Production process of high-strength ultrathin composite corrugated boards

A manufacturing process, corrugated board technology, applied in the direction of machining/deformation, etc., can solve the problems of troublesome manufacturing and affecting the strength of composite board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

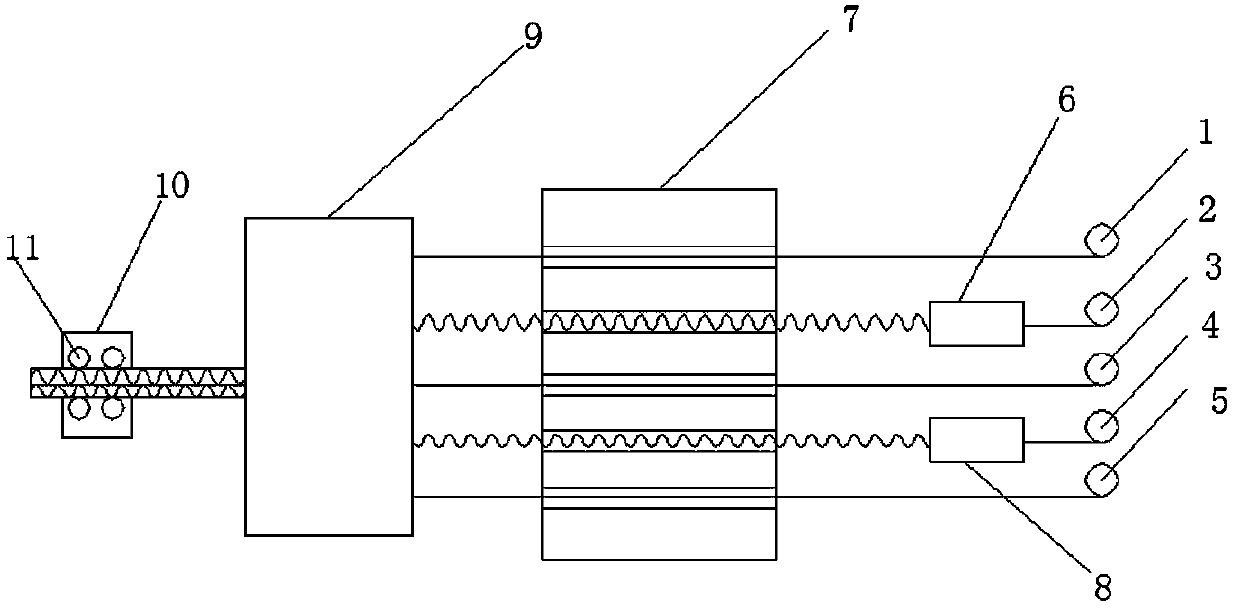

[0021] like figure 1 As shown, the waste corrugated paper is put into the pulper to disintegrate to form pulp, and then the pulp is passed through the pressure screen and the slag remover to remove impurities and thermal dispersion to remove ink. The pressure difference for sand removal is set at 0.2MPa; The pulp after the ink is beaten, and after beating, add auxiliary materials in the pulp, auxiliary materials include strengthening agent, sizing agent and aluminum sulfate, the dosage of strengthening agent, sizing agent and aluminum sulfate those skilled in the art will be based on the existing kraft paper manufacturing process It can be concluded that it will not be described here; then dehydrate the pulp with auxiliary materials, press and dehydrate after dehydration, and then dry the pressed and dehydrated pulp to form kraft paper; wind the kraft paper on the first paper roll respectively 1. On the second paper roll 2, the third paper roll 3, the fourth paper roll 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com