Patents

Literature

67results about How to "Improve hot pressing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous and stable hot-pressing equipment for furniture boards

InactiveCN106493806AEnsure safetyQuality assurancePlywood pressesVeneer pressesEngineeringWood panel

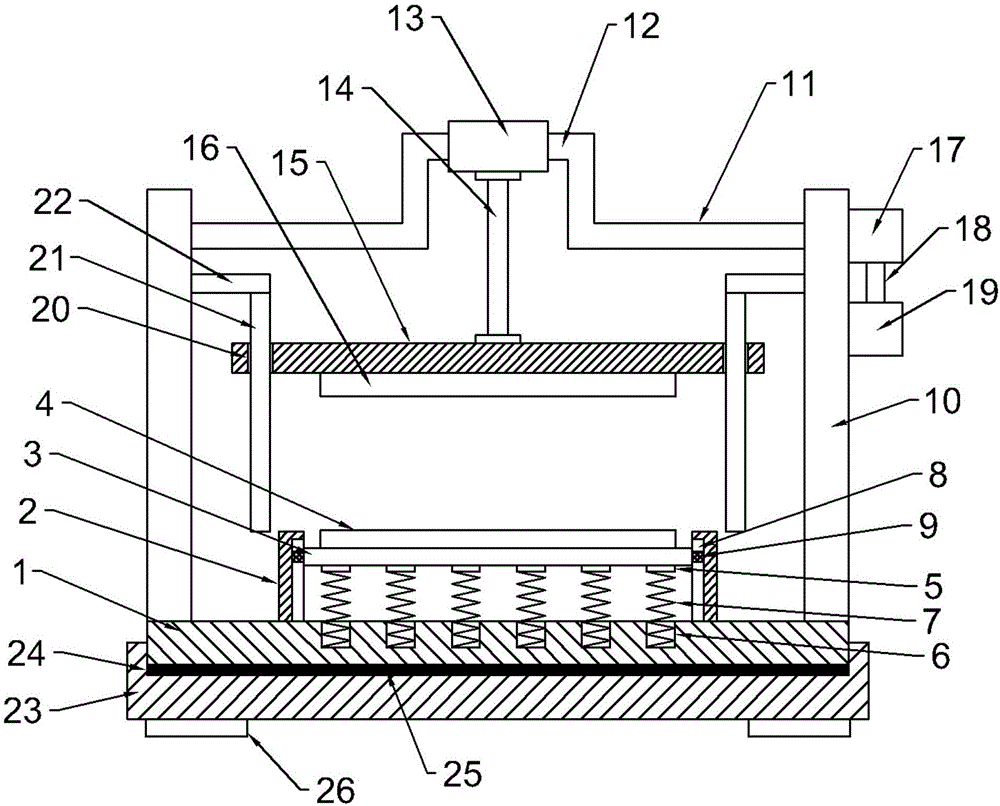

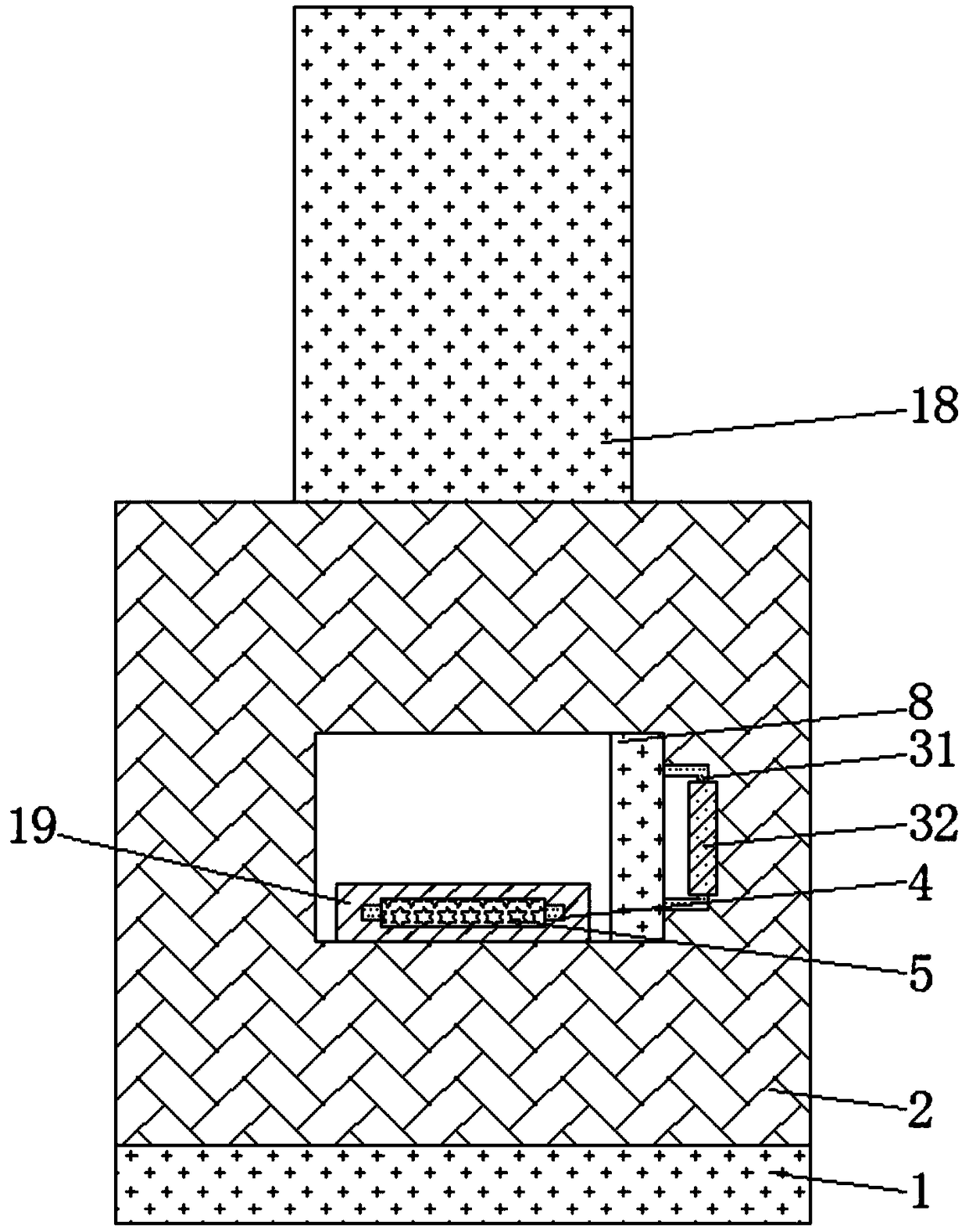

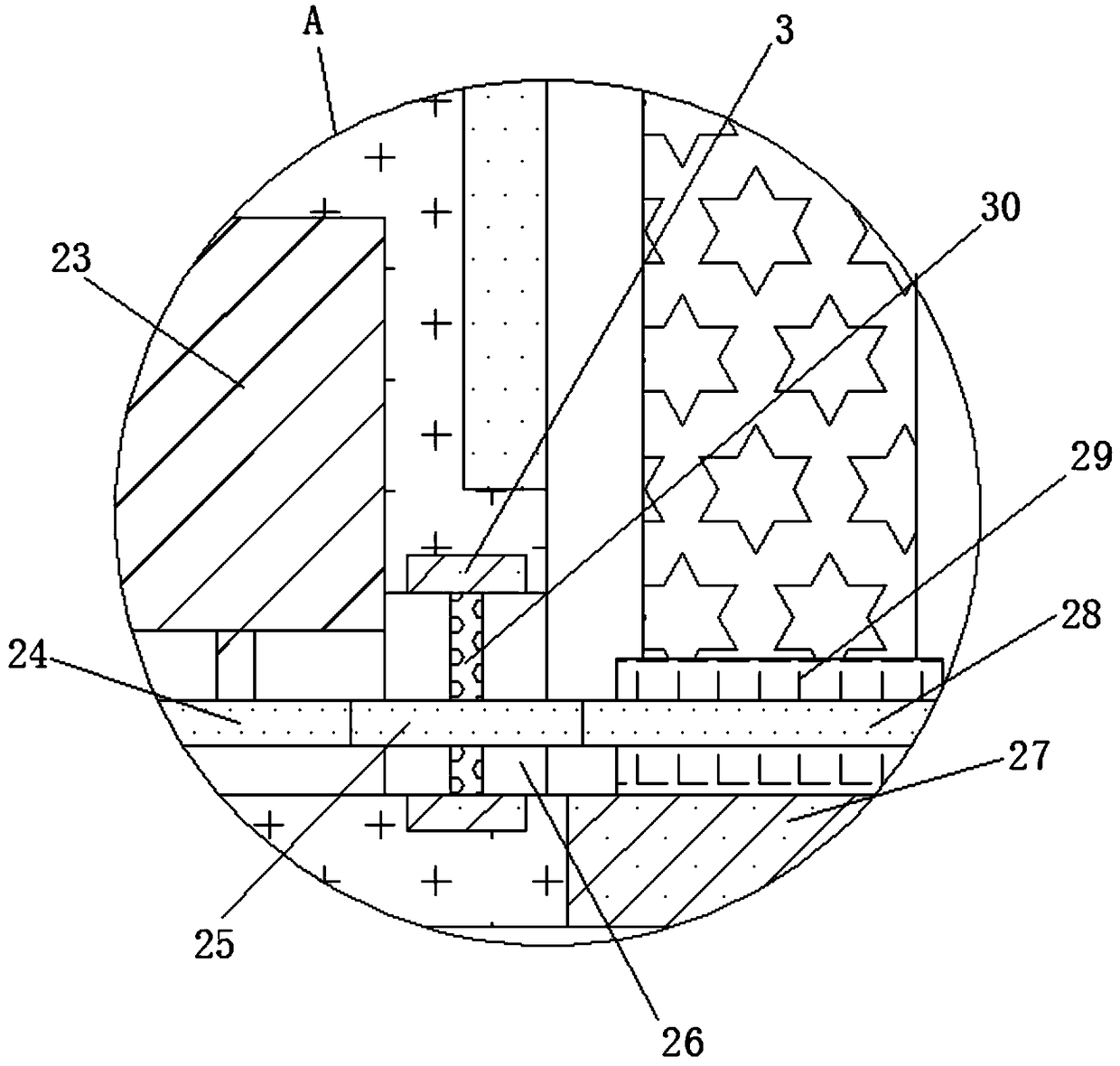

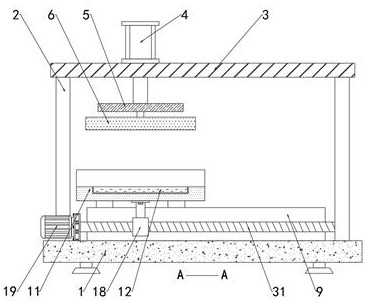

The invention discloses continuous and stable hot-pressing equipment for furniture boards. The equipment comprises a bottom plate, limiting plates, a supporting plate, a work table, connectors, grooves, buffering springs, sliding grooves and sliding blocks; supporting columns are installed at the upper end of the bottom plate, a crank shaft is arranged between the two supporting columns, a rod journal is arranged in the middle of the crank shaft and is provided with a shaft sleeve in a sleeved mode, the lower end of the shaft sleeve is connected to a lifting plate through a connecting rod, and a hot-pressing plate is arranged on the lower surface of the lifting plate; and guide holes are formed in the left end and the right end of the lifting plate, and guide rods penetrate into the guide holes. According to the equipment, the boards placed on the work table can be hot-pressed continuously, and the hot-pressing is higher relative to traditional hot-pressing; the supporting plate under the work table has the buffering function, the safety of the boards can be guaranteed in the process of continuous hot-pressing, damage caused by excessive hot-pressing force can be avoided, and the hot-pressing quality is guaranteed; and the overall base has the buffering performance, and therefore the hot-pressing equipment can be stable and safe and is suitable for being popularized and used.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

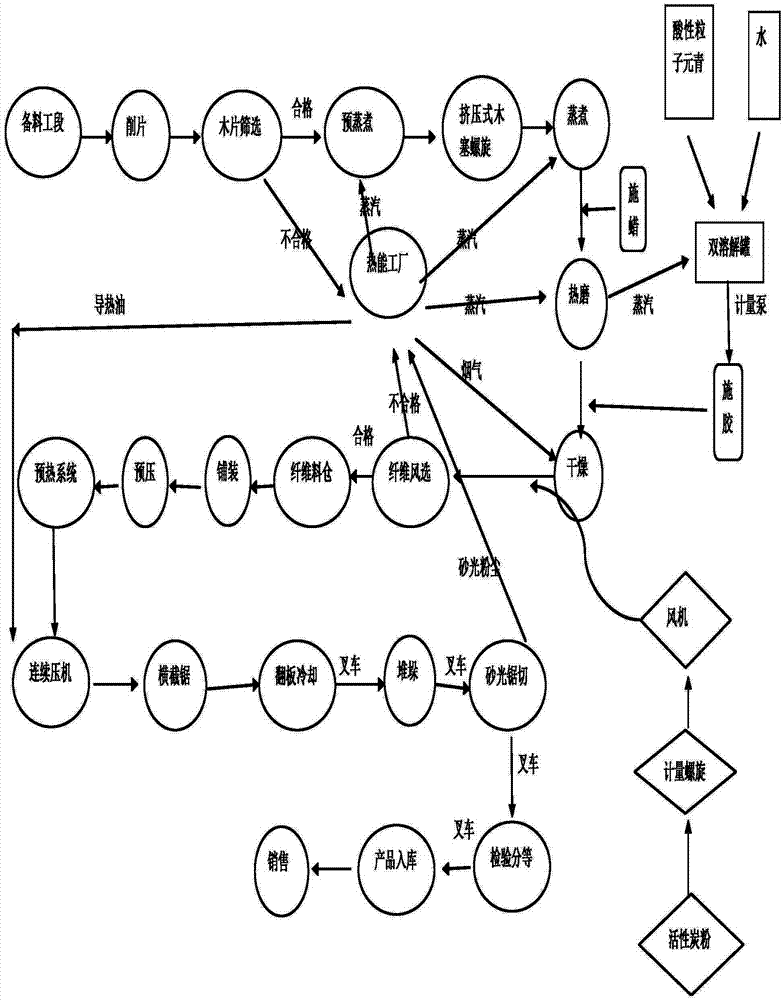

Preparing method for dampproof mould-proof low-formaldehyde medium and high density fiberboard

The invention discloses a preparing method for a dampproof mould-proof low-formaldehyde medium and high density fiberboard. In the hot grinding process, 200 kg / m<3>-230 kg / m<3> of a urea resin adhesion agent, 6 kg / m<3>-8 kg / m<3> of refined paraffin wax, 1.5 kg / m<3>-2 kg / m<3> of a curing agent and an acid particle deep black solution accounting for 1% to 2% of absolutely-dried fibers are added into a slurry spraying pipe; and in the drying process, 100-200-mesh activated carbon powder is added. Through the special process, the effects that the product quality is improved, the dampproof and mould-proof effects are improved, and the formaldehyde emission amount is reduced are achieved; and in the board heating process, a preheating system heats fibers in advance, the fiber temperature is improved, the fibers are softened, the hot press time is shortened, the hot pressing efficiency is improved, the product quality is improved, the working cost is reduced, and the working efficiency is improved.

Owner:JINAN CAIMING IND CO LTD

Method for establishing moisture content gradient of shaving board

ActiveCN103950085AReduce drying energy consumptionGuaranteed drying qualityWood working apparatusFlat articlesWood shavingsSurface layer

The invention discloses a method for establishing a moisture content gradient of a shaving board. The method consists of three technological links, namely drying in levels, respective glue mixing and respective paving. The drying in levels is characterized in that two levels of drying systems are established and a shaving sorting procedure is set up between the first-level drying system and the second-level drying system; the shavings subjected to drying in levels are respectively stored, metered and mixed with glue, and the moisture content difference between shavings in a core layer and shavings on a surface layer are stabilized; after the shavings are metered, the shavings are respectively paved, and the moisture content gradient is finally established on a cross section of a blank of the shaving board. By the moisture content gradient, the moisture on the surface of the blank is quickly vaporized in the heating process, a steam impact effect is generated, the heat transfer speed is improved, the temperature rise speed of the core layer is improved and the aims of shortening hot-pressing time and improving hot-pressing efficiency are finally fulfilled; in addition, by establishing the moisture content gradient of the blank, the performance and the surface quality of the finished shaving board can be obviously improved, the static bending intensity of the board is improved, the made shaving board is more smooth in surface, and the sanding loss of the shaving board is reduced.

Owner:SOUTHWEST FORESTRY UNIVERSITY

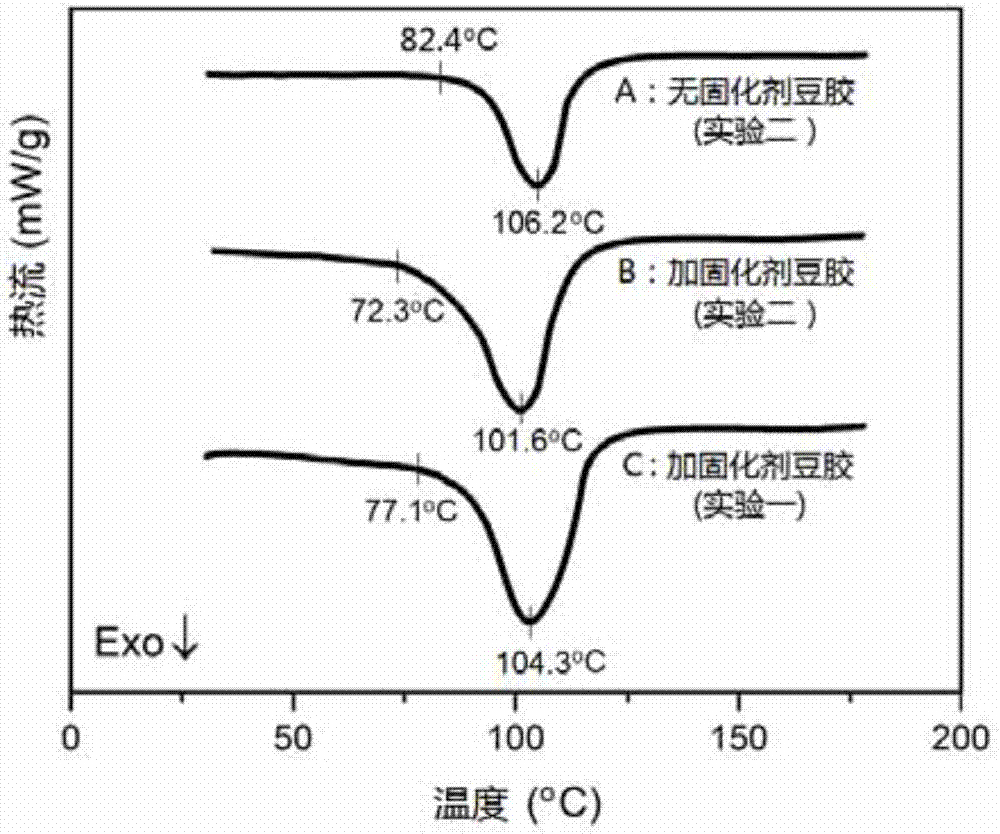

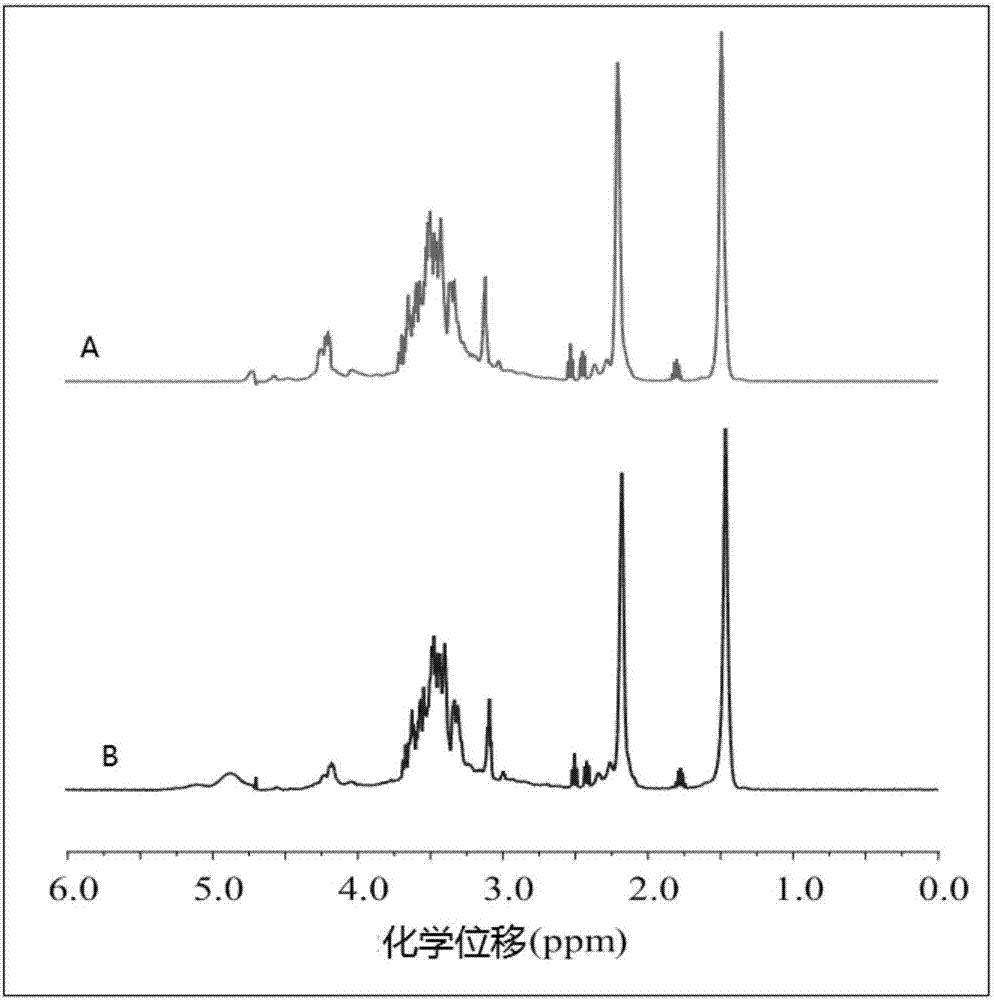

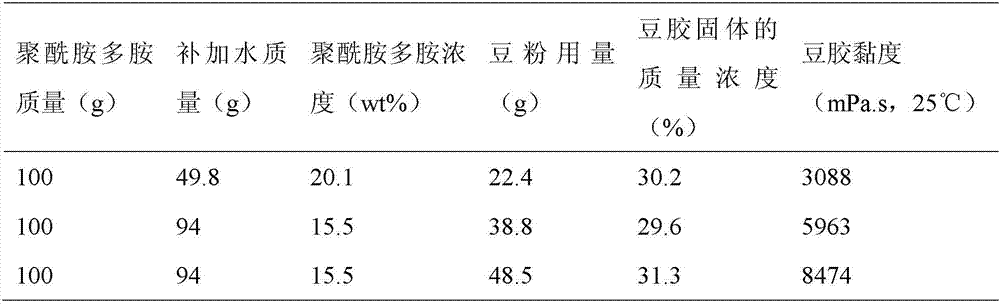

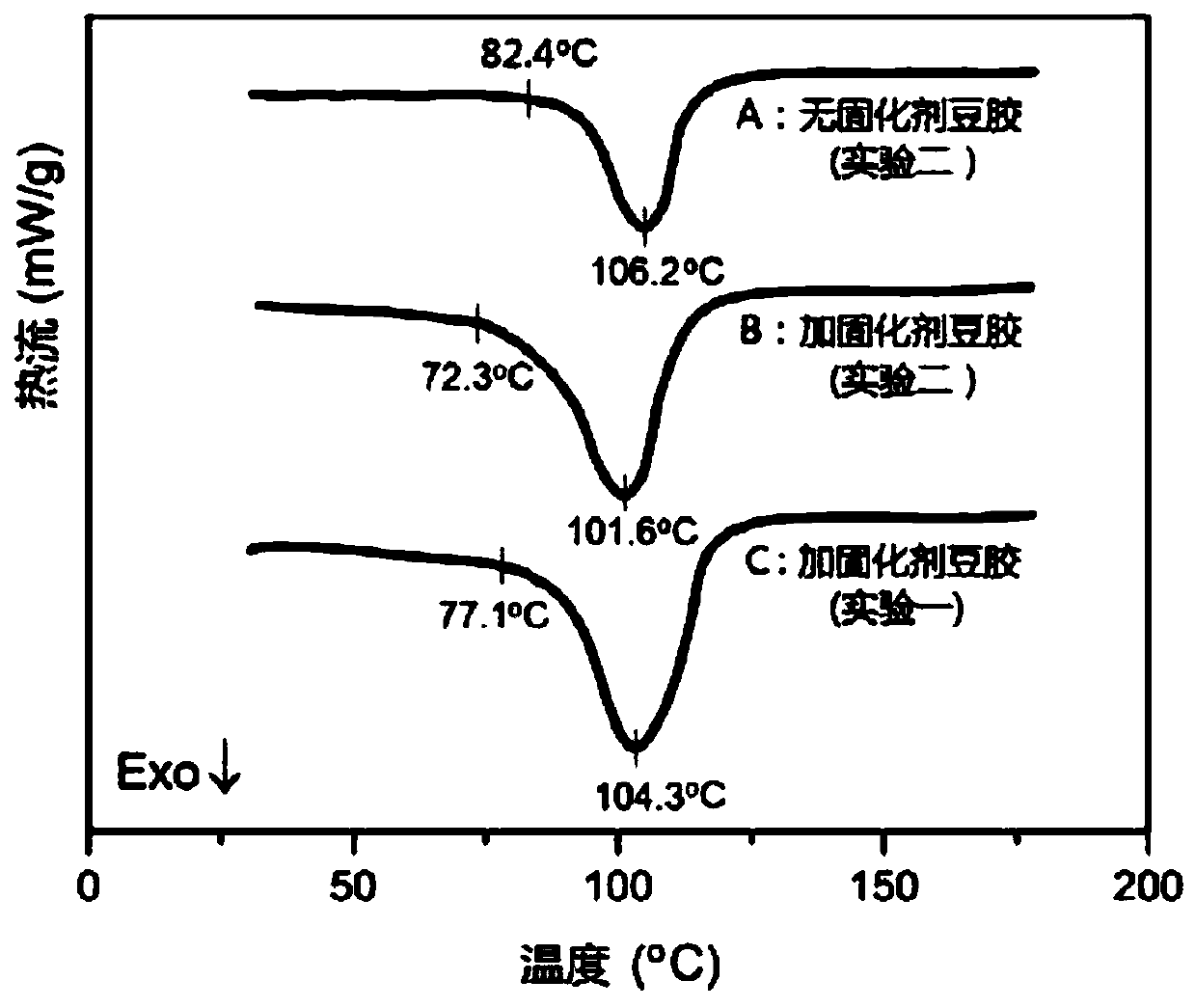

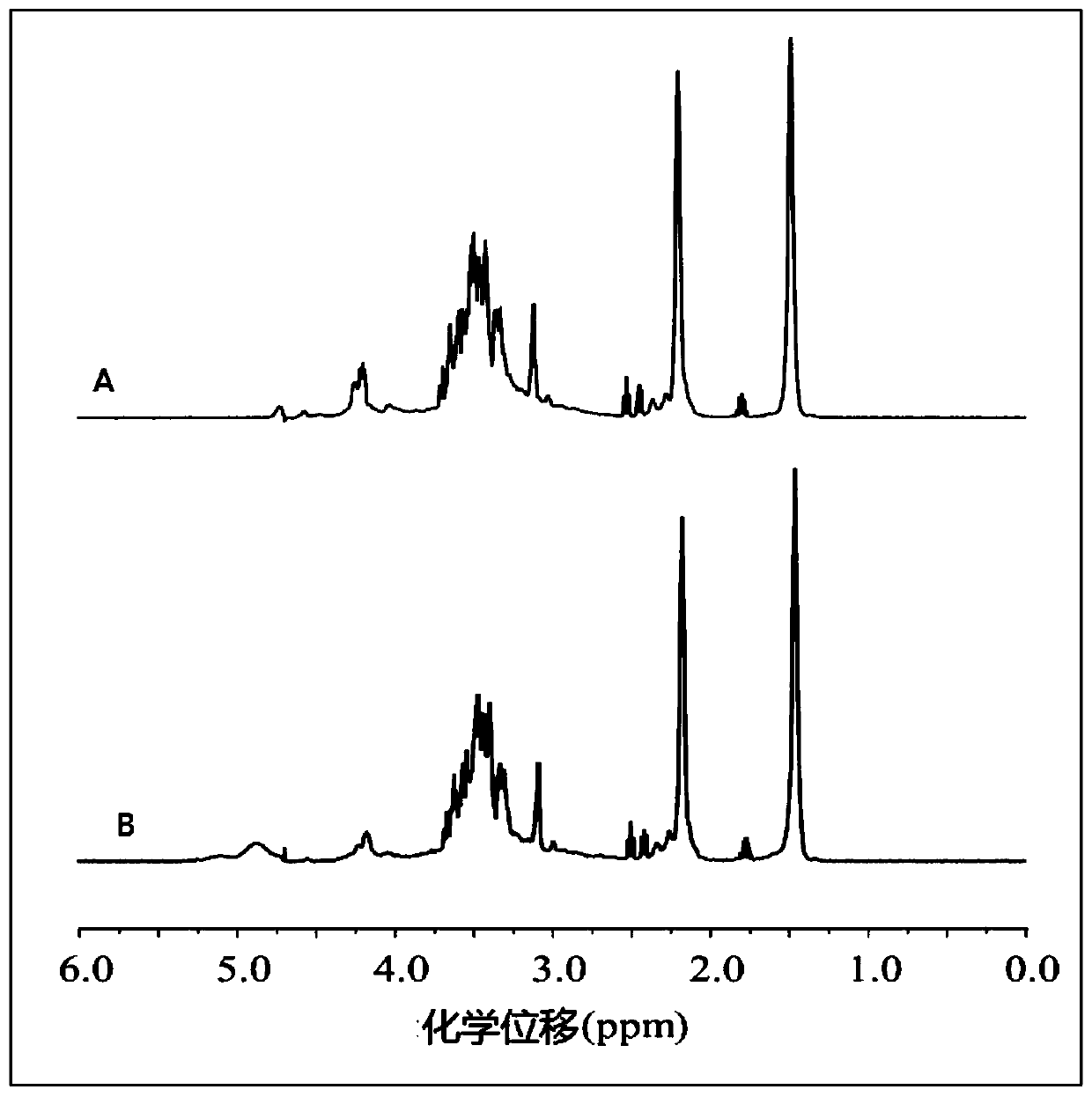

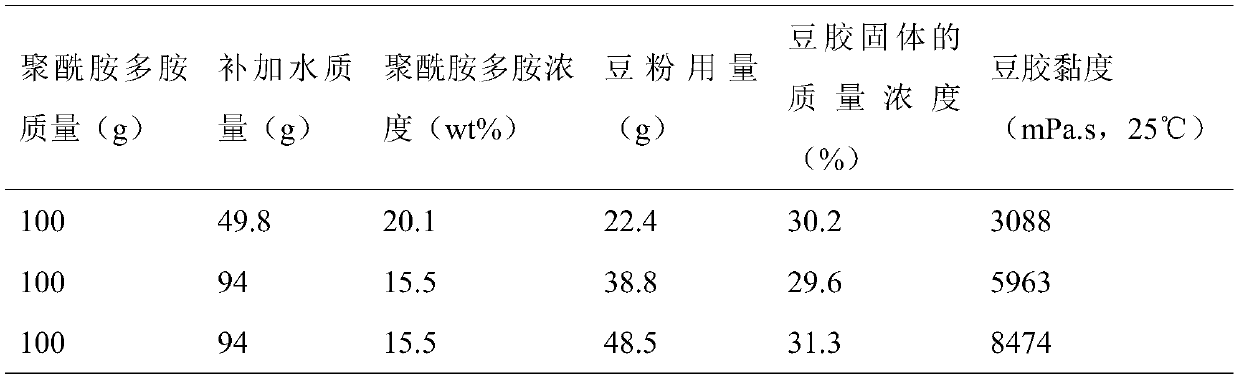

Soybean adhesive for water-resistant shaving board and preparation method thereof

ActiveCN107216849AMeet spraying requirementsEnsure water resistanceNon-macromolecular adhesive additivesProtein adhesivesProduction lineAdhesive

The invention discloses a soybean adhesive for a water-resistant shaving board and a preparation method thereof, and relates to an adhesive and a preparation method thereof, in particular to a modified soybean adhesive for production of boiling water boiling-resistant shaving boards, which aims at solving the technical problems of difficulty in adhesive applying in the production process of the shaving board due to large viscosity and difficulty in adapting to the production of the shaving board due to long hot pressing time in the existing soybean adhesive. The method comprises the following steps of 1, synthesizing of modified polyamide polyamine resin; 2, preparing of the adhesive. The prepared soybean adhesive for the water-resistant shaving board is prepared by adding 0.3 to 1.5% of curing agent and 10 to 25 parts of soybean meal into 100 parts of modified polyamide polyamine resin and mixing at room temperature. The soybean adhesive has the advantages that the viscosity is low, the adhesive is conveniently and uniformly sprayed onto the shaving board, the curing speed is high, the water-resistant property is good, and the soybean adhesive is especially suitable for preparing the boiling water boiling-resistant shaving board in the existing shaved board production line. The soybean adhesive belongs to the field of preparation of adhesives.

Owner:牡丹江恒源生化有限责任公司

Abrasion-resistant S-shaped grinding wheel and hot-press forming technology thereof

ActiveCN105945741AImprove performanceReasonable ratioGrinding carriagesTransportation and packagingAlloyCopper

The invention discloses an abrasion-resistant S-shaped grinding wheel and a hot-press forming technology thereof. The abrasion-resistant S-shaped grinding wheel comprises the following main materials in volume fraction: 12 to 15% of diamond, 20 to 25% of copper, 40 to 45% of iron, 3 to 8% of tin, 5 to 8% of nickel, 5 to 8% of cobalt and 3 to 5% of auxiliary material alloy powder. The continuous tooth S-shaped grinding wheel is produced through the steps of batching, premixing, total mixing, cold pressing performing, hot pressing sintering, primary cooling, high frequency welding, secondary cooling, surface treatment, paint spraying, edging, and the like. According to the S-shaped grinding wheel produced through the formula and the technology, the strength is improved, the abrasion resistance is improved as well, the service life is prolonged in the actual use process, the production cost is greatly reduced, the resources are saved, and the technology is environment-friendly, sanitary and safe in the production process.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

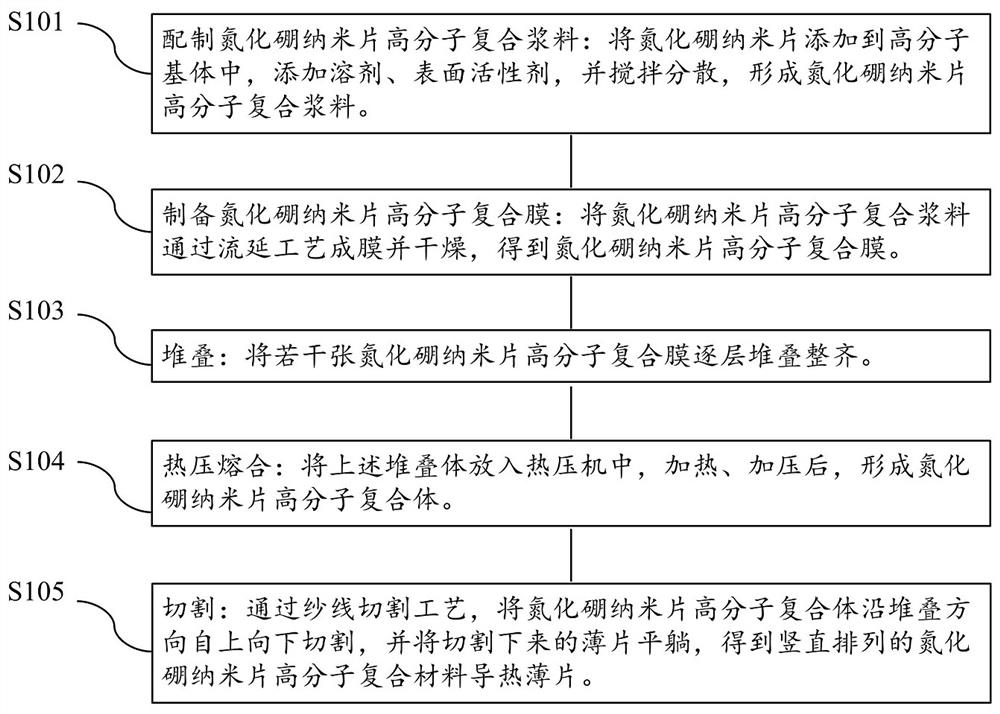

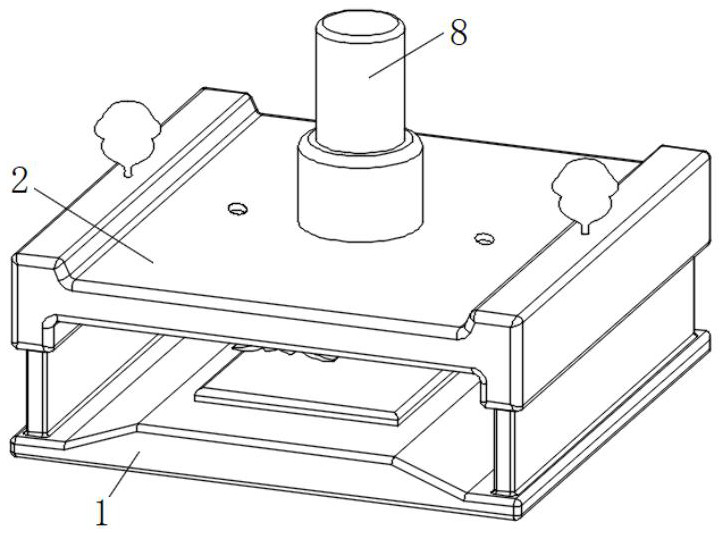

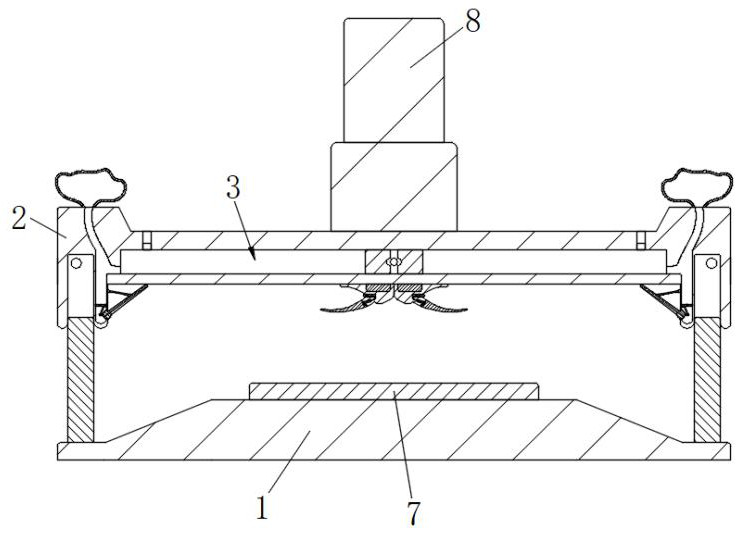

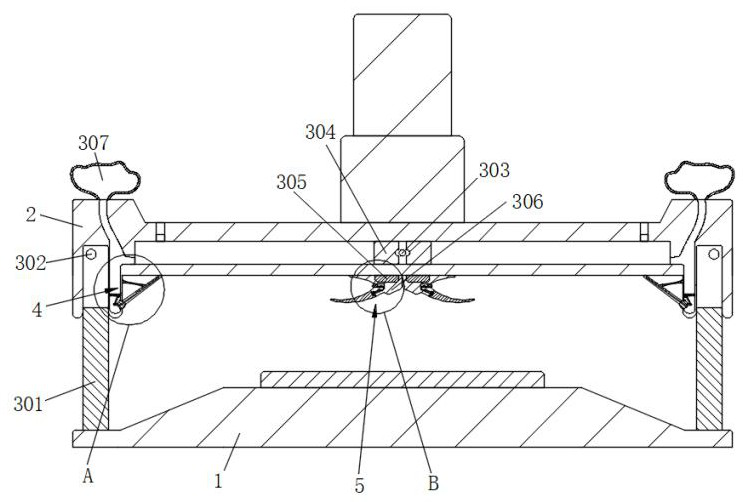

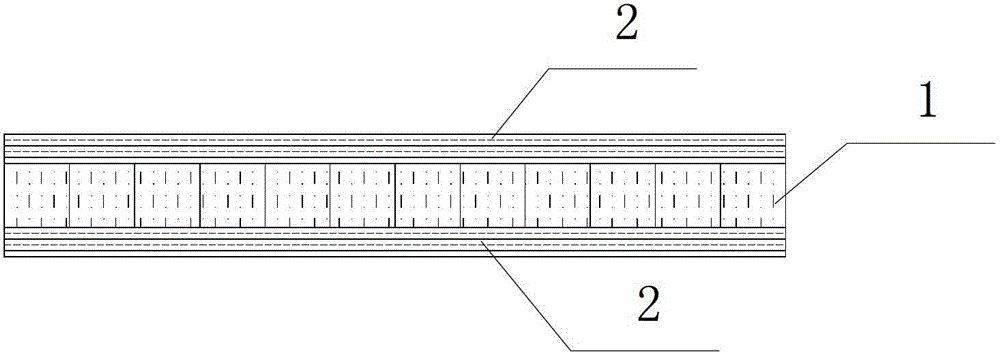

Vertically-arranged boron nitride nanosheet polymer composite material heat-conducting sheet and preparation method thereof

InactiveCN113524741AOvercoming the Problem of Polymer CompoundingEasy to prepareFlat articlesYarnBoron nitride

The invention provides a vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet and a preparation method thereof. A composite material takes a boron nitride nanosheet with a sheet structure as a filler, the filler is added into a polymer matrix, and a horizontally arranged boron nitride nanosheet polymer composite film is formed through stirring and casting processes, and stacking, hot-pressing fusion and yarn cutting processes are performed on the boron nitride nanosheet polymer composite film to prepare the vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet. Boron nitride nanosheets are vertically arranged in the polymer matrix, so that the interface thermal resistance is reduced, the heat conductivity coefficient of the material is improved, the composite material heat-conducting sheet with the thickness of 0.05-0.40 mm can be obtained through the yarn cutting process, the thermal resistance is smaller, and heat transfer is facilitated. The method is simple, reliable and high in operability, and can be applied to preparation of polymer composite materials of boron nitride nanosheets and various systems. The boron nitride nanosheet composite material heat-conducting sheet prepared by the method provided by the invention can be widely applied to heat management of electronic products.

Owner:HARBIN INST OF TECH AT WEIHAI

Hot pressing mechanism convenient to clean

ActiveCN113580285AGuaranteed cleanlinessImprove hot pressing efficiencyPlywood pressesVeneer pressesAdhesive glueMechanical engineering

The invention discloses a hot pressing mechanism convenient to clean, and relates to the technical field of hot pressing. The hot pressing mechanism convenient to clean comprises a pressing plate, wherein an electric telescopic rod is fixedly connected to the top of the pressing plate, a bottom plate is arranged at the bottom of the pressing plate, a plate is arranged at the top of the bottom plate, and a gluing automatic cleaning and scraping mechanism is arranged in the pressing plate.The invention relates to the technical field of hot-pressing. According to the hot-pressing mechanism convenient to clean, by arranging the gluing automatic cleaning and scraping mechanism, when the pressing plate descends, an arc-shaped sliding plate automatically and comprehensively scrapes the bottom of the pressing plate once, glue which overflows and adheres to the bottom of the plate due to hot pressing at the bottom of the pressing plate every time is fully automatically scraped, the bottom of the pressing plate is guaranteed to be clean, the hot-pressing efficiency of the plate at each time is improved, then it is guaranteed that when the pressing plate descends at each time, enough space can be reserved for hot-pressing contact between the pressing plate and the plate, scraping and cleaning work and hot-pressing work do not interfere with each other, and mutual working efficiency is guaranteed.

Owner:JIANGSU LEADER ELECTRONICS INFORMATION TECH

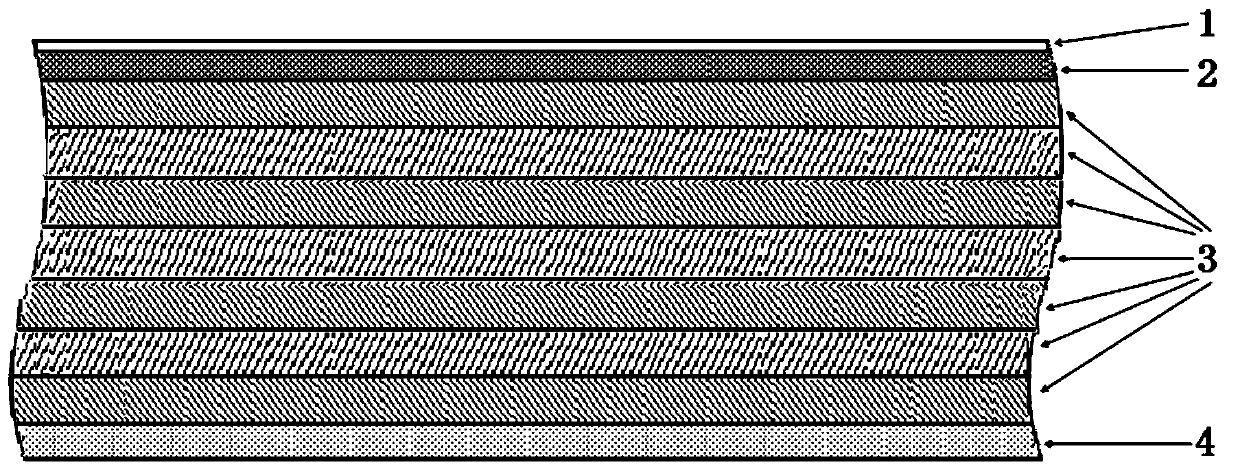

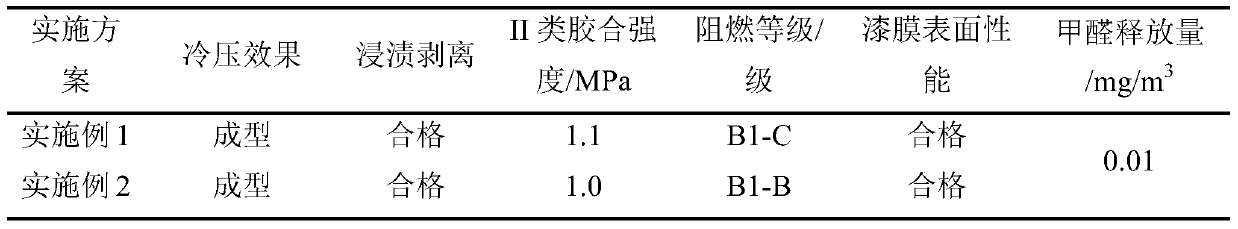

Modified soybean aldehyde-free flame-retardant adhesive and preparation method thereof

ActiveCN111234774ALow costHigh strengthNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceMelamine phosphate

The invention aims to provide a modified soybean aldehyde-free flame-retardant adhesive. The modified soybean aldehyde-free flame-retardant adhesive comprises the following components in parts by weight: 100 parts of a cross-linking modifier, 50-100 parts of water, 100-200 parts of degreased bean flour, 50-150 parts of an activated modified flame retardant, 5-7 parts of a water-based tackifier and0.1-0.2 part of an assistant, wherein the activated modified flame retardant is prepared from the following components in parts by weight: 20-40 parts of ammonium polyphosphate APP, 10-20 parts of melamine phosphate MP, 2-3.5 parts of a coupling agent, 4-7 parts of a dispersing agent and 50-80 parts of aluminum hydroxide or magnesium hydroxide.

Owner:浙江云峰莫干山地板有限公司

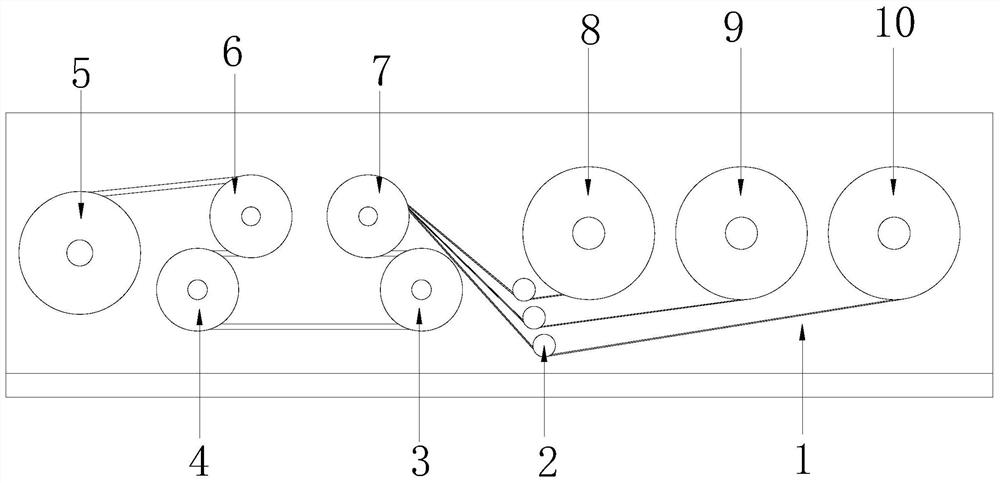

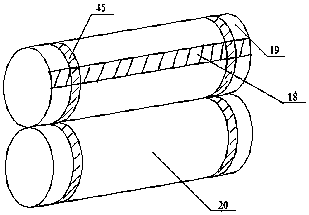

Hot-pressing equipment for composite non-woven fabric

InactiveCN111845011AEasy to panAvoid Rigid CollisionsLamination ancillary operationsLaminationNonwoven fabricGlass wool

The invention discloses hot pressing equipment for a composite non-woven fabric. The hot pressing equipment structurally comprises a machine body, a first guide roller, a first hot-pressing roller, athird guide roller, a composite non-woven fabric winding device, a second hot-pressing roller, a second guide roller, a non-woven fabric roll, an interlayer fabric roll and an inner fabric roll, wherein the non-woven fabric roll, the interlayer fabric roll and the inner fabric roll are sequentially arranged on the machine body. Compared with the prior art, the invention has the following beneficial effects: the contact area of the non-woven fabric and a heating roller can be greatly increased, which is beneficial for improvement of hot pressing efficiency and reduction in hot pressing time; invirtue of magnetism principles and the fact that an air suction ball is pressed to exhaust air and sucks air to realize resetting, the composite non-woven fabric can be adsorbed and clamped, so the composite non-woven fabric is allowed to quickly enter an annular cavity, and the composite non-woven fabric is located in the annular cavity for hot pressing; and heat preservation and insulation areconducted through glass wool, and an inner roller is hidden in an outer roller to prevent the inner roller from being exposed outside, so heat dissipation can be effectively reduced, and hot pressingcompositing of the non-woven fabric is better facilitated.

Owner:陈晓瑜

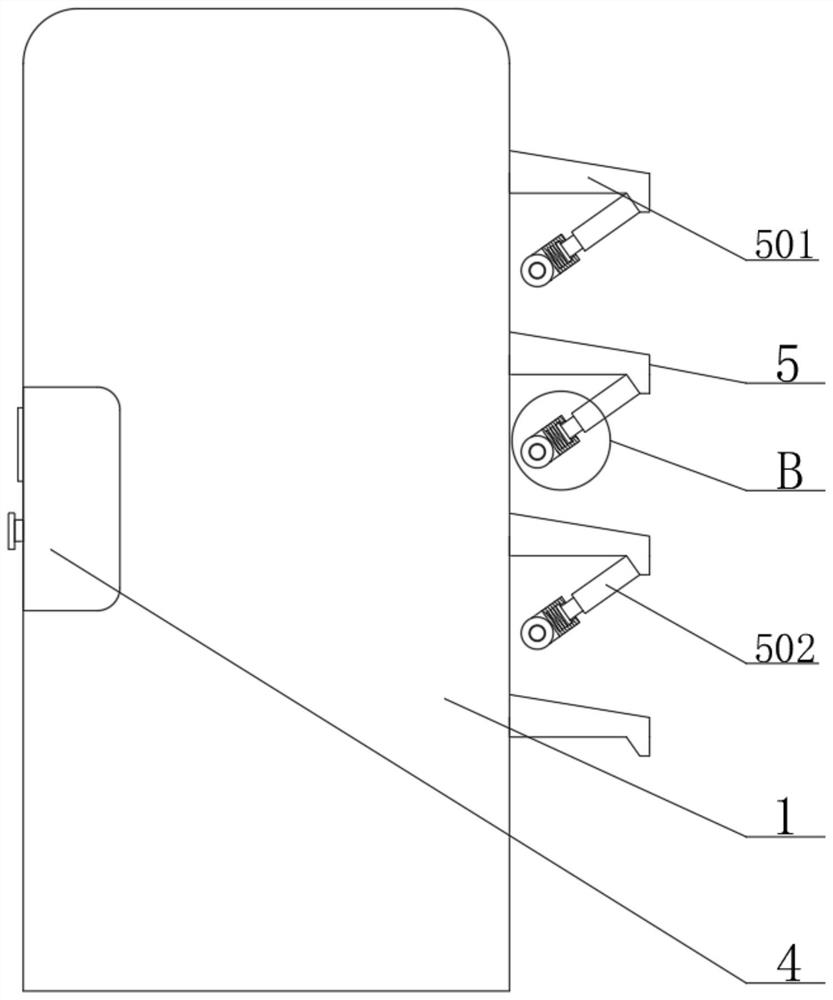

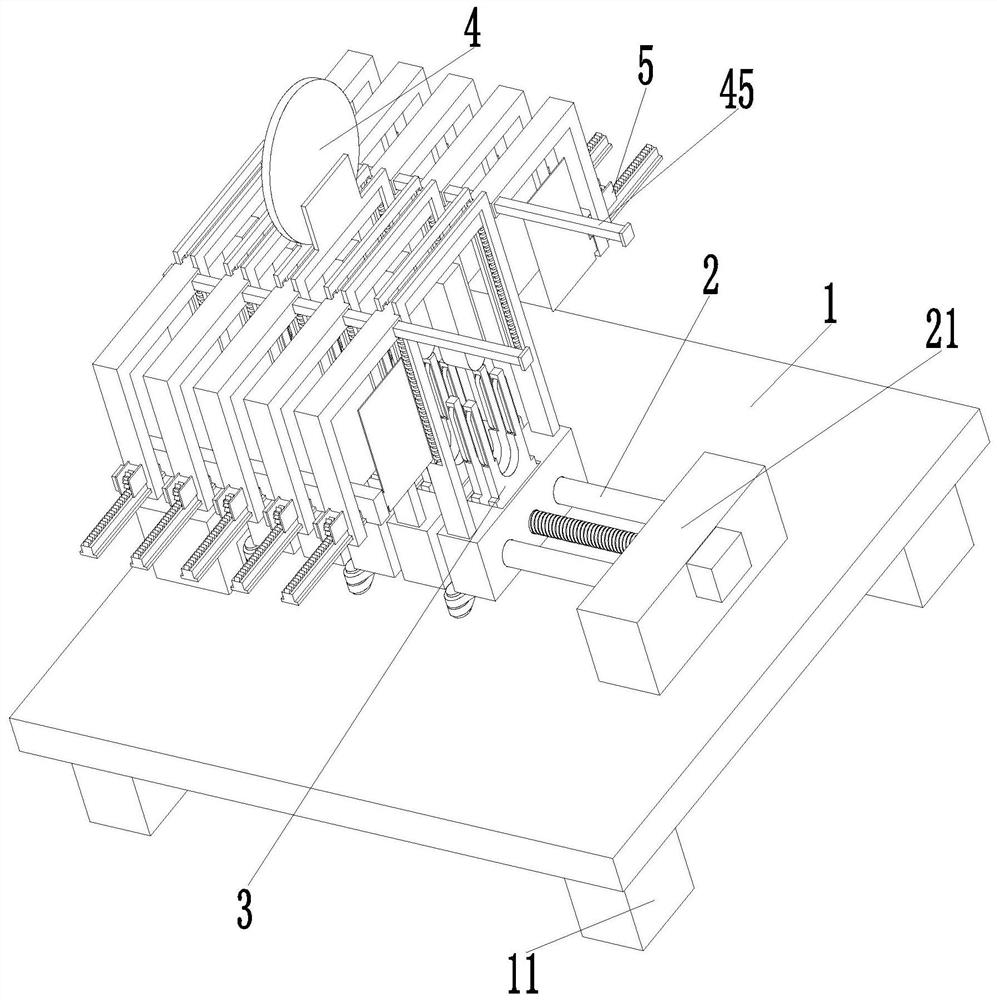

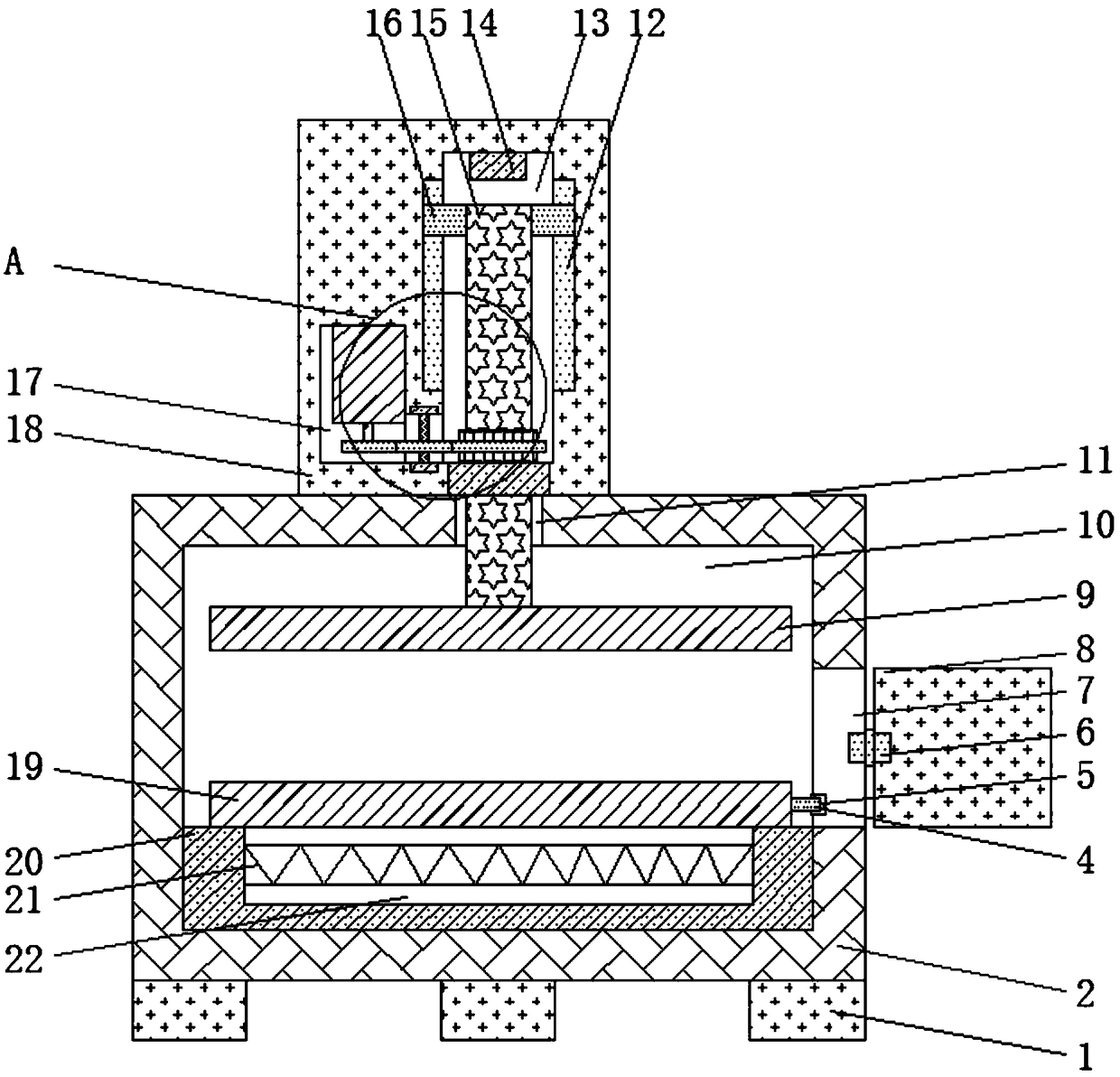

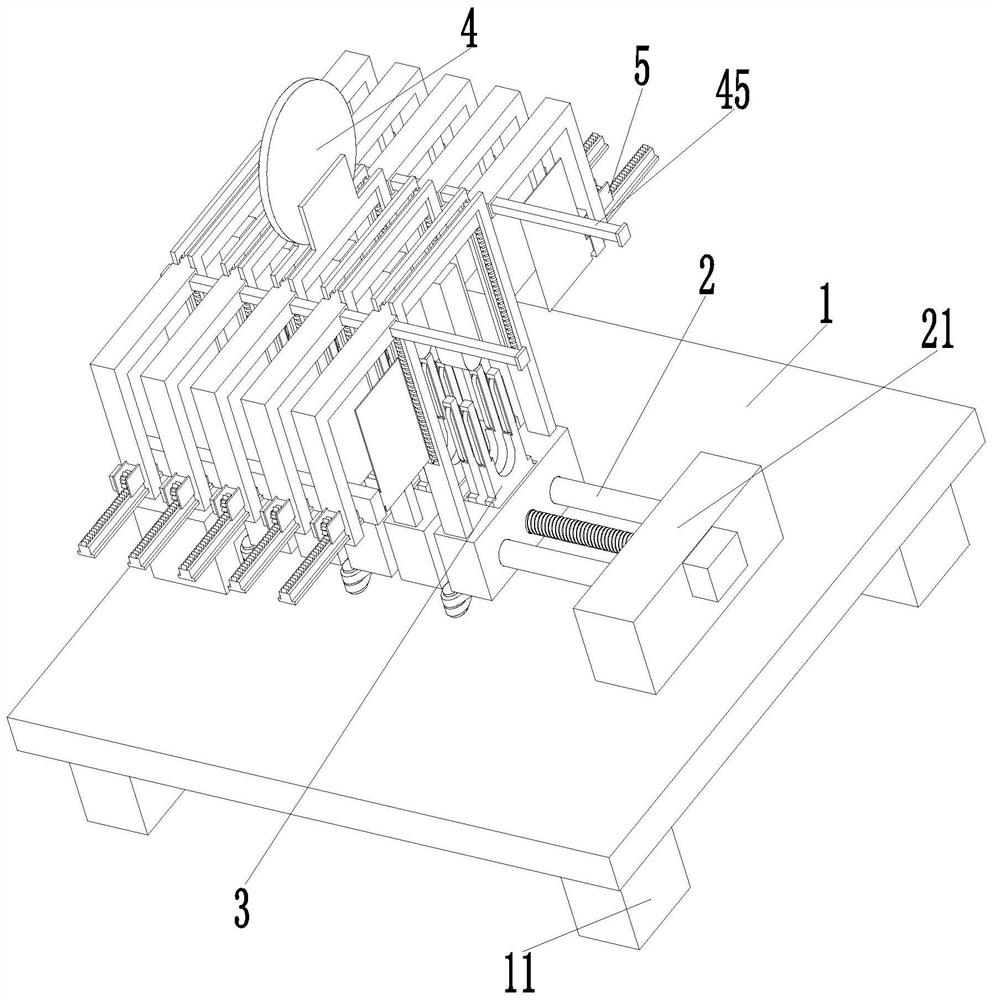

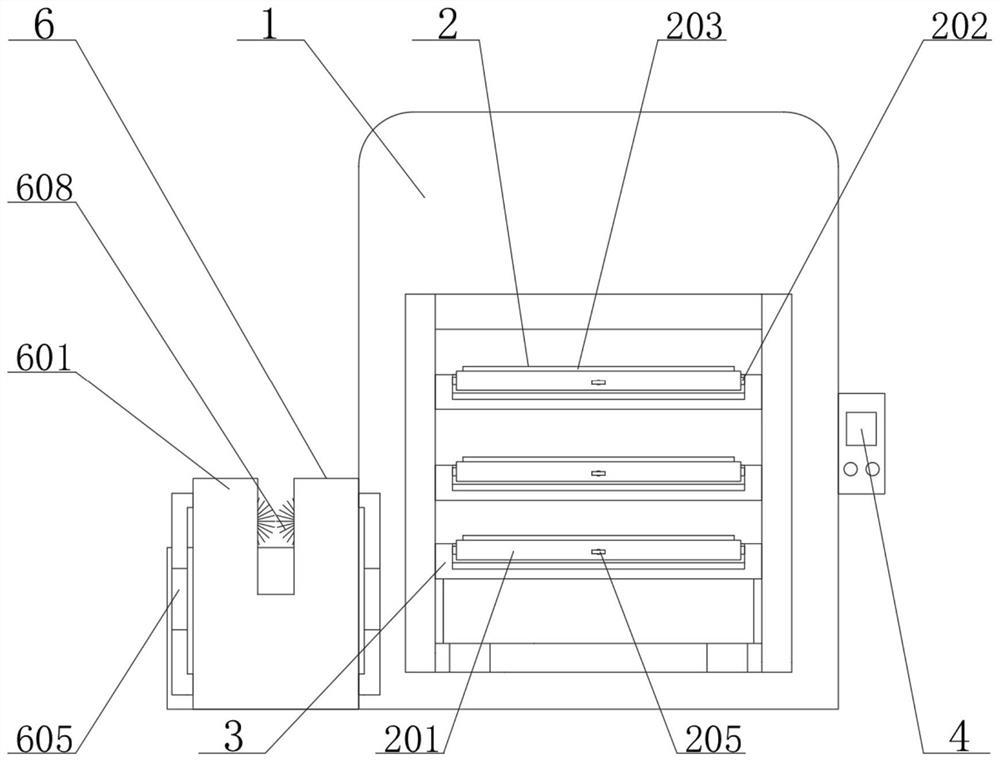

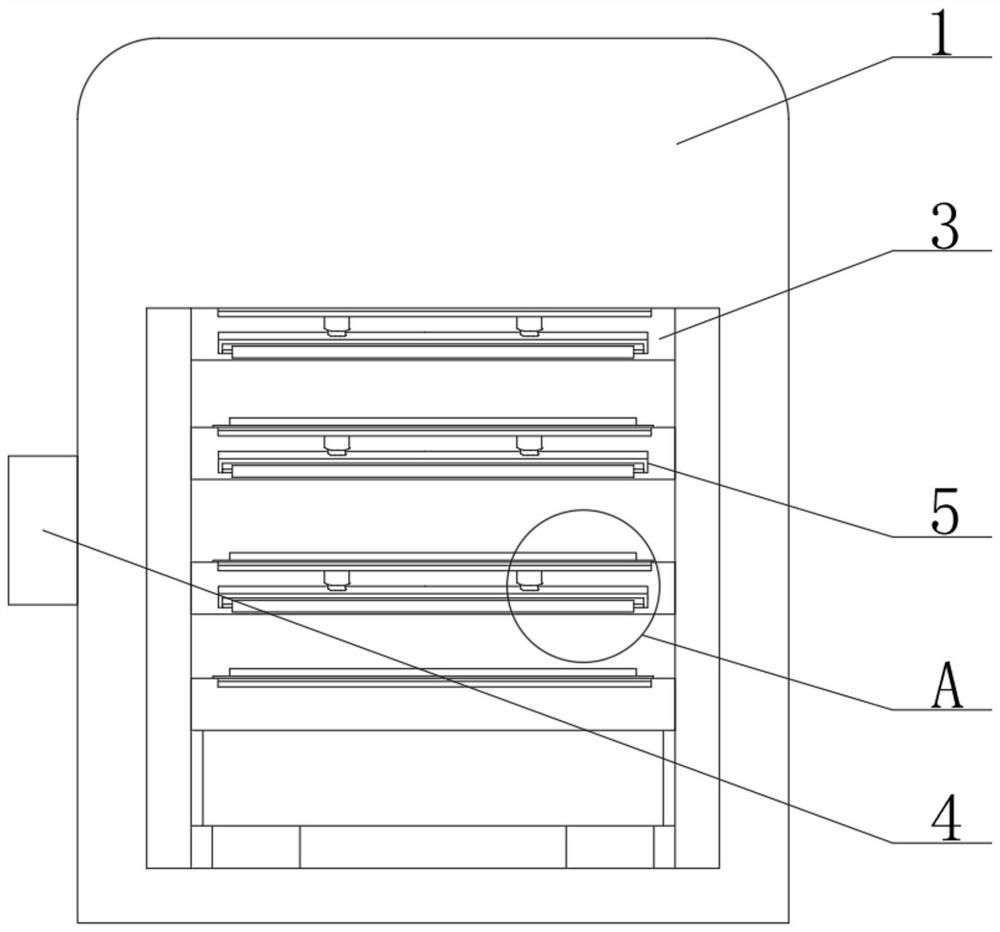

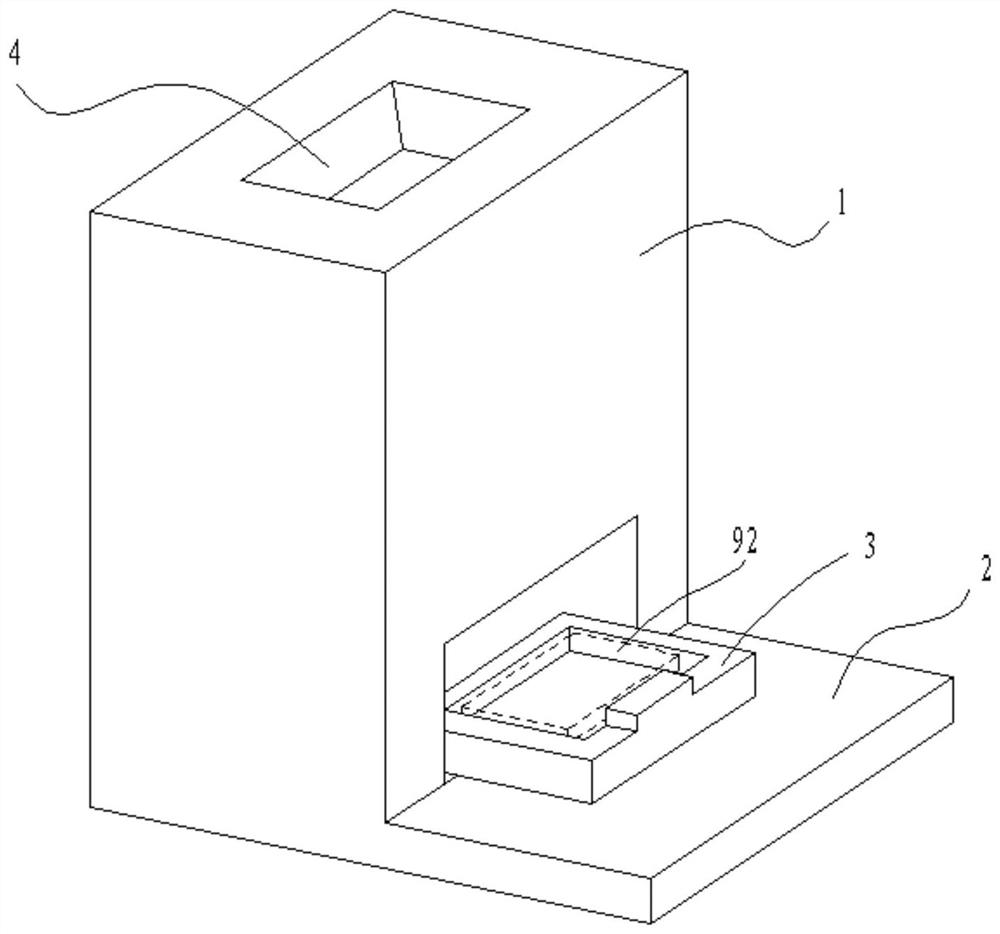

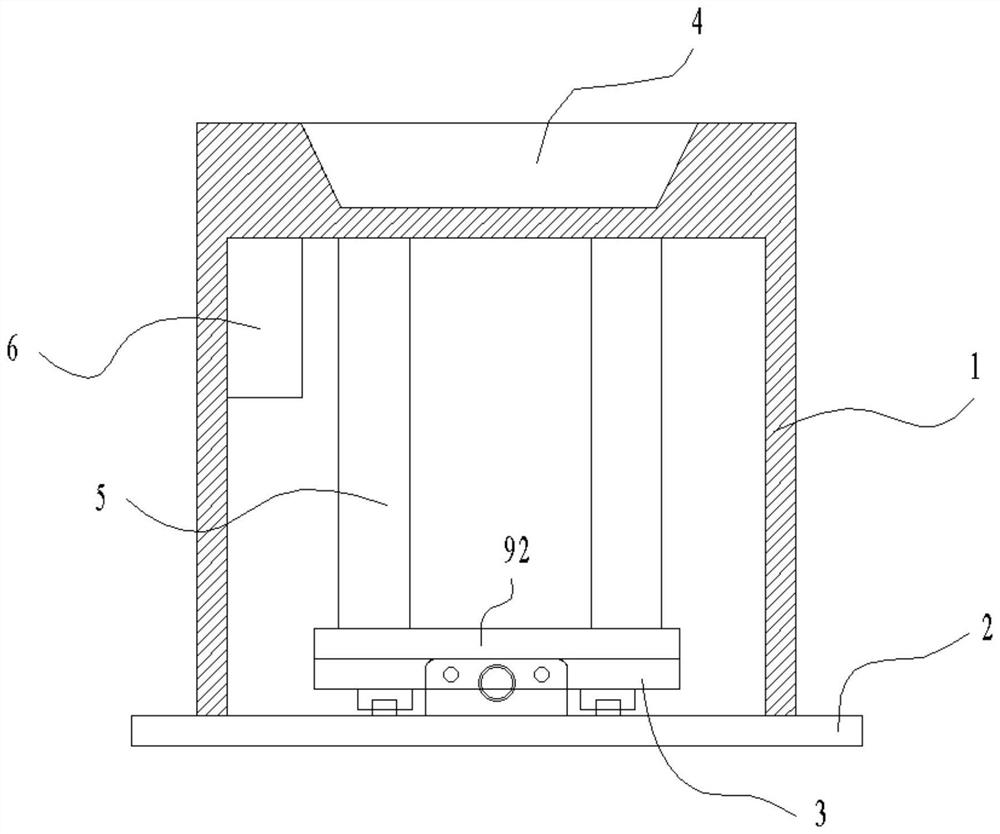

Composite board pressing processing equipment

ActiveCN111823689AEnsure safetyAccurate placementLamination ancillary operationsDispersed particle filtrationEngineeringComposite plate

The invention relates to the technical field of composite board processing, particularly to composite board pressing processing equipment, which comprises a hot press, supporting devices, a blanking device and a cleaning device. The inner side of the hot press is fixedly connected with hot pressing plates, the supporting devices are arranged on the inner sides of the hot pressing plates, each supporting device comprises a supporting plate, a rotating shaft, a limiting plate, a first spring and a handle, the inner sides of the three hot pressing plates located at the bottom end are connected with the supporting plates in a sliding mode, the rear ends of the inner sides of the supporting plates are rotationally connected with the rotating shafts, and the rotating shafts are in sliding connection with three hot pressing plates at the bottom end. In the present invention, the limiting plates and the rotating shafts are arranged, by means of the arrangement, in cooperation with rotary connection of the rotating shafts and the supporting plates, sliding connection of the rotating shafts and the hot pressing plates, and the elastic force of the first springs to the limiting plates, when the composite boards are fed, the supporting mechanism can be pulled out to be fed and then placed quickly and precisely, operation is easy and convenient, and the safety of workers is guaranteed.

Owner:安徽润象新材料科技有限公司

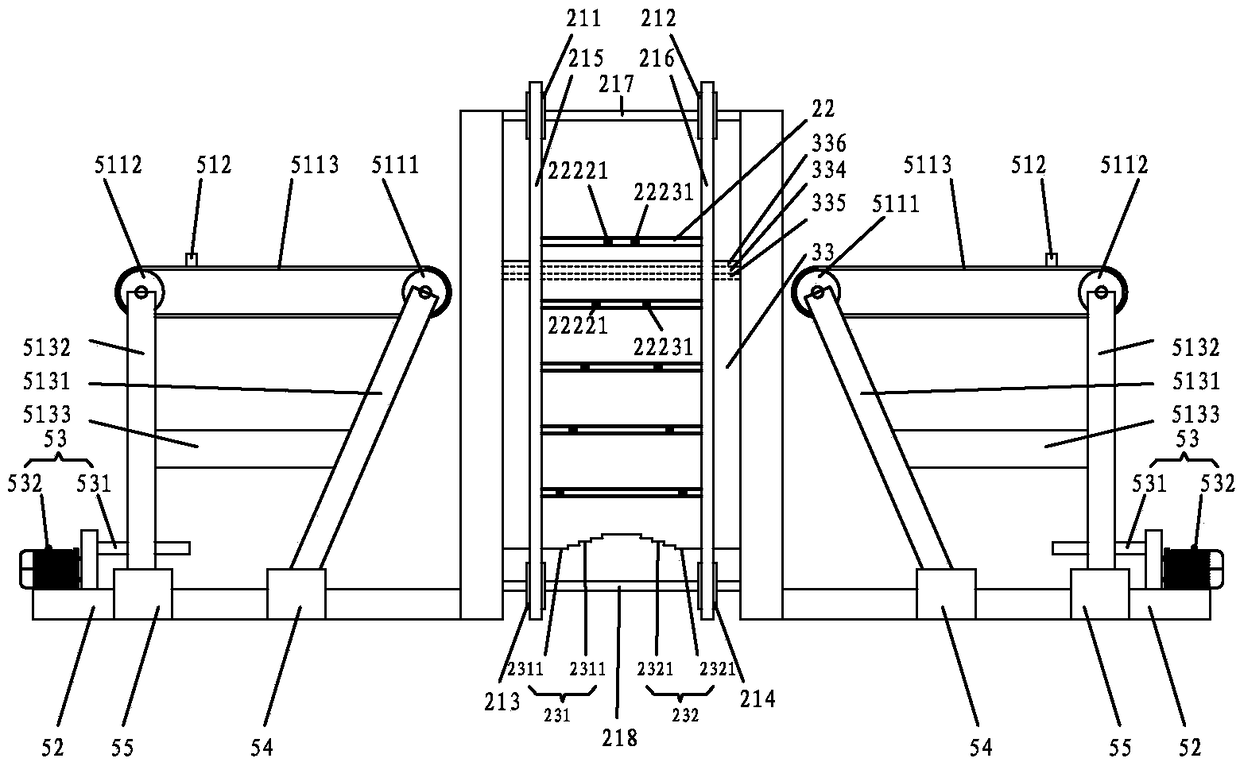

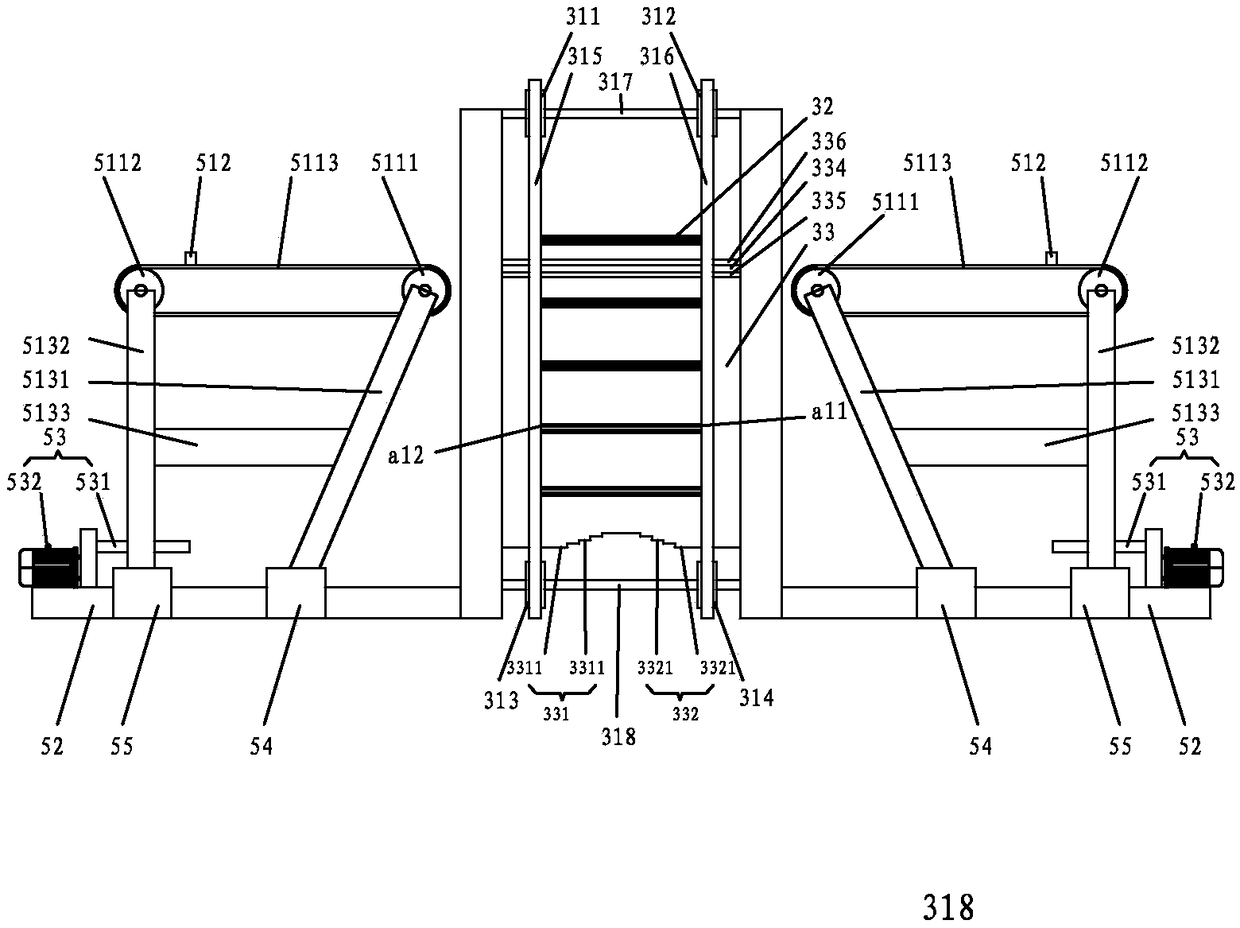

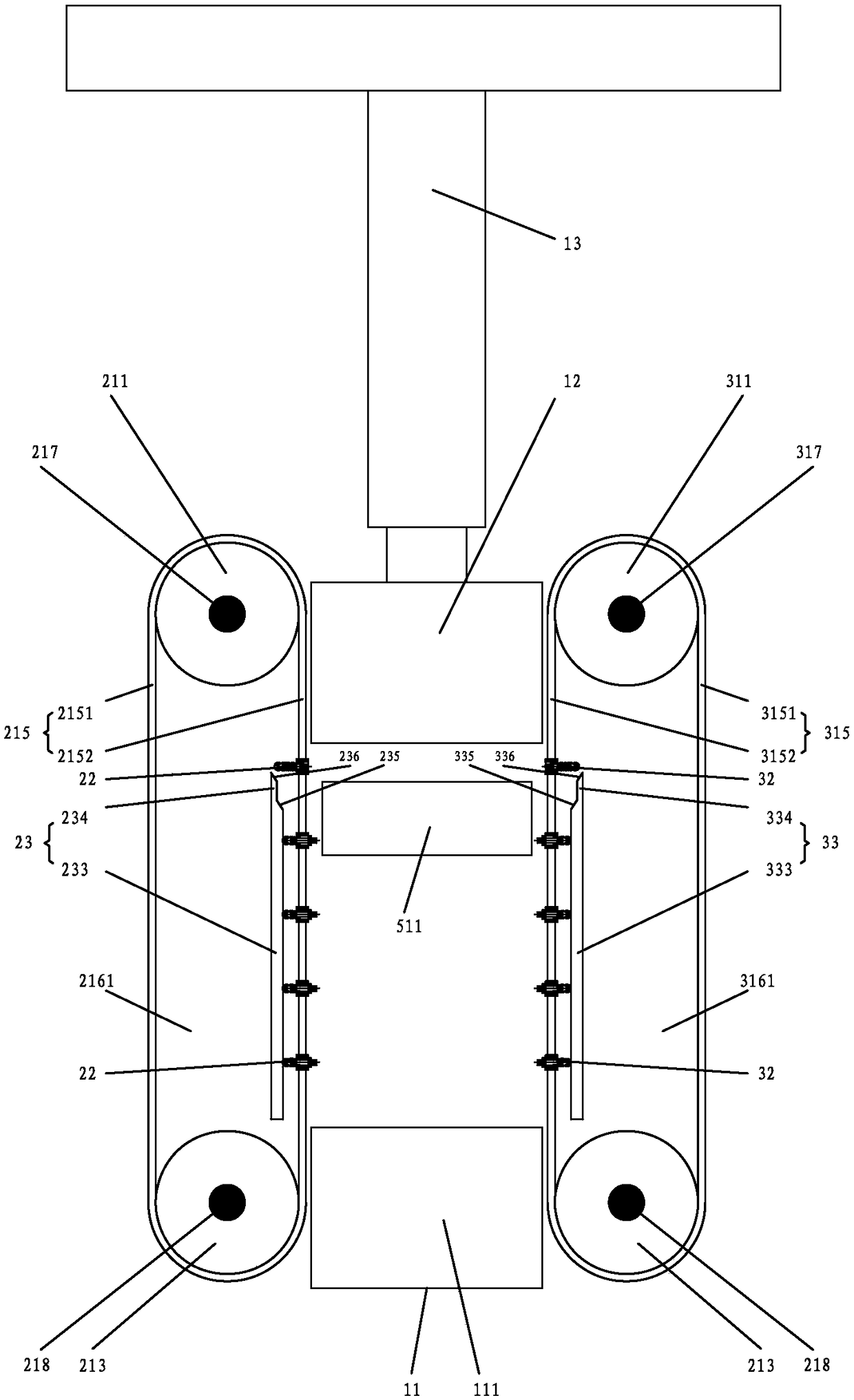

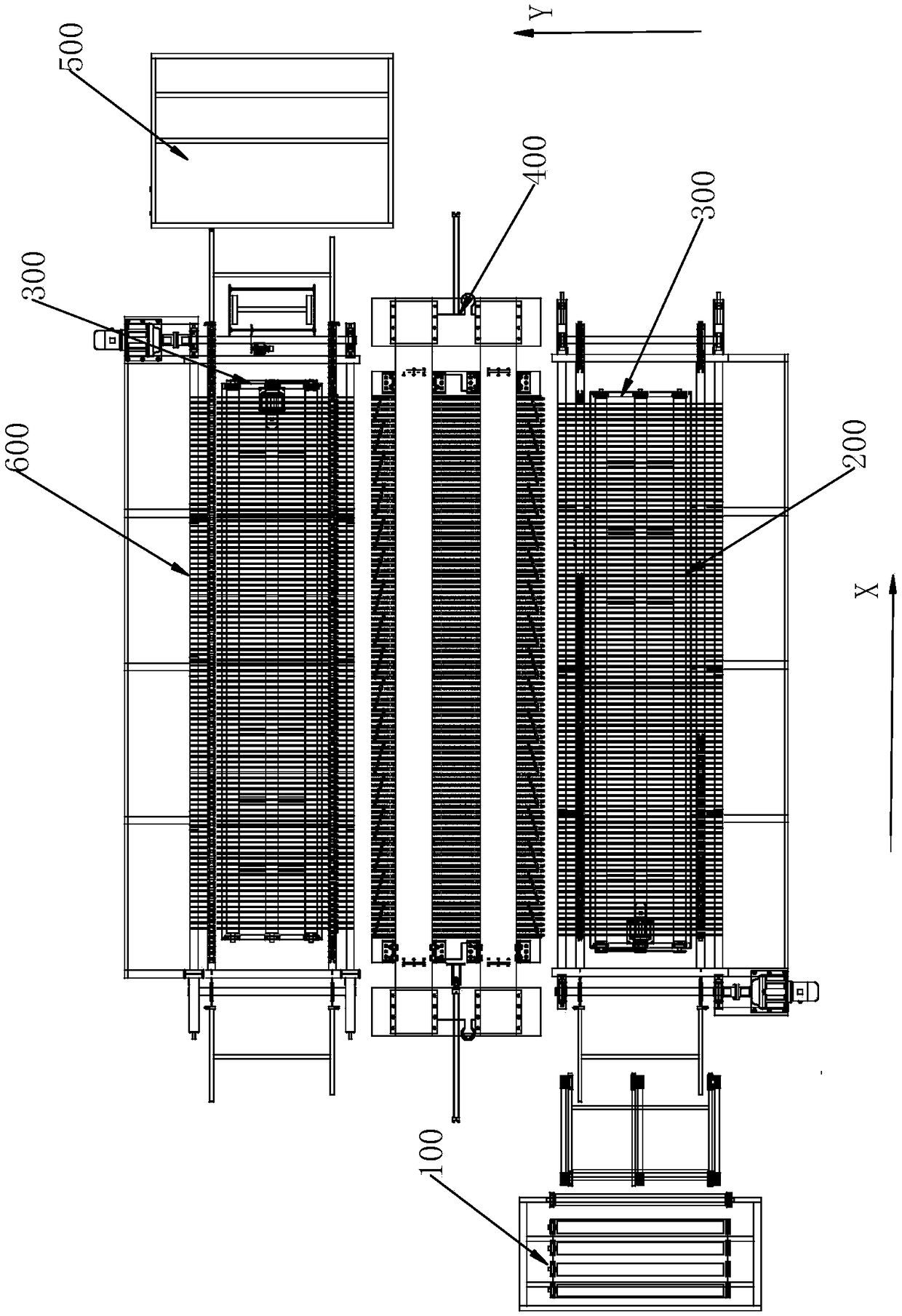

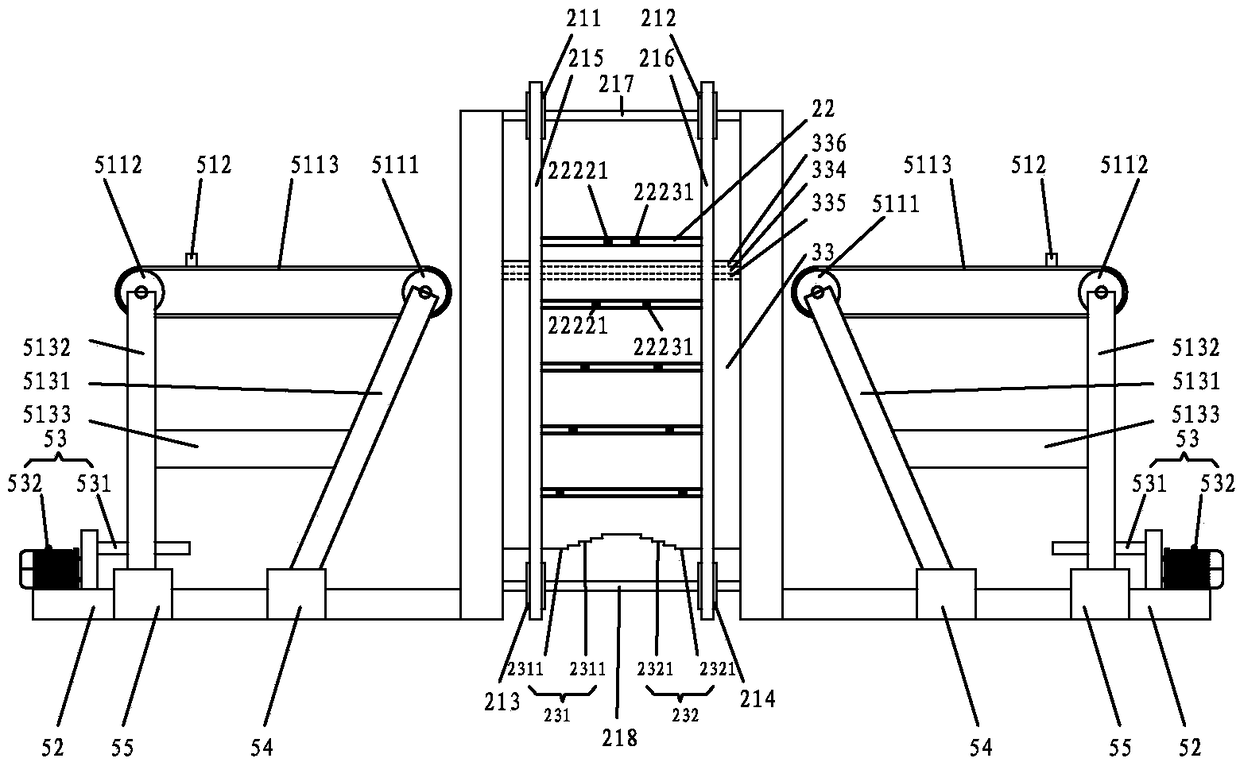

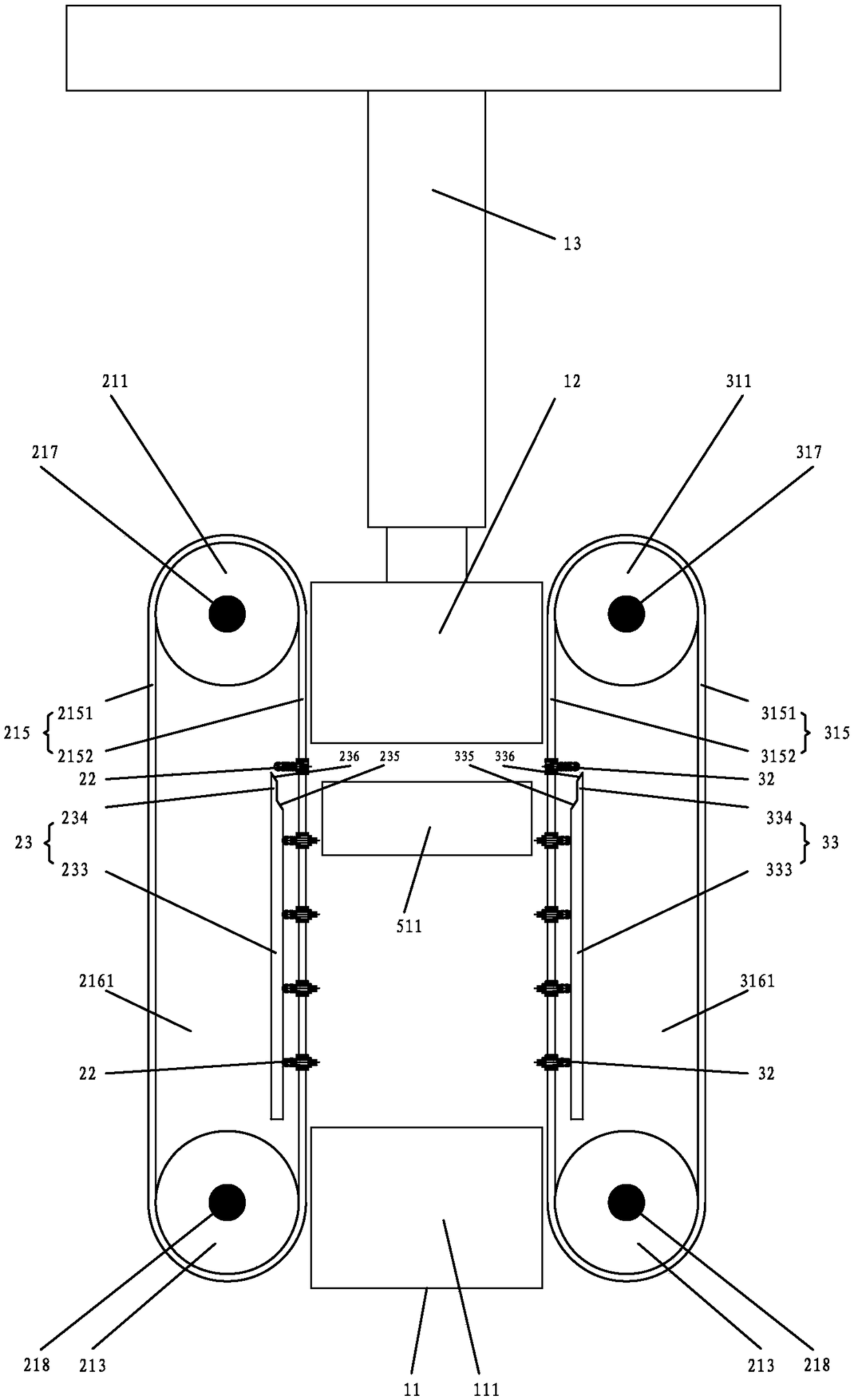

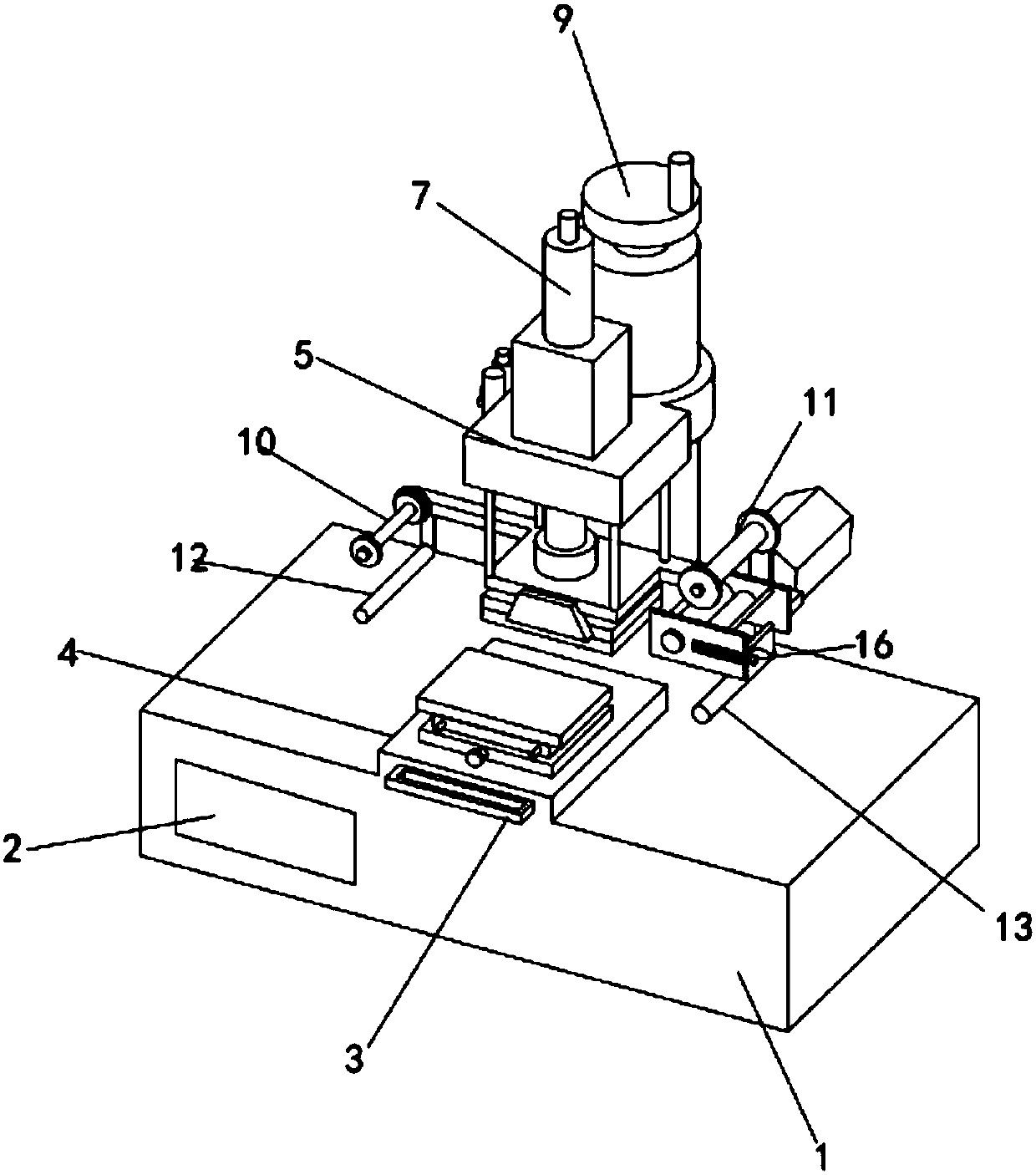

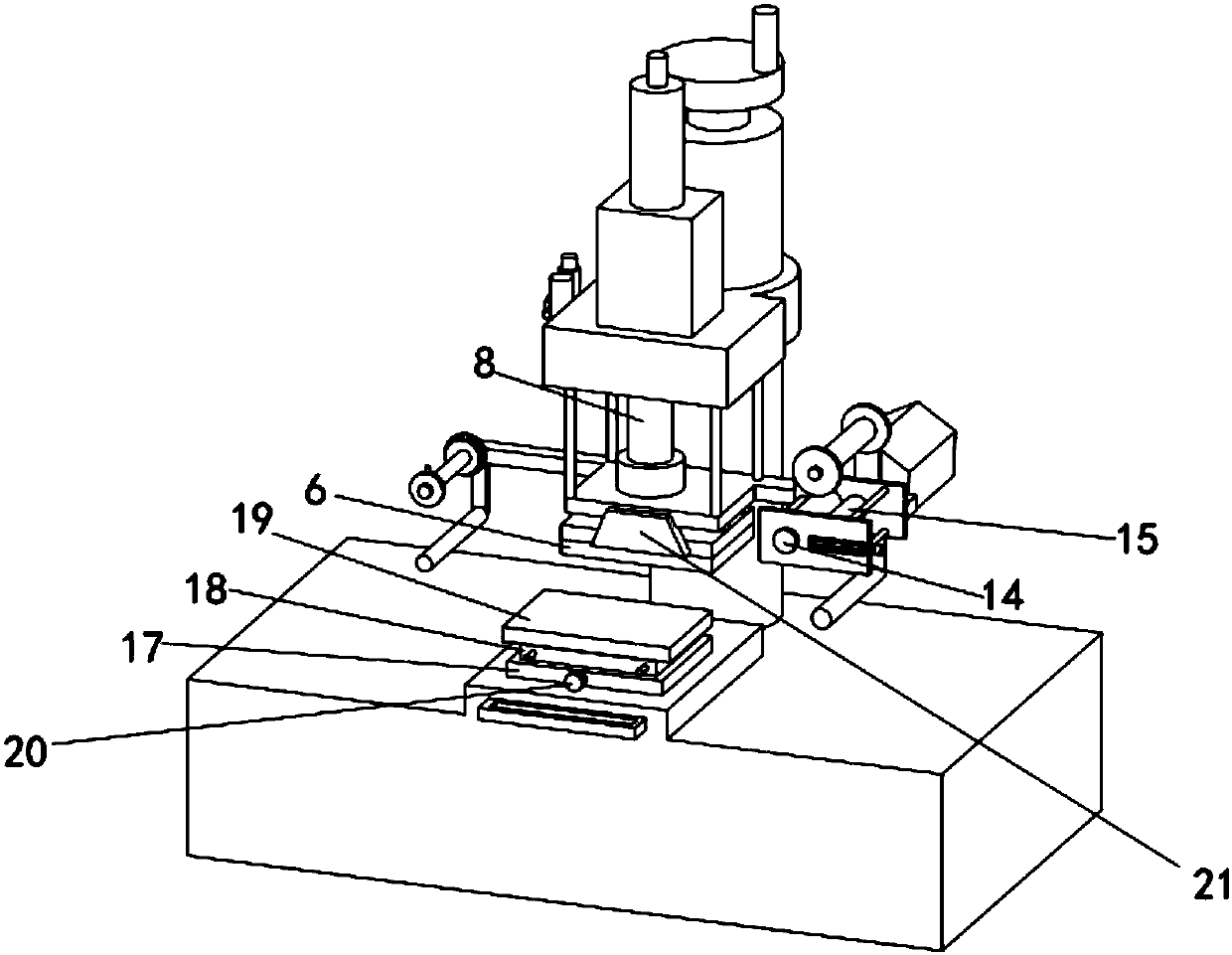

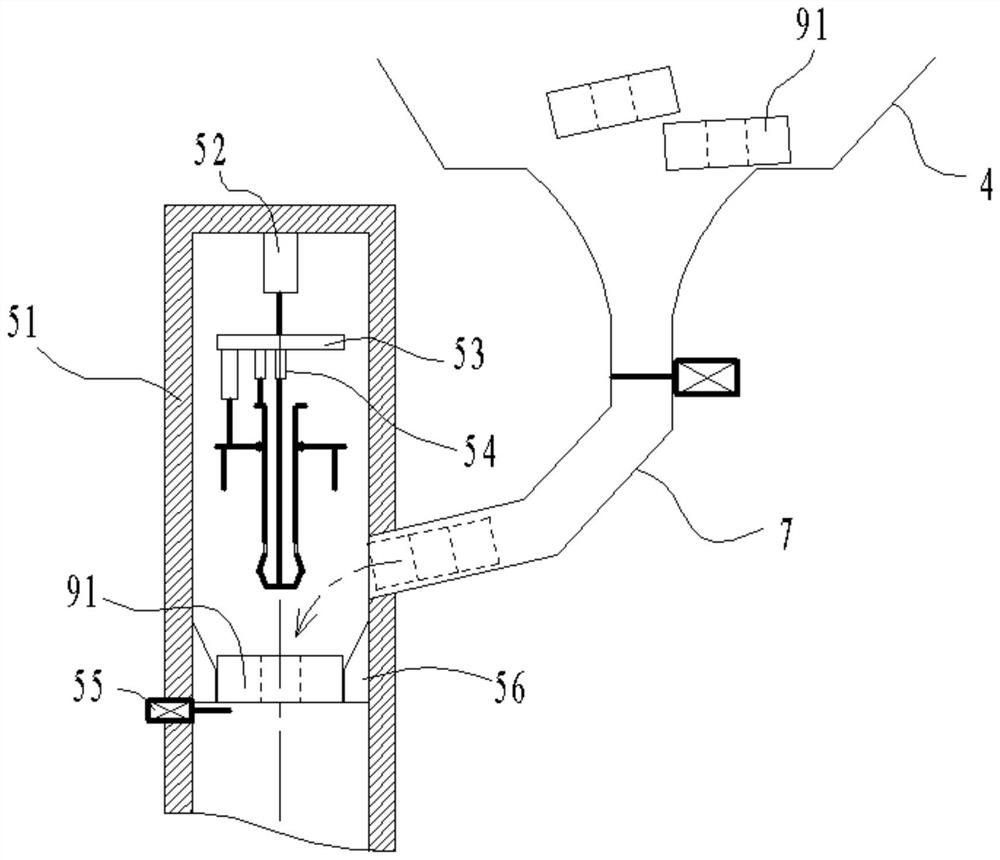

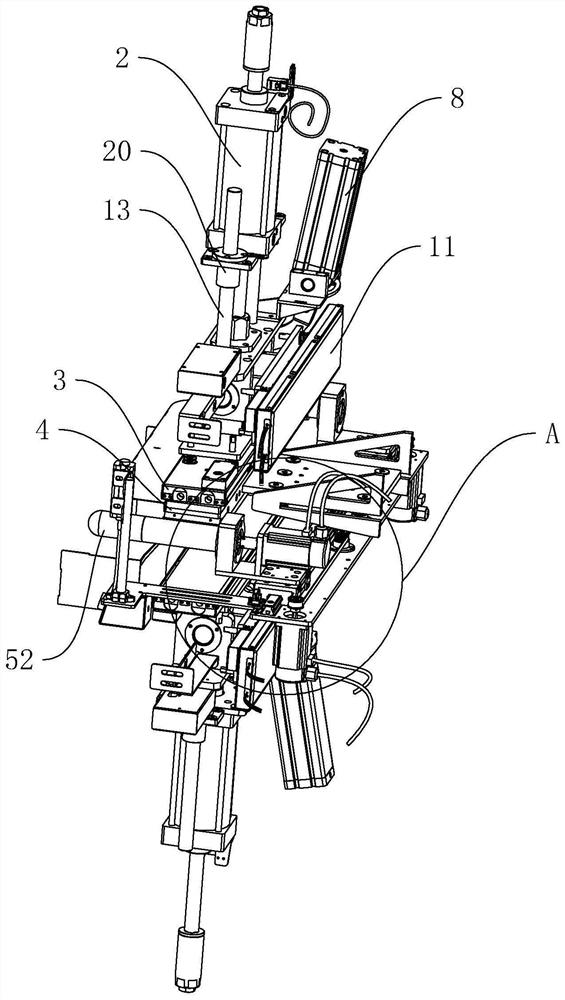

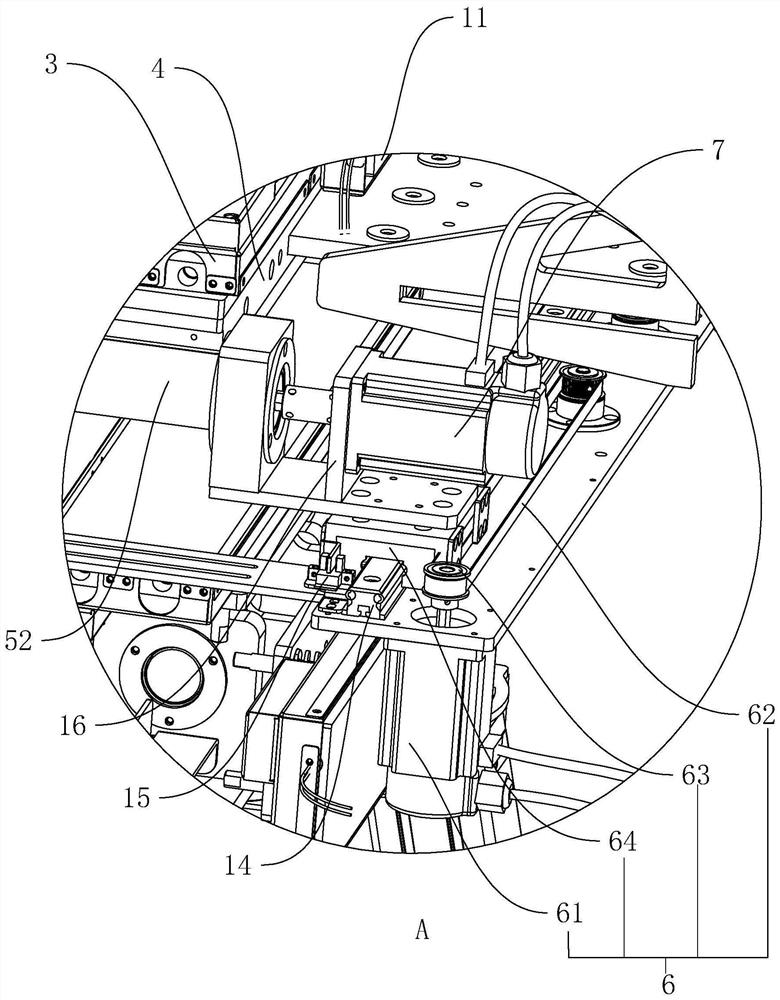

Efficient hot-pressing machine

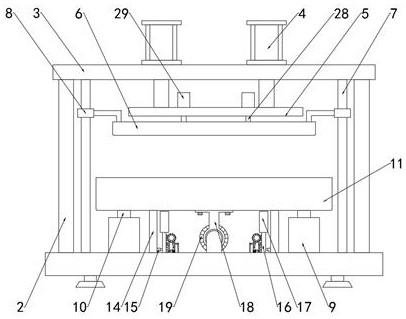

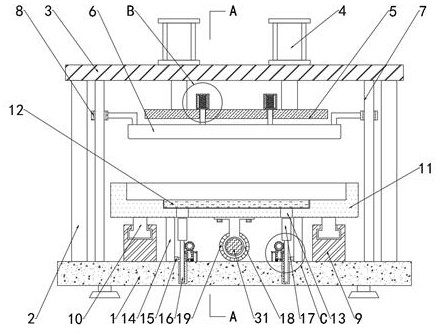

ActiveCN108908537AAchieve precise positioningStable deliveryOther plywood/veneer working apparatusPlywood pressesMechanical engineeringScratching

The invention provides an efficient hot-pressing machine, which comprises a controller for controlling a hot-pressing device, an arrangement device, a glue distribution device and a supply device in apractical operating process. Under control of the controller, mould plate blanks are conveyed to the arrangement device one by one by the supply device, then subjected to glue distribution by the glue distribution device and finally pressed together to form a plywood by the hot-pressing device. Stable and smooth guiding and supporting of each crossbeam in horizontal period motion can be realizedthrough each butting wheel. Inclined lower-end steps arrayed step by step adapt to height of the mould plate blanks arranged layer by layer, and each bearing portion is enabled to rebound timely to avoid scratching of lower mould plate blanks and a hot-pressing bottom plate. Compared with the prior art, the efficient hot-pressing machine has advantages of smoothness and stability in automatic conveying, arrangement, glue distribution and once hot-press forming of the mould plate blanks, high efficiency and high practicality.

Owner:漳州鑫华成机械制造有限公司

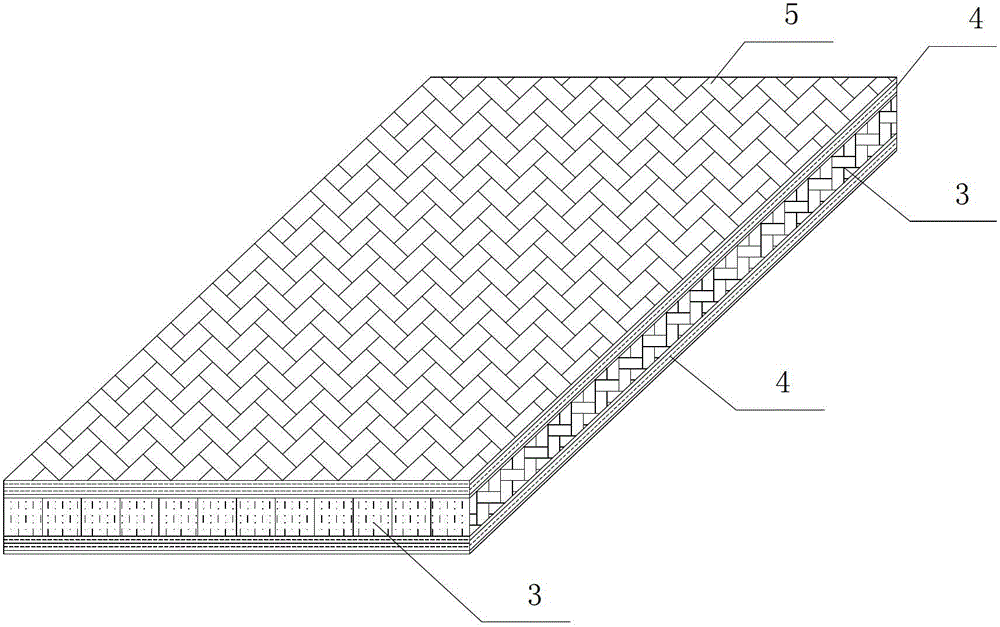

Bamboo plywood for structure

InactiveCN104015231AImprove gripThe problem of realizing double-sided nailingWood veneer joiningWood layered productsEngineeringLath

The invention discloses bamboo plywood for a structure. The bamboo plywood for the structure comprises a core board layer and hot-pressed layers arranged on the two sides of the core board layer. The core board layer is made of battens through lateral cold pressing and gluing and sanding thickness determining, wherein the battens are formed by cutting bamboo plywood GluBam which is used in a structure and has the thickness of 25 mm to 30 mm. The pressed forming surfaces of all the battens in the formed core board layer are perpendicular to pressed forming surfaces of the hot-pressed layers. According to the bamboo plywood for the structure, nails can be driven into two sides of the bamboo plywood, the thickness in each bamboo plywood layer is even, and the thickness tolerance between the plywood layers is small; in addition, the hot-pressing technology efficiency is high, and the mechanical property is high. The bamboo plywood for the structure can completely overcome the inherent defects of the existing plywood GluBam and is used for production and construction of the bamboo structure.

Owner:HUNAN UNIV

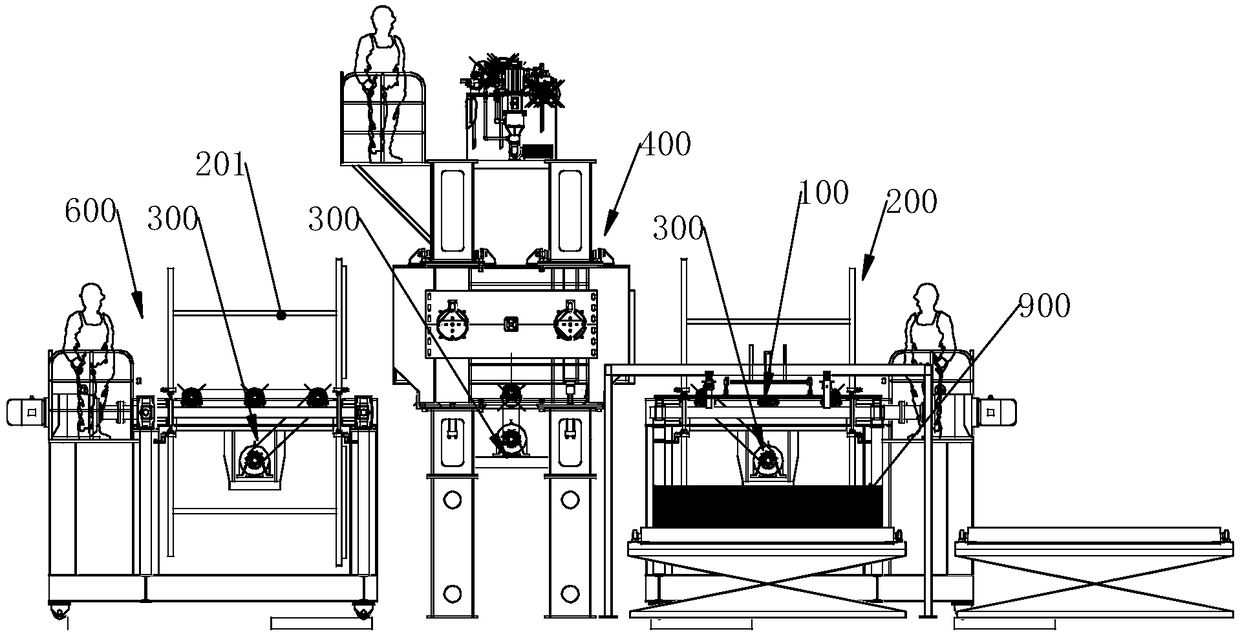

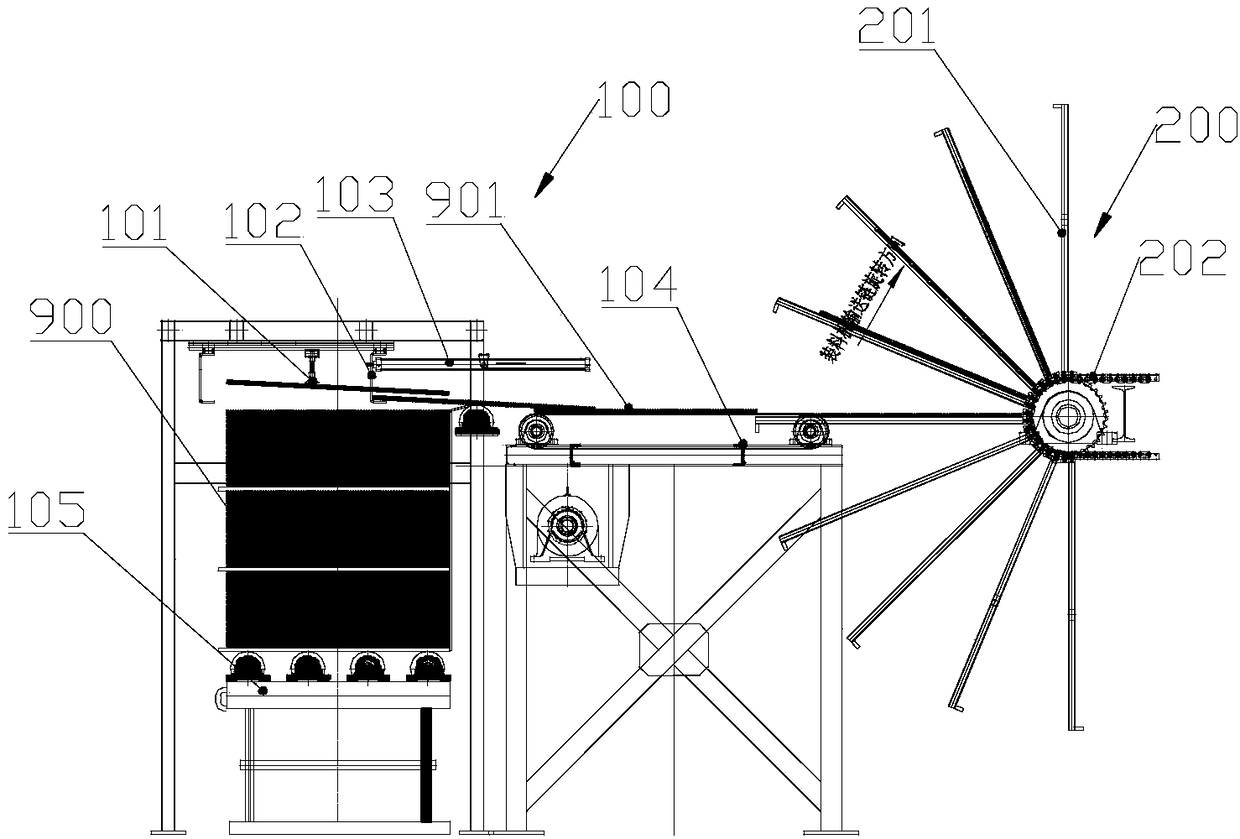

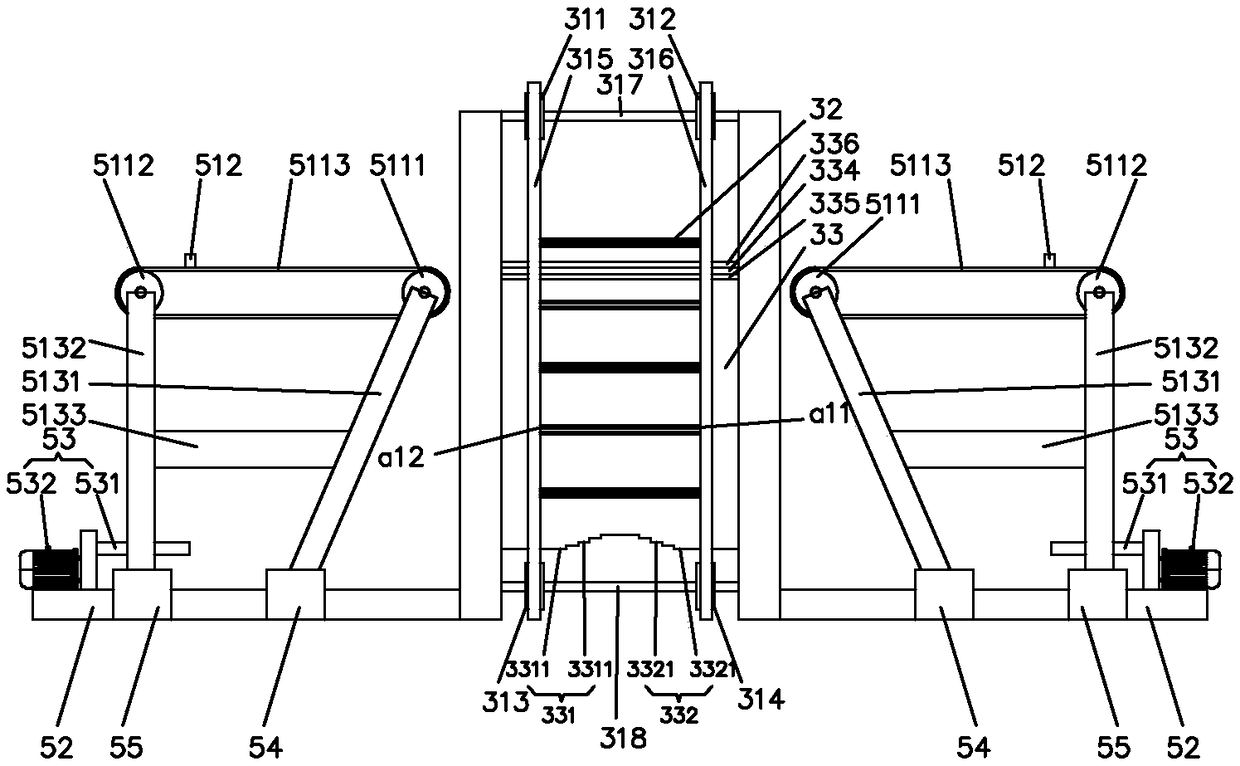

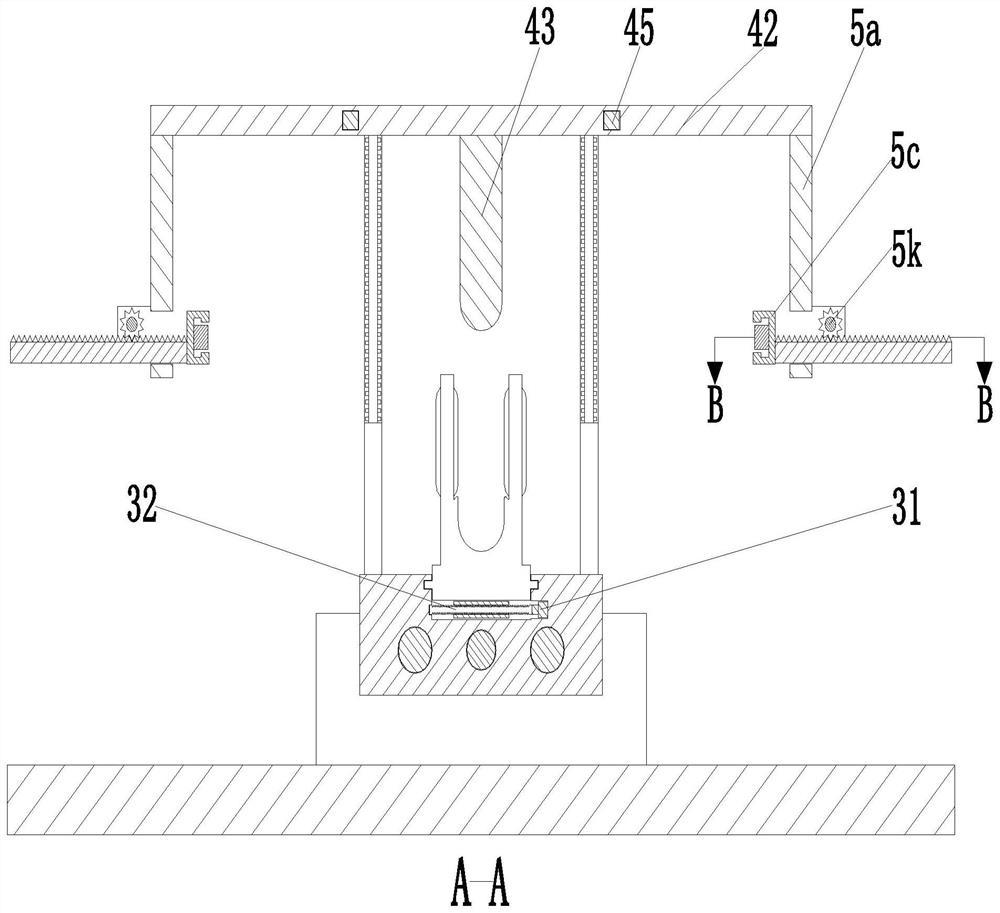

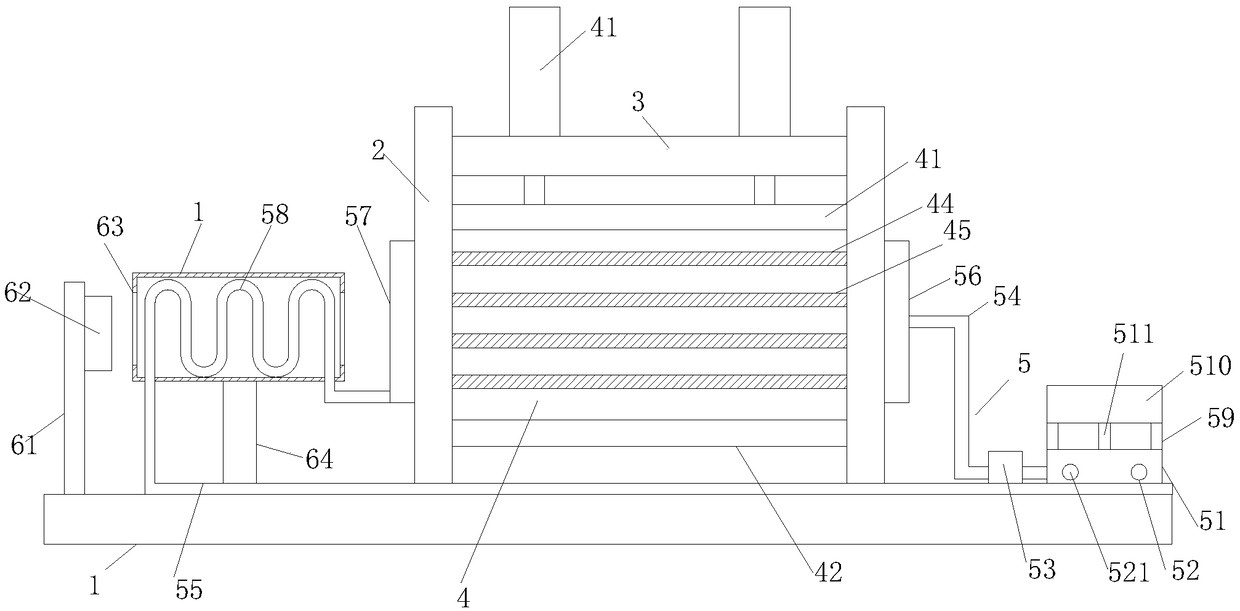

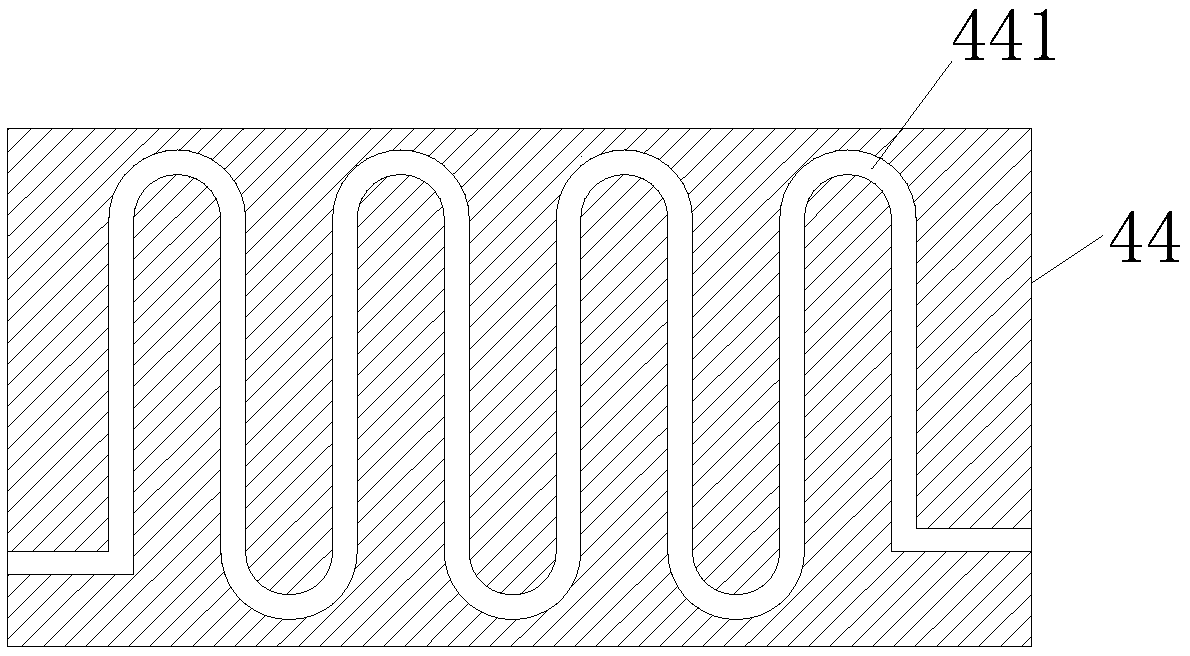

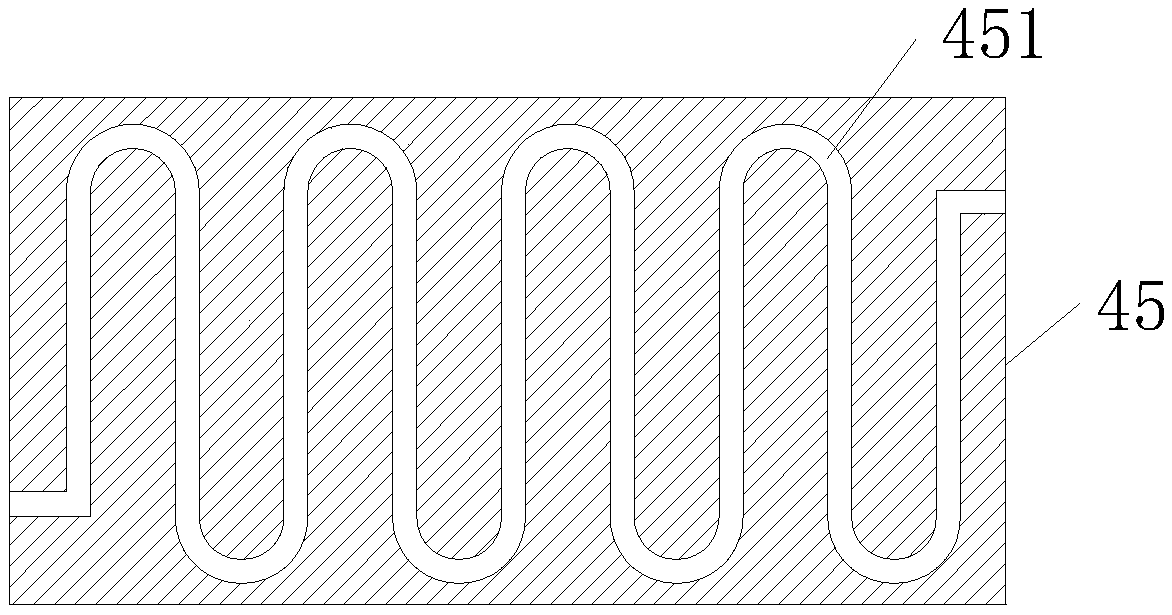

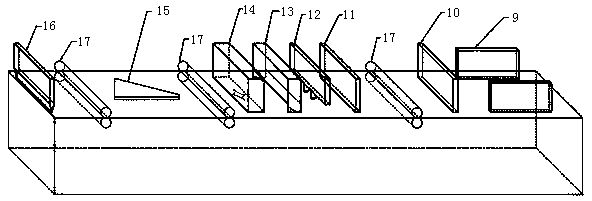

Horizontal hot-pressing machine set

InactiveCN109465920ARealized by hot pressingAchieve clampingPlywood pressesVeneer pressesMechanical engineeringHot press

The invention provides a horizontal hot-pressing machine set, which comprises a feeding assembly, a hot-pressing machine main body and a discharging assembly. Each of the feeding assembly and the discharging assembly comprises a rotatable conveying chain and a plurality of supports rotating along the conveying chain, and spaces for accommodating plates are formed among adjacent supports. The hot-pressing machine main body is arranged between the feeding assembly and the discharging assembly, and comprises a plurality of hot pressing plates arranged parallel to one another and are vertically, all the hot pressing plates are connected with a driving assembly, and all the hot pressing plates move towards one another or move away from one another in opposite directions under the driving of thedriving assembly so as to realize clamping or releasing of the plates. At least two transfer assemblies are respectively arranged below the conveying chain of the feeding assembly and below the conveying chain of the discharging assembly to realize the conveying of the plate from the feeding assembly to the main body of the hot-pressing machine main body and from the hot-pressing machine main body to the discharging assembly. The invention can simultaneously realize the feeding and discharging of the hot-pressing machine main body, realize the uniform heating of a plurality of plates and theequal compression of each plate.

Owner:上海秋林机械有限公司

Automatic plate feeding hot press

ActiveCN108943207AAvoid breakingAchieve precise positioningOther plywood/veneer working apparatusPlywood pressesHeat pressHot pressing

The invention provides an automatic plate feeding hot press. In the actual working process, the automatic plate feeding hot press further comprises a controller for controlling a hot pressing device,an arranging shaping device, a rubberizing device and a supplying device; and under control of the controller, the supplying device conveys template slabs to the arranging shaping device one by one, all the template slabs are rubberized through the rubberizing device, and then the template slabs are pressed into plywood through the hot pressing device. All abutting wheels can stably and smoothly guide and support the movement of horizontal cross beams operating periodically. Moreover, lower end steps which are inclined and arranged step by step can be adapted to the height of the template slabs arranged layer by layer, and all support parts can be rebounded in time without scraping the lower template slabs and a hot pressing base plate. Compared with the prior art, through the automatic plate feeding hot press, the template slabs can be transported, arranged, shaped, rubberized and hot-pressed in one time smoothly, stably and automatically, and the efficiency and practicability are high.

Owner:漳州鑫华成机械制造有限公司

Environment-friendly packaging bag forming processing system

ActiveCN112223845ADecrease productivityIncrease costBag making operationsPaper-makingHot pressManufacturing engineering

The invention relates to an environment-friendly packaging bag forming processing system which comprises a bottom plate, a telescopic device, an adjusting device, a downward pressing device and a hotpressing device. The telescopic device is installed on the bottom plate, the adjusting device and the downward pressing device are installed on the telescopic device, and the hot pressing device is installed on the downward pressing device. The environment-friendly packaging bag forming processing system can solve the following problems existing in existing packaging bag bending and hot pressing:a, during traditional packaging bag bending and hot pressing, a packaging bag needs to be bent manually, and meanwhile, a hot pressing tool is used for performing manual hot pressing operation on thepackaging bag, as a result, the packaging bag produced through manual hot pressing is low in working efficiency and high in cost; and b, when existing packaging bag bending and hot-pressing equipmentbends a packaging bag, the packaging bag is bent unevenly, wrinkles exist on the hot-pressed packaging bag, the attractiveness of the packaging bag is affected, and raw materials are wasted. The environment-friendly packaging bag forming processing system can improve the bending and hot-pressing efficiency and quality of the packaging bag.

Owner:上海众集巨合环保科技集团有限公司

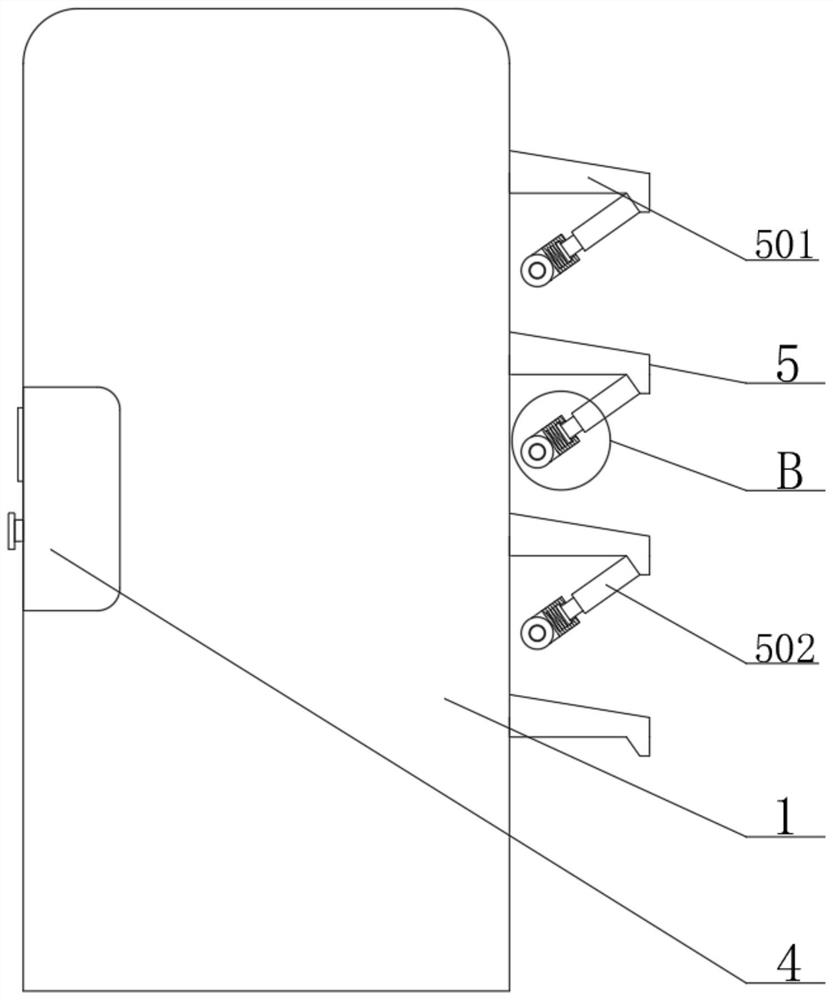

Gold stamping machine

InactiveCN109849502AEasy to operateImprove hot pressing efficiencyRotary pressesHot stampingMotor drive

The invention relates to the technical field of printing machining mechanical research and development design, in particular to a gold stamping machine. According to the adopted following technical scheme, the gold stamping machine comprises a base, a control panel arranged in front of the base, a drawing-type worktable arranged on the upper part of the base, and an adjustable working plate arranged on the upper part of the drawing-type worktable; and a gold stamping device is arranged on the upper part of the adjustable working plate and comprises a heating plate and an air cylinder, a pistonrod is arranged on the upper part of the heating plate, the air cylinder is in driving connection with the piston rod to push a heating block to vertically move, an air cylinder lifting hand wheel isarranged on the rear part of the gold stamping device, and the air cylinder lifting hand wheel is connected with the air cylinder. The gold stamping machine is characterized in that the two sides ofa bracket on the upper part of the heating plate are connected with a feeding reel and a receiving reel correspondingly, a stepping motor drives the feeding reel to rotate through a gear and a conveying belt, and a feeding device is driven to rotate through rotating of the receiving reel. The gold stamping machine has the advantages that a pneumatic automation principle is adopted, operation is easy and convenient, the hot stamping efficiency is high, and the hot stamping effect is good.

Owner:林锦浩

Soybean Adhesive for Water Resistant Particleboard

ActiveCN107216849BMeet spraying requirementsEnsure water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesivePolyamide

The invention discloses a soybean adhesive for a water-resistant shaving board and a preparation method thereof, and relates to an adhesive and a preparation method thereof, in particular to a modified soybean adhesive for production of boiling water boiling-resistant shaving boards, which aims at solving the technical problems of difficulty in adhesive applying in the production process of the shaving board due to large viscosity and difficulty in adapting to the production of the shaving board due to long hot pressing time in the existing soybean adhesive. The method comprises the following steps of 1, synthesizing of modified polyamide polyamine resin; 2, preparing of the adhesive. The prepared soybean adhesive for the water-resistant shaving board is prepared by adding 0.3 to 1.5% of curing agent and 10 to 25 parts of soybean meal into 100 parts of modified polyamide polyamine resin and mixing at room temperature. The soybean adhesive has the advantages that the viscosity is low, the adhesive is conveniently and uniformly sprayed onto the shaving board, the curing speed is high, the water-resistant property is good, and the soybean adhesive is especially suitable for preparing the boiling water boiling-resistant shaving board in the existing shaved board production line. The soybean adhesive belongs to the field of preparation of adhesives.

Owner:牡丹江恒源生化有限责任公司

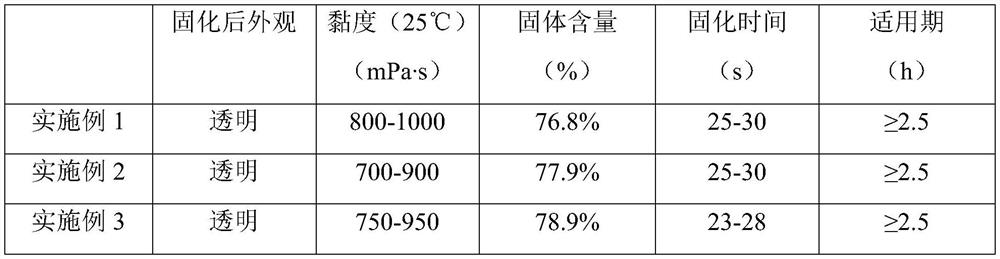

Novel water-resistant composite resin for impregnation of surface layer of laminated wood floor and preparation method of novel water-resistant composite resin

ActiveCN114134751AAppropriate molecular weightSuitable viscositySpecial paperWater-repelling agents additionPolymer sciencePtru catalyst

Owner:山东亿森美居新材料科技有限公司

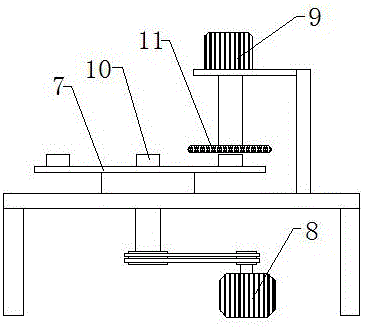

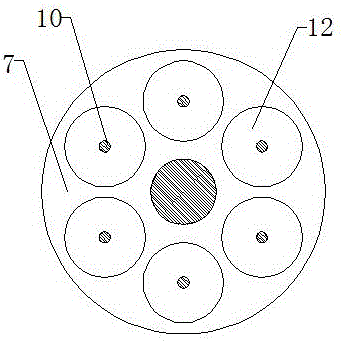

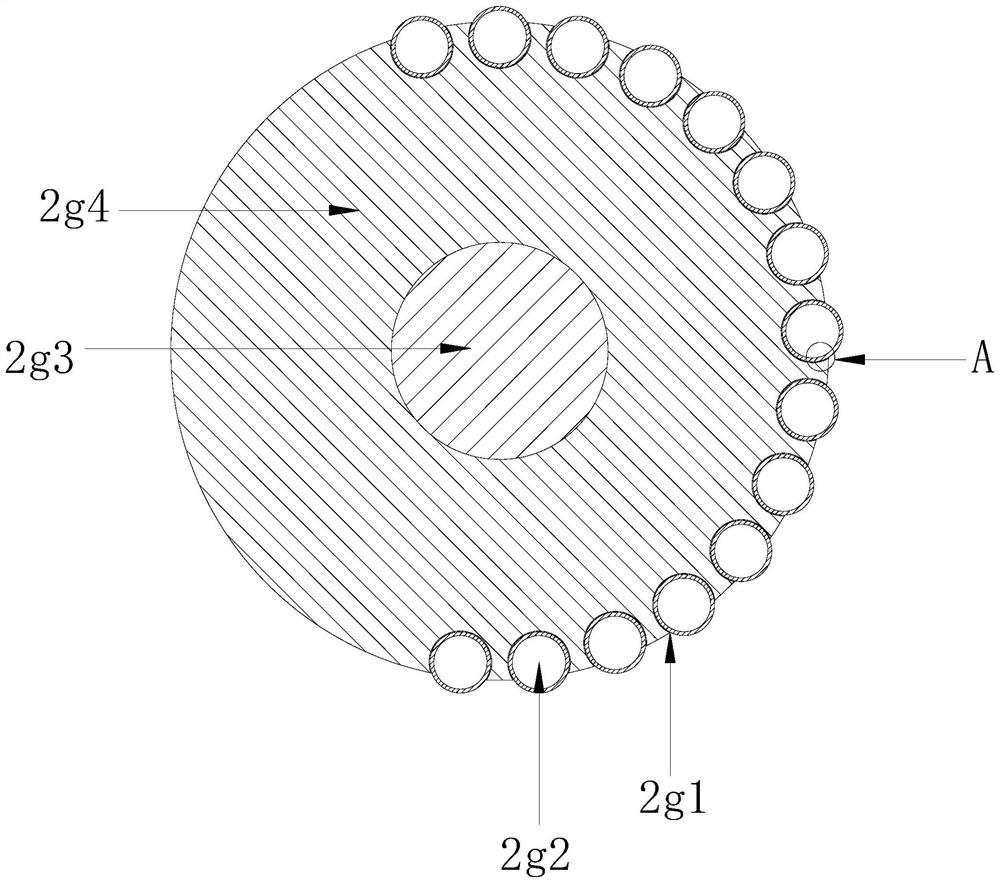

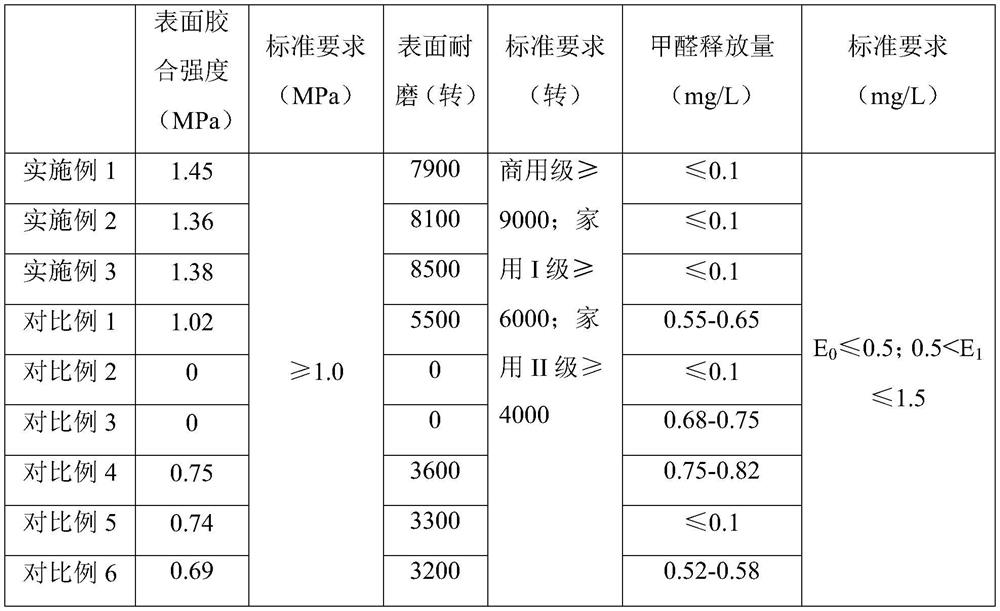

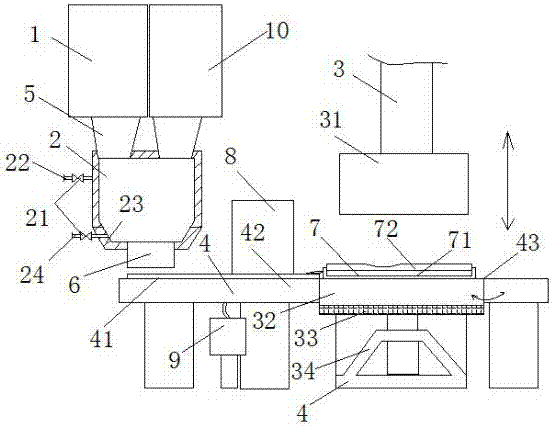

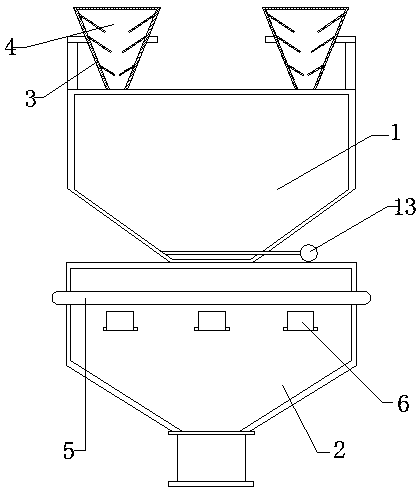

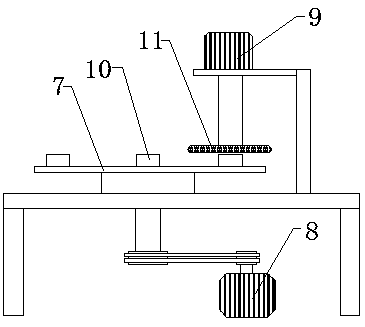

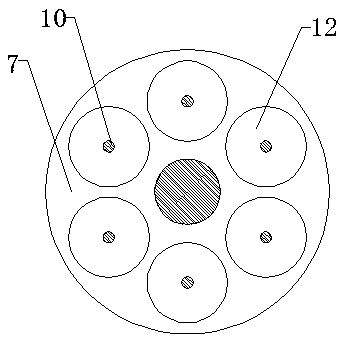

Wood fiber thermal modified wood-plastic composite device and preparation technology of wood-plastic composite

The invention discloses a wood fiber thermal modified wood-plastic composite device. The wood fiber thermal modified wood-plastic composite device comprises an impulse drying barrel, a concentration cyclone, a wood-plastic composite hot pressing device and a hot pressing platform which are sequentially connected, wherein the hot pressing platform is provided with a mold feeding station, a mold conveying device and a mold hot pressing station which are sequentially connected; the impulse drying barrel is connected at the top of the concentration cyclone through a transparent discharge pipe; an upper exhaust pipe is connected in the central height position of the concentration cyclone through a check valve; a vacuum feeding pipe is connected with a mold placed on the mold feeding station, so that dried wood fibers are conveyed; the wood-plastic composite hot pressing device comprises a reciprocating telescopic hot pressing punch, a centrifugal rotary table, a heating unit and a jack support frame which are sequentially arranged from top to bottom; and the mold comprises a mold box body and a piston type cover body which is connected at the top of the mold box body and can extend and retract up and down. According to a thermal modification treatment device, thermal modification performance of a wood-plastic composite is improved, and environmental protection performance and density of the wood-plastic composite are further improved.

Owner:JIANGSU KENTIER WOOD

Plywood hot press

InactiveCN108890809AImprove hot pressing efficiencyImprove the heating effectPlywood pressesVeneer pressesHeating effectEngineering

The invention discloses a plywood hot press. The plywood hot press comprises a base, two symmetrically arranged first brackets, a cross beam, a hot-press device, an oil way device and an air-drying device. The first brackets are welded at the top of the base. The cross beam is welded between the two first brackets. The hot-press device is connected with the cross beam. The oil way device is connected with the hot-press device and the air-drying device. The air-drying device is arranged at the top of the base. The air-drying device is positioned at the left front side of the hot-press device. The plywood hot press is capable of, through using conduction oil as a heating source, enabling the heating effect to be more excellent compared with the heating effect of steam heating, improving hot-press efficiency, saving energy sources, and through a design of the air-drying device, adequately using hot air generated by waste heat of the conduction oil to perform dehumidification operation ona plywood, improving the hot-press effect of the plywood, and further saving the energy sources.

Owner:临泉县荣兴木业有限公司

Plastic fastener hot-pressing device for textile silk thread bundle head

The invention discloses a plastic fastener hot-pressing device for a textile silk thread bundle head. The plastic fastener hot-pressing device comprises a base, a first cavity is formed in the base, the inner bottom wall of the first cavity is fixedly connected with a metal block, a groove is formed in the upper surface of the metal block, the inner side wall of the groove is fixedly connected with an electric heating wire, and a first through hole is formed in the inner side wall of the first cavity. The plastic fastener hot-pressing device for the textile silk thread bundle head is simple tooperate, convenience of the plastic fastener hot-pressing device for the textile silk thread bundle head is ensured, the problem of inconvenience in operation of an existing pressing device is solved, the plastic fastener hot-pressing device for the textile silk thread bundle head has the advantages of convenience in use and high efficiency, the hot-pressing efficiency of the plastic fastener hot-pressing device for the textile silk thread bundle head is improved, practicability of the plastic fastener hot-pressing device for the textile silk thread bundle head is ensured, and the problem ofinconvenience in heat insulation of the existing pressing device is solved.

Owner:浙江鼎兴纺织机械科技有限公司

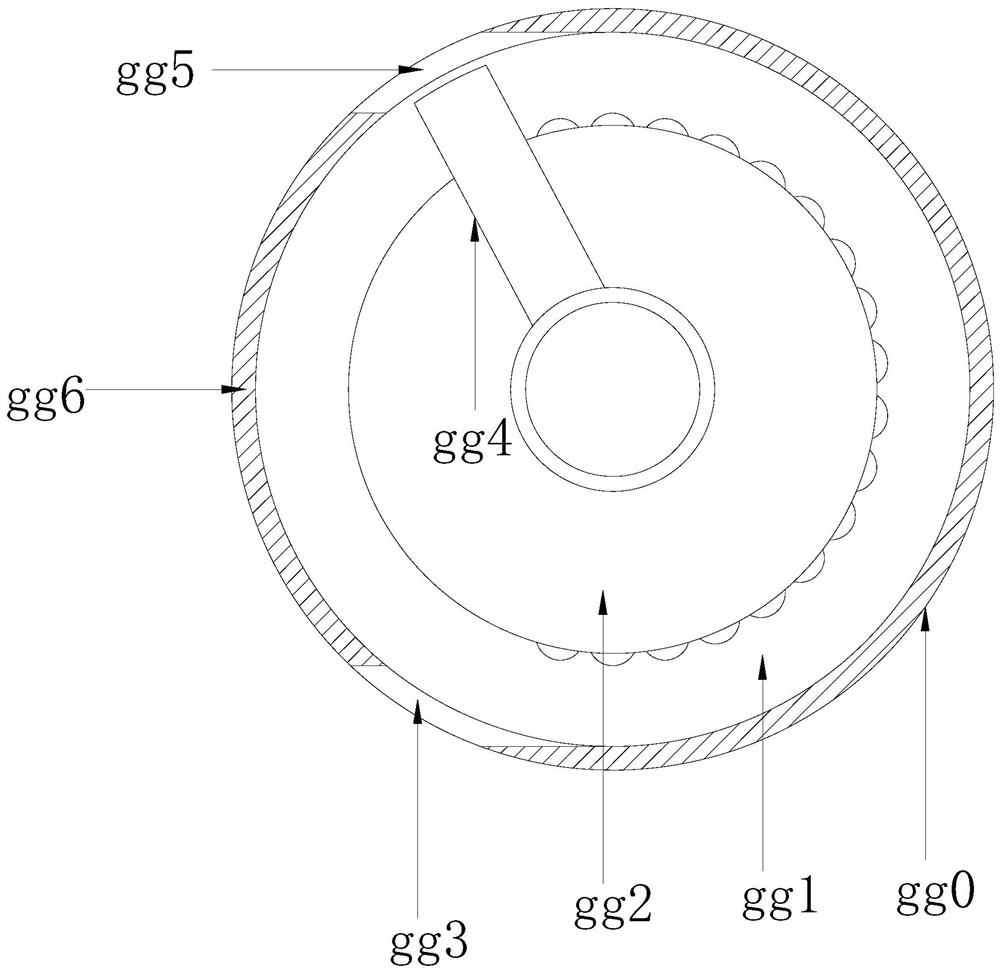

New energy motor shell hot press mounting equipment

InactiveCN111958745AEasy to separateImprove hot pressing efficiencyWood working apparatusDomestic articlesNew energyElectric machine

The invention discloses new energy motor shell hot press mounting equipment, comprising a base, wherein vertical posts are set on the upper end face of the base, a top plate is set at the top ends ofthe vertical posts, symmetrically distributed guide rails are set on the upper end face of the base, and first sliding blocks are in sliding connection within the guide rails. According to the equipment, when the equipment is used, a to-be-processed motor shell is placed on a lower press mold. Cylinders are started. The cylinders drives a base plate to move downward. The base plate drives an upperpress plate to move downward through fixing rods, thereby carrying out hot press on the motor shell. The upper press plate drives sliding sleeves to slide downward out of sliding rods. When the upperpress plate contacts with the motor shell, under the effect of pressure, the upper press plate moves upward, the upper press plate drives the fixing rods to slide upward and first springs are compressed, so a buffering process exists in a downward press process of the upper press plate, the motor shell is prevented from being damaged due to excessive press force of the upper press plate, and thehot press quality of the new energy motor shell hot press mounting equipment is improved.

Owner:巢湖宜安云海科技有限公司

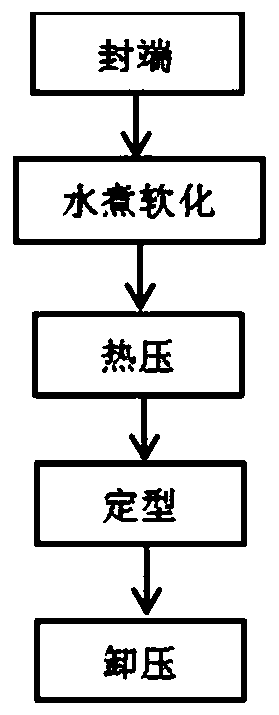

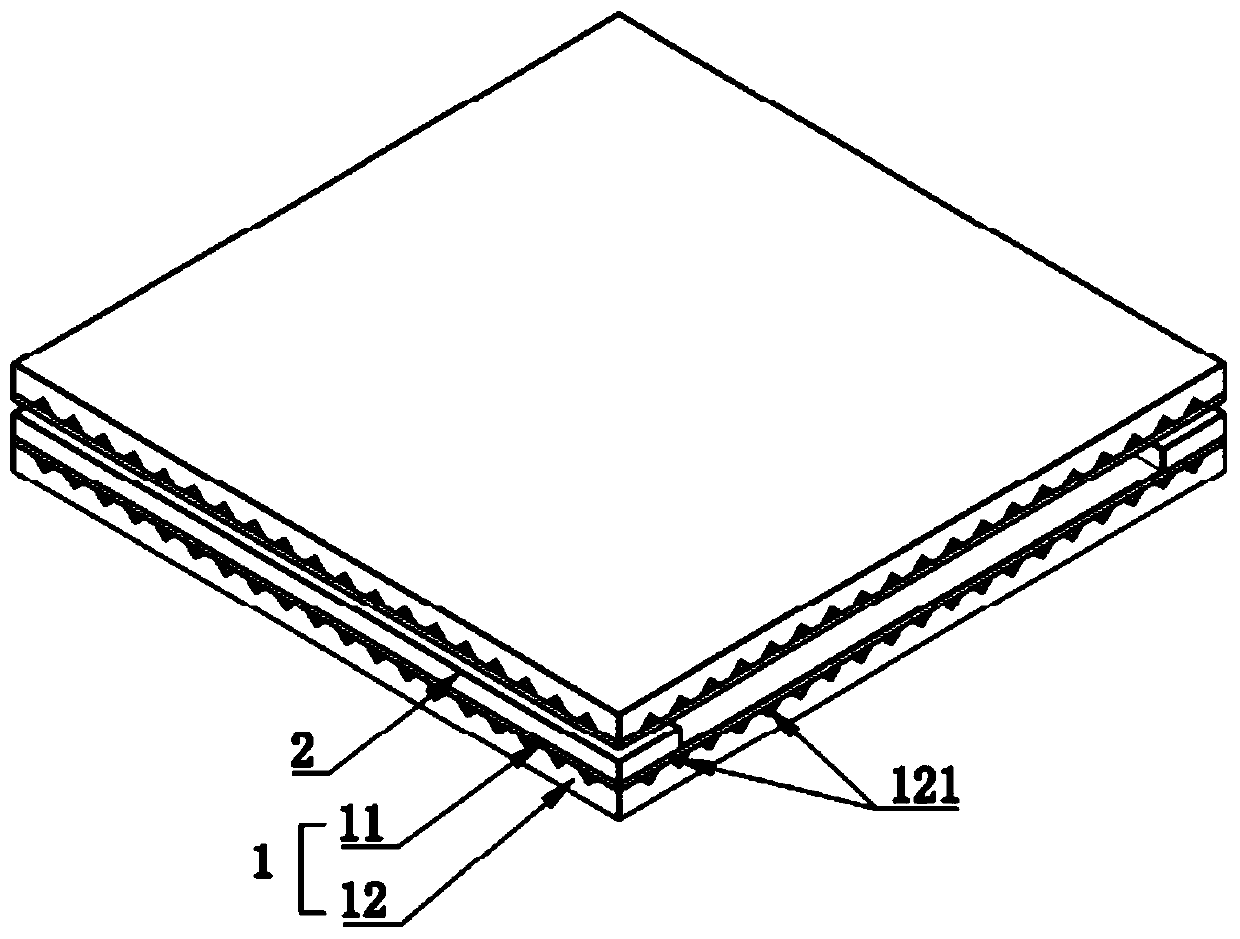

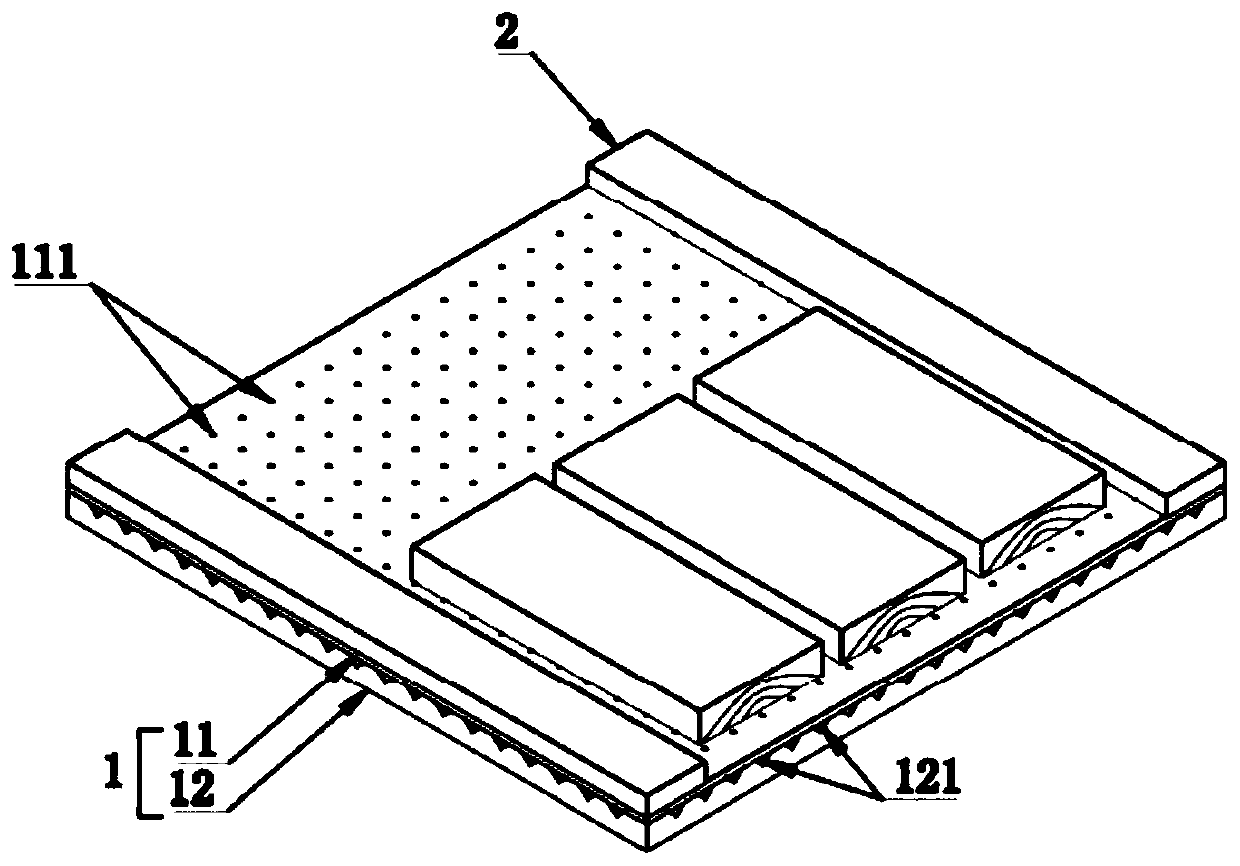

Processing method of compression-enhanced fast growing wood

InactiveCN111300575AAccelerated heat press settingImprove hot pressing efficiencyWood compressionWood treatment detailsAgricultural engineeringStructural engineering

The invention discloses a processing method of compression-enhanced fast growing wood. The processing method comprises the following steps: S1, a pretreated fast growing wood test piece is softened; and S2, the fast growing wood test piece is placed into a hot-pressing die for hot-pressing shaping treatment, and after pressure relief cooling, the compression-enhanced fast growing wood is obtained.The hot-pressing die comprises two symmetrically-arranged pressing plates, the fast growing wood test piece is located between the two pressing plates, the upper surface and the lower surface of thefast growing wood test piece directly make contact with the two pressing plates correspondingly, a plurality of releasing holes are formed in the surface, close to the fast growing wood test piece, ofeach pressing plate, the other ends, in the direction away from one side of the fast growing wood test piece, of the releasing holes communicate with grooves, and water on the surface of the fast growing wood test piece is discharged into the grooves through the releasing holes. Operation is easy, and the water of the compressed wood can be quickly released.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Cutting device and bag making machine

InactiveCN108454175AImprove die-cutting efficiencyImprove die-cut qualityBag making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a cutting device and a bag making machine. The cutting device comprises an integrated die-cutting roller and a die-cutting pressing roller, wherein the integrated die-cutting roller and the die-cutting pressing roller are each in a cylindrical shape. The integrated die-cutting roller is provided with one or more cutters. Each cutter is in a shape the same as that of a cut packaging bag. The cutters are higher than the surface of the integrated die-cutting roller. The die-cutting pressing roller is provided with a groove, and the integrated die-cutting roller and the die-cutting pressing roller move in a face-to-face manner. The bag making machine comprises the cutting device, a hot-press sealing roller and a hot-press pressing roller. Electric heating ceramic blocksare fixed to the hot-press sealing roller. By means of the bag making machine, heat sealing, hole tearing, arc-shaped side corner cutting, arc-shaped corner central corner cutting and longitudinal and transverse slitting are integrated onto the cylindrical hot-press sealing roller and the integrated die-cutting roller to be completed; the original mode of pressing a flat object into a flat objectis changed into the mode of pressing a round object into a round object; and the bag making machine carries out actions without stopping and has the beneficial effects of being compact in structure,small in occupied area, high in bag making speed and high in splitting quality.

Owner:长沙乾伟知识产权服务有限公司

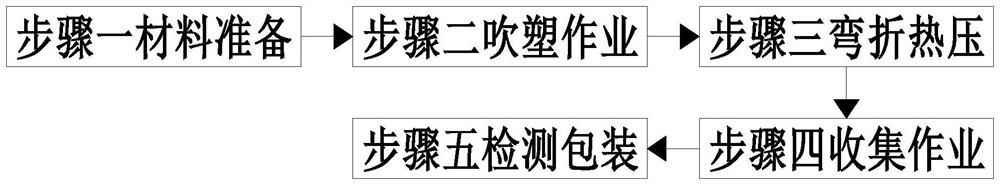

A method for forming an environmentally friendly packaging bag

ActiveCN112238651BDecrease productivityImprove efficiencyBag making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention relates to a method for forming and processing an environmentally friendly packaging bag, which mainly includes the following steps: material preparation, blow molding operation, bending and hot pressing, collection operation, and testing and packaging. The used packaging bag bending and hot pressing equipment includes: Bottom, stretching device, adjusting device, pressing device and hot pressing device, the present invention can solve the following difficult problems existing in the bending and hot pressing of the existing packaging bag, a, when the traditional packaging bag is bent and hot pressed, manual adjustment is required The packaging bag is bent, and the packaging bag is manually hot-pressed with a hot-pressing tool. The manual hot-pressing production of the packaging bag has low work efficiency and high cost; b, the existing packaging bag bending and hot-pressing equipment When the bag is bent, the packaging bag will not be bent evenly, and there will be wrinkles in the hot-pressed packaging bag, which will affect the appearance of the packaging bag, waste raw materials, and can improve the bending and hot-pressing efficiency and quality of the packaging bag.

Owner:揭西县绿雅印刷有限公司

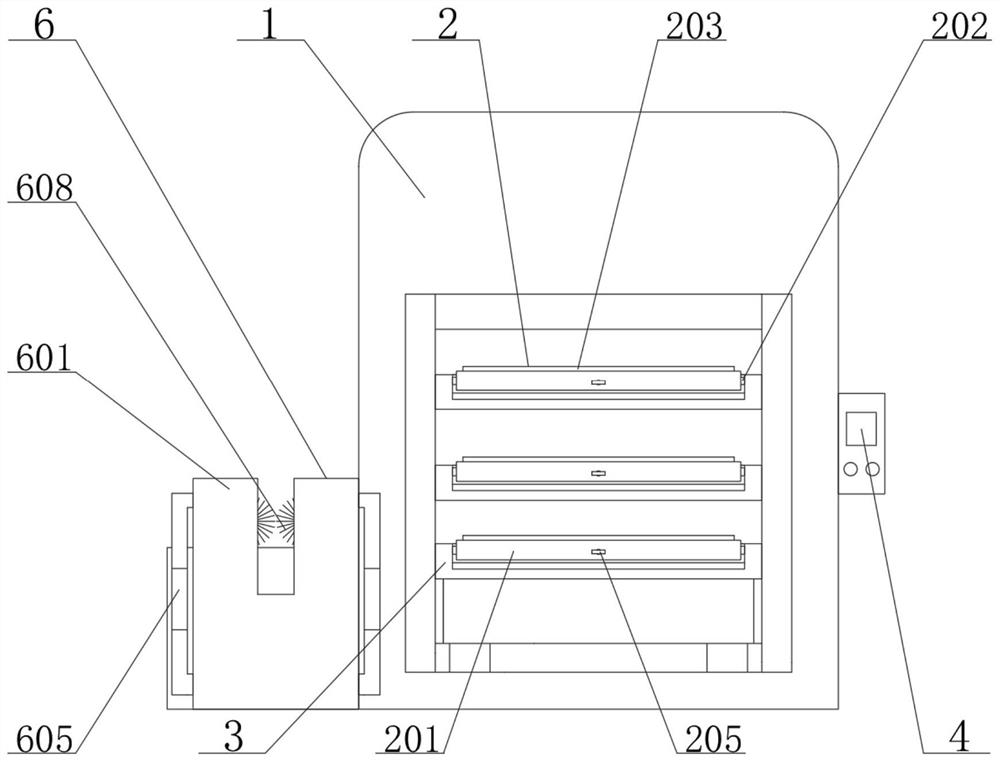

Composite plate pressing processing equipment

ActiveCN111823689BEnsure safetyAccurate placementLamination ancillary operationsDispersed particle filtrationEngineeringComposite plate

The invention relates to the technical field of composite plate processing, in particular to a composite plate press processing equipment, including a hot press, a supporting device, a feeding device and a cleaning device. The inner side of the hot press is fixedly connected with a hot pressing plate. The inner side of the pressing plate is provided with a supporting device, and the supporting device includes a supporting plate, a rotating shaft, a limit plate, a first spring and a handle, and the inner sides of the three hot pressing plates at the bottom are slidably connected with a supporting plate, and the supporting plate The inner rear end is rotatably connected with a rotating shaft, and the rotating shaft is slidably connected to the three hot-pressing plates located at the bottom end. In the present invention, through the set limit plate and the rotating shaft, this setting is coordinated with the rotating connection between the rotating shaft and the support plate. , The sliding connection between the rotating shaft and the hot pressing plate and the elastic force of the first spring on the limit plate, when loading the composite plate, the support mechanism can be pulled out for loading, and then it can be placed quickly and accurately, and the operation Simple and convenient, ensuring the safety of staff.

Owner:安徽润象新材料科技有限公司

A kind of plywood and hot pressing method thereof

ActiveCN111319102BImprove performanceHigh bonding strengthLaminationLamination apparatusSingle plateEngineering

The invention provides a plywood and its hot-pressing method. The hot-pressing method comprises the following steps: applying glue to the veneer, forming a billet, and after cold-pressing, boosting the pressure to 1.20‑1.30 MPa for the first time; then releasing the pressure for the first time to 0.3 ‑0.5MPa, the steam exhausting time is not more than 6 times of the initial boosting stabilization time; the second boosting to 1.20‑1.30MPa, the duration is not longer than the initial boosting stabilization time, after the thickness of the slab is fixed, the second pressure relief ; When the pressure is released to 0MPa for the second time, take out the plate. The hot-pressing method described in the present invention is a preferred hot-pressing mode for plywood under the synergy of multiple factors. By reducing the relative time of high pressure and efficiently discharging the moisture inside the slab, it not only effectively shortens the hot-pressing time and improves the hot-pressing efficiency, but also can Strengthen the performance of the board, reduce the compression rate of the board itself, so as to improve the utilization rate of wood.

Owner:BEIJING FORESTRY UNIVERSITY +3

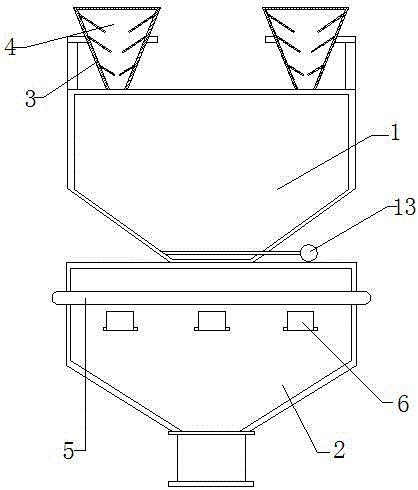

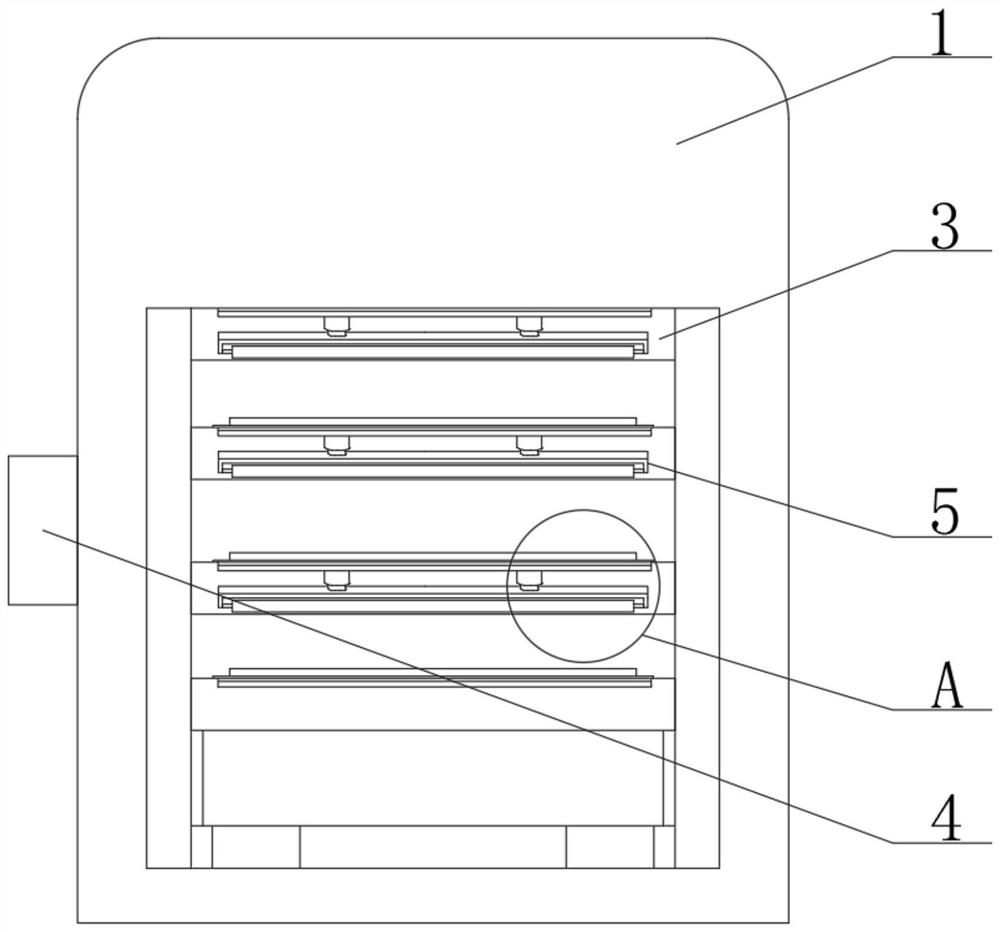

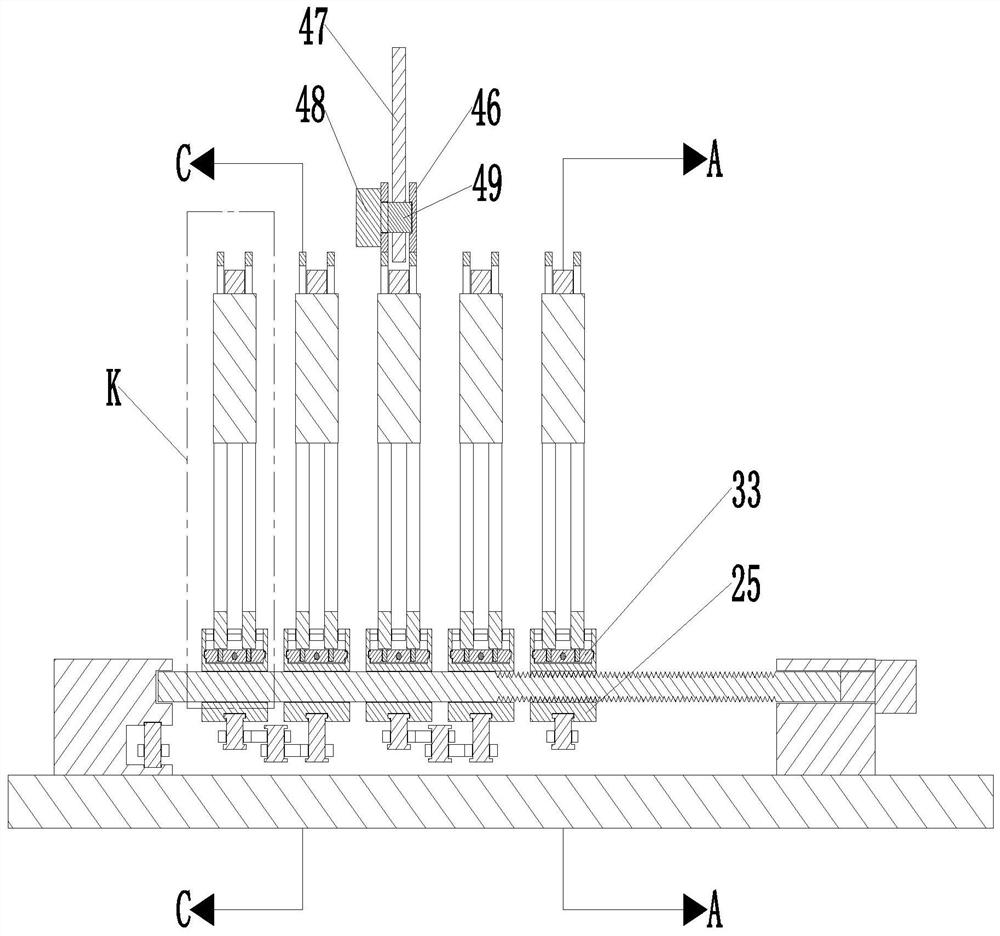

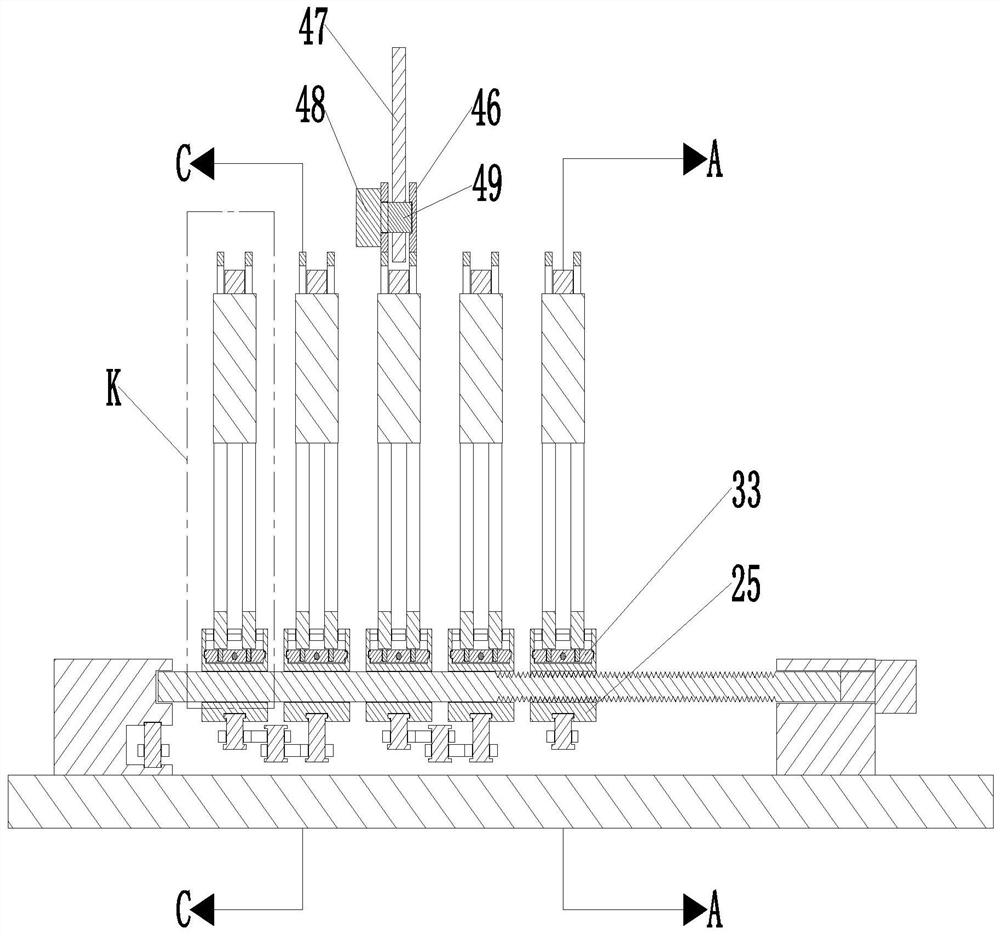

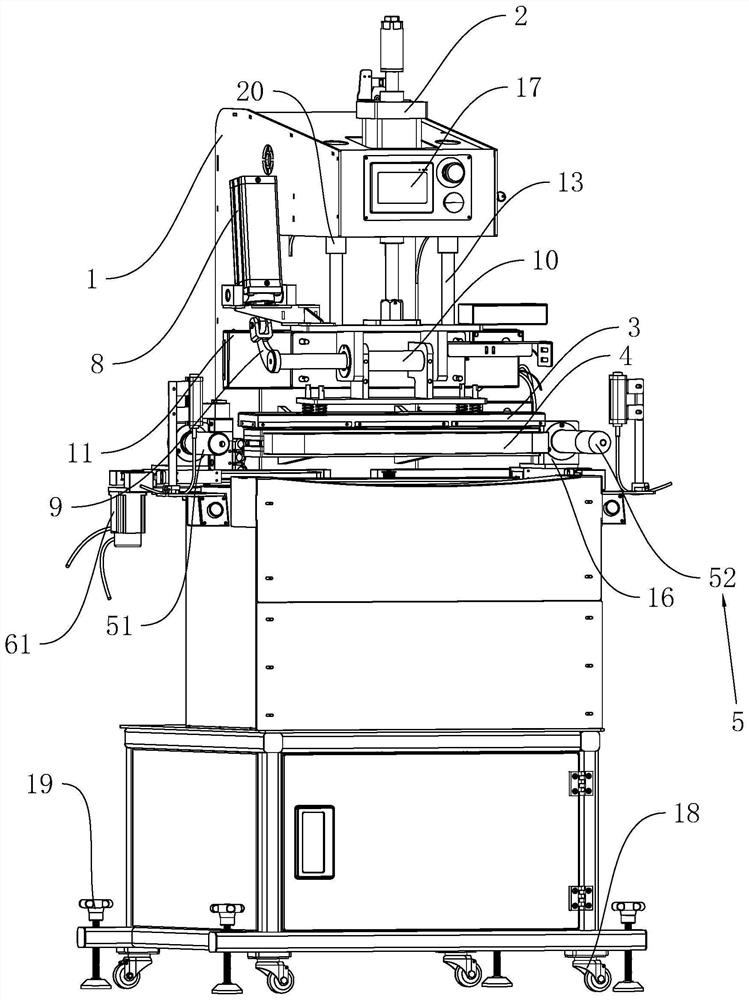

Automatic hot pressing equipment

The invention discloses automatic hot pressing equipment which comprises a shell, a bottom plate, a positioning plate, a stock bin, discharging channels, a controller and guide-in channels. The shell is arranged on the bottom plate, the positioning plate, the discharging channels and the controller are arranged at the bottom in the shell, the positioning plate is located at the bottom in the shell, the stock bin is arranged at the top of the shell, the multiple discharging channels are vertically arranged, the upper portions of the discharging channels are connected with the stock bin through the guide-in channels, the controller is electrically connected with the discharging channels, and discharging switches are arranged on the guide-in channels. A plastic plate into which nuts are to be pressed is placed on the positioning plate, a plurality of nuts to be pressed into the plastic plate are placed in the stock bin, the nuts enter the upper portions of the discharging channels from the leading-in channels, the nuts are pressed down in the discharging channels, the nuts are heated in the downward movement process, after the nuts make contact with the plastic plate, downward pressure is continuously applied by parts in the discharging channels, the nuts are pressed into the plastic plate, and the multiple discharging channels synchronously press the nuts into the plastic plate.

Owner:珠海捷派自动化科技有限公司

Hot-press forming process of high-strength continuous-tooth diamond saw blade

ActiveCN105834518BImprove performanceReasonable ratioMetal sawing tool makingStone-like material working toolsAlloyCobalt

The invention discloses a high-strength continuous-tooth diamond saw blade and a hot press molding technology thereof. The continuous-tooth diamond saw blade comprises the following main materials according to volume fractions: 12-15% of diamond, 20-26% of copper, 40-42% of iron, 3-8% of tin, 5-10% of nickel, 5-10% of cobalt and 3-5% of alloy powder as an auxiliary material. A method for producing the continuous-tooth diamond saw blade comprises the following steps: batching, pre-mixing, total mixing, cold press pre-molding, hot press sintering, primary cooling, high-frequency welding, secondary cooling, surface treatment, paint spraying, edging and the like. The strength and the wear resistance of the diamond saw blade which is produced by the formula and the technology of the invention are improved, in an actual using process, the service life is prolonged, the production cost is greatly saved, resources are saved, and moreover, the technology is environmentally friendly, sanitary and safe in a production process.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

Opening and hot-pressing equipment for underpants elastic band

ActiveCN112137220AImprove adhesionGood for controlling stretchLaminationLamination apparatusWorkbenchPhysics

The invention relates to opening hot-pressing equipment for an underpants elastic band. The equipment comprises a rack, a first air cylinder is fixed to the rack, a hot-pressing device used for hot pressing is fixed to the first air cylinder, an opening device used for opening an underpants elastic band and a first driving mechanism used for driving the opening device to move to open the underpants elastic band are arranged on the rack, a workbench is further fixed to the rack, when the underpants elastic band is unfolded by the unfolding device, the two sides of the underpants elastic band are arranged in the circumferential direction of the side face of the workbench in a winding mode, and the hot-pressing device is located above the workbench. The equipment has the advantages that: theunderpants elastic band and underpants can be better attached, and the underpants elastic band can bond the underpants in a more all-around mode.

Owner:广州高科制衣设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com