Hot-press forming process of high-strength continuous-tooth diamond saw blade

A diamond saw blade and hot pressing forming technology, applied in stone processing tools, metal sawing equipment, metal processing equipment and other directions, can solve the problems of short service life of diamond saw blades, influence of cutting effect, etc. Effect of uniformity, efficiency improvement, improvement of hot pressing efficiency and hot pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: High-strength continuous tooth diamond saw blade, the continuous tooth diamond saw blade includes main materials according to the volume fraction: diamond 12%, copper 26%, iron 40%, tin 6%, nickel 5%, cobalt 8% and auxiliary materials Alloy powder 3%.

[0038]The high-strength continuous-tooth diamond saw blade hot-press forming process includes the following steps:

[0039] (1) Ingredients: select the main materials diamond, copper, iron, tin, nickel, cobalt and alloy powder according to the volume fraction ratio, and reserve;

[0040] (2) Pre-mixing: Pre-mixing mechanism 1 is used to mix iron and cobalt for 40 minutes. After the iron and cobalt are mixed, add the remaining diamond, copper, tin and nickel from the feeding equipment of the pre-mixing mechanism at the same time. As well as alloy powder, the feed rate of copper is set to twice the feed rate of diamond, and the pre-mixing time of dry material is 6h;

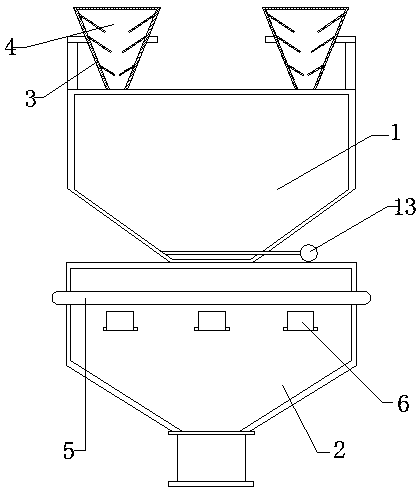

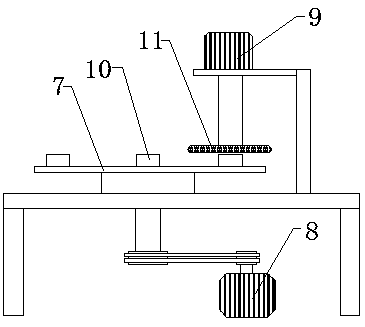

[0041] Such as figure 1 As shown, a pl...

Embodiment 2

[0056] Embodiment 2: High-strength continuous-toothed diamond saw blade, the continuous-toothed diamond saw blade includes main materials according to the volume fraction: 15% diamond, 20% copper, 42% iron, 3% tin, 10% nickel, 5% cobalt and auxiliary materials Alloy powder 5%.

[0057] The difference with the technique of embodiment one is:

[0058] (2) Pre-mixing: Pre-mixing mechanism 1 is used to mix iron and cobalt for 35 minutes. After the iron and cobalt are mixed, add the remaining diamond, copper, tin and nickel from the feeding equipment of the pre-mixing mechanism at the same time. As well as alloy powder, the feeding speed of copper is set to 1.5 times of the feeding speed of diamond, and the pre-mixing time of dry material is 5.5h;

[0059] And the blanking opening diameter of a transition funnel 4 at the lowermost end in the feeding trough of copper is set as 1.5 times of the blanking opening caliber size of a transition funnel 4 at the lowest end in the diamond f...

Embodiment 3

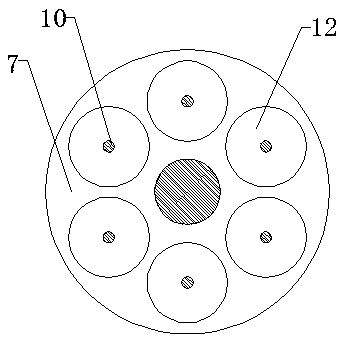

[0069] Embodiment 3: High-strength wear-resistant diamond saw blade 12, the diamond saw blade 12 includes main materials according to the volume fraction: 15% diamond, 20% copper, 42% iron, 3% tin, 10% nickel, 5% cobalt and auxiliary materials Alloy powder 5%.

[0070] The difference with the technique of embodiment one is:

[0071] (2) Pre-mixing: Pre-mixing mechanism 1 is used to mix iron and cobalt for 30 minutes. After the iron and cobalt are mixed, add the remaining diamond, copper, tin and nickel from the feeding equipment of the pre-mixing mechanism at the same time. As well as alloy powder, the feed rate of copper is set to 1.5 times of the feed rate of diamond, and the pre-mixing time of dry material is 5h;

[0072] And the blanking opening diameter of a transition funnel 4 at the lowermost end in the feeding trough of copper is set as 1.5 times of the blanking opening caliber size of a transition funnel 4 at the lowest end in the diamond feeding trough;

[0073] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com