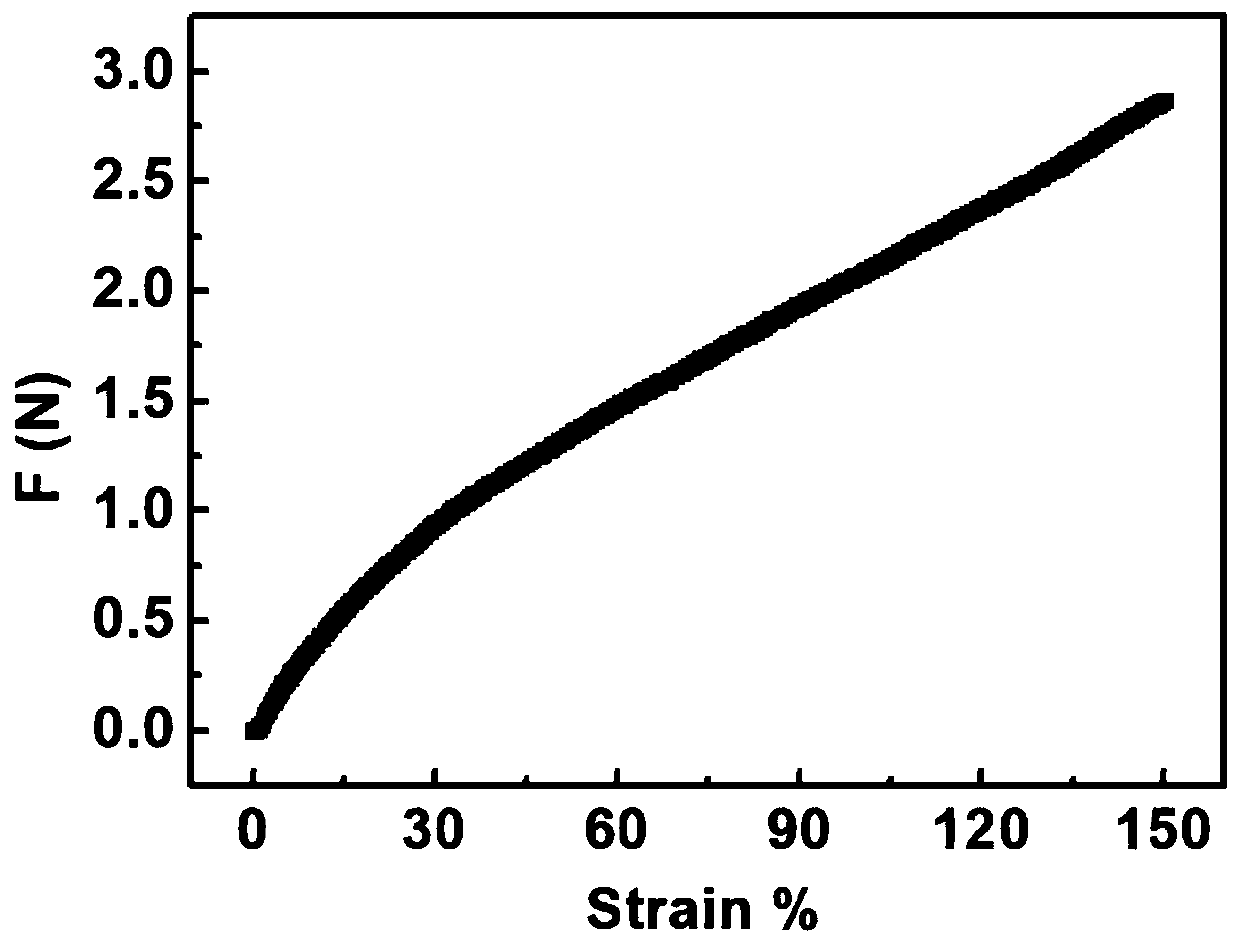

A technology of strain sensor and tensile stress, which is applied in the direction of instruments, measuring force, electric/magnetic solid deformation measurement, etc., can solve the problems of inability to apply stress/strain measurement, difficulty in detecting small deformation, insufficient tensile performance, etc., and achieve realization Effects of miniaturization and integration, large tensile range, good mechanical properties and resistance to strain properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific implementation methods.

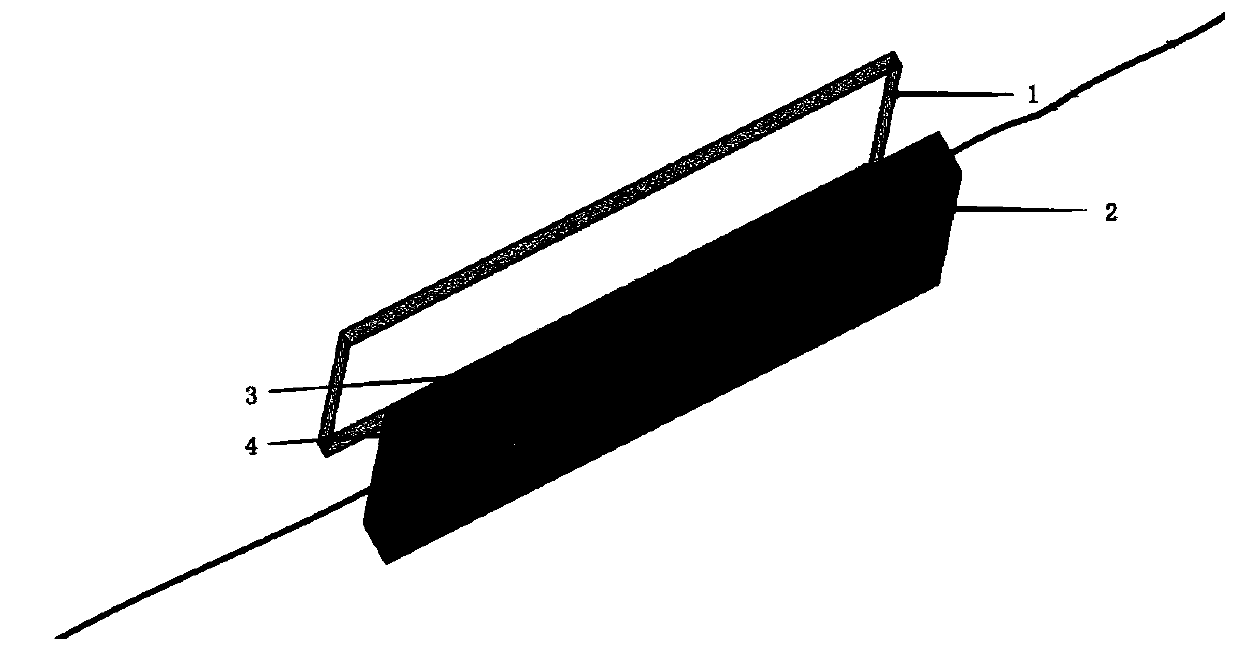

[0030] (1) Use a small machine tool to mill out a 40×25×2mm on a piece of plexiglass 3 Dimensions of the groove surface as a mold, washed with absolute ethanol and deionized water;

[0031] (2) Cut 25×10mm on 60-mesh rough dry sandpaper 2 A piece of sandpaper strip of size, washed with absolute ethanol and deionized water in turn, dried and glued to the center of the bottom surface of the mold with double-sided adhesive, with the frosted side of the sandpaper facing up;

[0032] (3) Mix Components A and B of 00-30 Ecoflex silicone rubber with a total mass of 8g at a mass ratio of 1:1, stir for 5 minutes, and then place it in a vacuum environment for degassing treatment for 15 minutes, and inject it into the prepared mold. Then put it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com