Manufacture method evenly distributing and orderly arranging diamond saw blades

A technology of orderly arrangement and uniform distribution, applied in the tool manufacturing, manufacturing tools, metal sawing equipment and other directions of sawing machines, can solve the problem of low effective utilization of diamond, and achieve the effect of good sharpness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

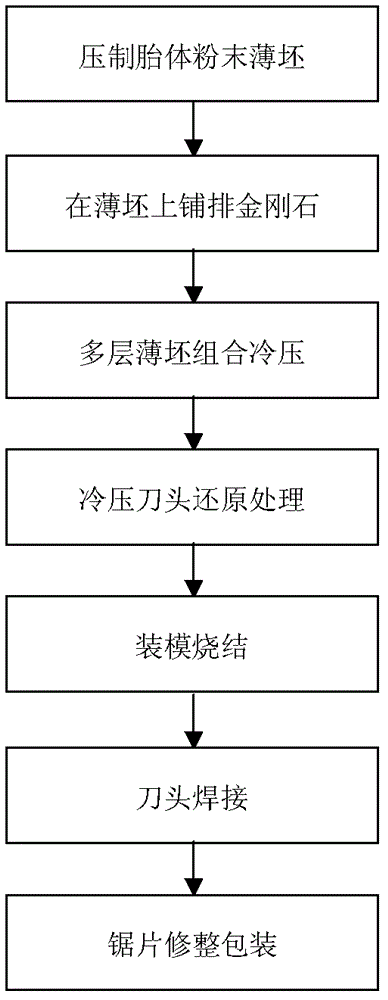

[0019] A uniformly distributed and ordered diamond saw blade preparation process is as follows:

[0020] The first step: mix the carcass powder evenly, and make the carcass sheet-shaped thin billet through the cold pressing forming process;

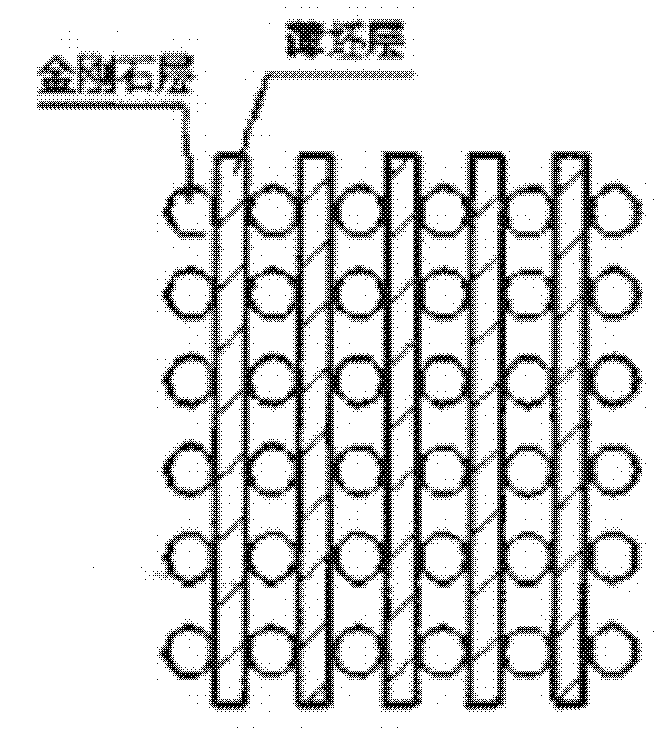

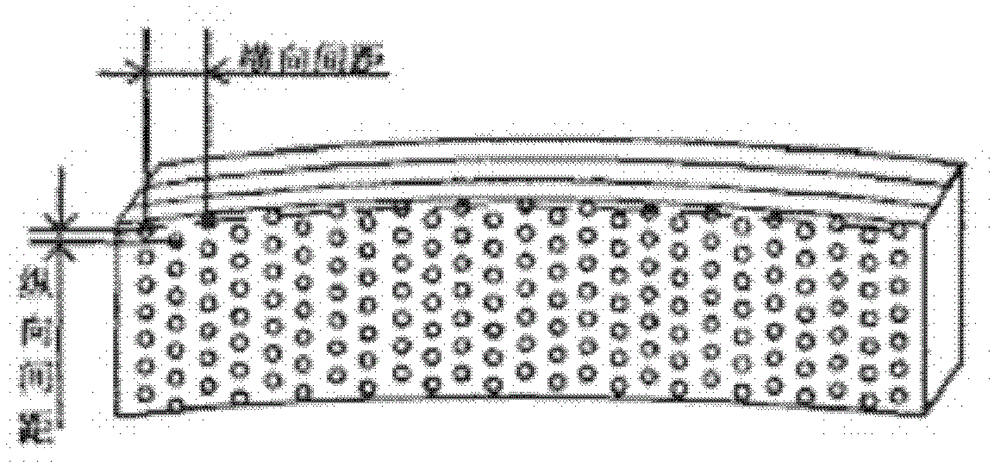

[0021] Step 2: Design the uniform distribution and orderly arrangement of diamonds and use laser drilling to make copper templates. The thickness of the copper template is 1 / 3 to 2 / 3 of the average particle size of diamonds, and the aperture of the copper template is 1 / 3 of the average particle diameter of diamonds. ~2 times.

[0022] Step 3: Spray a thin layer of special pressure-sensitive adhesive on the surface of the carcass sheet-shaped thin billet, and place the copper template on the surface of the carcass sheet-shaped thin billet, then sprinkle diamonds on the copper template and use a steel plate Swipe the diamond to ensure that each hole in the copper template can fall into a diamond;

[0023] Step 4: Clean up the excess diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com