Environment-friendly bamboo wood adhesive and method for preparing novel bamboo wood product by using adhesive

A kind of adhesive, bamboo and wood technology, applied in the joint of wooden veneers, adhesive application device, manufacturing tools, etc., can solve the problems of uneven spraying, uneven coating, low spraying efficiency, etc., and achieve uniform thickness of glue coating , the effect of uniform glue coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

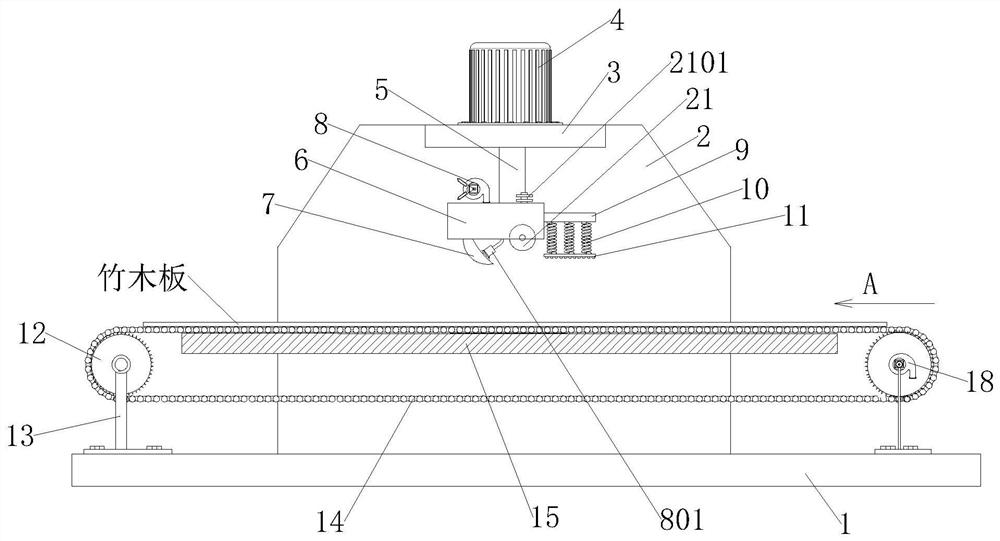

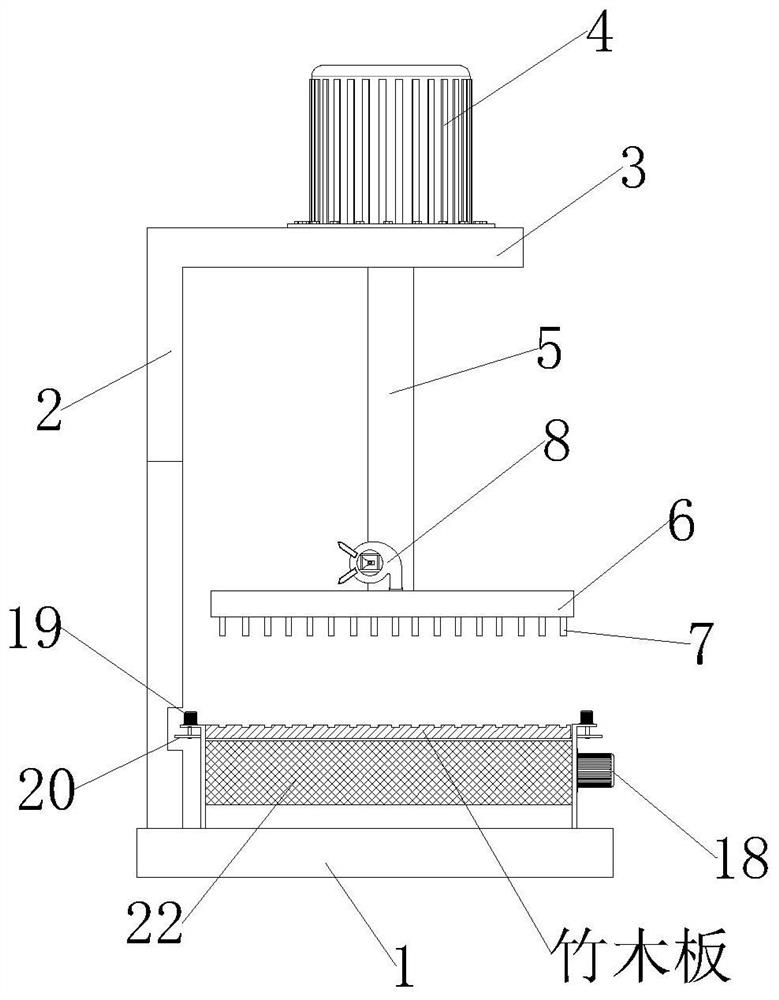

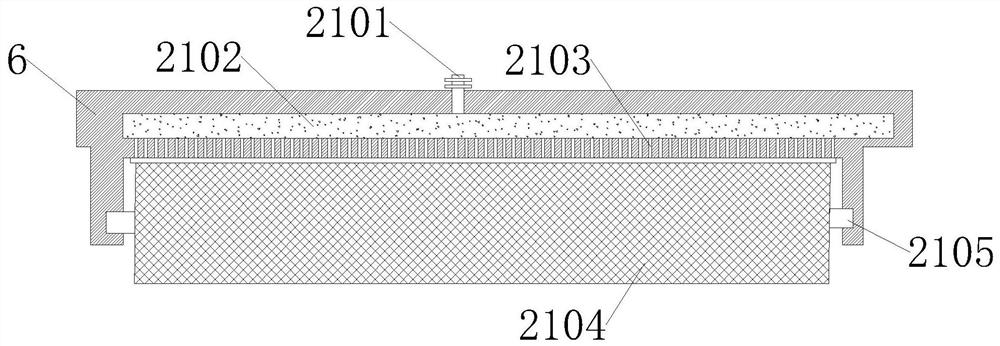

[0046] see Figure 1-9 , which is a schematic diagram of the overall structure of an environmentally friendly bamboo wood adhesive and a method for preparing a new type of bamboo wood product using the adhesive;

[0047] An environment-friendly bamboo wood adhesive is characterized in that it is composed of the following components and parts by mass: 100 parts of acrylate adhesive; 1-2 parts of crosslinking agent; 3-8 parts of auxiliary agent; The adhesion force of the above-mentioned acrylate adhesive to the FPC board is 12-20gf / 25mm, and the above-mentioned auxiliary agent is a non-ionic surfactant.

[0048] Wherein, the nonionic surfactant is alkylphenol polyoxyethylene ether, polyoxyethylene fatty alcohol ether, polyoxyethylene polyoxypropylene block copolymer, isopropyl palmitate, sorbitan fatty acid One or more of sucrose esters and sucrose esters, according to the above-mentioned mass parts, mix and stir the acrylate adhesive, crosslinking agent and auxiliary agent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com