Patents

Literature

104results about "Glue guns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for low-adhesive-consumption environment-friendly multi-layer solid wood composite floor

ActiveCN105856343ASimple and fast operationImprove qualityOther plywood/veneer working apparatusTree debarkingEnvironmental resistanceFiber

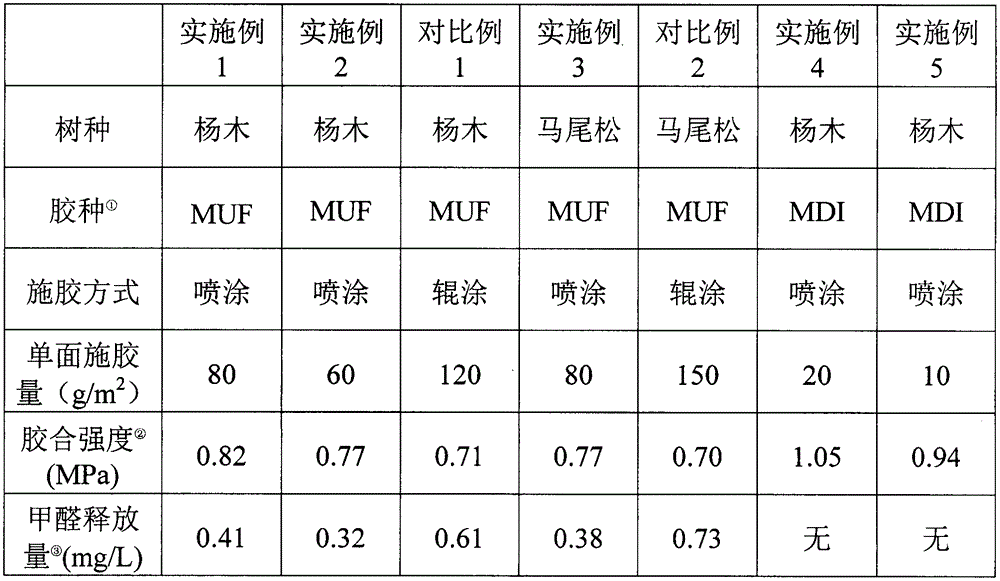

The invention relates to a manufacturing method for a low-adhesive-consumption environment-friendly multi-layer solid wood composite floor and belongs to the technical field of artificial board manufacturing. The method includes the steps that short-cut wood is subjected to rotary-cutting into 1-3 mm wooden veneers, and the veneers are dried, so that the moisture content is adjusted to be 8%-12%; the double sides of the veneers are subjected to normal-pressure low-temperature plasma modification treatment; through ultrasound and cyclone synergistic effect, an adhesive is atomized into particles with the diameter being smaller than 40 [mu]m, then the particles are sprayed onto the tight sides of the veneers, and the adhesive consumption of a single side is controlled to be 10-80 g / m<2>; mutually vertical assembly is performed according to fiber texture directions of the adjacent-layer veneers; and hot-pressing and sliced wood veneer lamination are conducted, and then the low-adhesive-consumption environment-friendly multi-layer solid wood composite floor is obtained. The properties of the low-adhesive-consumption environment-friendly multi-layer solid wood composite floor meet the requirement of national standards; the formaldehyde emission reaches E0 grade; the adhesive consumption is decreased by 30%-70% compared with that of a traditional adhesive coating mode; the product quality is remarkably improved; and the production cost is dramatically reduced. Besides, the production process of the method achieves energy saving and environment protection, production equipment is easy and convenient to operate, high in efficiency and good in controllability, and continuous automatic operation can be achieved.

Owner:NANJING FORESTRY UNIV

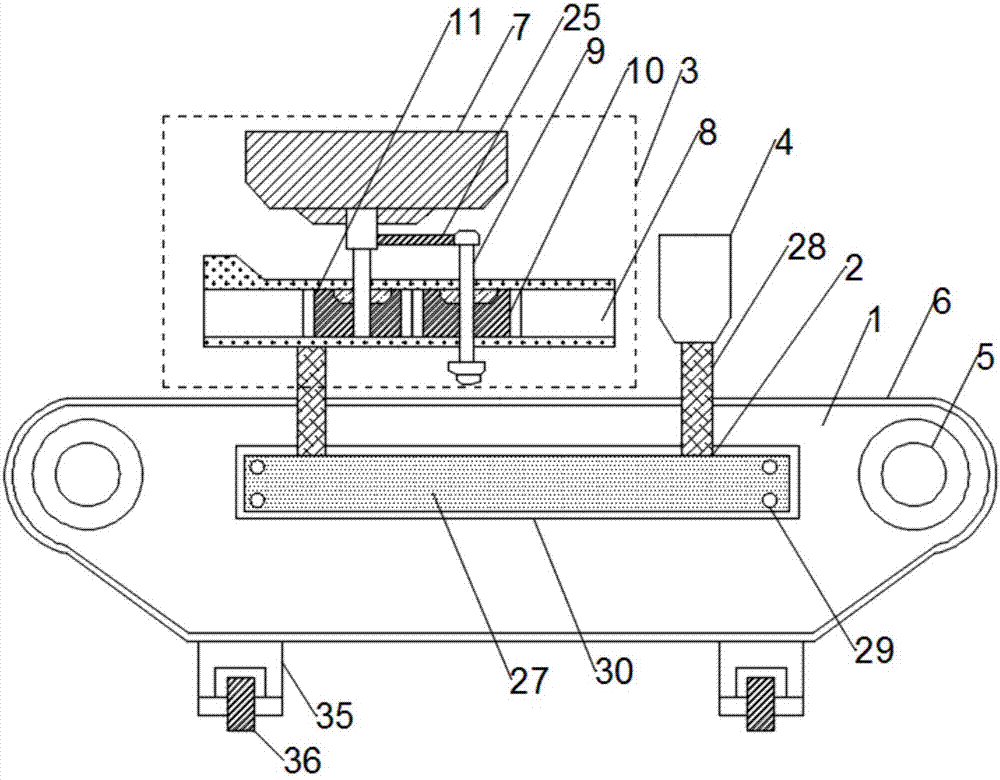

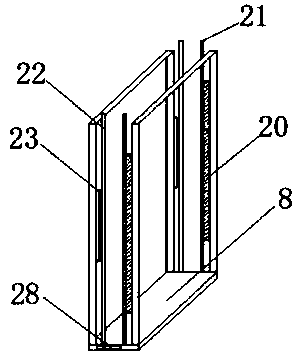

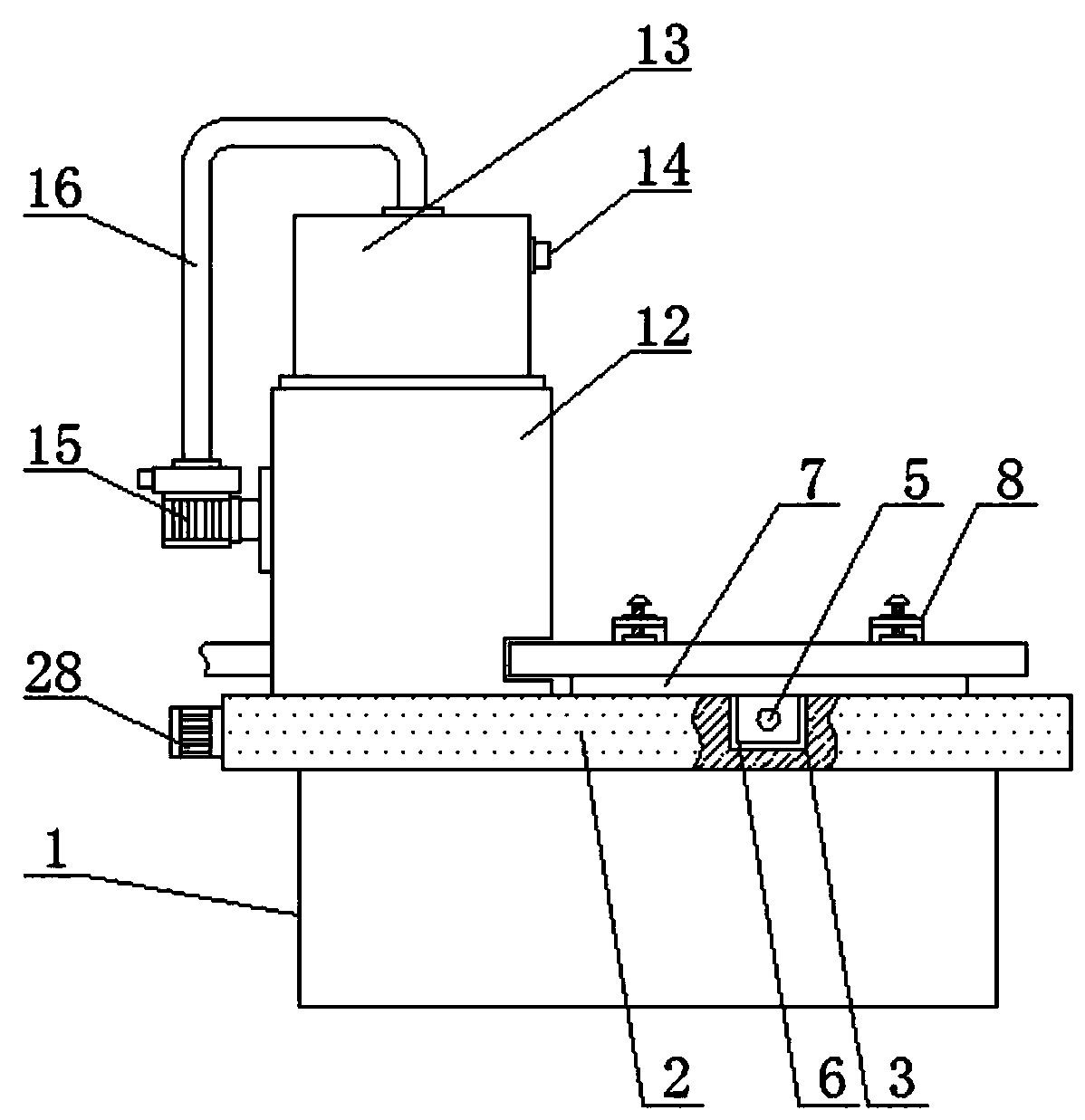

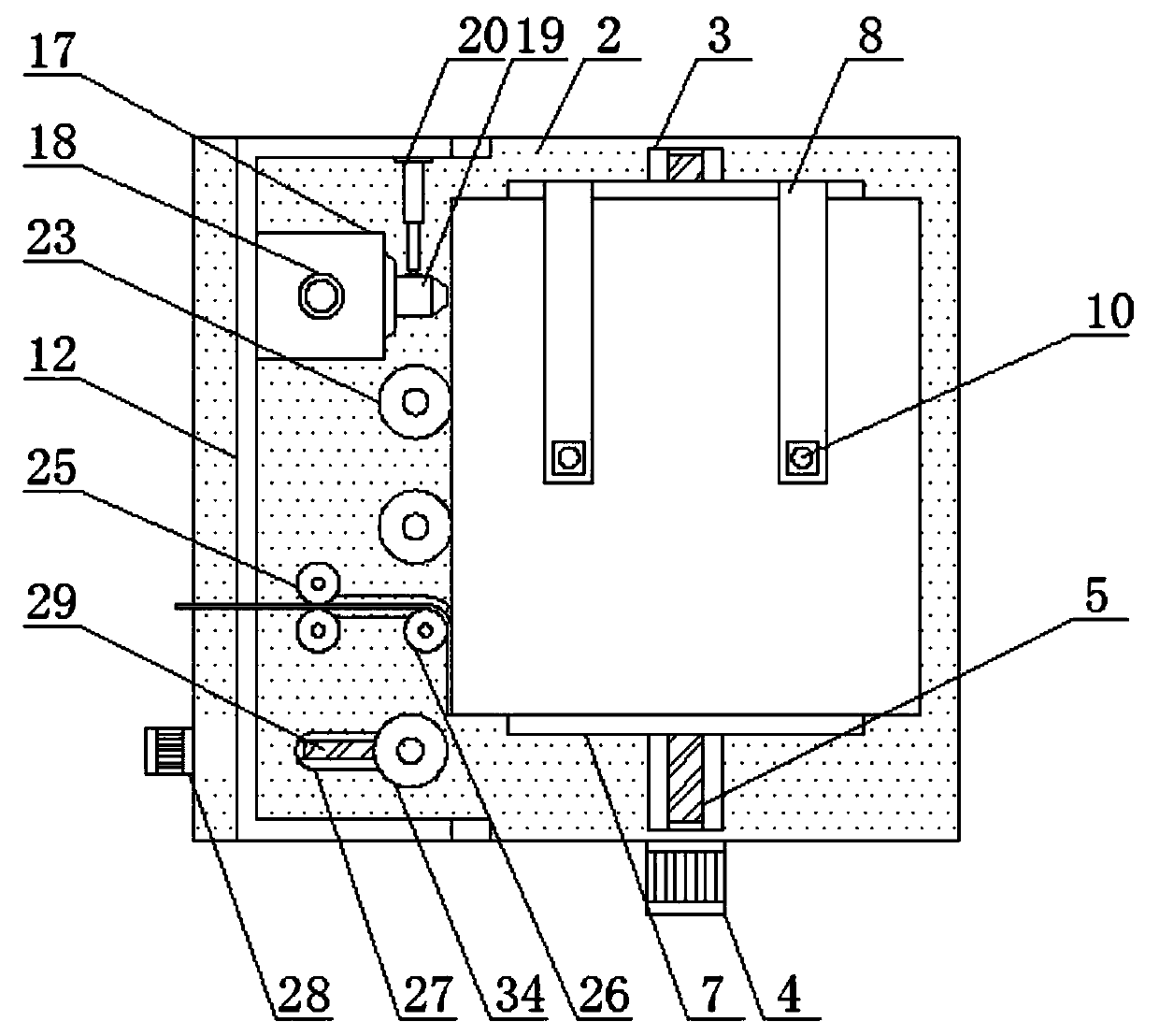

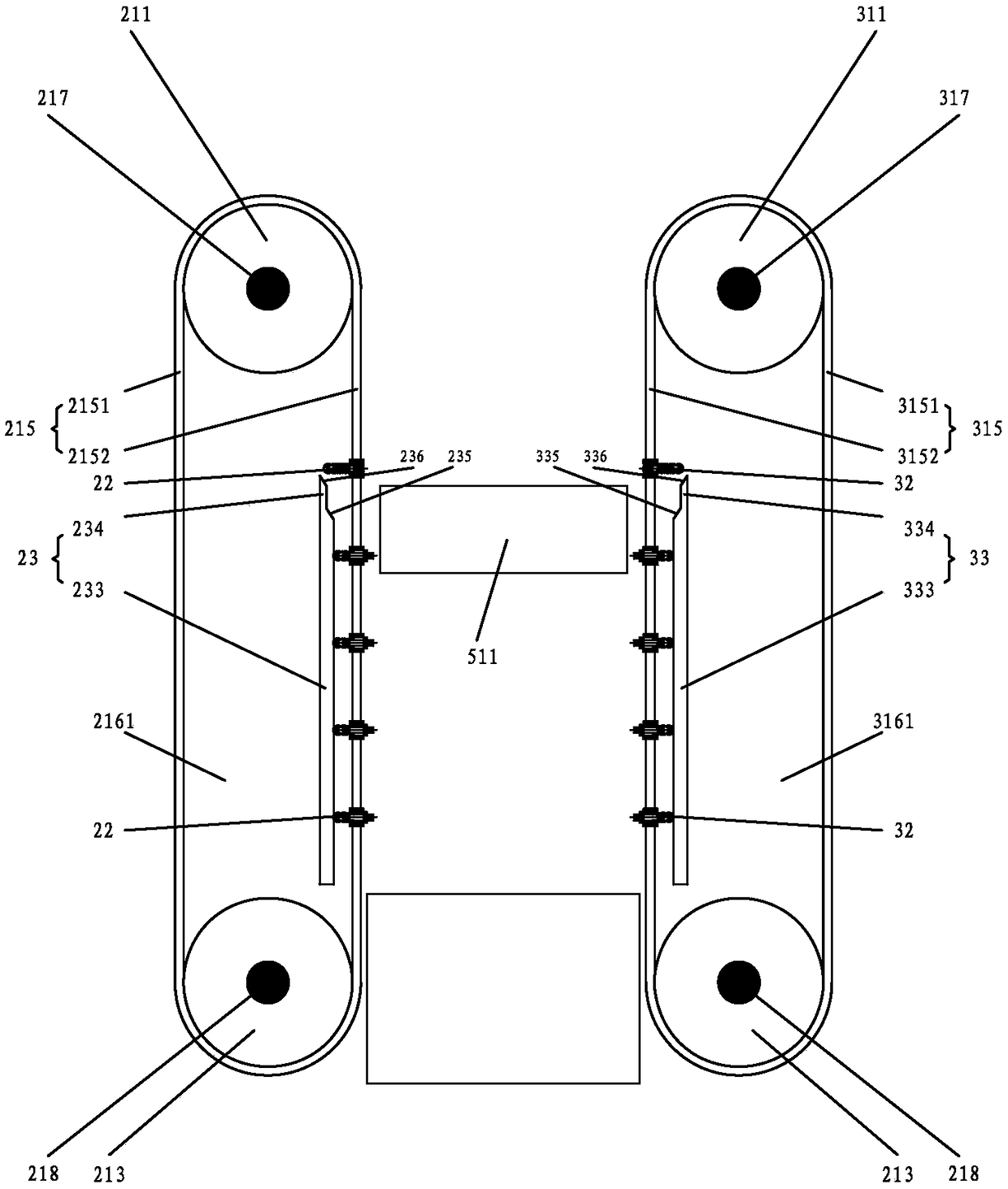

Efficient gluing device for plywoods

InactiveCN109227802AApply glue evenlyNozzle sprayingWood veneer joiningGlue gunsEngineeringMechanical engineering

The invention discloses an efficient gluing device for plywoods. The device comprises a base, the upper surface of the base is fixedly connected with two corresponding supporting plates, and the closeside walls of the two supporting plates are jointly rotatably connected with a first rotary shaft through bearings; one end of the first rotary shaft penetrates through the supporting plates and is fixedly connected with a transmission mechanism, the close side walls of the two supporting plates are jointly and rotatably connected with a second rotary shaft corresponding to the first rotary shaftthrough bearings, and first rollers are fixedly connected with the second rotary shaft and the first rotary shaft; the two first rollers are jointly wound with a conveying belt, the tops of the two supporting plates are fixedly connected with corresponding installing plates, the tops of the close side walls of the two installing plates are jointly and fixedly connected with a top plate, and a hot-air blower is fixedly connected to the upper surface of the top plate. The plywoods can be uniformly glued, after gluing, glue on the plywoods can be quickly dried, and the quality and efficiency ofuniformly gluing the plywoods are improved.

Owner:卓中朝

Novel pressing plate machine with gluing function

PendingCN108098942AReduce work stepsReduce work intensityPlywood pressesVeneer pressesKey pressingEngineering

The invention discloses a novel pressing plate machine with a gluing function. The structure of the novel pressing plate machine with the gluing function includes a pressing machine plate structure, non-slip mats, a rotary disk, a supporting plate, a fixed seat, a vertical pole, a placing base, a display screen, operation keys and an alarm lamp. The top portions of the non-slip mats are verticallyconnected with the bottom portion of the pressing plate machine structure, and the bottom portion of the fixed seat is welded to the top portion of the supporting plate. The bottom portion of the supporting plate is fixedly connected with the middle end of the pressing plate machine structure through rivet nails, and the rear end of the rotary disk is connected with the front end of the fixed seat in a threaded mode. The bottom portion of the vertical pole is vertically connected with the top portion of the supporting plate, and the top portion of the supporting plate is welded to the bottomportion of the placing base. The rear end of the display screen is connected with the front end of the pressing plate machine structure by a clamping groove. The novel pressing plate machine with thegluing function is provided with the pressing plate machine structure, and is capable of squeezing wood and gluing material so as to enable a pressing plate to be glued in one step. The work steps arereduced, the work intensity is reduced and the work efficiency is improved.

Owner:刘福原

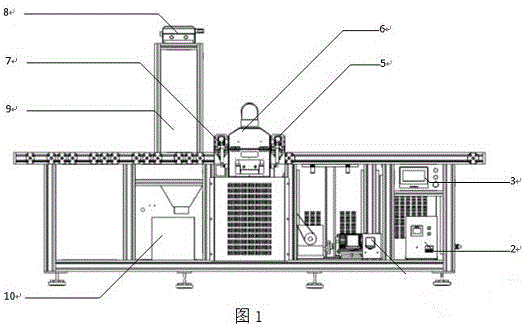

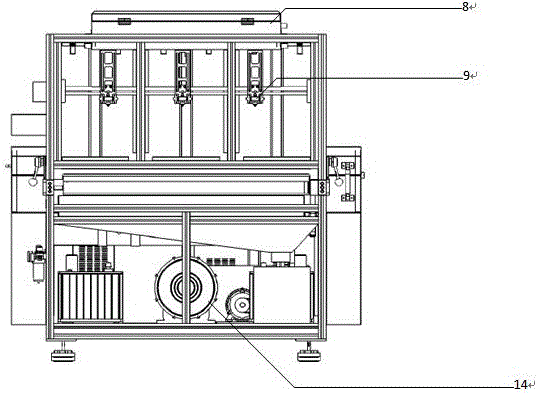

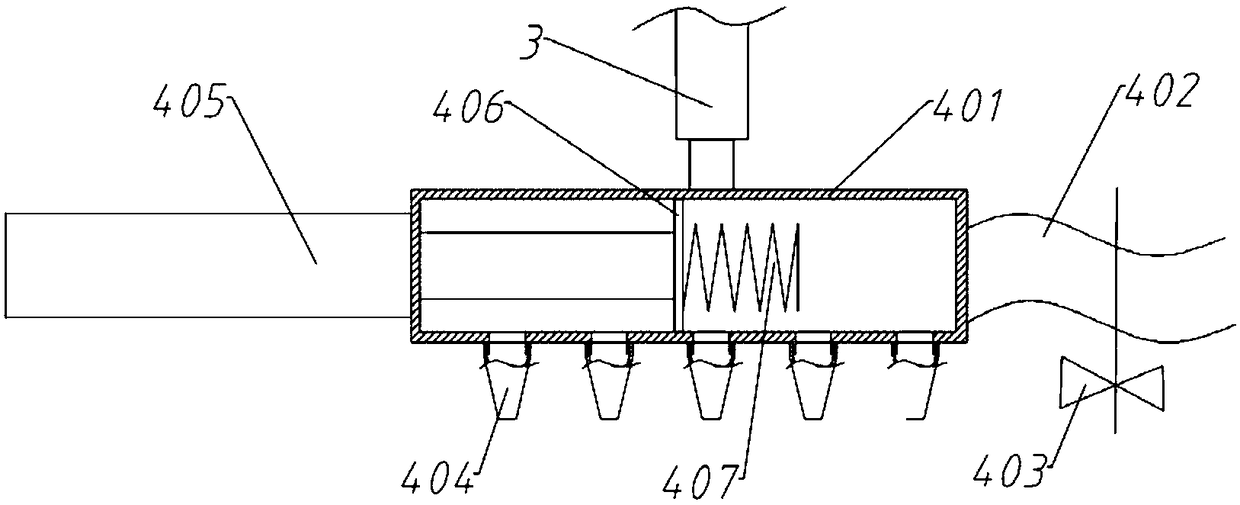

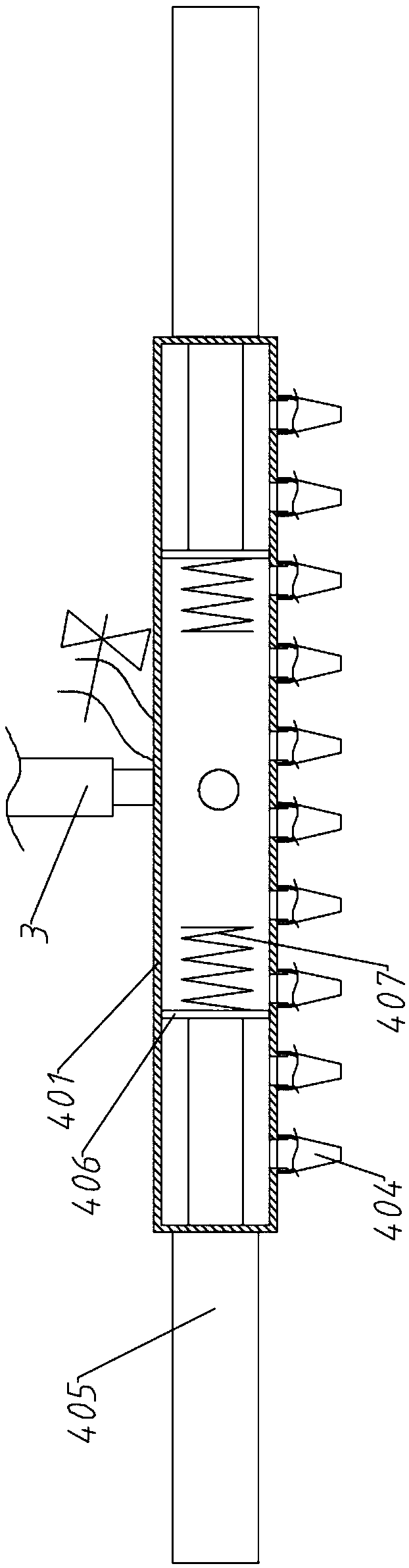

Low-glue-application-amount wood single composite low-temperature plasma processing equipment and operation method

InactiveCN106142265AReduce processing costsSimple and fast operationElectric wood treatmentWood treatment detailsEnvironmental resistanceEngineering

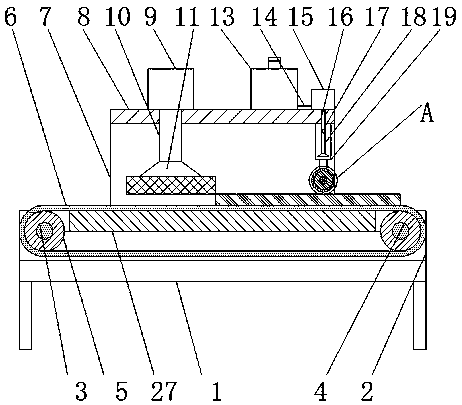

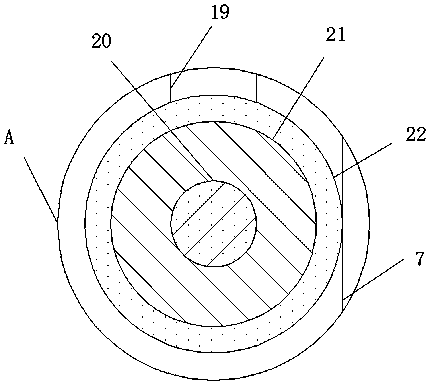

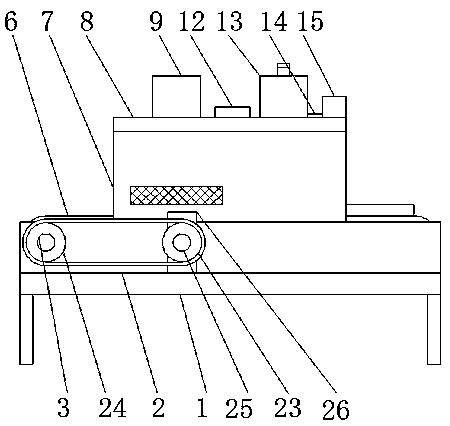

The invention discloses low-glue-application-amount environment-friendly wood single composite normal-pressure and low-temperature plasma processing equipment and an operation method thereof. According to the equipment, a machine body is formed by assembling profile frames; a low-temperature plasma electrode base station is mounted between a belt type conveying platform and a roller type conveying platform; the belt type conveying platform is mounted at the front end of the machine body and fixed on the profile frames; the roller type conveying platform is mounted at the tail end of the machine body and fixed on the profile frames; a trace glue application device is mounted on the profile frames, is located at the back end of the low-temperature plasma electrode base station and is located above the roller type conveying platform; a cooling fan is further arranged, is located in the machine body and is located below the low-temperature plasma electrode base station; an upper metal air collecting cover and a lower metal air collecting cover are further arranged outside the machine body; and a power device is further arranged. The invention further provides an operation method. The equipment is simple to operate, high in controllability and low in treatment cost.

Owner:NANJING SUMAN PLASMA TECH CO LTD

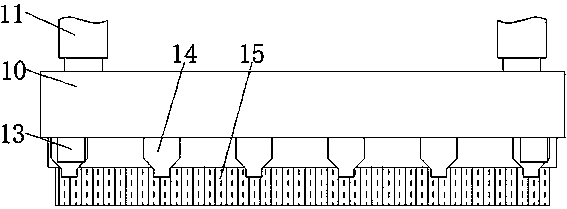

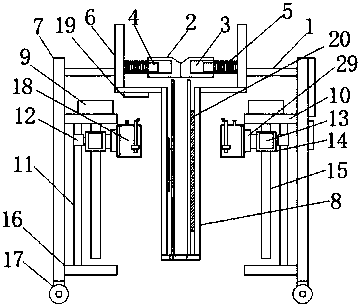

Efficient plywood gluing device

PendingCN107053385AImprove molding qualityQuick GlueDrying gas arrangementsGlue gunsDrive shaftEngineering

The invention discloses an efficient plywood gluing device. The efficient plywood gluing device comprises a conveying table, a mounting rack, a gluing device and a drying device. The mounting rack is fixedly installed on the side face of the conveying table. The gluing device comprises a rotating motor, a supporting shell and a screw rod. A first planetary gear and a second planetary gear are arranged inside the supporting shell and are further engaged together with each other. A transmission shaft is arranged at the center position of the inside of the first planetary gear, and the other end of the transmission shaft and a rotating shaft of a rotating motor are connected together. The transmission shaft is driven by the rotating shaft to rotate. The other end of the screw rod is connected with a nozzle table, and a plurality of nozzle holes are adjacently formed in the surface of the nozzle table. Gluing nozzles are installed in the corresponding nozzle holes, and the gluing nozzles communicate with one another through a communicating pipe to be connected together. By the adoption of the efficient plywood gluing device, plywood of different thicknesses can be reasonably glued, and gluing is uniform and free of leakage; and the drying speed is high after gluing, forming quality of the plywood is high, and production efficiency is greatly improved.

Owner:颍上县亚森木业有限责任公司

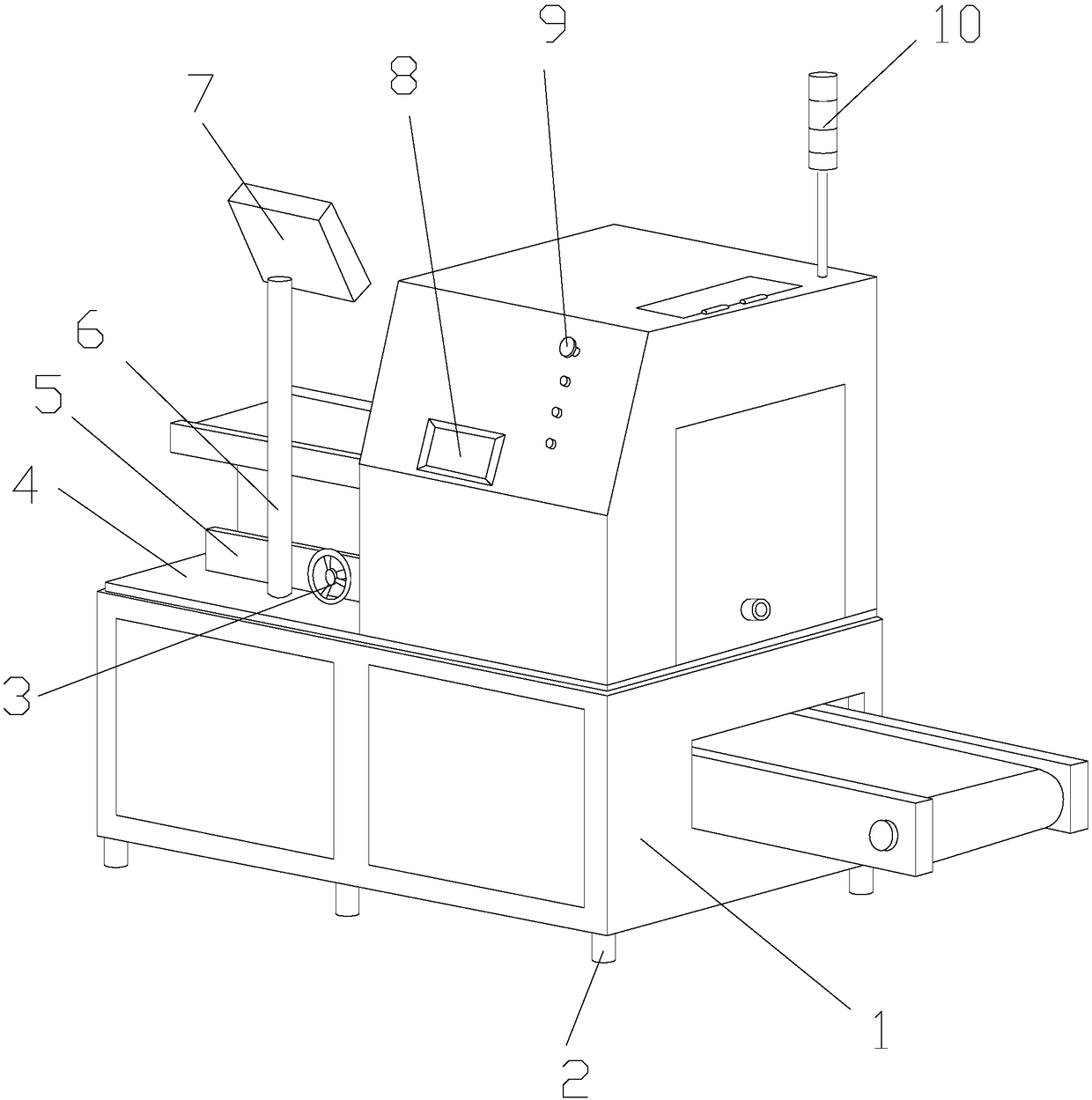

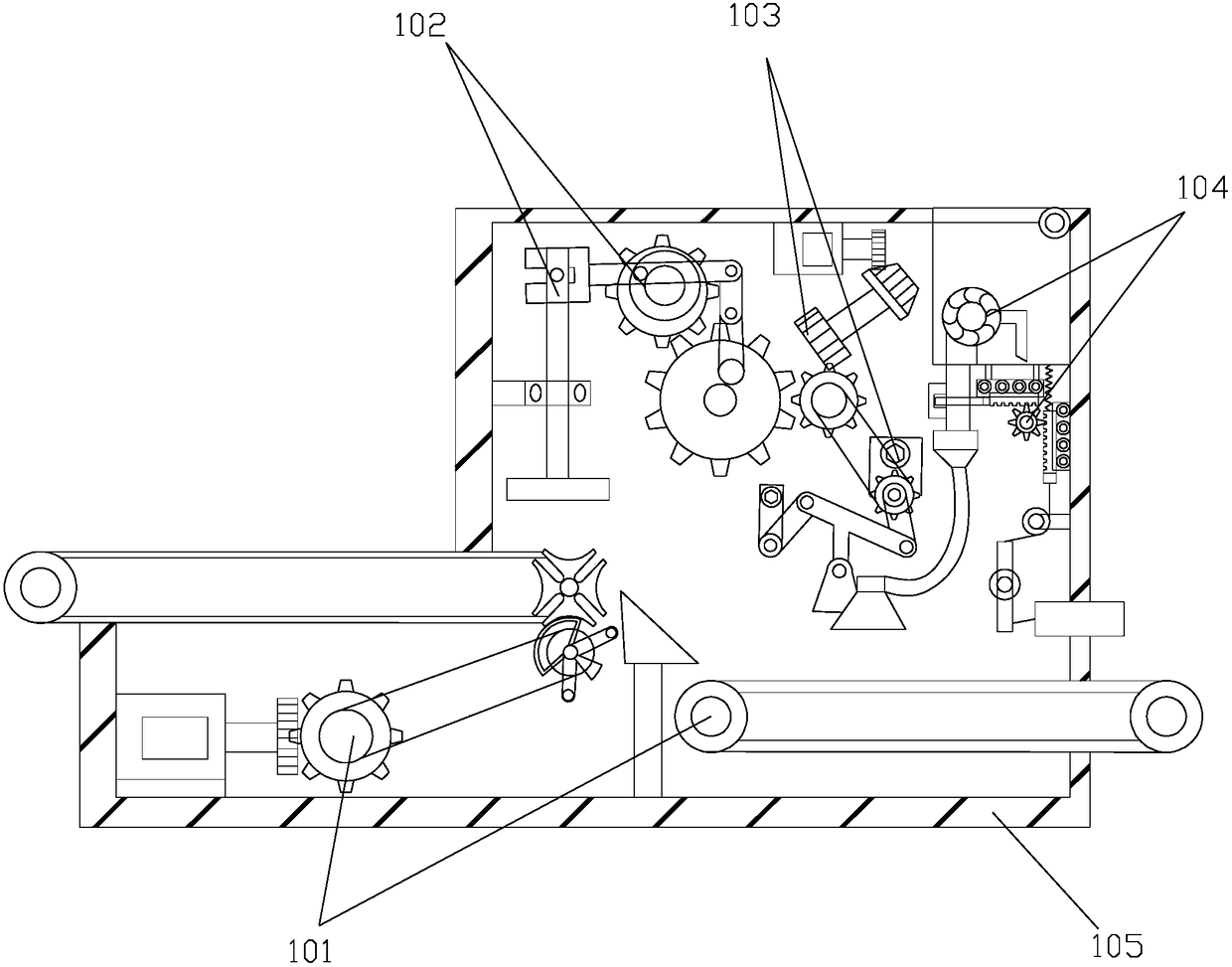

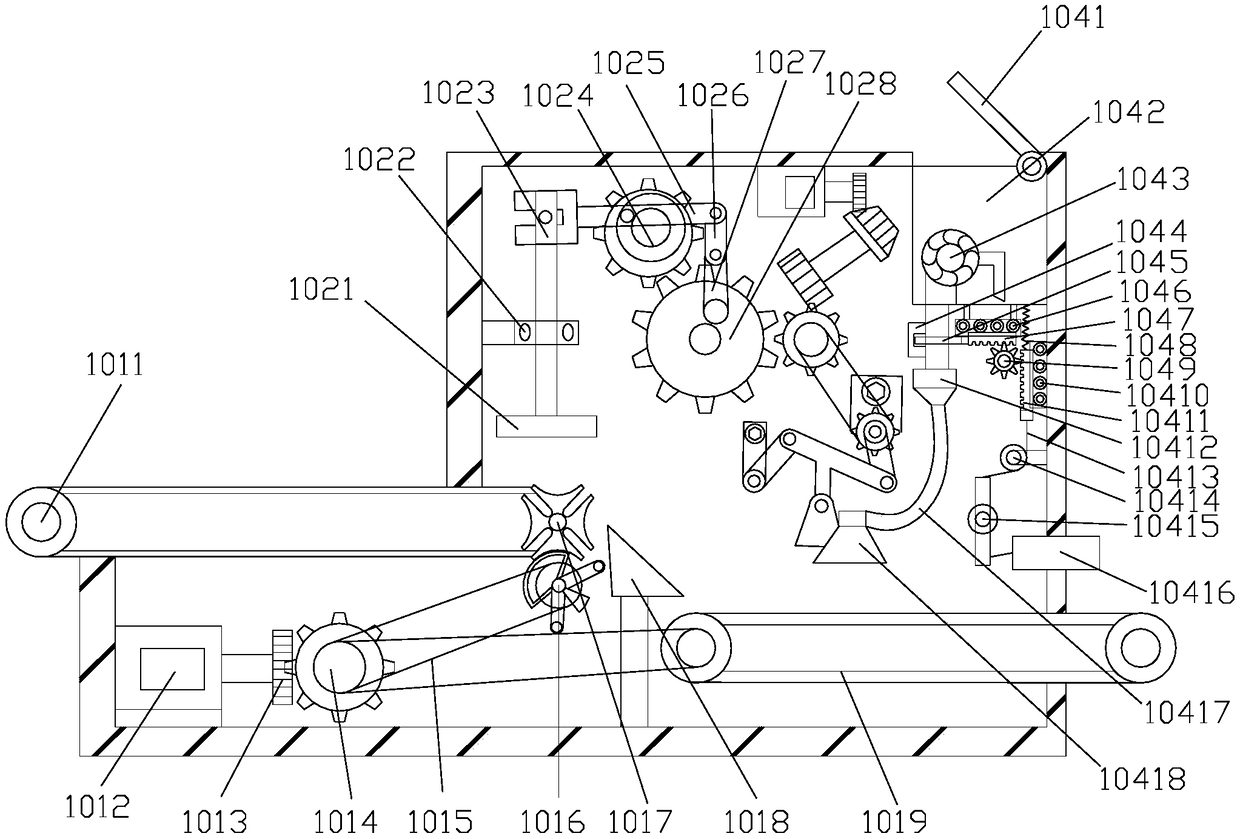

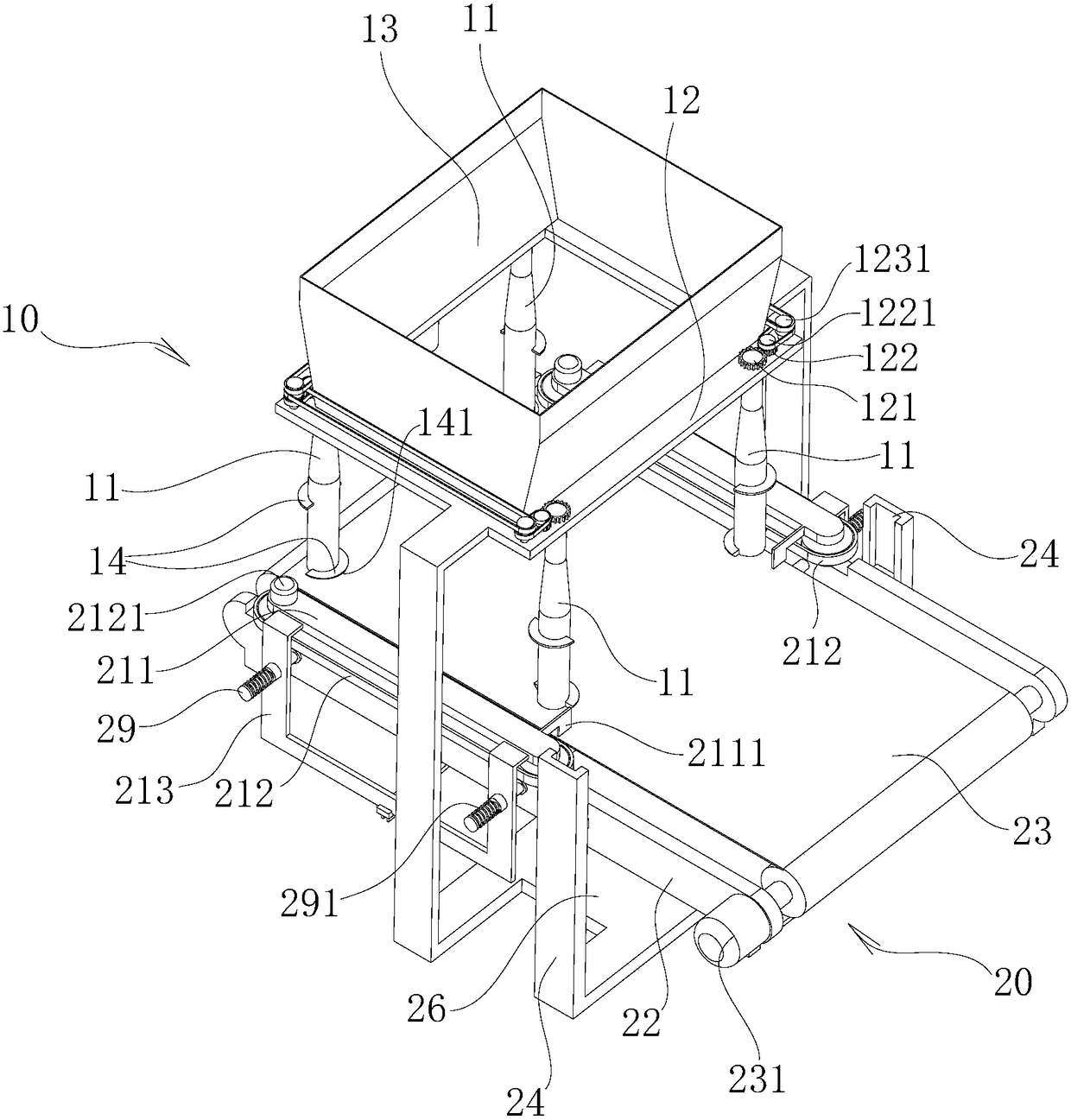

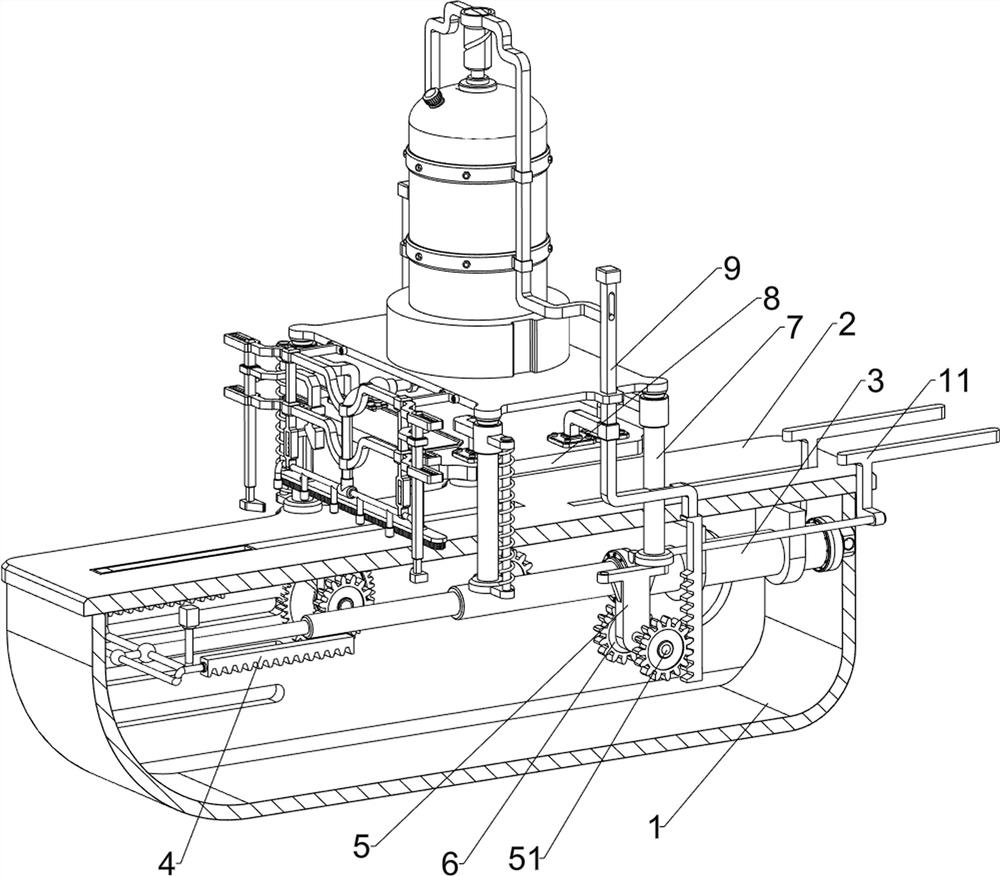

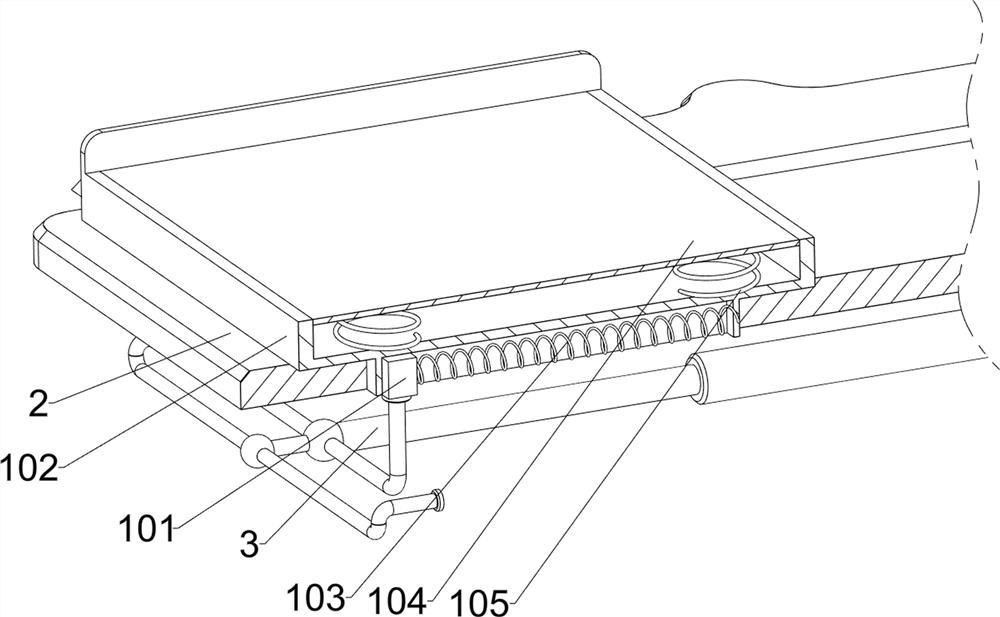

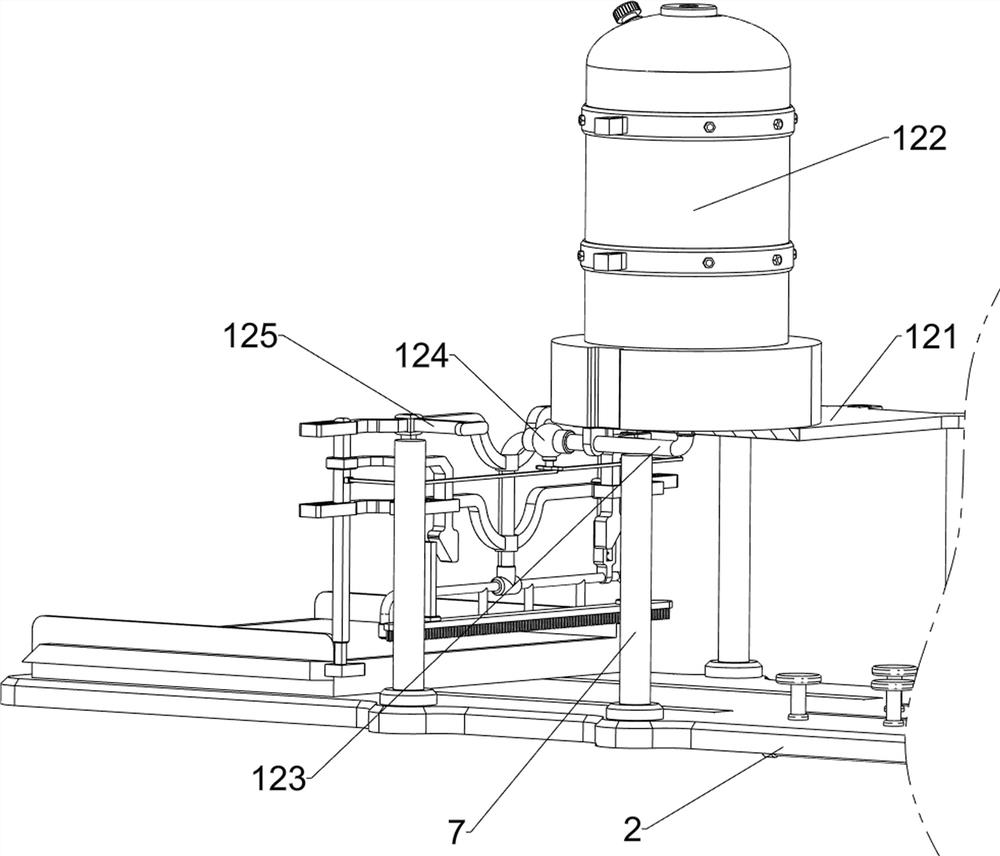

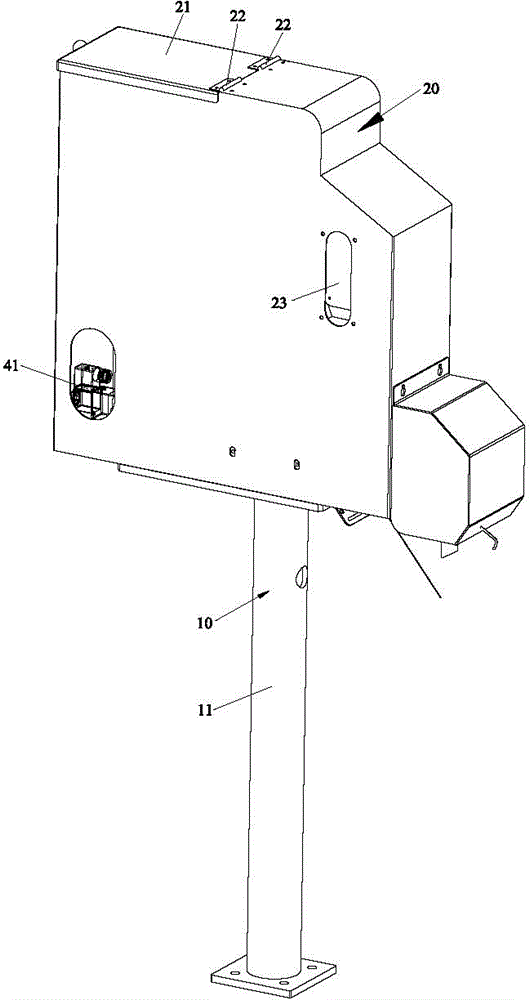

Equipment and process for processing bamboo split roll

InactiveCN109397437ANo disconnectionNo degumming will occurCane mechanical workingGlue gunsEngineeringMechanical engineering

The invention relates to the processing technology of bamboo split rolls, in particular to equipment and a process for processing a bamboo split roll, and specially relates to the processing field ofbamboo split rolls. The equipment comprises a feeding device for conveying and cutting off a bamboo split curtain along a braided wire direction and an axial feeding device for conveying bamboo splitsheets formed by cutting off the bamboo split curtain along the length direction of the bamboo split. The conveying directions of the feeding device and the axial feeding device are mutually perpendicular. The equipment also comprises an adhering device for adhering front and back bamboo split sheets end to end in the length direction of the bamboo split, a slitting device for slitting the bamboosplit curtain formed by adhering the bamboo split sheets in the length direction of the bamboo split curtain and a rolling device for rolling the slit bamboo split long curtains. The feeding device, the axial feeding device, the adhering device, the slitting device and the rolling device are arranged successively. The bamboo split rolls do not shift if being conveyed, split clash during slitting is avoided, distorsion is avoided during rolling, and no gaps are available in the middle of the bamboo split roll.

Owner:ZHEJIANG GUANGXIN BAMBOO BASED MATERIALS CO LTD

Solid wood table board splicing device for furniture processing

ActiveCN112140272AReach gluingTo achieve the splicing effectWood veneer joiningGlue gunsSolid woodAdhesive glue

The invention relates to a splicing device, in particular to a solid wood table board splicing device for furniture processing. According to the solid wood table board splicing device, manually smearing glue and splicing during operation are avoided, and therefore the working efficiency can be improved and the manpower can be saved. The solid wood table board splicing device for furniture processing comprises a support, a storage plate and a threaded rod, wherein multiple groups of first guide rails are uniformly connected to one side of the top of the support at intervals, and sliding platesare slidably connected between the multiple groups of first guide rails; the storage plate is connected to the other side of the top of the support; and the threaded rod is rotationally connected to one side, close to the sliding plates, of the support. The sliding plates, the threaded rod, a first fixing rod, a gluing component, a first rotating component, an inserting component and a limiting component are matched to glue and splice solid wood table boards.

Owner:江西团团圆家具有限公司

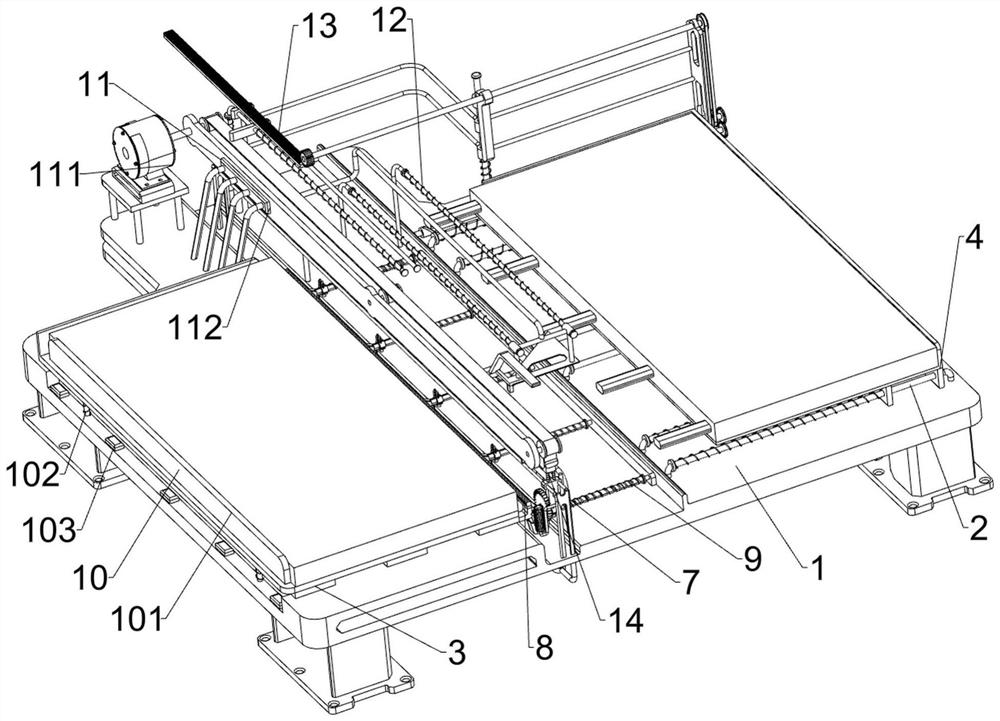

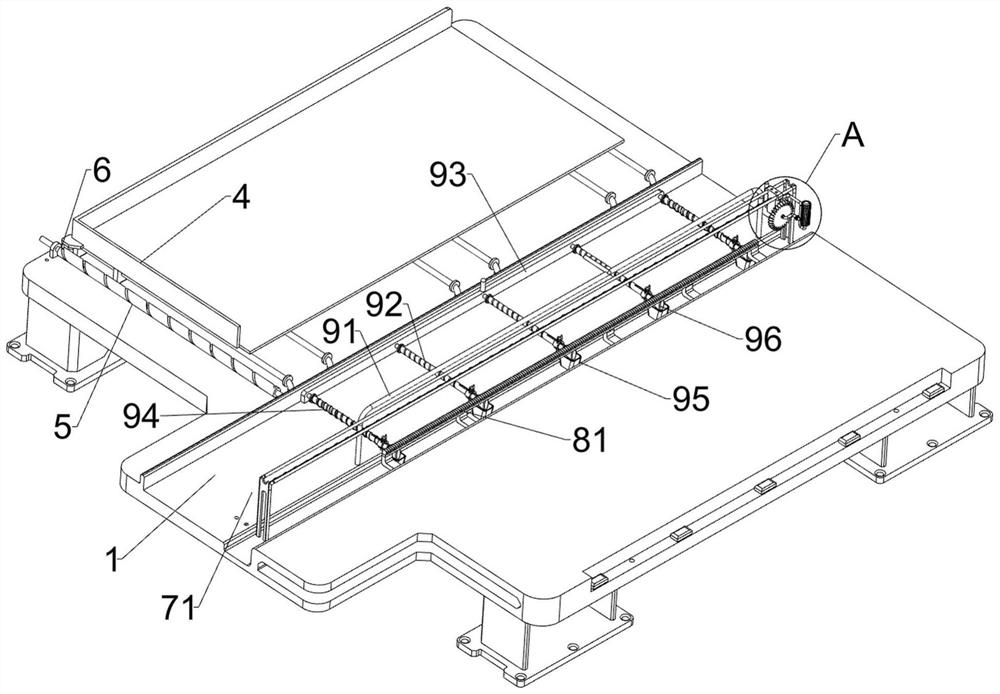

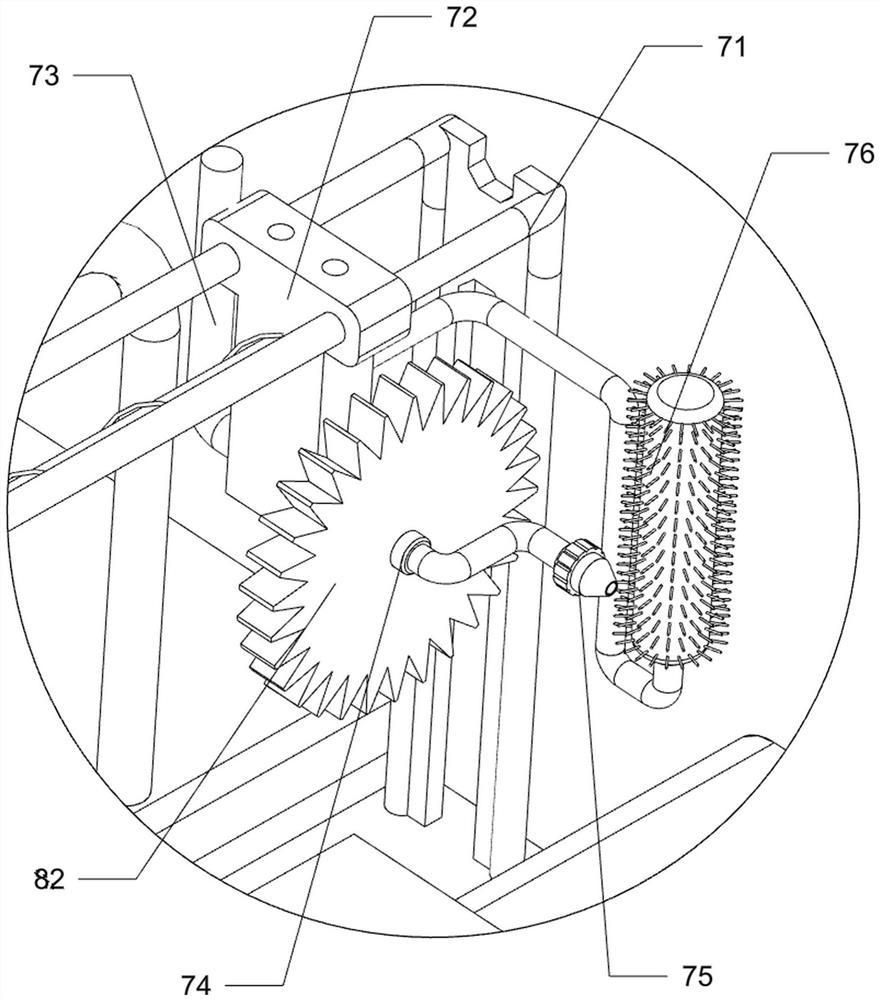

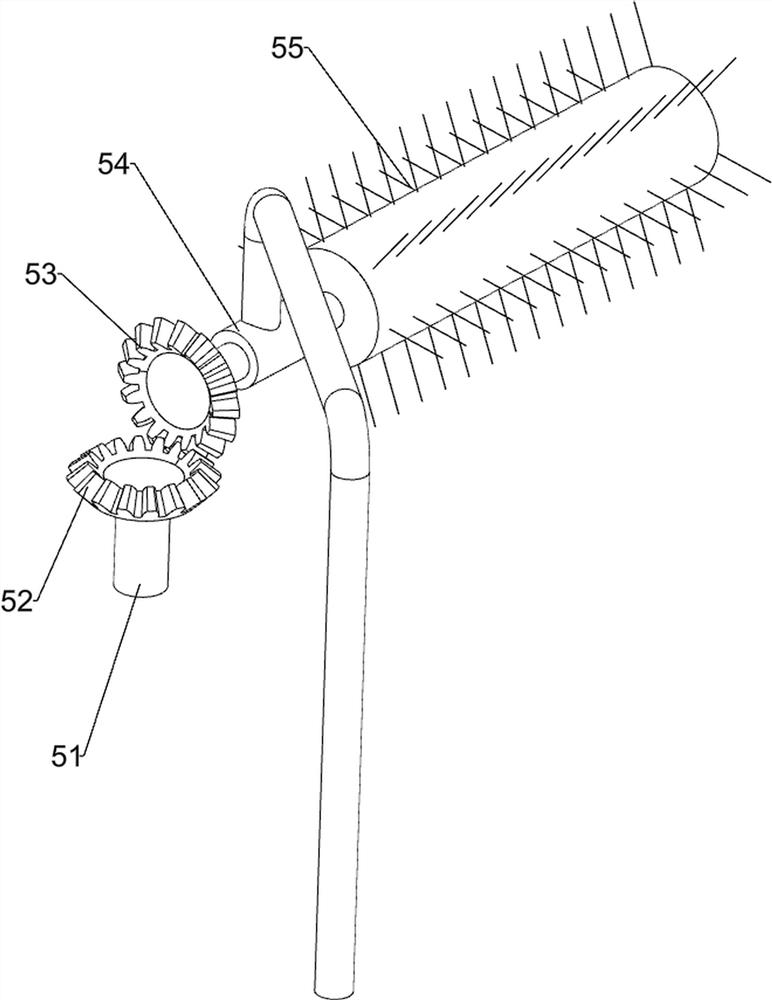

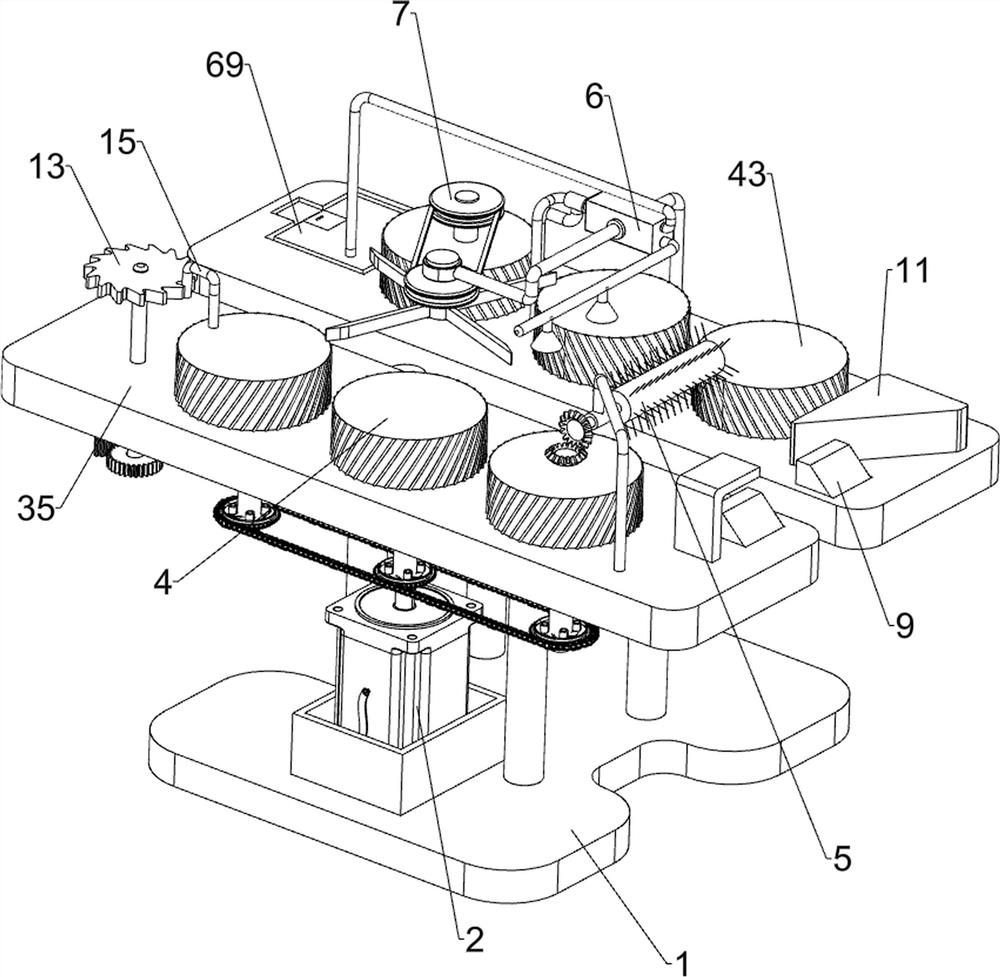

Glue smearing device for interval type wood boards

The invention relates to a glue smearing device, in particular to a glue smearing device for interval type wood boards. The glue smearing device for the interval type wood boards is characterized in that the surfaces of the wood boards can be cleaned, glue is evenly smeared, the working efficiency is high, and the quality is good. The glue smearing device for the interval type wood boards comprises a support, a servo motor, a moving device, a conveying device, a cleaning device, a glue spraying device and a uniform smearing device; the servo motor is arranged on the support; the moving deviceis arranged on the support and moves in a sliding mode; the conveying device is arranged on the moving device and conducts conveying in a rotating mode; the cleaning device is arranged on the moving device and conducts cleaning in a rotating mode; the glue spraying device is arranged on the moving device and conducts gluing in a sliding mode; and the uniform smearing device is arranged on the gluespraying device and conducts uniformly smearing in a rotating mode. According to the glue smearing device, the wood boards needing to be smeared with glue can be placed through the moving device, thewood boards can be conveyed through the conveying device, and dust and other impurities on the surfaces of the wood boards can be cleared through the cleaning device.

Owner:兰军义

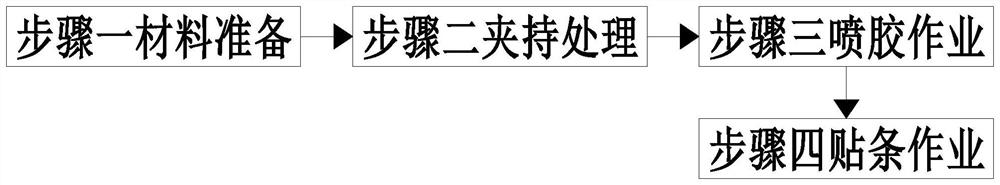

Edge sealing treatment method for artificial boards

ActiveCN111645165AImprove efficiencyGood effectGlue gunsDomestic articlesMaterials preparationAdhesive glue

The invention relates to an edge sealing treatment method for artificial boards. The method mainly includes the following steps of material preparation, clamping treatment, glue spraying operation, labeling operation and the like. Used edge sealing equipment for the artificial boards comprises a bottom plate, a glue spraying device, a clamping device and a labeling device. The following problems that a, during traditional artificial board edge sealing, glue needs to be manually sprayed to the edges of the artificial boards, then edge sealing strips are attached to the edges, to which the glueis sprayed, of the artificial boards for press fitting, the quality of manual edge sealing of the artificial boards is not consistent, the workload of workers is large, and the production efficiency of plywood is reduced; and b, when existing edge sealing equipment for the artificial boards is used for edge sealing of the artificial boards, the edge sealing strips cannot be stably attached to theedges of the artificial boards, the phenomenon that the edge sealing strips disengage frequently happens, the production efficiency of the artificial boards is affected, and raw materials are wasted existing in existing edge sealing of the artificial boards can be solved, and the efficiency and effect of edge sealing of the artificial boards can be improved.

Owner:东莞市中意厨房设备有限公司

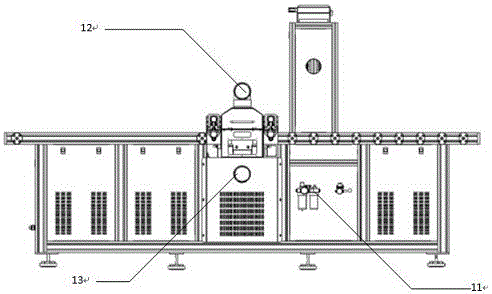

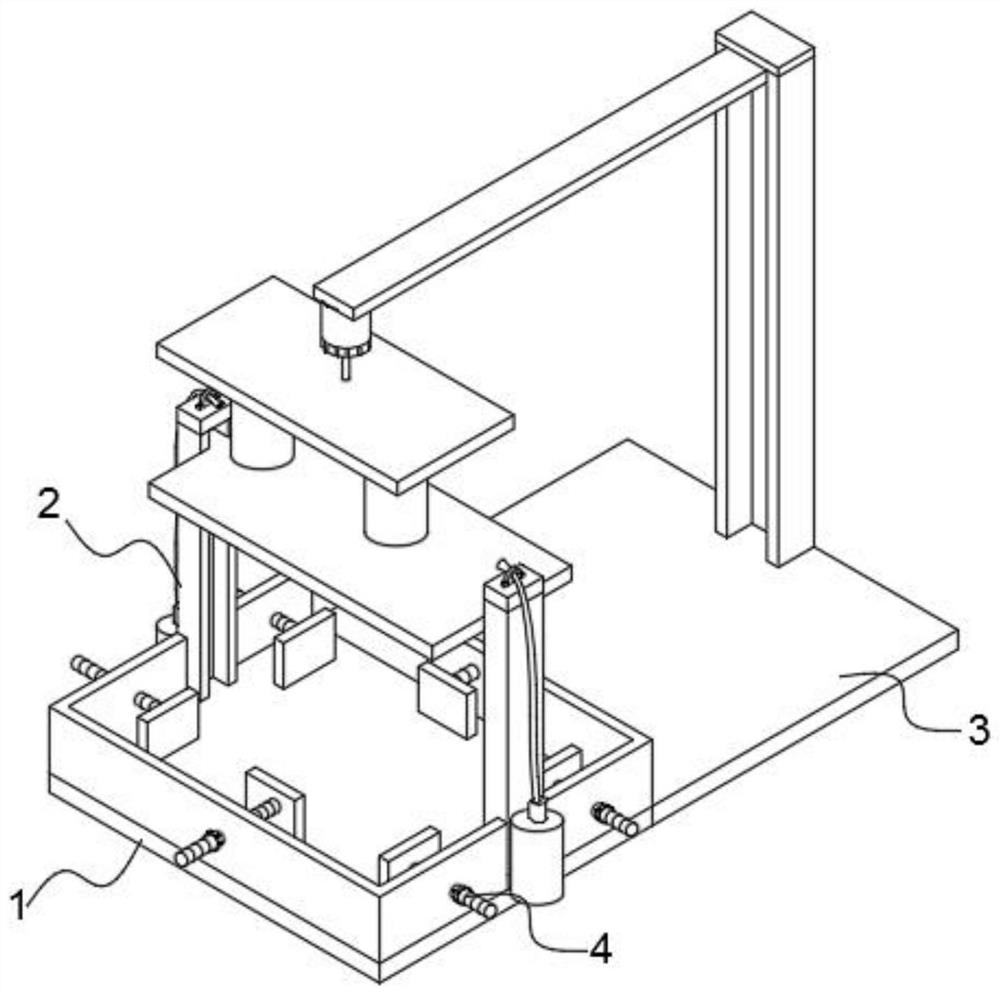

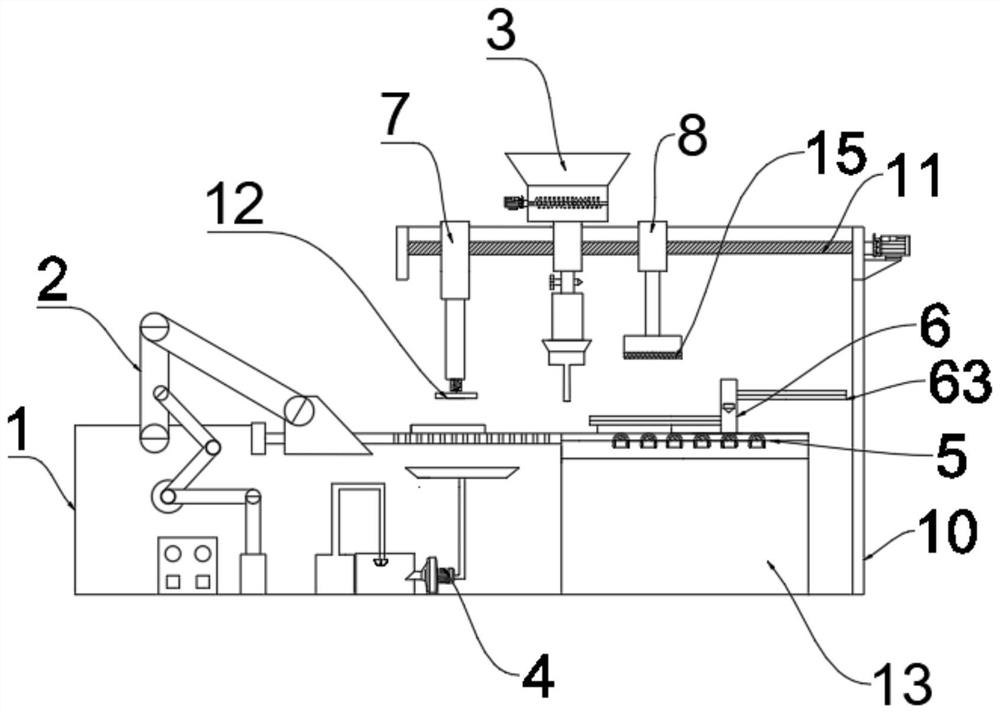

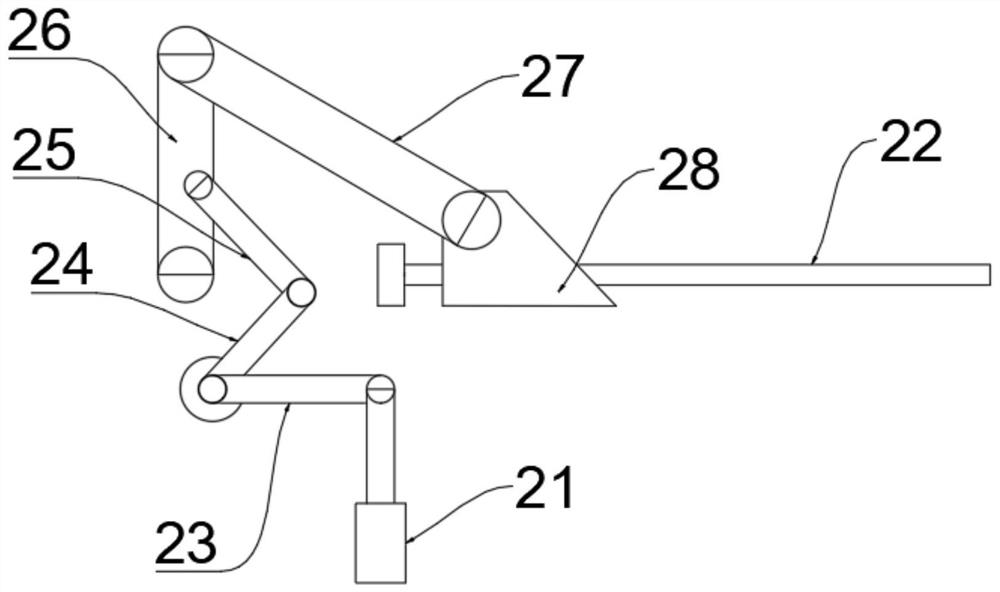

Plate gluing and nailing system

PendingCN111086084AEasy to processImprove processing efficiencyStapling toolsGlue gunsStructural engineeringMechanical engineering

The invention relates to a plate gluing and nailing system. The plate gluing and nailing system comprises a plate conveying platform, and a guide plate, a gluing machine, a nailing machine, a bottom plate discharging device, a top plate discharging device and a feeding device are arranged on the plate conveying platform; the guide plate is fixedly arranged on the plate conveying platform and extends in a plate conveying direction; the bottom plate discharging device and the top plate discharging device are arranged in one line in the plate conveying direction and are positioned on one side ofthe guide plate, and an interval is reserved between the bottom plate discharging device and the top plate discharging device and the guide plate, and forms a conveying channel, wherein the bottom plate discharging device is positioned at the inlet end of the conveying channel, and the top plate discharging device is positioned at the outlet end of the conveying channel; the gluing machine and thenailing machine are positioned on the other side of the guide plate, wherein the gluing machine is positioned at the inlet end of the conveying channel, and the nailing machine is positioned at the outlet end of the conveying channel; and a conveying device is arranged at the inlet end of the conveying channel. The plate gluing and nailing system can complete gluing and nailing of plates conveniently so as to improve the processing efficiency and reduce the fatigue strength of workers.

Owner:MINGZHU FURNITURE CO LTD

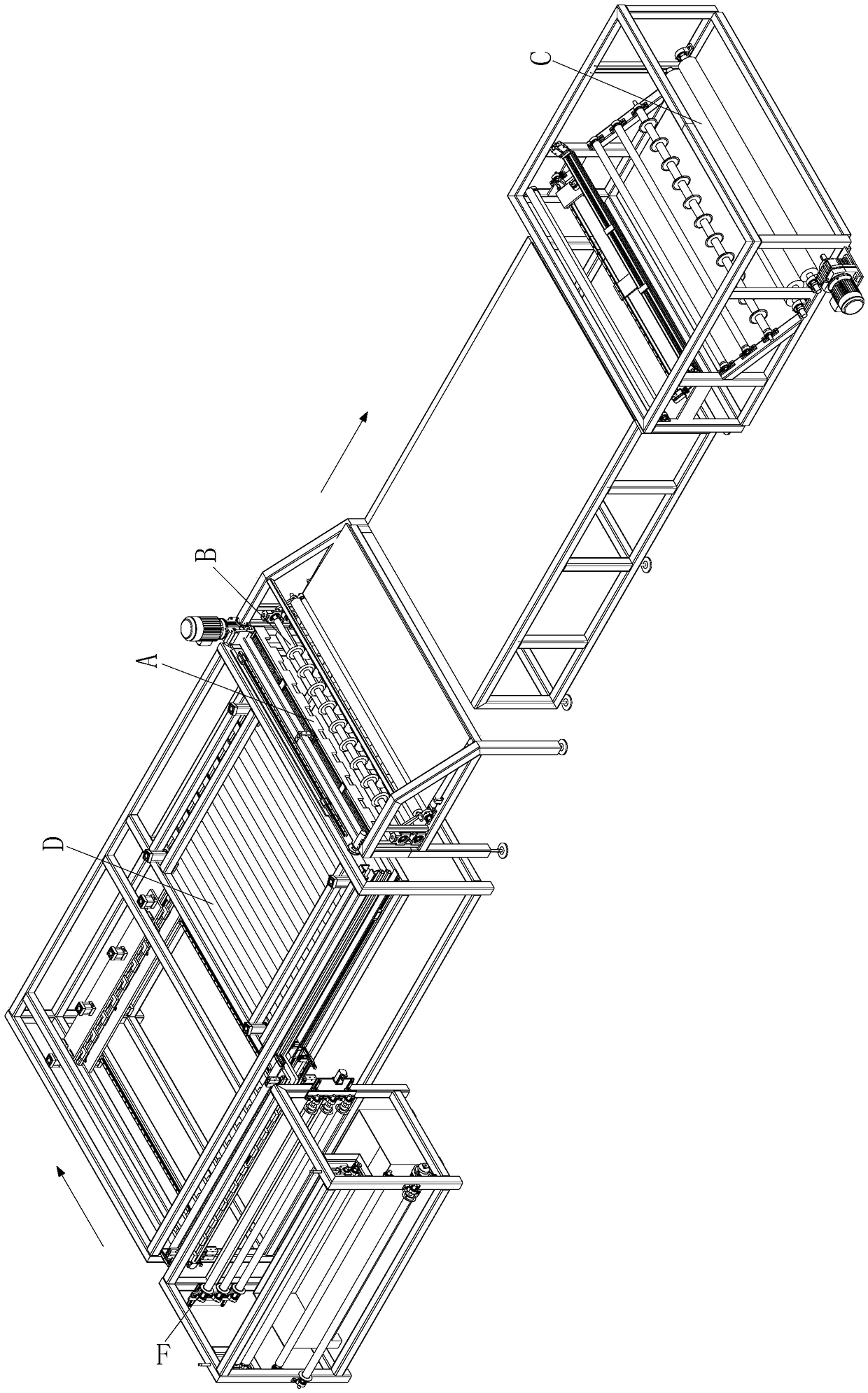

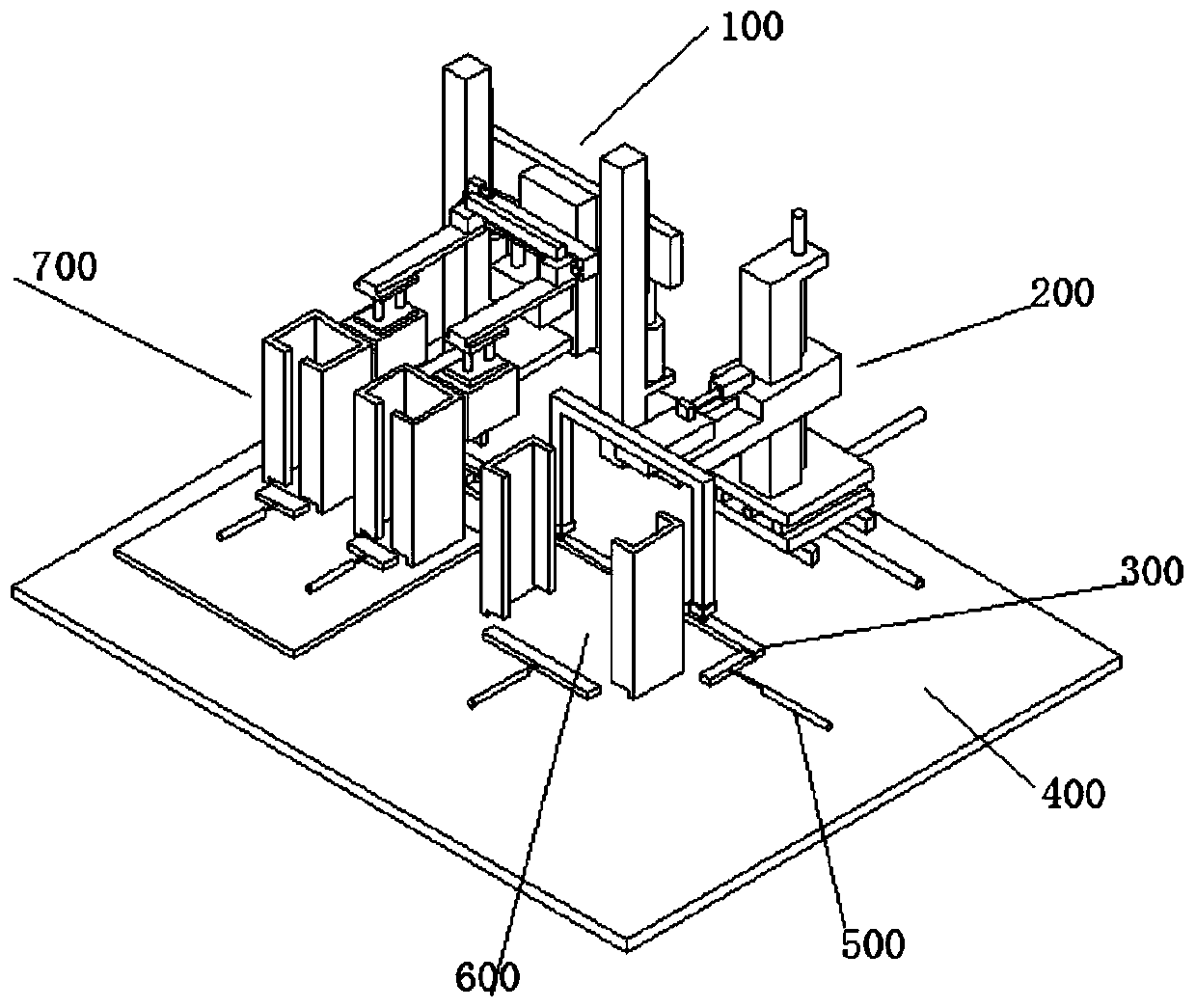

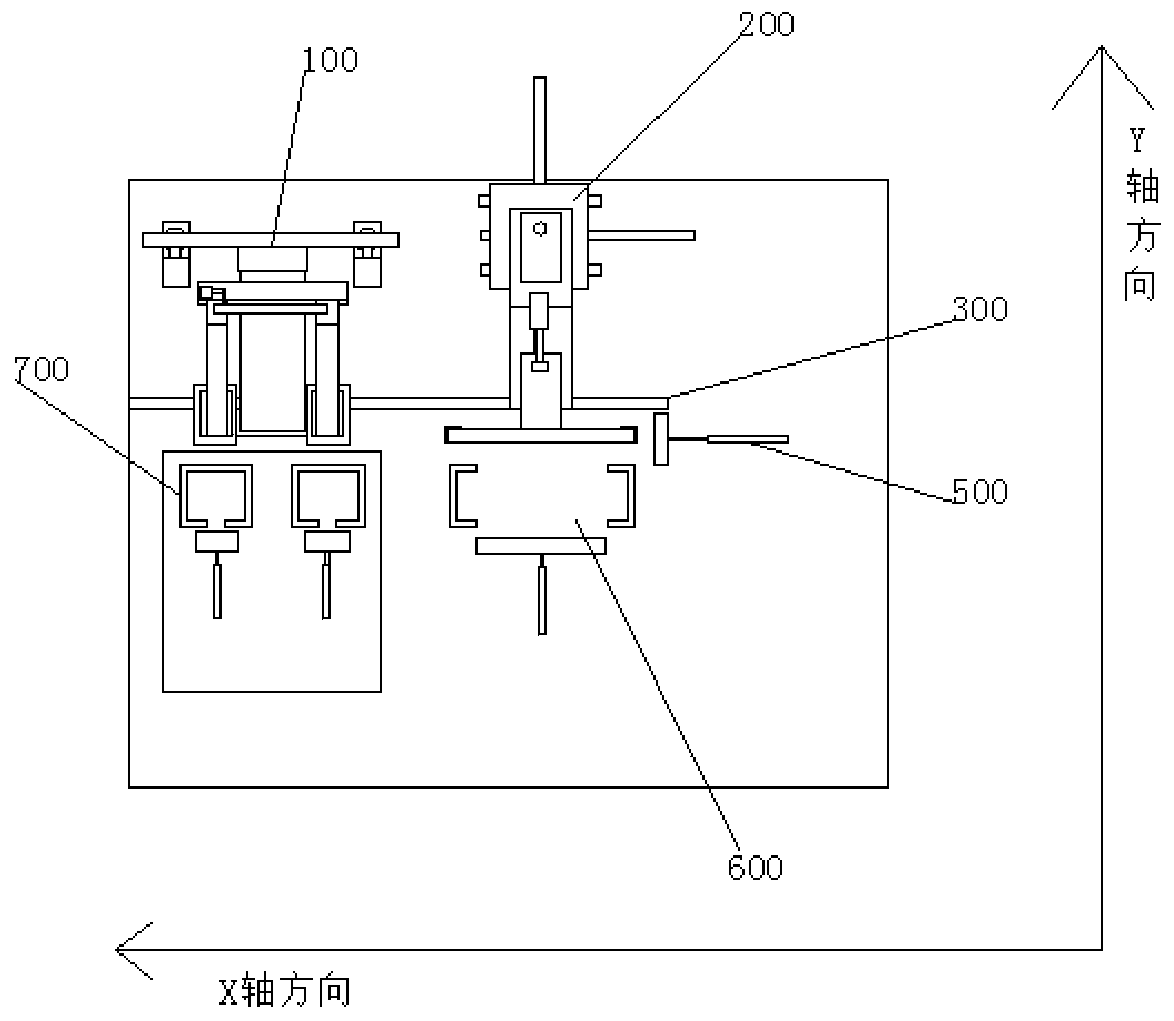

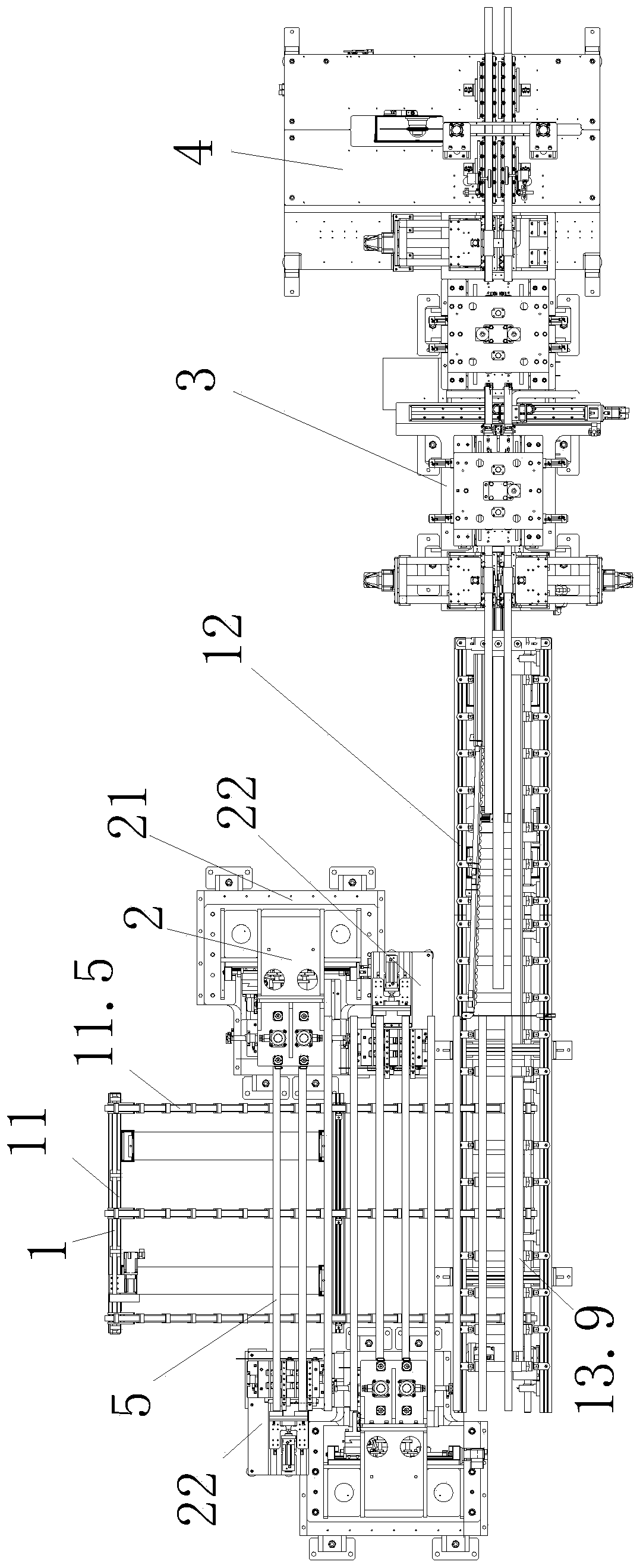

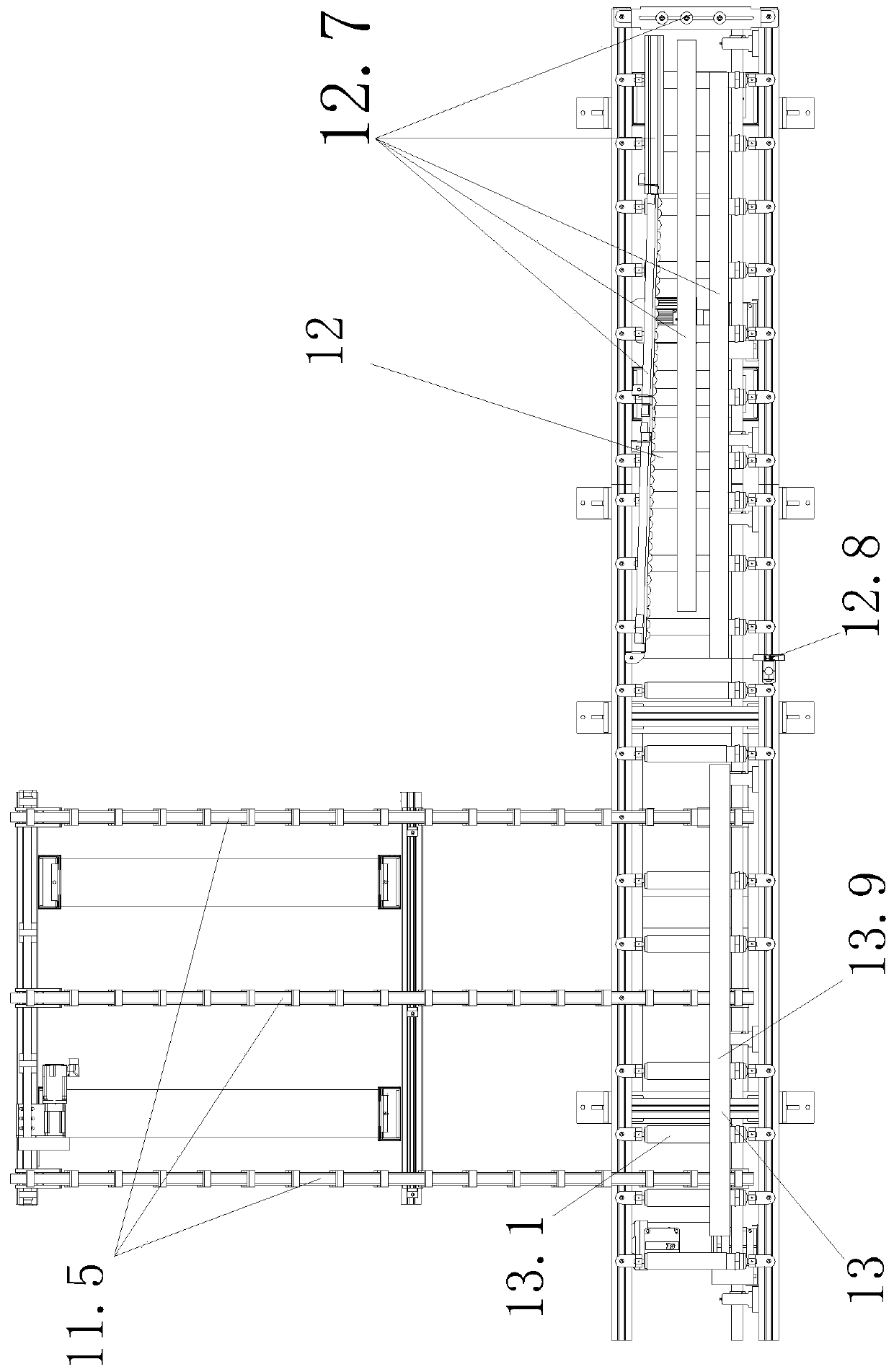

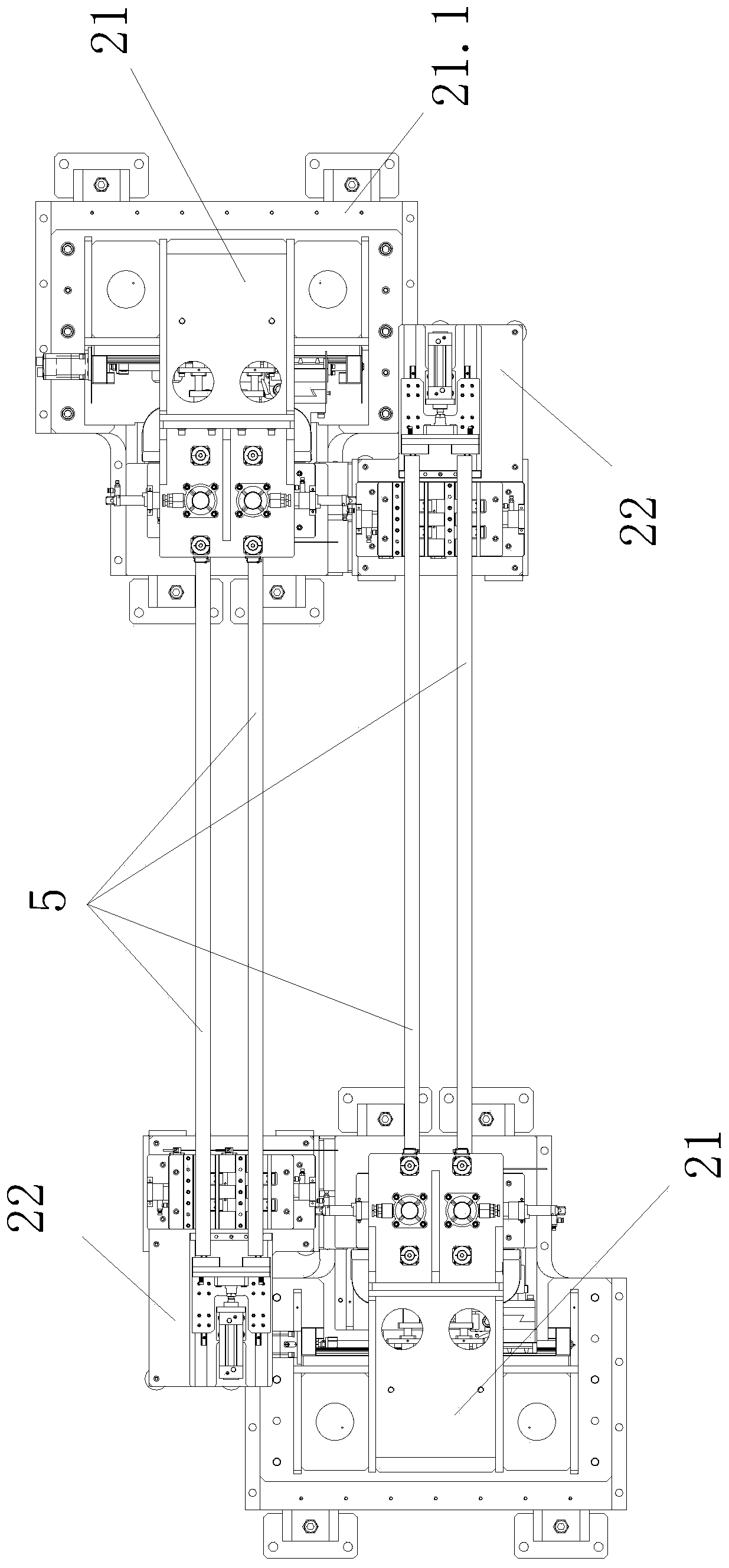

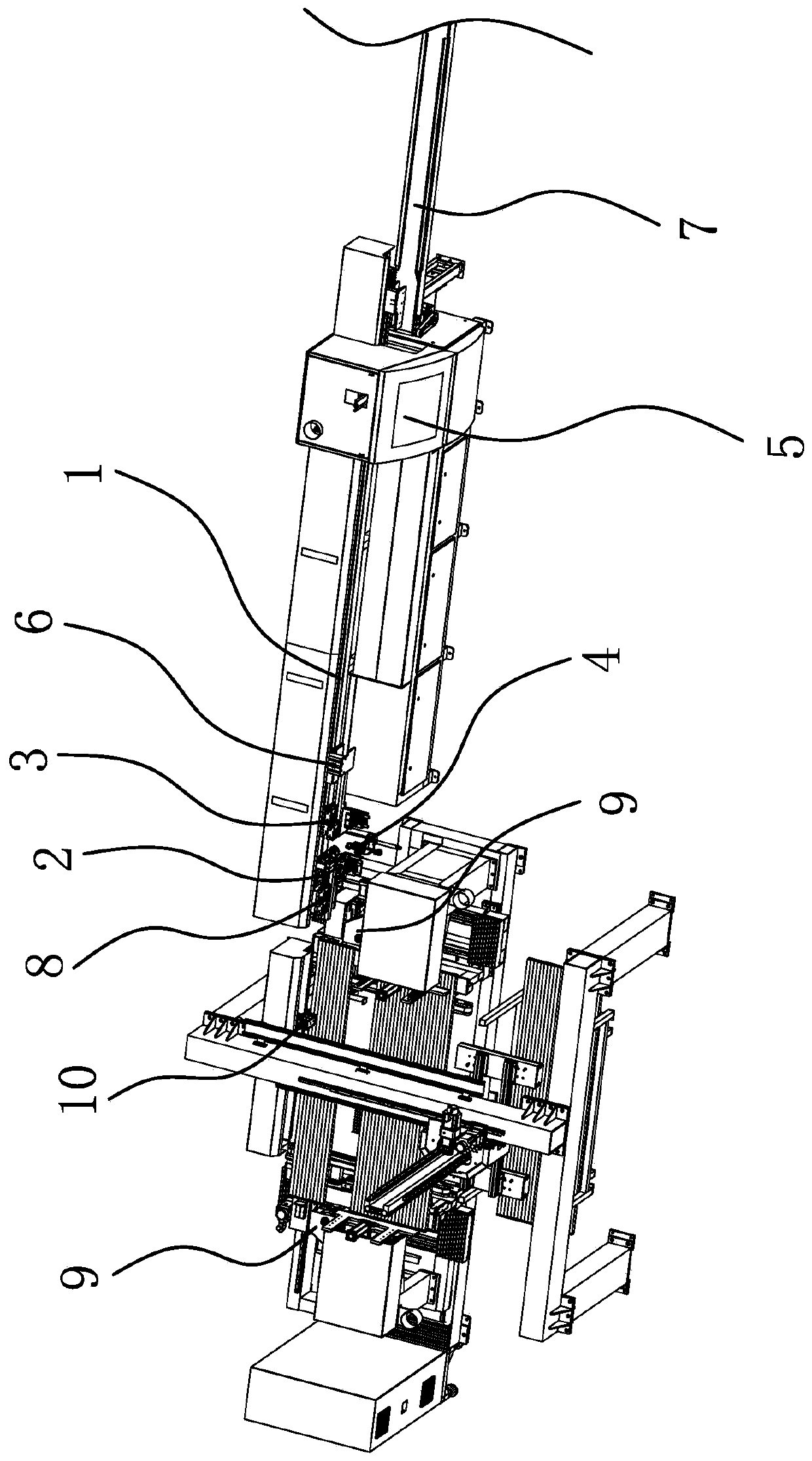

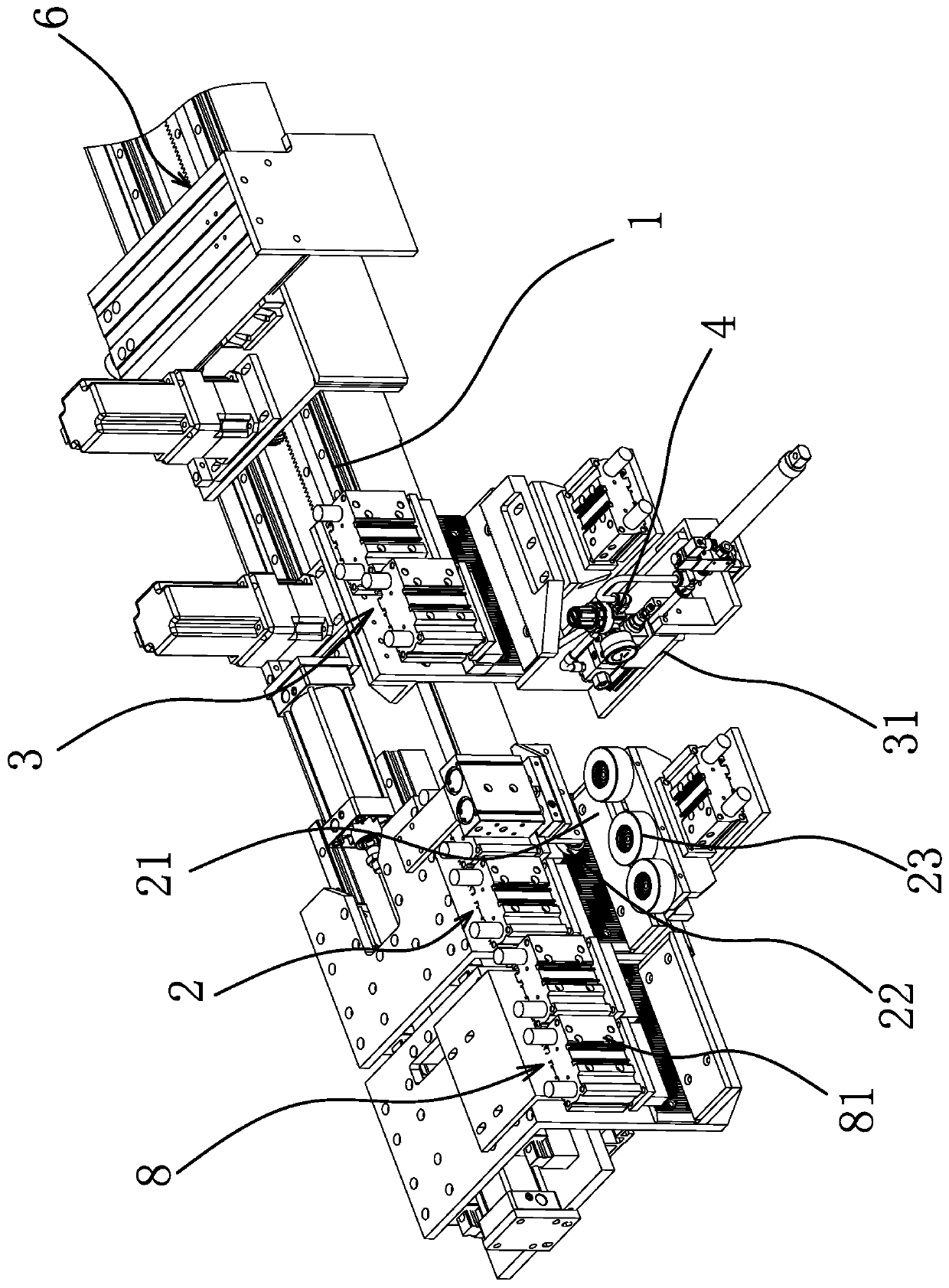

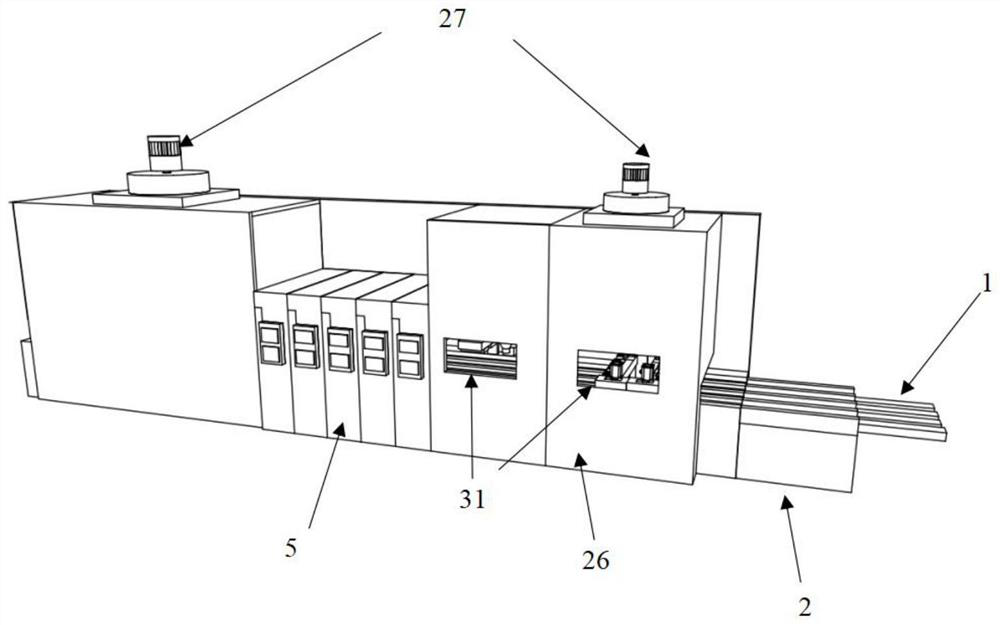

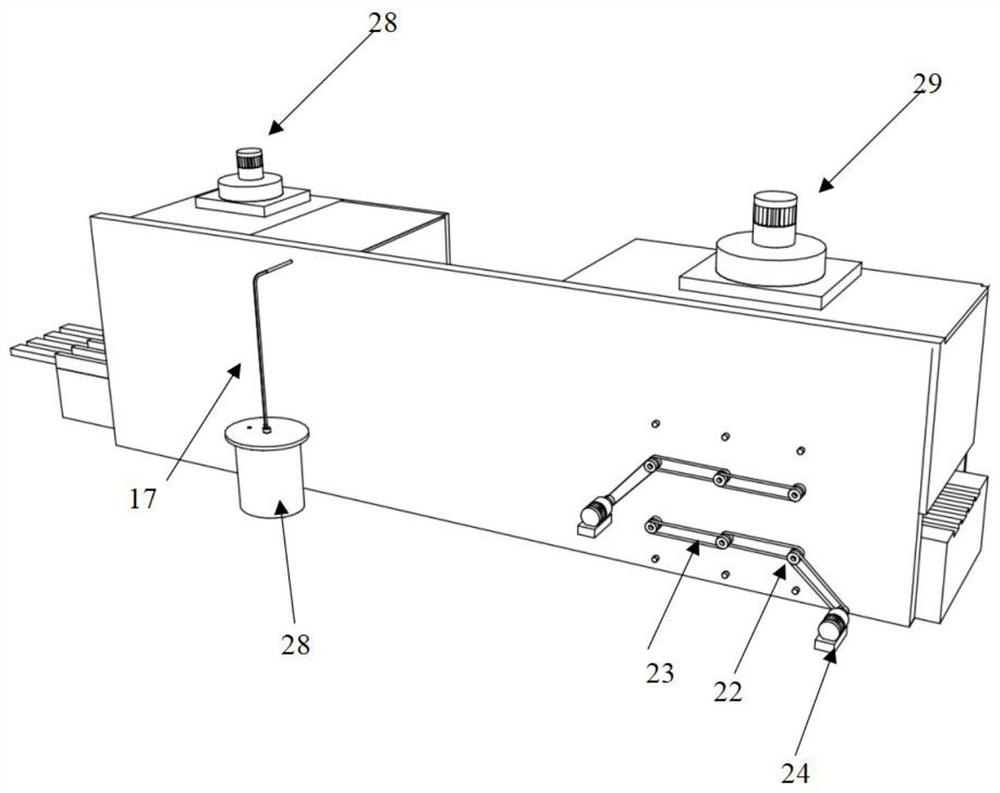

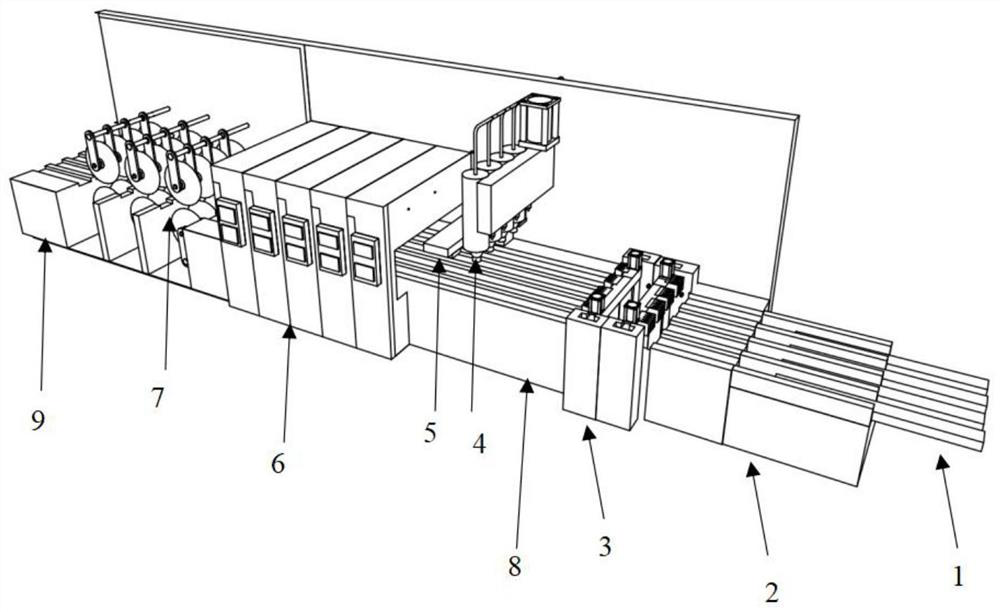

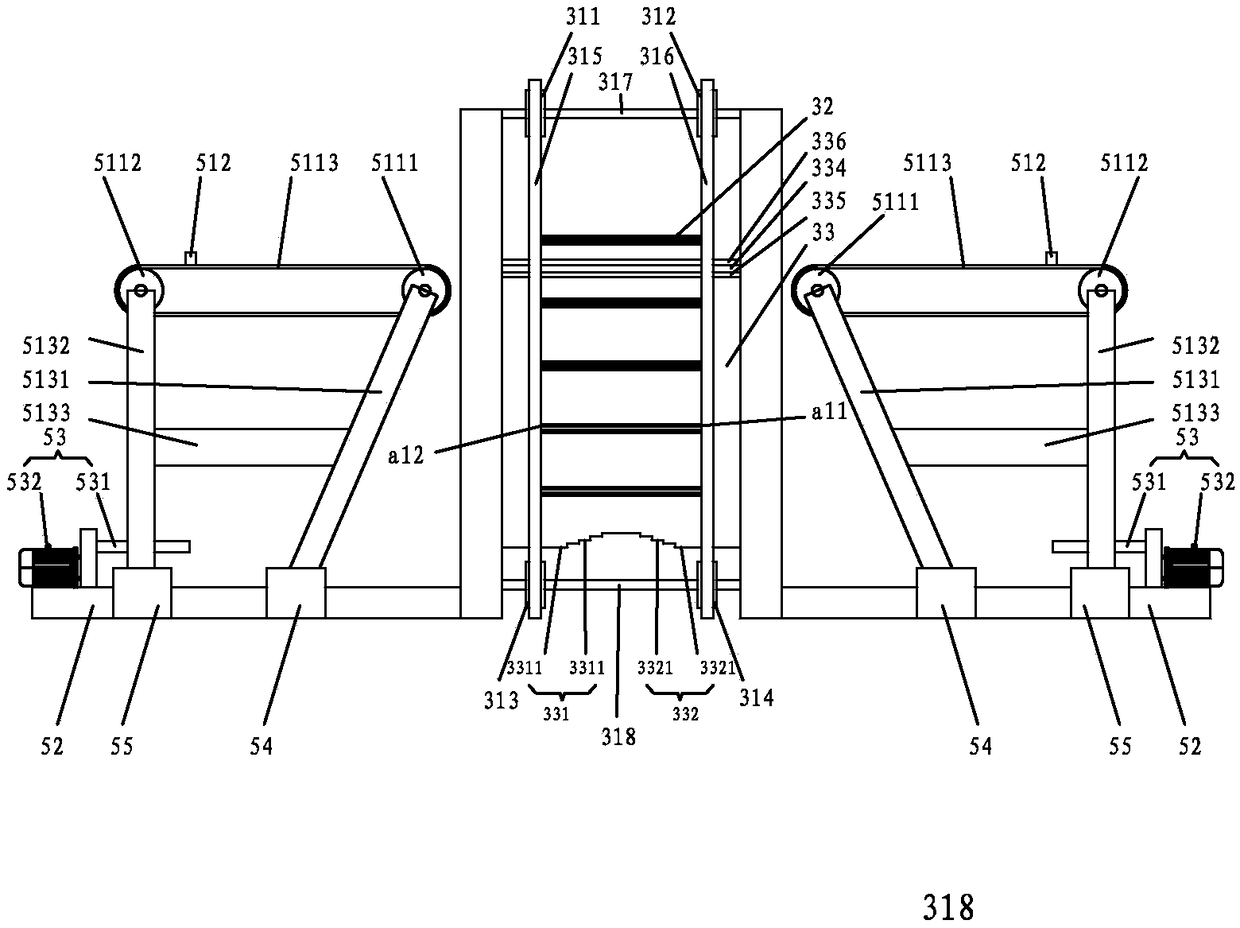

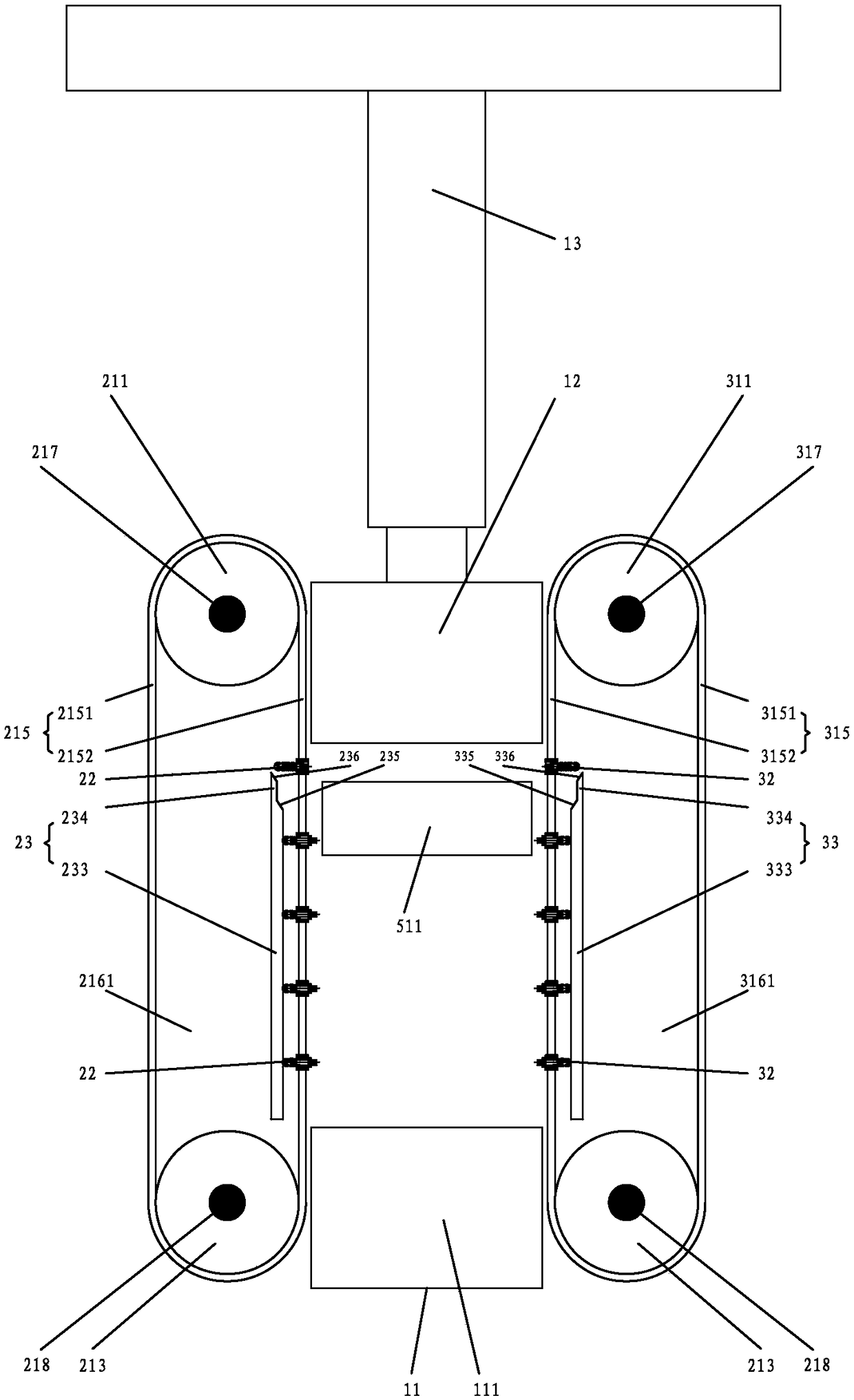

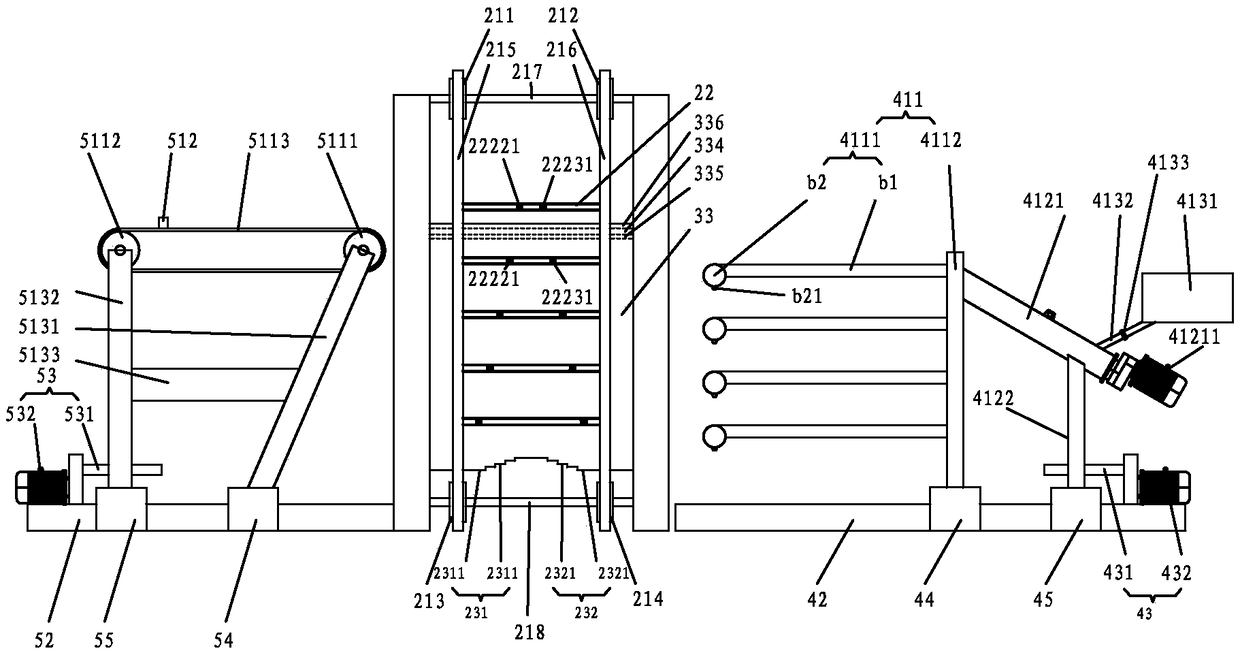

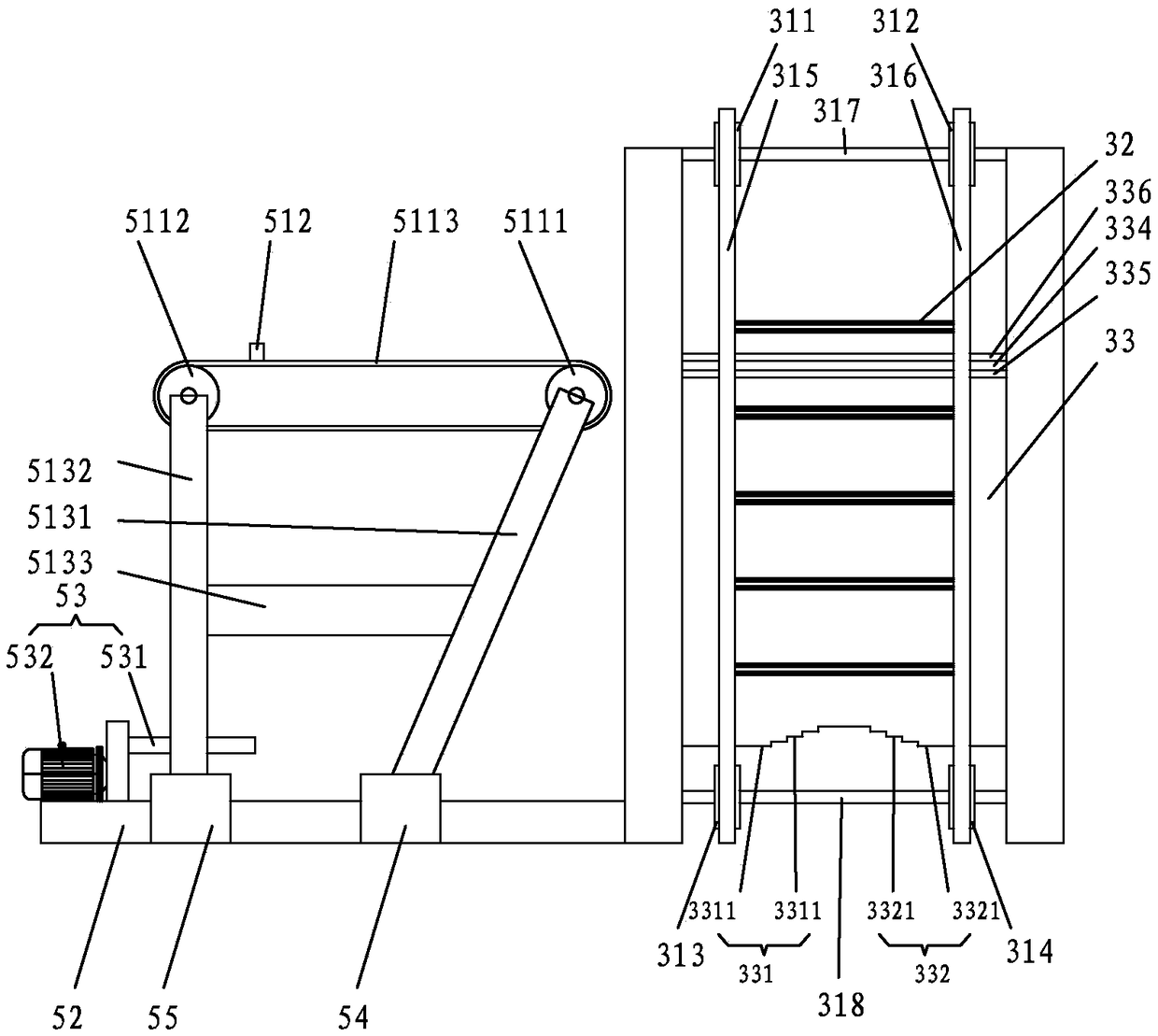

Equipment for splicing and fixed-length cutting blanking for laminated timbers

The invention discloses equipment for splicing and fixed-length cutting blanking for laminated timbers. The equipment for splicing and fixed-length cutting blanking for the laminated timbers comprisesan automatic loading device, a conveying device, a tooth milling device, a splicing device, a cutting device and a control center. The conveying device comprises a chain conveying device, a fixed roller conveying device and a lifting conveying device. The laminated timbers to be spliced are placed onto the automatic loading device at first, sequentially and intermittently placed onto the chain conveying device by the automatic loading device, and then sequentially and intermittently pushed forwards to reach the position of the tooth milling device by the chain conveying device, the right endsand the left ends of the laminated timbers to be spliced are sequentially and orderly milled, then the laminated timbers to be spliced are intermittently pushed forwards to reach the part of the lifting conveying device, then the laminated timbers to be spliced are intermittently conveyed to the right and onto the fixed roller conveying device by the lifting conveying device, finally the laminated timbers to be spliced are spliced on the splitting device, and then the spliced laminated timbers are conveyed to the right and onto the cutting device to be cut according to a specific length; andthe whole process is controlled by the control center to be automatically and orderly completed, and the advantage of high working efficiency is achieved.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

Multi-layer gluing and composite process of antibacterial plywood

ActiveCN112720733AImprove processing efficiencyPrevent outflowWood veneer joiningGlue gunsSingle plateAnti bacteria

The invention discloses a multi-layer gluing composite process of antibacterial plywood. The multi-layer gluing composite process comprises the following steps that dodecyl trimethyl ammonium chloride is added into water, stirred and dissolved to obtain a treating agent solution, a wood board veneer is dried, the dried wood board is soaked in the treating agent solution for 10-20 minutes, and after drying, the wood board veneer is glued and compounded by using a multi-layer gluing and compounding device. The surfaces of the boards are impregnated with dodecyl trimethyl ammonium chloride, so that the boards have certain antibacterial performance, meanwhile, the multiple boards can be automatically positioned and then glued and compounded through the multi-layer gluing and compounding device, and then the processing efficiency can be improved.

Owner:浦北县业鸿木业有限责任公司

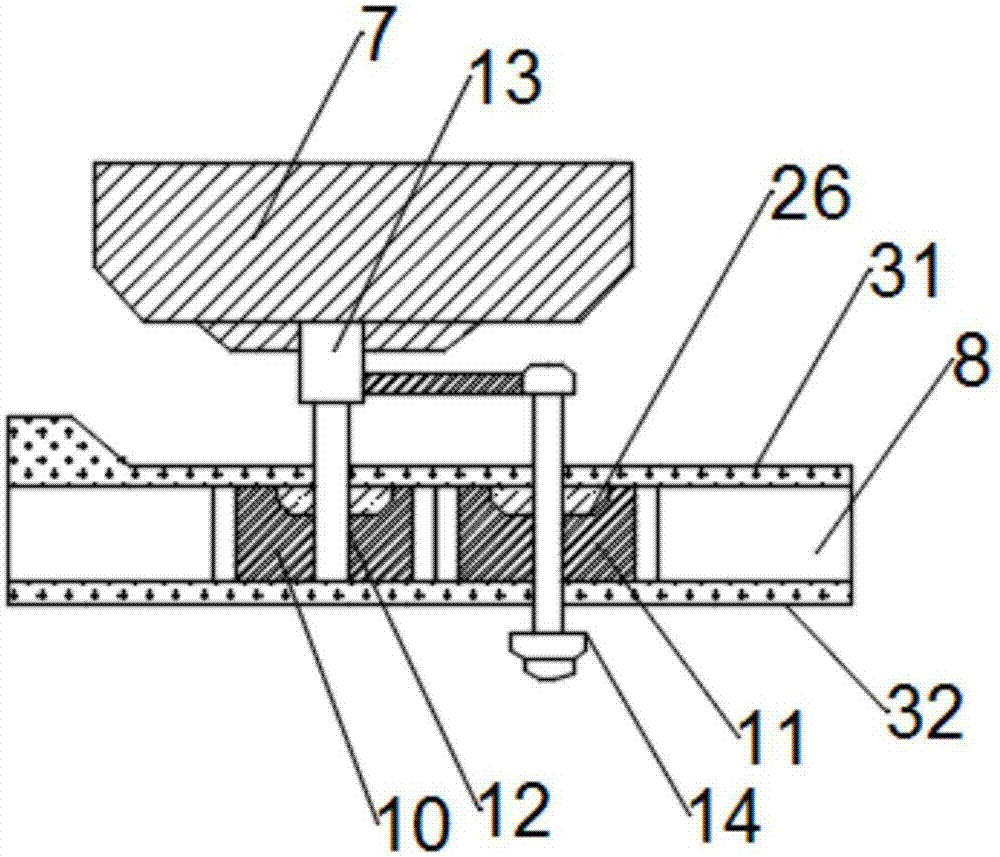

Gluing mechanism

The invention relates to a gluing mechanism. The gluing mechanism comprises a core plate feeding mechanism, wherein the discharging port of the core plate feeding mechanism is connected to the feedingport of a core plate polishing mechanism; the core plate polishing mechanism is used for polishing the surface of a core plate; the discharging port of the core plate polishing mechanism is connectedto the feeding port of a gluing mechanism; core plate spraying mechanisms are arranged between the discharging port of the core plate polishing mechanism and the feeding port of the gluing mechanism;the core plate spraying mechanisms are arranged on the two sides of the discharging port of the core plate polishing mechanism; the discharging port of the core plate polishing mechanism is connectedto the feeding port of a core plate guiding mechanism, and the discharging port of the core plate guiding mechanism is connected to the feeding port of the gluing mechanism; a core plate air draft mechanism is arranged below the core plate guiding mechanism and is arranged in the core plate feeding mechanism, polishing operation is performed through the core plate polishing mechanism, so that thesurface of the core plate is smooth; and bonding glue is coated on the smooth surface of the core plate, two core plates are pressed through a cold pressing mechanism, so that the bonding firmness ofthe two core plates is ensured. According to the gluing mechanism, the production efficiency of the plates can be effectively improved, and the quality of the plates can be ensured.

Owner:安徽企路石工程技术开发有限公司

Convenient-to-position high-applicability glue pressing device for furniture processing

The invention discloses a convenient-to-position high-applicability glue pressing device for furniture processing. The convenient-to-position high-applicability glue pressing device comprises a machine shell and a table frame, two electric telescopic rods are fixedly mounted in the machine shell, a mounting frame is fixedly mounted at the ends, away from the machine shell, of the electric telescopic rods, and limiting columns are fixedly mounted at the top and the bottom of an inner cavity of the mounting frame correspondingly; telescopic springs are fixedly mounted at the outer sides of the limiting columns, a glue pressing roller brush is fixedly mounted at the inner side of the mounting frame, sliding blocks are fixedly mounted at the opposite sides of the machine shell, two track grooves are formed in the table frame, a working plate is movably mounted at the inner side of the table frame, and micro electric telescopic rods are fixedly mounted in the opposite sides of the table frame; and plates needing to be subjected to glue pressing are conveniently fixed through the installation of clamping plates so as to prevent the plates from falling off in the glue pressing process, acontrol box controls the micro hydraulic telescopic rods to stretch out and draw back, the hydraulic telescopic rods at the opposite sides of the table frame apply acting force to the clamping plates,the clamping plates at the two sides extrude and fix the plates in the opposite directions, and therefore the plates can be effectively prevented from falling off.

Owner:浙江九和家具有限公司

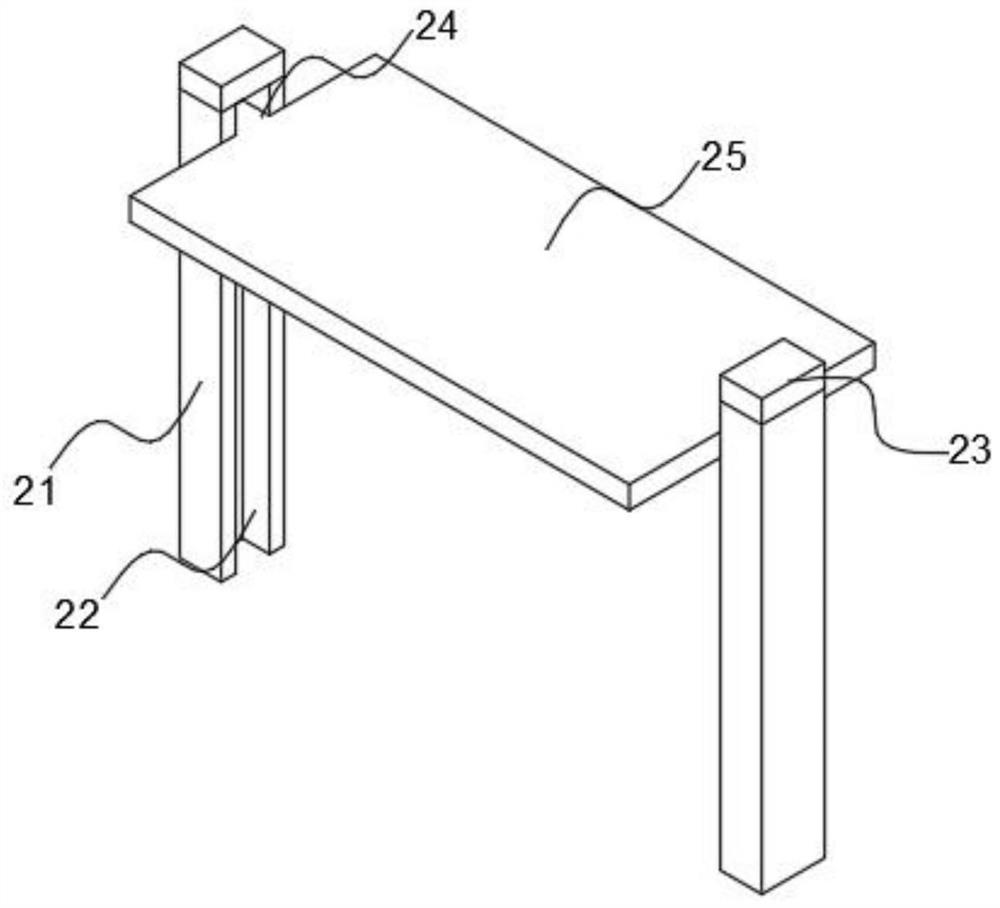

Continuous laminating device for multi-layer wood door

InactiveCN111775237AAvoid the problem of not being on the same planeEven by forcePlywood pressesVeneer pressesHydraulic ramPiston rod

The invention relates to the technical field of wood door machining, in particular to a continuous laminating device for a multi-layer wood door. The continuous laminating device comprises a base, wherein a moving mechanism is arranged on the base; the moving mechanism comprises upright posts symmetrically arranged above two sides of the base; sliding grooves are formed in the upright posts; fixing blocks are arranged at the top ends of the upright posts; sliding blocks matched with the two sliding grooves in size are arranged in the two sliding grooves; a laminating plate is integrally formedbetween the sliding blocks; the sliding blocks are slidably connected with the sliding grooves; a laminating table is arranged on one side of the base; a lifting rod is arranged above the laminatingtable; an empty groove is formed in the lifting rod; a hydraulic oil cylinder fixing plate is arranged in the empty groove; a hydraulic oil cylinder is mounted below the hydraulic oil cylinder fixingplate; and a piston rod of the hydraulic oil cylinder is vertically downward and fixedly connected with a laminating hammer mounting plate. According to the continuous laminating device for the multi-layer wood door, the wood door on the laminating plate is laminated through a laminating hammer on the hydraulic oil cylinder fixing plate, and the wood door is fixed through a positioning mechanism,so that the door laminating effect is more uniform.

Owner:浙江香乡门业有限公司

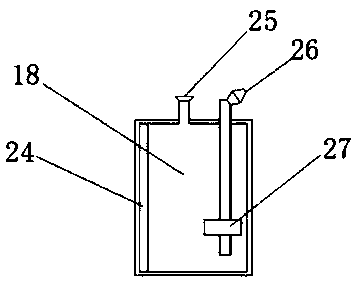

Gluing device for gluing straw board

InactiveCN108527563AAvoid issues that pose a health hazardImprove work efficiencyGlue gunsGlue vesselsEngineeringDistance sensors

The invention discloses a gluing device for gluing a straw board. The device comprises a conveyor and a controller, wherein supporting rods are fixedly connected to two sides of the top part of the conveyor; a top plate is fixedly connected to the top parts of the supporting rods, and a glue box is fixedly connected to the right side of the top part of the top plate; a liquid level sensor is fixedly connected to the bottom part of the right side of an inner chamber of the glue box; an alarm is fixedly connected to the right side of the top part of the glue box; a hose communicates with the bottom part of the left side of the glue box; and a suction pump communicates with one end, far away from the glue box, of the hose. According to the gluing device for gluing the straw board, the conveyor, the controller, the glue box, the liquid level sensor, the alarm, the hose, the suction pump, a glue injecting pipe, an electric telescoping rod, a fixing plate, an infrared distance sensor, an injecting head and a brush are matched to use to mechanically glue the straw board, so that the working efficiency is improved, and the labor cost is decreased; and meanwhile, the problem that the body health of workers is damaged can be avoided.

Owner:许昌亚丹生态家居有限公司

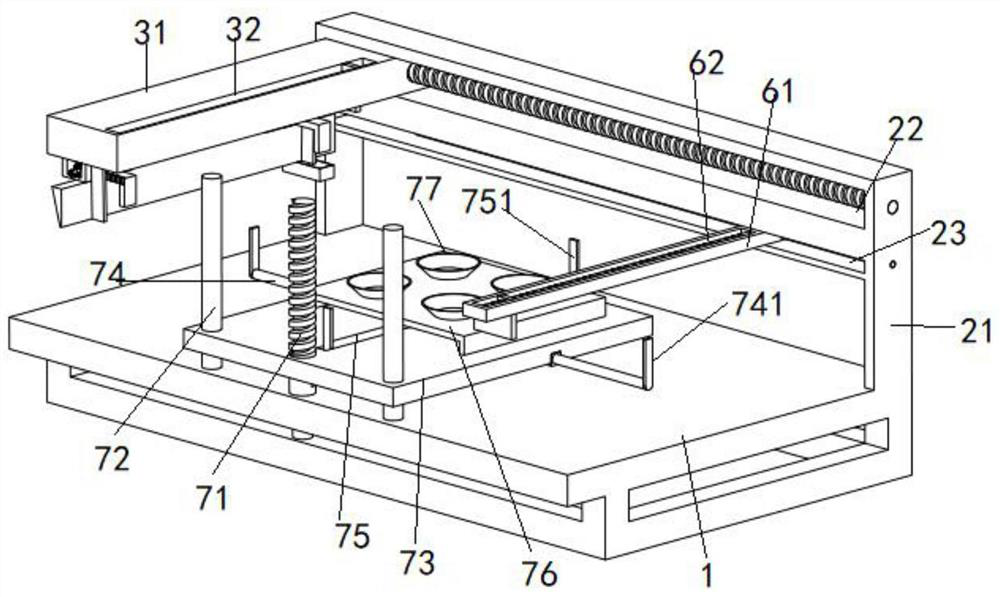

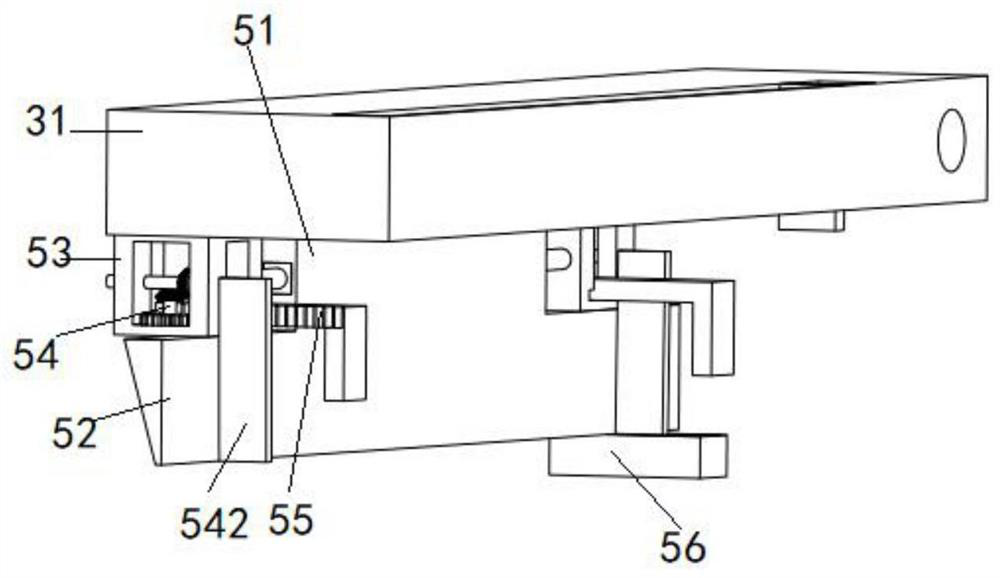

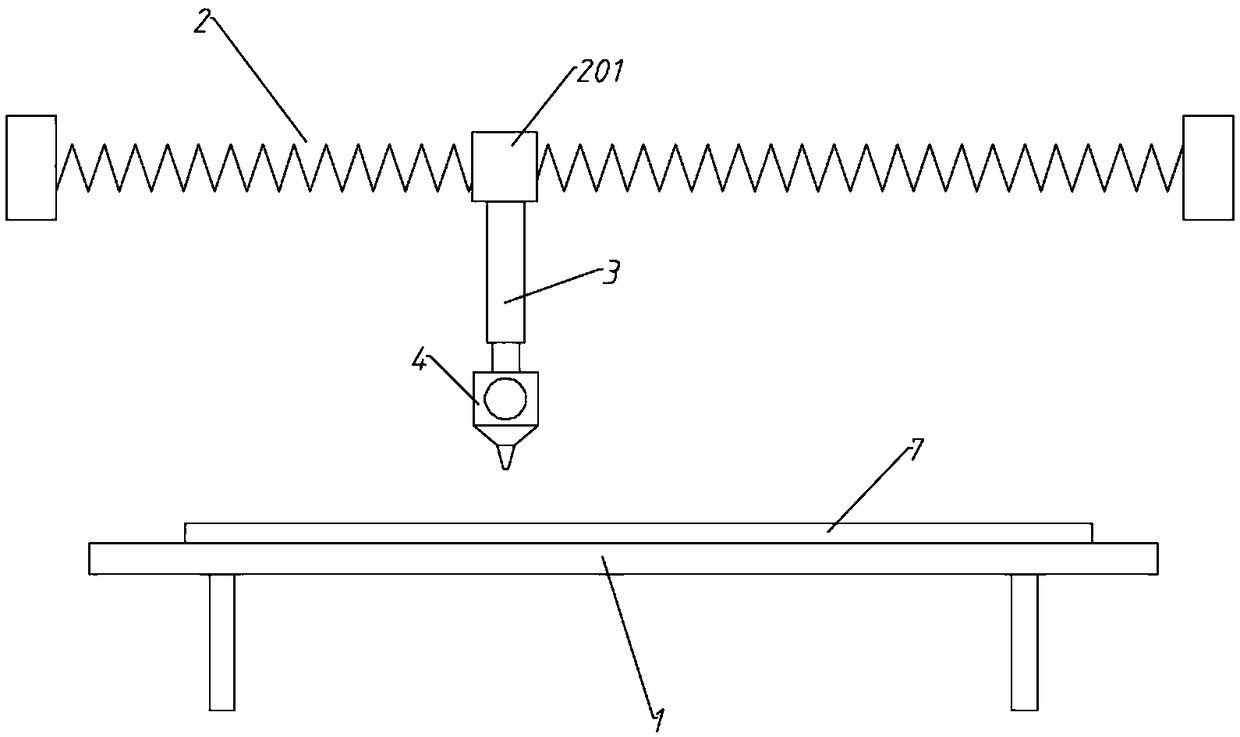

Gluing device and gluing method for plate combined machining

The invention relates to the technical field of plate combined machining and specifically relates to a gluing device and a gluing method for plate combined machining. The device comprises a placementtable, a linear module, a positioning air cylinder and a gluing component. Through mechanical design, the linear module serves as a spraying path, the spraying interval and spraying distance are adjusted according to the parameters such as length and width of the plate, and then the gluing plate is glued along a single direction; during batch production machining of large-size plates, compared with direct manual gluing, the dead angle in gluing is effectively reduced, and the efficiency is remarkably improved.

Owner:挪亚家家具(广东)有限公司

Plywood glue spraying process device

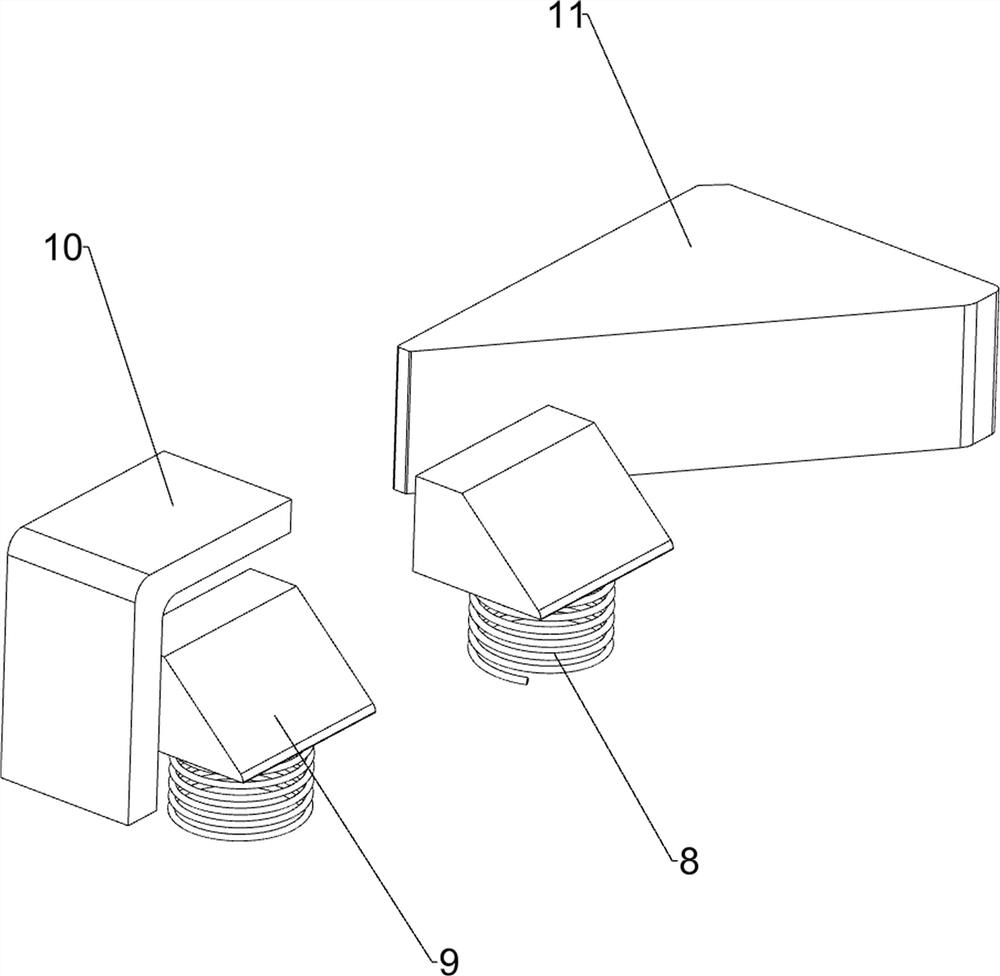

InactiveCN109333691AGood adhesionIncrease stickinessWood veneer joiningGlue gunsViscosityComputer engineering

The invention discloses a plywood glue spraying process device. The device comprises a machine body, wherein the machine body is of a central symmetry structure, fixing rods are fixedly arranged on one side of the machine body, the other side of the machine body is fixedly provided with a supporting plate, one sides of the fixing rods are fixedly provided with inserting rods, clamping blocks are arranged on one sides of the inserting rods, inserting grooves are formed inside the clamping blocks, the inserting grooves are matched with the inserting rods, reset springs sleeve the inserting rods,one ends and the other ends of the reset springs are elastically connected with the clamping blocks and the fixing rods correspondingly, and the fixing rods are fixedly connected with connecting rods. According to the device, a heater is started to work by opening a heater switch so as to heat glue in storage boxes, the viscosity of the glue can be improved by the glue heating, meanwhile, the glue can be softened, a glue pumping pump switch is opened to enable a glue pumping pump to start to work, so that the glue in the storage boxes on the two sides is pumped to a spray head to be sprayed out.

Owner:江苏树仁木业有限公司

Plywood manufacturing equipment based on dry heat method

ActiveCN114425805AHigh degree of intelligenceSave human effortWood veneer joiningGlue gunsHydraulic cylinderManufactured material

The invention relates to plywood manufacturing equipment, in particular to plywood manufacturing equipment based on a dry heat method. The plywood manufacturing equipment based on the dry heat method does not need excessive manual operation and is high in automation degree and production efficiency. According to the technical scheme, the plywood manufacturing equipment based on the dry heat method comprises a bottom plate, a first mounting plate, a multi-stage hydraulic cylinder, mounting columns, a pressing plate and the like, the first mounting plate is arranged at the top of the bottom plate, the multi-stage hydraulic cylinder is arranged on the right side of the bottom of the first mounting plate, and the mounting columns are arranged on the front side and the rear side of the top of the first mounting plate in a bilateral symmetry mode; a pressing plate used for extruding the plate is slidably connected between the upper sides of the mounting columns. After raw materials for manufacturing the plywood are placed on the equipment, the plywood can be automatically manufactured by controlling the multi-stage hydraulic cylinder to work, so that the intelligent degree is high, excessive manual operation is not needed, and manpower is saved.

Owner:林少山

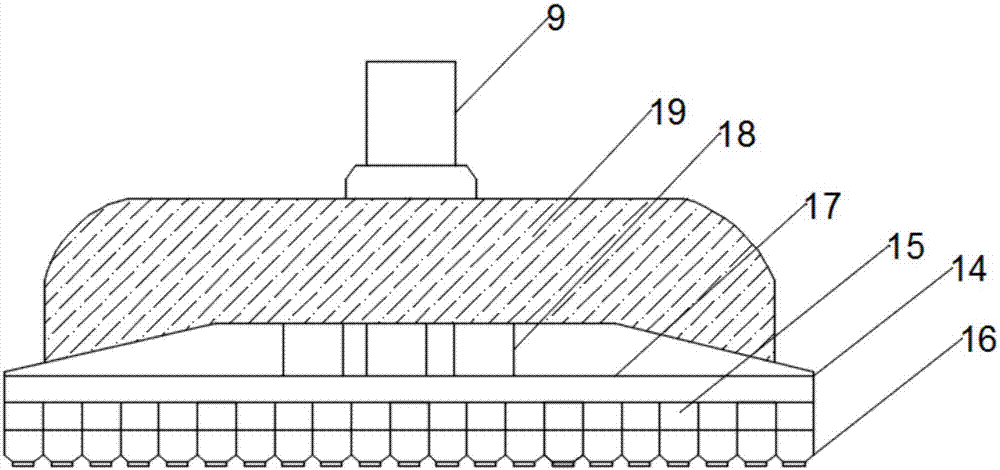

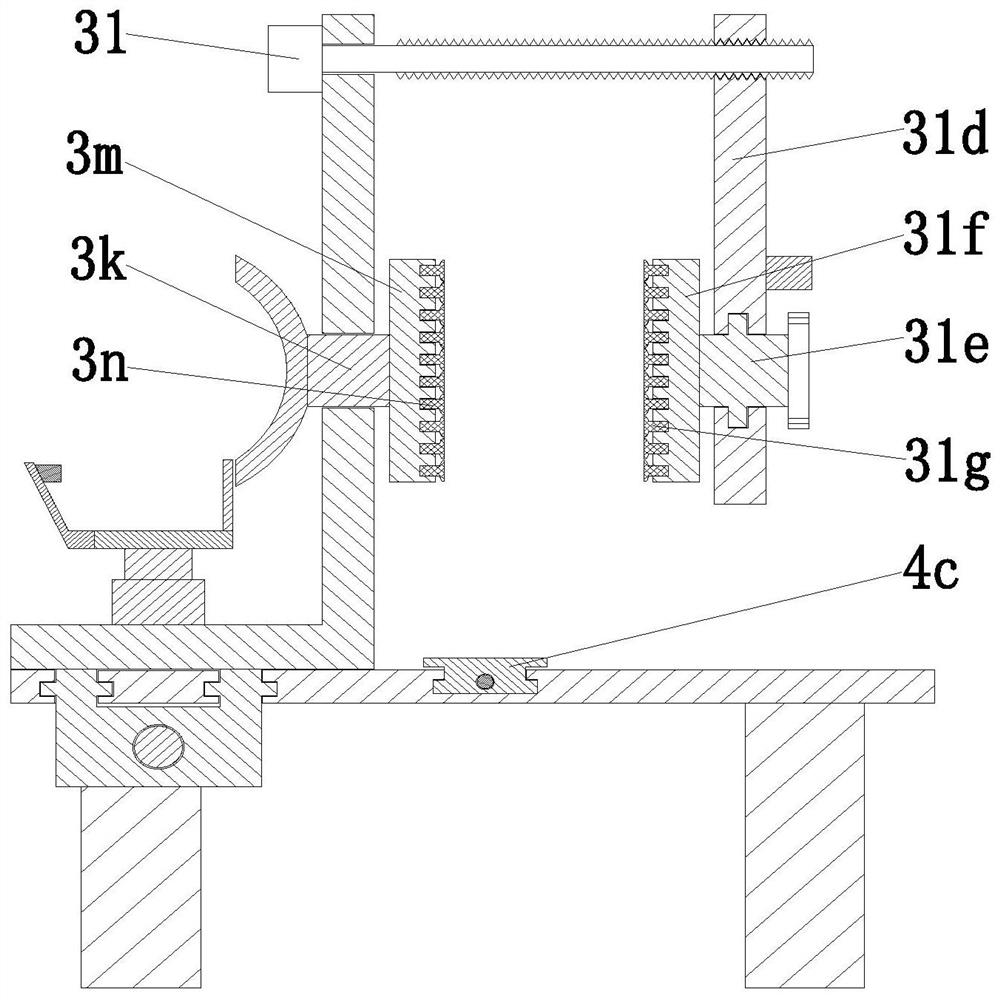

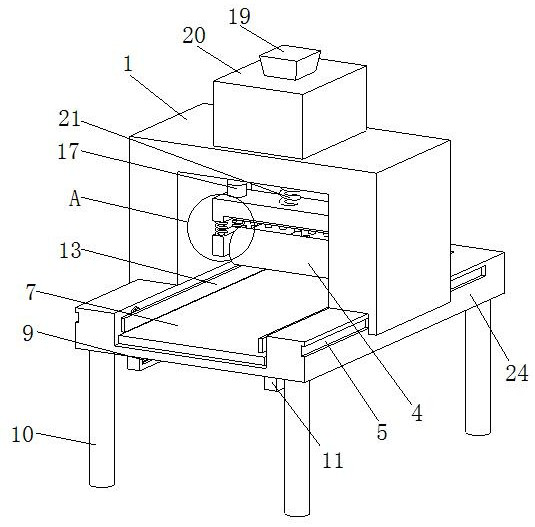

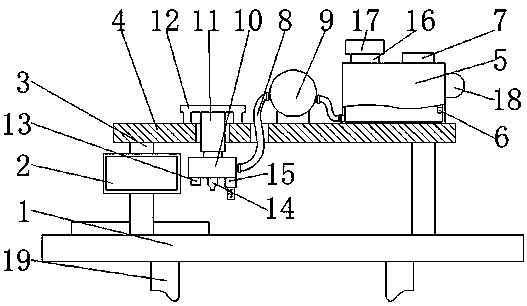

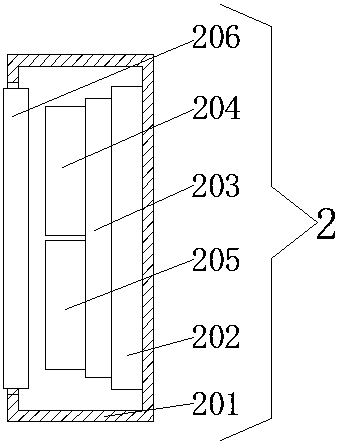

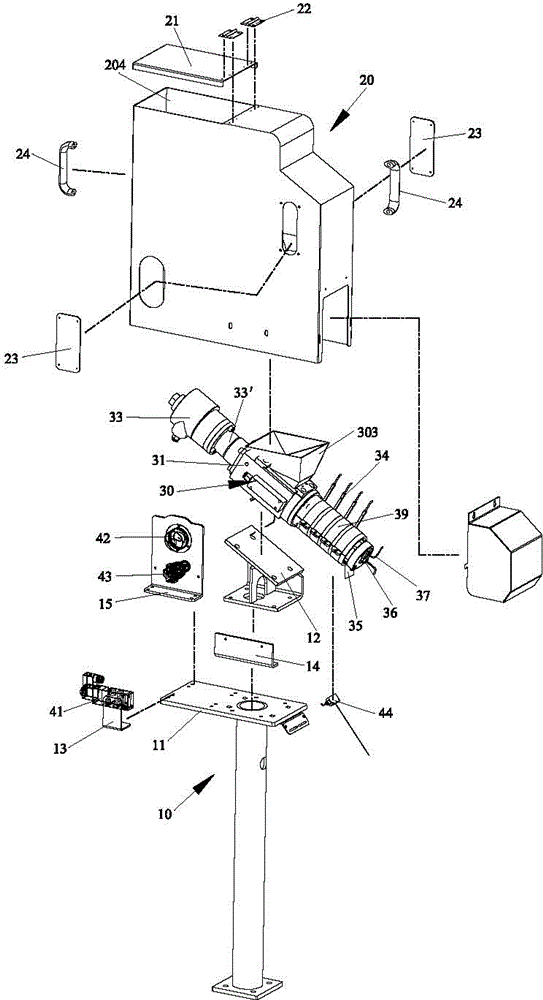

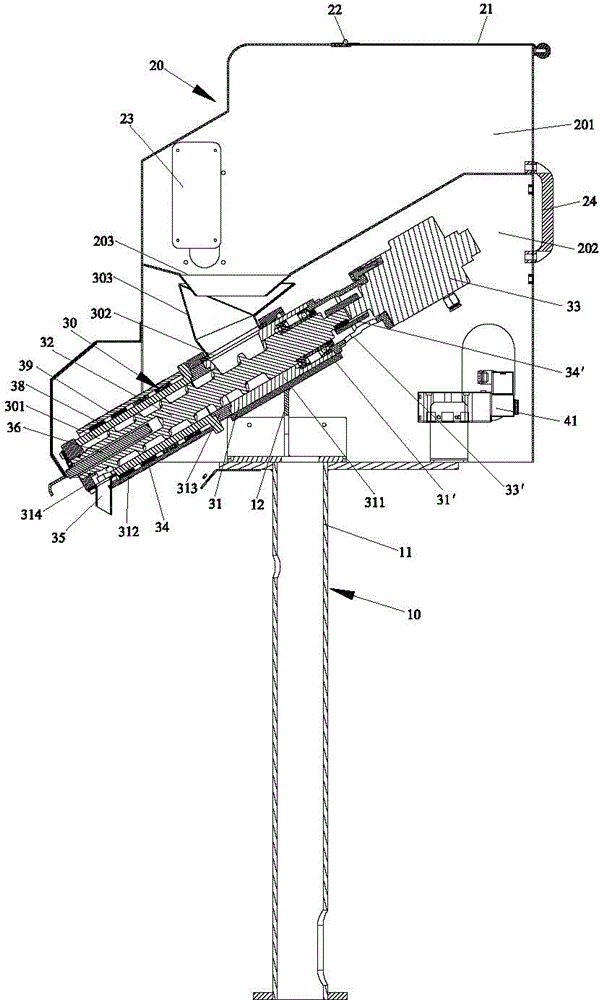

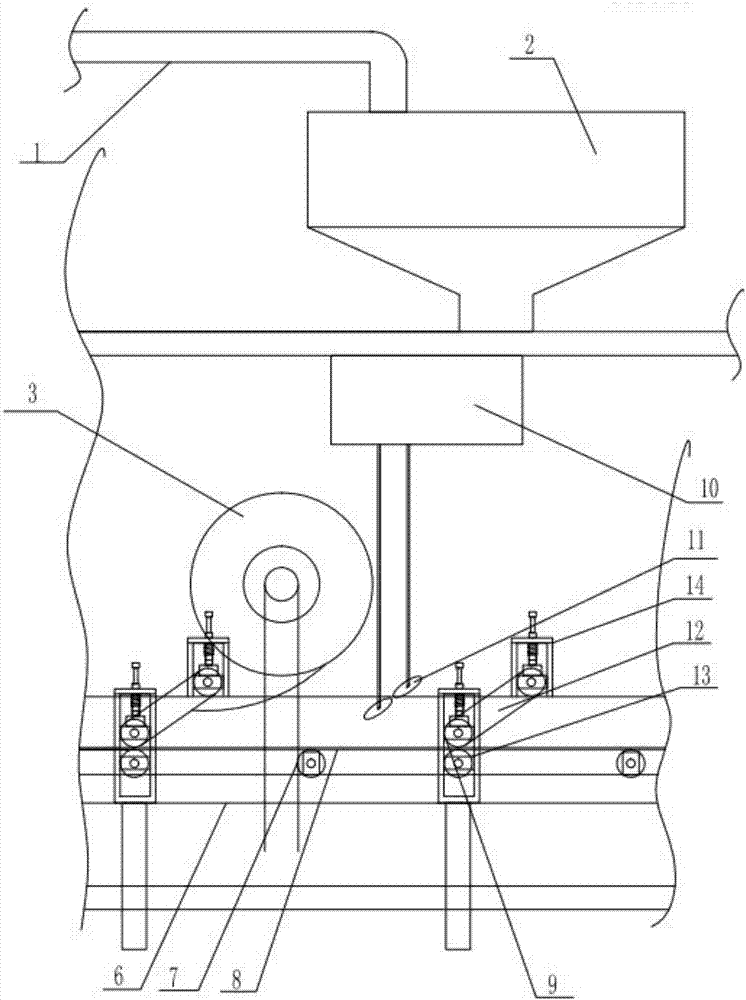

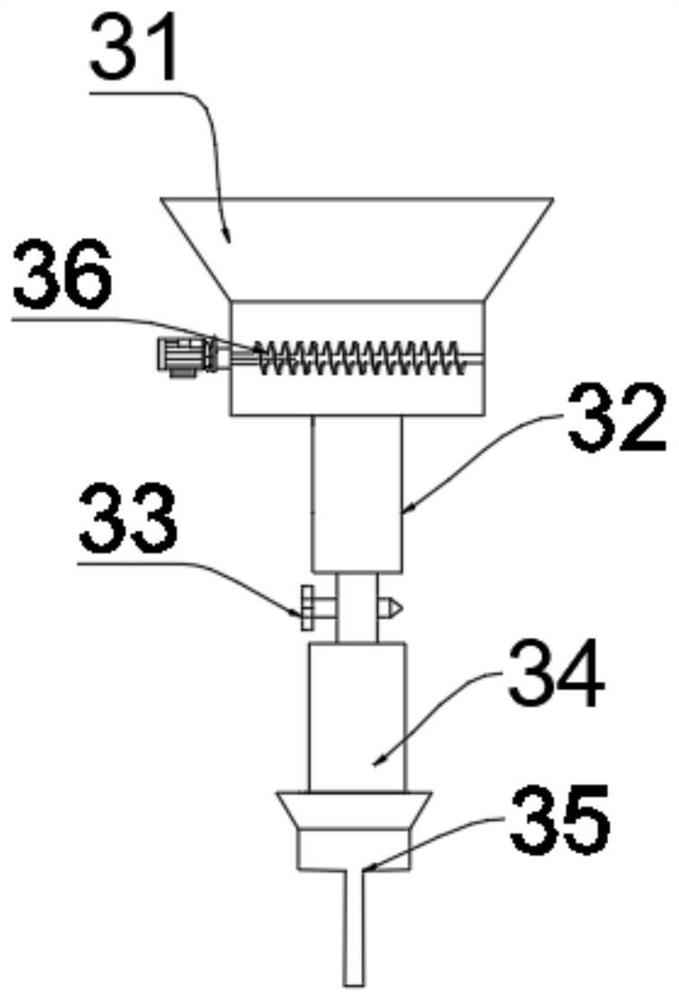

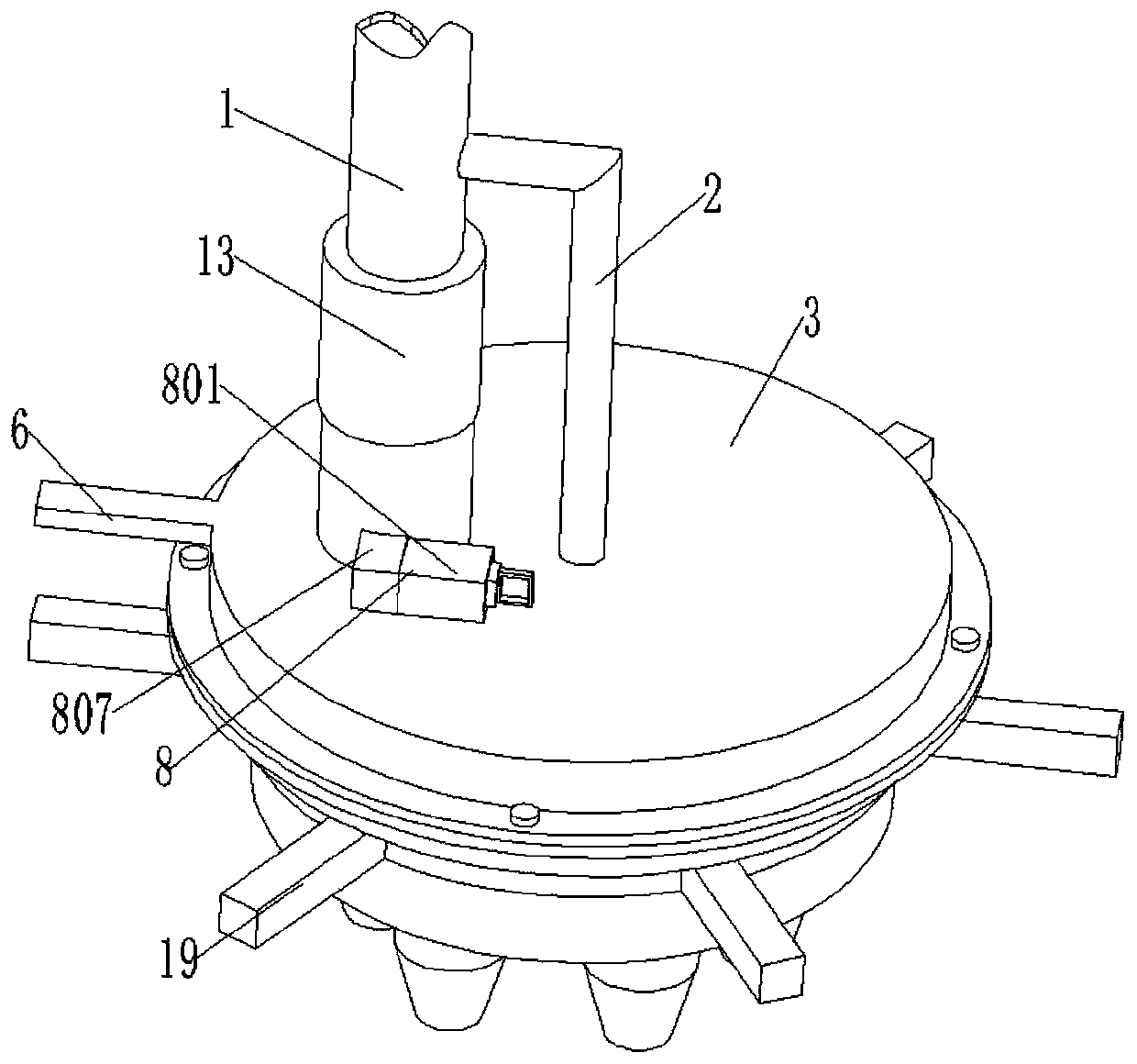

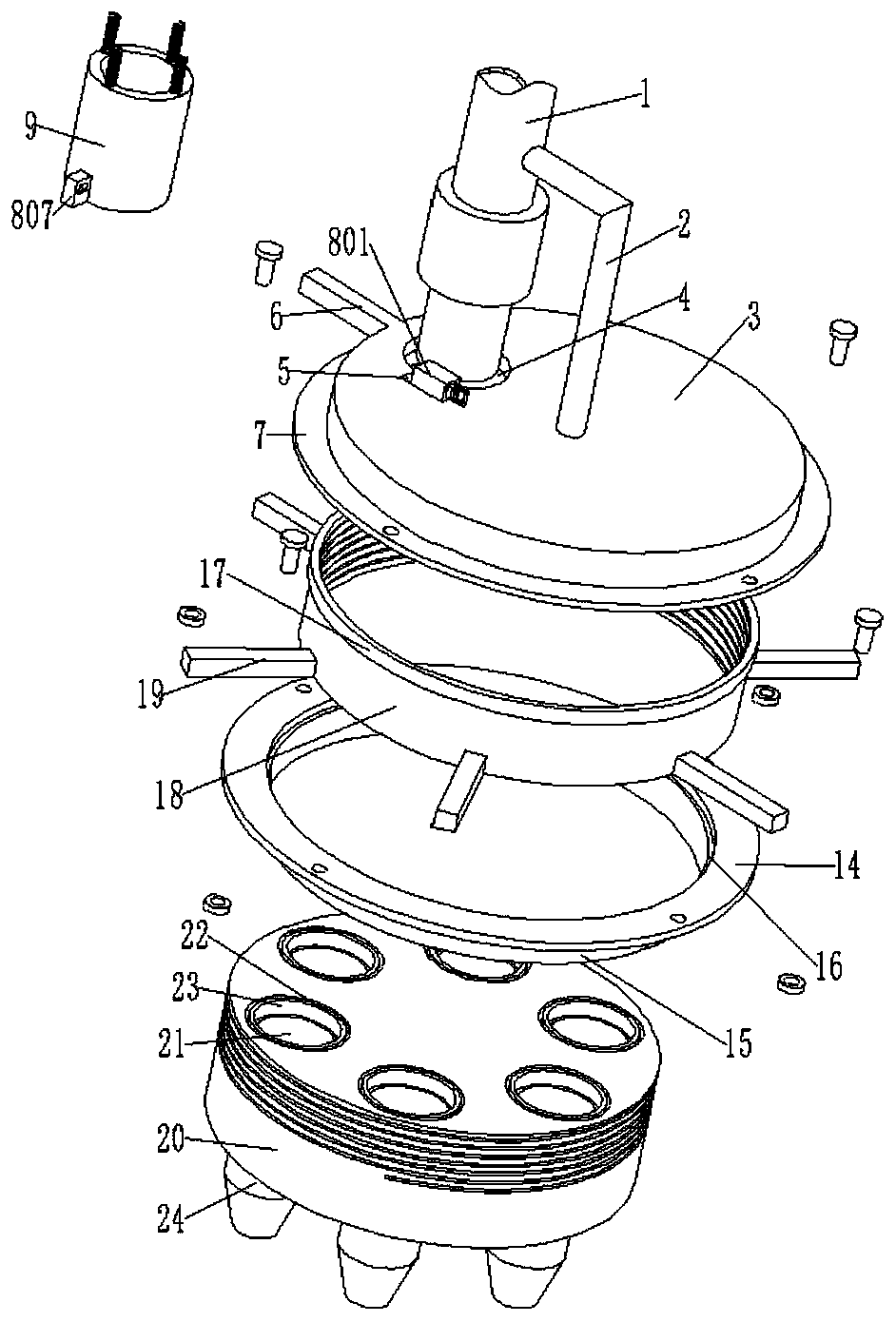

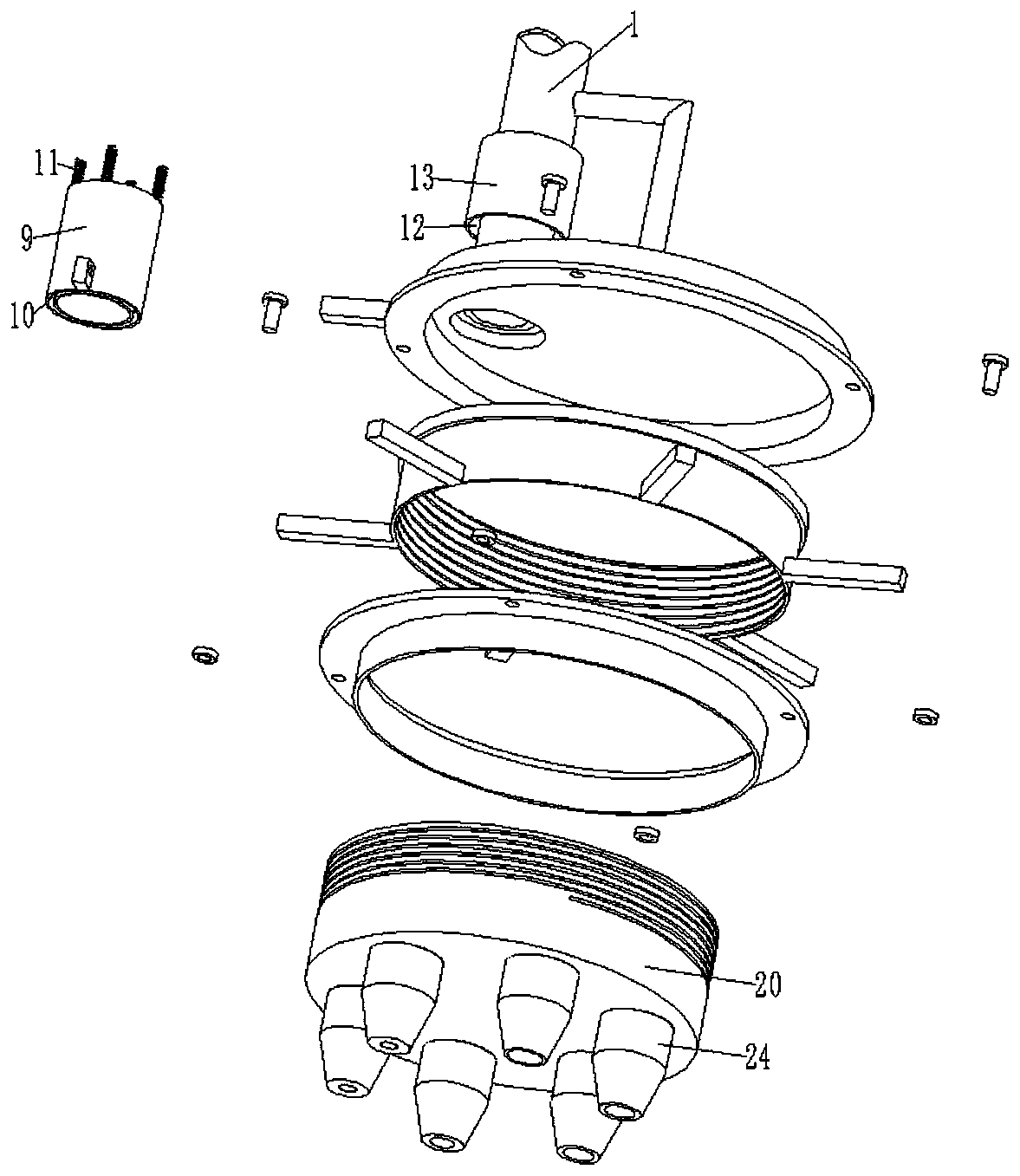

Spiral upper-end glue feeding device of automatic edge bonding machine

ActiveCN104552551AIncrease powerAvoid refractory problemsDomestic articlesGlue gunsDual actionHeat transfer efficiency

The invention discloses a spiral upper-end glue feeding device of an automatic edge bonding machine. The spiral upper-end glue feeding device comprises a frame, a hopper-type housing and a glue core melting component. The glue core melting component comprises a shell, a screw rod and a reducing pneumatic motor. The shell comprises a shaft sleeve seat and a heating cylinder. Heating devices sleeve the heating cylinder. The lower end of the heating cylinder is provided with a diversion pipe communicated with a flow channel. The screw rod is matched with the flow channel and rotatably arranged in the same. A heating pipe is arranged in the lower end of the screw rod. The spiral upper-end glue feeding device has the advantages that the the heaters sleeving the heating cylinder are high in power and heat transferring efficiency, the screw rod extrudes hot melt glue for plasticizing, and glue melting speed is high, besides, by heating in the screw rod and constantly rotary stirring, mixing and extruding under driving of the reducing pneumatic motor, the melt glue is constantly extruded out of the heating cylinder, thus the problems of the traditional cylinder extruding glue of idle running and melting difficulty of solid particles in a cylinder glue extruding cylinder core are solved, and glue melting efficiency and quality is effectively increased.

Owner:NANXING MACHINERY CO LTD

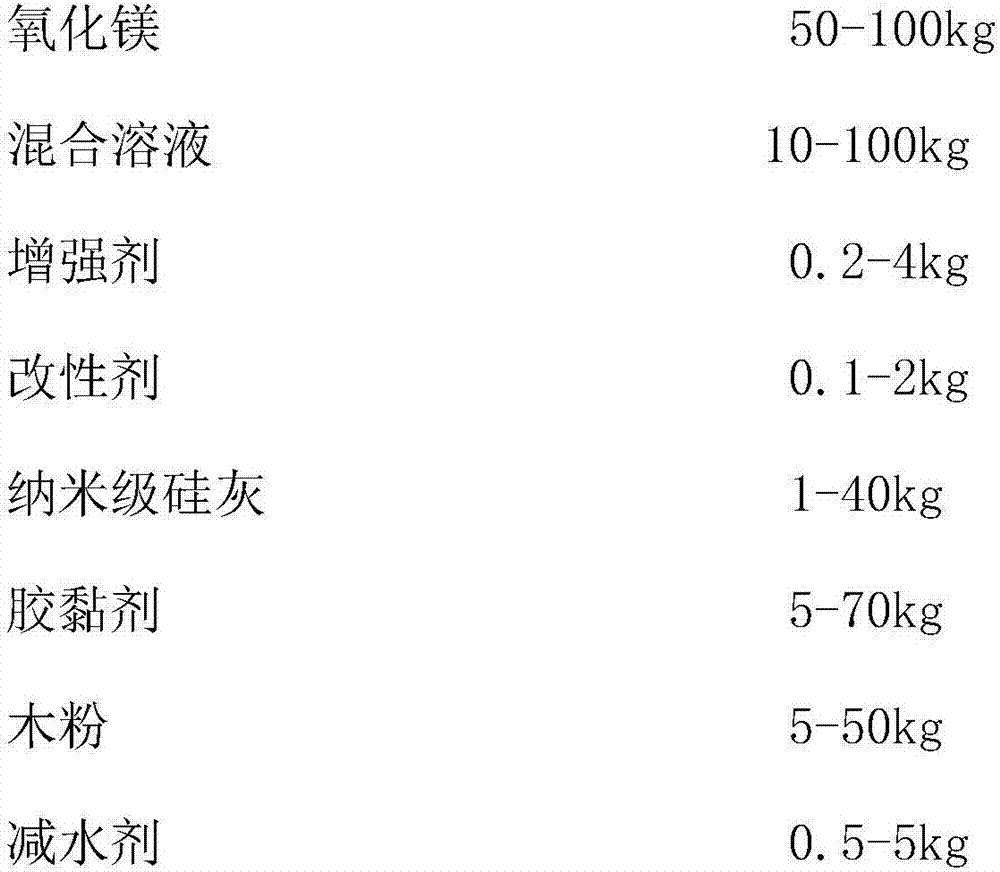

Board production process and modification of inorganic glue

InactiveCN107498657ASolve process problemsReduce energy consumptionOther plywood/veneer working apparatusNon-macromolecular adhesive additivesEngineeringEnergy consumption

The invention provides a board production process and modification of inorganic glue. A spreading machine spreads a face material to a spreading machine conveying belt; the inorganic glue is conveyed to a coating machine through a pipeline at the lower end of a glue hopper; the coating machine conveys the inorganic glue to a glue spraying device; the glue spraying device is provided with a plurality of spraying holes; the inorganic glue is coated to a single board at the upper end of the conveying belt through the spraying holes; an unreeling machine paves the reeled single board; a thickness-fixed roller rolls on the single board; the glue spraying device, the unreeling machine and the thickness-fixed roller apply glue, unreel and roll synchronously, and the above pavement sequence is the basic odd number pavement; and after the face board is paved, the thickness-fixed roller rolls evenly to fix the thickness, then short cutting and prepressing are conducted according to the board length, the prepressing is cold pressing and is 0.1-1 MPa, the cold pressing time is 3-24 hours, and thus molding is achieved. The prepared product does not contain formaldehyde and has the good bonding strength, the problems that in the production of plywood, the process is complex, energy consumption is high, pollution is high, and formaldehyde in finished products is released are solved, the procedure is simplified, the production efficiency is high, and energy consumption is reduced.

Owner:白光瑞

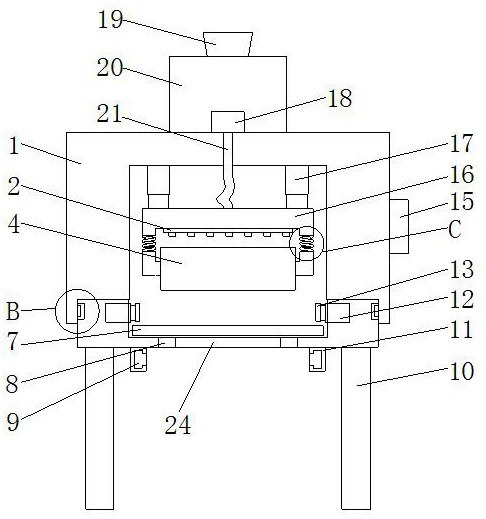

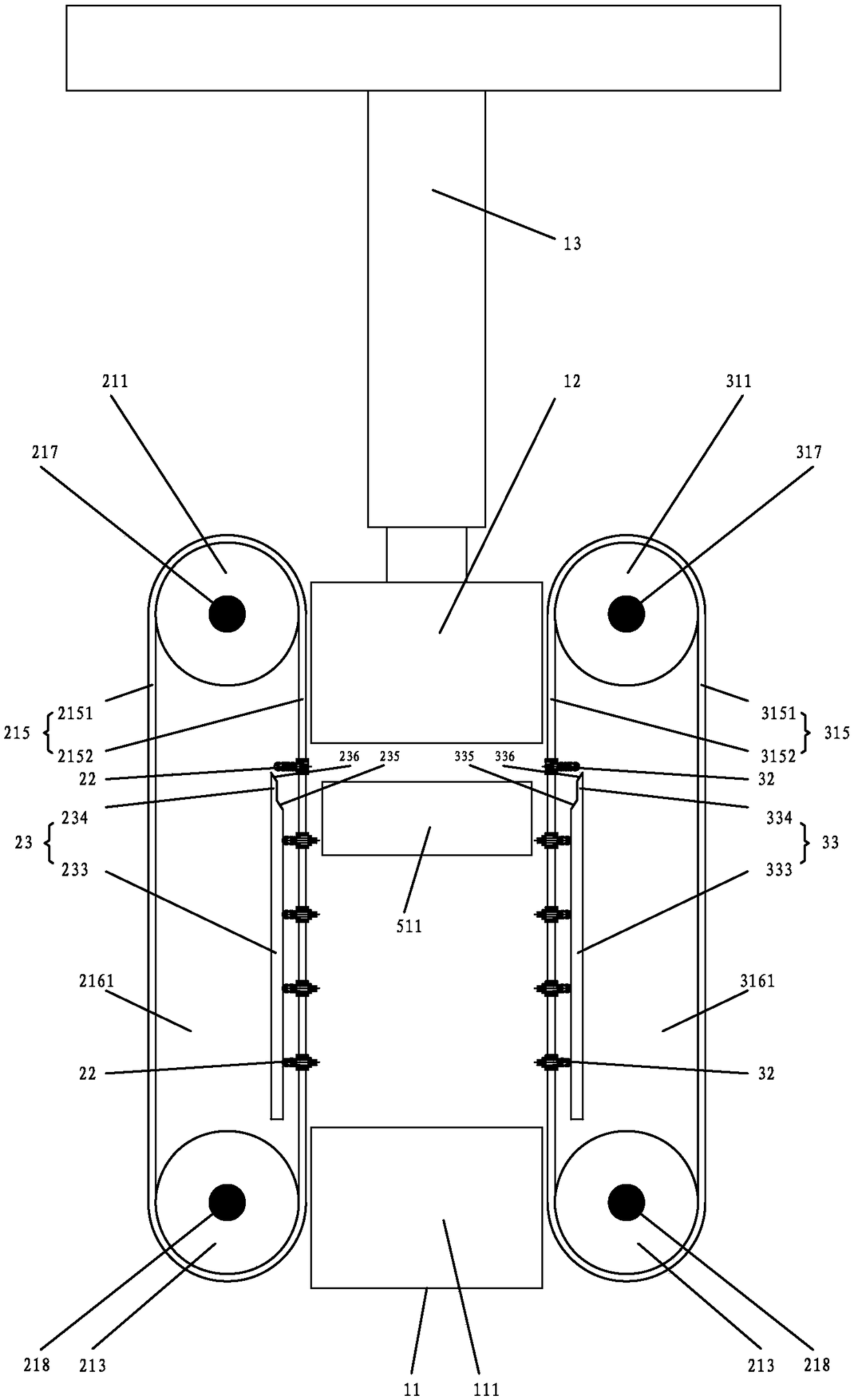

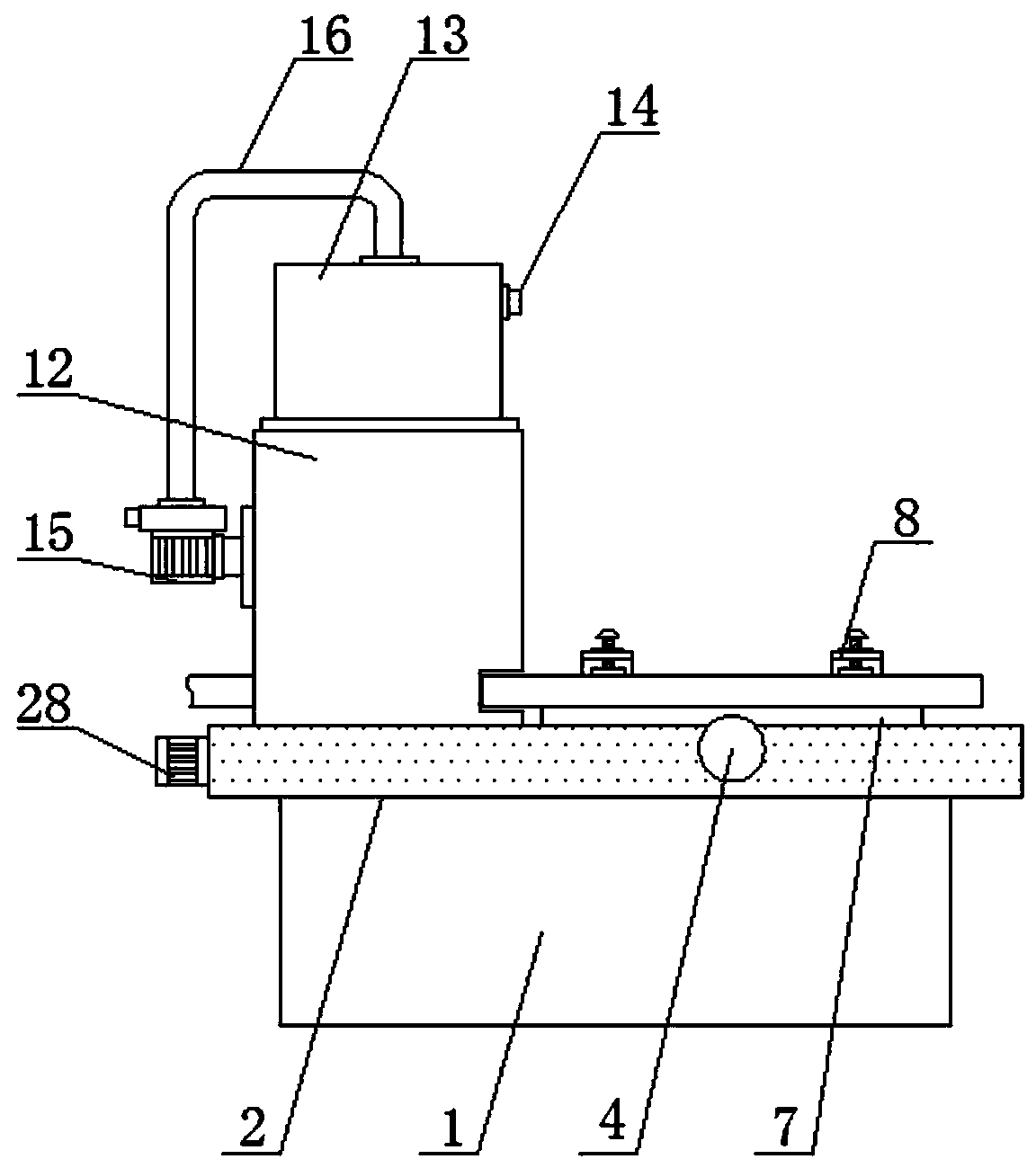

Automatic plate feeding hot press

ActiveCN108943207AAvoid breakingAchieve precise positioningOther plywood/veneer working apparatusPlywood pressesHeat pressHot pressing

The invention provides an automatic plate feeding hot press. In the actual working process, the automatic plate feeding hot press further comprises a controller for controlling a hot pressing device,an arranging shaping device, a rubberizing device and a supplying device; and under control of the controller, the supplying device conveys template slabs to the arranging shaping device one by one, all the template slabs are rubberized through the rubberizing device, and then the template slabs are pressed into plywood through the hot pressing device. All abutting wheels can stably and smoothly guide and support the movement of horizontal cross beams operating periodically. Moreover, lower end steps which are inclined and arranged step by step can be adapted to the height of the template slabs arranged layer by layer, and all support parts can be rebounded in time without scraping the lower template slabs and a hot pressing base plate. Compared with the prior art, through the automatic plate feeding hot press, the template slabs can be transported, arranged, shaped, rubberized and hot-pressed in one time smoothly, stably and automatically, and the efficiency and practicability are high.

Owner:漳州鑫华成机械制造有限公司

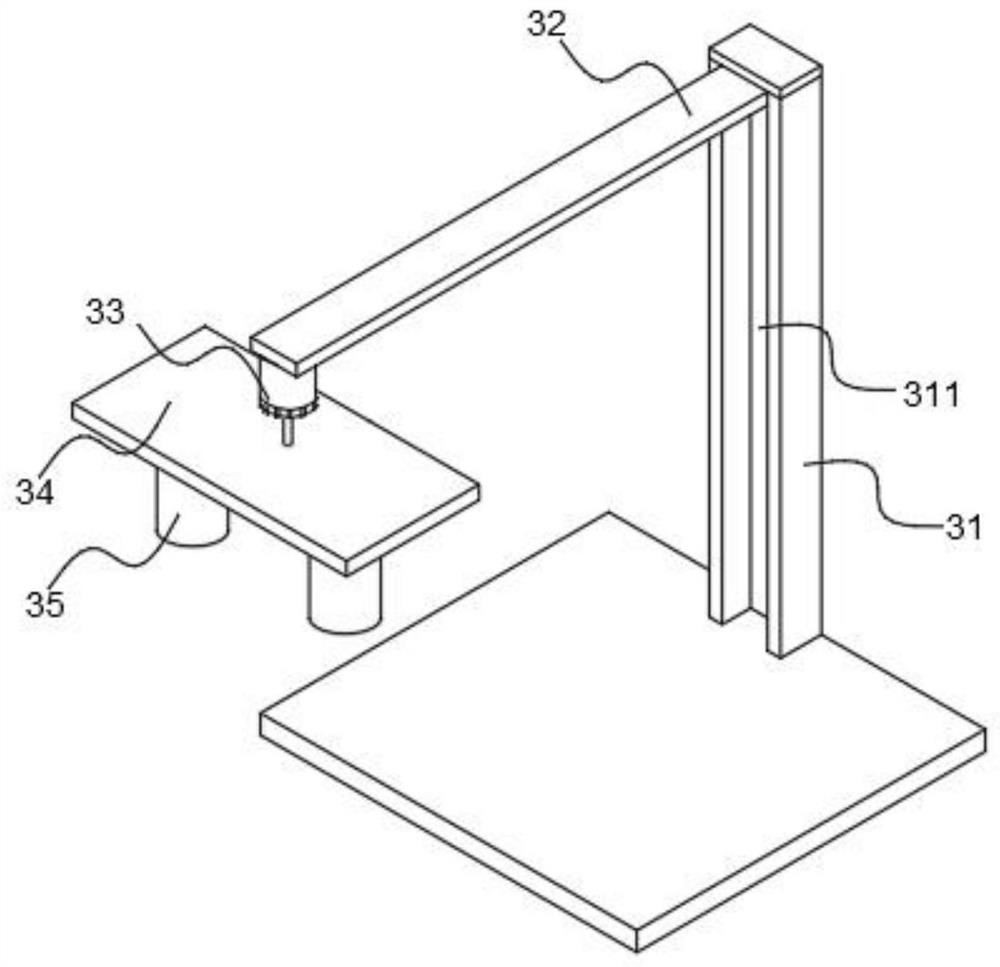

Gluing and sealing equipment for multi-layer splicing position of plywood

InactiveCN112276758AEasy to remove by sandingEasy to handleLiquid surface applicatorsGrinding machinesStructural engineeringWorkbench

The invention discloses gluing and sealing equipment for a multi-layer splicing position of plywood. The gluing and sealing equipment for the multi-layer splicing position of the plywood comprises a base, a feeding device and a workbench arranged on the side face of the base, a stand column is arranged on the side, away from the base, of the workbench, the side face of the stand column is connected with a screw rod, the screw rod is connected with a grinding device, a glue spraying device and a compacting device through threads, the glue spraying device is arranged between the grinding deviceand the compacting device, the feeding device comprises a telescopic rod, a rotating rod and a second rotating rod, and the telescopic rod is rotatably connected with the rotating rod. According to the gluing and sealing equipment, by arranging the feeding device, feeding of the device in the plywood manufacturing process is facilitated; by arranging the grinding device, dust and impurities on thesurface of a plate can be ground and removed in time conveniently before gluing is conducted; by arranging the glue spraying device, glue spraying treatment can be conducted on plywood conveniently;and then a gluing device is used for uniformly coating the surface of the plywood with glue.

Owner:TAOJIANG HONGSEN WOOD IND

Edge sealing machine for manufacturing seamless plates

InactiveCN110712266AEasy to fixAvoid position shiftDomestic articlesGlue gunsElectric machineryWorking environment

The invention relates to the technical field of edge sealing machines, and discloses an edge sealing machine for manufacturing seamless plates. The edge sealing machine comprises a base; a platform isfixedly mounted at the top of the base; a top port is formed in the right side of the top of the platform; a driving motor is fixedly mounted on the front surface of the platform; and a first lead screw fixedly sleeves the other end of an output shaft of the driving motor. In the edge sealing machine for manufacturing the seamless plates, through arrangement of a thread rod, a rubber soft pad, anair pressure cylinder and a clamping plate, and due to cooperation between the thread rod and the rubber soft pad, an excellent fixing effect on the plates is achieved, and the position deviation ofthe plates in the edge sealing process is effectively prevented; and due to cooperation between the air pressure cylinder and the clamping plate, glue in a glue bottom box can be stopped to prevent leakage, meanwhile, the tidiness of the working environment can be guaranteed, the production cost can be saved, and the practicability of the edge sealing machine is improved.

Owner:广州智法装饰材料有限公司

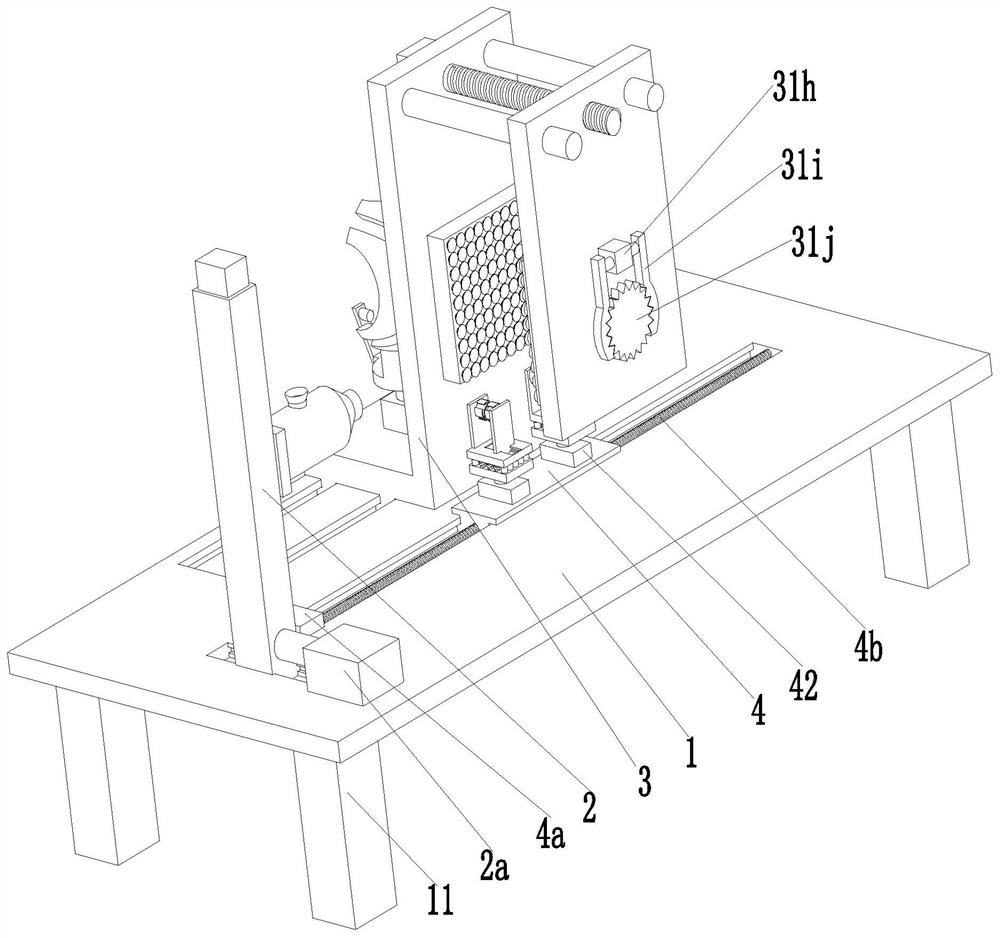

Method for moving connecting and cutting in woodworking

ActiveCN110815435AImprove continuityImprove docking efficiencyProfiling/shaping machinesWood veneer joiningBattenIndustrial engineering

The invention provides a method for moving connecting and cutting in woodworking, and belongs to the technical field of timber processing. Through the method, the problem that an existing wood connecting method does not have continuity, and consequently the wood connecting efficiency is affected is solved. The method for moving connecting and cutting in woodworking comprises the steps that a, feeding is conducted, specifically, a machine table is arranged, a first clamp assembly and a second clamp assembly are arranged on the machine table, and a second wood batten with the two combed ends ismoved onto the second clamp assembly located at the initial position, so that the second clamp assembly clamps the second wood batten, and a first wood batten with the two combed ends is transferred onto the first clamp assembly located at the initial position, so that the first clamp assembly clamps the first wood batten; and b, moving connecting is conducted, a glue spraying machine is further arranged on the machine table, the front end of the machine table is provided with a cutting mechanism, and the first wood batten and the second wood batten are driven by the first clamp assembly and the second clamp assembly correspondingly to move towards the cutting mechanism synchronously, so that the glue spraying machine and the first clamp assembly or the second clamp assembly keep synchronous moving. Through the method for moving connecting and cutting in woodworking, the wood connecting and cutting efficiency can be improved.

Owner:TAIZHOU EVOK MASCH CO LTD

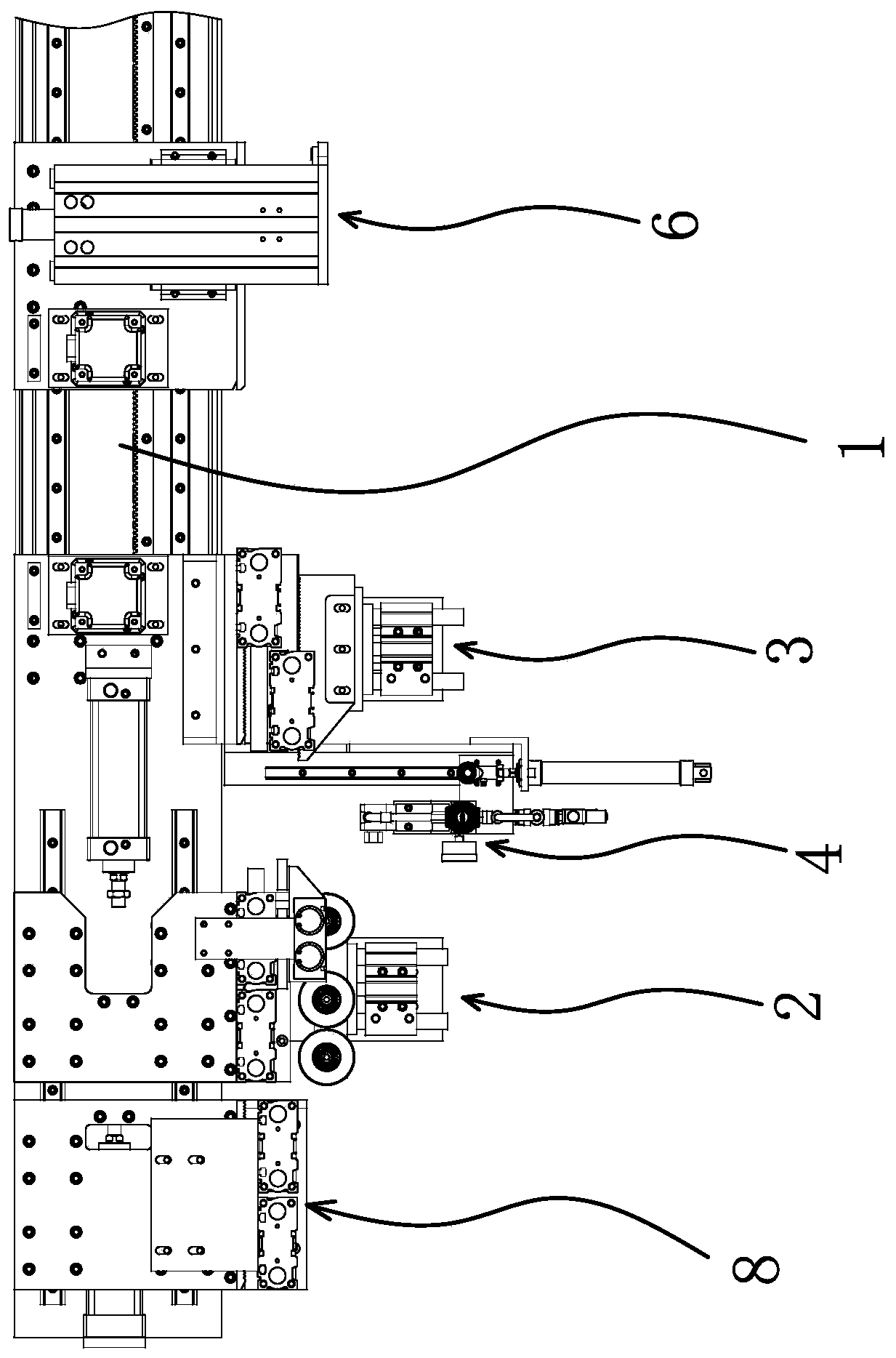

Novel batten lengthening device and method thereof

InactiveCN112873450AQuick cutIncrease connection flexibilityProfiling/shaping machinesWood veneer joiningBattenMechanical engineering

The invention discloses a novel batten lengthening device and a method thereof. The novel batten lengthening device mainly comprises battens, a first conveying guide rail, a batten two-end cutting device, a second conveying guide rail, a glue spraying device, a batten flattening device, a segmented heating device, a batten grinding device and a third conveying guide rail. The first conveying guide rail, the second conveying guide rail and the third conveying guide rail are each provided with a plurality of batten rails, the battens are placed on the batten rails, and the batten two-end cutting device is arranged in the gap between the first conveying guide rail and the second conveying guide rail. The glue spraying device, the batten flattening device and the segmented heating device are sequentially arranged over the second conveying guide rail, and the batten grinding device is arranged in the gap between the second conveying guide rail and the third conveying guide rail. The batten two-end cutting device is adopted to enable the front battens and the rear battens to be embedded with each other, then the battens are subjected to surface polishing after being solidified by glue, the connecting flexibility is high, and the joint is stable. Meanwhile, the multiple sets of battens can be lengthened through the multiple rails, and the lengthening efficiency is higher.

Owner:沭阳凤凰画材有限公司

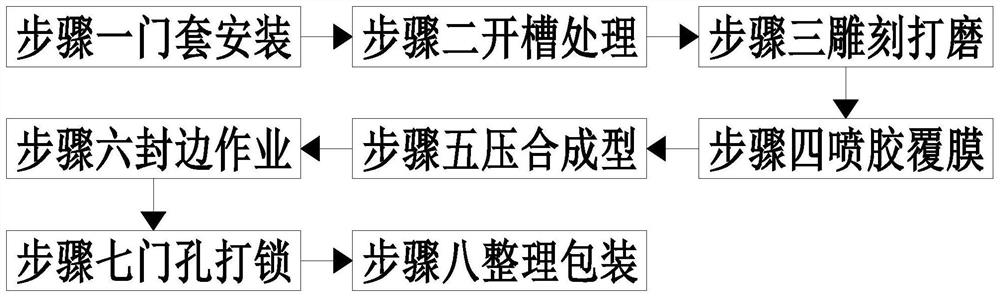

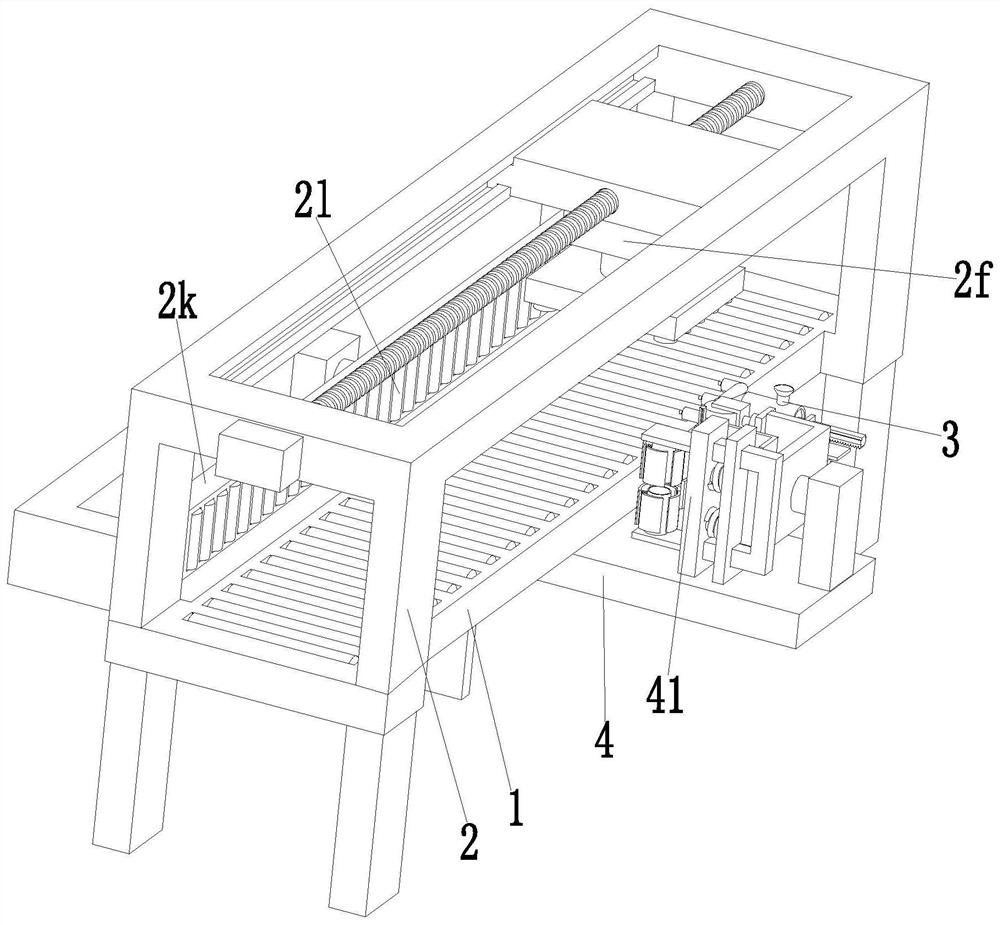

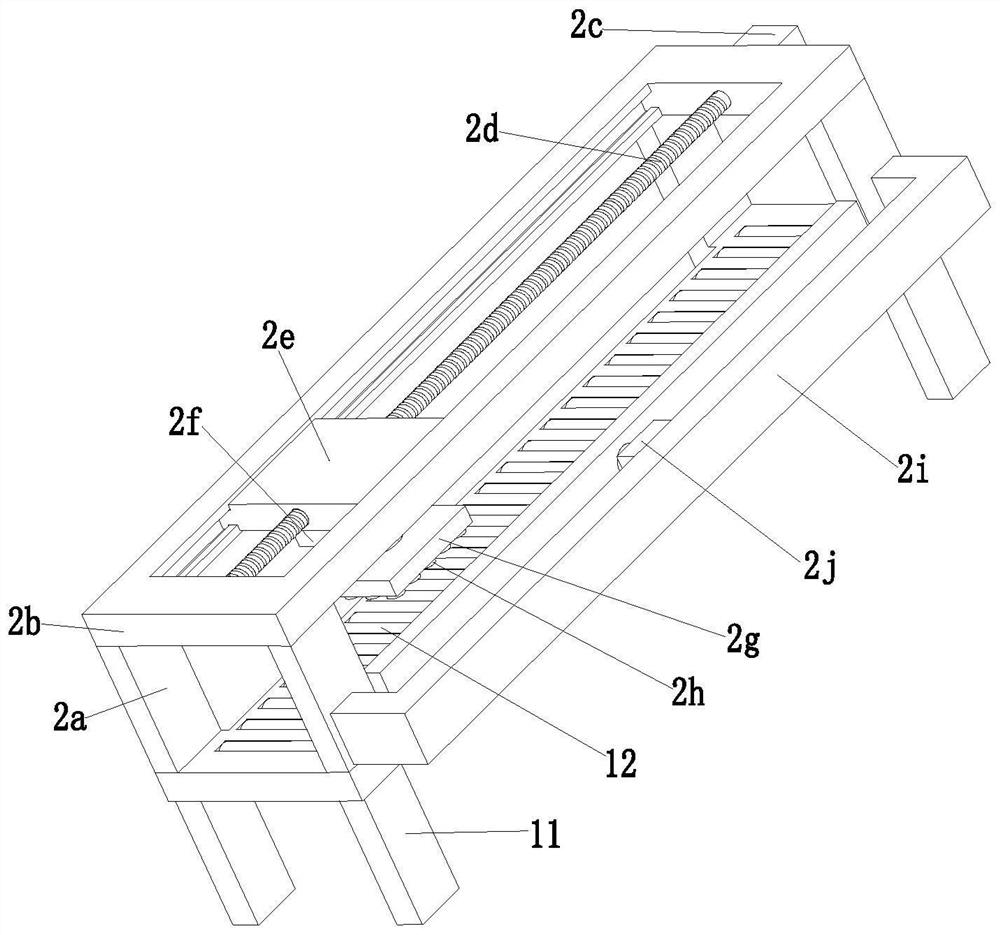

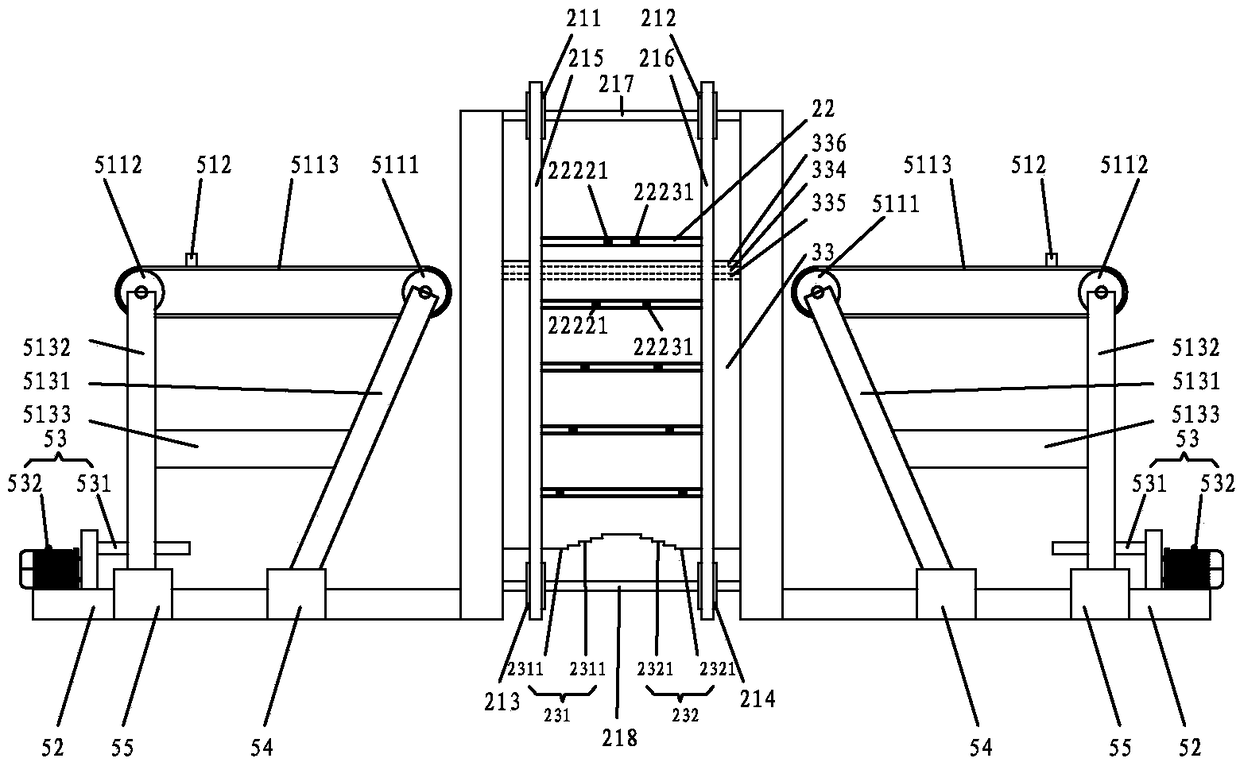

Production method of environment-friendly paint-free door

ActiveCN111761679AQuality improvementImprove efficiencyOther plywood/veneer working apparatusWood mortising machinesAdhesiveIndustrial engineering

The invention relates to a production method of an environment-friendly paint-free door. The production method mainly comprises the following steps of plate cutting, slotting treatment, carving and grinding, adhesive spraying and film laminating, pressing molding, edge banding operation, door lock perforating, finishing and packaging, etc. The used paint-free door plate edge banding equipment comprises a bottom plate, a moving device, an adhesive spraying device and an edge banding device. The production method can solve the difficult problems existing in the existing door plate edge banding process, as follows: a, during traditional door plate edge banding, a worker needs uses an adhesive spraying machine to spray adhesive on a door plate, and then the adhering operation of edge bands iscarried out; when the edge bands are manually adhered, a board is easy to skew, and the force on the edge banding position is not uniform so that the edge banding quality is affected; the effective ofmanually door plate edge banding is low, and the labor intensity is high; and b, in the operation process of the existing door plate edge banding equipment, the air between the edge bands and a doorend face is not easily drained, and the edge bands bubble easily. The quality and efficiency of door plate edge banding are improved.

Owner:宿迁普奈家居科技有限公司

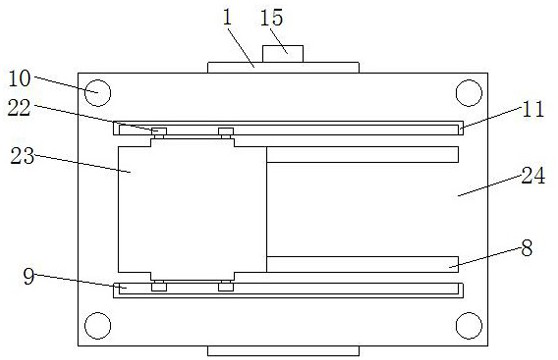

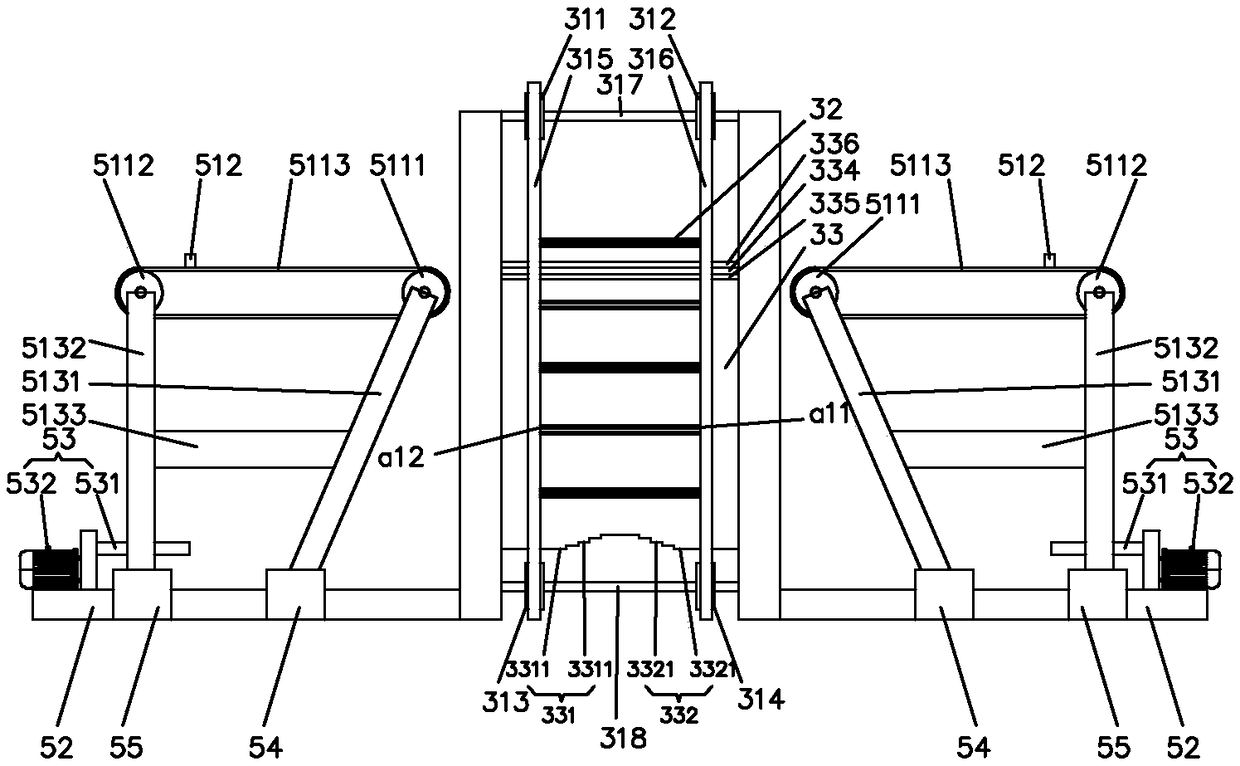

Efficient hot-pressing machine

ActiveCN108908537AAchieve precise positioningStable deliveryOther plywood/veneer working apparatusPlywood pressesMechanical engineeringScratching

The invention provides an efficient hot-pressing machine, which comprises a controller for controlling a hot-pressing device, an arrangement device, a glue distribution device and a supply device in apractical operating process. Under control of the controller, mould plate blanks are conveyed to the arrangement device one by one by the supply device, then subjected to glue distribution by the glue distribution device and finally pressed together to form a plywood by the hot-pressing device. Stable and smooth guiding and supporting of each crossbeam in horizontal period motion can be realizedthrough each butting wheel. Inclined lower-end steps arrayed step by step adapt to height of the mould plate blanks arranged layer by layer, and each bearing portion is enabled to rebound timely to avoid scratching of lower mould plate blanks and a hot-pressing bottom plate. Compared with the prior art, the efficient hot-pressing machine has advantages of smoothness and stability in automatic conveying, arrangement, glue distribution and once hot-press forming of the mould plate blanks, high efficiency and high practicality.

Owner:漳州鑫华成机械制造有限公司

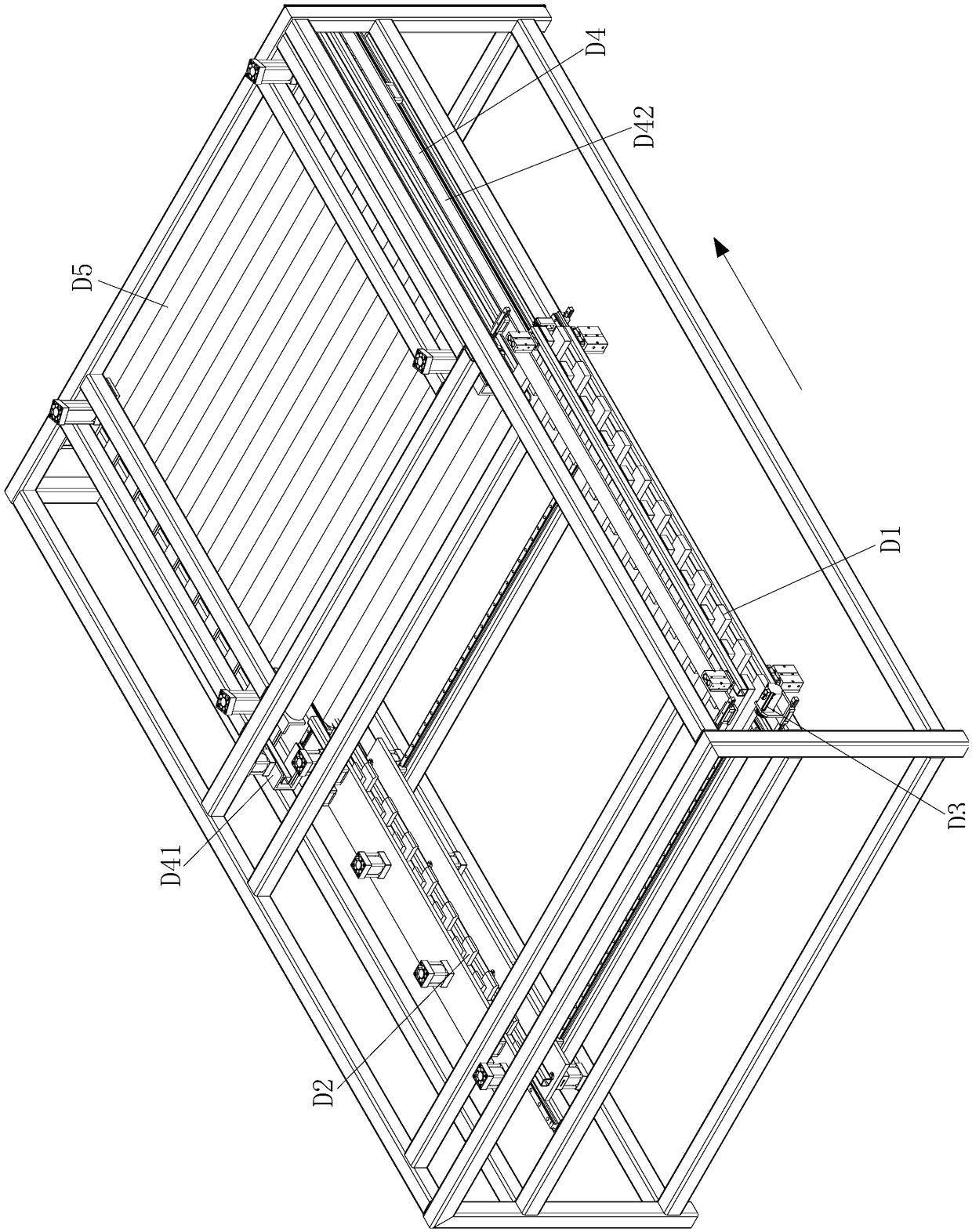

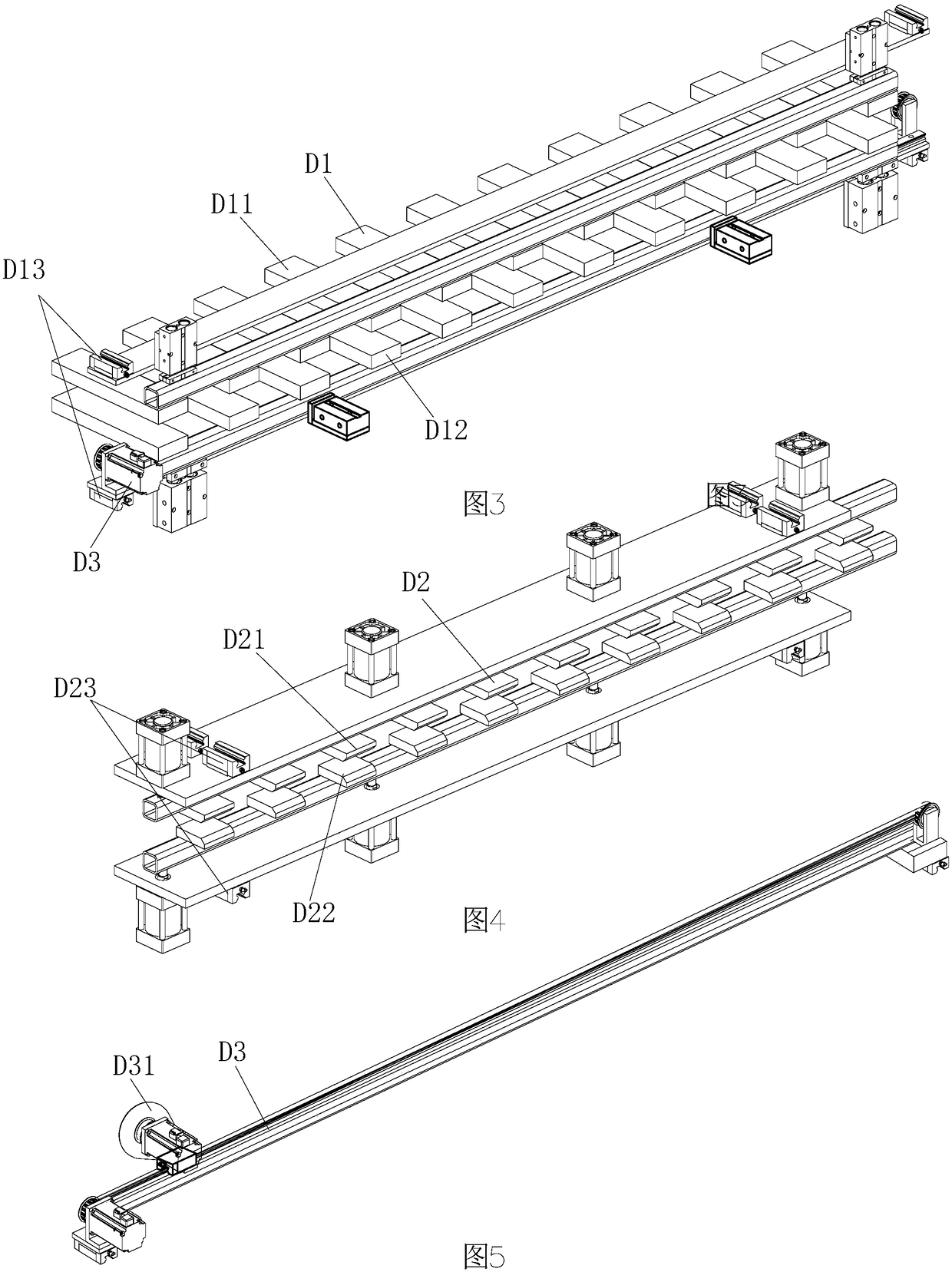

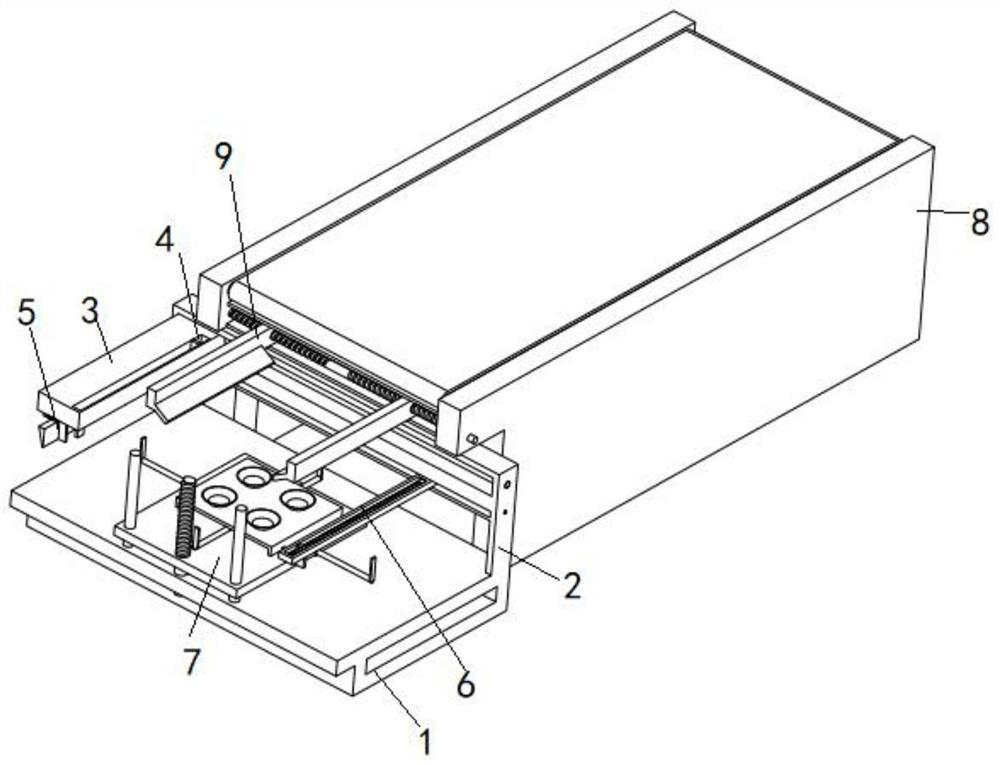

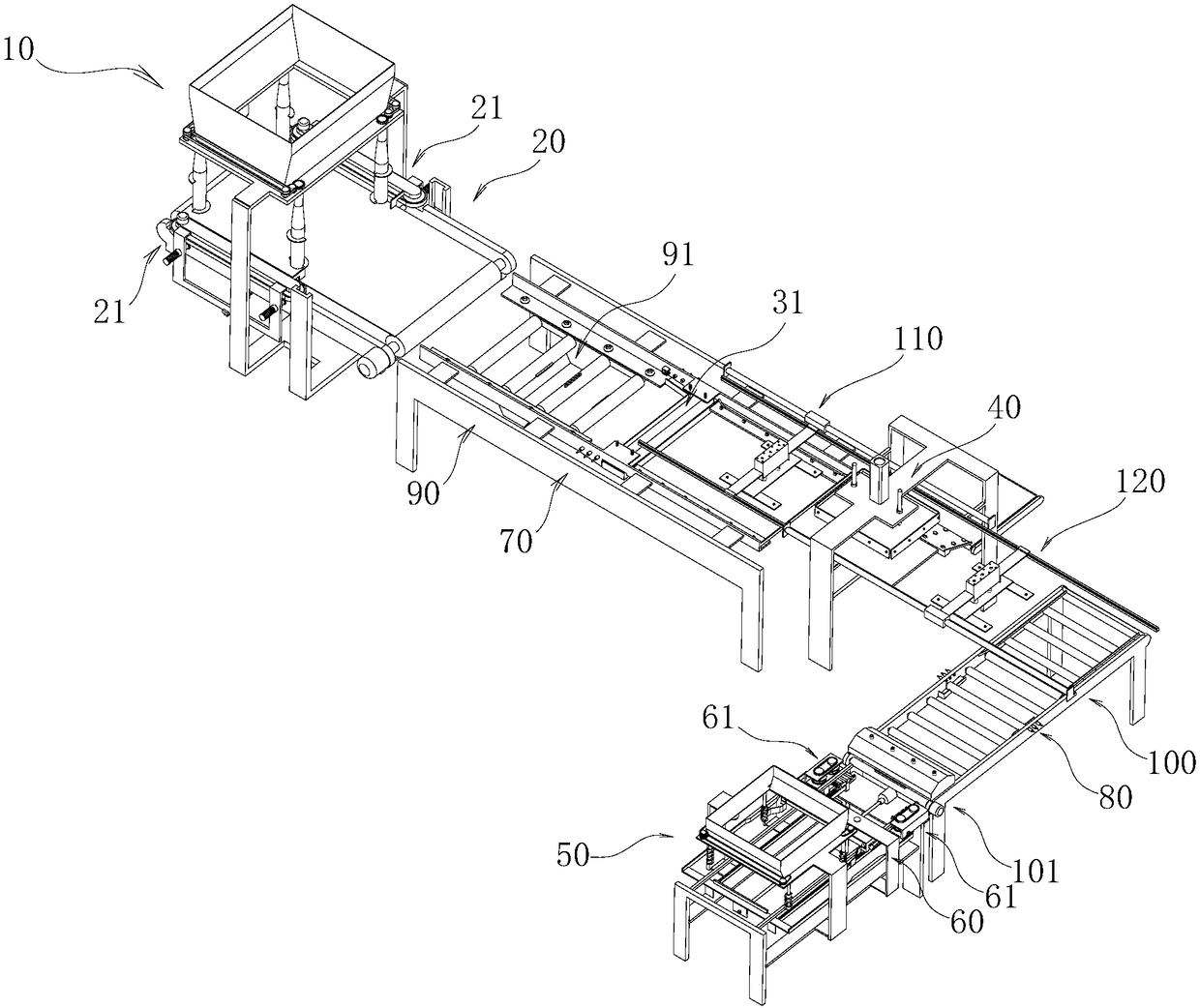

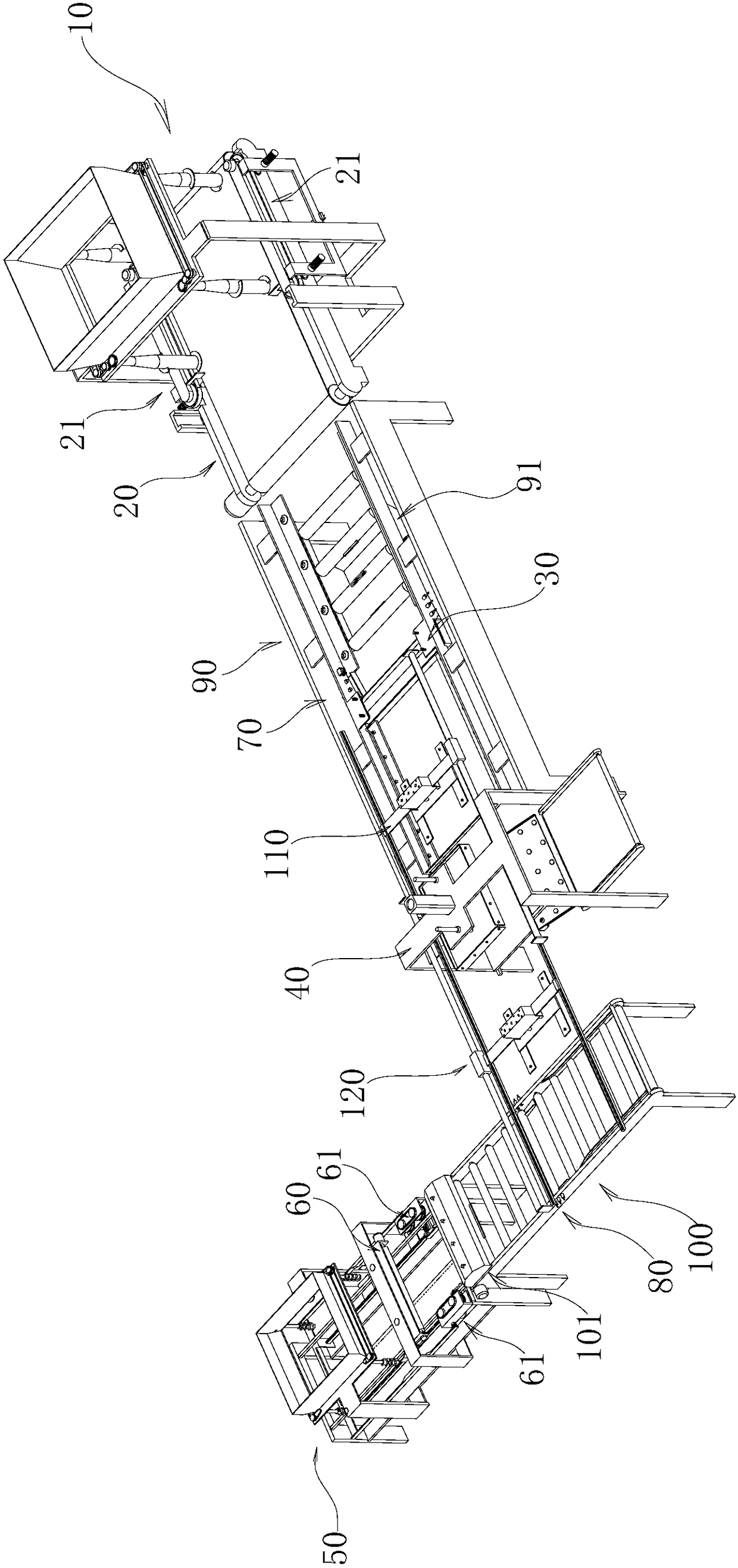

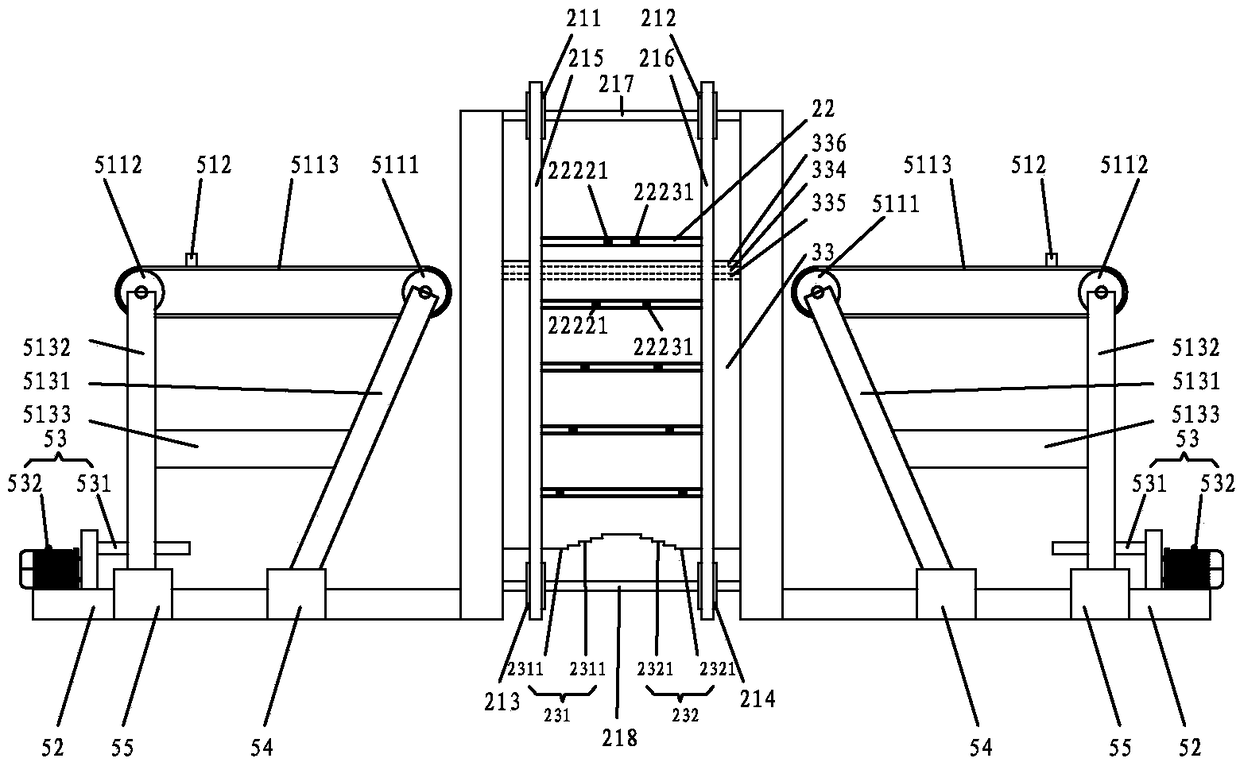

Automatic plate arranging line

ActiveCN109203125AAchieve precise positioningStable deliveryWood veneer joiningGlue gunsEngineeringMechanical engineering

The invention provides an automatic plate arranging line. The automatic plate arranging line comprises a cutting device, a plate arranging device, a gluing device and a controller for controlling a conveying device; under the control of the controller, template blanks are subjected to specified shape and size cutting through the cutting device firstly; the conveying device conveys the template blanks to the plate arranging device one by one; each template blank is coated by the gluing device; then the plate arranging device is used for carrying out plate arranging on the template blanks of all the layers; each abutting wheel can stablly and smoothly guide and support the movement of each horizontal bearing strip; and each lower end step which is inclined and arranged step by step can be adapted to the height of the template blanks arranged in a layer-by-layer mode, so that each bearing part can rebound in time without scratching the lower template blank and a lower bearing plate. Compared with the prior art, the automatic plate arranging line can convey, glue and arrange the template blanks smoothly, stable and automatically, the efficiency is high, and the practicability is high.

Owner:漳州鑫华成机械制造有限公司

Environment-protecting dispensing device with controllable adhesive spreading amount for plywood processing

The invention discloses an environment-protecting dispensing device with controllable adhesive spreading amount for plywood processing. The dispensing device comprises a pipeline, a fixing device andadhesive spraying heads, wherein a connecting rod is arranged on the pipeline in an integrally formed mode, and the other end of the connecting rod is arranged on an upper cover disc in an integrallyformed mode; and a first circular through groove is formed in the upper cover disc in a penetrating mode, a clamping groove is formed in the side of the first circular through groove, a calibration rod is arranged on one side of the upper end of the upper cover disc in an integrally formed mode, a first fixing convex ring is arranged on the side of the bottom end of the upper cover disc in an integrally formed mode, and a fixing device is arranged on the upper cover disc. According to the environment-protecting dispensing device with the controllable adhesive spreading amount for the plywood processing, the adhesive spraying heads with different diameters can be adjusted and converted according to needs in the adhesive spreading work, and the adhesive spreading amount is controlled so thatthe optimal adhesive spreading work can be achieved, waste is avoided while the adhesive spreading work quality is guaranteed, therefore not only is the work efficiency improved, but also work economic benefits can be guaranteed.

Owner:宿州中和木业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com