Automatic plate feeding hot press

A technology of automatic board feeding and hot pressing, which is applied in veneer presses, plywood presses, forming/shaping machines, etc., and can solve the problems of high labor intensity, affecting the qualification rate, and dry glue of formwork blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

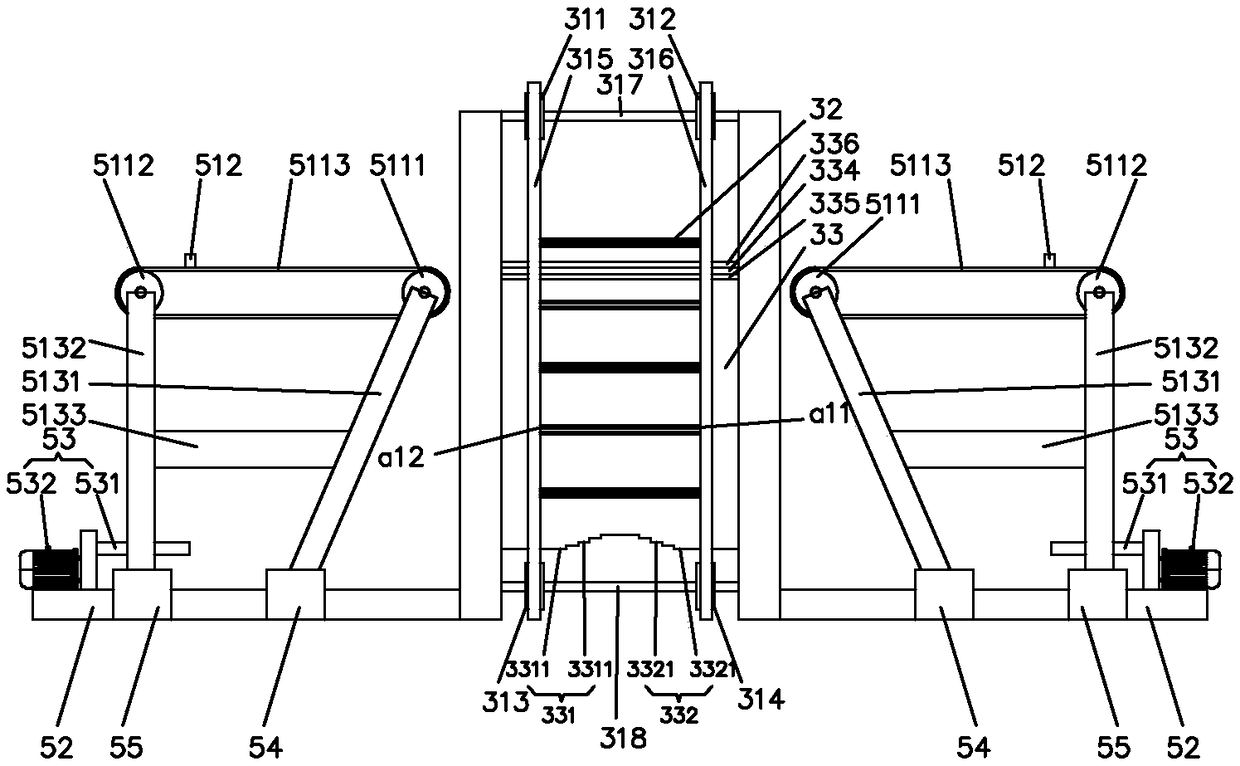

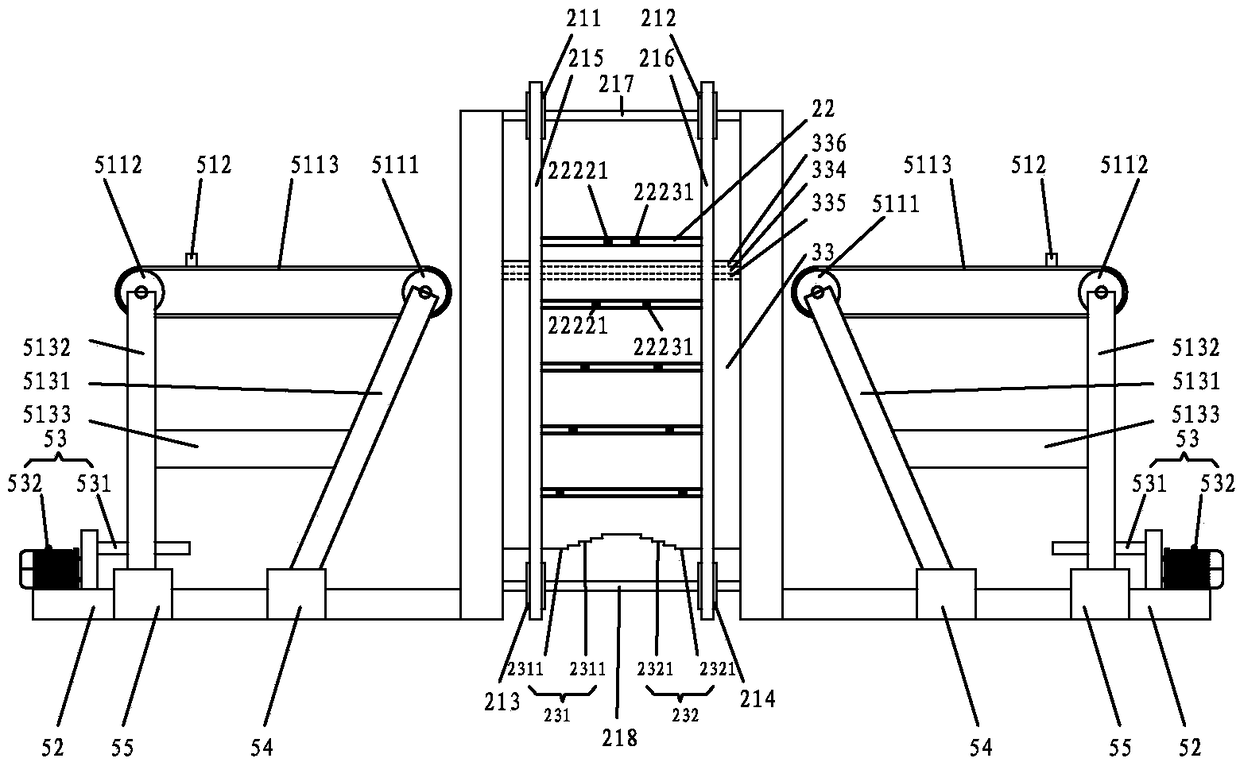

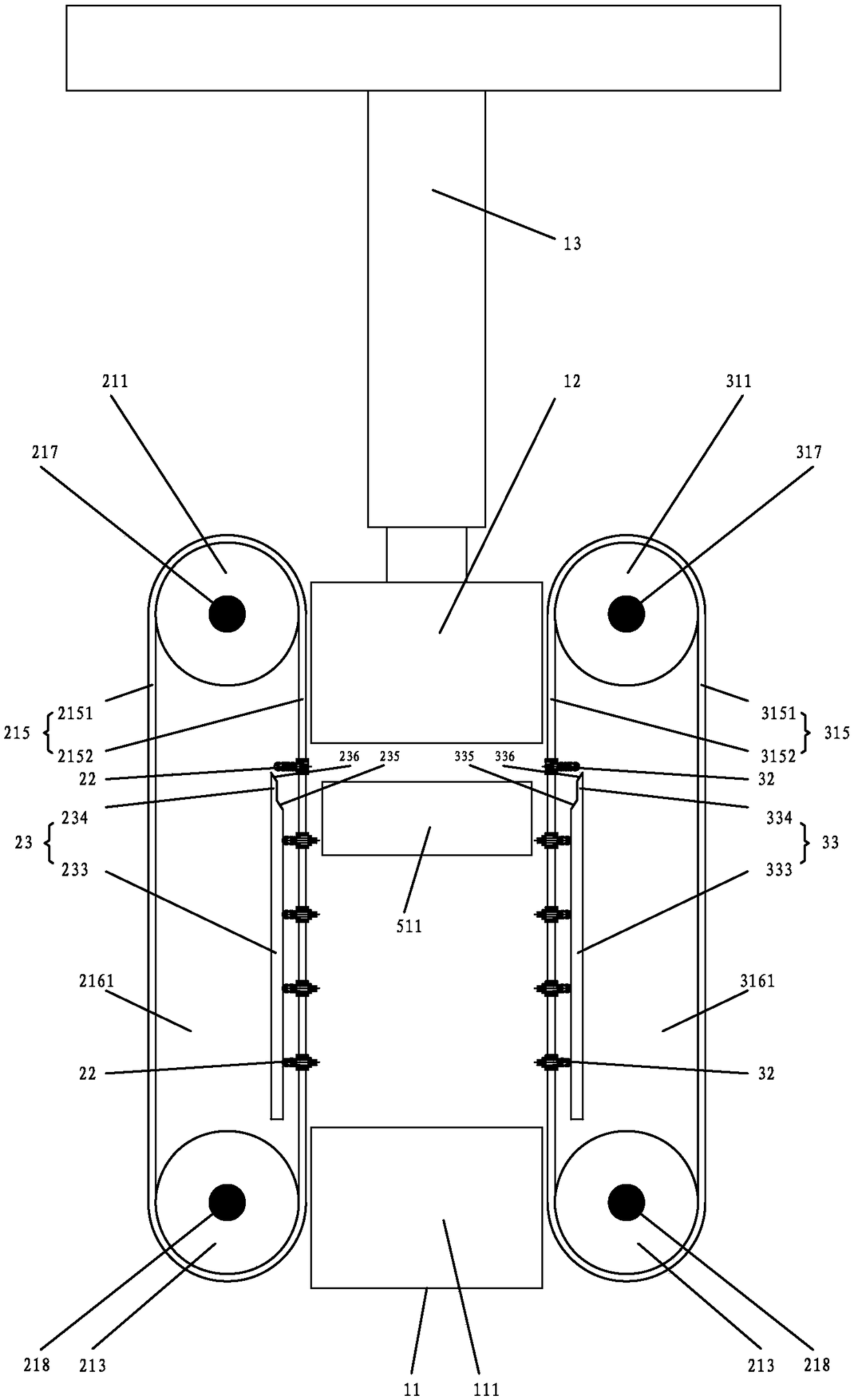

[0038] A kind of automatic plate-feeding hot press of the present invention, as Figure 1-10 As shown, it includes a hot pressing device, an arrangement and shaping device for arranging and shaping the template blank 7, a cutting device for cutting the solid rubber sheet 8 and the template blank 7, and a cloth for laying the solid rubber sheet 8 on the surface of the template blank 7. glue device, and the supply device for supplying template blank 7 to arrangement shaping device;

[0039] The hot-pressing device comprises a hot-pressing bottom plate 11 below, a mobile hot-pressing top plate 12 directly above the hot-pressing bottom plate 11, and a top plate lifting drive device 13 for driving the moving hot-pressing top plate 12 to lift; the hot-pressing bottom plate 11 has successively adjacent the first vertical side, the second v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com