Patents

Literature

480 results about "Diamond blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, coal balls, glass, and ceramics in the construction industry; cutting semiconductor materials in the IT industry; and cutting gemstones, including diamonds, in the gem industry.

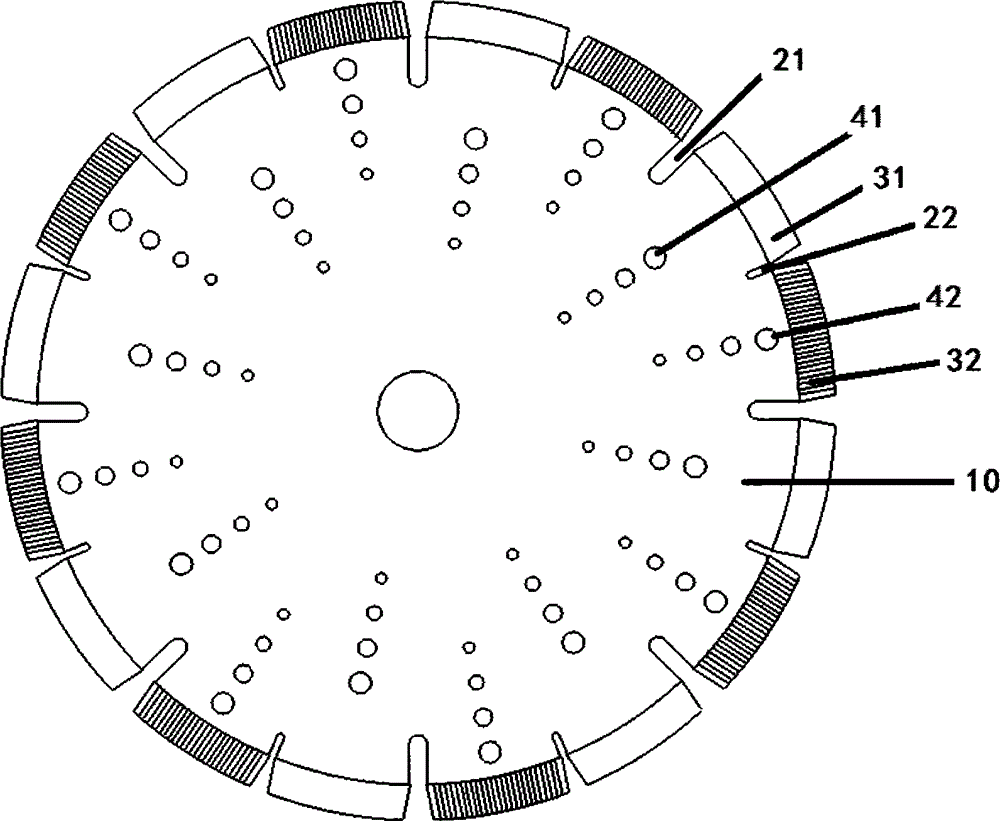

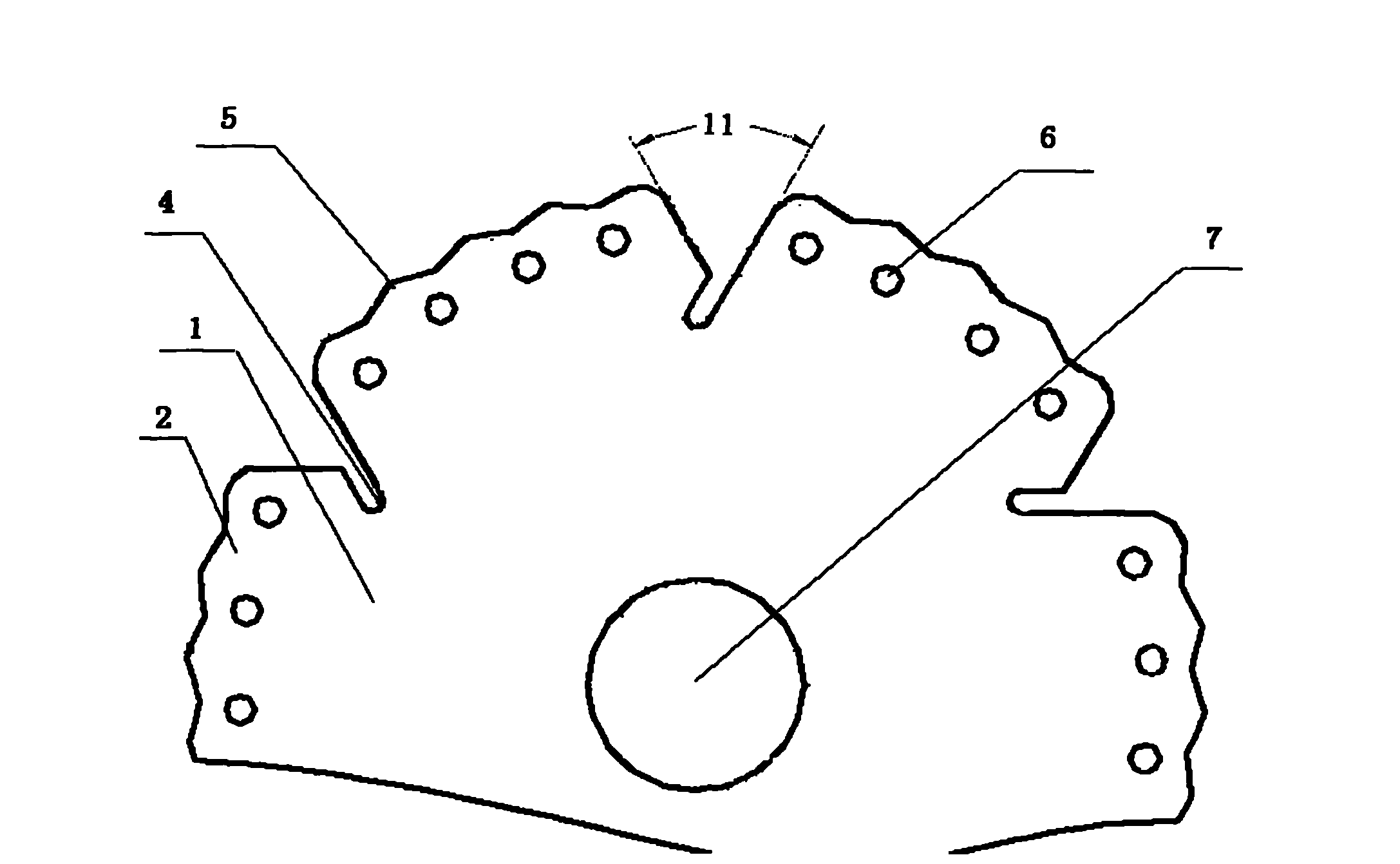

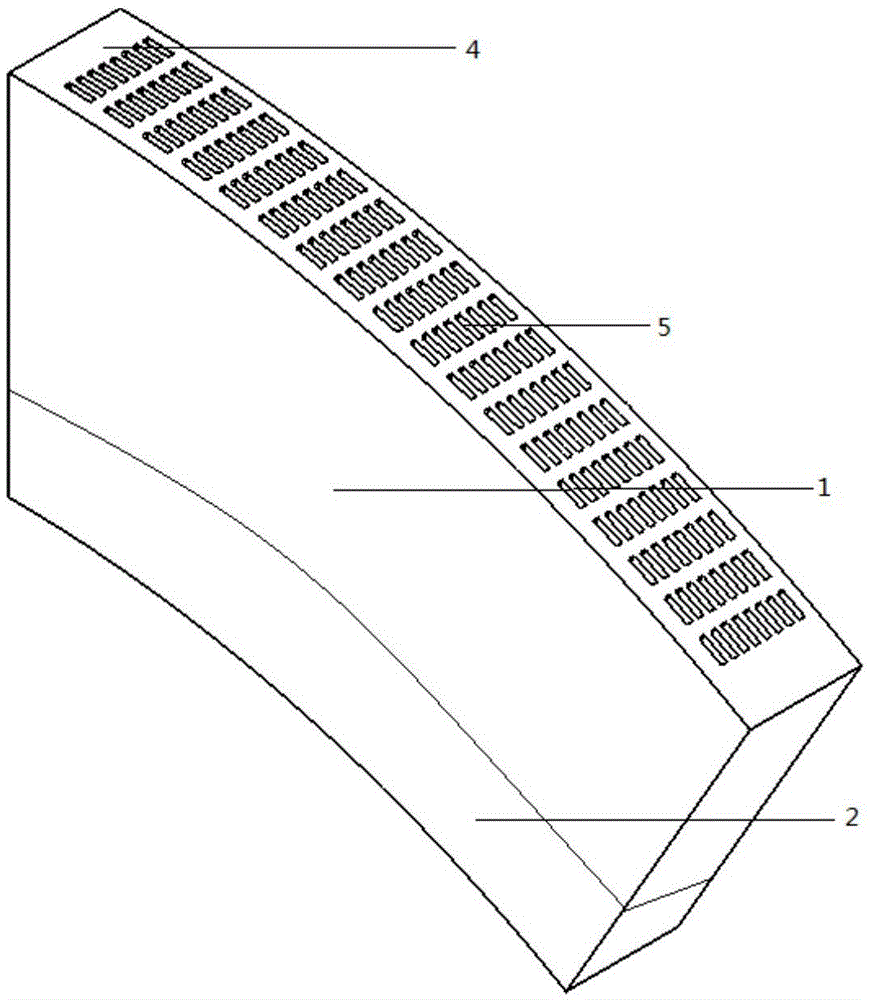

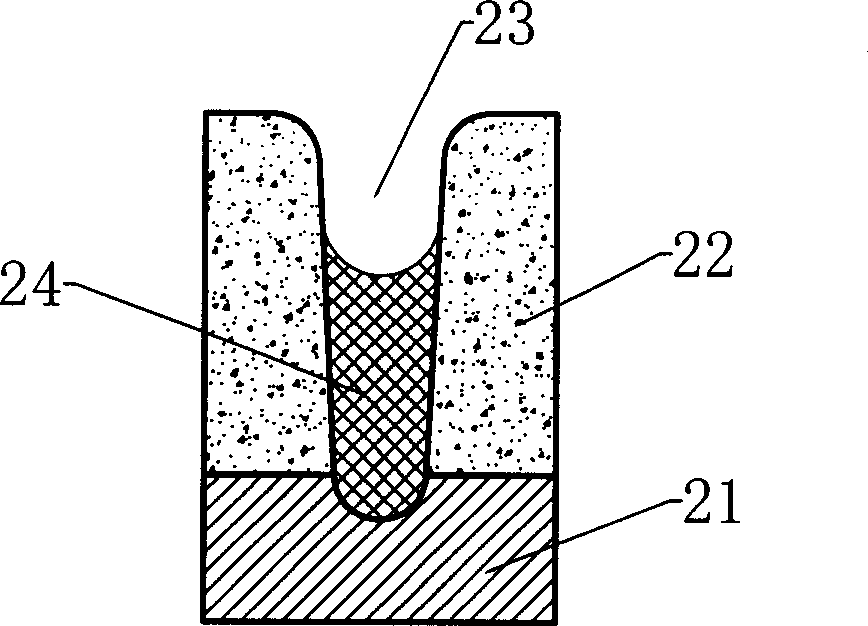

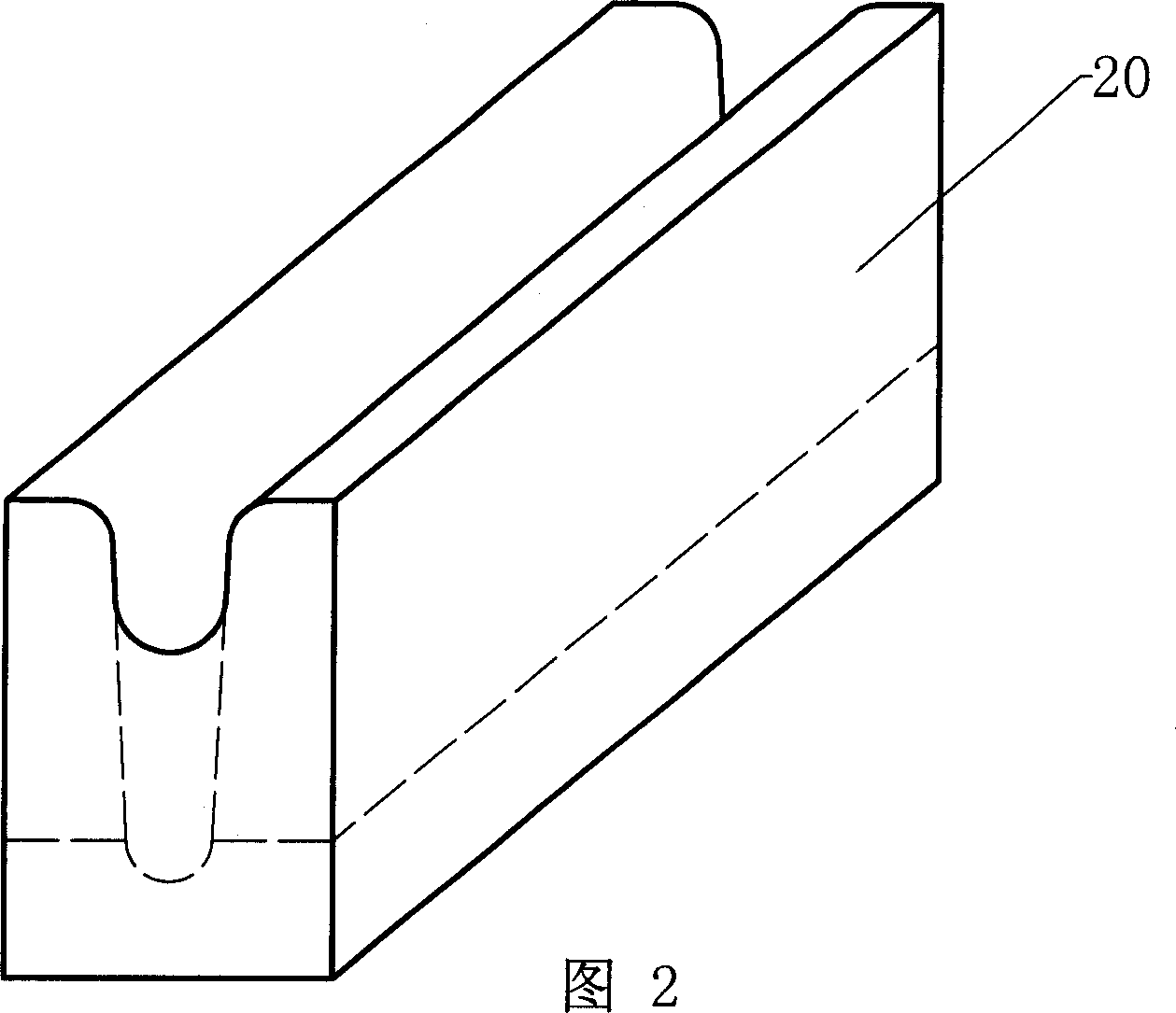

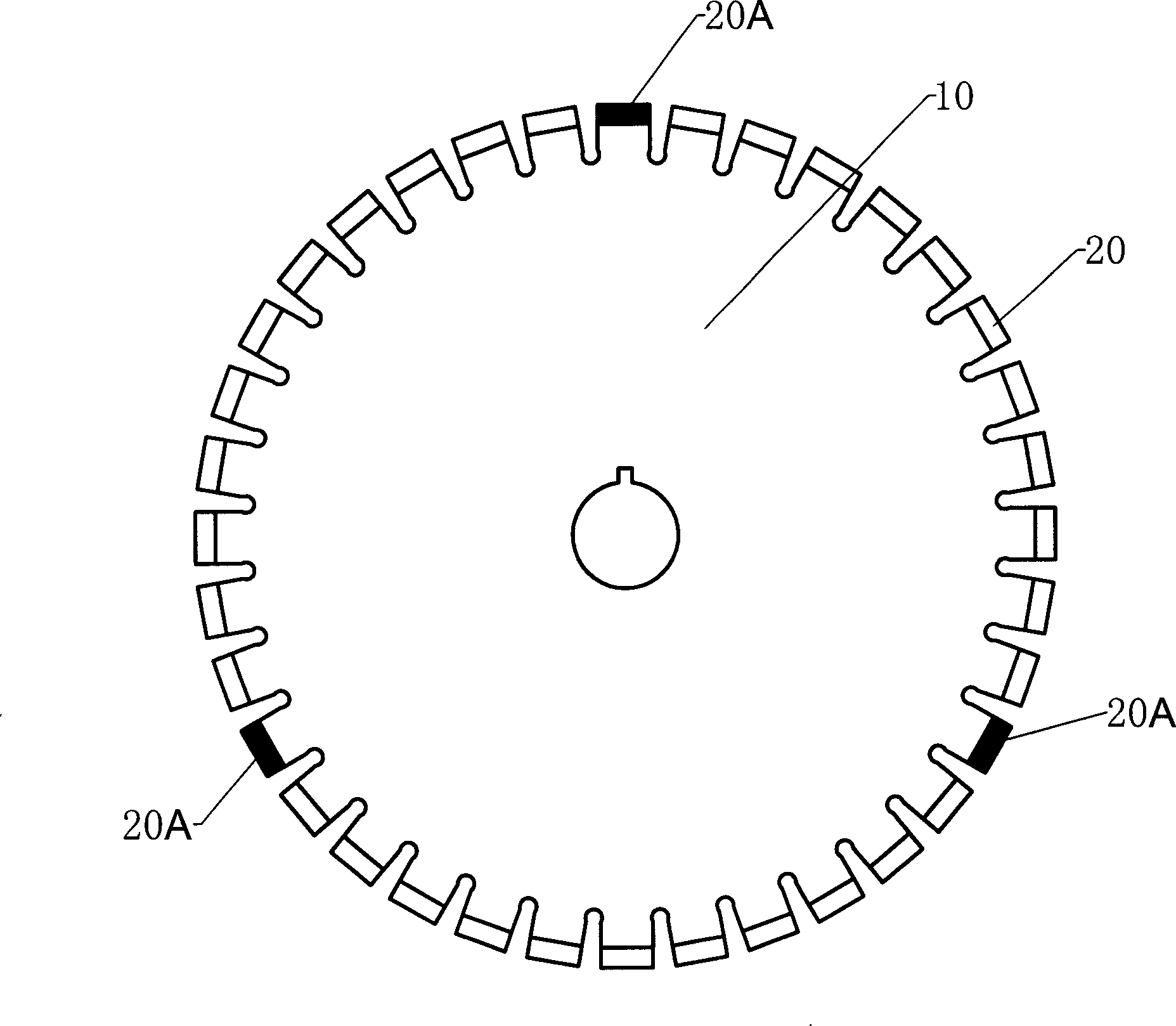

Dry and wet dual-purpose laser welding diamond saw blade

ActiveCN104875287AImprove cutting efficiencyImprove cutting effectStone-like material working toolsDual purposeMaterials science

The invention relates to a dry and wet dual-purpose laser welding diamond saw blade, and belongs to the technical field of diamond processing tools. The diamond saw blade comprises a circular base body which comprises a side circumferential surface located on the edge. A plurality of chip removal grooves extending in the circle center direction inwards are formed in the side circumferential surface at intervals. Diamond tool bits are formed between the chip removal grooves. The chip removal grooves include the first chip removal grooves and the second chip removal grooves, wherein the first chip removal grooves and the second chip removal grooves are formed at intervals. The diamond tool bits include the first diamond tool bits and the second diamond tool bits, wherein the first diamond tool bits and the second diamond tool bits are arranged at intervals. The cross sections of the first chip removal grooves are larger than those of the second chip removal grooves. The surfaces of the first diamond tool bits are planes. A plurality of protruding strips are arranged on the surfaces of the second diamond tool bits. Grooves are formed between the protruding strips. Chip removal and heat dissipation can be well conducted through the diamond saw blade in the cutting process, the good cutting performance can be kept under the condition of no cooling water grinding, and the purpose of conducting processing under extreme conditions is achieved for users.

Owner:JIANGSU FENGTAI TOOLS

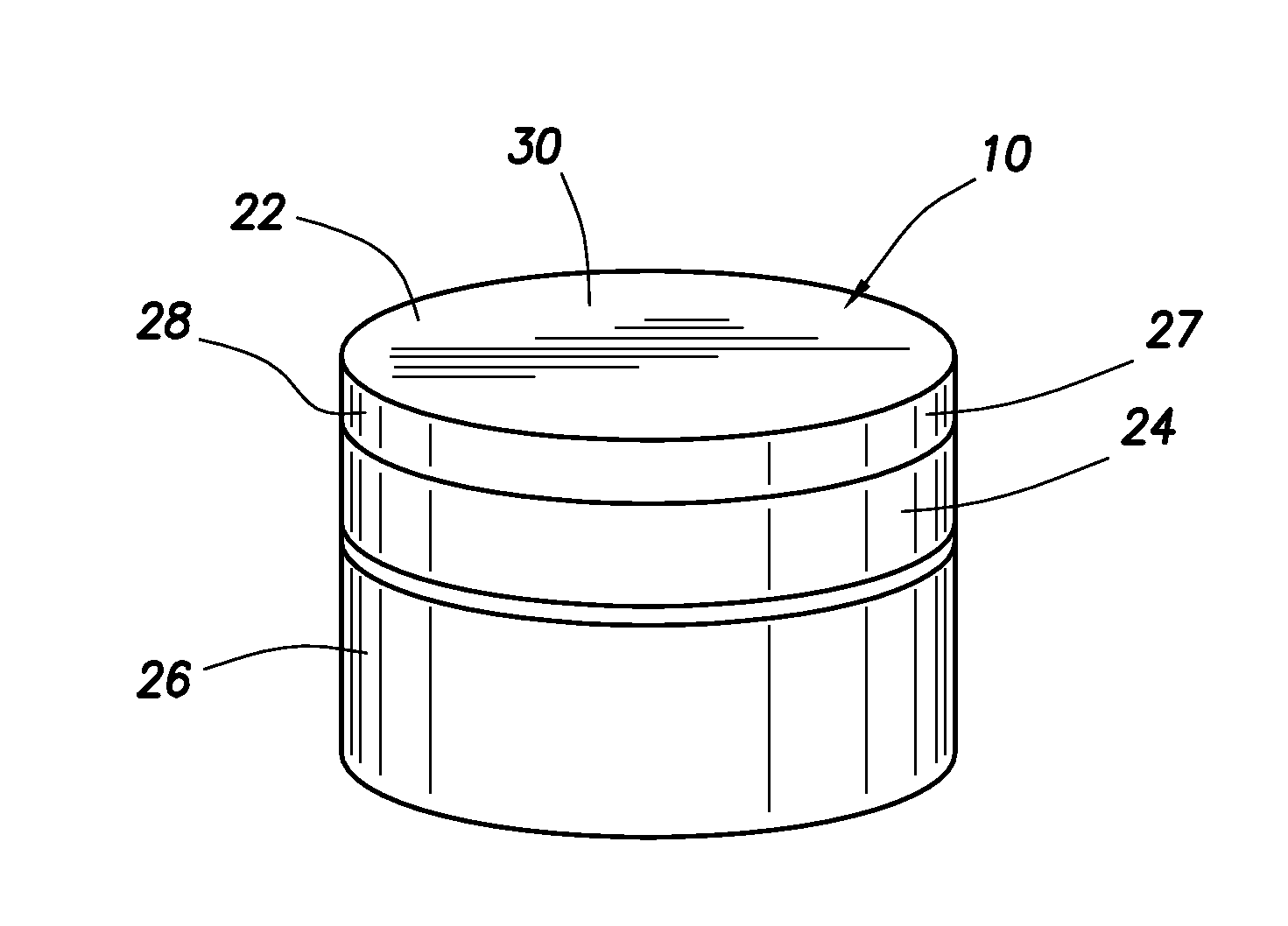

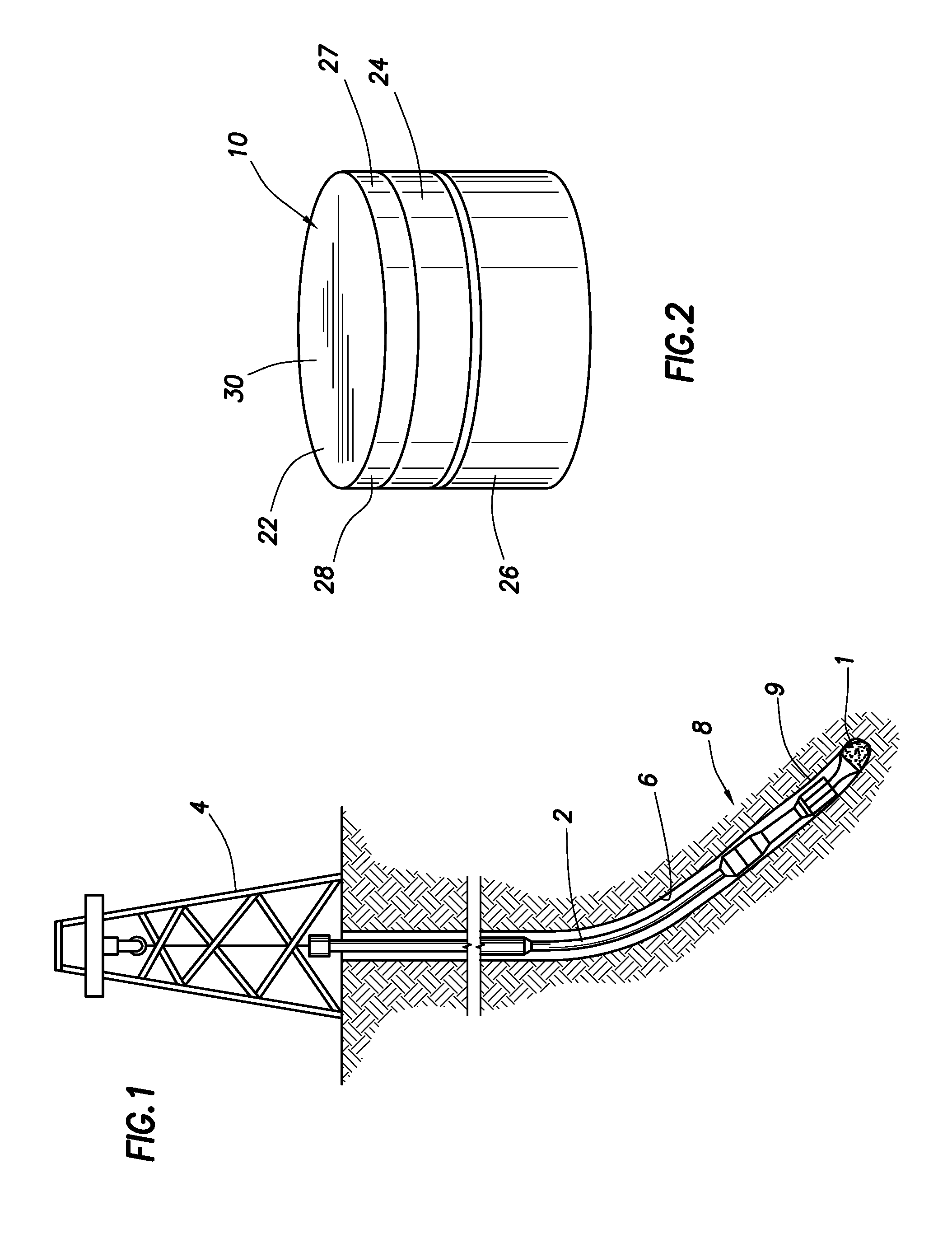

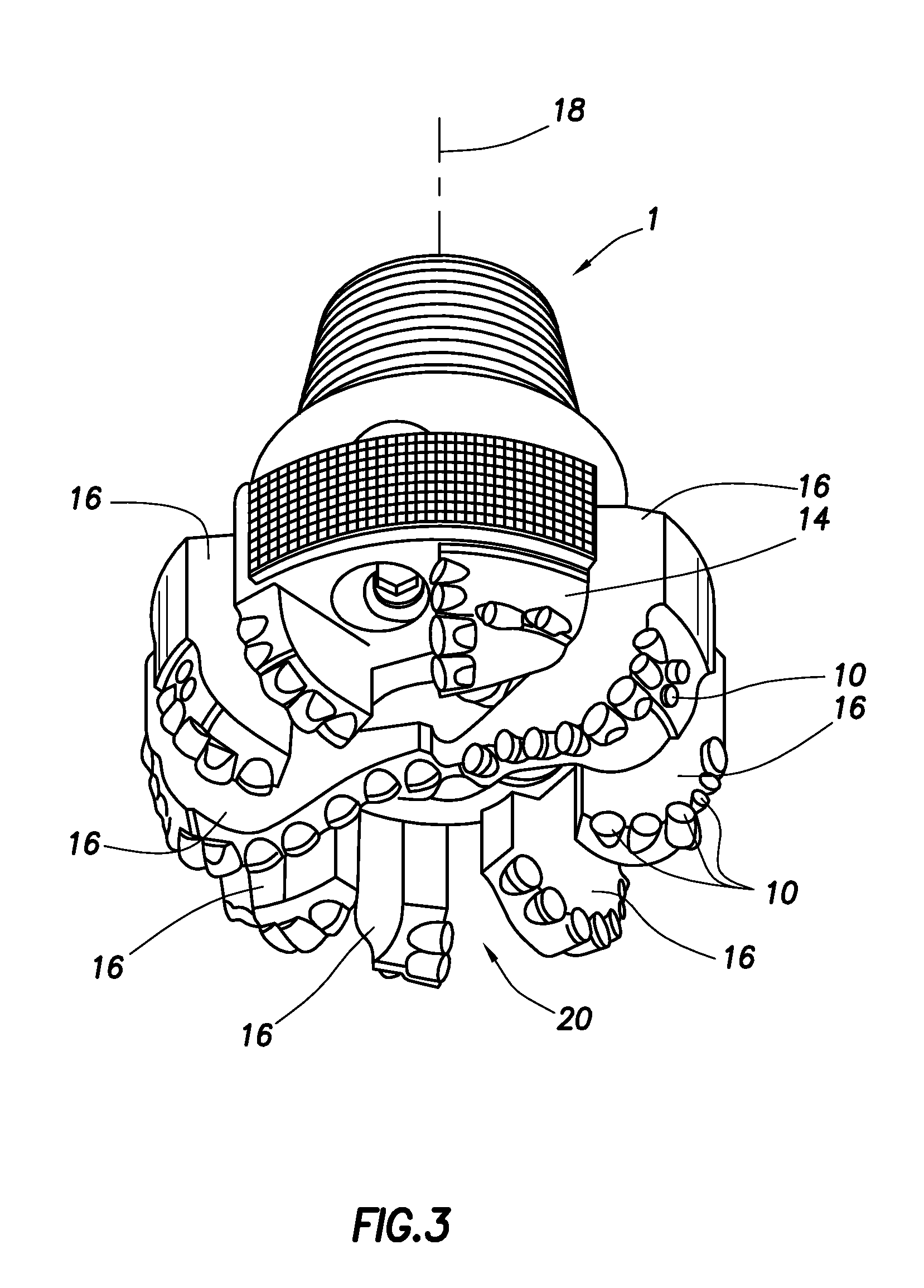

Polycrystalline diamond cutting element

ActiveUS20120097457A1Improve wear lifeImprove featuresDrill bitsConstructionsPolycrystalline diamondDrill bit

A polycrystalline-diamond cutting element for a drill bit of a downhole tool. The cutting element includes a substrate and a diamond table bonded to the substrate. The diamond table includes a diamond filler with at least one leached polycrystalline diamond segment packed therein along at least one working surface thereof. The cutting element may be formed by positioning the diamond table on the substrate and bonding the diamond table onto the substrate such that the polycrystalline diamond segment is positioned along at least one working surface of the diamond table. A spark plasma sintering or double press operation may be used to bond the diamond table onto the substrate.

Owner:NAT OILWELL DHT

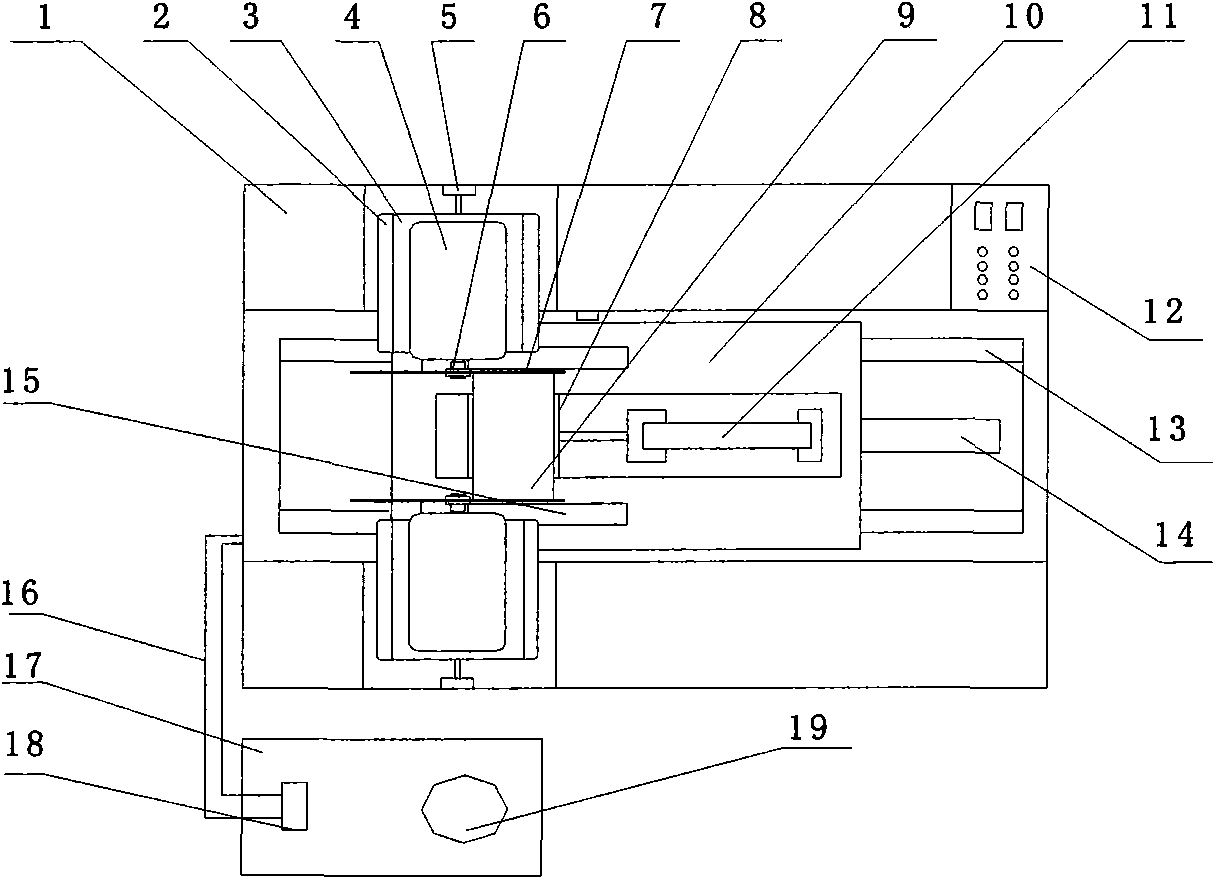

Honeycomb ceramic dry green body dual-blade cutting machine

InactiveCN101579887ANo deformationNo damageCeramic shaping apparatusWorking accessoriesControl systemElectric machinery

The invention relates to a honeycomb ceramic dry green body dual-blade cutting machine, which consists of a cutting device, a linear working table, a hydraulic system, a dust collector and a control system, wherein the cutting device adopts a dual-blade structure, and two parallel round diamond blades are connected with a main shaft driven by one or two motors respectively; and the linear working table conveys a green body to the cutting device and consists of a green body clamping device and a green body conveying device provided with a travel switch for controlling motion. The green body clamping device consists of a cylinder, a green body clamp and a green body liner plate and is used for clamping and cutting a dry green body, and the clamping degree of the green body is controlled by adjusting the pressure of compressed air with a pressure adjusting valve so that a finished product after cutting is not deformed and damaged; and the green body conveying device drives the working table to perform linear feeding motion under the control of the hydraulic system and the travel switch.

Owner:JIANGSU GAOCHUN CERAMICS +1

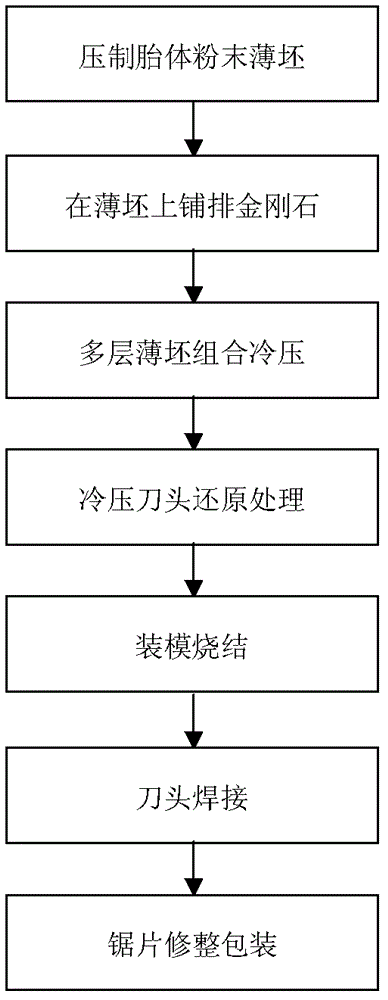

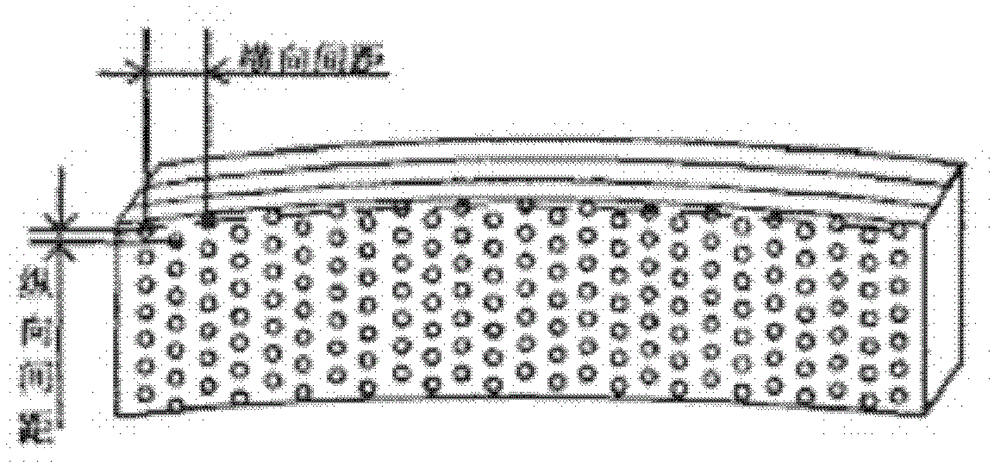

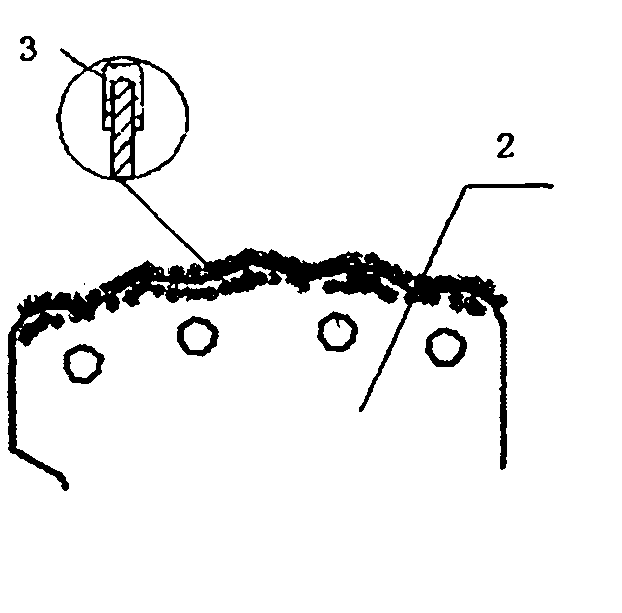

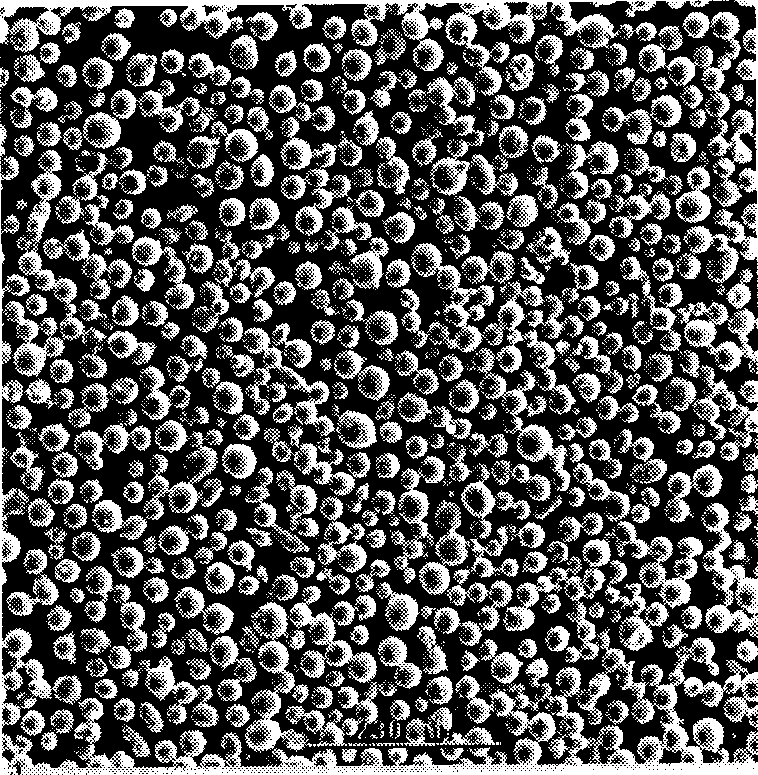

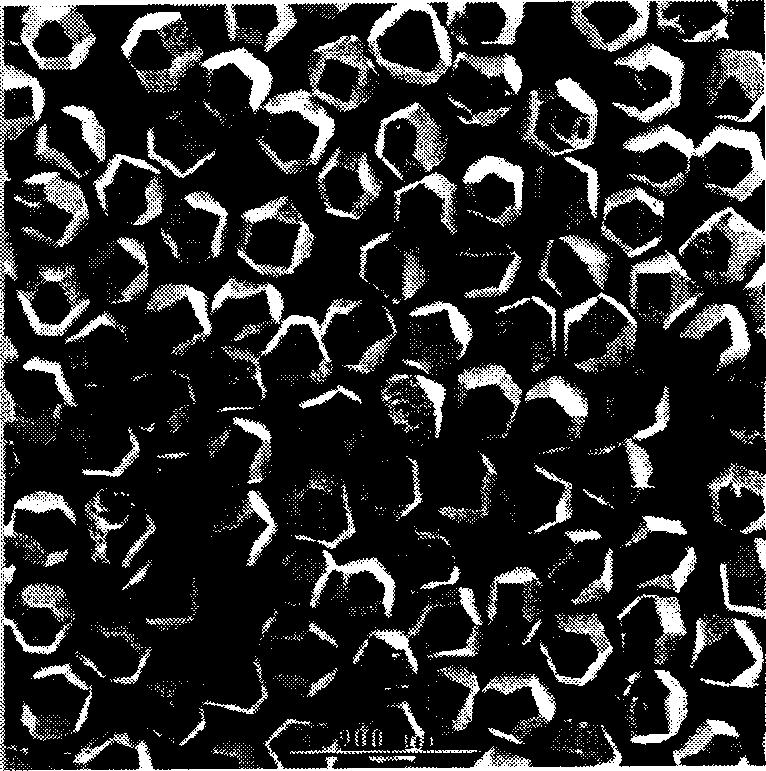

Manufacture method evenly distributing and orderly arranging diamond saw blades

InactiveCN103056450AImprove sharpnessExtended service lifeMetal sawing tool makingThree-dimensional spaceGraphite

The invention relates to a manufacture method evenly distributing and orderly arranging diamond saw blades. The manufacture method mainly resolves the problems that diamond saw blade segments are low in sharpness and short in service life caused by the fact that diamond particles are arranged and distributed unevenly and disorderly in existing diamond saw blade segments. The manufacture method includes the steps: enabling casing powder to be mixed evenly, manufacturing casing-sheet-shaped thin stocks through a cold-pressing forming technology; designing the methods of even distribution and order arrangement, adopting laser boring to manufacture red copper frameworks, spraying one layer of thin and special pressure-sensitive glue on the surfaces of the casing-sheet-shaped thin stocks, enabling the red copper frameworks to be placed on the surfaces of the casing-sheet-shaped thin stocks, and then enabling diamonds to be released on the red copper frameworks and using a steel flat plate to slightly sweep the diamonds, guaranteeing that a diamond can fall into each hole in each red copper framework, cleaning extra diamonds on the red copper frameworks, uncovering the red copper frameworks, due to the fact that pressure-sensitive agents on the casing-sheet-shaped thin stocks play a cementing action to the diamonds, and the diamonds can be fixed on the surface of the casing-sheet-shaped thin stocks and form even distribution and orderly arrangement; enabling the casing thin stocks with a multiple layers with the diamond particles to be overlapped together to combine metal segments to be installed inside a graphite mould, and forcing power-on sintering on a hot pressing machine. Therefore, the obtained diamond segments not only have the structure of even distribution and orderly arrangement of three-dimensional space, but also improve sharpness of the diamond blades and prolong service life of the diamond blades.

Owner:HUNAN FEIYUE NEW MATERIAL TECH

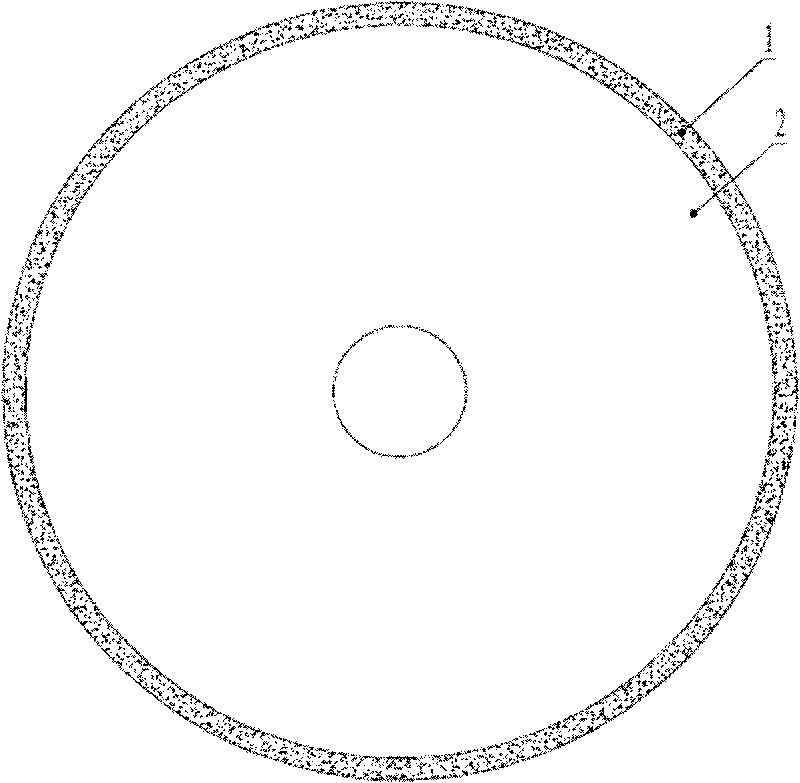

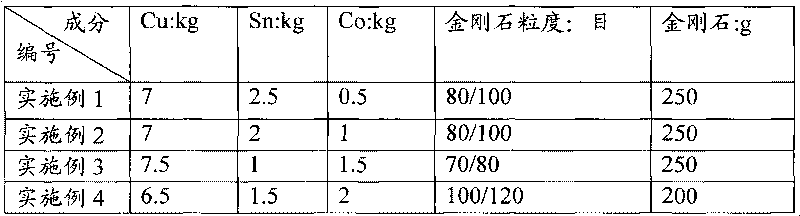

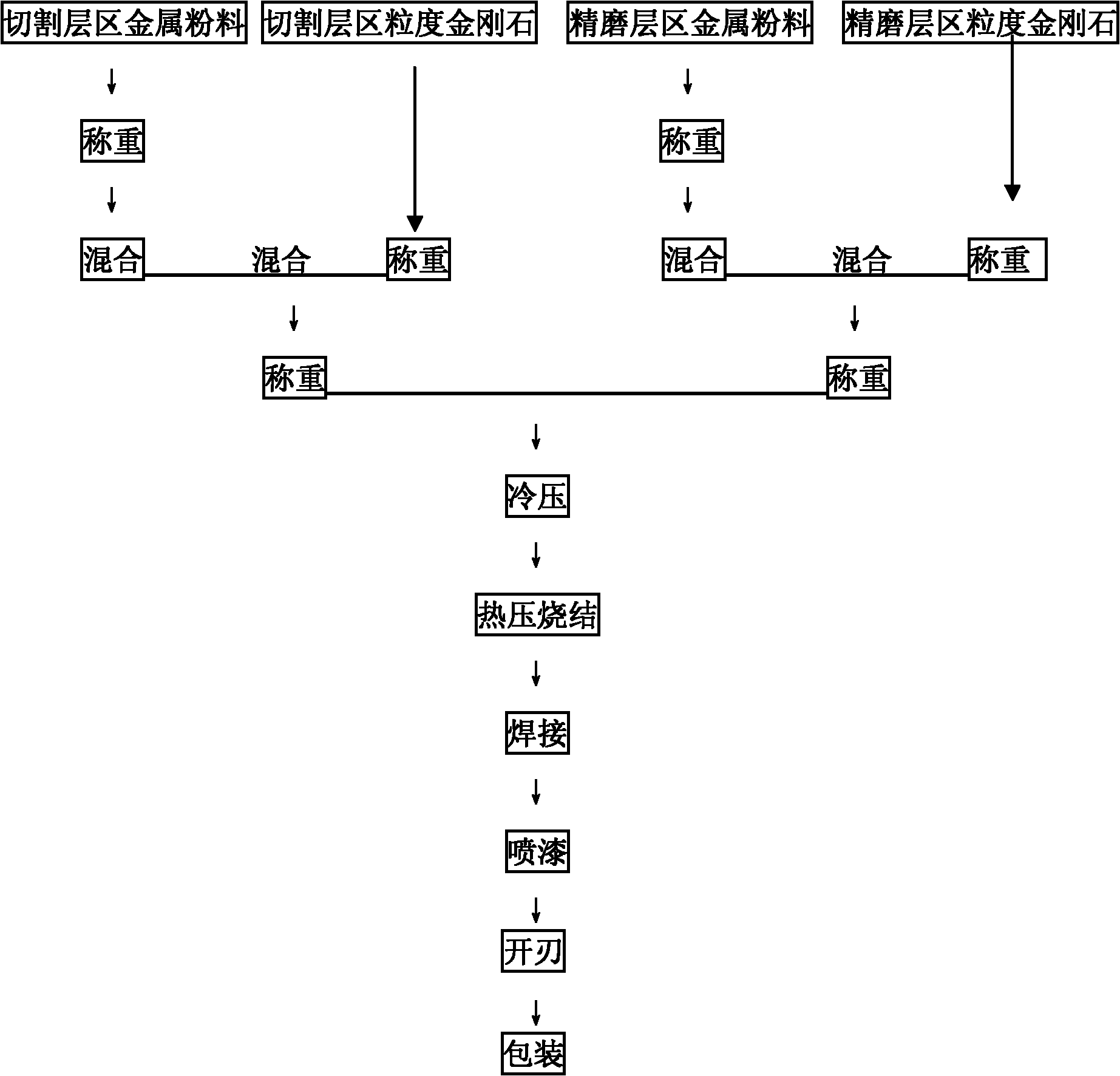

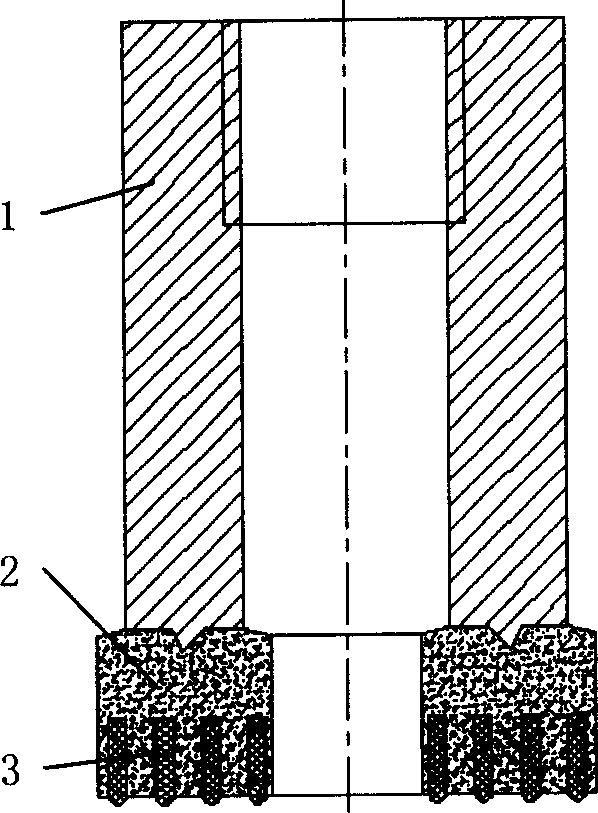

Marble cutting saw blade and preparation method thereof

ActiveCN101758560AFast cutting speedPromote infiltrationStone-like material working toolsAlloyPowder metallurgy

The invention relates to a super-hard tool and a preparation method thereof in the field of powder metallurgy, in particular to a marble cutting saw blade and a preparation method thereof. The saw blade comprises a matrix (1) and a tool bit (2), wherein the tool bit (2) is formed by mixing, thermally pressing and then sintering the matrix powder and the diamond particle; the component of the matrix powder includes 65 to 75 wt% of Cu, 10 to 20 wt% of Sn and 5 to 20 wt% of Co; and the weight of the diamond particle is 2 to 2.5 wt% of that of the matrix powder. The diamond saw blade is prepared after the steps of batching materials, mixing materials, cold press moulding, hot press moulding and subsequent treatment. Compared with the similar products, the Cu-base alloy diamond saw blade of the invention prolongs 1 to 3 times of the service life and reduces 30 to 50% of the cost on the premise of ensuring the constant sharpness and saw-cutting flatness.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

High-strength diamond saw blade

The present invention is a high-strength diamond saw blade, which includes a substrate and a diamond cutter head. The substrate of the diamond saw blade includes the following components by weight: 28-37 parts of copper powder, 0-5 parts of aluminum powder, and 2-6 parts of tin powder , 2-4 parts of zinc powder, 5-8 parts of rare earth, 15-18 parts of titanium powder, 11-15 parts of nickel powder, 8-12 parts of cobalt powder, 1-3 parts of manganese powder, 0-1 part of phosphorus powder, silicon 1-3 parts of vanadium powder, 0.2-0.9 parts of vanadium powder, 2-5 parts of silver powder, 2-6 parts of molybdenum powder, 0.1-2 parts of tungsten powder, 0.5-3 parts of chromium powder, and the rest are iron and unavoidable impurities; diamond The cutter head of the saw blade includes the following components by weight: copper powder 35‑40 parts, tin powder 8‑11 parts, zinc powder 1‑2 parts, titanium powder 6‑10 parts, diamond 13‑18 parts, iron powder 9‑ 14 parts, nickel powder 1-5 parts, rare earth 1-4 parts, tungsten powder 1-3 parts. The invention can effectively improve the cutting performance of the diamond saw blade, and has high strength, high wear resistance, firmness and durability, great pressure resistance and low cost.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

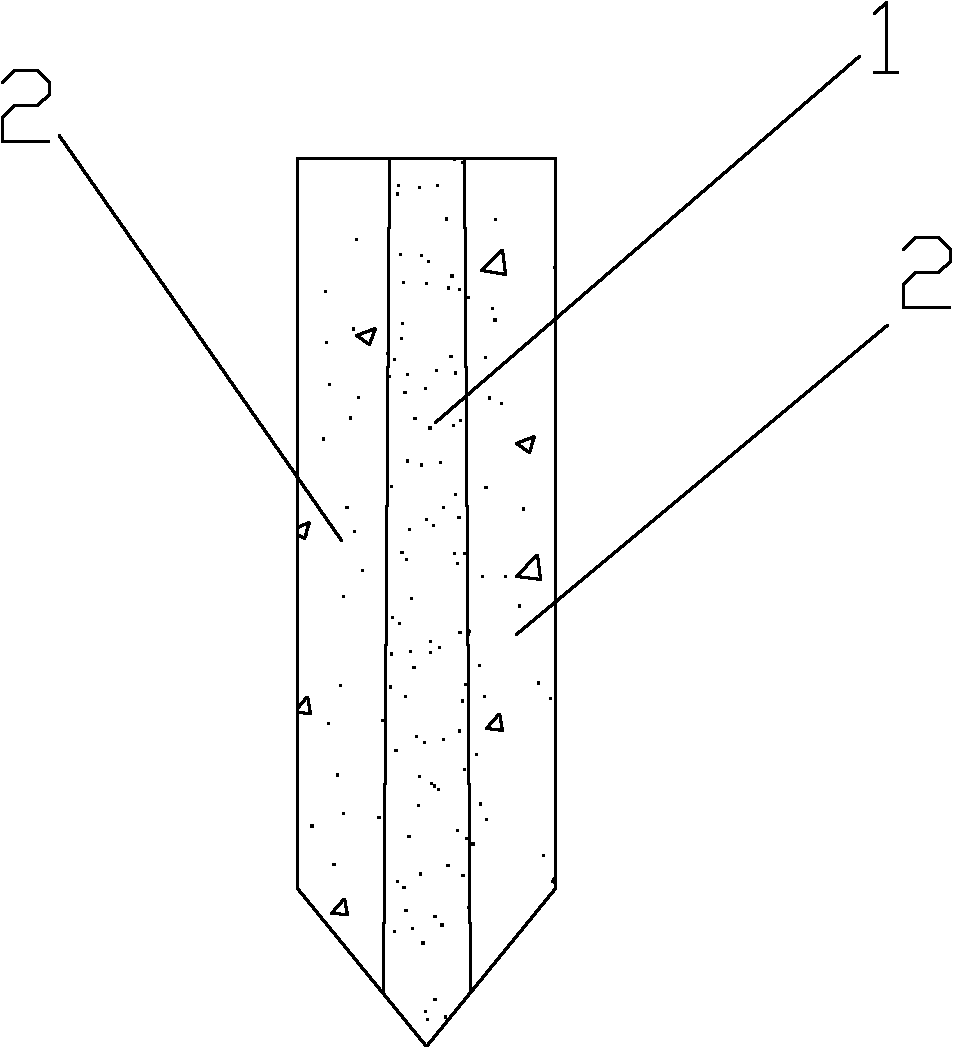

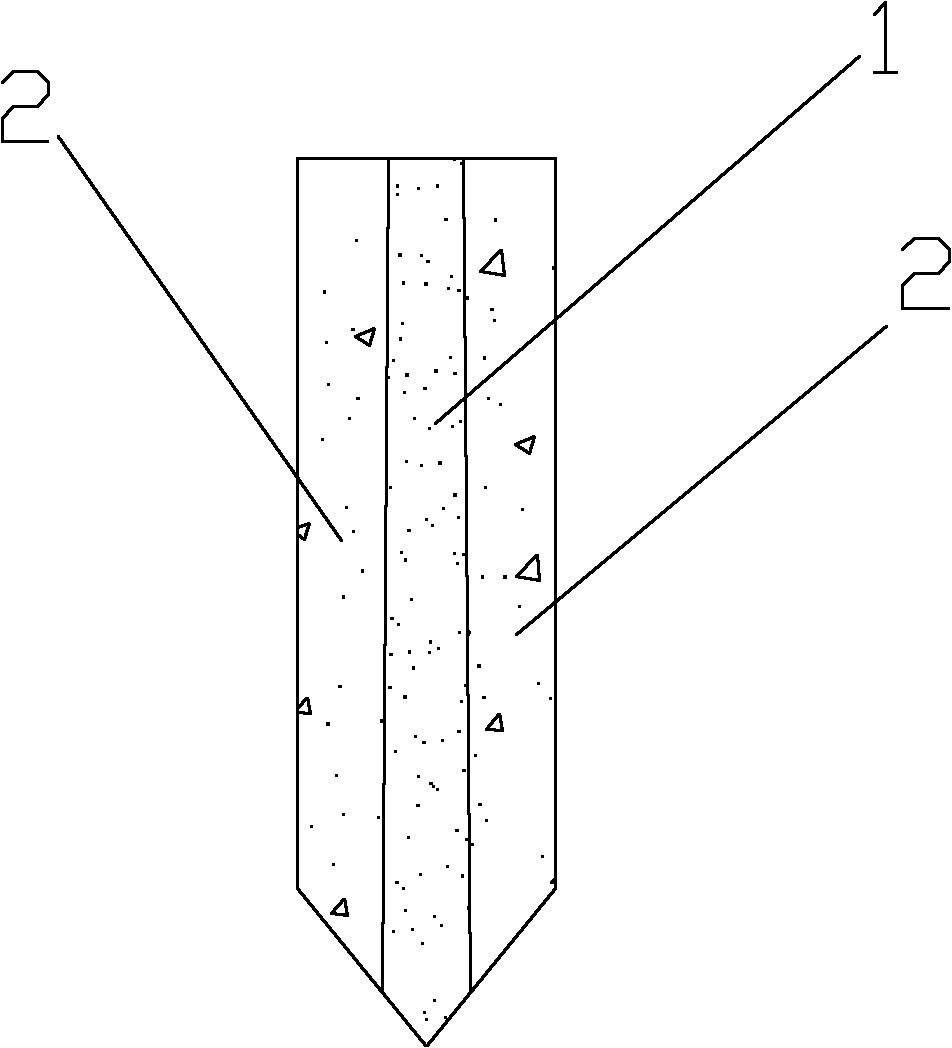

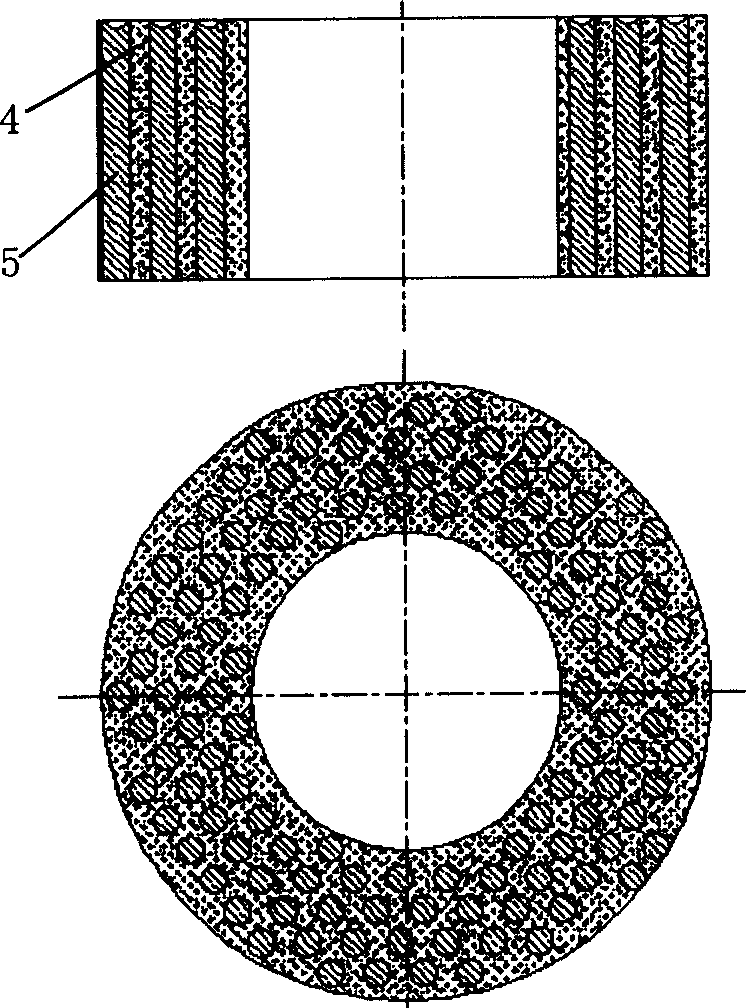

Diamond saw blade and manufacturing method thereof

InactiveCN102049814ANo problems such as precipitation and discolorationVersatileLayered productsMetal sawing tool makingWear resistanceMetal

The invention relates to a diamond saw blade and a manufacturing method thereof, in particular to the diamond saw blade with combined cutting and accurate grinding functions. A tool bit of the saw blade forms a sharp corner, and consists of two performance layers which are a cutting layer and an accurate grinding layer respectively, wherein the cutting layer comprises components such as coarse diamonds and a wearable metallic bond, and has the characteristics of quick cutting and wear resistance; and the accurate grinding layer comprises the components such as fine diamonds and a synchronously wearable metal bond. When the diamond saw blade provided by the invention cuts ceramic veneers and floor tiles, the cutting layer finishes cutting operations and the accurate grinding layer performs grinding to remove rough cut surfaces and edge cracks so as to form even undamaged sections.

Owner:CHANGZHOU HUAZHONG GROUP

Cutting method of LED chip

InactiveCN104347760AAvoid ablationDoes not affect electrical characteristicsSemiconductor/solid-state device manufacturingFine working devicesEngineeringLaser cutting

The invention discloses a cutting method of an LED chip. The method comprises drawing scratches by use of laser on the back surface of the chip and performing saw cutting by use of a diamond saw blade knife, wherein the saw blade knife is an isosceles inverted triangle with a symmetrical left portion and right portion, and the included angle between a knife side surface and a horizontal line is 30 DEG to 60 DEG. The method further comprises performing overturning and film reversing on the back-cut chip and cutting the front surface of the chip along grooves to form crystal grains by use of a splinter knife. According to the invention, the problems of backside collapse, burr and the like by use of a conventional saw blade process are solved, the problem of ablation brought by laser cutting is avoided, and the method is simple to operate and easy to realize.

Owner:LATTICE POWER (JIANGXI) CORP

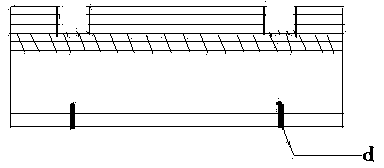

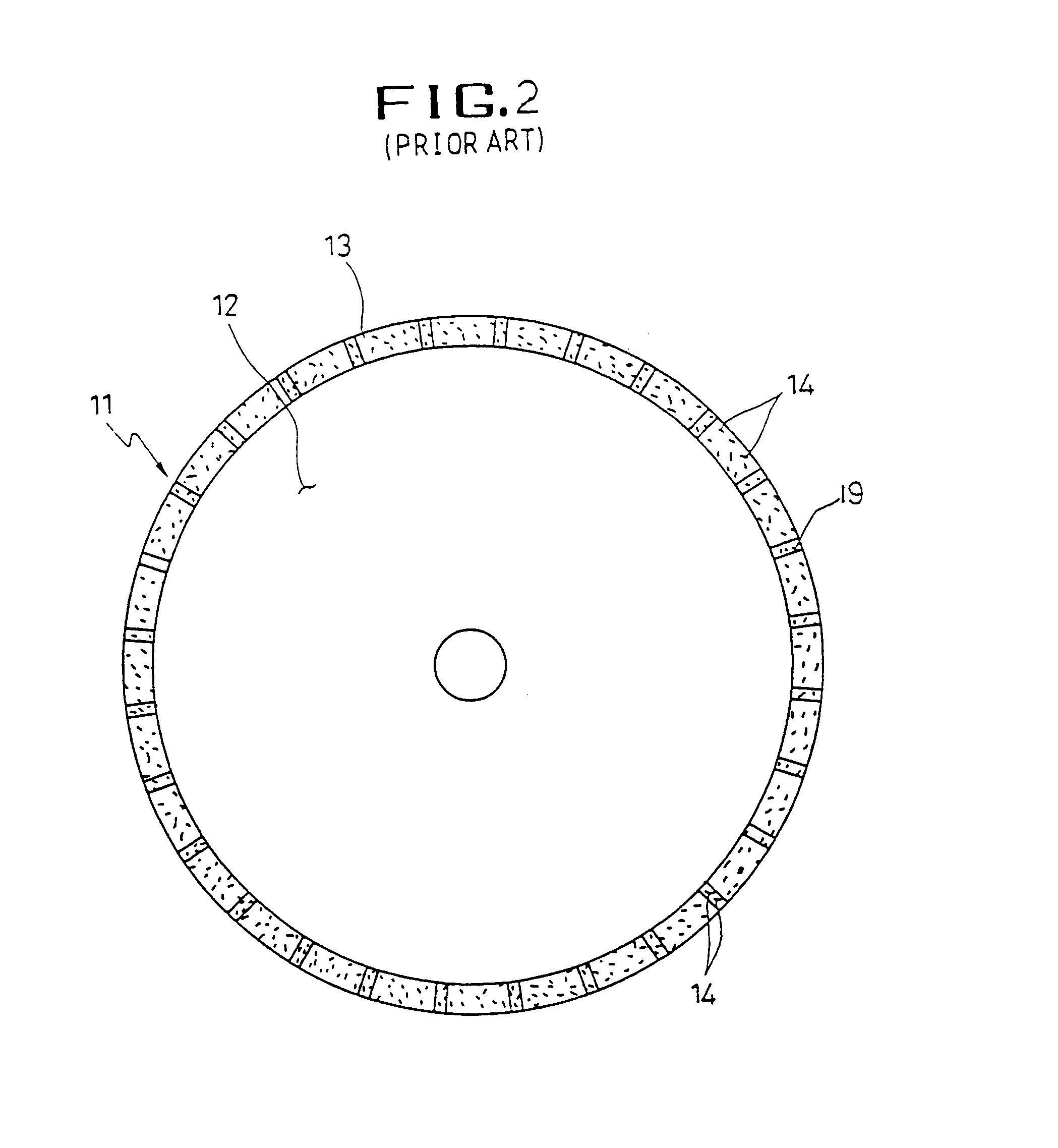

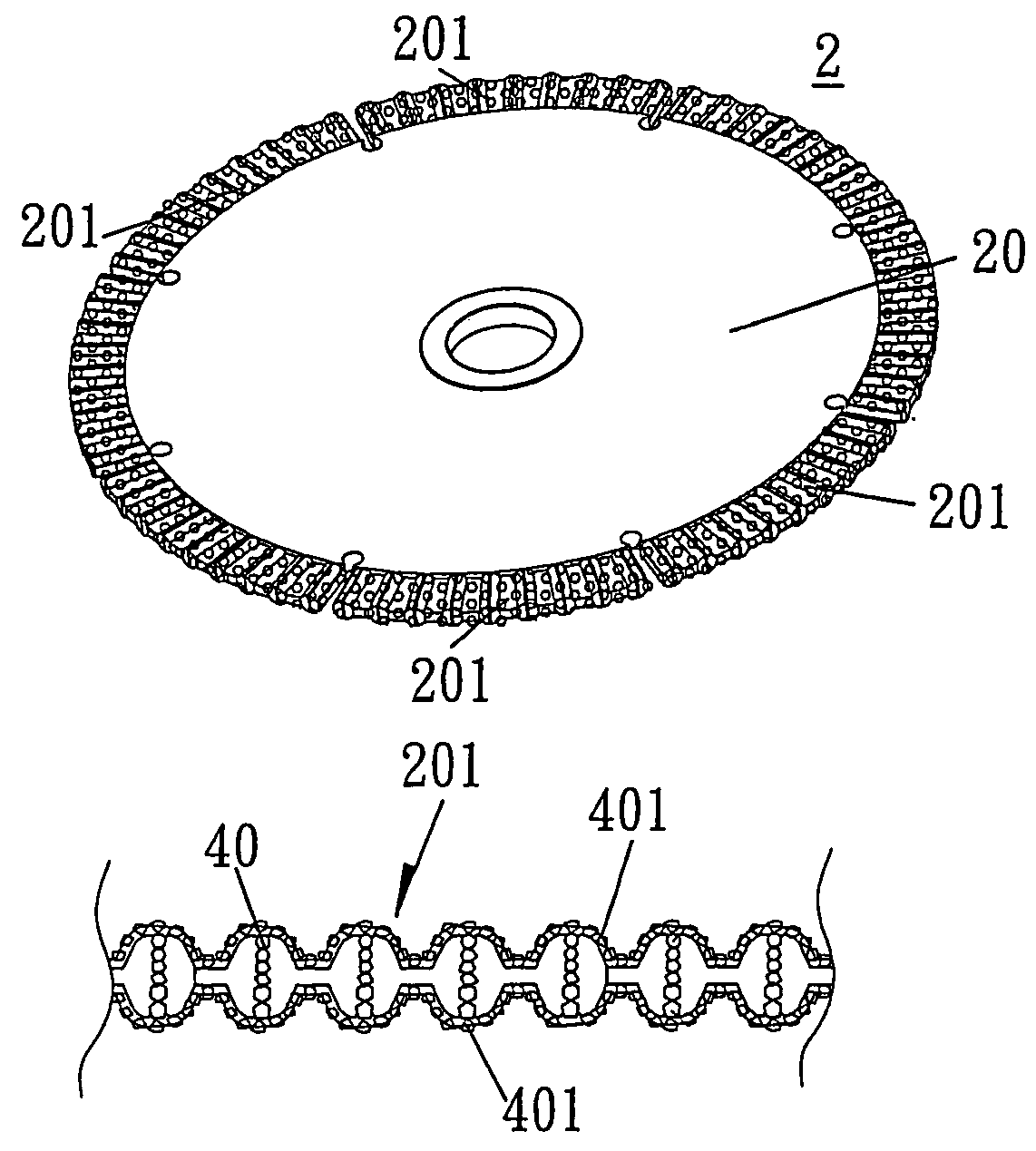

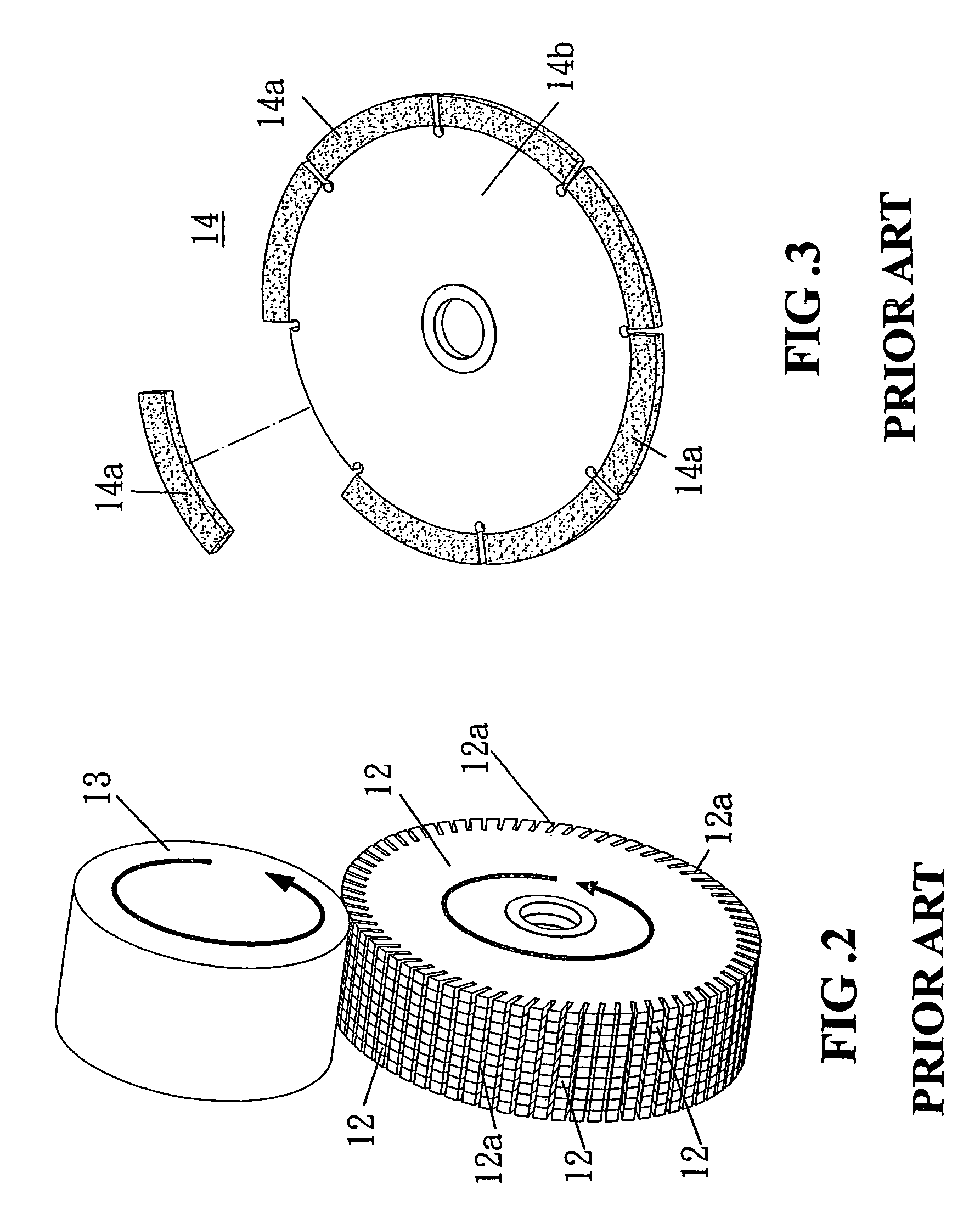

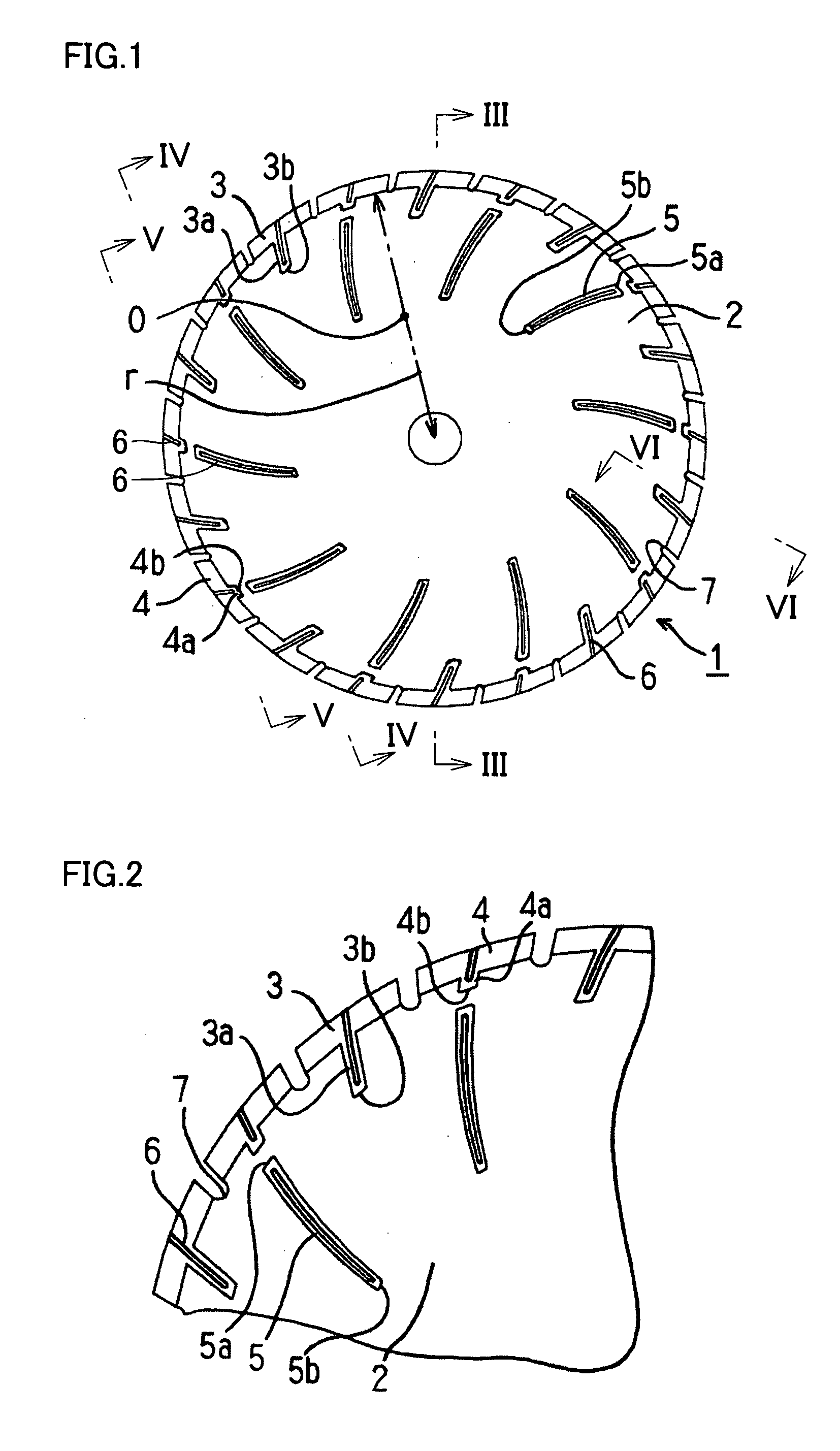

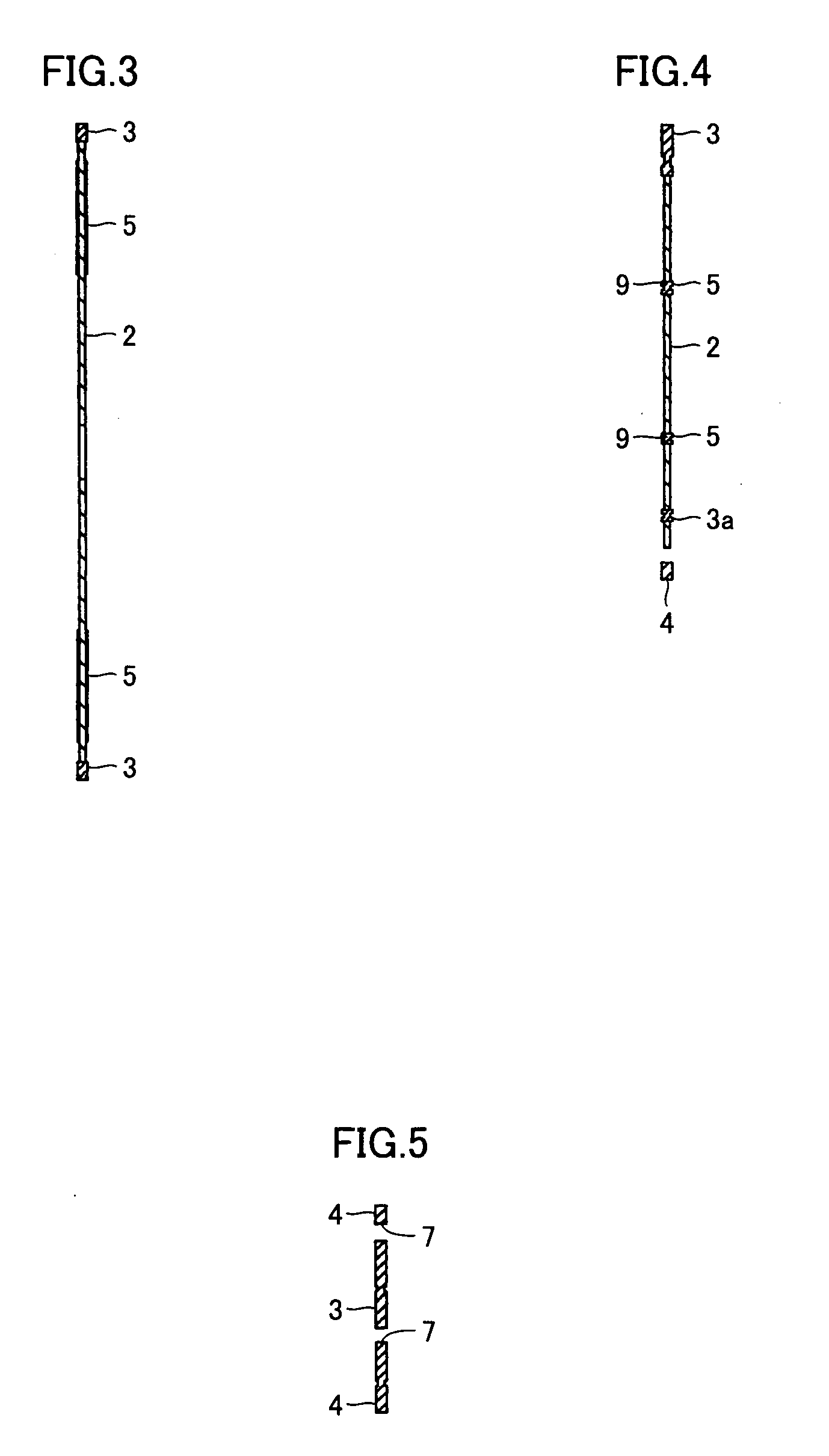

Diamond blade having rim type cutting tip for use in grinding or cutting apparatus

InactiveUS6890250B1Fast cutting speedEasy to crushDrill bitsRevolution surface grinding machinesFriction reductionEngineering

A diamond blade having rim type cutting tip for use in apparatus such as cutting saw machine having a structure which rim type cutting tip is able to produce cutting chips with relative large size during cutting operation so that those chips are easily discharged outside with reducing the friction with cutting tip of blade, thereby to increase cutting ability and to prevent the chips dispersing in the air and giving rise to the bad effects to user's health and the contamination of environment. The diamond blade according to the present invention comprises a wheel body connected with a shaft of electric motor, and rim type cutting tip for cutting or grinding crushable materials disposed on the circumference of the wheel body and composed of at least two diamond layers longitudinally disposed parallel with the rotation direction of the blade in which diamond particles are included, and non-diamond portion disposed between the diamond layers in which diamond particles are not included.

Owner:NIWA DAIYAMONDO INDS +1

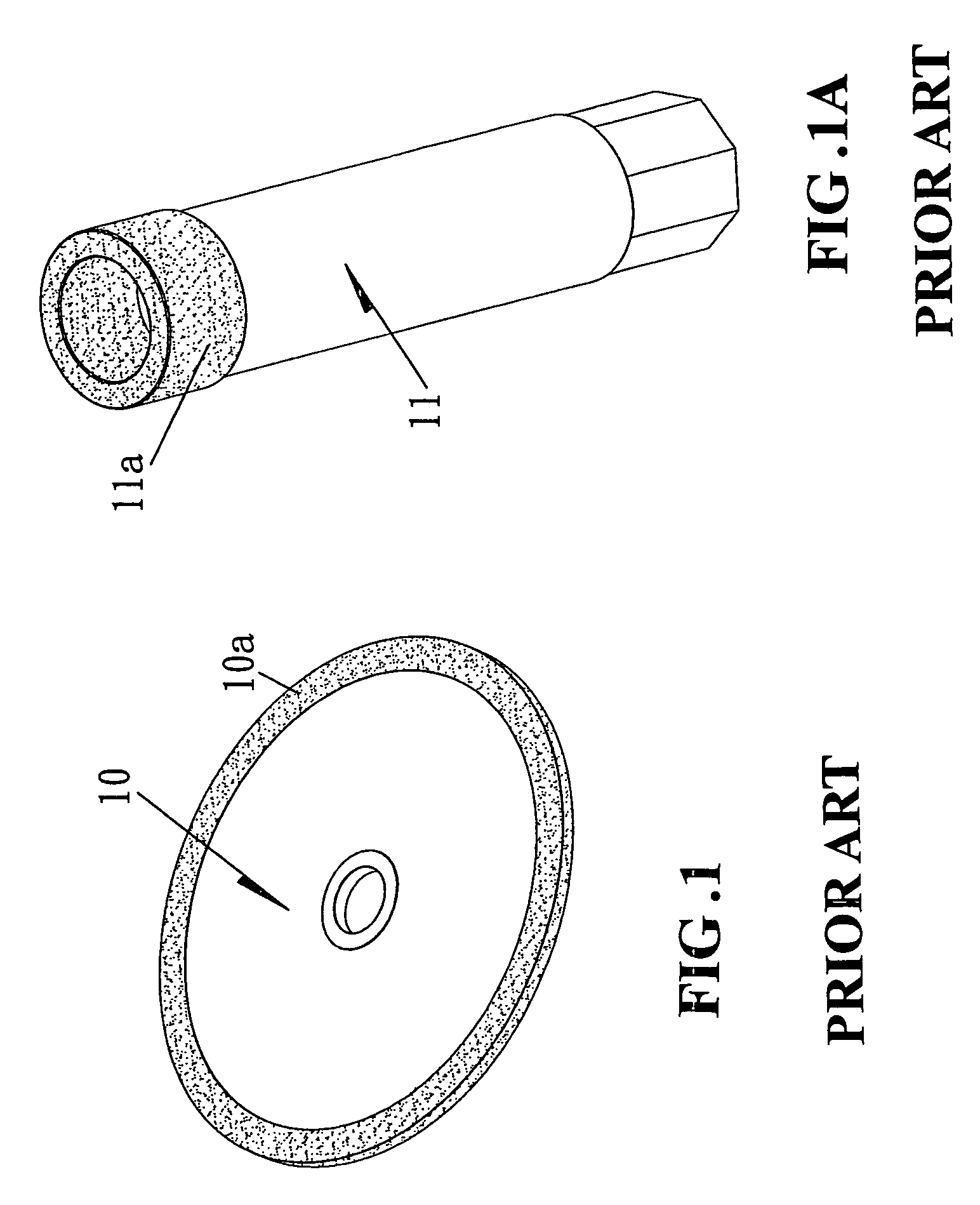

Superthin diamond circular saw web matrix and mfg. method thereof

InactiveCN1401454AThe overall thickness is thinLow costMetal sawing tool makingMetal sawing toolsCircular sawQuenching

An ultra-thin matrix of circular diamond saw with 3-6.5 mm of thickness is prepared through blanking, machining, quenching, pressure tempering, levelling and grinding. Its advantages are high productivity increased by 10-20%, low energy consumption decreased by 30%, and high utilization rate of raw material (increased by 10-15%).

Owner:HEIXUANFENG SAW IND

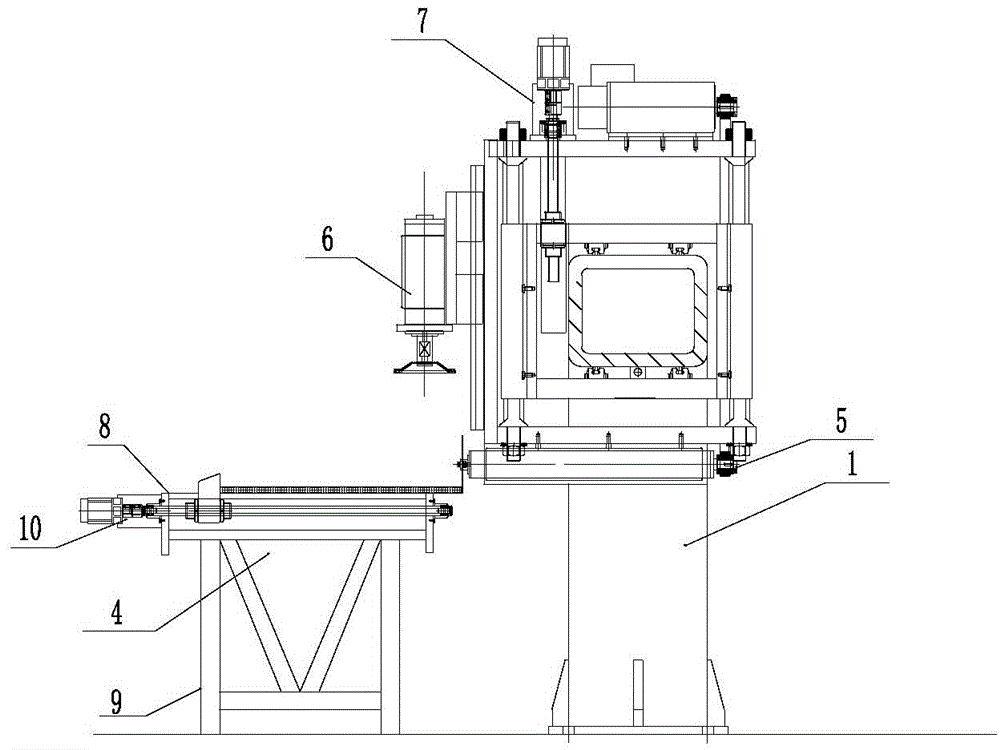

Cutting device for preparing rock samples containing different dip angle structural surfaces and operation method

ActiveCN105773850AAvoid offsetAvoid damagePreparing sample for investigationWorking accessoriesEngineeringRock sample

The invention discloses a cutting device for preparing rock samples containing different dip angle structural surfaces and an operation method, relates to the technical field of rock mechanics tests, and comprises a base device, a sample fixing device, a combined bracket and the cutting device. A sample fixing mode is perfect, can realize fixation of the rock samples by various dip angles, guarantees symmetric stress of the samples in the cutting process, and prevents deviation and fracture of the cutting samples and unevenness of cut surfaces; rubber layers cover the surfaces of a fixed baffle plate and an auxiliary baffle plate, so that the rock samples are guaranteed to be not damaged in the clamping and fastening process; length marks, depth marks and angle marks are arranged for precisely controlling fixing angles, fixing positions and cutting depths of the samples; the cutting device uses a diamond saw blade with excellent rigidity and small thickness, so that the damage of the rock samples can be reduced in the cutting process, the integrity of the rock samples is guaranteed, and the service life is longer; and the cutting device is simple in structure, safe and convenient for operation, low in cutting cost and maintenance cost, small in size, light in weight and convenient for carrying.

Owner:ANHUI UNIV OF SCI & TECH

Preparation method of nano-diamond coating and nano-diamond blade

ActiveCN105506574AImprove machining accuracyExtended service lifeChemical vapor deposition coatingPhysical vapor depositionDiamond blade

The invention provides a preparation method of a nano-diamond coating. The preparation method comprises the following concrete steps of depositing a transition layer on the surface of a hard alloy matrix by using a physical vapor deposition method; then, carrying out ultrasonic cleaning by using an ultranano-diamond suspension liquid to obtain a hard alloy precipitate pretreatment body; and depositing a nano-diamond coating on the surface of the hard alloy precipitate pretreatment body by using a chemical vapor deposition method. The invention also provides a nano-diamond blade comprising a blade matrix, the transition layer and the nano-diamond coating, wherein the transition layer and the nano-diamond coating are sequentially deposited on the surface of the blade matrix by using the methods. The nano-diamond coating and the hard alloy matrix prepared by using the methods have a relatively high binding force so that the nano-diamond blade has relatively high machining precision and relatively long service life.

Owner:FUNIK ULTRAHARD MATERIAL +1

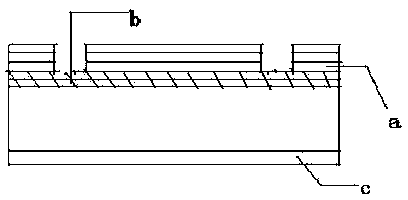

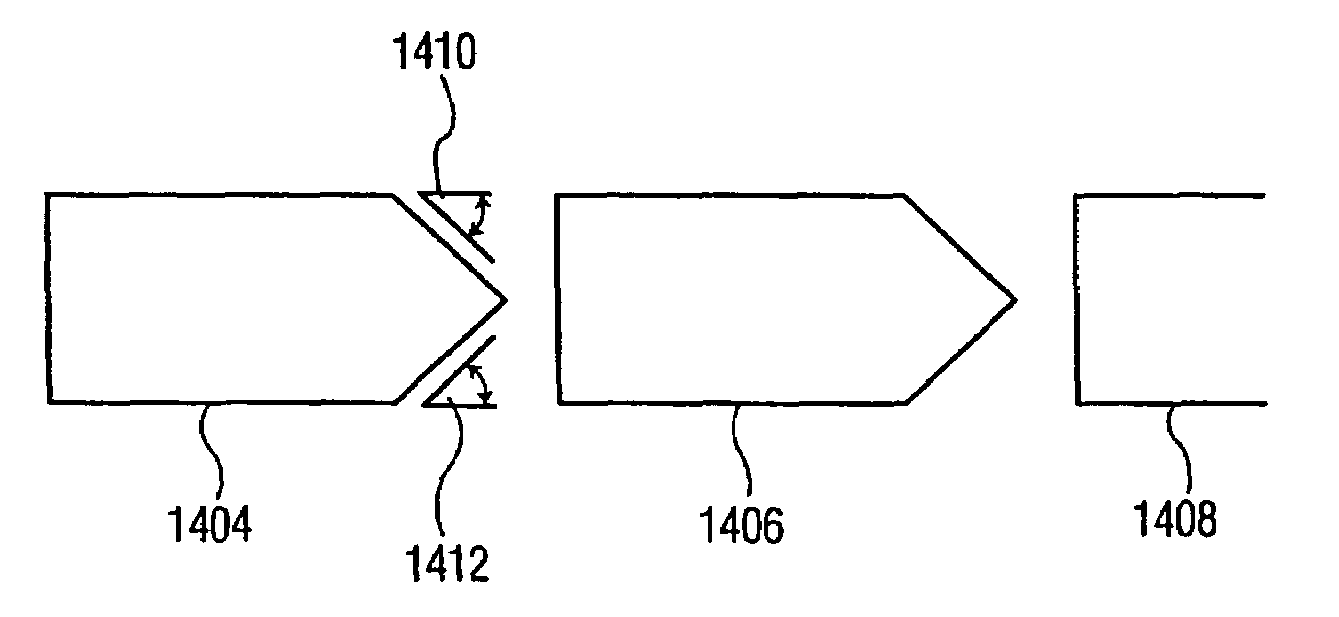

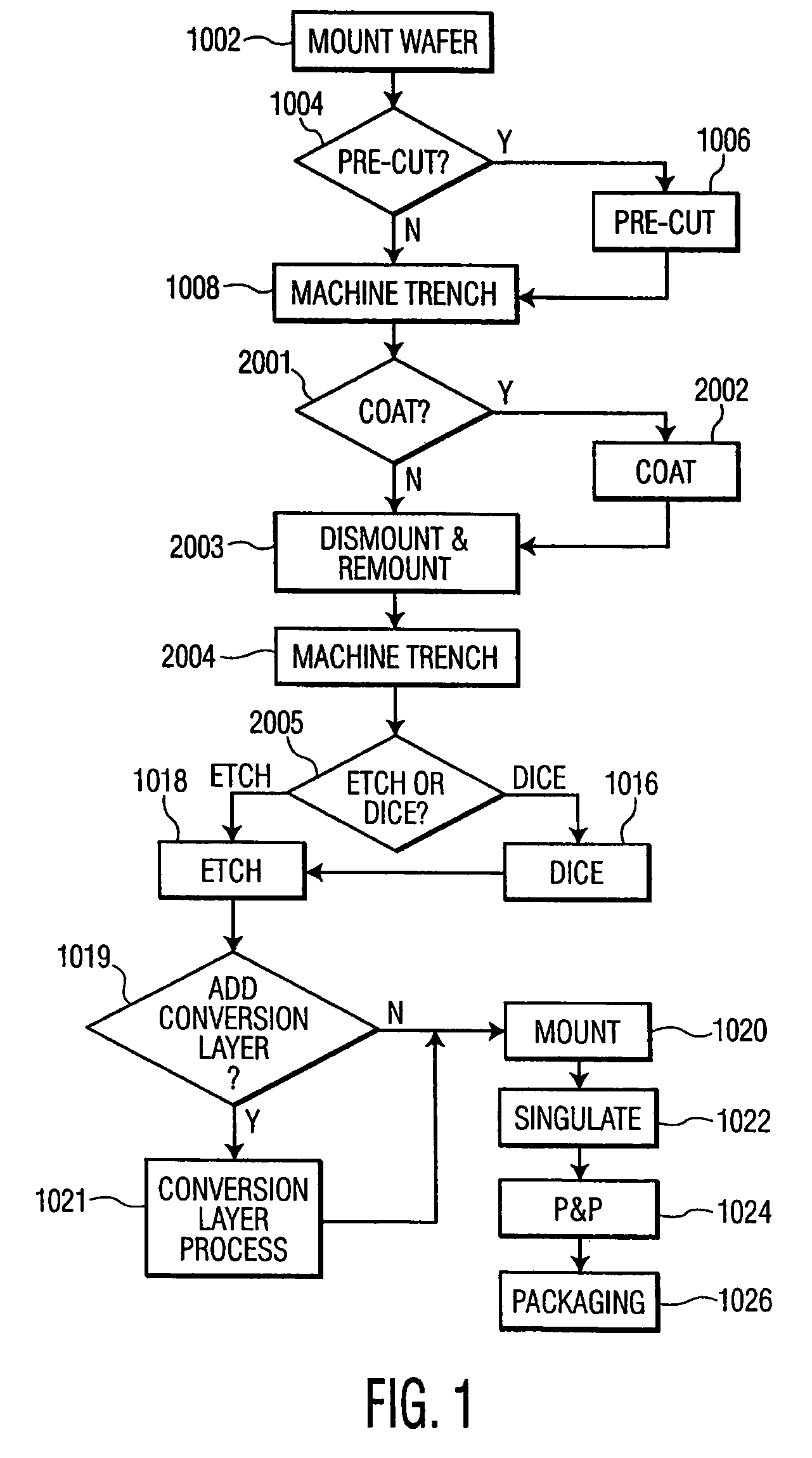

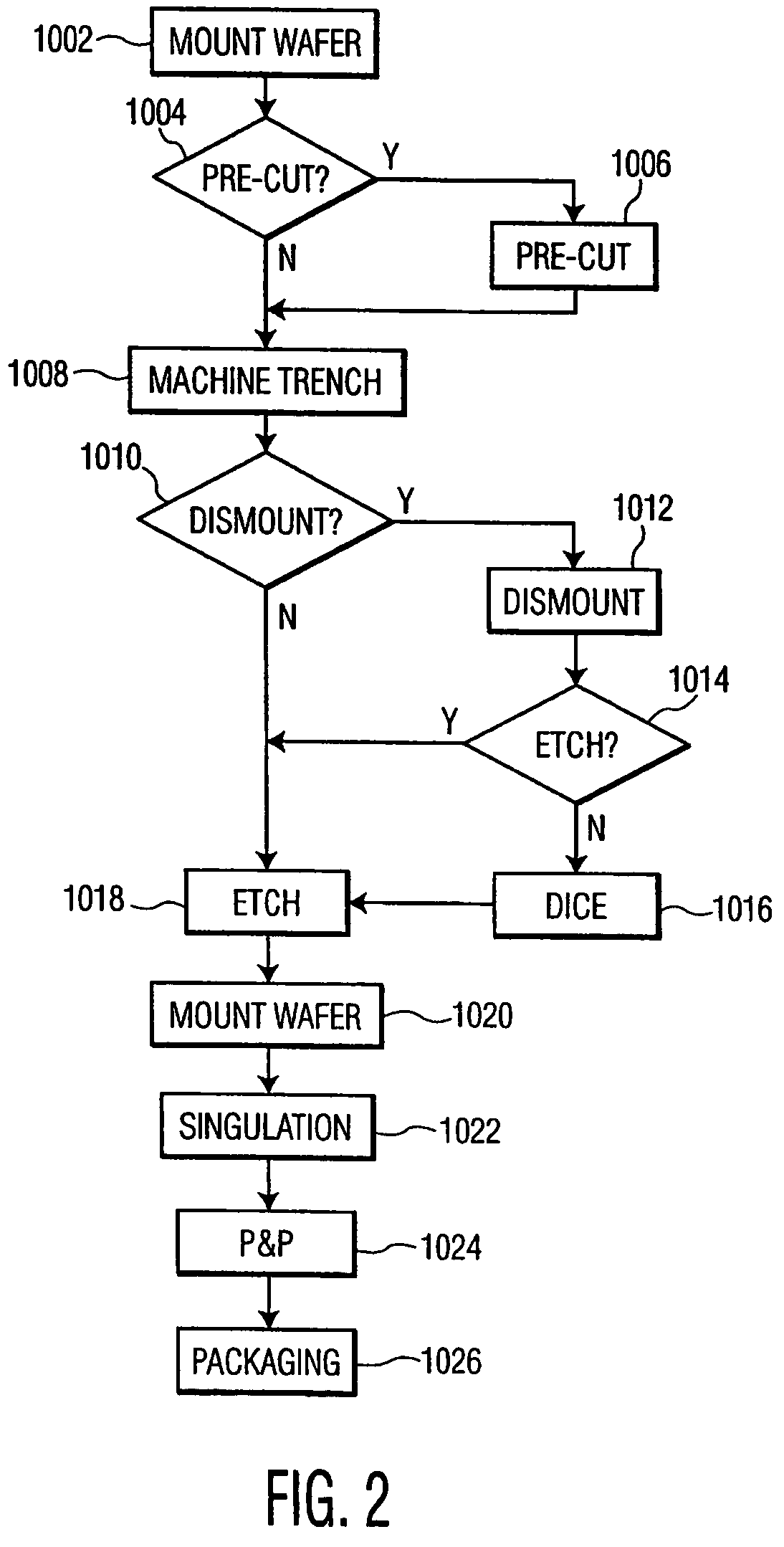

Methods of fabricating complex blade geometries from silicon wafers and strengthening blade geometries

ActiveUS7396484B2Quality improvementUniform radiusIncision instrumentsDecorative surface effectsSurgical bladeSingle crystal

Ophthalmic surgical blades are manufactured from either a single crystal or poly-crystalline material, preferably in the form of a wafer. The method comprises preparing the single crystal or poly-crystalline wafers by mounting them and etching trenches into the wafers using one of several processes. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. Other processes include wet etching (isotropic and anisotropic) and dry etching (isotropic and anisotropic, including reactive ion etching), and combinations of these etching steps. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or poly-crystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any angle can be machined into the wafer, and the machined angle remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. A range of radii may be 30 to 60 nm, with a specific implementation being about 40 nm. The blade profile may have an angle of, for example, about 60°. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes. Surgical and non-surgical blades and mechanical devices manufactured as described herein can also exhibit substantially smoother surfaces than metal blades.

Owner:BEAVER VISITEC INT US

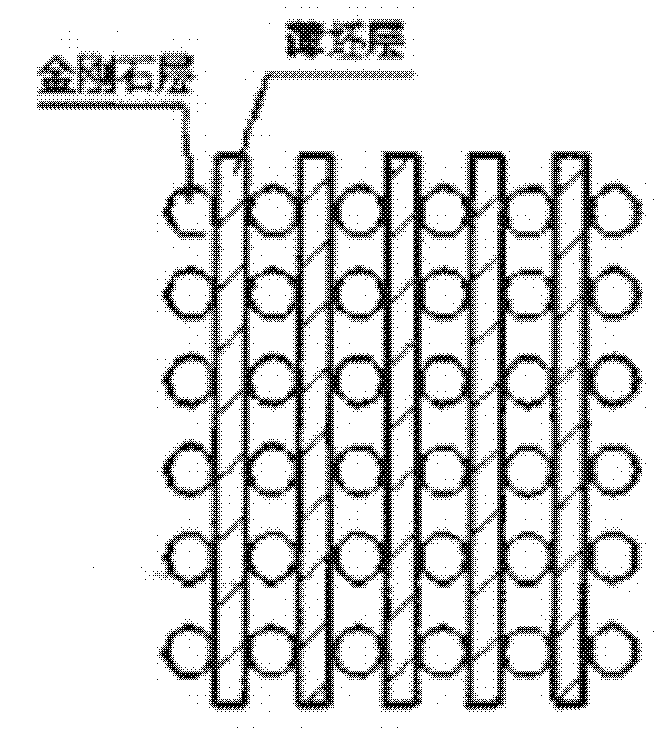

Diamond orderly-arranged ultra-thin cold-rolled sintered tablet

The invention relates to a diamond orderly-arranged ultra-thin cold-rolled sintered tablet, which is manufactured by a process comprising: firstly, uniformly mixing matrix powder, adding proper organic binder, solvent and the like, and making a thin layer by using a rolling method; secondly, making a molding board according to the distribution and arrangement of diamonds, wherein the thickness ofthe molding board is one third or two thirds of the average grain diameter of the diamonds; distributing the diamonds on the molding board and pressing the diamonds into a matrix through the molding board by using a steel plate; and fourthly, removing excessive diamonds on the molding board, removing the molding board, pressing the diamonds into the thin layer m of the matrix by using the steel plate, making a tool bit by combining a plurality of layers of thin layers embedded with the diamonds and placing the tool bit in a graphite mold to sinter the tool bit. The ultra-thin diamond ornamentmanufactured by the process can remarkably improve the cutting efficiency of diamond saw bit by 60 percent.

Owner:丹阳华昌钻石工具制造有限公司

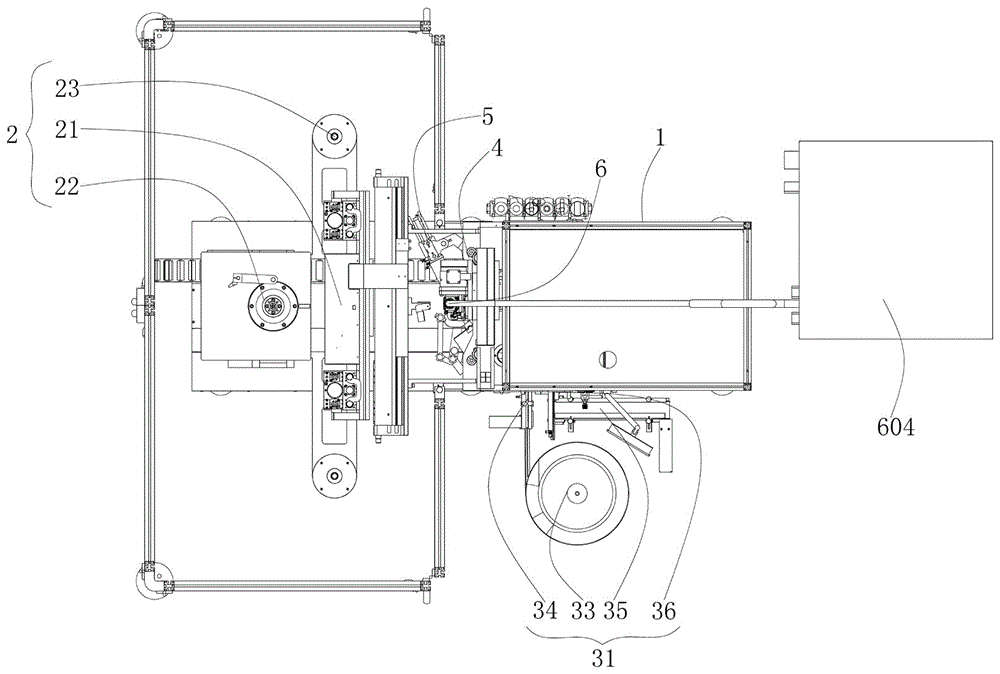

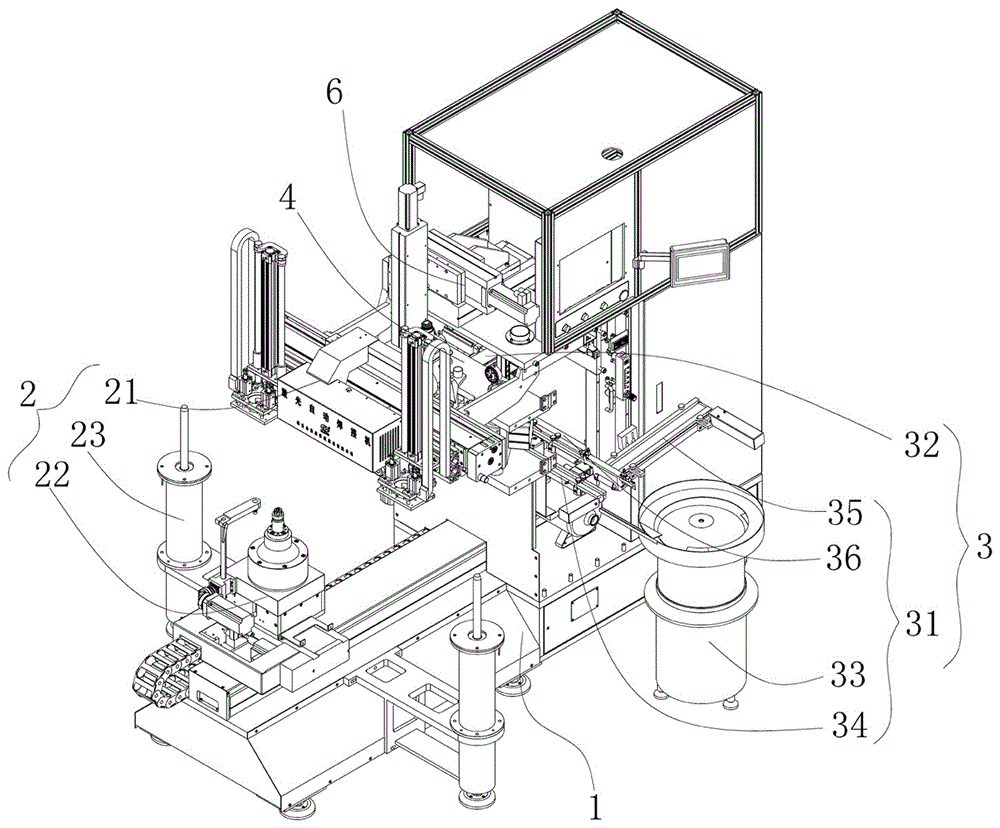

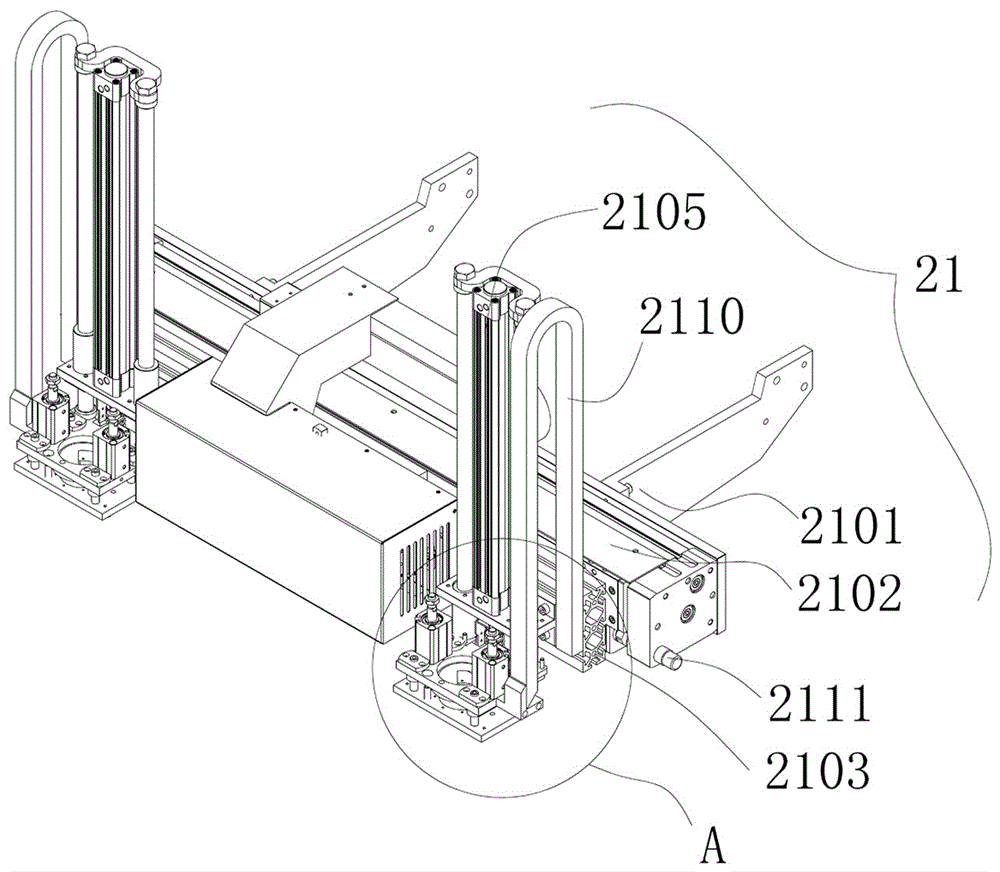

Laser automatic welding machine for diamond saw blades

ActiveCN106425095AHigh degree of mechanizationReduce manufacturing costLaser beam welding apparatusHigh volume manufacturingEngineering

The invention belongs to the technical field of diamond saw blade welding, and particularly relates to a laser automatic welding machine for diamond saw blades. The machine comprises a machine body, a saw blade absorbing grabbing system, a base body rotary indexing system, a tool bit conveying grabbing system, a welding clamping assembling system and a laser welding light path system; saw blade base bodies and tool bits are grabbed and subject to alignment pairing through the saw blade absorbing grabbing system and the tool bit conveying grabbing system, clamping positioning is completed through the welding clamping assembling system, and welding is carried out through the laser welding light path system; after the tool bits are welded, the saw blade base bodies are rotated to the next welding station through the base body rotating indexing system until the tool bits on the saw blade base bodies are welded, and the finished product saw blades are conveyed and discharged to the storing position through the saw blade absorbing grabbing system. The machine is a producing machining device which is high in speed, free of contact and small in deformation, large-batch production can be achieved, the welding strength is high, in the cutting and using process, the tooth disengaging phenomenon is avoided, and use safety of the machine is greatly improved.

Owner:郑州金海威科技实业有限公司

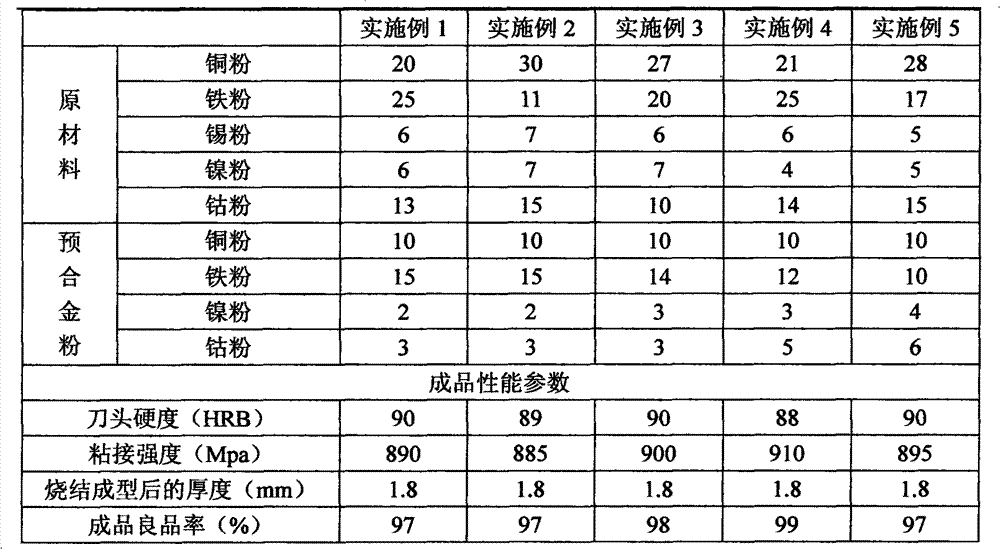

Production process of diamond saw blade formed by compressing granular powders

Disclosed is a production process of a diamond saw blade formed by compressing granular powders. The production process includes steps of using a copper powder, an iron powder, a tin powder, a nickel powder and a cobalt powder as raw materials, adding liquid paraffin for mixing and stirring, and then performing procedure steps of compressing, sintering and post-treating. The production process is characterized in that an agglomerating procedure is performed before a compressing procedure, and the powder raw materials are agglomerated to be granular and then compressed. According to experiments, the production process is obvious in effects, no defect is produced after the compression, and the yield of the finished diamond saw blade can reach above 97%.

Owner:SHIJIAZHUANG XINDA DIAMOND TOOLS CO LTD

Brazing process of diamond saw blade

ActiveCN102319934AReduce heat damagePromote infiltrationSoldering apparatusMetal sawing toolsPorositySand blasting

The invention relates to a brazing process of a diamond saw blade. The brazing process is characterized by comprising the following steps: (1) pre-treating a saw blade matrix of steel 45: sequentially performing sand-blasting, alkaline-washing and acid-washing on the saw blade matrix of the steel 45; (2) preparing a brazing material: mixing nickel-based brazing powder with the average particle size of 10-200mu m with diamond particles with the average particle size of 3-50mu m; (3) pre-coating the brazing material: pre-coating the mixed brazing powder on the surface of saw teeth of the saw blade matrix; and (4) brazing under a vacuum condition at the temperature of 850-980 DEG C for 20-30 minutes. The diamond saw blade obtained by the brazing process has the advantages of low porosity, firm combination between diamond and the matrix, high finished product rate and stable quality.

Owner:江苏华昌工具制造有限公司

Diamond saw blade for milling

InactiveUS7178517B1Improve cutting performanceHigh-speed cutting performanceBonded abrasive wheelsGrinding devicesElectroplatingDiamond blade

The present invention relates to a diamond saw blade for milling. The rim of the circular metal with a shaft or the front end of the tubular body or an edge of the strip metal has multiple equidistant openings for positioning the diamond grains. The width of the opening is slightly wider or equal to the diameter of the diamond grain. After the diamond grains are positioned in each opening, the metal surface on both sides of each opening is pressed by the jig through two directions. The metal surface on both sides of the opening is deformed by the pressure from the jig, and extrudes along the direction of each opening for bonding diamond grains. Further, the surface forms a rugged cutting edge. More, a diamond layer with diamond grains is electroplated on the surface of the cutting edge. It, therefore, has a long lifecycle and becomes a high-speed cutting edge for milling without deformation.

Owner:YU FANG CHUN

Biomimetic golden-embedded diamond drilling bit and its production

InactiveCN1896451ASolution to short lifeIncrease drilling speedDrill bitsBiological bodyTransition layer

This invention discloses a kind of bionic diamond-impregnated bit and its producing method. It uses the shape characteristic that the surface of organism is not smooth. This invention is fit for various saw blades of diamond, diamond abrasive tips and solid rock geologic drillings. This invention includes the steel body; the transition-layer; the shape material with unsmooth surface; the diamond; the carcass. The shape materials with unsmooth surfaces are distributed at working layer according to the request. Thus, it decreases the cutting adherence and cutting frictional resistance. It also increases the service life and cutting efficiency of the cutting tool. Compared with normal diamond products, this invention has long lifetime and quick drilling rate. The energy consumption is low.

Owner:JILIN UNIV

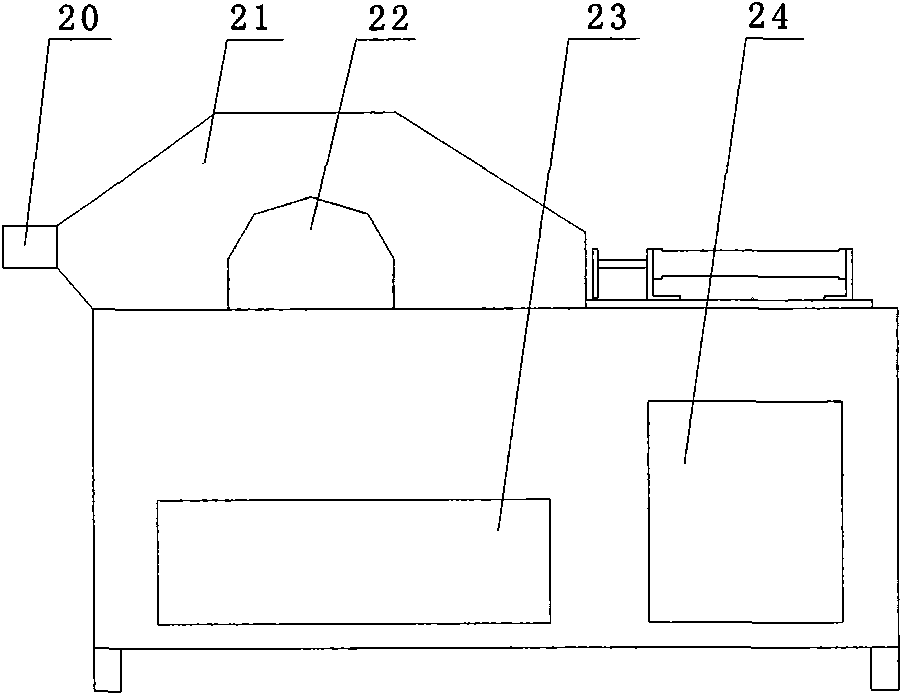

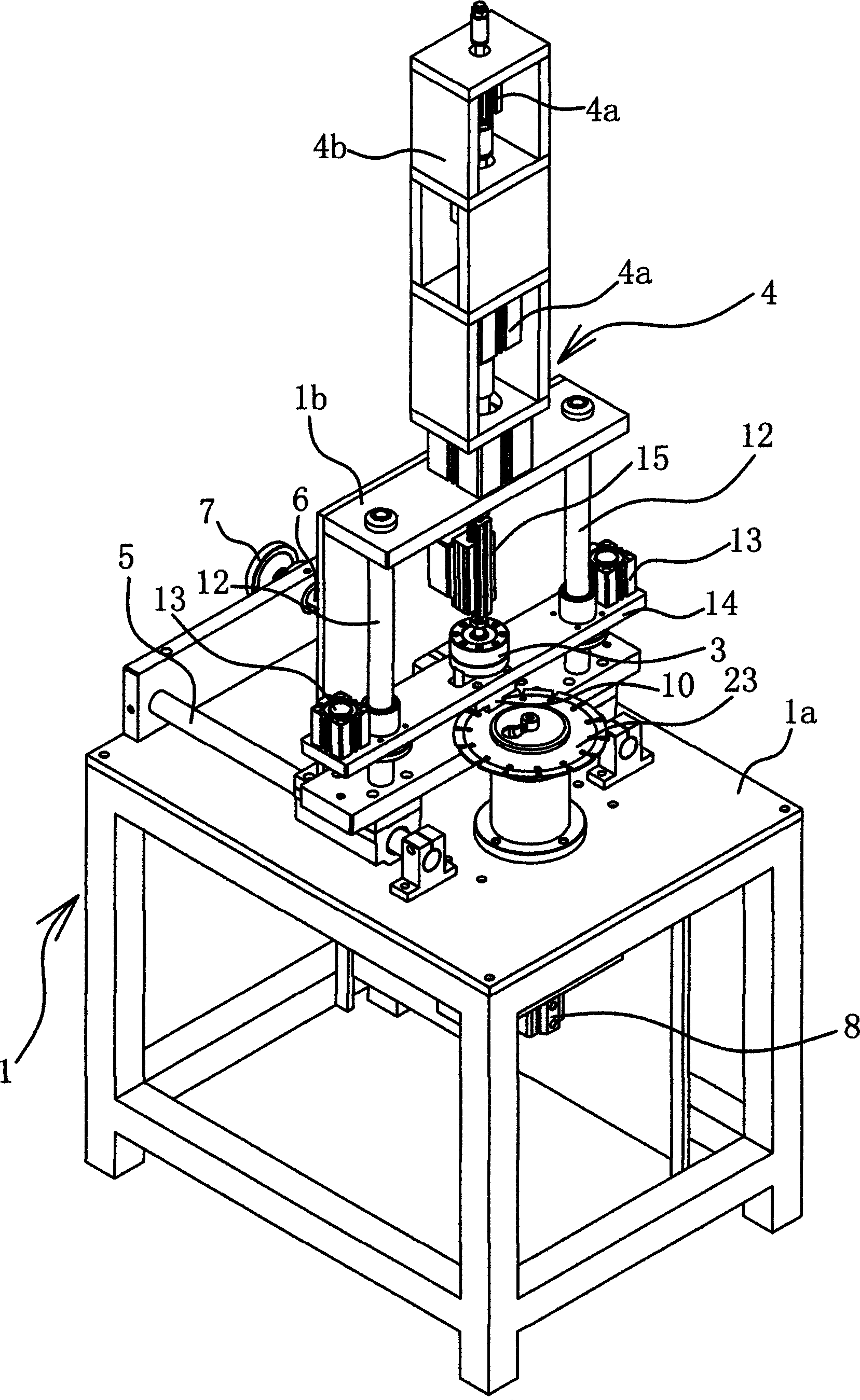

Full-automatic diamond saw blade welding machine

InactiveCN102806418ALow costImprove efficiencyMetal sawing tool makingHigh frequency current welding apparatusTool bitEngineering

The invention discloses a full-automatic diamond saw blade welding machine, which comprises a frame, an automatic discharging mechanism arranged on the frame, an automatic spiral feeding mechanism which conveys a diamond tool bit output from the automatic discharging mechanism to a tool bit welding position, an automatic rotor positioning mechanism used for positioning a diamond saw blade, and high-frequency induction heating equipment for welding the diamond tool bit to the diamond saw blade. By the full-automatic diamond saw blade welding machine, the tool bit welding is completely finished by the machine, manual discharging, rotating or positioning is not required, the welding machine is accurate in welding, stable, reliable, durable in use, high-efficiency, high in precision, full-automatic and easy to operate and use, multiple machines can be simultaneously operated by a worker, the production efficiency is improved, and the cost of the welding tool bit of the diamond saw blade is greatly saved.

Owner:张林

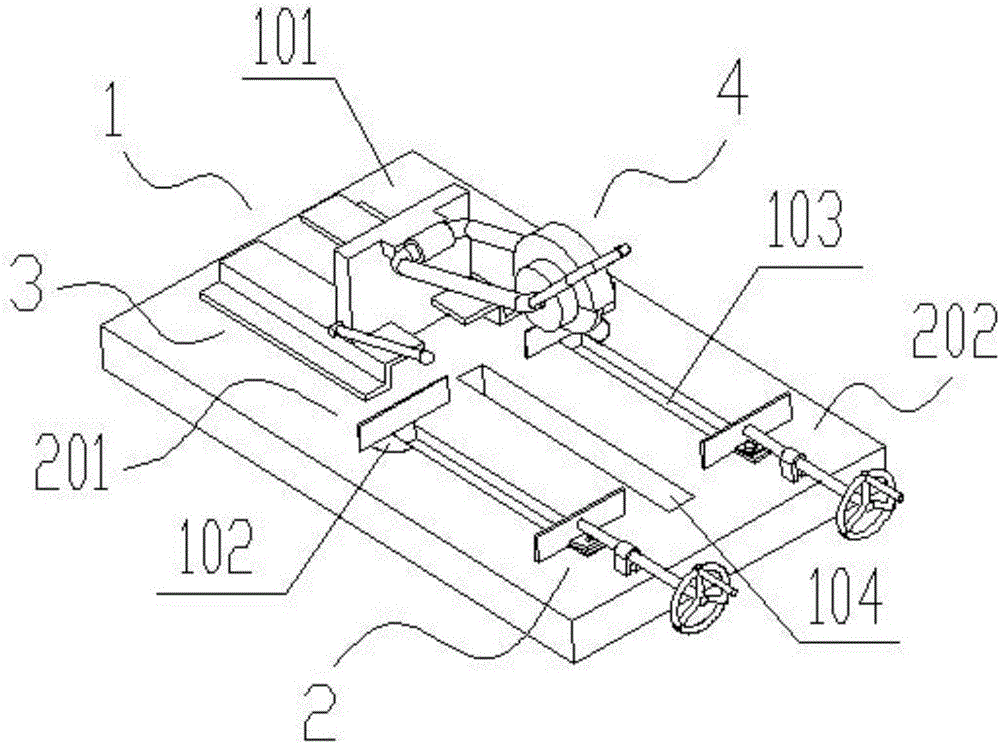

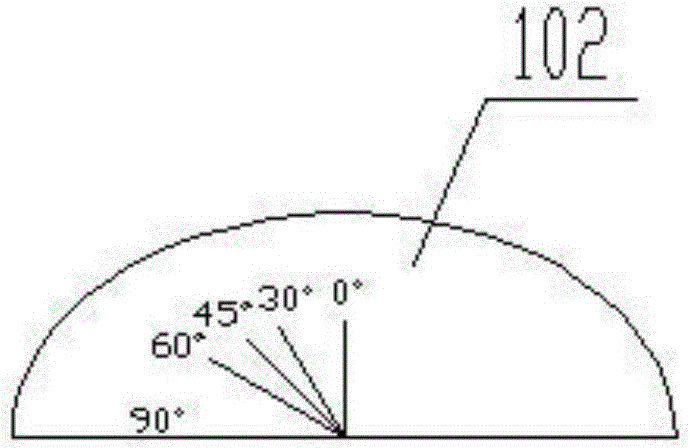

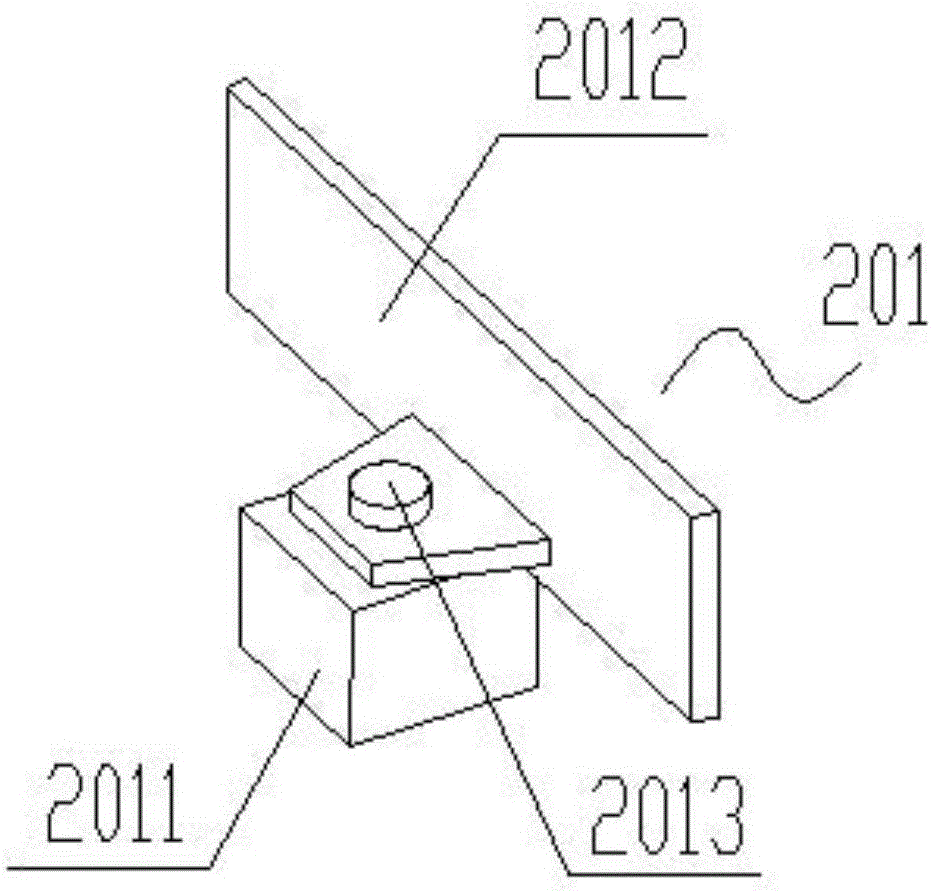

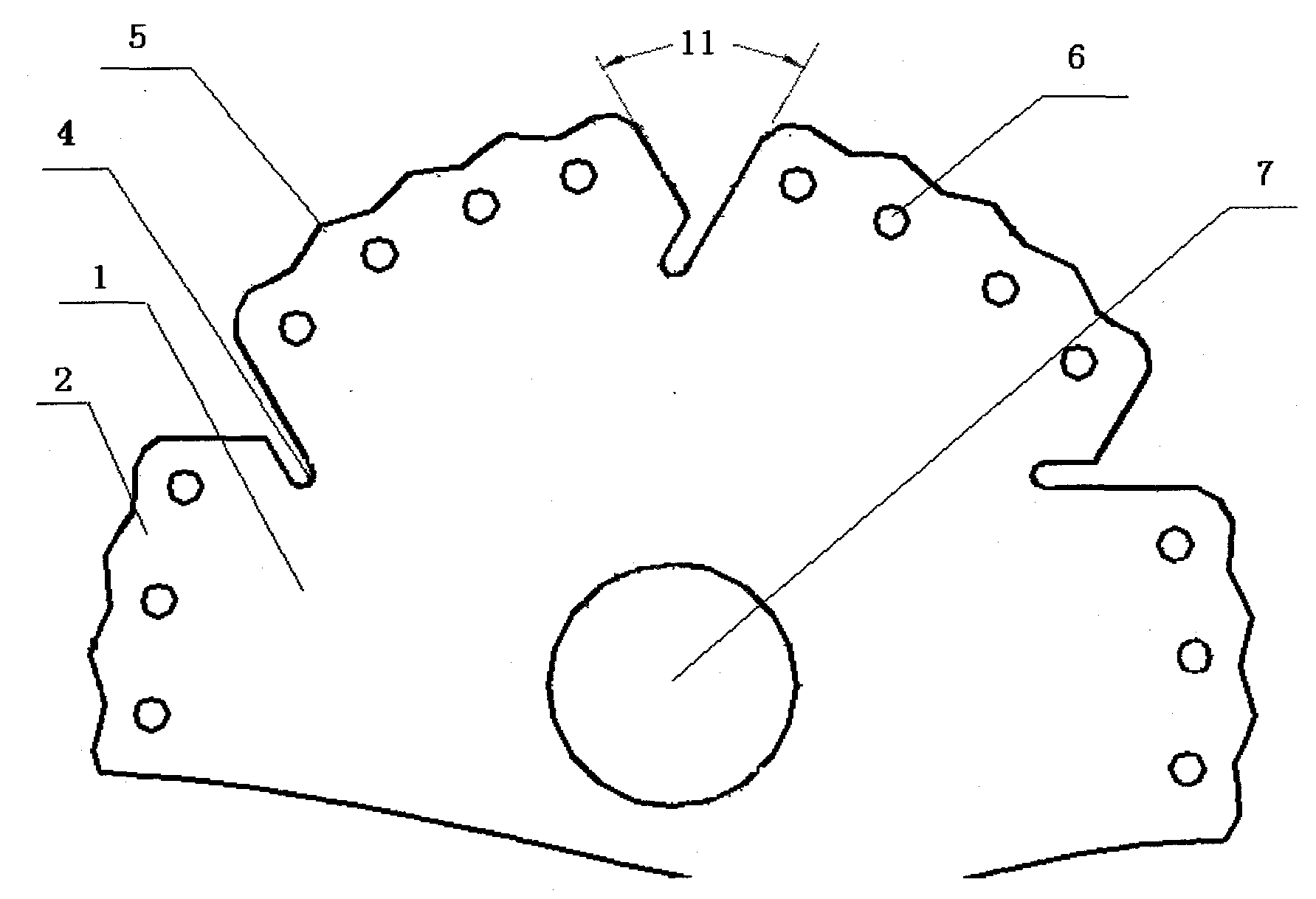

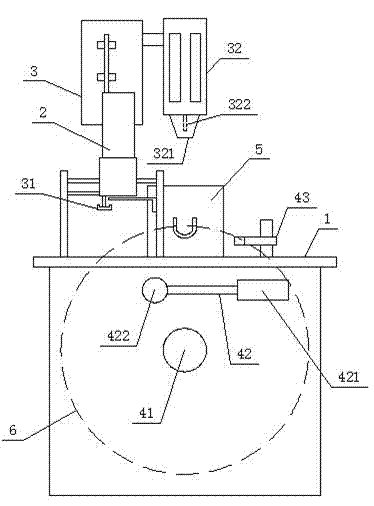

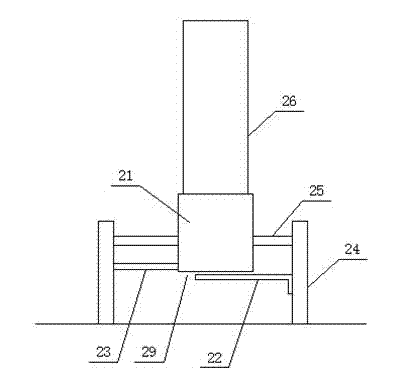

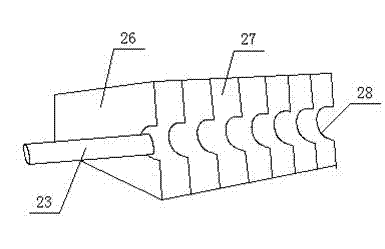

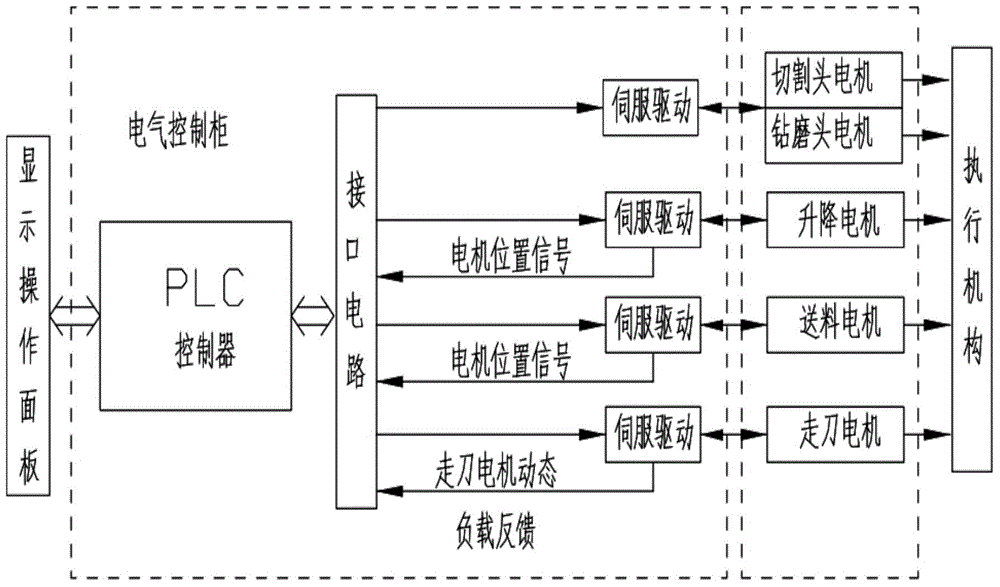

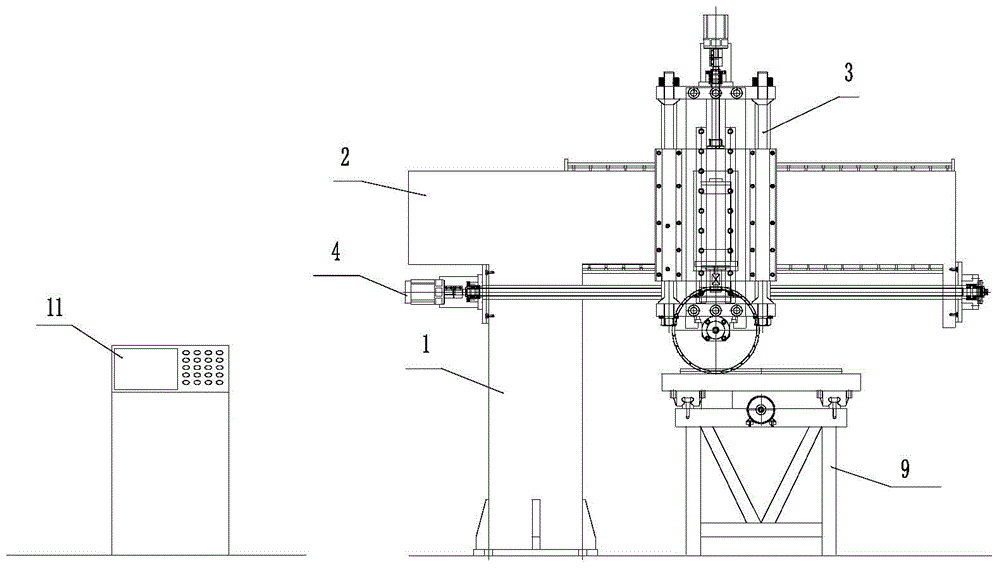

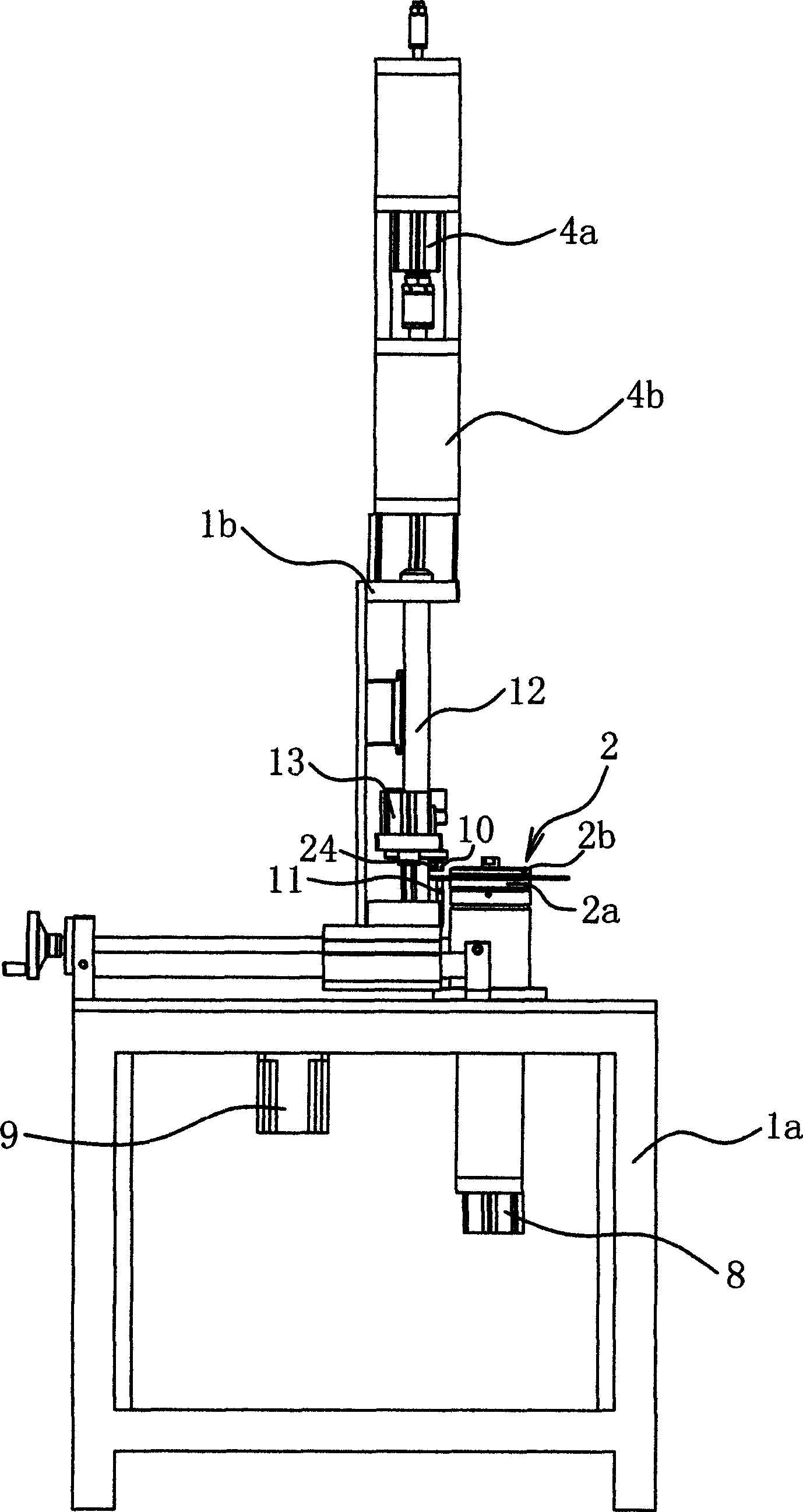

Saw blade cutting performance test machine and test method thereof

ActiveCN104406876AAvoid burnt teethMeet specific needsInvestigating machinabilityFeed drivePolishing

The invention relates to diamond saw blade performance testing, in particular to a saw blade cutting performance test machine and a test method thereof. The test machine comprises a stand column (1), a cross beam (2), a feed frame (3), a feed drive device (4), a cutting power head (5), a drilling polishing power head (6), a power head lifting mechanism (7), a feed carriage (8), a feed rack (9) and a feed drive mechanism (10). The test machine can be used for standardized quantitative verification testing of cutting performance of cutting, drilling and polishing tool products, fills up blank in the industry, has the characteristic of being capable of performing different cutting tests for different plates, not only avoids tooth burning of a test product due to overload but also can prevent the situation that the due efficiency of the test product cannot be reflected due to excessively small load to enable the test product to completely meet the specific requirements of merchants, is also suitable for serving as a process technology research and development test machine, and provides a powerful test verification way for extension of the cutting, drilling and polishing tools to the high-tech field.

Owner:CHENGDU HUIFENG NEW MATERIAL TECH CO LTD

Powder catalyst for synthesizing high strength and excellent quality diamond with low prodn. cost

InactiveCN1903429AMany holesHigh activityUltra-high pressure processesMetal/metal-oxides/metal-hydroxide catalystsAlloyAdamite

A powdered catalyst for synthesizing high-strength and high-quality diamond with low cost contains proportionally Ni, Mn, C, N, O, one or more of Cr, Ce and Si, and Fe. The resultant diamond has high output rate, integrity, transparency and thermal stability.

Owner:石门县顺超科技发展有限公司

Diamond round saw blade

The invention discloses round saw bits mainly made of diamond, which is composed of Cu, Fe, Sn, Ni, additional element, fluid wax and diamond. Fe and Cu are taken as mixed backing to improve heat-conducting and heat-eliminating effect of fetal bodies efficiently. Poor effect in dry cutting process with saw bits can be solved. Good cost performance is kept and cost is depressed by 40%-60% than that of saw bits made of cobalt-base diamond. Based on properties of stone in different areas, the saw bits are applicable for both dry and wet cutting. Diamond saw bits for different stone and building materials are developed to remedy defect of iron-base dry cutting.

Owner:BOSUN TOOLS CO LTD

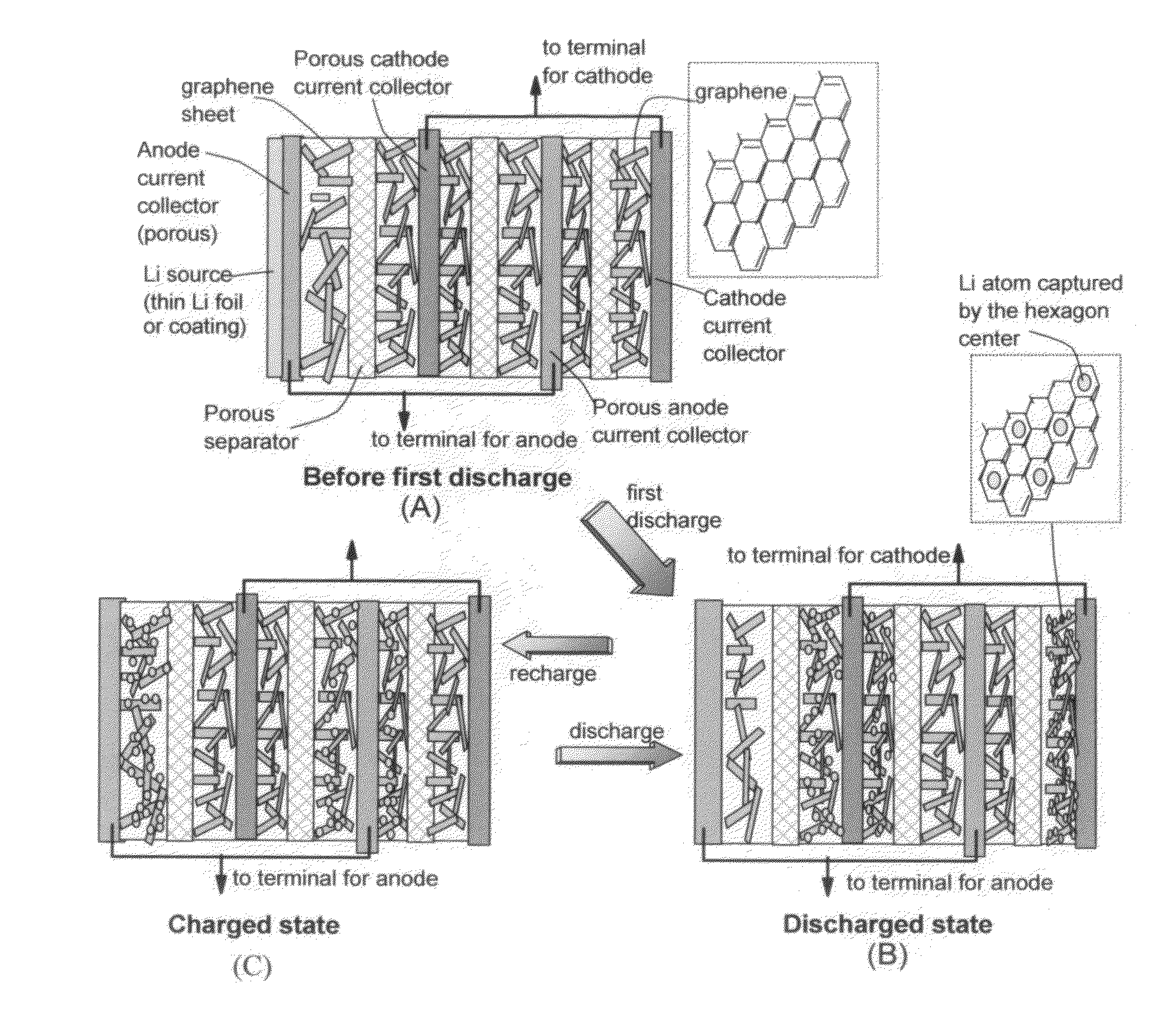

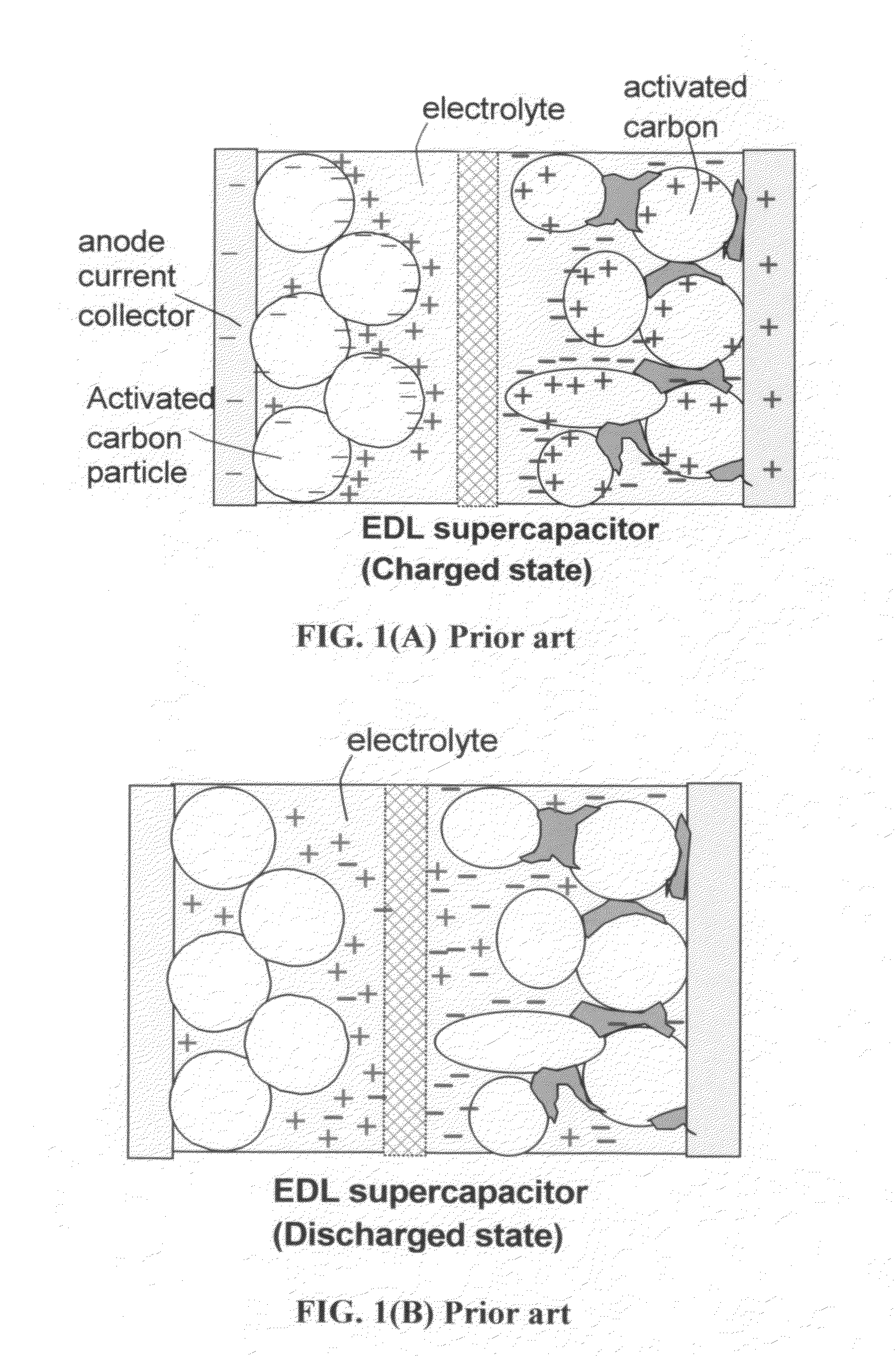

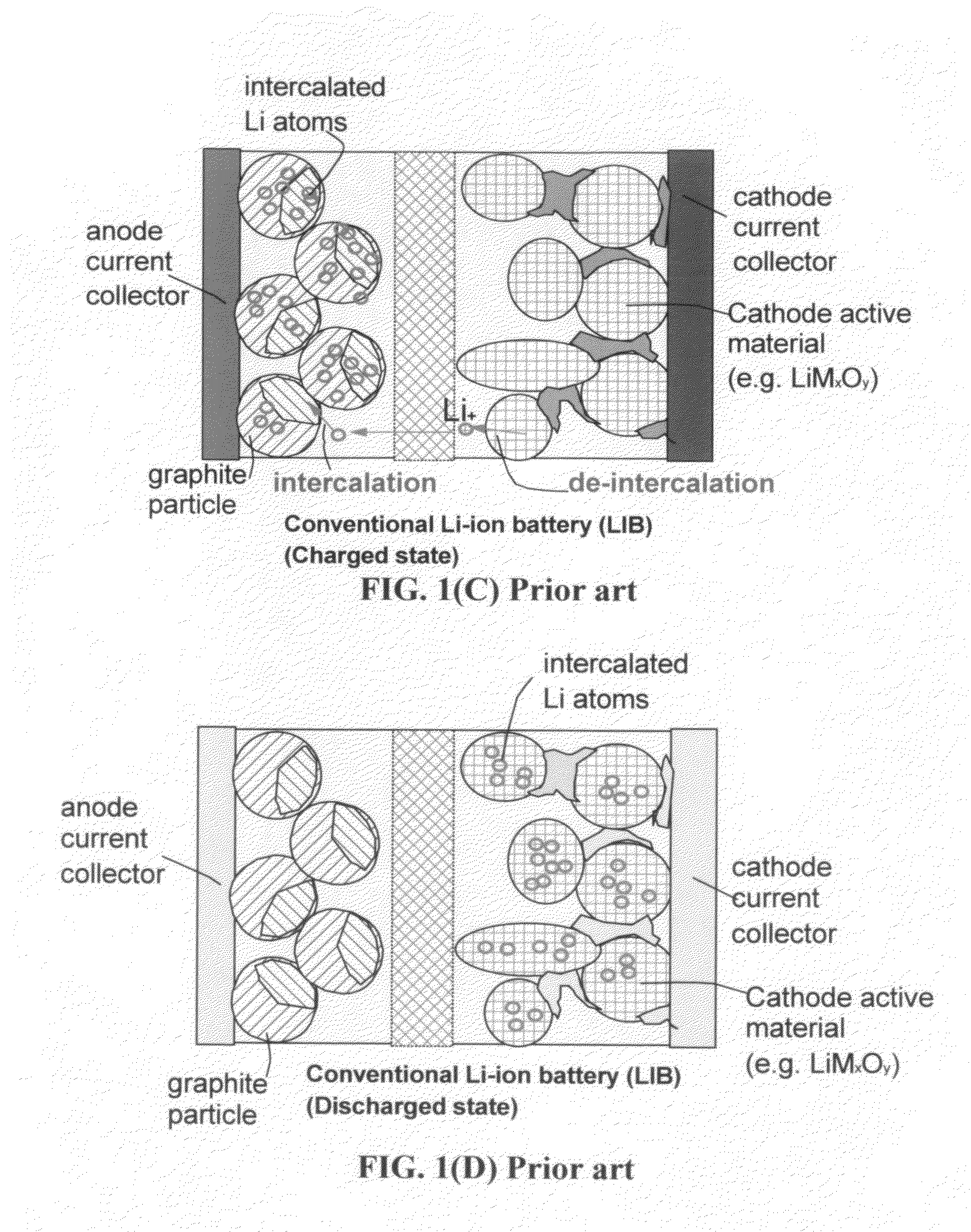

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS20130213677A1Improve power densityEasy dischargeDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

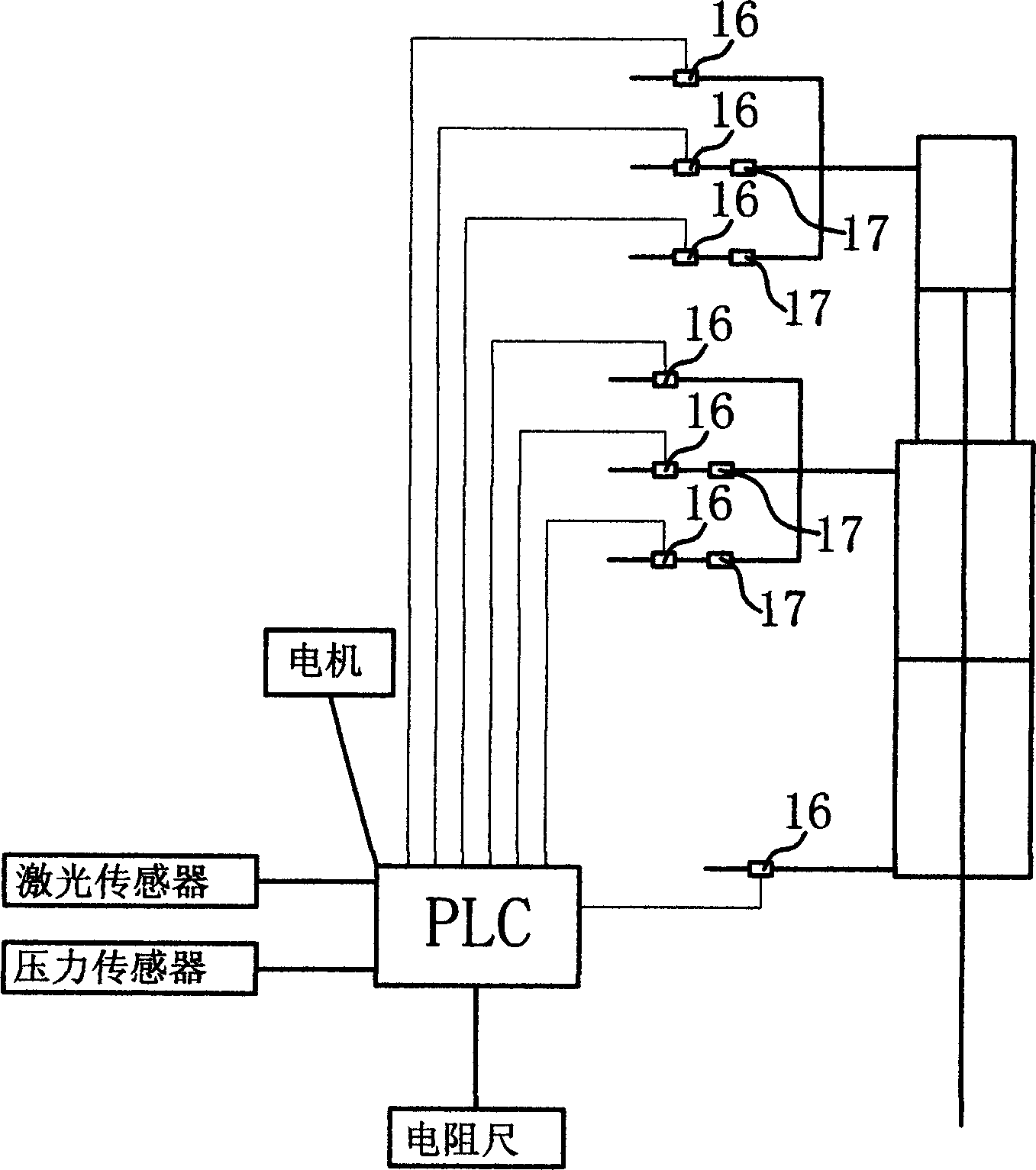

Automatic diamond cutter head welding strength detector

ActiveCN103383324AImprove detection efficiencyImprove detection accuracyMaterial strength using tensile/compressive forcesElectrical connectionEngineering

Belonging to the field of operation techniques, the invention provides an automatic diamond cutter head welding strength detector, and solves the problem of low detection efficiency in existing strength detectors. The automatic diamond cutter head welding strength detector includes a frame and a fixture for fixing a diamond saw blade. The frame is provided with a driving mechanism for driving the fixture to rotate. The frame is equipped with a chuck assembly that can be clamped at the periphery of the diamond saw blade matrix. The strength detector also includes a PLC based control cabinet, a pressure sensor and a pressure head. The frame is equipped with an air cylinder assembly that can drive the pressure head to move up and down. The pressure head and the air cylinder assembly are connected by the pressure sensor. The air cylinder assembly is in connection with electromagnetic valves. The electromagnetic valves and the pressure sensor are all in electrical connection with the PLC. The automatic diamond cutter head welding strength detector has the advantages of high detection efficiency and high detection accuracy. Due to employment of air cylinder driving, the automatic diamond cutter head welding strength detector has the advantages of low production cost.

Owner:项大清

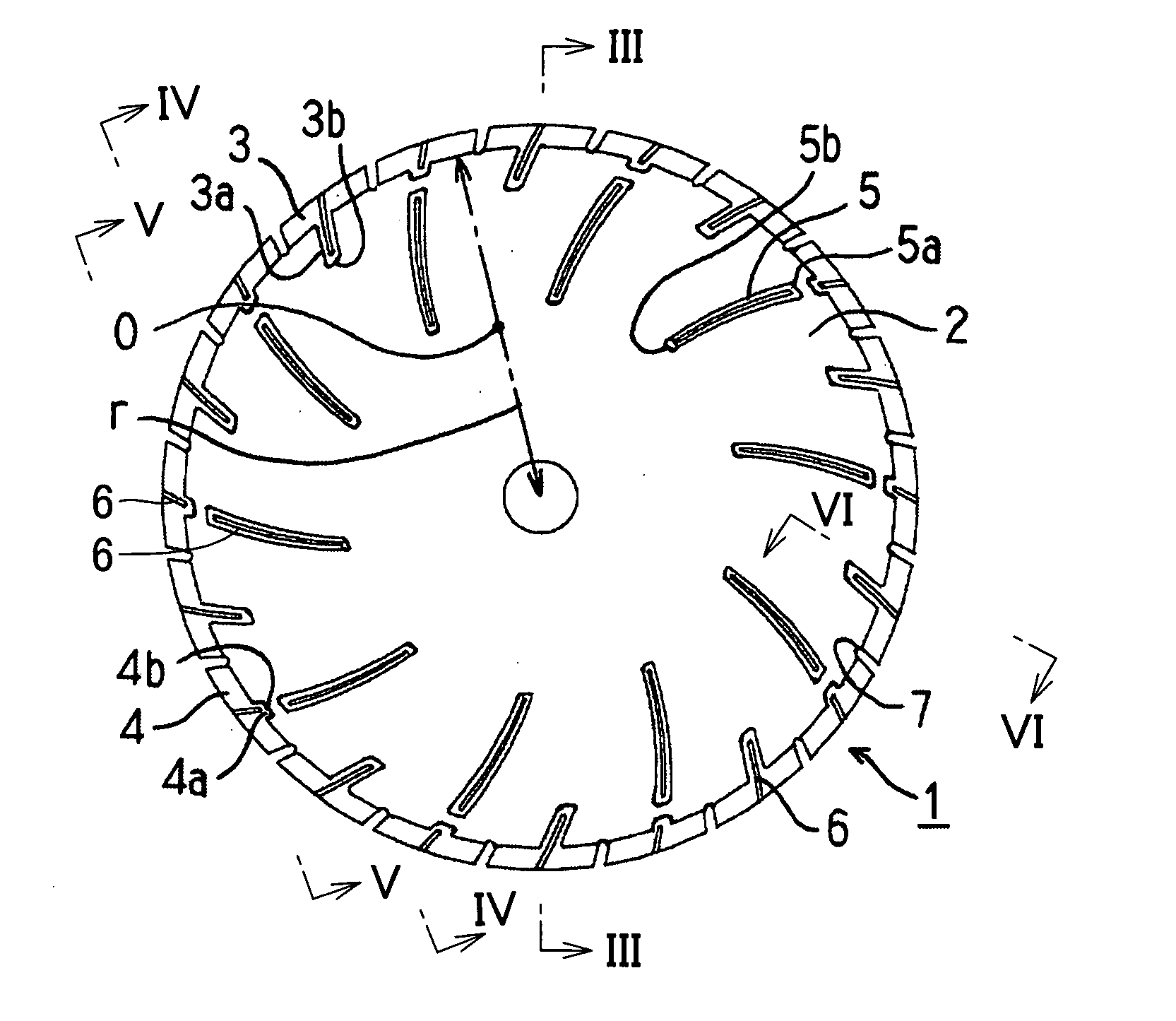

Diamond blade

InactiveUS20050121017A1Avoid undercutLittle wobbleRevolution surface grinding machinesMetal sawing toolsMechanical engineeringDiamond blade

In relation to a blade cutting stone or concrete, a blade, preventing wearing of a core while preventing the core from wobbling, cuttable at a stable speed is provided. In a blade formed by providing slots on the outer peripheral edge of a circular core and fixing a superabrasive layer to a portion of the outer peripheral surface of the core located between the slots, the superabrasive layer consists of a first superabrasive layer having an extension formed by partially extending the superabrasive layer toward the inner periphery of the core and a second superabrasive layer. A reinforcing superabrasive layer extending from the outer periphery toward the inner periphery of the core is formed on the inner peripheral side of the second superabrasive layer while the reinforcing superabrasive layer is located closer to the outer periphery than a radial central portion of the core, and an outer peripheral end of the reinforcing superabrasive layer is located closer to the outer periphery than an inner peripheral end of the extension of the first superabrasive layer. The second superabrasive layer can also be provided with an extension having a relatively short radial length with respect to the extension of the first superabrasive layer.

Owner:ALLIED MATERIAL

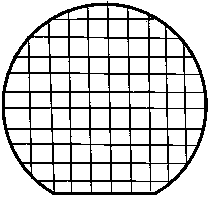

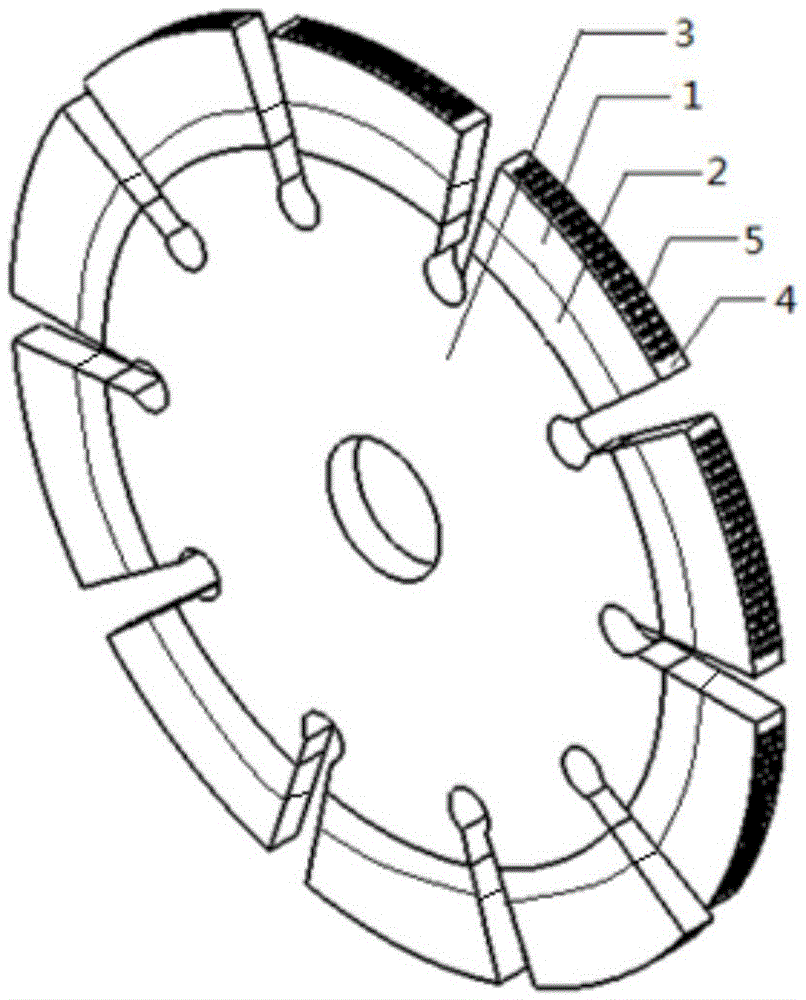

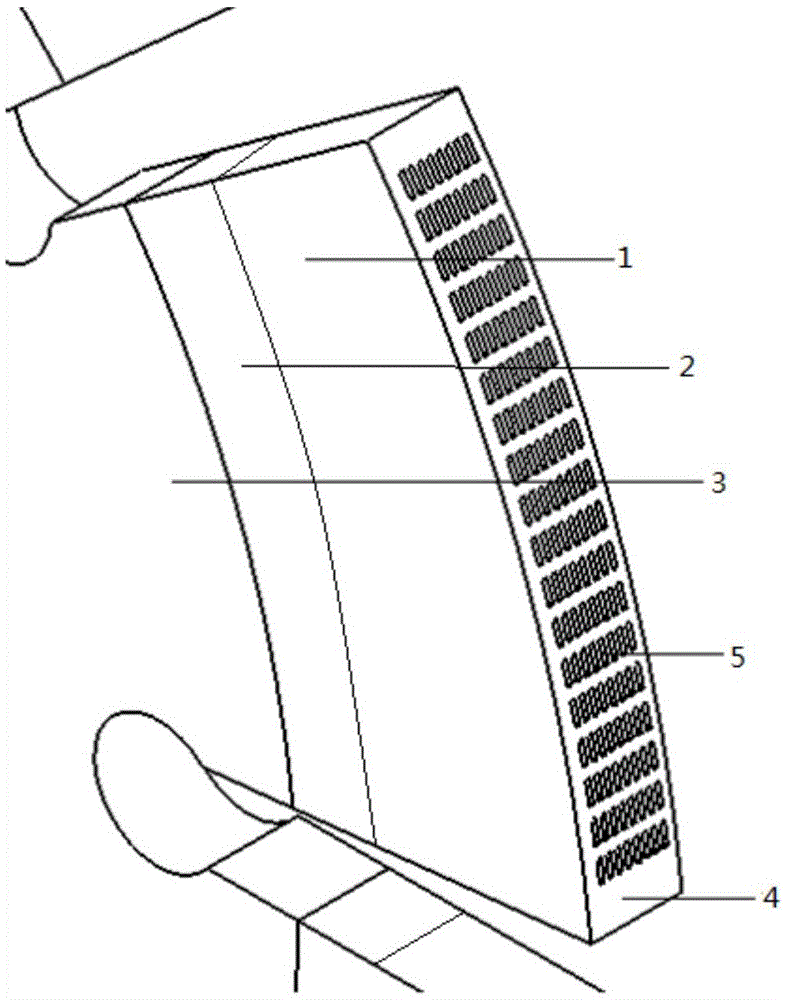

Metallic-bond complicated-surface diamond saw blade and 3D printing and making process thereof

InactiveCN105562825AExtended service lifeIncrease productivityMetal sawing tool makingMetal sawing toolsWhole bodyEngineering

The invention relates to a metallic-bond complicated-surface diamond saw blade and a 3D printing and making process thereof. According to the invention, a latticed segment working layer is formed by distribution of solid bodies and blank bodies along radial and circumferential directions, and the latticed segment working layer, a segment welding layer and a saw blade base body jointly form a saw blade whole body. In the segment welding layer, the latticed segment working layer is printed in a 3D manner by adopting a laser sintering process. According to the invention, in work, due to existence of gaps, chippings produced in grinding can be effectively removed, so that an effect of cleaning a grinding surface can be achieved; and the saw blade is prevented from carrying out secondary grinding on the chippings, so that the working efficiency is improved. Meanwhile, heat produced in grinding can be quickly dissipated through the gaps, so that failure of a working surface caused by high temperature is avoided, and the service life of the saw blade is prolonged. By adopting a 3D printing manner, printing can be performed just by setting parameters on a computer, thus ensuring precision and dimension requirements and improving production efficiency.

Owner:CENT SOUTH UNIV

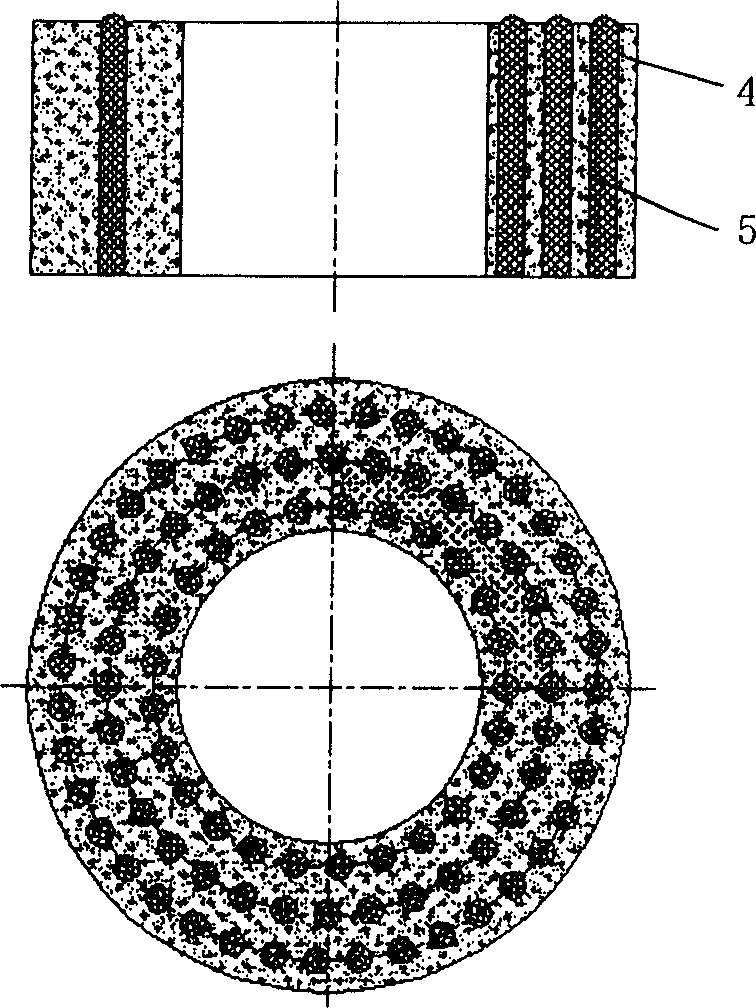

Diamond bits and saw disc therewith

InactiveCN1583388AImprove cutting work efficiencyReduce vibrationStone-like material working toolsGraphiteCeramic

A diamond cutter and its saw blade used for machining stone, ceramics, or glass are disclosed. Said diamond cutter is composed of steel base, metallic supporter, diamond, filing discharging slot and graphite on the bottom of said slot. Said diamond saw blade consists of the steel base and diamond cutters welded to said steel base.

Owner:JIEYANG HESHENG MACHINERY STONE

Copper base diamond saw blade

InactiveCN101716803AEfficient sawing performanceImprove wear resistanceStone-like material working toolsEnhanced serviceMaterials science

The invention relates to a copper base diamond saw blade, which comprises a cutter head and a steel base body and is characterized in that the cutter head is made by mixing and firing metal powder, abrasive grade diamond and nano grade diamond; and the metal powder comprises pure copper powder, iron powder, nickel powder, tungsten carbide, tin powder and bronze powder. The preparation method comprises the steps of: uniformly mixing the metal powder according to a proportion; sequentially adding the abrasive grade diamond and the nano grade diamond for mixing; finally adding liquid olefin; packing the mixed formed material into a cold pressing mould to form; and sintering to prepare the diamond saw blade. Compared with the prior art, the diamond saw blade has the advantage that the abrasive grade diamond and the nano grade diamond are simultaneously added in the saw blade for achieving the purpose of organically combining the cutting function of the abrasive grade diamond with the friction-reducing abrasion resistant function of the nano grade diamond, therefore, the copper base diamond saw blade has effective sawing performance and better abrasion resistant performance. Compared with a similar saw blade, the copper base diamond saw blade has obviously enhanced service life by a test.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

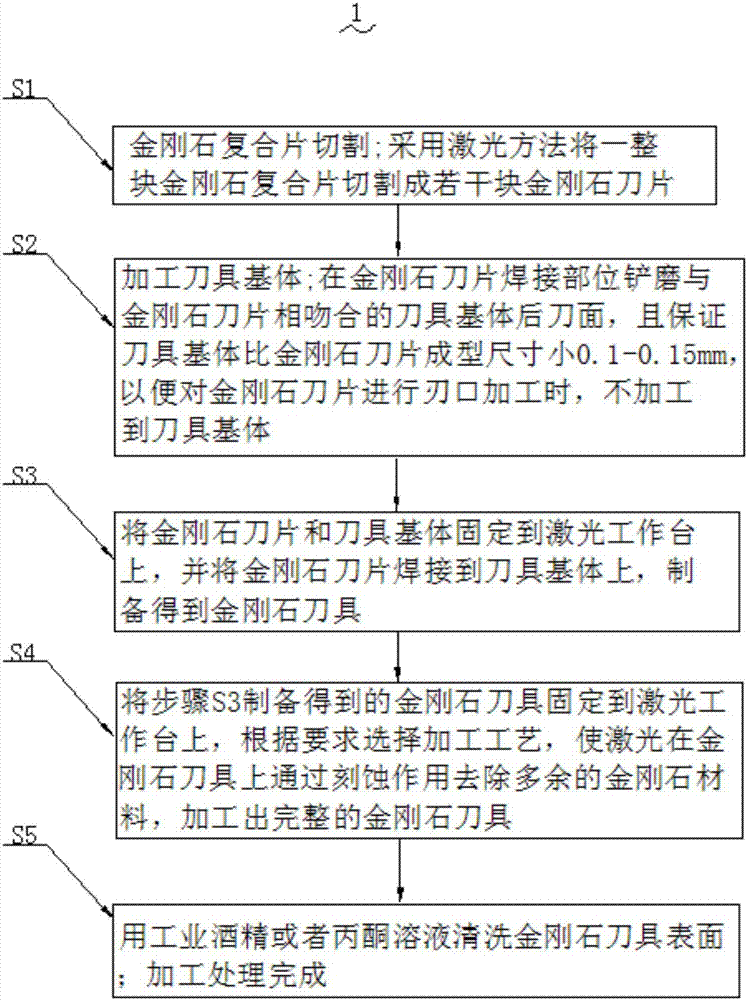

Full-laser manufacturing method of diamond cutter

ActiveCN106984913AIncrease profitImprove processing efficiencyLaser beam welding apparatusMaterials scienceLaser

The invention provides a full-laser manufacturing method of a diamond cutter. The full-laser manufacturing method of the diamond cutter comprises the following steps that S1 a diamond compact is cut, and the complete diamond compact is cut into a plurality of diamond blades in a laser manner; S2, cutter matrixes are machined, relief grinding is conducted on a cutter matrix flank face at the welding position of each diamond blade, and it is guaranteed that the forming dimension of each cutter matrix is 0.1-0.15 mm smaller than that of the corresponding diamond blade; S3, each diamond blade and the corresponding cutter matrix are fixed to a laser workbench, and each diamond blade is welded to the corresponding cutter matrix, and the diamond cutter is manufactured; S4, the diamond cutter manufactured in the step S3 is fixed to the laser workbench, a machining technology is selected according to requirements, redundant diamond materials on the diamond cutter are removed by means of the etching function of the laser, and a complete diamond cutter is machined; and S5, the surface of the diamond cutter is cleaned with industrial alcohol or an acetone solution, and then machining is completed. The full-laser manufacturing method of the diamond cutter is high in machining efficiency, not high in requirement for the manual technological level and suitable for large-scale industrial production.

Owner:深圳光韵达激光应用技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com