Patents

Literature

67 results about "Thickness planer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thickness planer (also known in the UK and Australia as a thicknesser or in North America as a planer) is a woodworking machine to trim boards to a consistent thickness throughout their length and flat on both surfaces.

Surface-mediated cell-driven power tools and methods of operating same

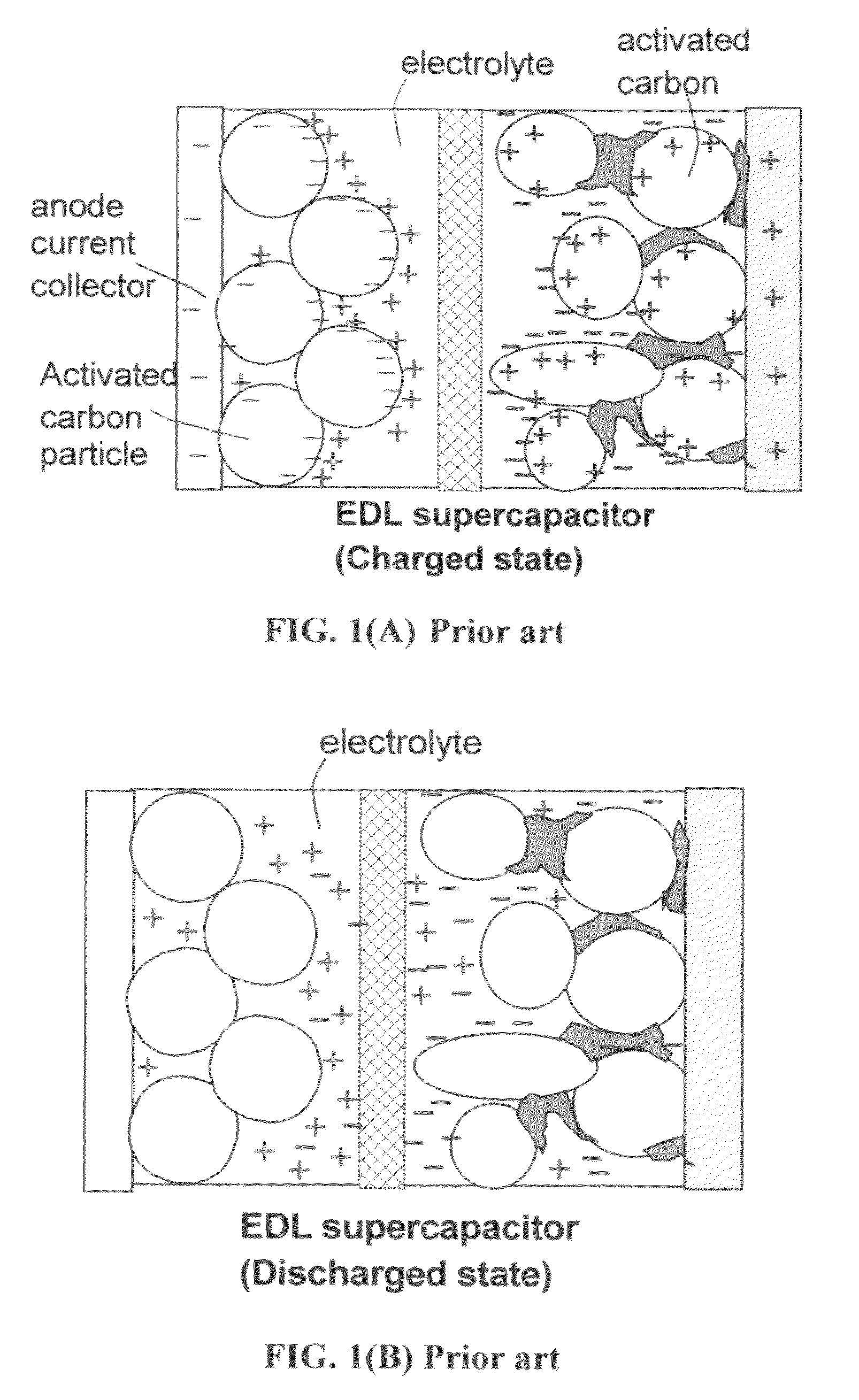

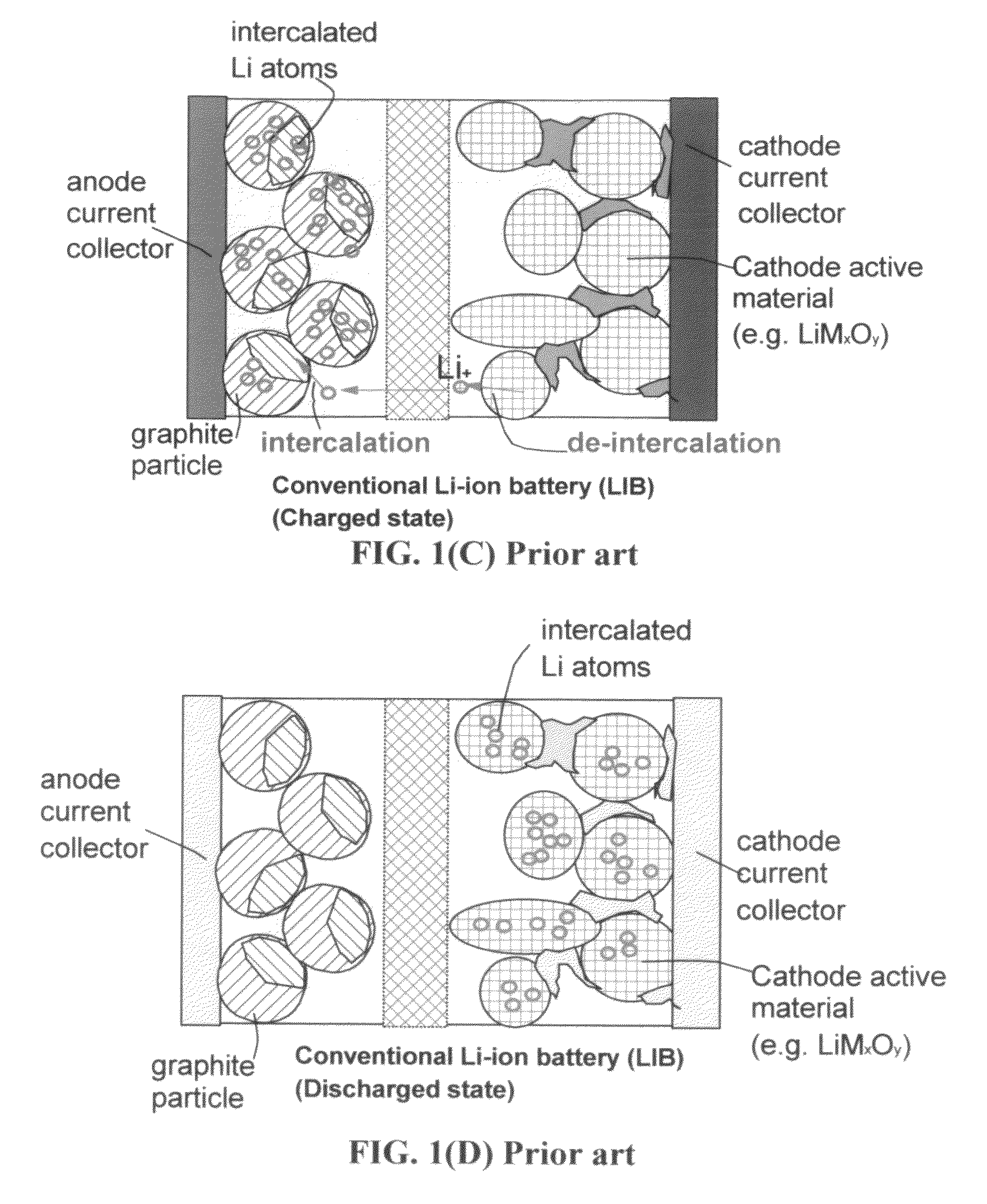

ActiveUS20130213677A1Improve power densityEasy dischargeDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

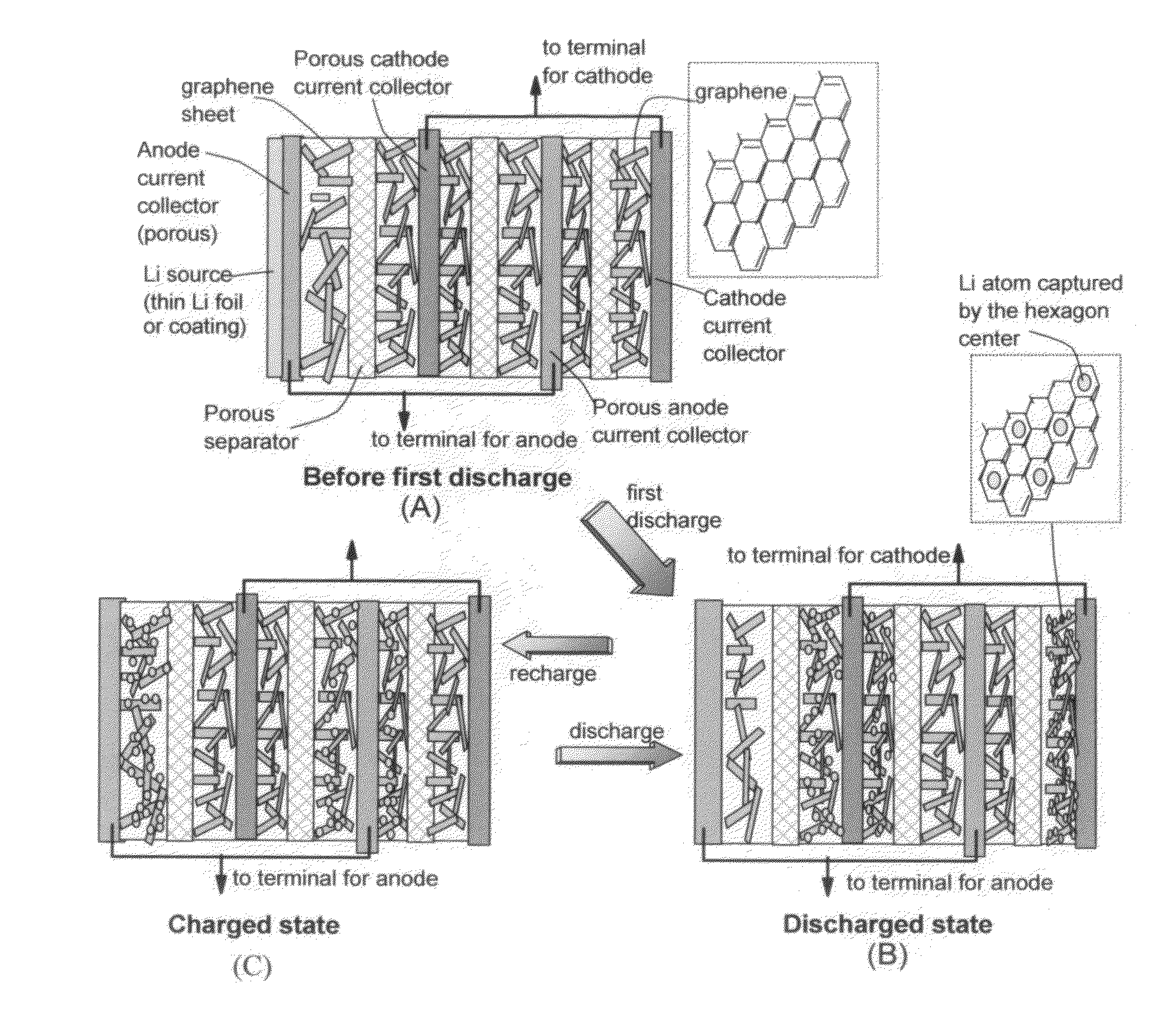

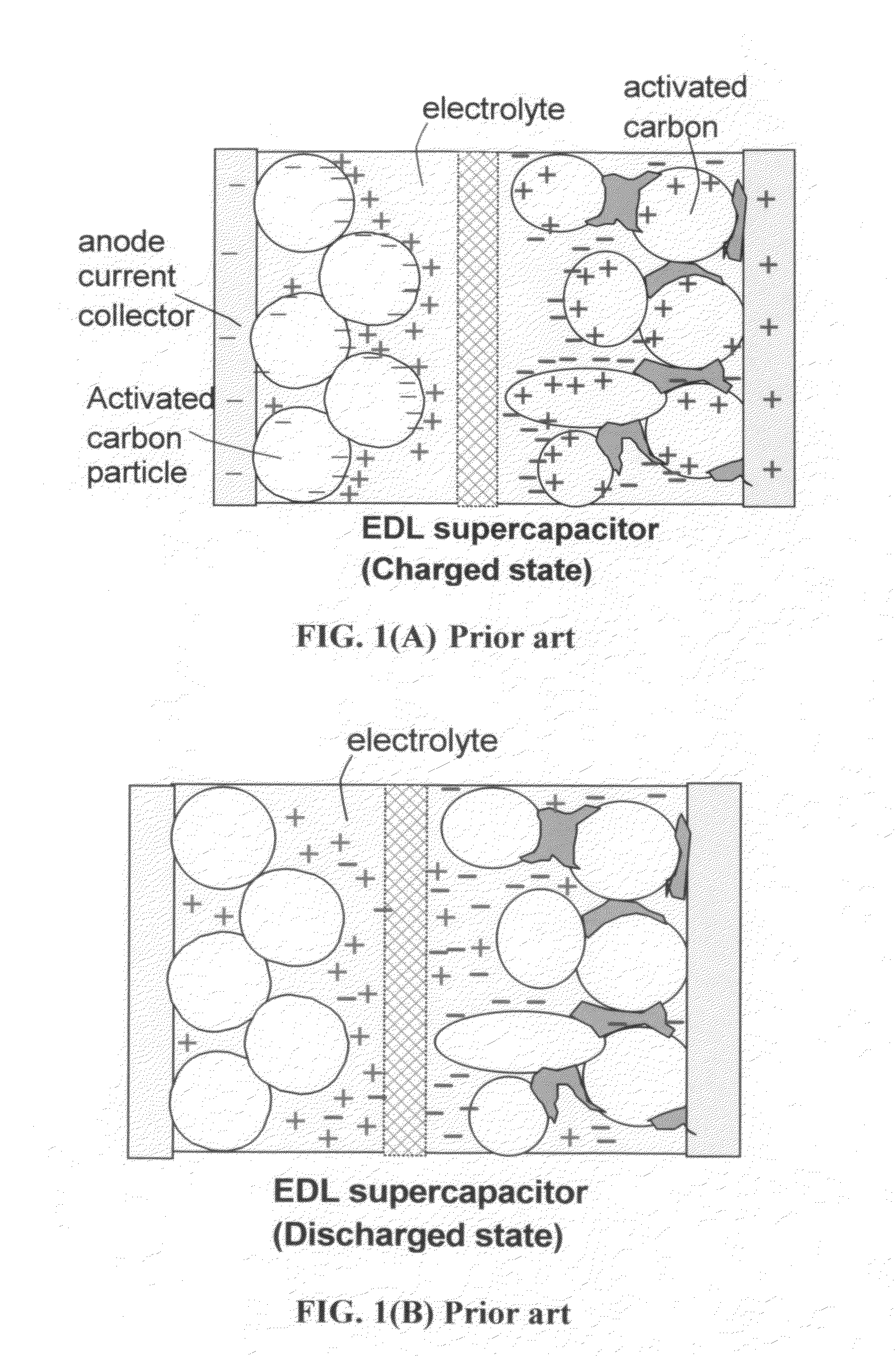

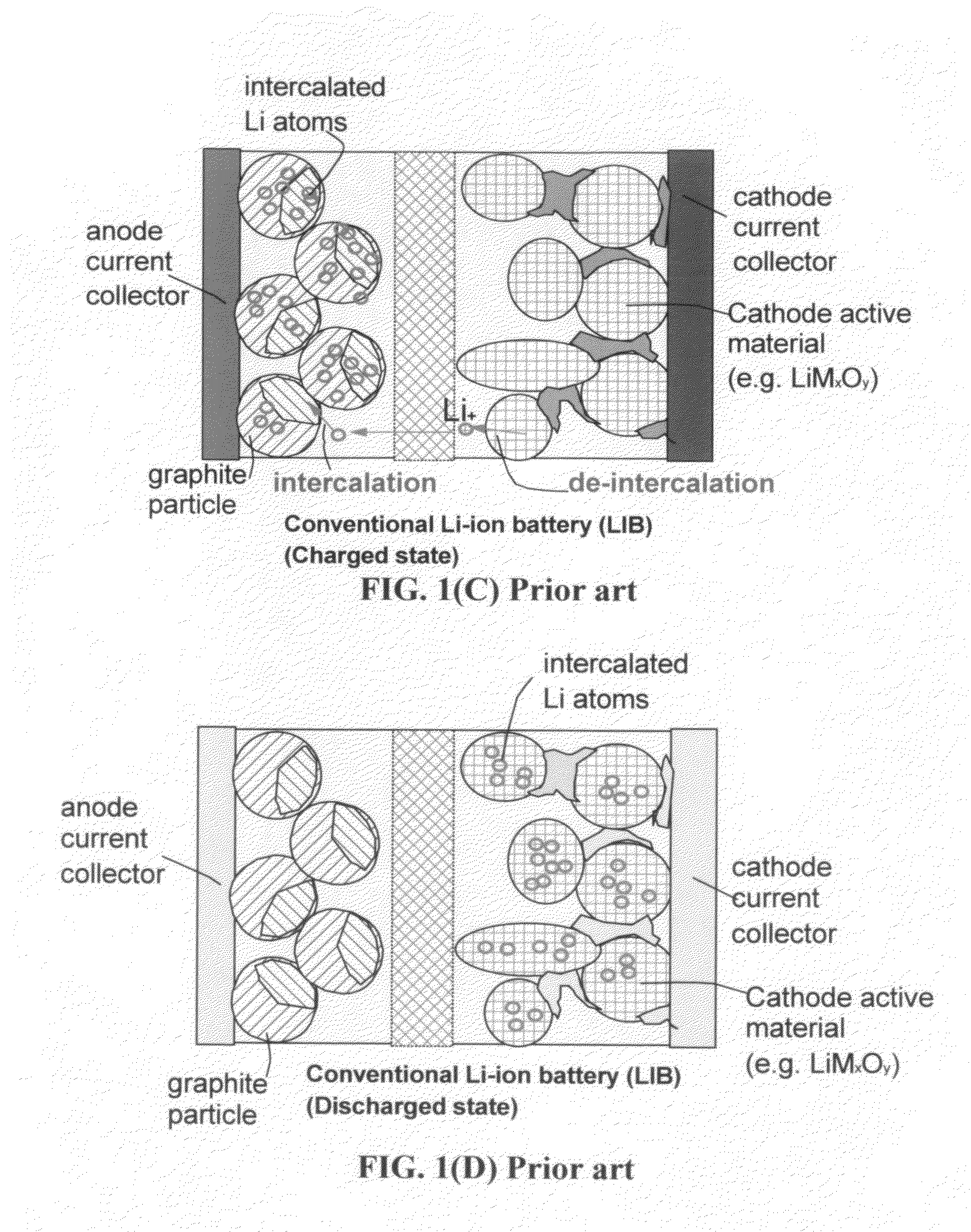

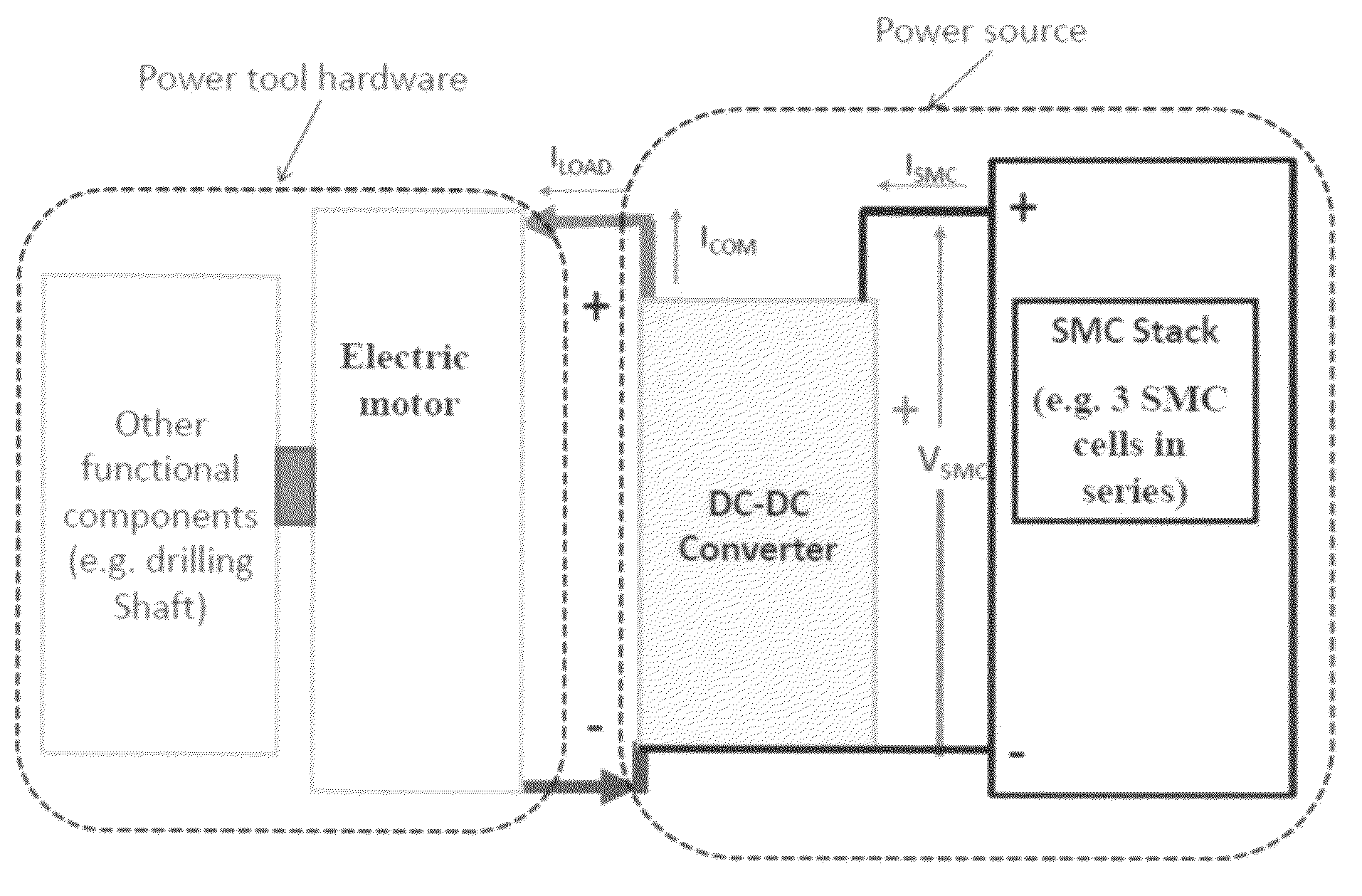

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS9085076B2Increase electrode areaHigh currentDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

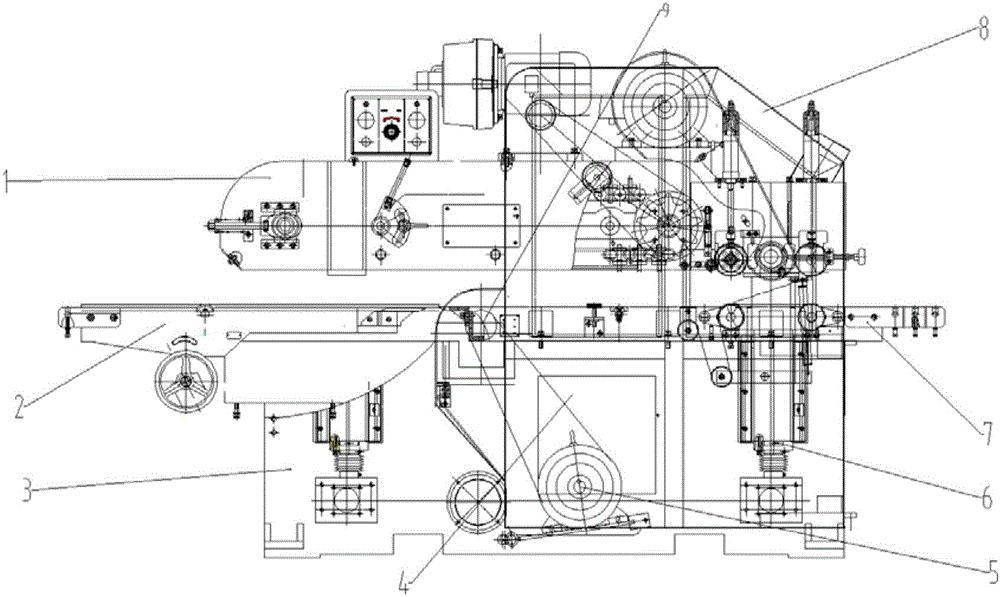

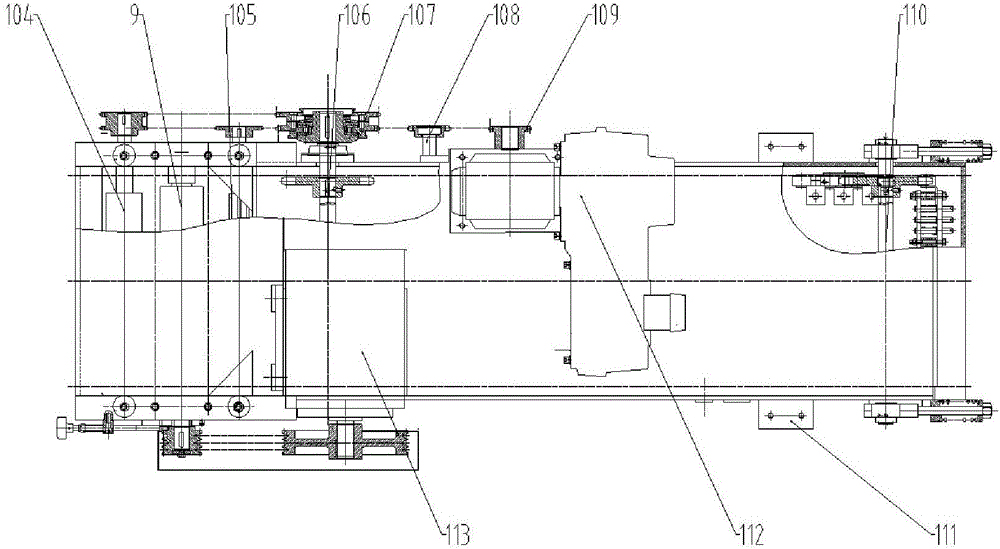

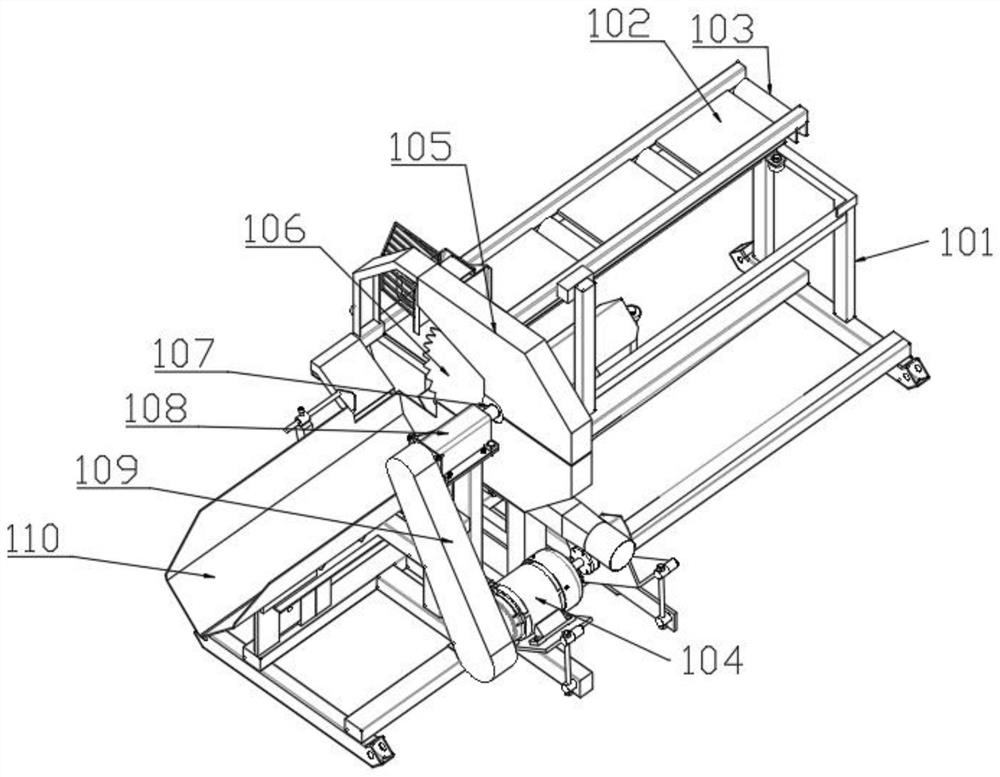

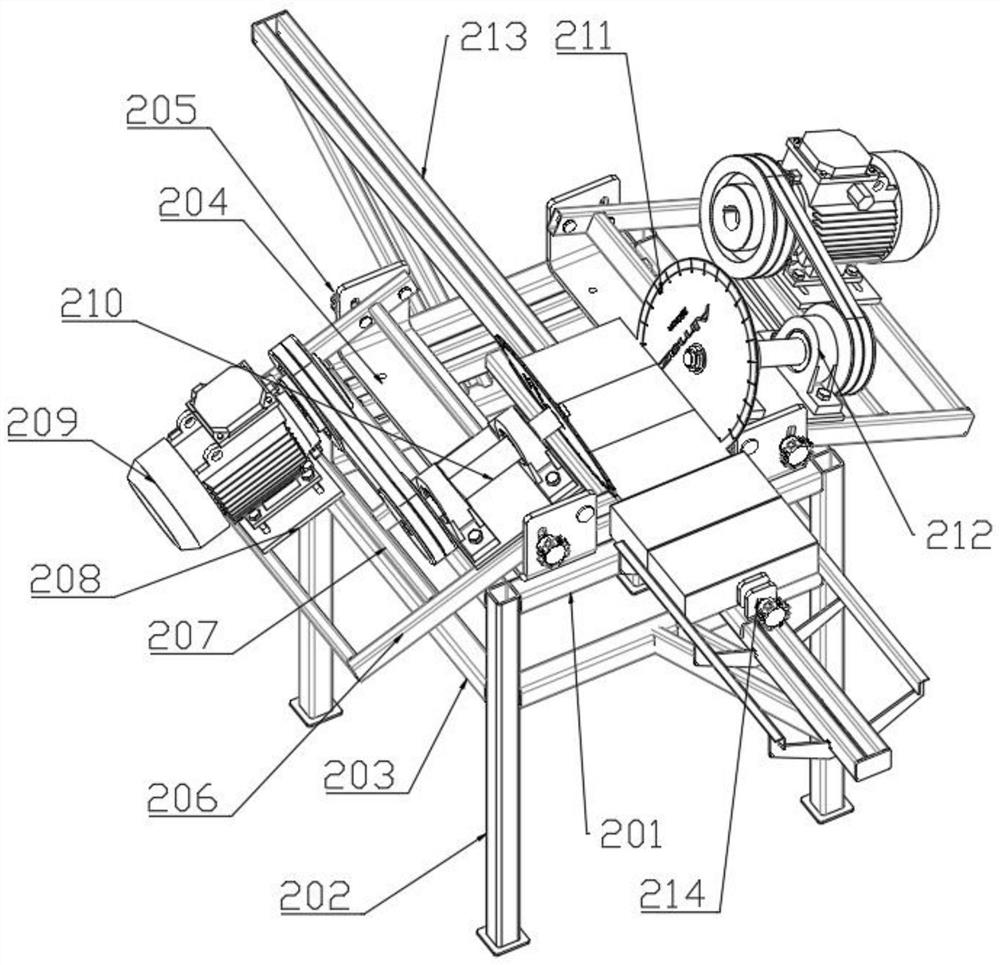

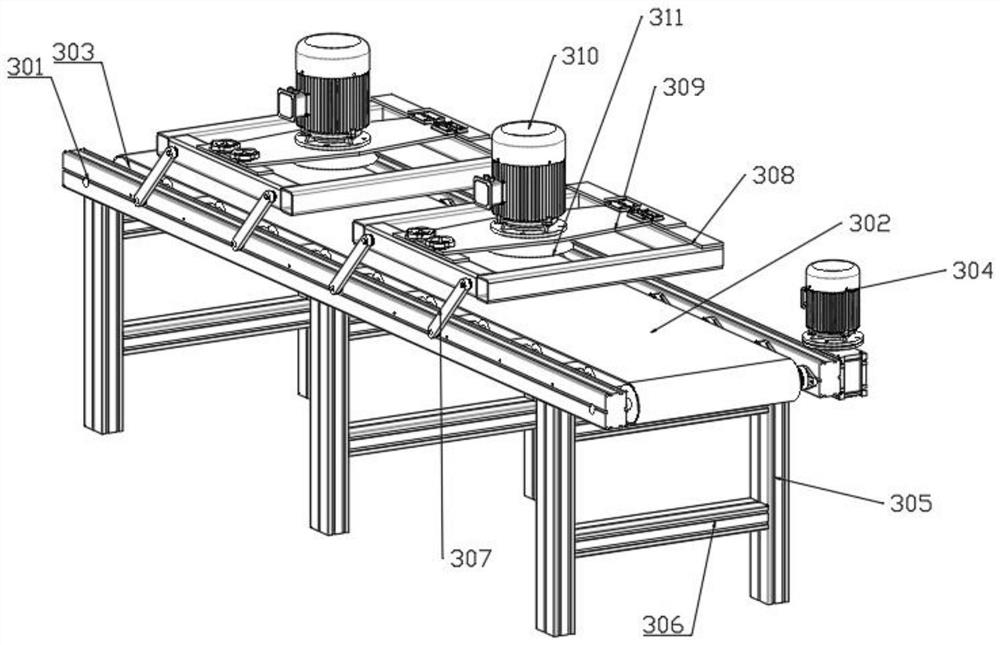

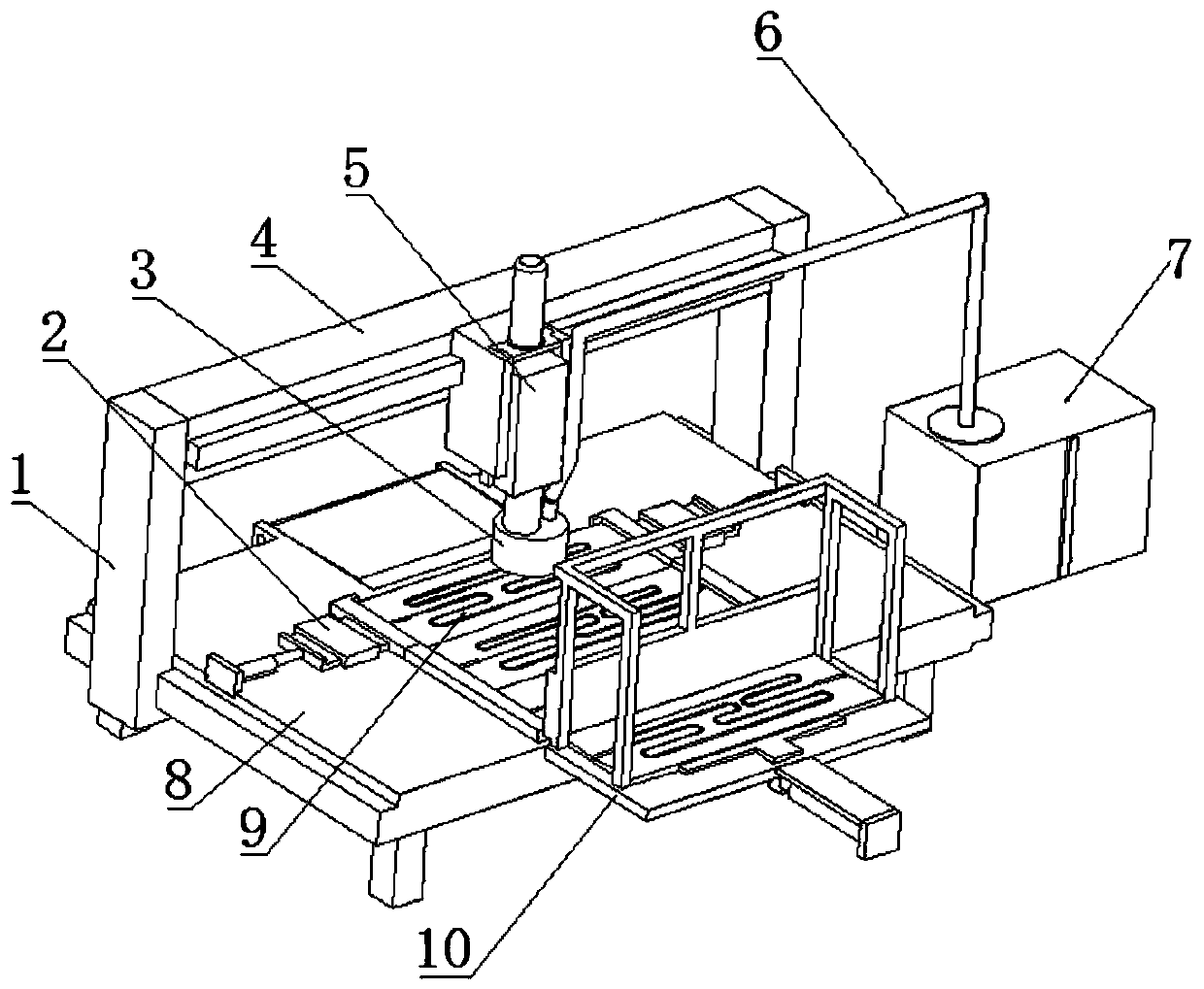

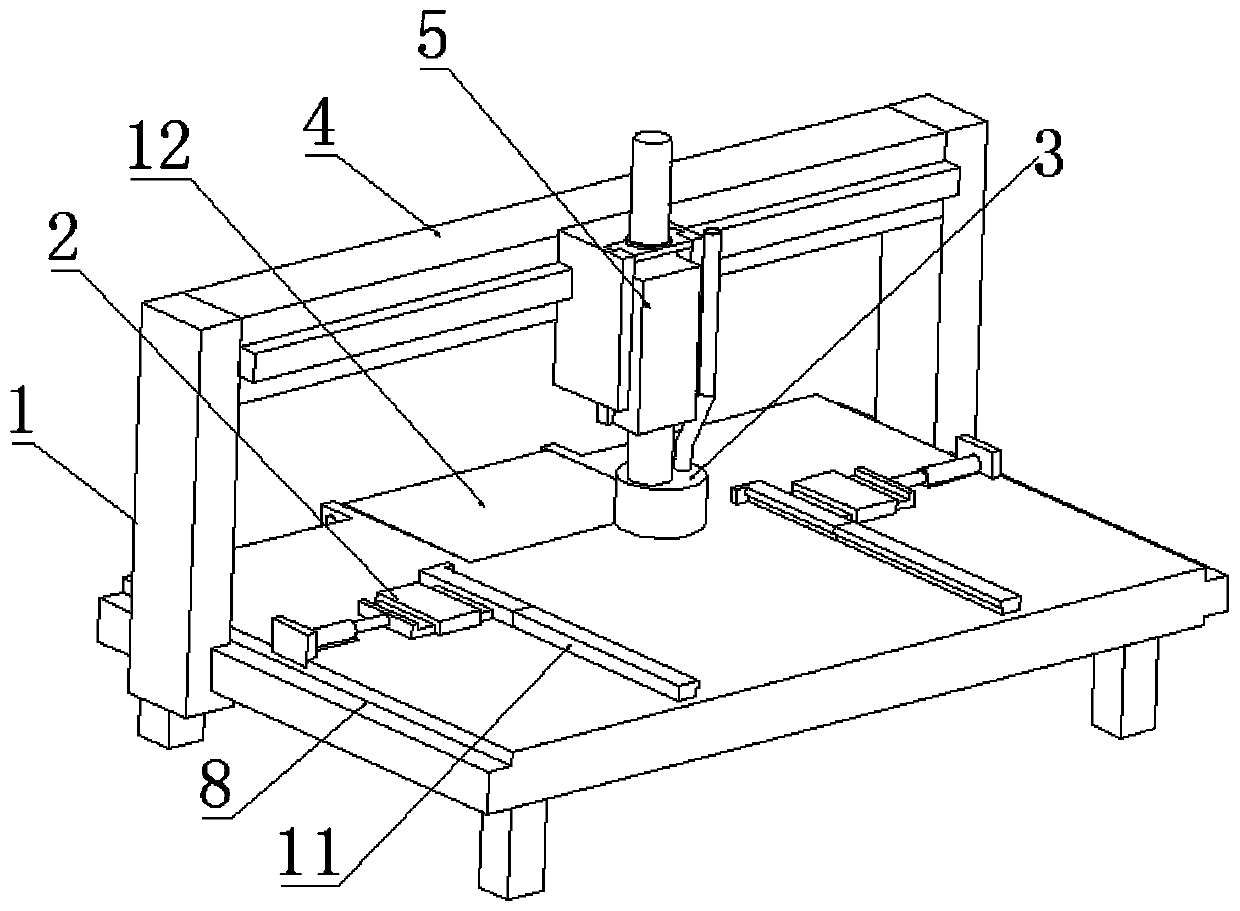

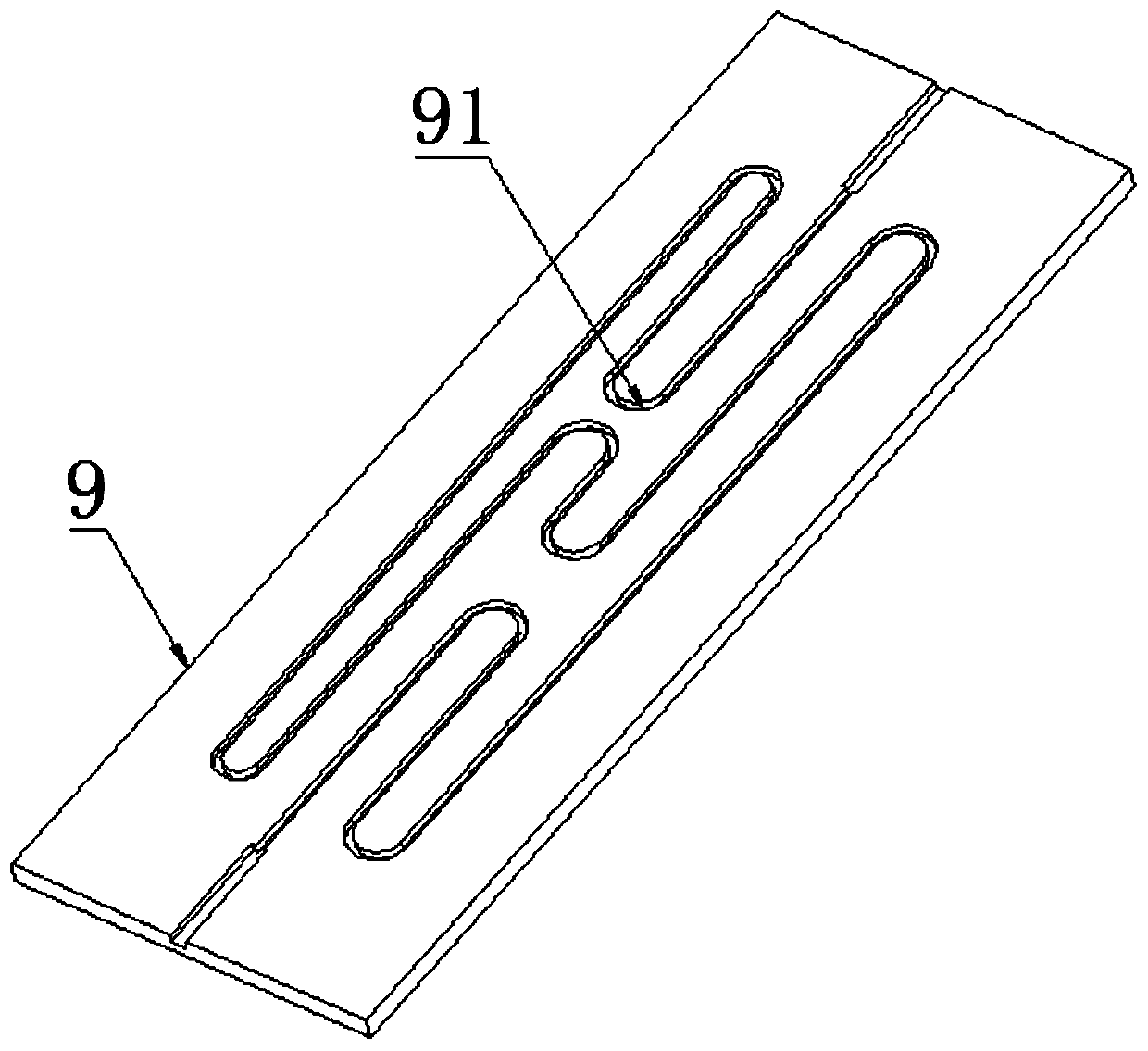

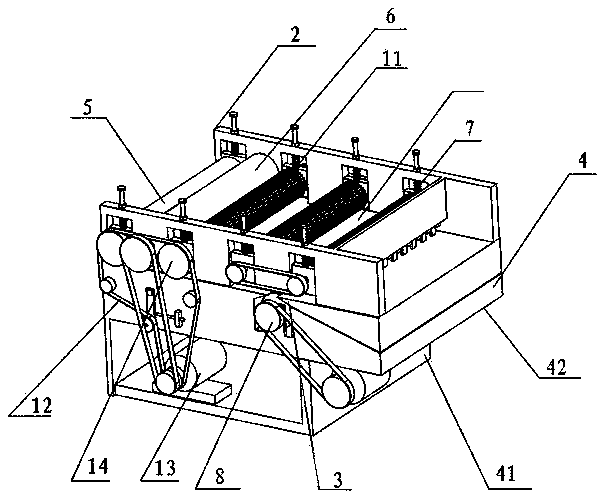

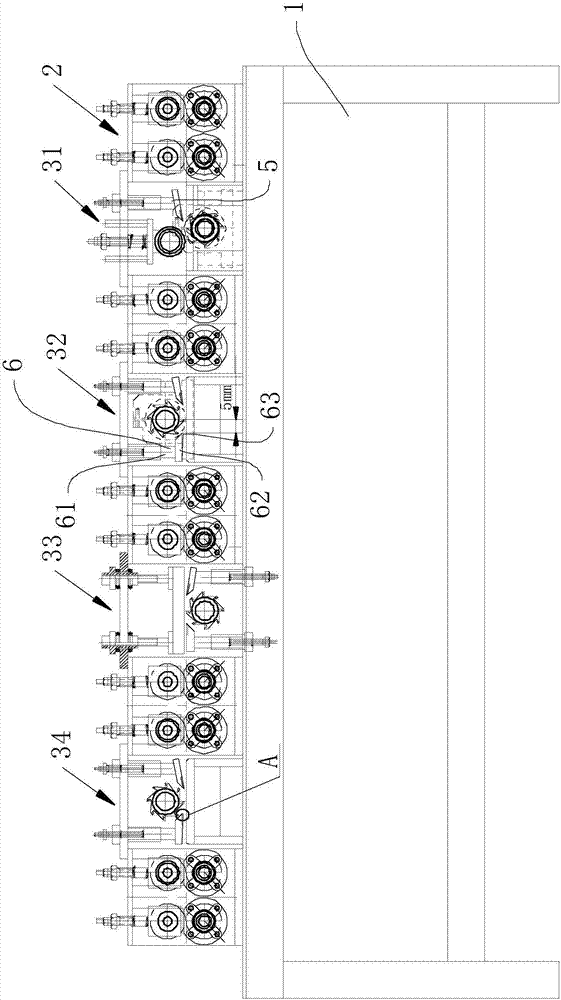

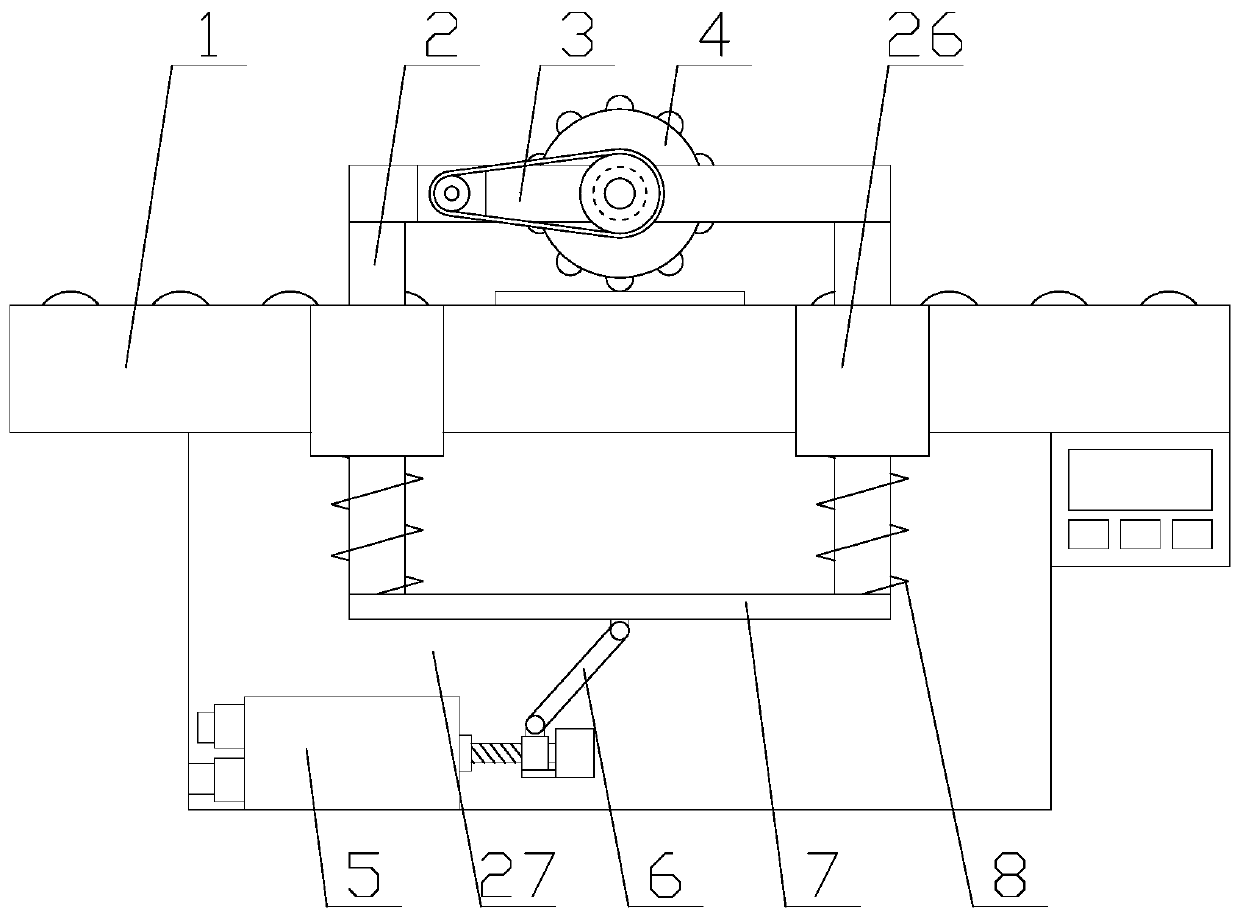

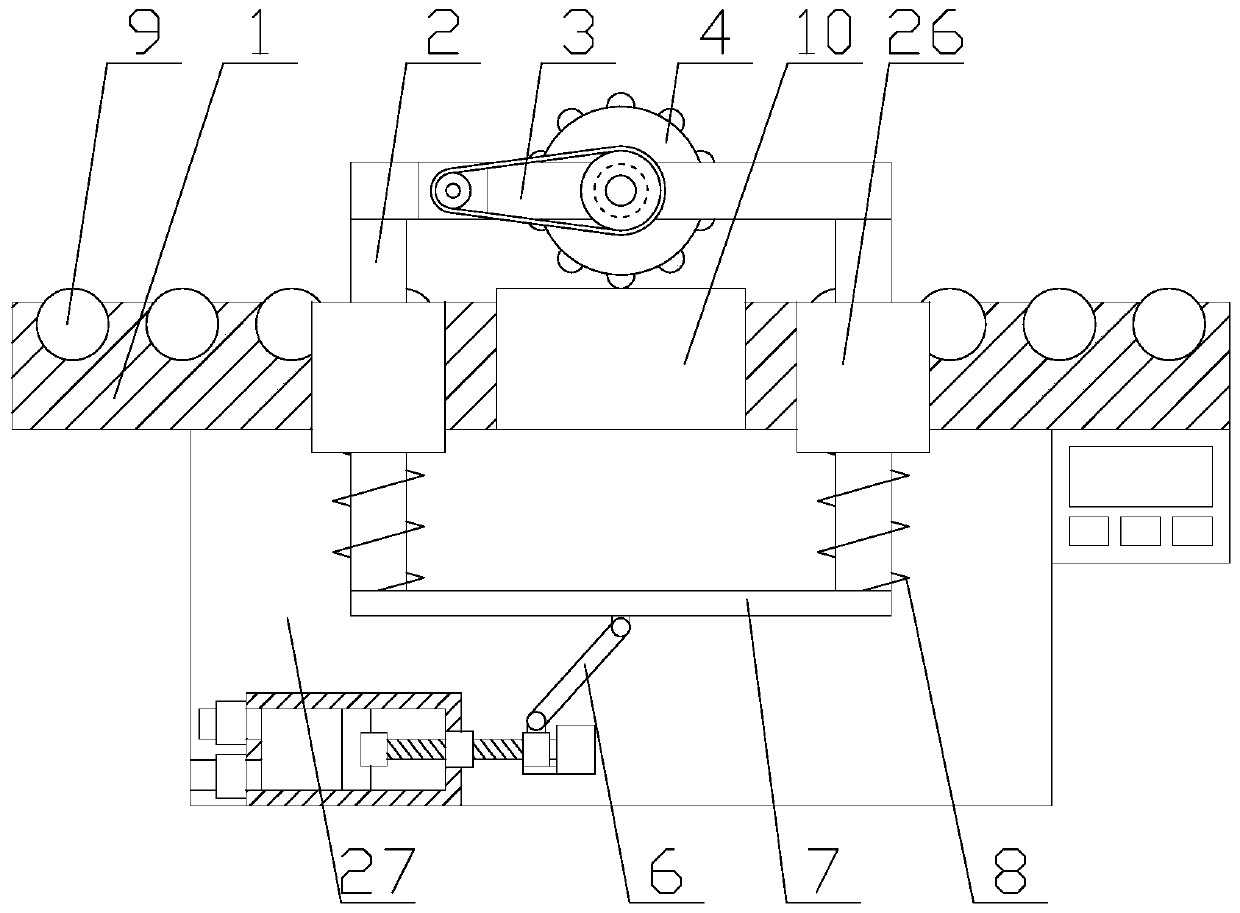

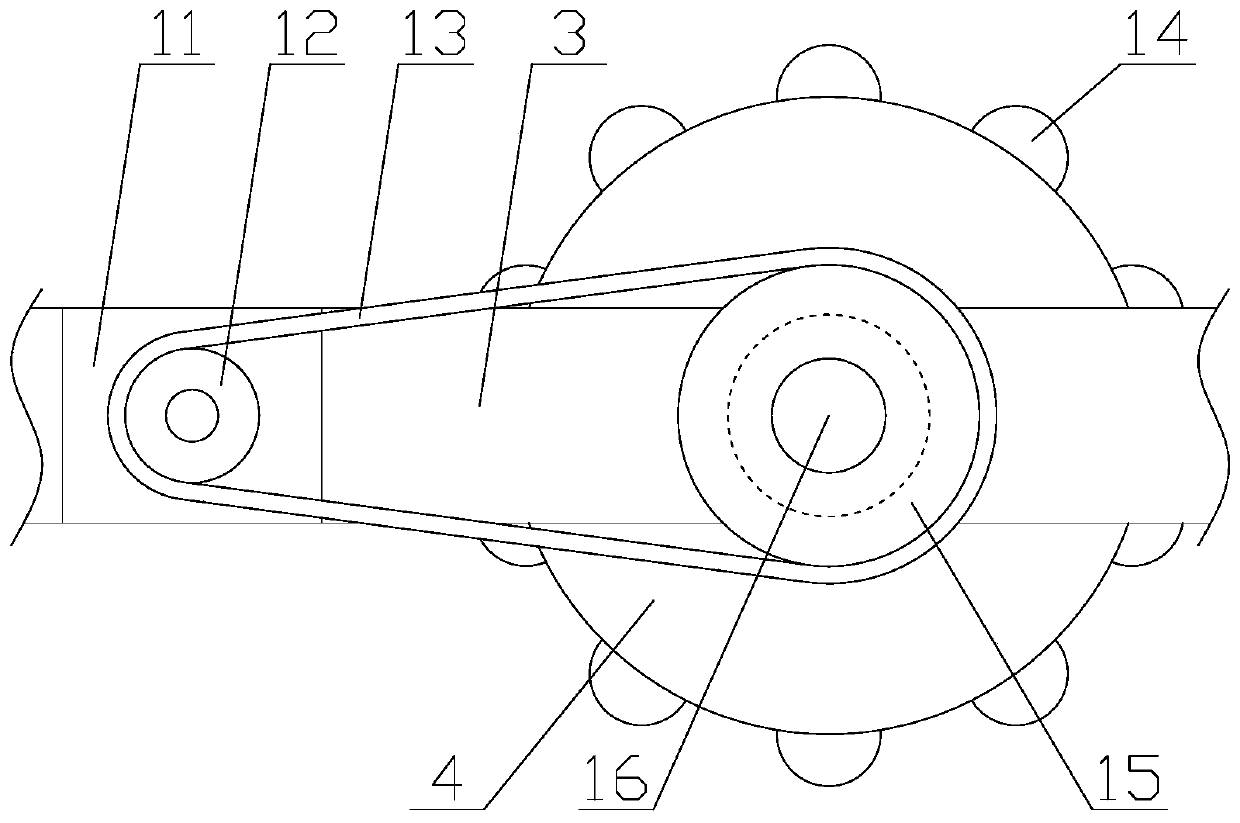

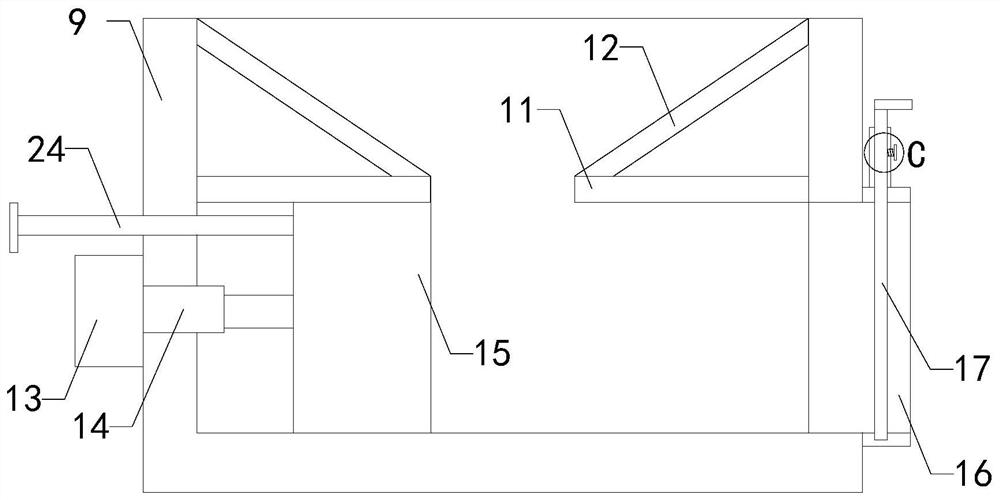

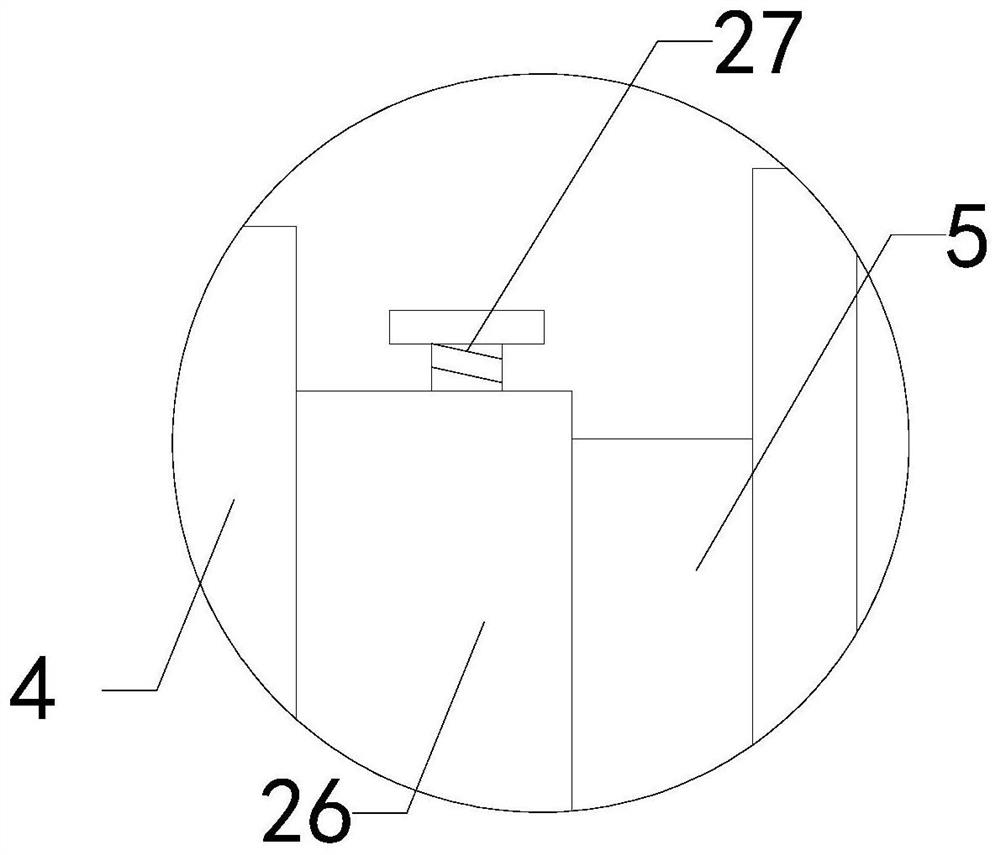

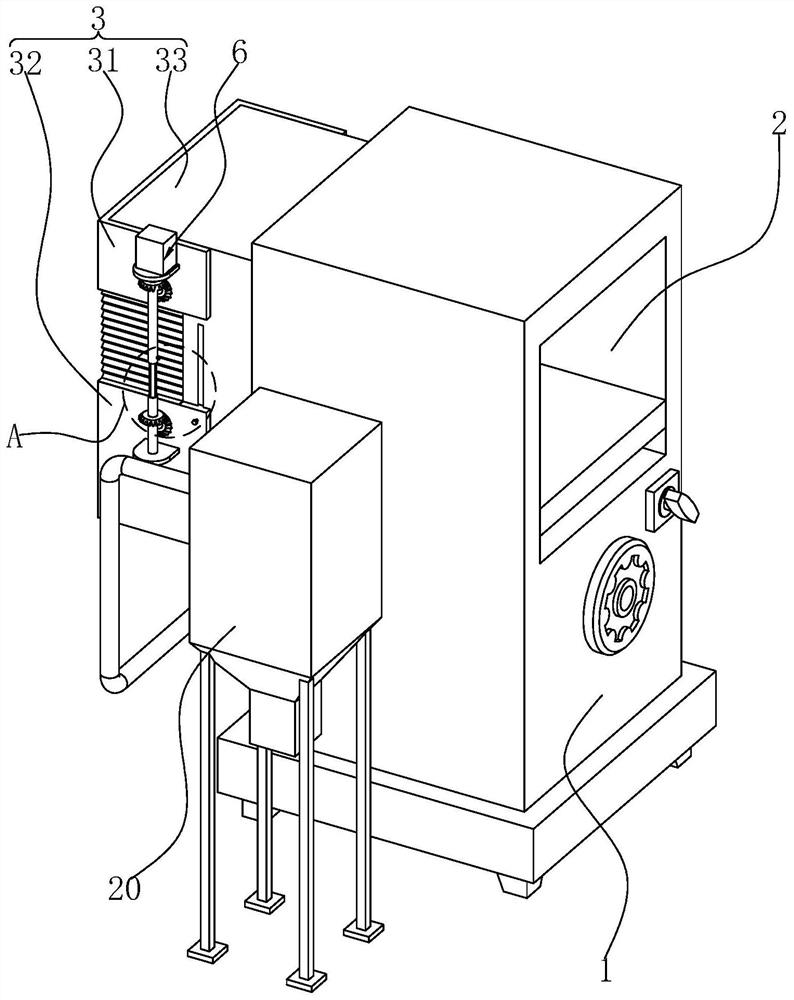

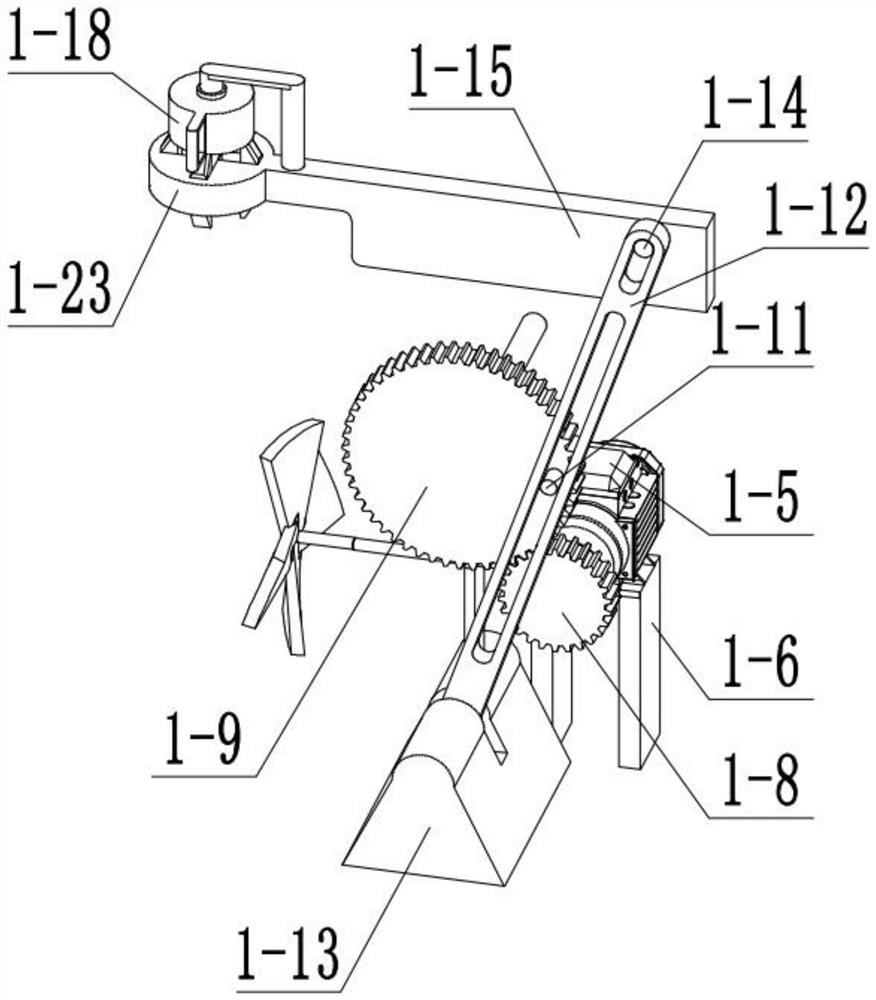

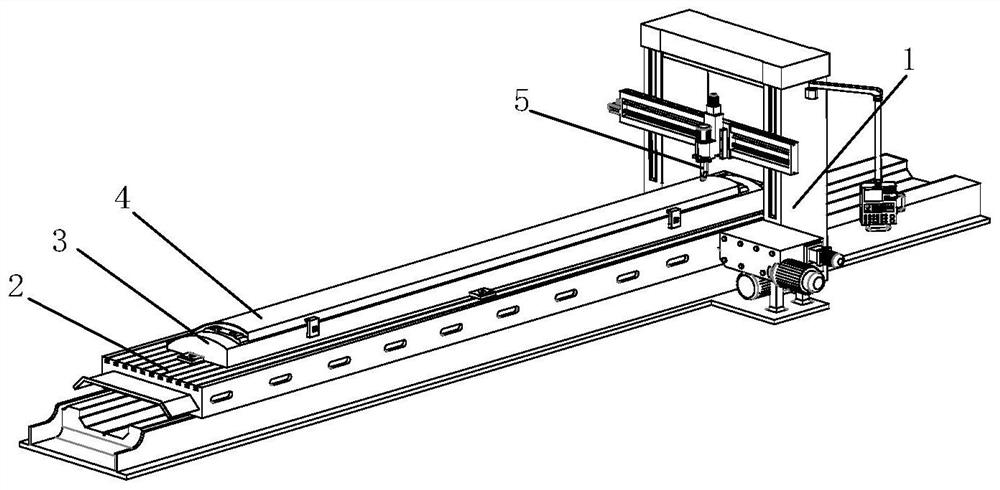

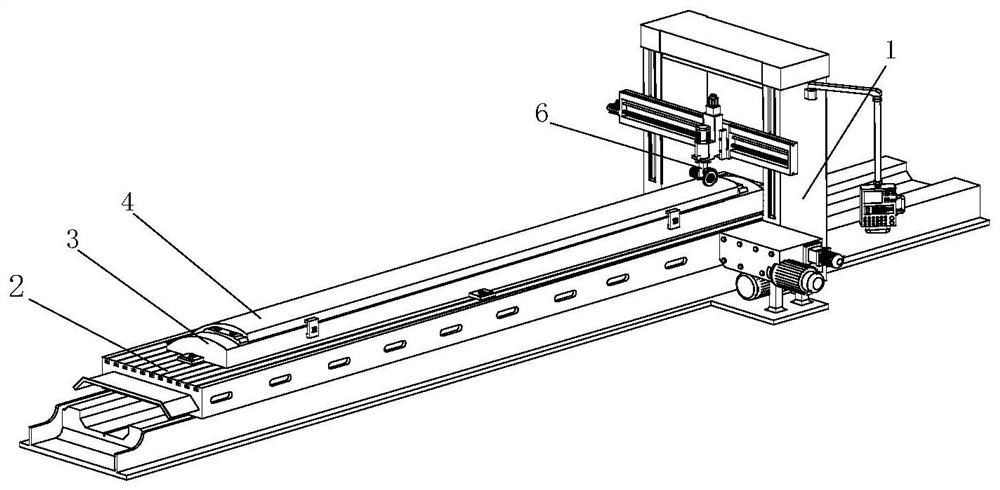

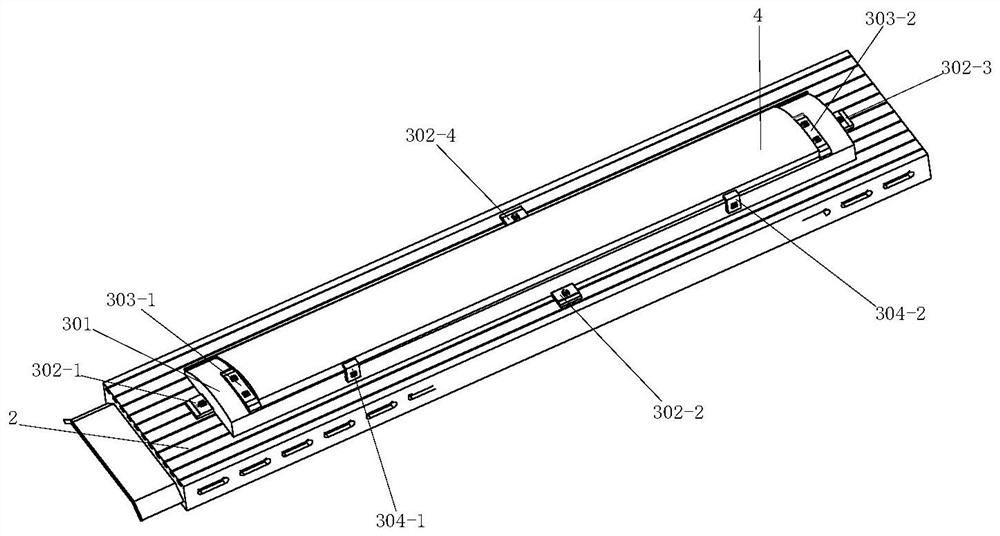

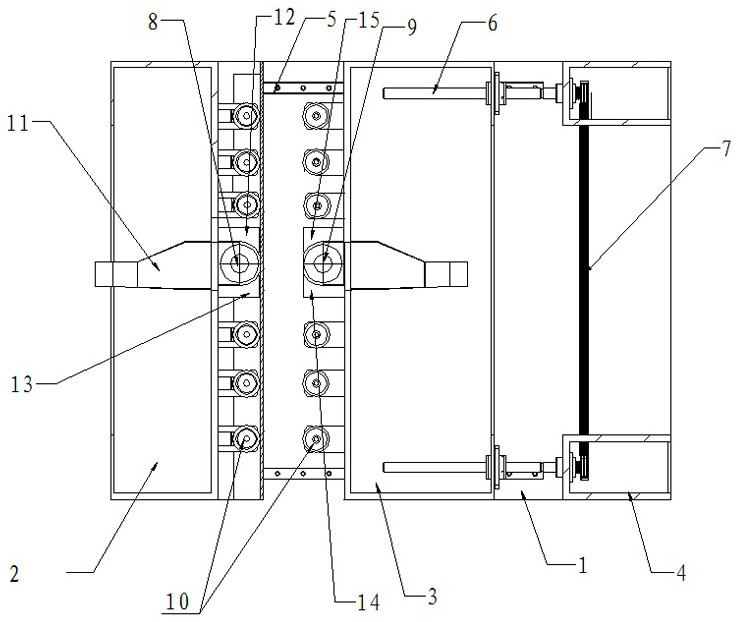

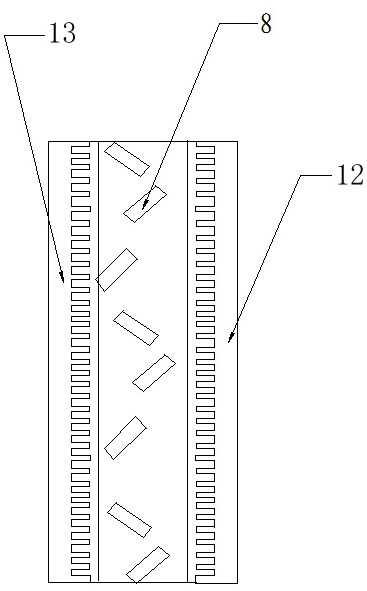

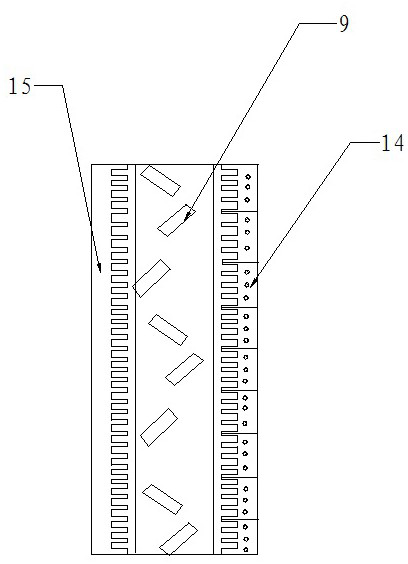

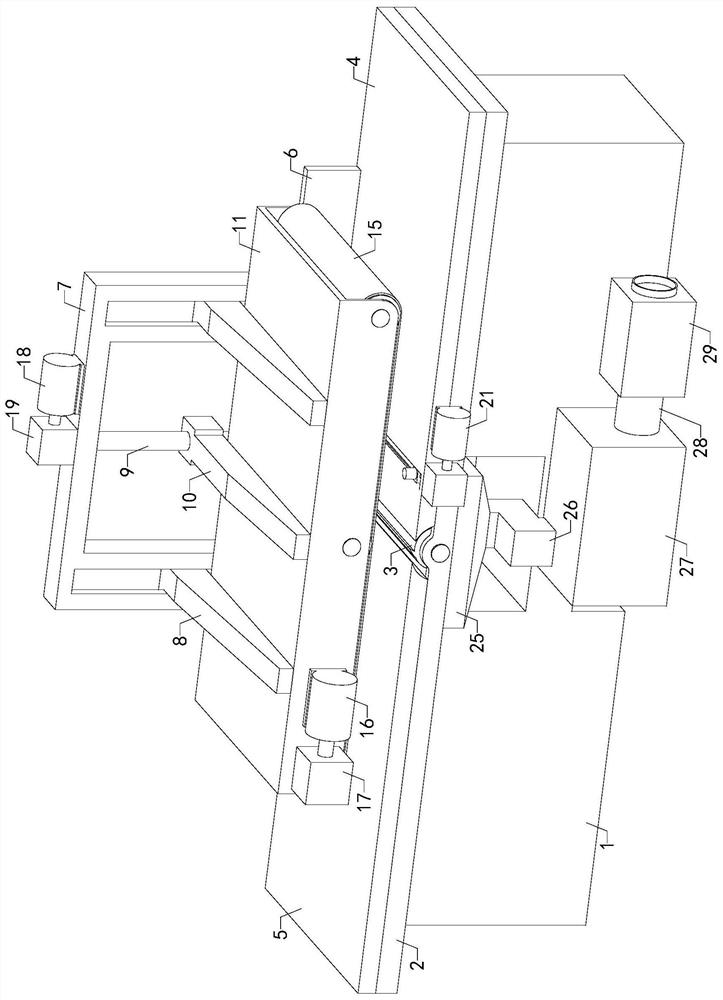

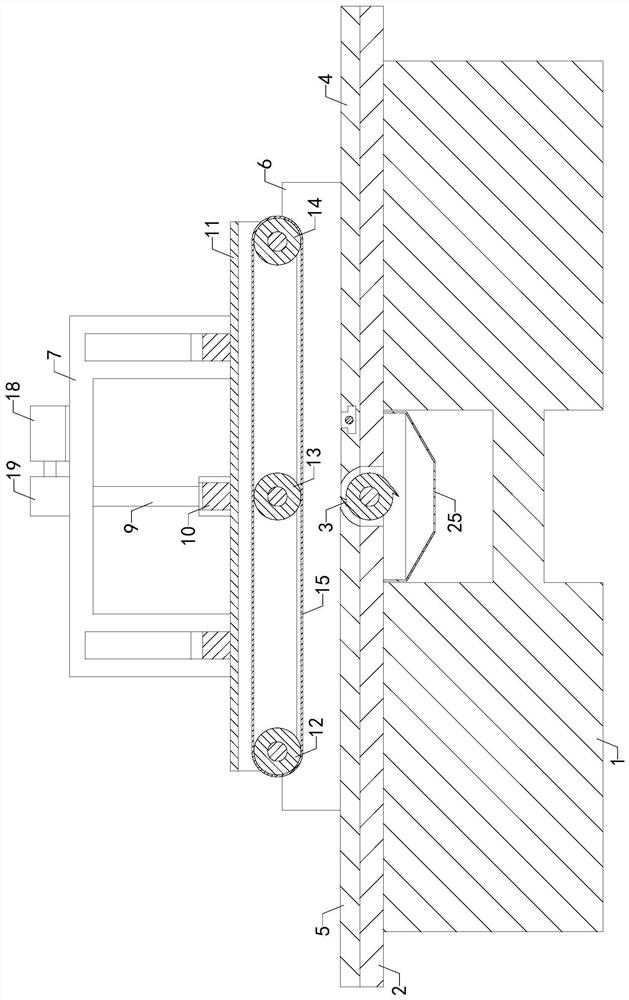

Heavy-cut double-faced woodworking thickness planer and processing method thereof

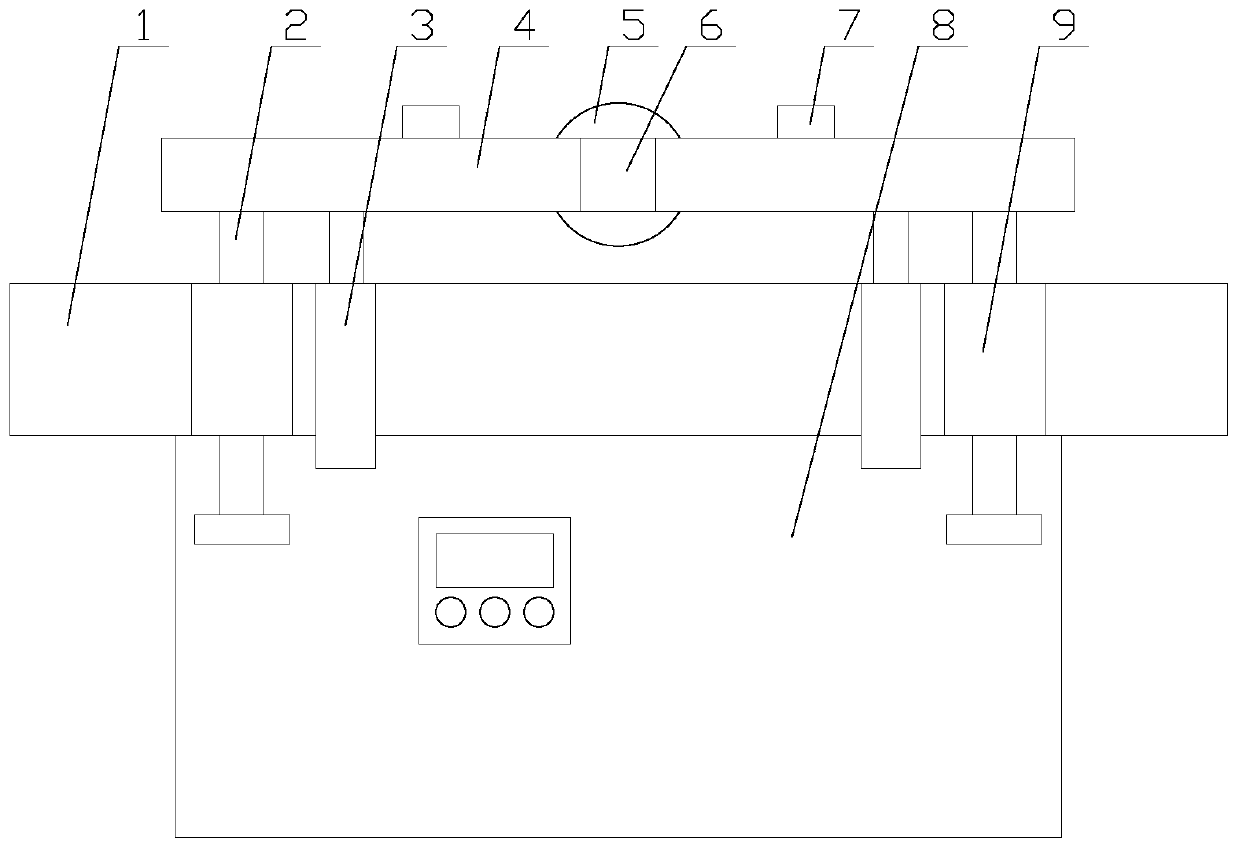

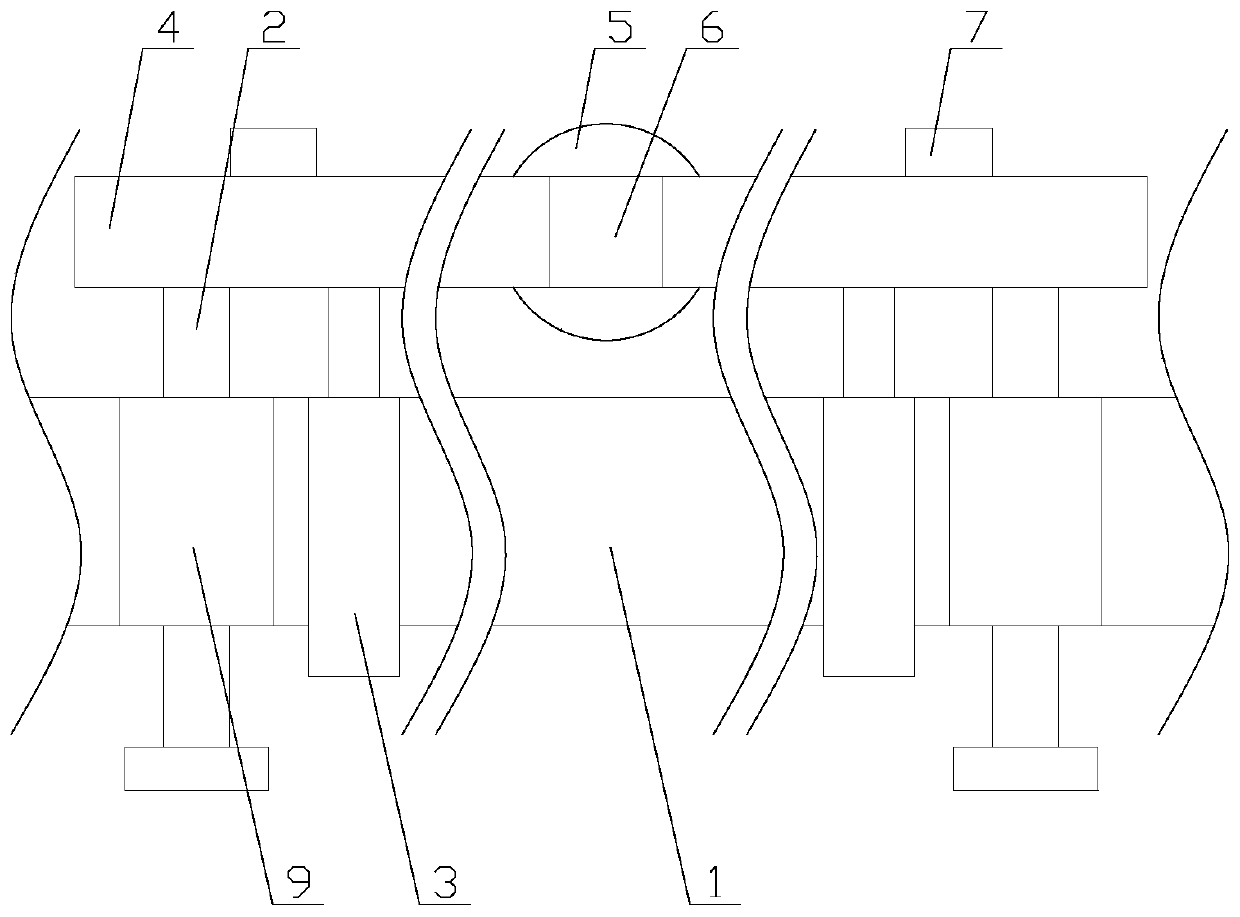

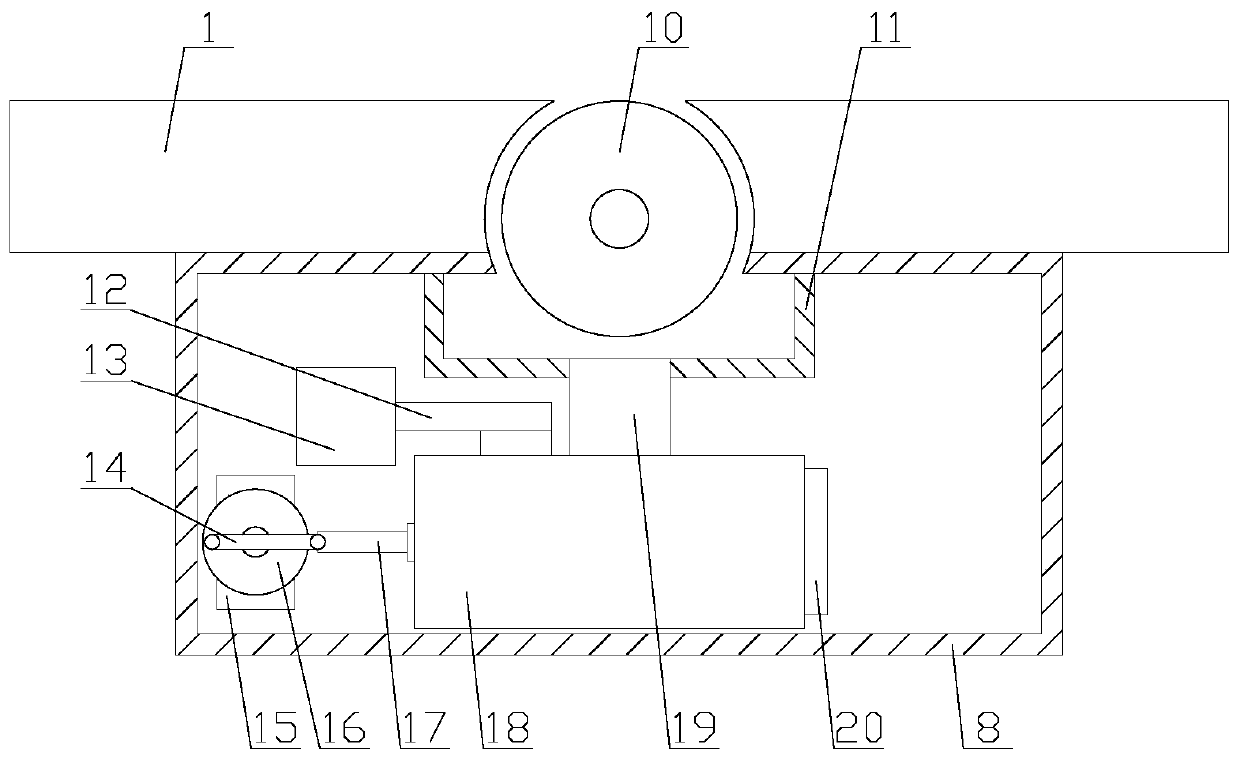

The invention discloses a heavy-cut double-faced woodworking thickness planer and a processing method thereof. The heavy-cut double-faced woodworking thickness planer structurally comprises a lathe bed assembly, a front worktable assembly, bed legs, a control box, a motor belt tensioning assembly, a lifting transmission assembly, a rear worktable assembly, a rear cover and planer assemblies, wherein the front worktable assembly and the rear worktable assembly are fixed on bed legs and are respectively provided with a front worktable carrier roller and a rear worktable carrier roller, and a pressing roller and a feeding roller assembly are arranged on the lathe bed assembly and are used for conveying timbers; one planer assembly is connected between the front worktable assembly and the rear worktable assembly, the other planer assembly is arranged on the lathe bed assembly, and the planer assemblies are respectively used for planing the upper and lower surfaces of the timbers; the lifting transmission assembly is used for controlling the height, relative to the bed legs, of the lathe bed assembly through the transmission of a lead screw so as to realize the thickness regulation of the planed timbers; and after the planer assemblies are drawn out and plane cutters are replaced, the planer assemblies can be put back, so that processing requirements of different timbers can be conveniently and rapidly met.

Owner:JINGHUA POWERFUL WOODWORKING MACHINERY

Bending forming process for V-shaped groove wood veneer

ActiveCN113103393AEasy to handleEasy to transportEdge grinding machinesWood treatment detailsWood veneerPulp and paper industry

The invention discloses a bending forming process for a V-shaped groove wood veneer, and relates to the technical field of basic processes. The method comprises the following steps that firstly, wood is processed, and processed wood is placed on a log cutting machine to be processed; secondly, wood slicing is conducted, specifically, the processed wood is placed on a slicing machine to be processed and sliced; thirdly, burr cleaning is conducted, specifically, the sliced wood is placed on a grinding machine to be processed and ground; fourthly, wood board cutting is conducted, specifically, the processed wood board is placed on a multi-functional wood planer, and the wood board is cut into sections and roughly planed through the multi-functional wood planer; and fifthly, polishing and grinding are conducted, specifically, the wood board obtained after section cutting is polished and ground, and the wood veneer is formed by the wood board. Through the arrangement of the log cutting machine, the unprocessed wood can be processed, and subsequent treatment of the device on the wood is facilitated.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

Wood floor processing technology

InactiveCN111113615AEasy and convenient milling operationImprove the efficiency of slot millingCombination devicesProfiling/shaping machinesStructural engineeringConveyor belt

The invention discloses a wooden floor processing technology. The wooden floor processing technology includes the following steps that S1, plate processing is carried out, specifically, aging treatment is carried out on purchased plates placed in a warehouse to achieve natural drying treatment of the plates so as the achieve anti-corrosion and mothproof effects; and S2, plate thickness is carriedout, specifically, the surfaces of the plates are planed by a planer to ensure the accurate thickness of the plates. According to the wooden floor processing technology, automatic feeding of wooden floors is realized by arranging a feeding mechanism, and clamping of the wooden floors pushed by the feeding mechanism is realized by arranging a clamping mechanism, manual clamping and fixing are not needed, the groove milling operation of the wooden floors is more easy and convenient, after the groove milling process is completed, the clamping mechanism releases the clamped wooden floors, and theprocessed wooden floors are pushed out by the feeding mechanism and are automatically discharged through a discharge conveyor belt, so that the efficiency of groove milling of the wooden floors is greatly improved.

Owner:湖州练市皇盛木业有限公司

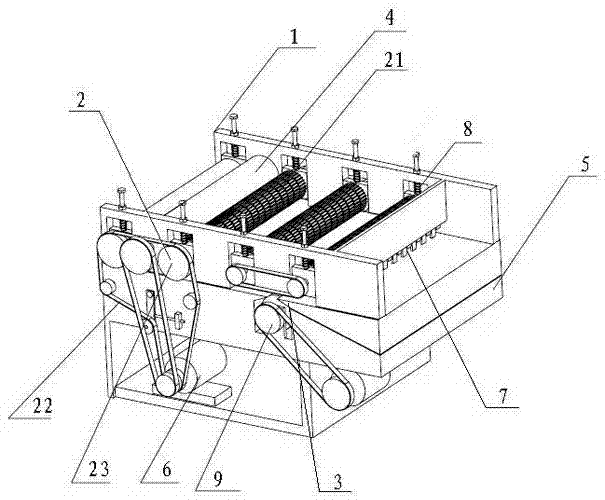

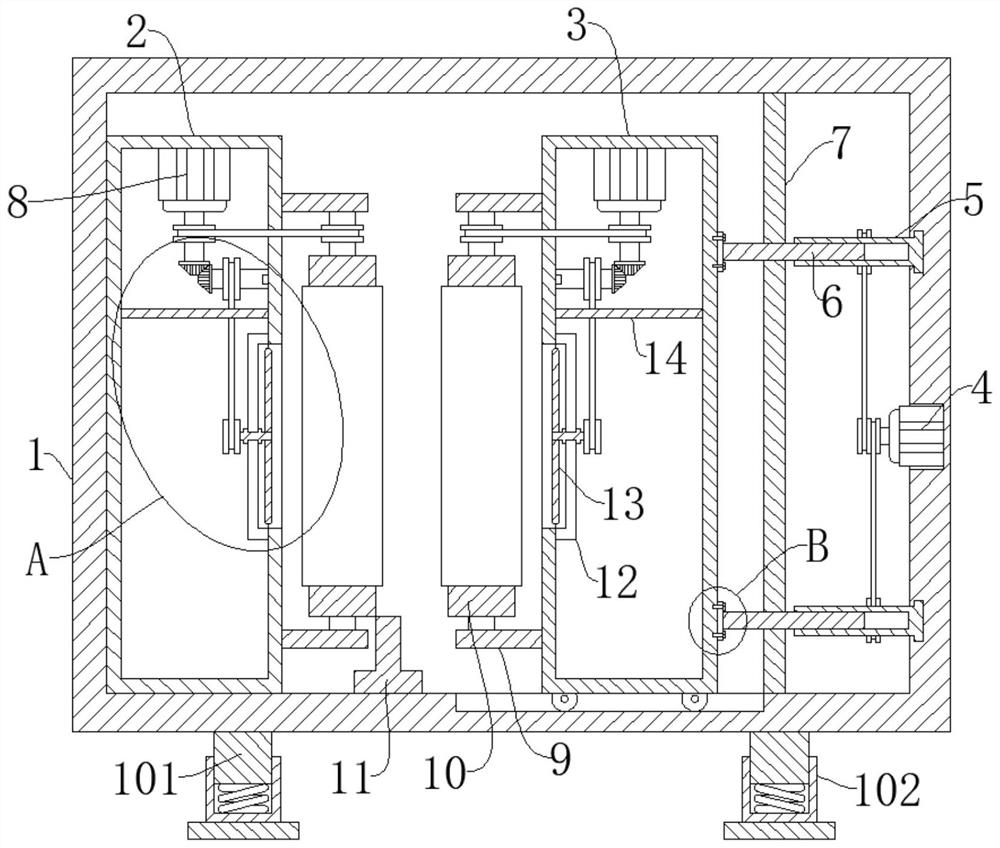

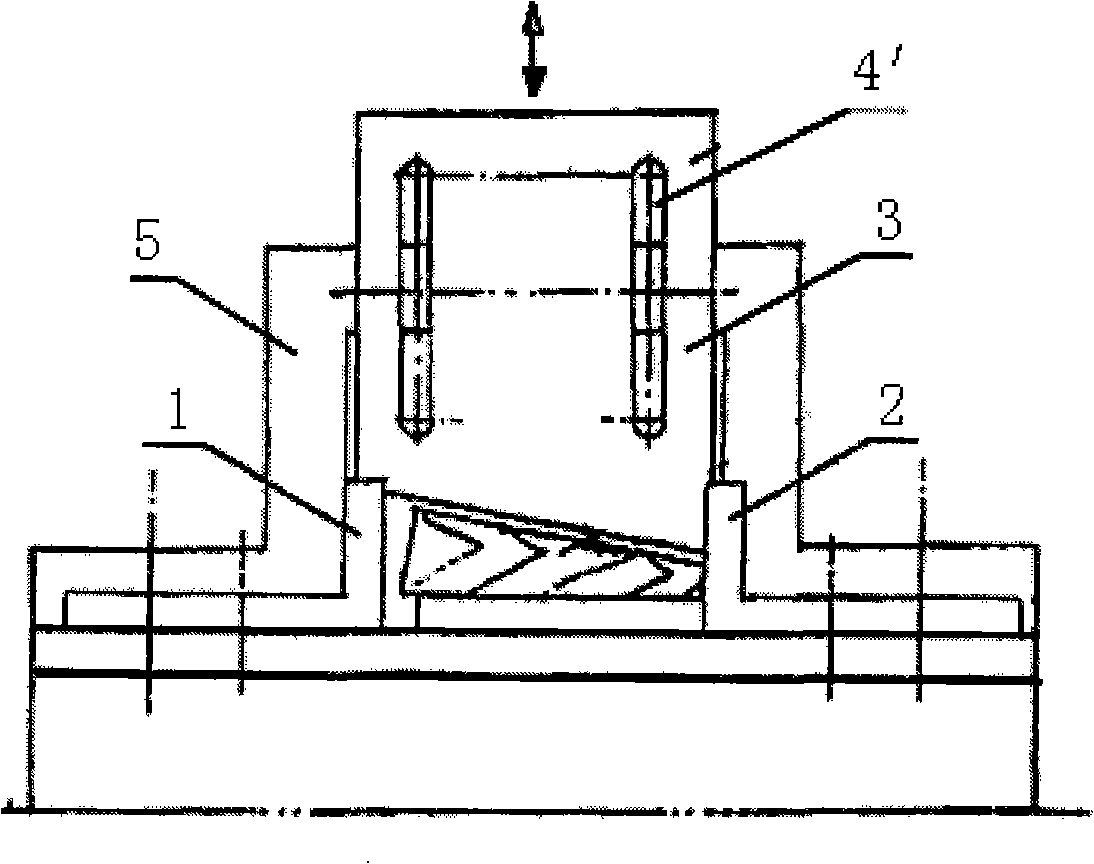

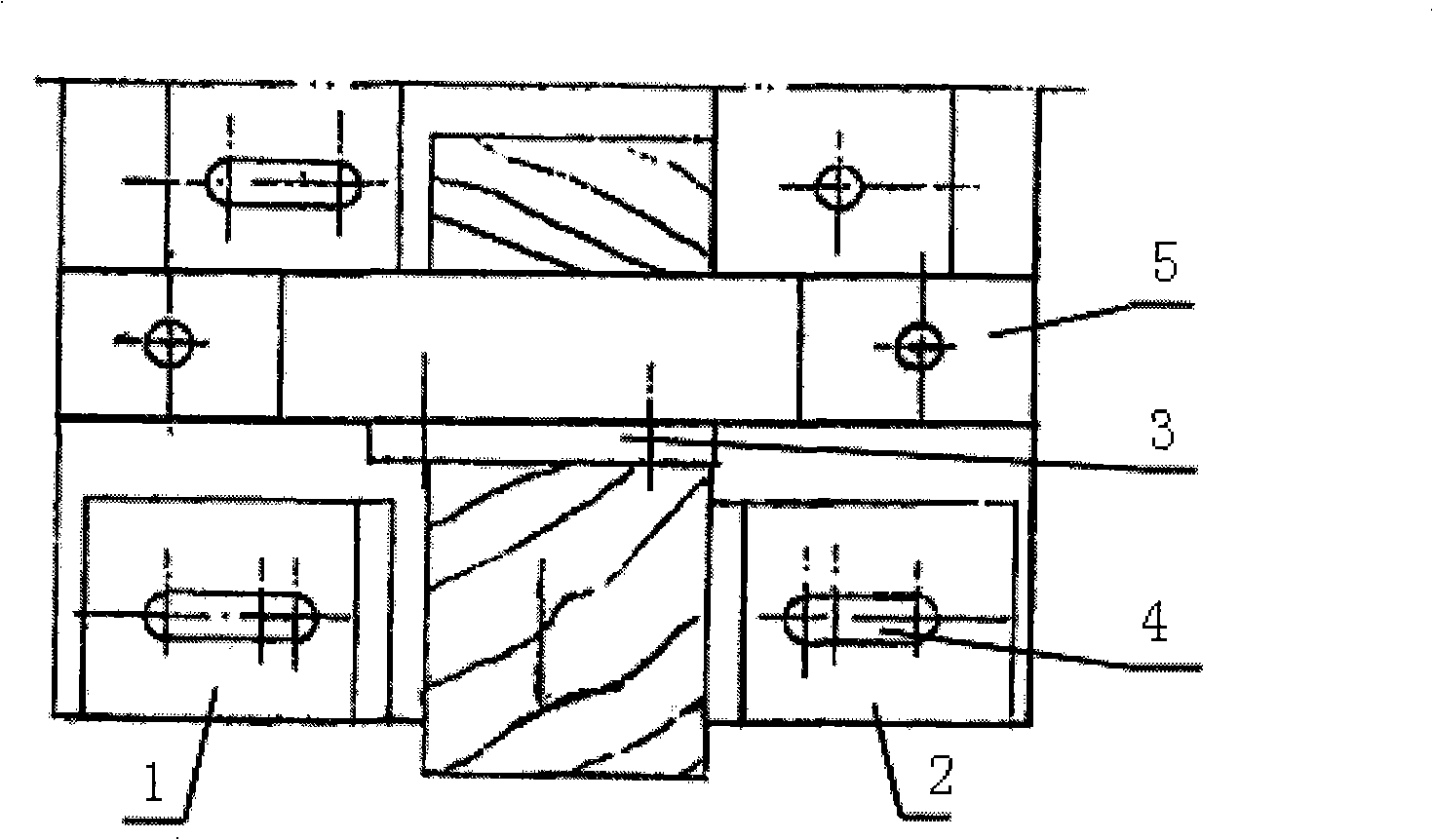

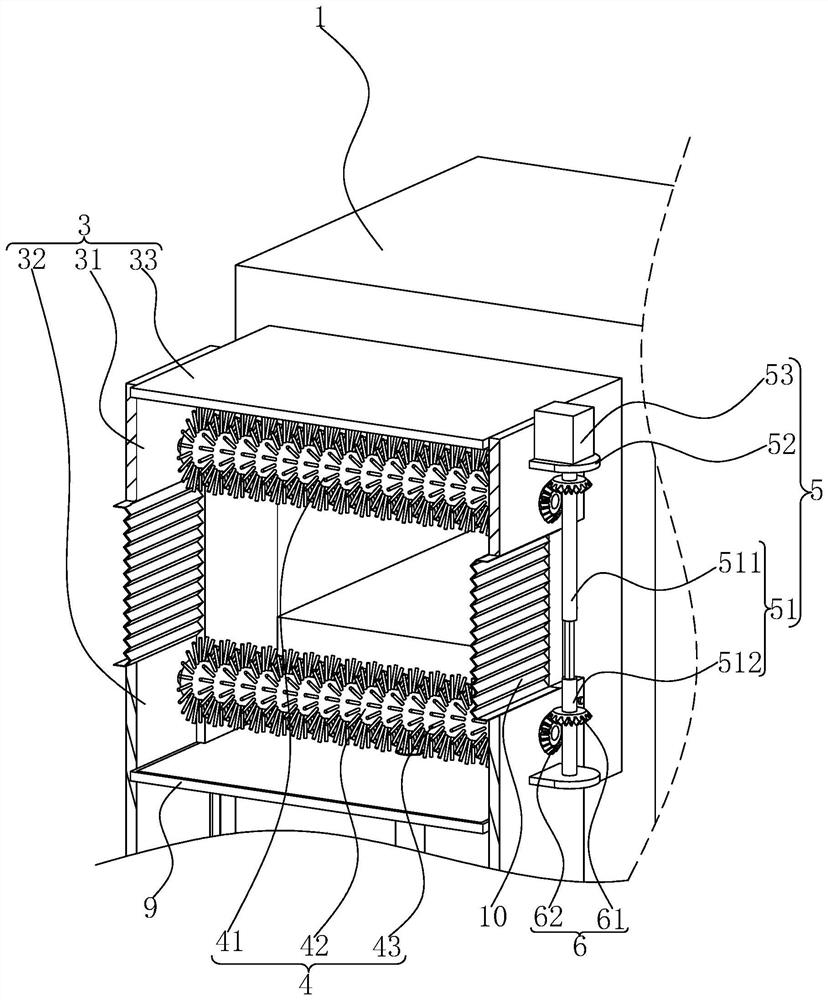

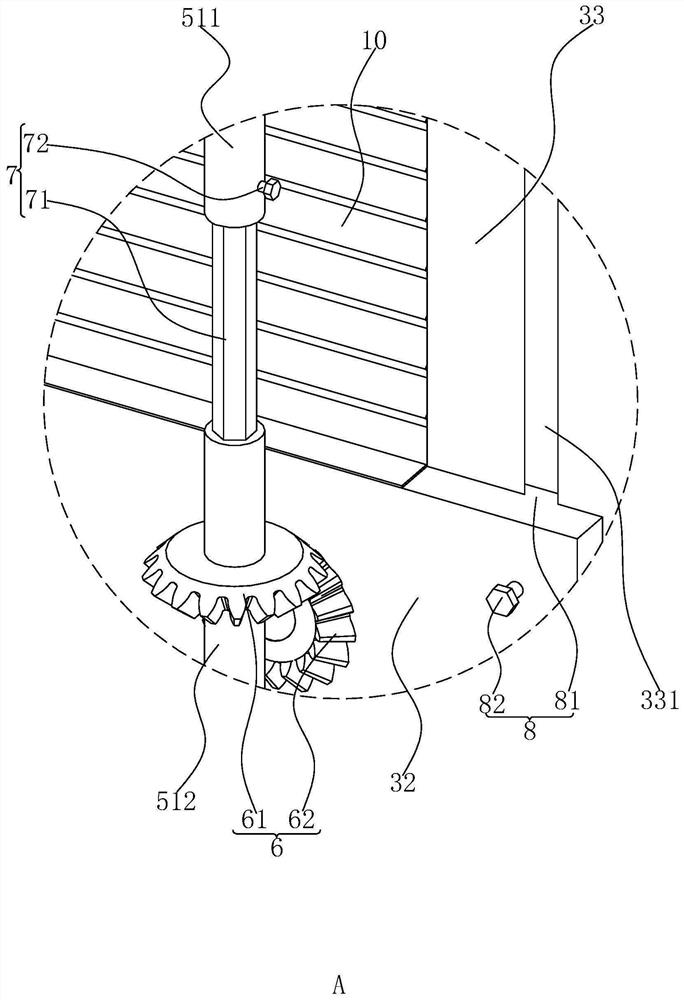

Wood planing machine with backstop

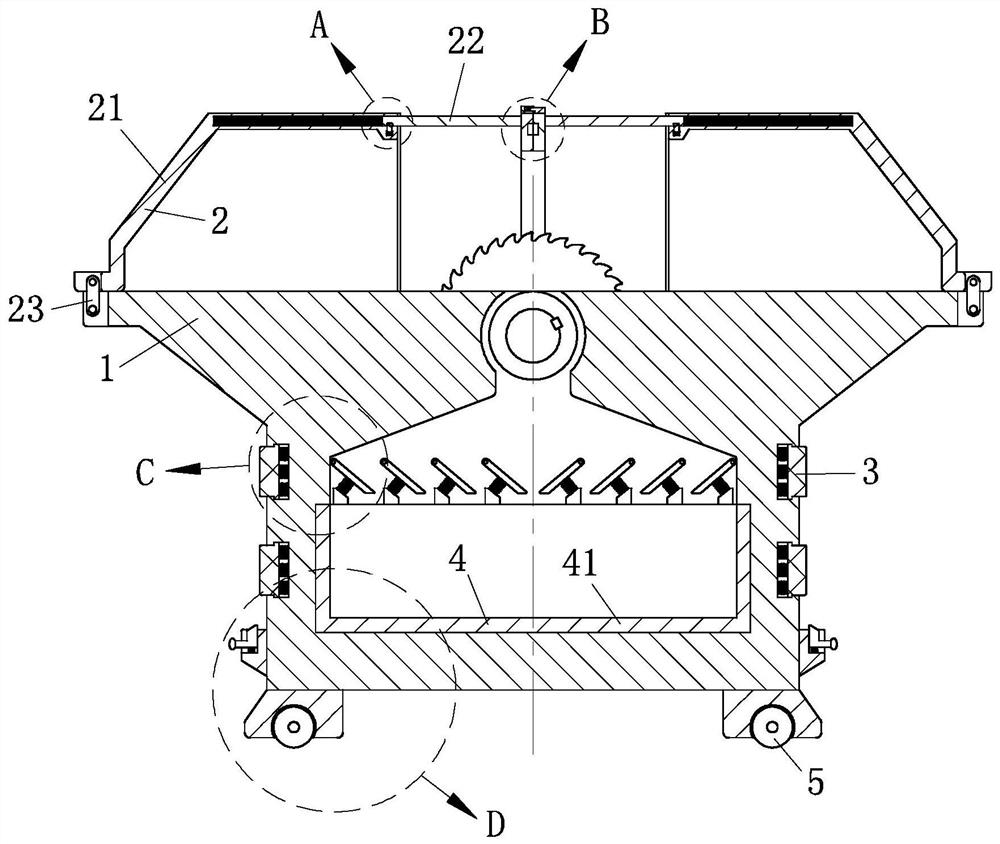

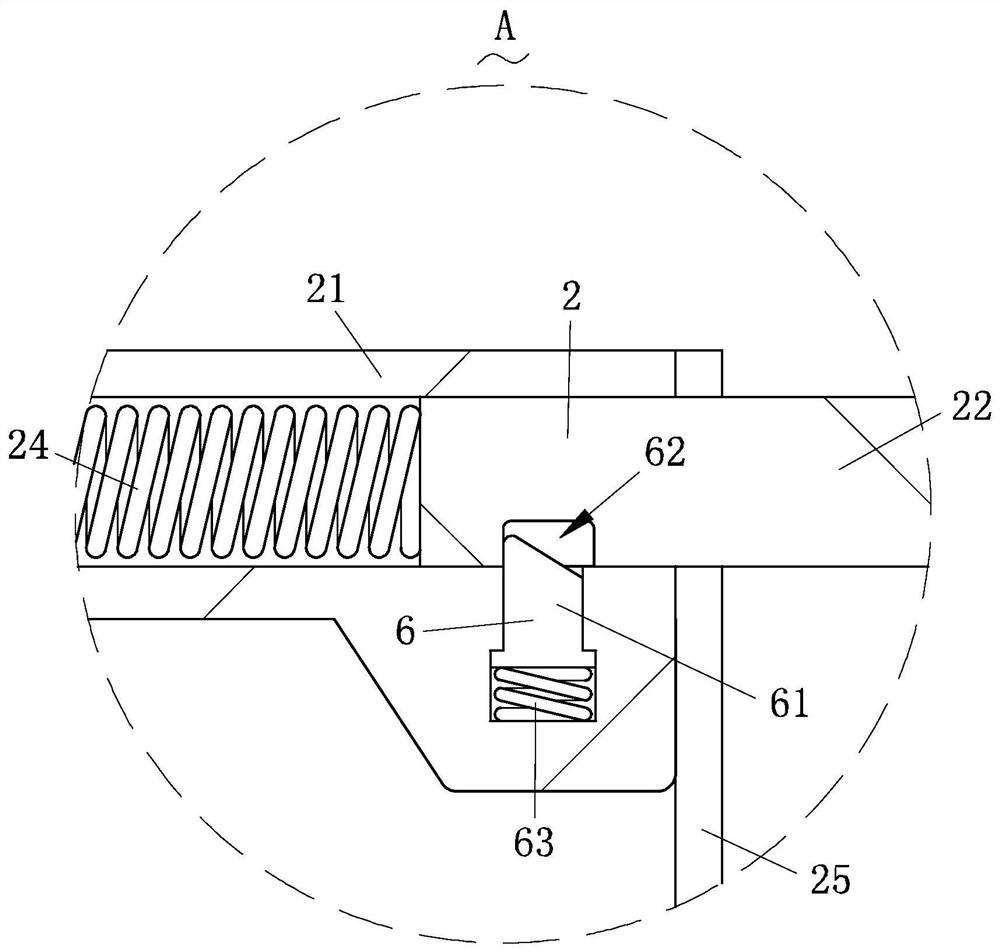

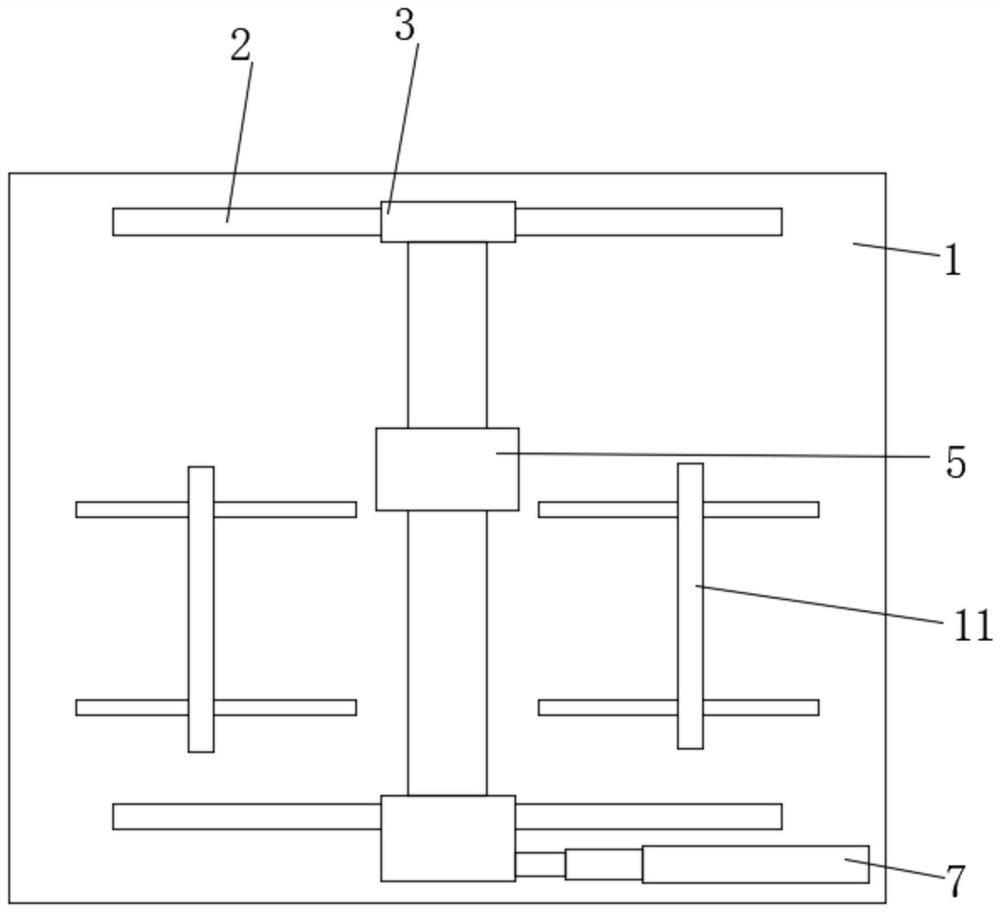

InactiveCN104260155AHigh degree of automationAdjust planing depth at willFlat surfacing machinesThickness planerWoodworking machinery

The invention discloses a planing machine, particularly relates to a double-faced wood planing machine with a backstop, and belongs to the technical field of wood-working machines. The double-faced wood planing machine comprises a rack, a conveying mechanism, a lower planing mechanism, an upper planing mechanism, a worktable and a driving mechanism, wherein the rack is arranged on the worktable and supports the conveying mechanism; the conveying mechanism is used for conveying a wood on the worktable; the upper planing mechanism and the lower planing mechanism are driven by the driving mechanism to plane the upper end and lower end of the wood; a plurality of non-returning sheets are arranged between the lower planing mechanism and the rack to form the backstop and a height difference is formed between the adjacent two non-returning sheets; and the worktable comprises a fixed platform and a movable platform. According to the double-faced wood planing machine with the backstop, the automation degree of machining the wood is improved and the planing depth of the wood can be adjusted randomly; the backstop can effectively prevent the potential safety hazard caused by the factor that the wood backs up; and meanwhile, the double-faced wood planing machine has double-faced planing capability and damages on a cutting surface of the planed wood, caused by secondary machining, are avoided, so that the production efficiency is improved and the energy consumption is reduced.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

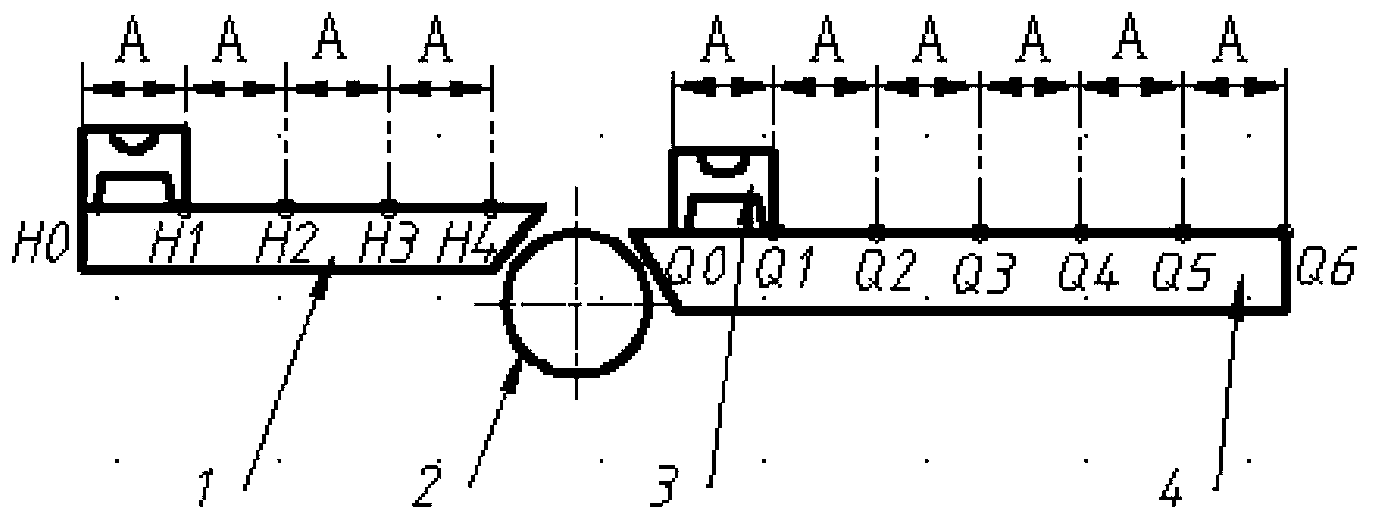

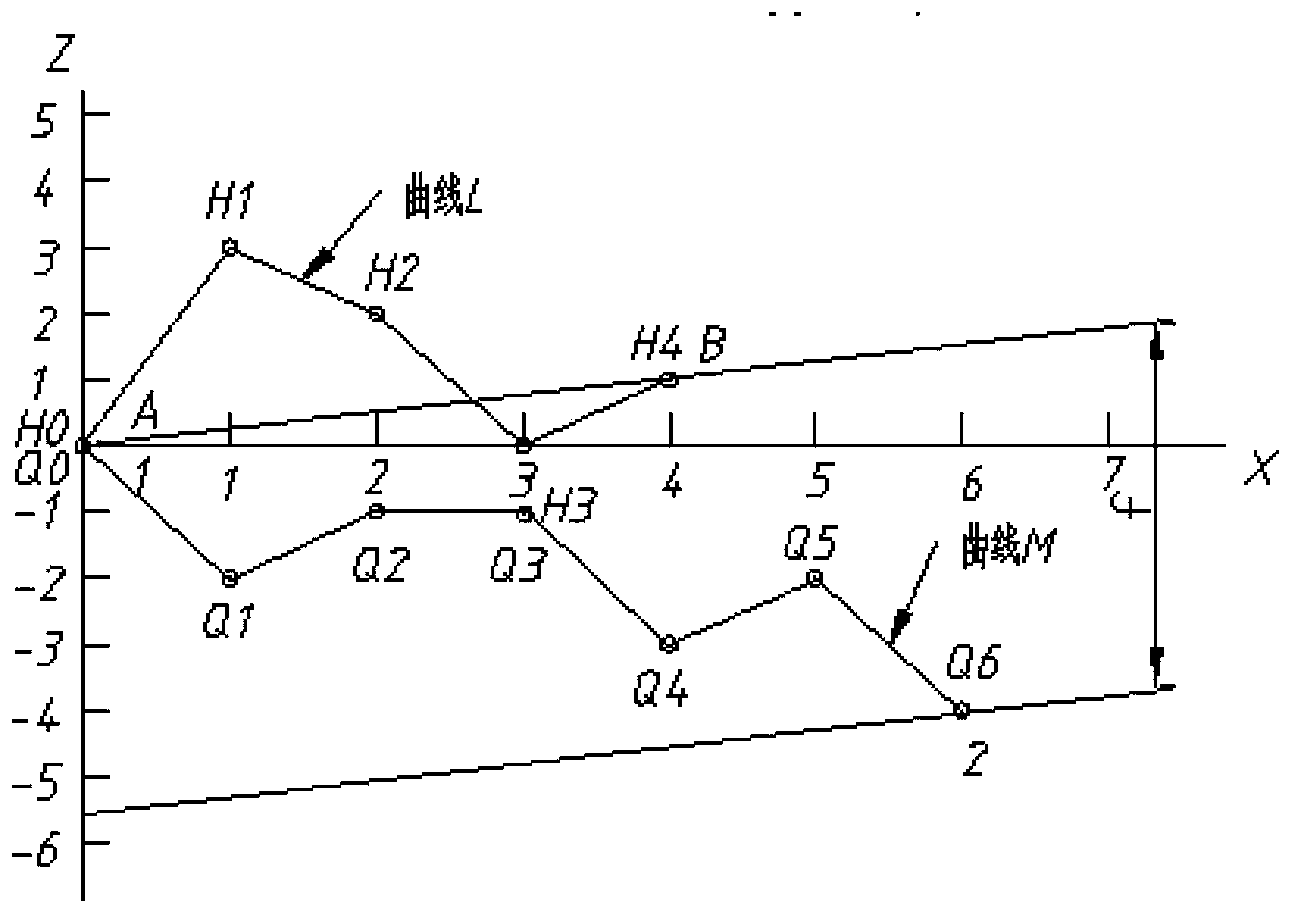

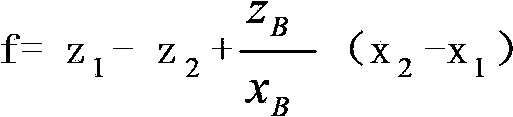

Method for measuring depth of parallelism of two planes

InactiveCN103673966AReduce measurement errorMeet the standardsMeasurement devicesThickness planerWorkbench

The invention discloses a method for measuring the depth of parallelism of two planes. The method is utilized to measure the longitudinal depth of parallelism of a front workbench and a rear workbench of a woodworking planning machine, and the method is accurate in measurement, high in accuracy, simple in operation, economical and applicative. The method is realized through the following technical scheme: the rear workbench of the woodworking planning machine is used as a datum plane, the front workbench is used as a measured plane, and the front workbench and the rear workbench are respectively divided into a plurality of measuring points with an equal interval A; indicating values are obtained by the measuring points of the rear workbench, the accumulated values of corresponding indicating values are calculated, an error curve L of the rear workbench is drawn, and the head point A and the tail point B of the error curve are connected to form a datum line AB; indicating values are obtained by the measuring points of the front workbench, the accumulated values of corresponding indicating values are calculated, and an error curve M of the front workbench is drawn; then the high vertex and the lower vertex of the curve M are respectively passed to form a parallel line parallel with the datum line AB, and the coordinate distance f in a z direction between the two parallel straight lines is the error value of the longitudinal depth of parallelism of the front workbench and the rear workbench conforming to the examination requirement.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

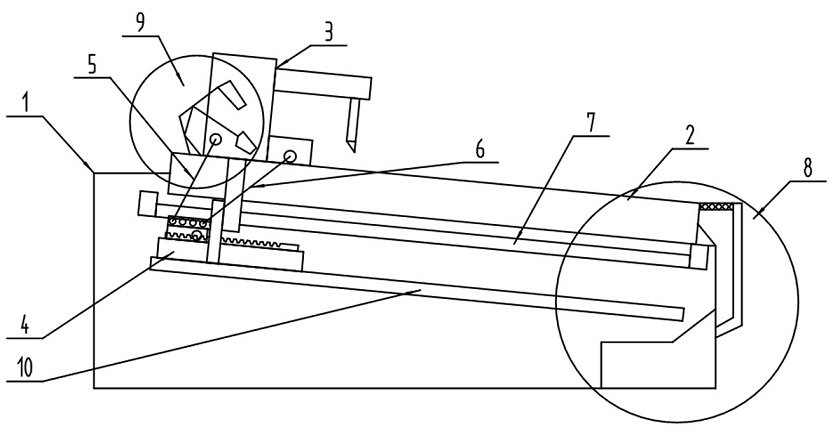

Planing machine

InactiveCN104209989AEasy to planHigh degree of automationWood feeding arangementsGear driveGear wheel

The invention discloses a planing machine, in particular a two-sided planing machine capable of planing upper and lower surfaces of a timber, and belongs to the technical field of wood-working machines. The planing machine comprises a conveying mechanism, a frame, a lower planing mechanism and a working table, wherein the frame is arranged on the working table, and supports the conveying mechanism; the conveying mechanism comprises a conveying roller, a conveying chain, a conveying motor and a conveying gear; the conveying motor rotates to drive the conveying chain and the conveying gear and to finally drive the conveying roller to rotate; a timber passing space is formed between the conveying roller and the working table; the lower planing mechanism is arranged on the working table; the working table comprises a fixed table and a movable table; the movable table vertically moves, and fits the conveying roller to clamp the timber; and an upper planing mechanism is additionally arranged on the frame. The planing machine can synchronously plane the upper and lower end surfaces of the timber to prevent secondary processing, so that the production efficiency is improved, and the energy consumption is reduced.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

Planer board

InactiveUS20080307692A1Easy and expeditious removalEasy to disassembleLinesEngineeringBuilding construction

Owner:HAGEN KEVIN H +1

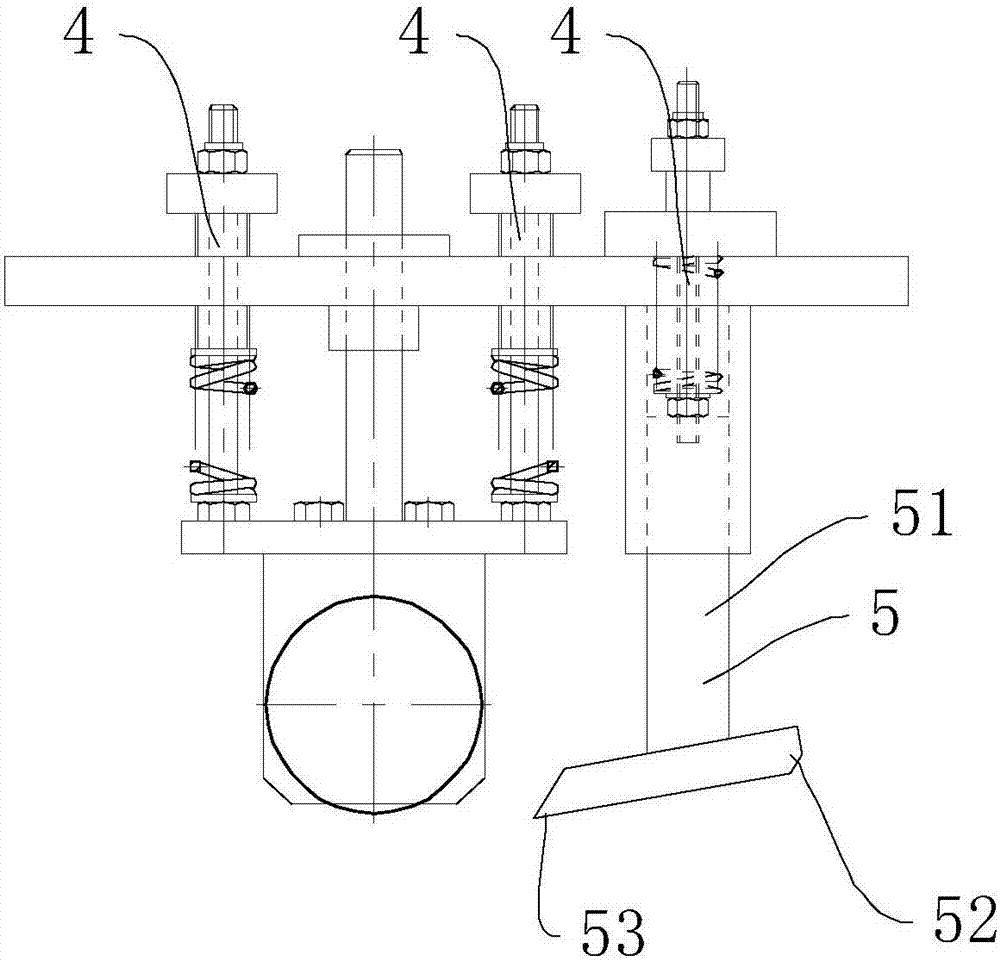

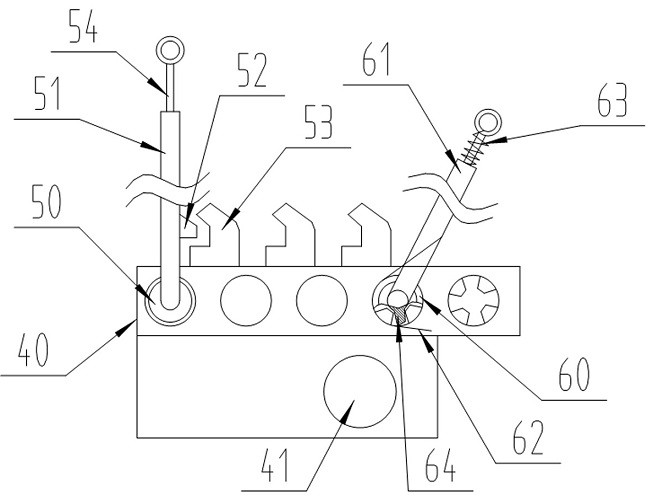

Double-side planer for machining bamboo flattened plate

PendingCN106926323APrevent disengagementImprove surface qualityThicknessing machinesStructural engineeringMechanical engineering

The invention discloses a double-side planer for machining a bamboo flattened plate. The double-side planer comprises a frame, a conveying mechanism and a planing mechanism; the planing mechanism comprises a worktable mounted on the frame, a planing tool, and a pressing piece driven by multiple elastic presses; the pressing piece is formed by transversely arranging multiple pressing units independent from each other; each pressing unit is independently acted on the bamboo flattened plate; the pressing piece comprises a feed end pressing piece and a discharge end pressing piece; in a feeding direction of the bamboo flattened plate, the pressing unit of the feed end pressing piece comprises a guide front end and a pressing back end; the guide front end is higher than the pressing back end; a bamboo flattened plate guide inclined port is formed between the guide front end and the worktable; and a pressing force applying point of the pressing back end is positioned near a planing tool cutting point. The force applying point of the pressing piece is nearer the planing tool cutting point, so that the feeding is smoother, the bamboo flattening plate is prevented from deviating from the planing tool cutting point due to warping, the planing quantity consistency is improved, and the surface quality of a flat plate is improved.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

Environment-friendly woodworking planer convenient to use

InactiveCN111267185AImprove convenienceImprove securityWood feeding arangementsBark-zones/chip/dust/waste removalDrive wheelDust control

The invention relates to an environment-friendly woodworking planer convenient to use. The environment-friendly woodworking planer convenient to use comprises a main body, a platform and a slicing device and further comprises a pushing mechanism and a dust removal mechanism, the pushing mechanism comprises a support, a driving shaft, a roller, a driving assembly, a lifting rod, two supporting rods, two supporting sleeves, two springs and at least two protruding strips, the dust removal mechanism comprises an exhaust cylinder, a lead screw, a ball screw bearing, a piston block, a transmission rod, an air extraction pipe, an exhaust pipe, a first one-way valve, a second one-way valve, a generator and two mounting bearings, and the driving assembly comprises a motor, a driving wheel, a drivenwheel and a transmission belt. The planer has the advantages that a plank can be pushed to move automatically through the pushing mechanism, convenience in use of the planer is improved, sawdust generated during production of the planer can be collected through the dust removal mechanism, and environmental friendliness of the planer is improved.

Owner:夏士桀

Thickness planer for forming solid wood lines

InactiveCN109093771AHeight adjustableImprove use comfort performanceThicknessing machinesSolid woodArchitectural engineering

The invention discloses a thickness planer for forming solid wood lines. The thickness planer comprises a worktable, a clamping unit and a working unit, wherein the lower surface of the worktable is fixedly connected with a bottom plate through two lifting devices; each lifting device comprises a threaded rod fixedly connected with the lower surface of the worktable, the rod wall of the threaded rod is movably sleeved with a sleeve, the lower end of the sleeve is fixedly connected with the upper surface of the bottom plate, the inner wall of the sleeve is rotationally connected with a threadedbarrel which is in threaded connection with the threaded rod, the lower end of the threaded barrel is fixedly connected with a driven bevel gear which is movably arranged on the rod wall of the threaded rod in a sleeving manner, a through hole is formed in the outer wall of the sleeve, and a rotating rod is rotationally connected in the through hole through a bearing. Height of the thickness planer can be adjusted according to the height of a user, use comfort is improved, automatic rotation of the rotating rod can be avoided, and stability of the lifting devices is improved.

Owner:柳州市品尚木业有限公司

Double-sided planer for vertical planing

InactiveCN112497351AImprove practicalityPrevent fallingWood feeding arangementsBark-zones/chip/dust/waste removalEngineeringStructural engineering

The invention discloses a double-sided planer for vertical planing, and belongs to the technical field of double-sided planers. The double-sided planer for vertical planing comprises a fixed frame, afixed box and a movable box, wherein the upper ends and the lower ends of the inner sides of the fixed box and the movable box are fixedly connected with a plurality of groups of matched supporting blocks, a conveying roller is rotationally connected between every two supporting blocks, a plurality of planing tools are fixedly connected to the surface of the middle conveying roller, and a cleaningbrush is fixedly connected between every two planing tools. According to the double-sided planer, a collecting mechanism is arranged, so that impurities such as wood chips can be prevented from drifting around and falling into a planer body, the cleaning difficulty of workers is increased, and meanwhile, the body health of the workers can be prevented from being influenced by chippings; and the cleaning brushes are arranged, so that the surface of a planed plate can be cleaned, the problem that the wood chips are conveyed backwards along with the plate, the wood chips are extruded by the conveying rollers, so that indentations are generated on the surface of the plate, and the flatness of the plate surface is influenced can be solved, and the practicability of the planer during use is effectively improved.

Owner:肖轩杰

Wood planer with high processing accuracy and wood dust recycling function

InactiveCN110757589AImprove securityImprove environmental performanceWood feeding arangementsBark-zones/chip/dust/waste removalWOOD TREATERSElectric machine

The invention relates to a wood planer with high processing accuracy and a wood dust recycling function. The wood planer with the high processing accuracy and the wood dust recycling function comprises an operation table, a planer tool and a base, and further comprises a positioning mechanism and a cleaning mechanism, wherein the positioning mechanism comprises a lifting rod, a positioning roller,a first motor, a distance sensor, two air cylinders and two fixed components; the cleaning mechanism comprises a dust suction hood, a collection box, a conveying pipe, a driving component, a second transmission rod, a supporting casting pipe, an extrusion plate, cleaning bars, an exhaust pump, an exhaust pipe and a filter screen; each fixed component comprises a fixed casing pipe and a fixed rod;and the driving component comprises a second motor, a rotary table, and a first transmission rod. According to the wood planer with the high processing accuracy and the wood dust recycling function,the positioning mechanism can be used for controlling the speed of wood movement and the pressure on wood, so that the precision of processing the wood by the planer is improved; and the cleaning mechanism can be used for collecting wood dust generated when the planer works, and thus, the environmental protection performance of the planer is improved.

Owner:何桂华

Big core board planer

InactiveCN112548184AEasy to operateEasy to reusePlaning/slotting machinesPositioning apparatusStructural engineeringMachining process

The invention relates to the technical field of board machining equipment, in particular to a big core board planer. According to the planer, a board is placed on a base and then is clamped and fixedby a clamping plate, chippings generated in the machining process directly fall into a collecting box through a collecting cover, an air cylinder is started to push a pressing plate to compress the chippings after the quantity of the chippings in the collecting box reaches a certain quantity, and finally the chippings are discharged from a discharging pipe. The whole operation is simple, and the chippings are effectively collected to facilitate subsequent reutilization. When the planer needs to be moved, second screw pipes are rotated to enable universal wheels to make contact with the groundand support bottom columns to be away from the ground, then the device is pushed to move, and the practicability is high. The planer comprises the base and the bottom columns which are fixedly arranged at the bottom of the base; and the planer further comprises a left plate, a right plate, a first screw pipe, a first screw rod, the clamping plate, a bottom plate, the collecting box, the collectingcover, transverse plates, inclined plates, the air cylinder, a telescopic rod, the pressing plate, the discharging pipe, an insertion plate, the second screw pipes, second screw rods, mounting platesand the universal wheels.

Owner:山东舒尔家具有限公司

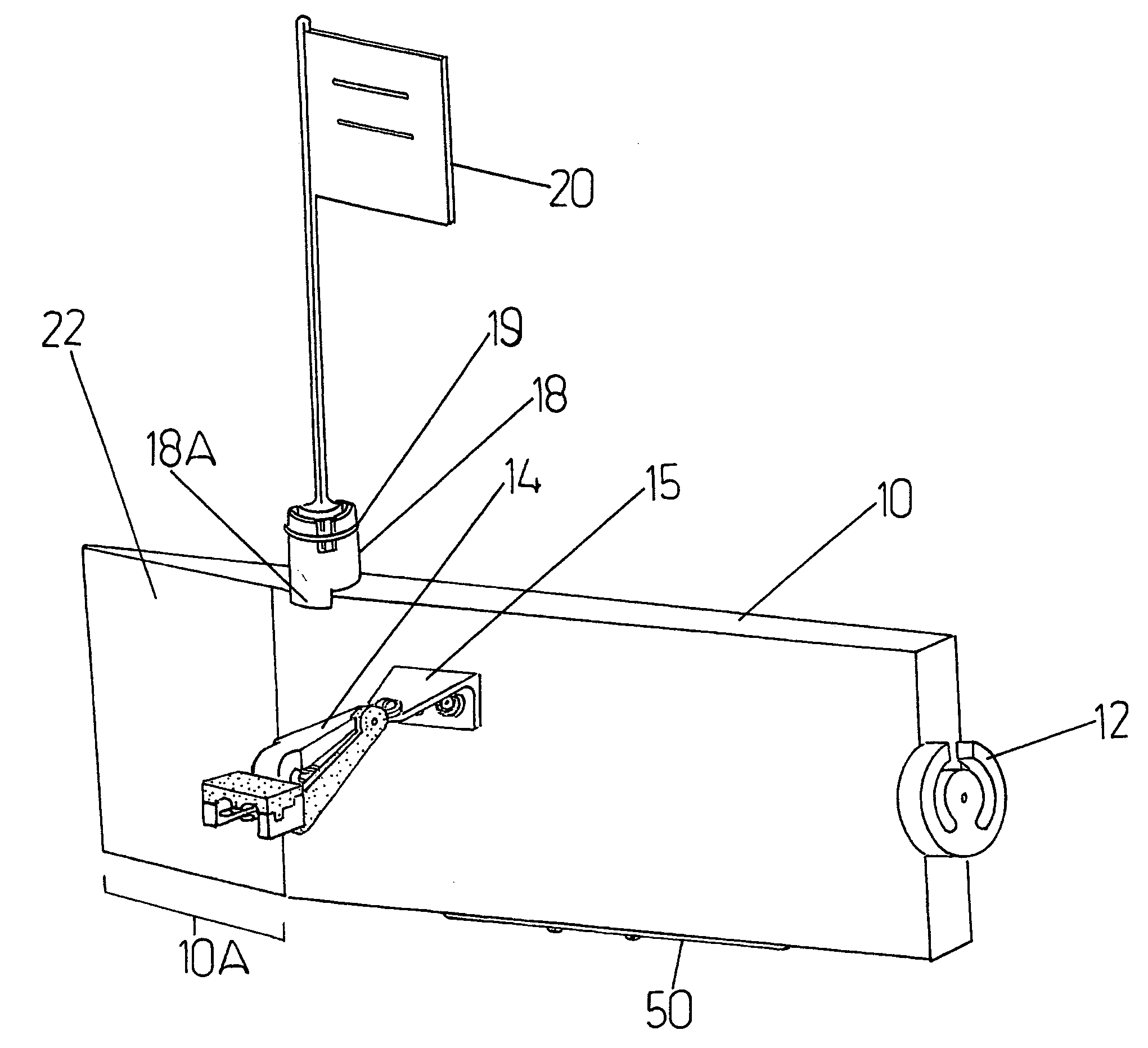

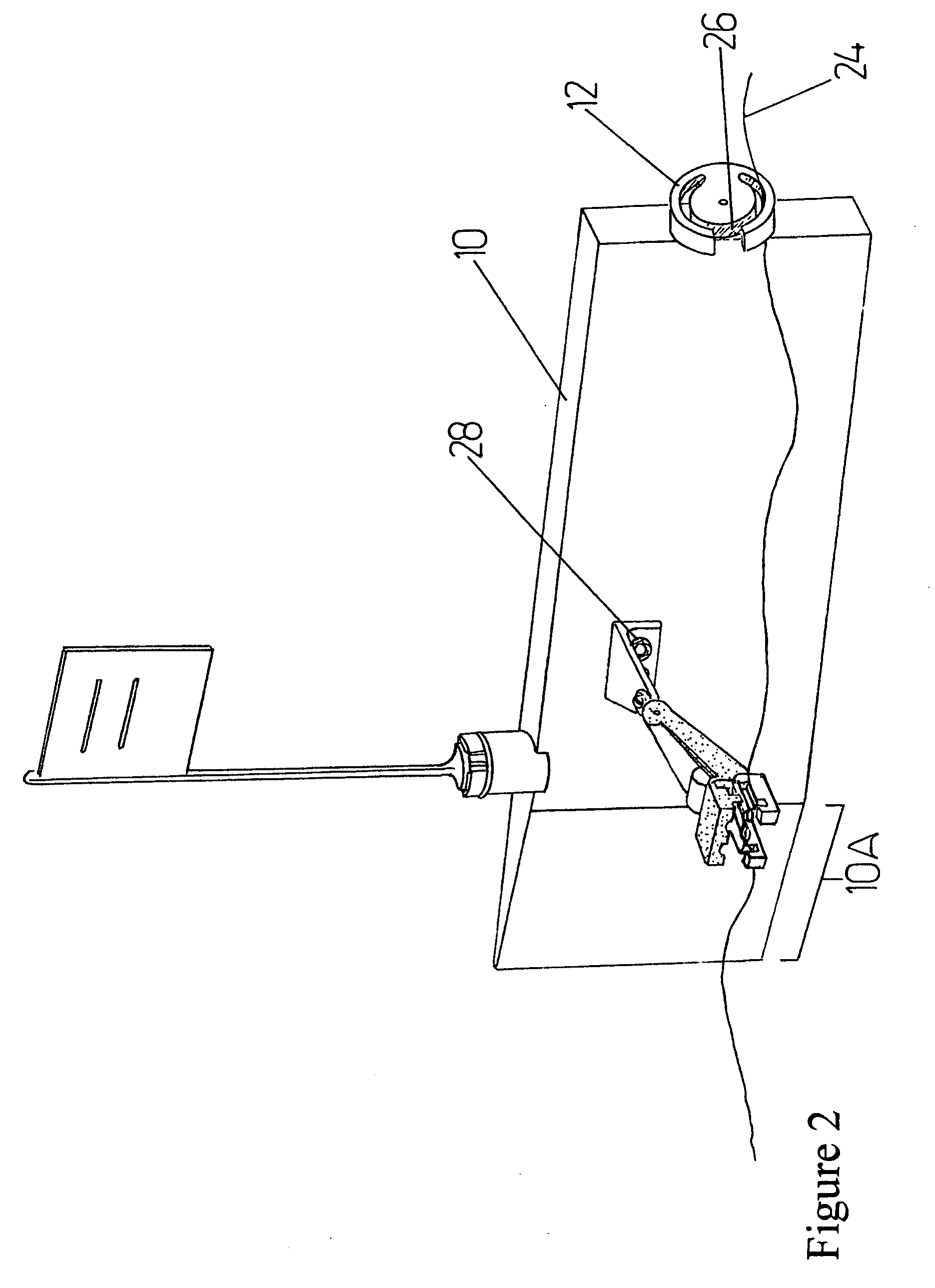

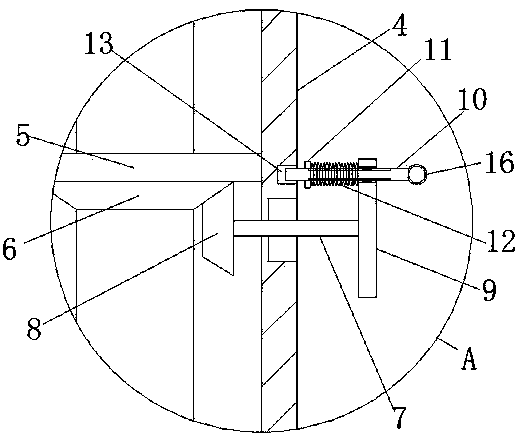

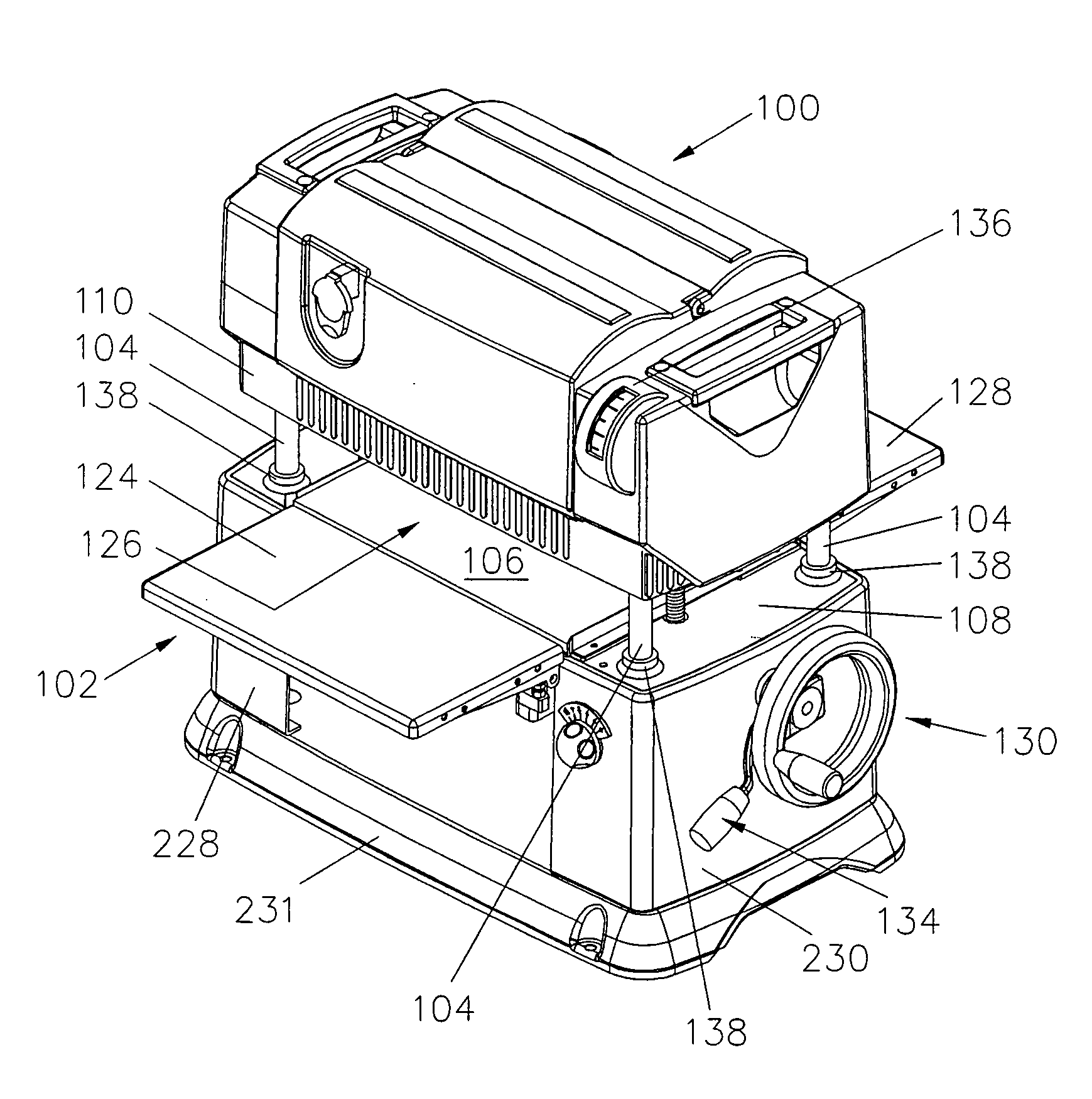

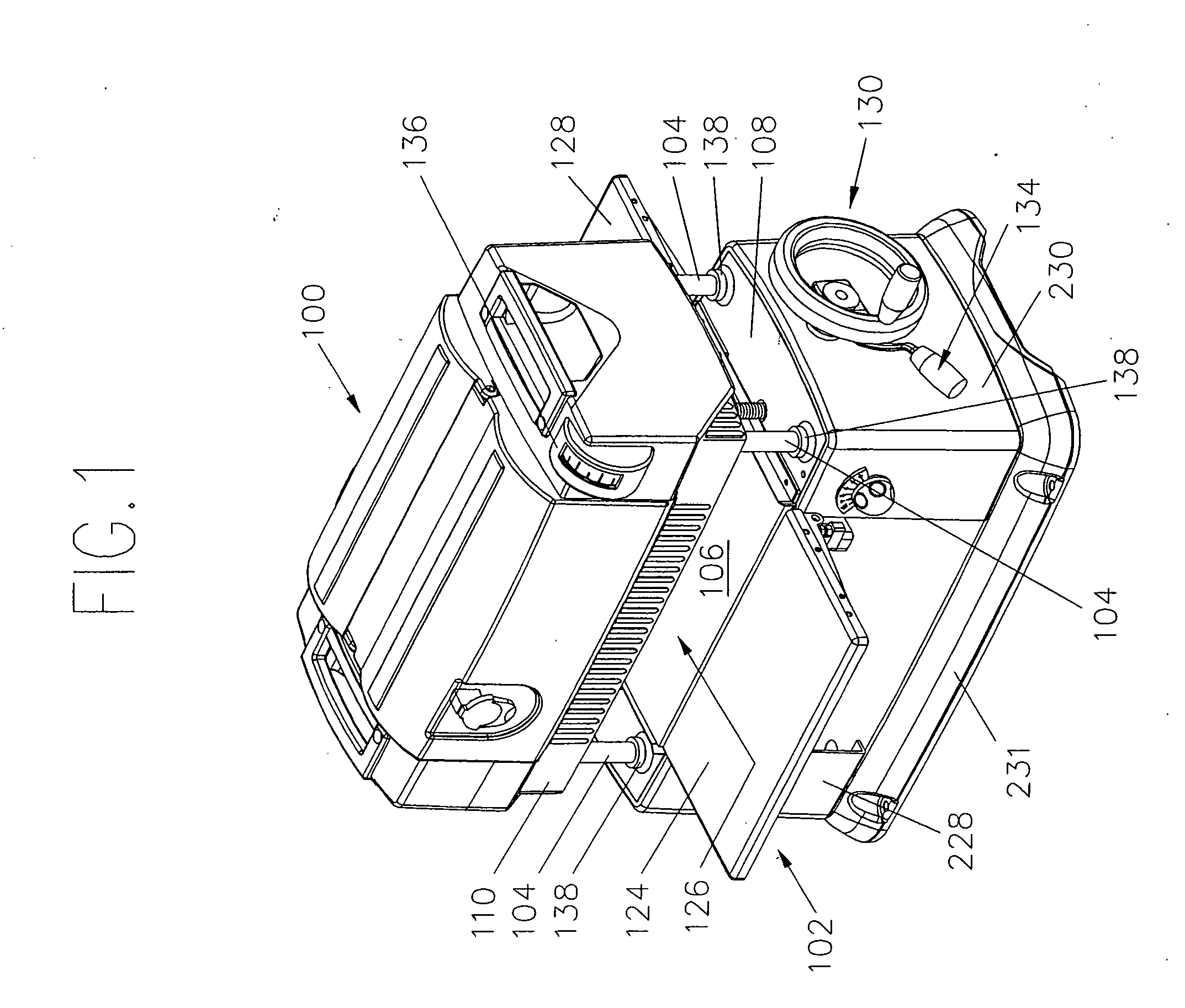

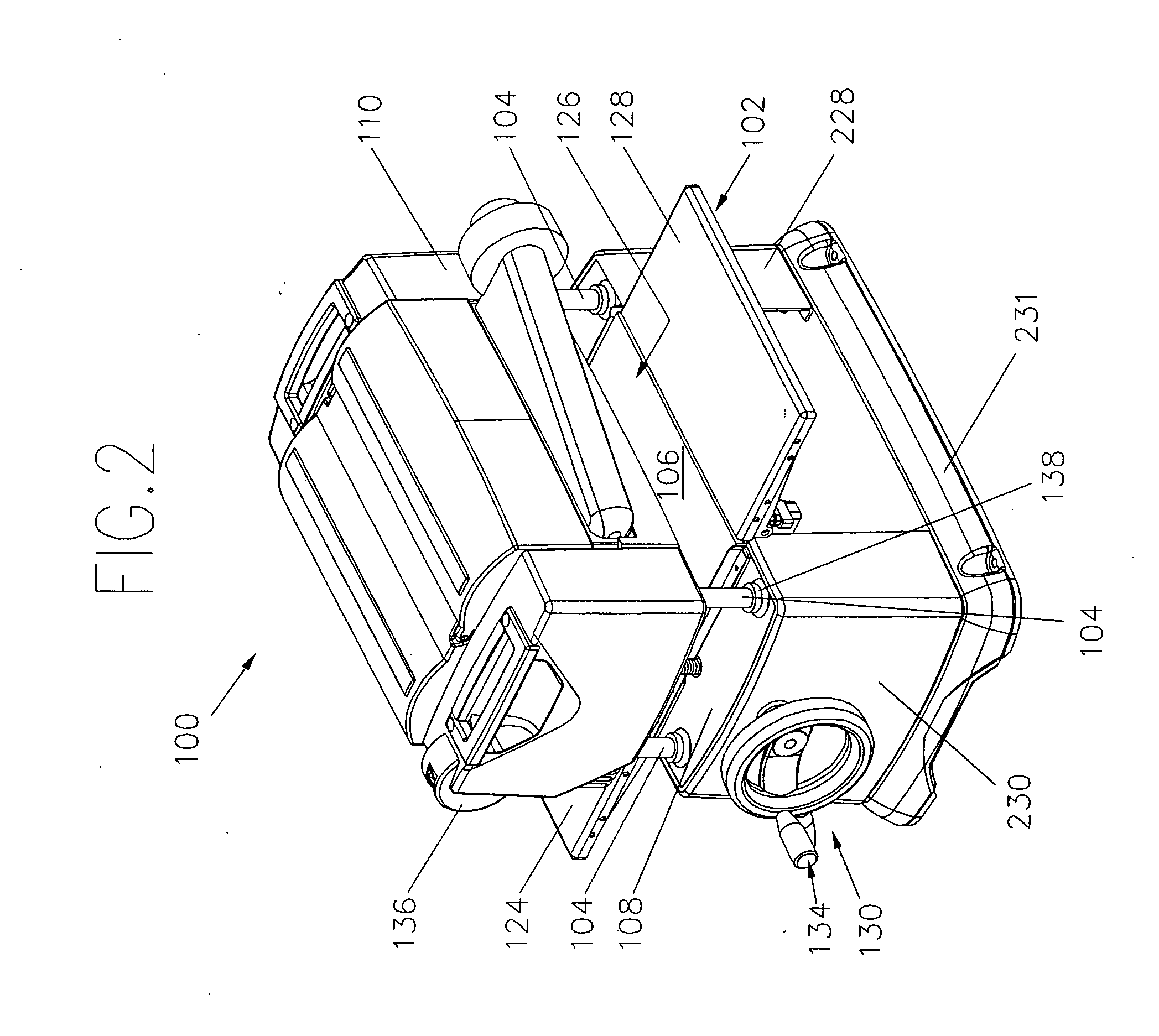

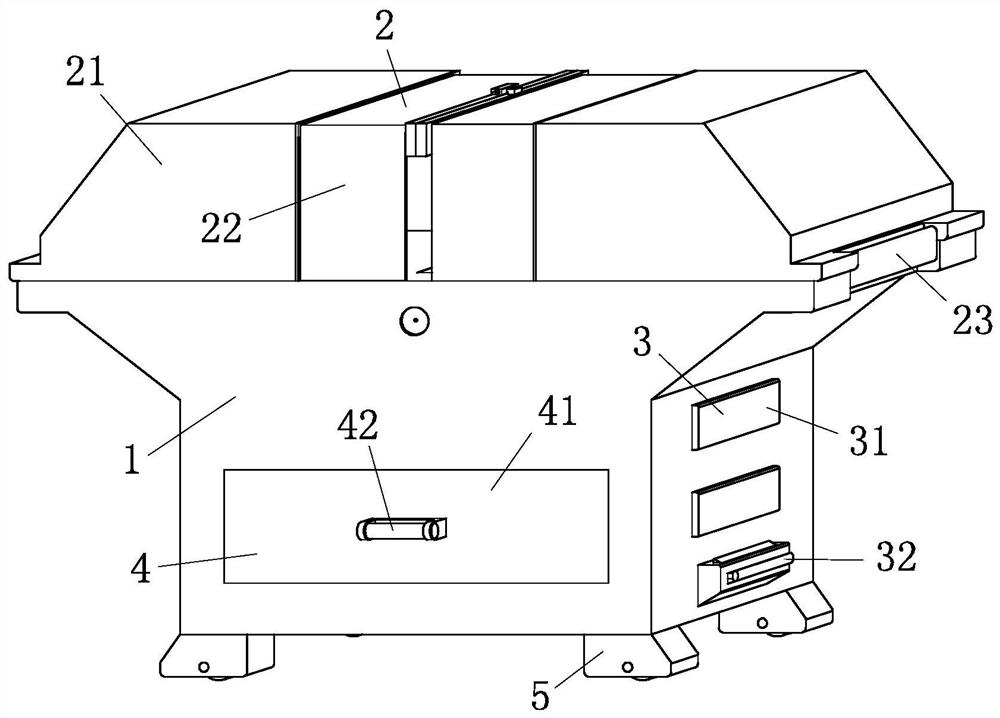

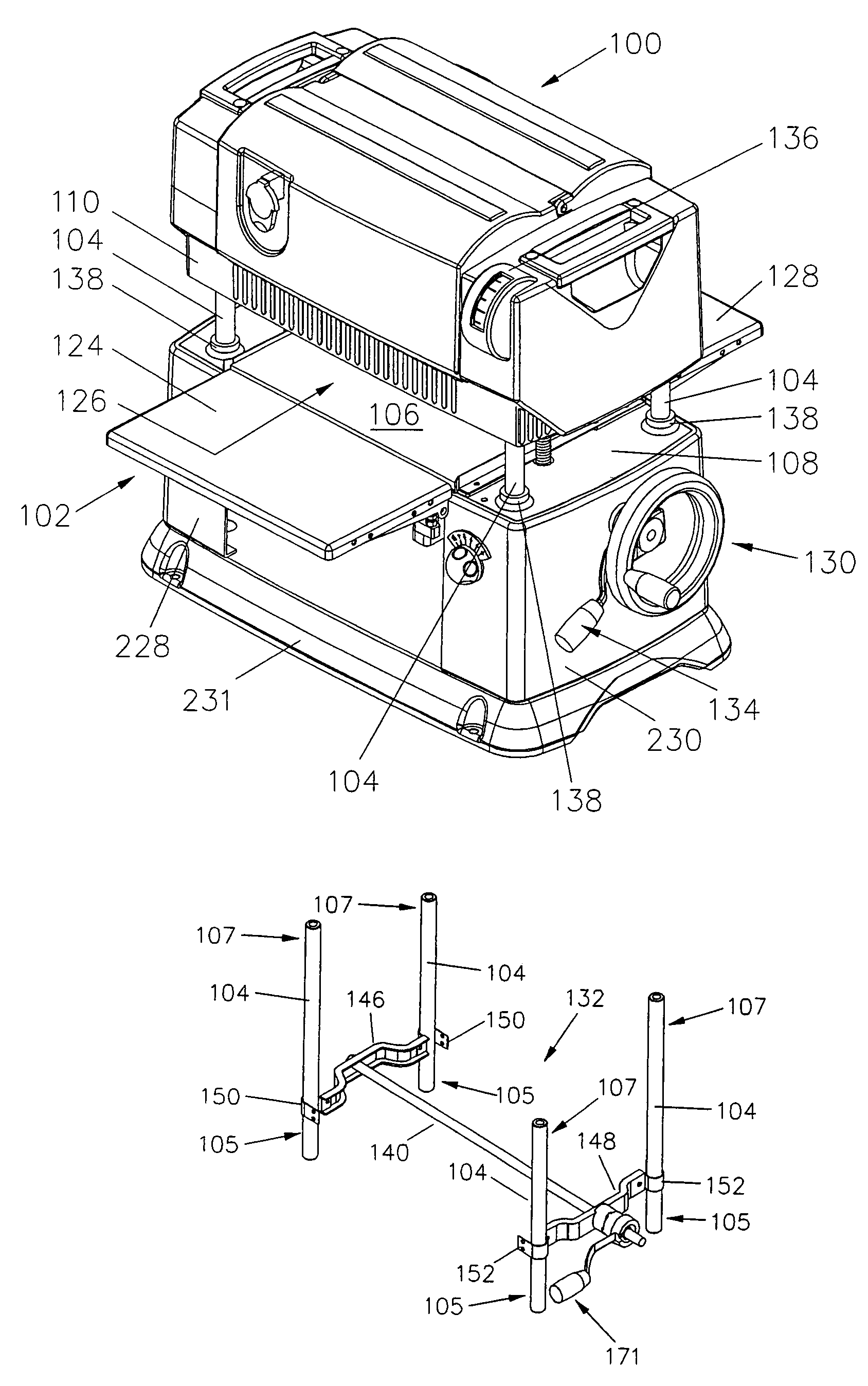

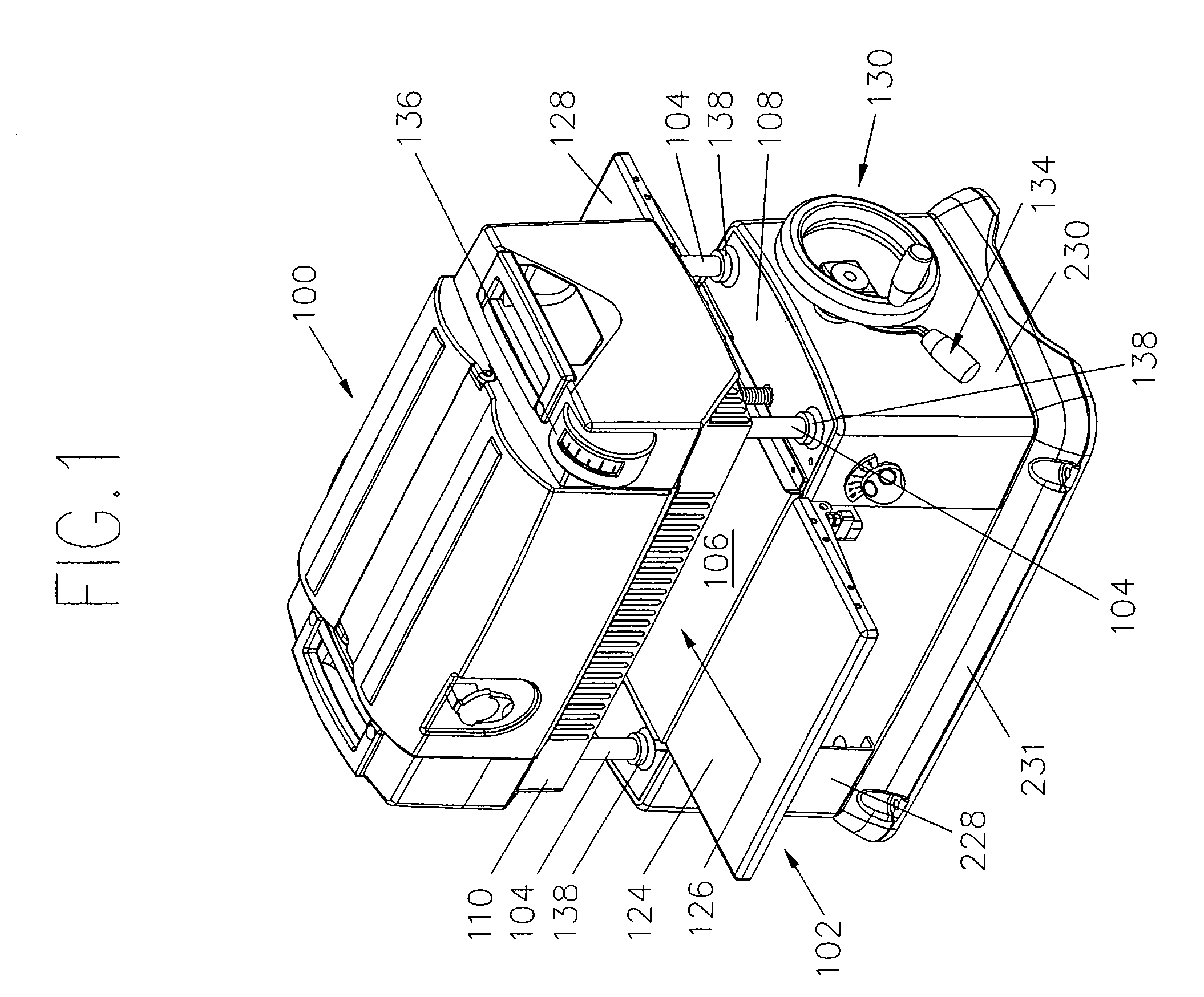

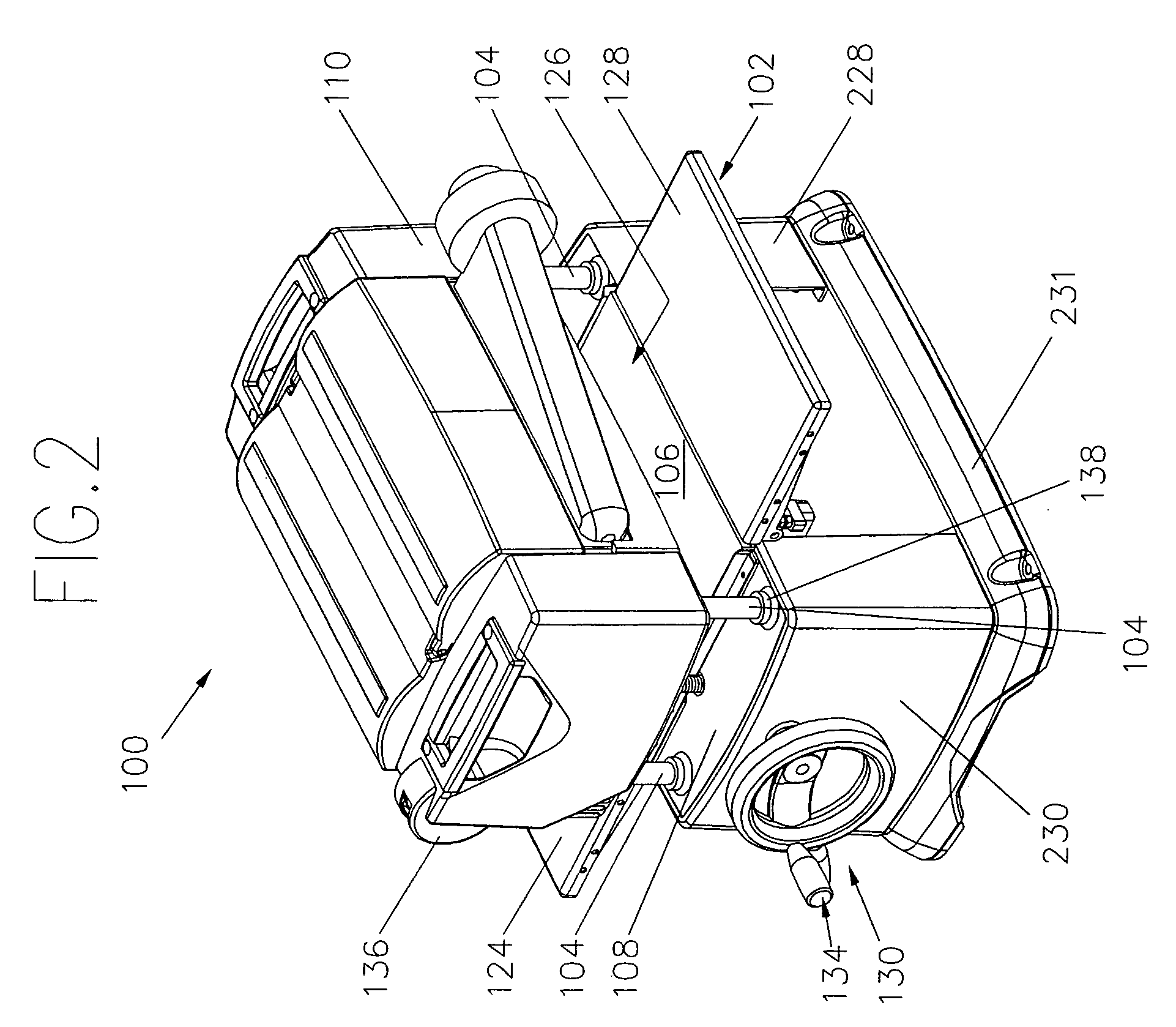

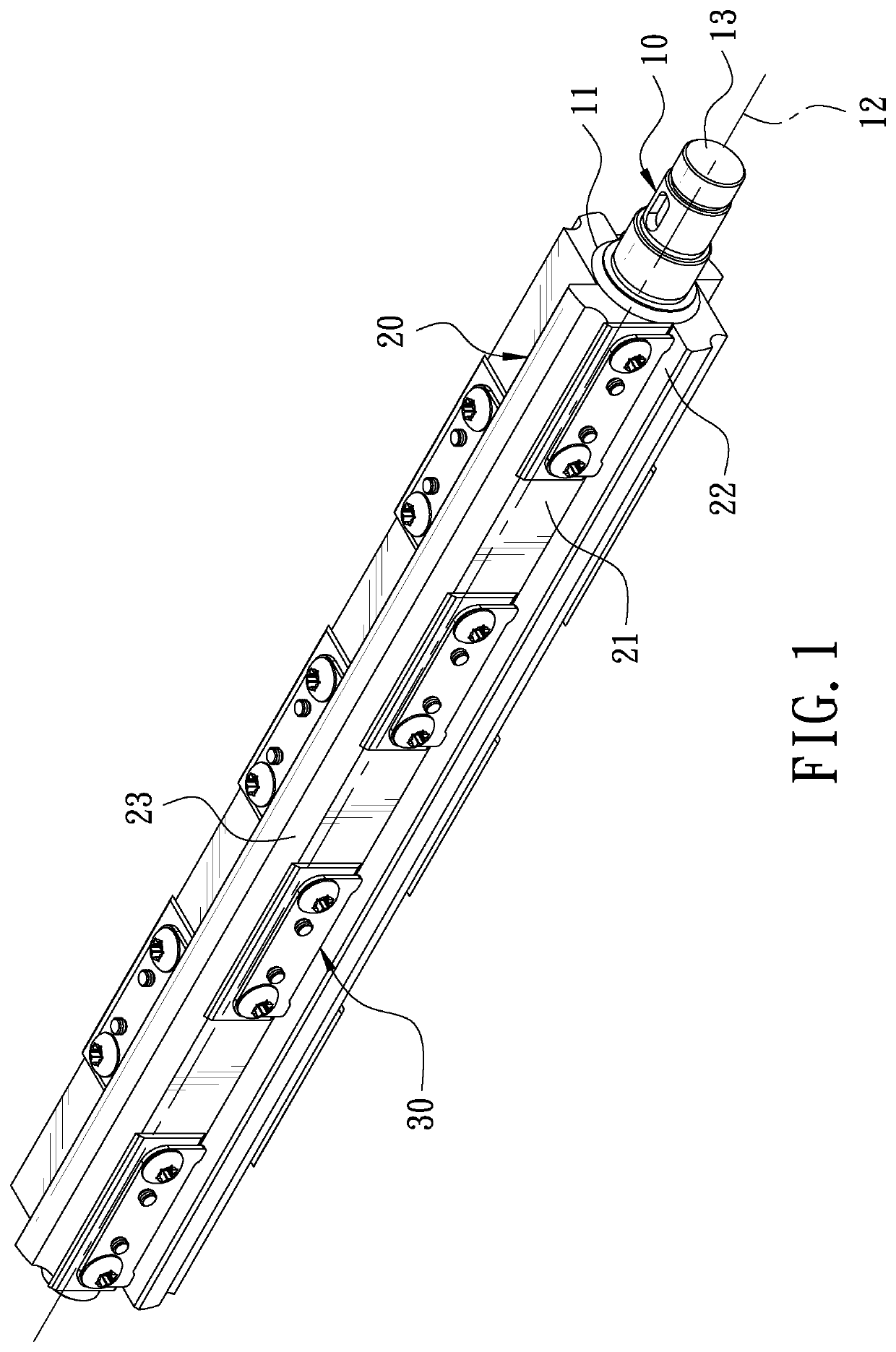

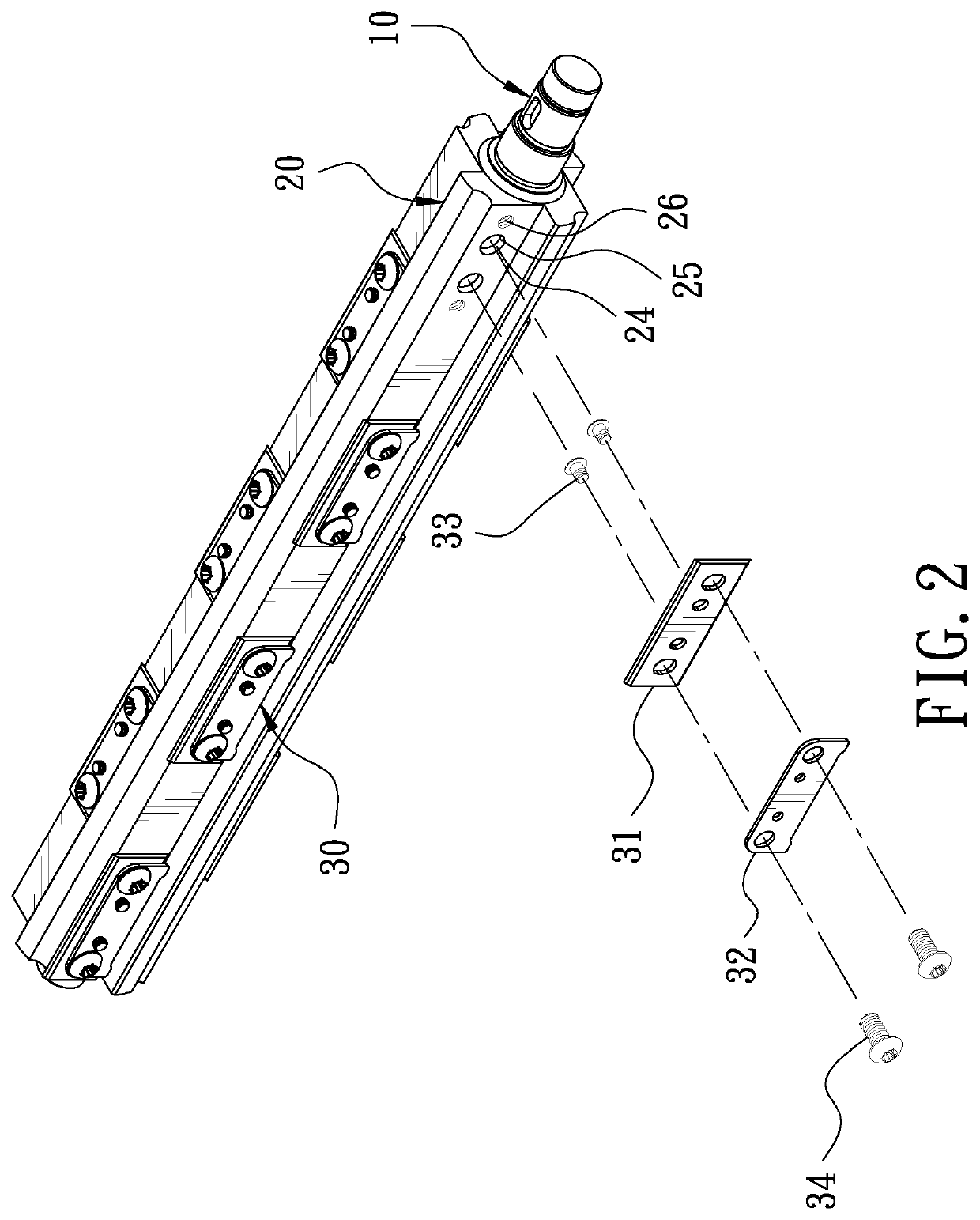

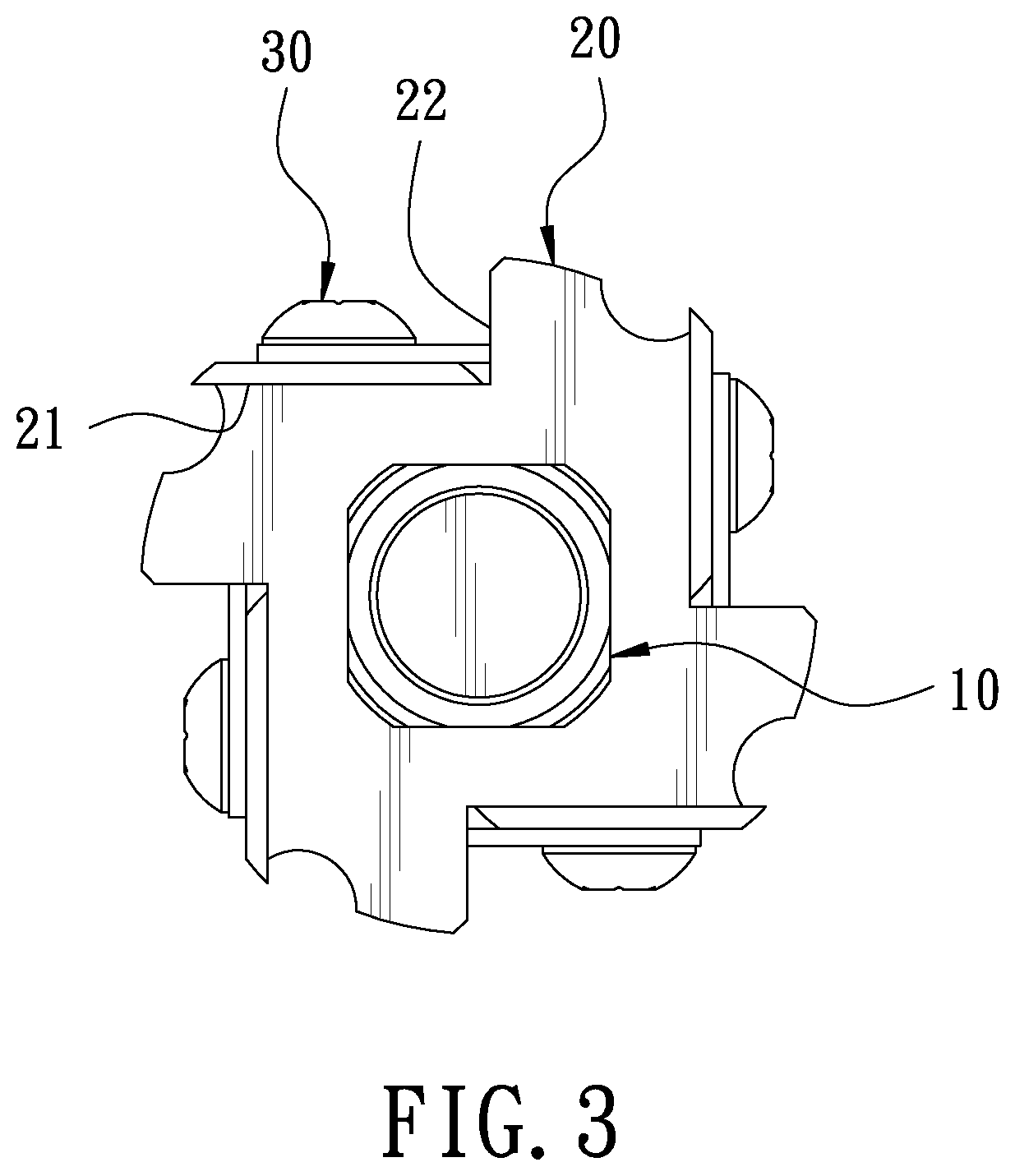

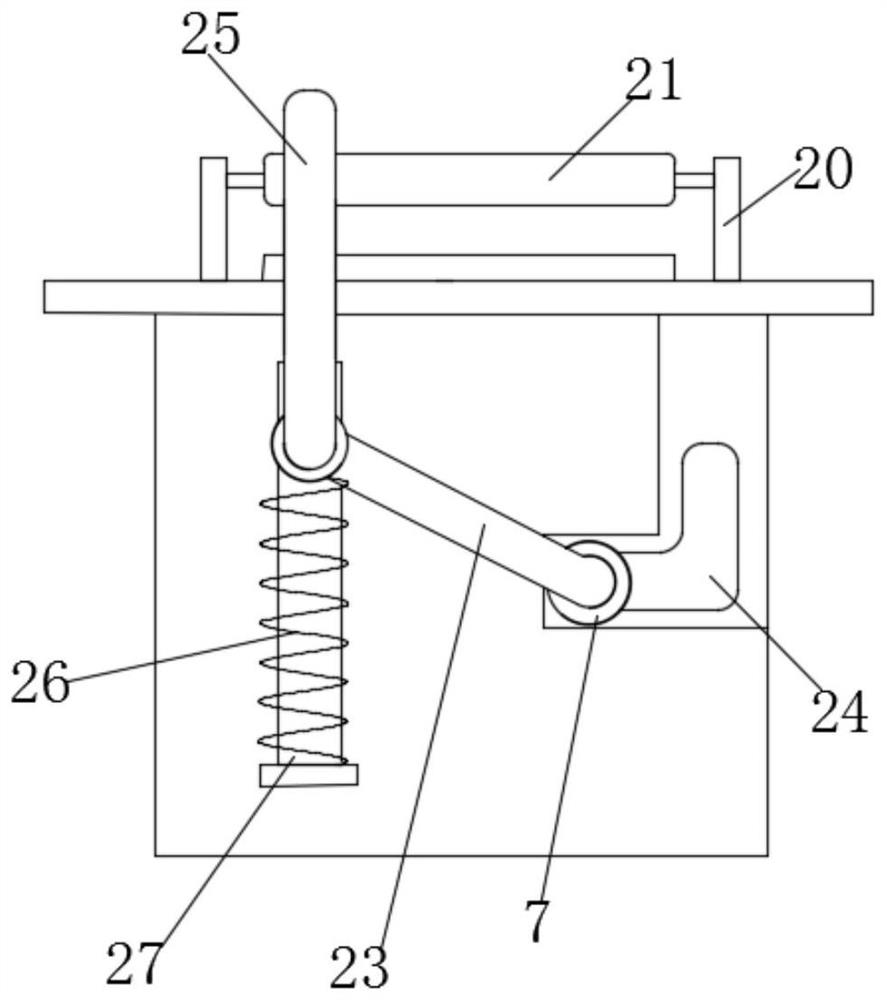

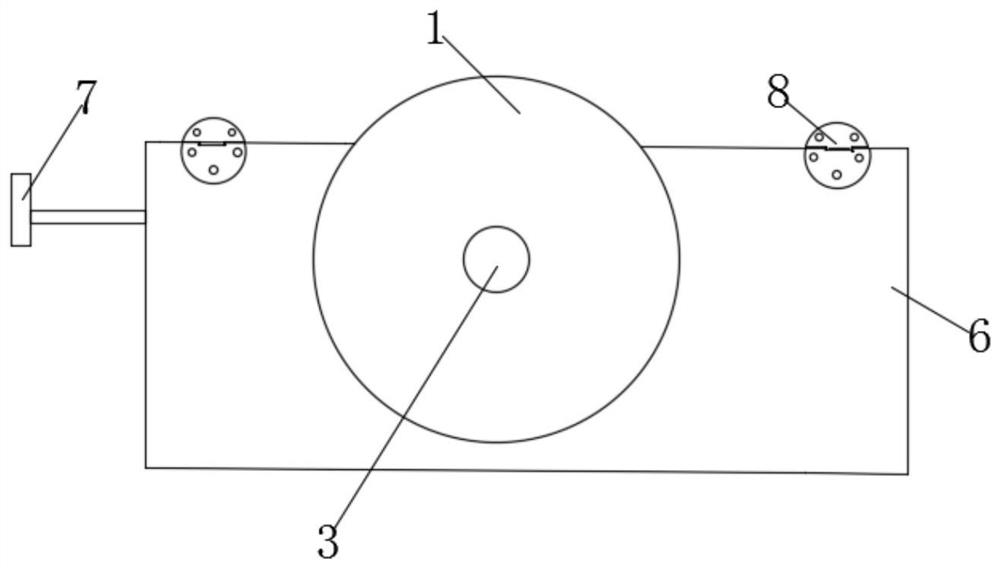

Planer with carriage locking mechanism

InactiveUS20090183799A1Improve stabilityImprove performanceWood feeding arangementsThicknessing machinesLocking mechanismEngineering

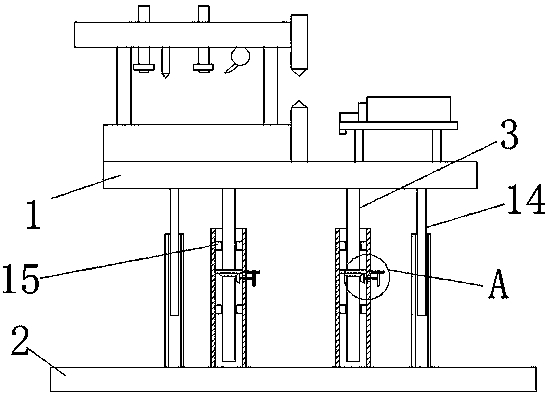

A locking mechanism for a thickness planer having a base and a carriage with a cutting head. The carriage is mounted to a plurality of support columns movably attached to the base. The locking mechanism includes a first lock plate associated with the base and positioned adjacent to a first pair of the support columns and a second lock plate associated with the base and positioned adjacent to a second different pair of the support columns. An actuator is coupled to the first lock plate and the second lock plate and is configured for causing the first lock plate to engage the first pair of the support columns and the second lock plate to engage the second pair of the support columns to exert a clamping force by moving the first and second lock plates towards each other to firmly secure the carriage in position.

Owner:LIAO CHIH HUNG

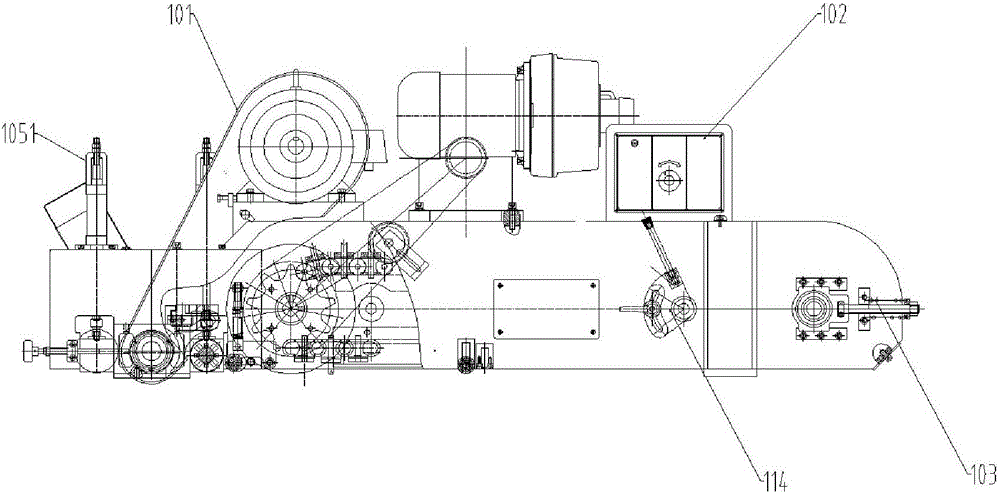

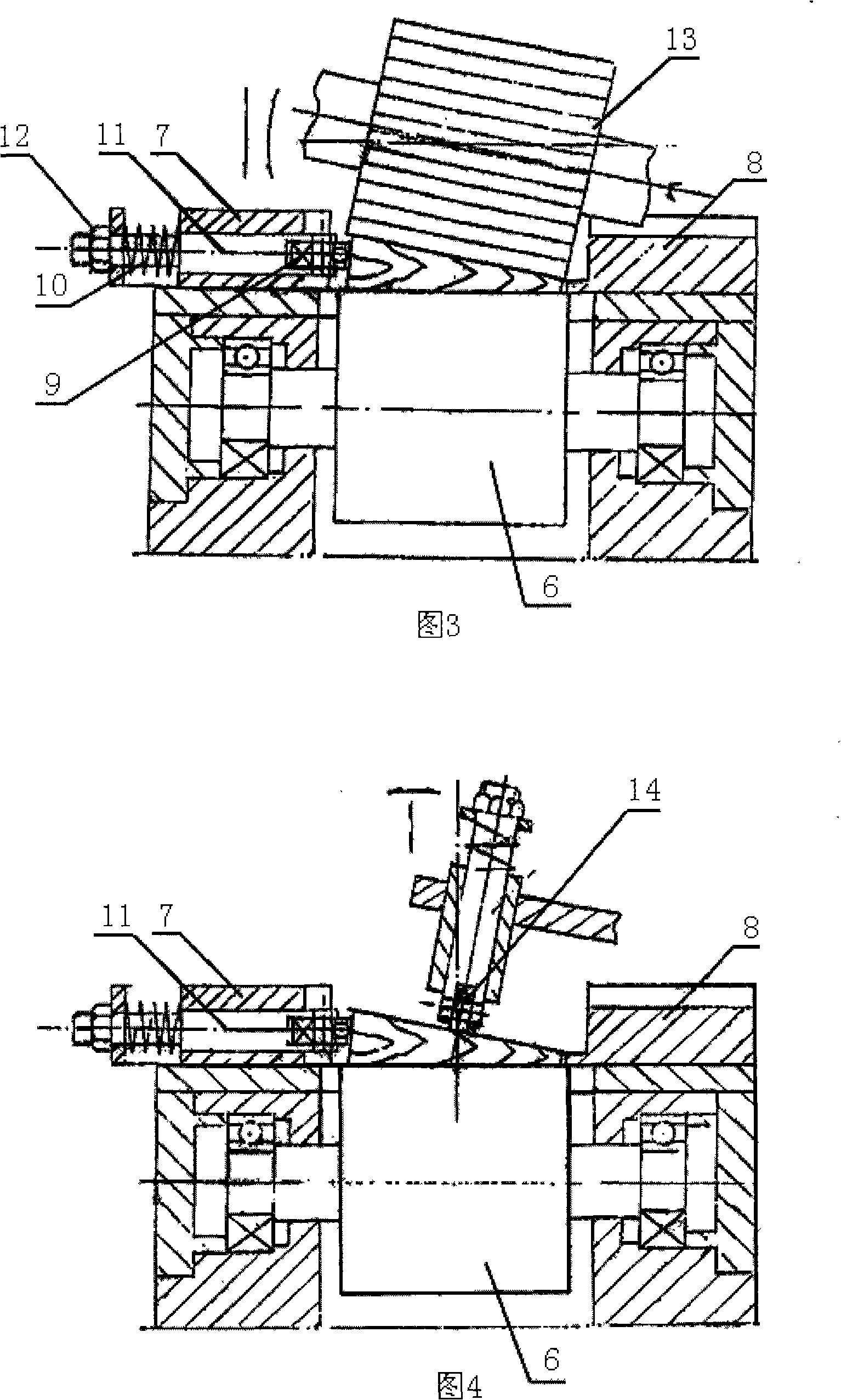

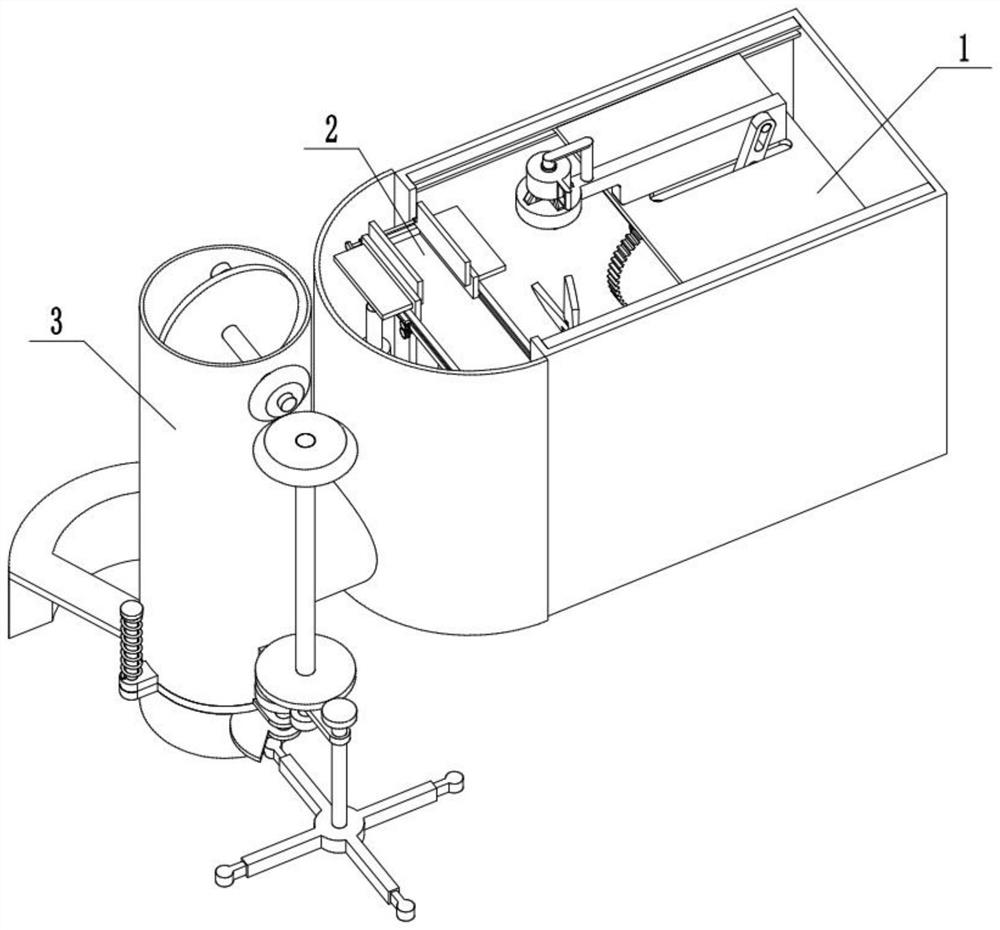

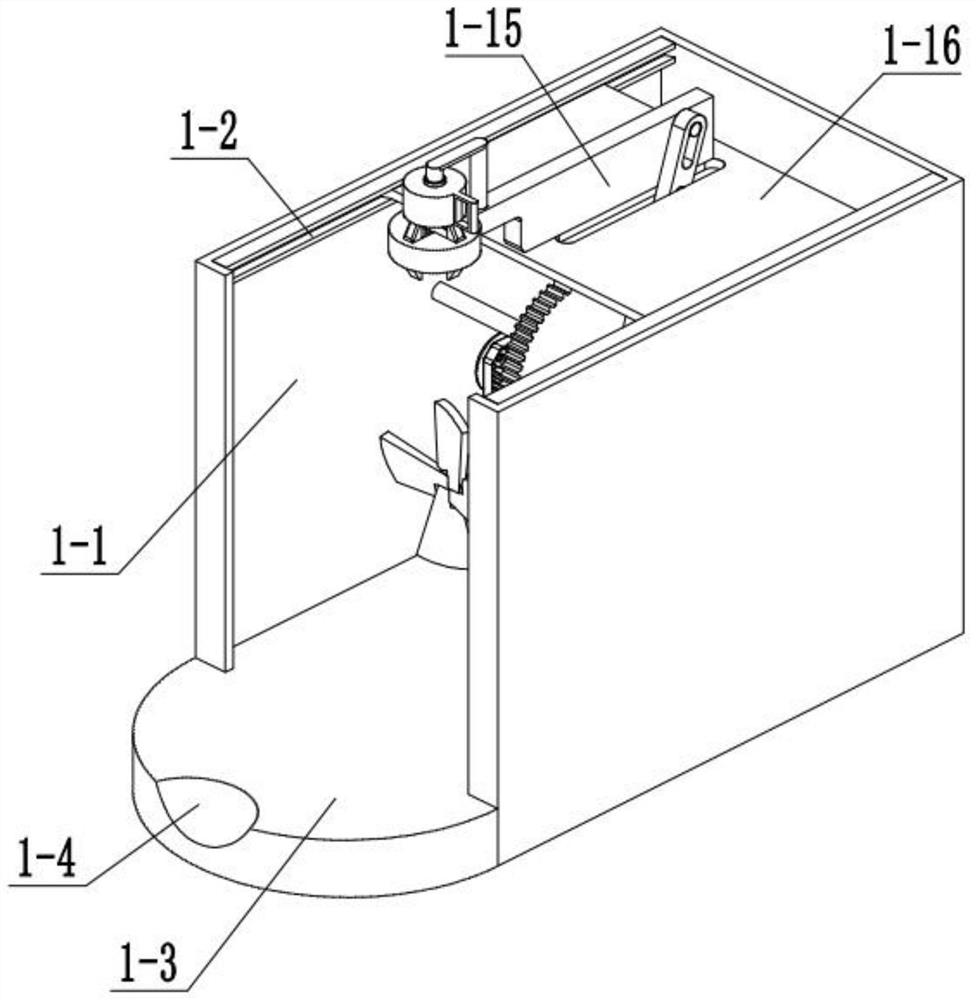

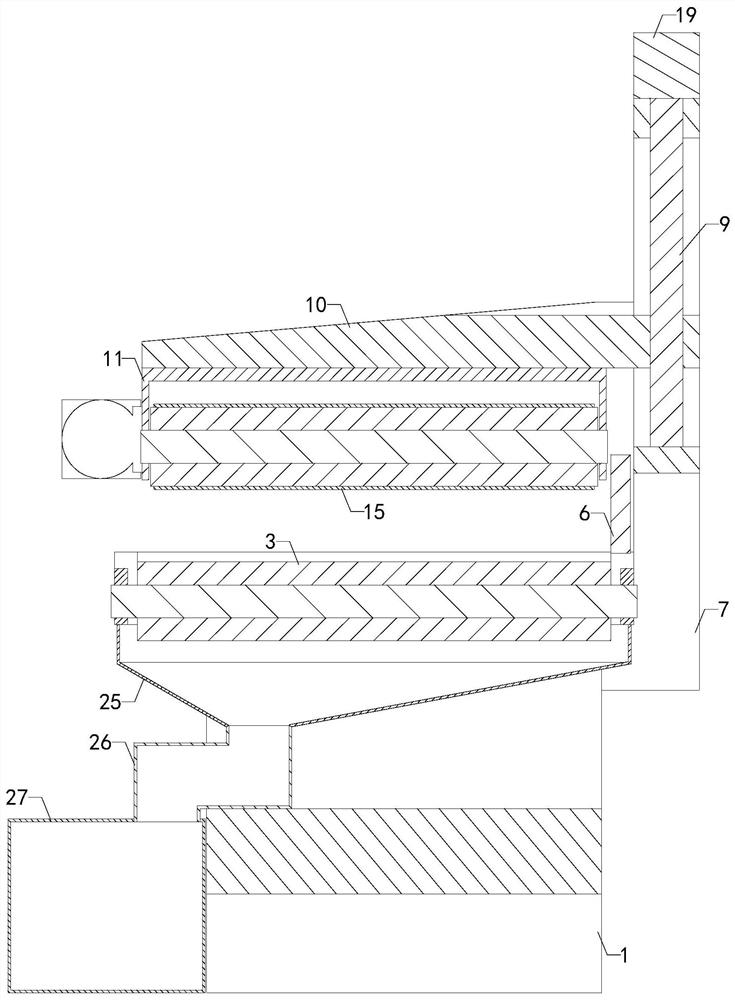

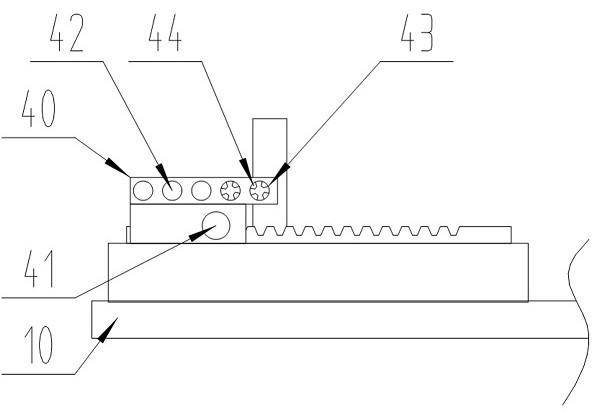

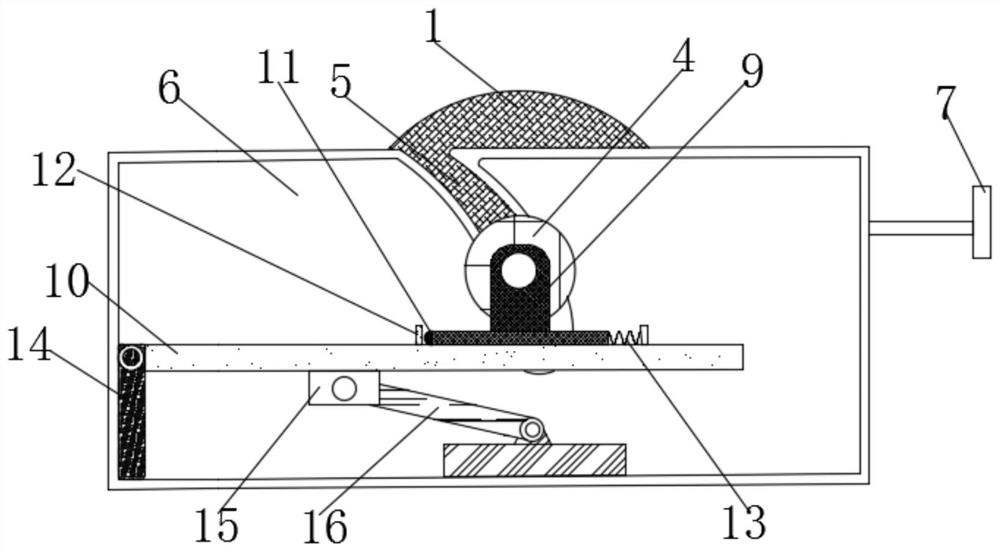

Automatic planer capable of processing one-face, two-face or short wood slide with angle

ActiveCN101508122BContinuous processingStable processingWood feeding arangementsBark-zones/chip/dust/waste removalRatchetElectric machinery

The invention discloses an automatic planer capable of simultaneously processing one-sided, two-sided or angular short and small piece wood, which mainly comprises a worktable, a drive motor and an upper planning tool and a lower planning tool arranged on the worktable. A control door mechanism consisting of a left control panel, a right control panel and an upper control panel is arranged at a feeding opening of the worktable; a delivery tug is arranged below the worktable; the left side and the right side of the worktable are provided with a left occulting bar and a right occulting bar respectively so as to form a closed delivery passage, wherein the a transverse compress roller wheel on the left occulting bar is provided with a spring, a directional traveler and a nut for adjusting thecompress distance; and a delivery ratchet wheel capable of adjusting angle, compress force and up-down distance is arranged above the delivery passage. The automatic planer solves the problem that the prior equipment cannot process short and small piece wood, and can continuously and efficiently manufacture products with stable size, angle and quality; and the equipment has low fault rate and high safety, does not damage the bodies of operators, and has quite convenient use, debugging and maintenance.

Owner:重庆谭木匠工艺品有限公司

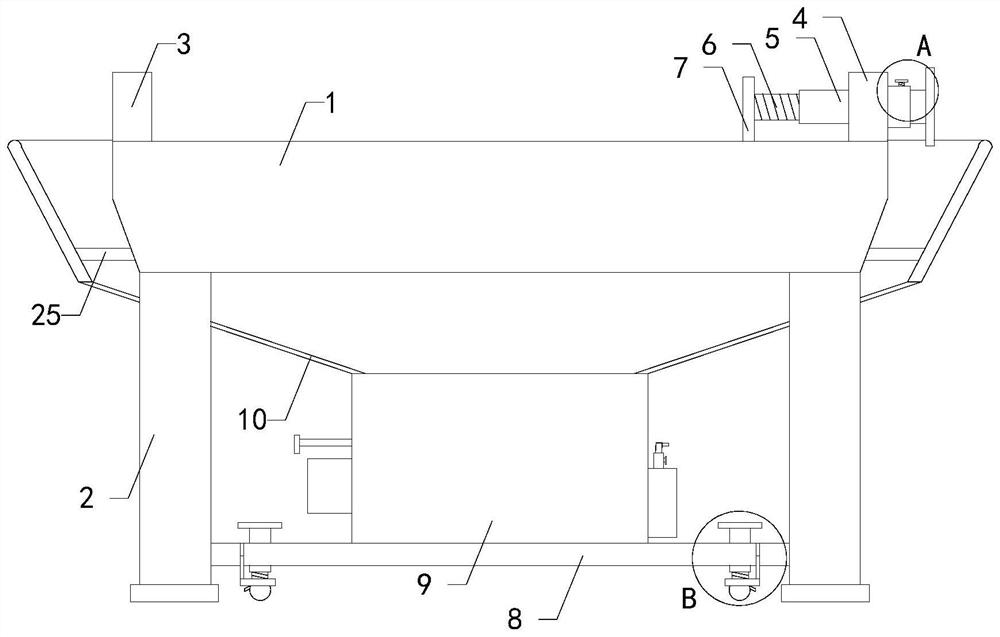

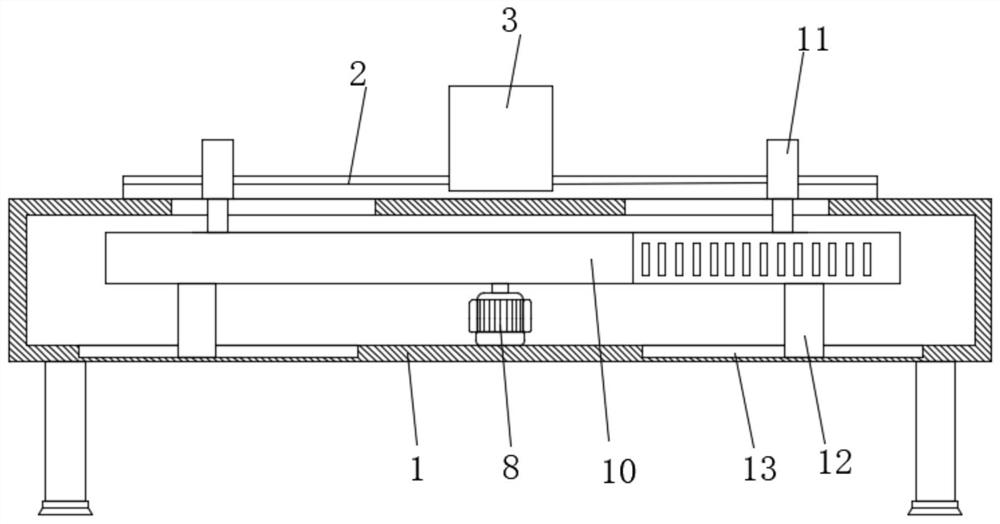

Panel planer and thicknesser for wooden packaging box production

ActiveCN112873428AReduce pollutionImprove synchronicityThicknessing machinesBark-zones/chip/dust/waste removalThickness planerWood plank

The invention relates to the technical field of construction production of wooden packaging boxes, in particular to a panel planer and thicknesser for wooden packaging box production. The panel planer and thicknesser comprises a machine body and a planing device, the machine body is vertically arranged, the planing device is fixedly connected with the machine body, a wood chip collecting device is arranged at the planing device, the wood chip collecting device comprises an upper sealing groove, a lower sealing groove and a collecting barrel, the collecting barrel is arranged at a discharging port of the planing device in a sleeving mode and fixedly connected with the machine body, the upper sealing groove and the lower sealing groove are formed in the other end of the collecting barrel, the upper sealing groove is fixedly connected with the collecting barrel, an adjusting device is arranged between the lower sealing groove and the collecting barrel, a gap between the upper sealing groove and the lower sealing groove only allows wood boards to pass therethrough, a wood board cleaning device is arranged between the upper sealing groove and the lower sealing groove, and the collecting barrel is connected with an air suction device. The panel planer and thicknesser has the effect of reducing pollution to a production workshop when the panel planer and thicknesser works.

Owner:昆山市中裕包装物资有限公司

Wood cutting equipment capable of being folded and stored

ActiveCN112356154AEasy to lockPrevent reset shakingCircular sawsBark-zones/chip/dust/waste removalAgricultural engineeringThickness planer

The invention relates to the technical field of wood cutting, in particular to wood cutting equipment capable of being folded and stored. The wood cutting equipment comprises a planer body, a foldingmechanism, a limiting mechanism, a collecting mechanism, a rolling mechanism, a protecting mechanism and a locking mechanism. Under the action of the folding mechanism, a cutter at the top of a planeris hidden and protected, and thus the safety coefficient is increased. Meanwhile, the folding mechanism can be locked easily through the locking mechanism to be prevented from resetting and shaking,and the folding mechanism cannot slide out and disengage during sliding under the action of the protection mechanism. Meanwhile, the folding mechanism can be conveniently stored and fixed under the action of the limiting mechanism, and the situation that safe production is affected by shaking of the planer during work is prevented. Wood chips generated by the planer during work are conveniently stored under the action of the collecting mechanism, and thus subsequent cleaning is facilitated. Meanwhile, the collected wood chips are effectively prevented from flowing out upwards to affect work. Under the action of the rolling mechanism, the planer can be moved and carried conveniently, and thus physical exhaustion is reduced.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

Planing machine capable of conveniently planing any plane of material

InactiveCN113714545AEasy to replaceEasy to adjustPlaning/slotting toolsPlaning/slotting machinesReciprocating motionMachine

The invention relates to the field of machine tools, in particular to a planing machine capable of conveniently planing any plane of a material. When the planing machine is used for machining, a common machine tool is used, a traditional planing machine cannot conveniently adjust the machining plane, and machining waste scraps cannot be treated. The planing machine solves the problems, a planing combination can drive a cutter to do reciprocating motion to plane the material, the cutter is convenient to replace, a clamping combination can clamp the material in any shape, the machining plane can be conveniently adjusted, the position of the material can be adjusted according to the reciprocating motion of the cutter, planing is facilitated, a scrap iron pressing combination can collect scrap iron generated by planing and press the scrap iron into blocks, collection and treatment are facilitated, and resource waste is avoided.

Owner:宋淑兰

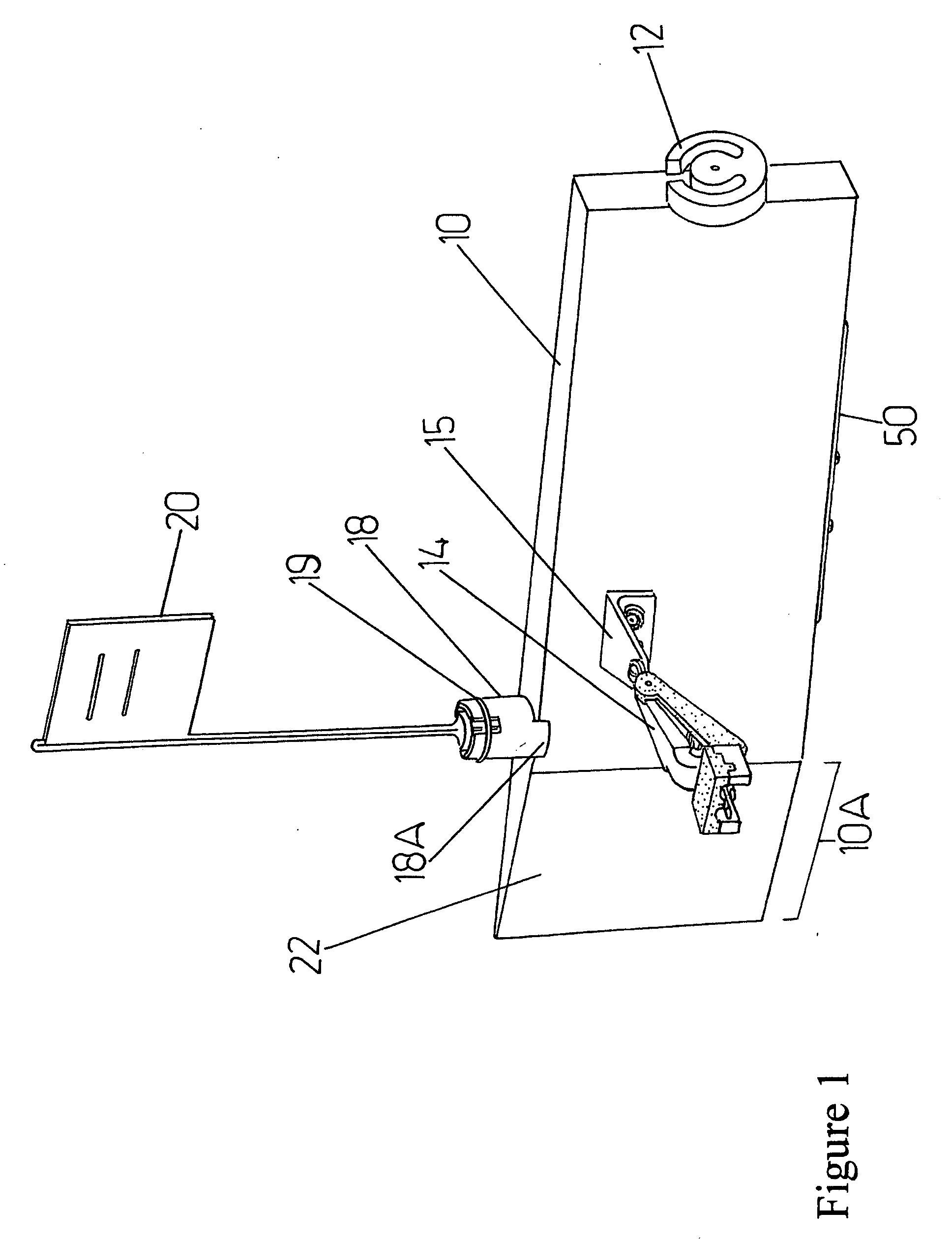

Planer with carriage locking mechanism

InactiveUS7757733B2Improve stabilityImprove performanceWood feeding arangementsThicknessing machinesLocking mechanismEngineering

A locking mechanism for a thickness planer having a base and a carriage with a cutting head. The carriage is mounted to a plurality of support columns movably attached to the base. The locking mechanism includes a first lock plate associated with the base and positioned adjacent to a first pair of the support columns and a second lock plate associated with the base and positioned adjacent to a second different pair of the support columns. An actuator is coupled to the first lock plate and the second lock plate and is configured for causing the first lock plate to engage the first pair of the support columns and the second lock plate to engage the second pair of the support columns to exert a clamping force by moving the first and second lock plates towards each other to firmly secure the carriage in position.

Owner:LIAO CHIH HUNG

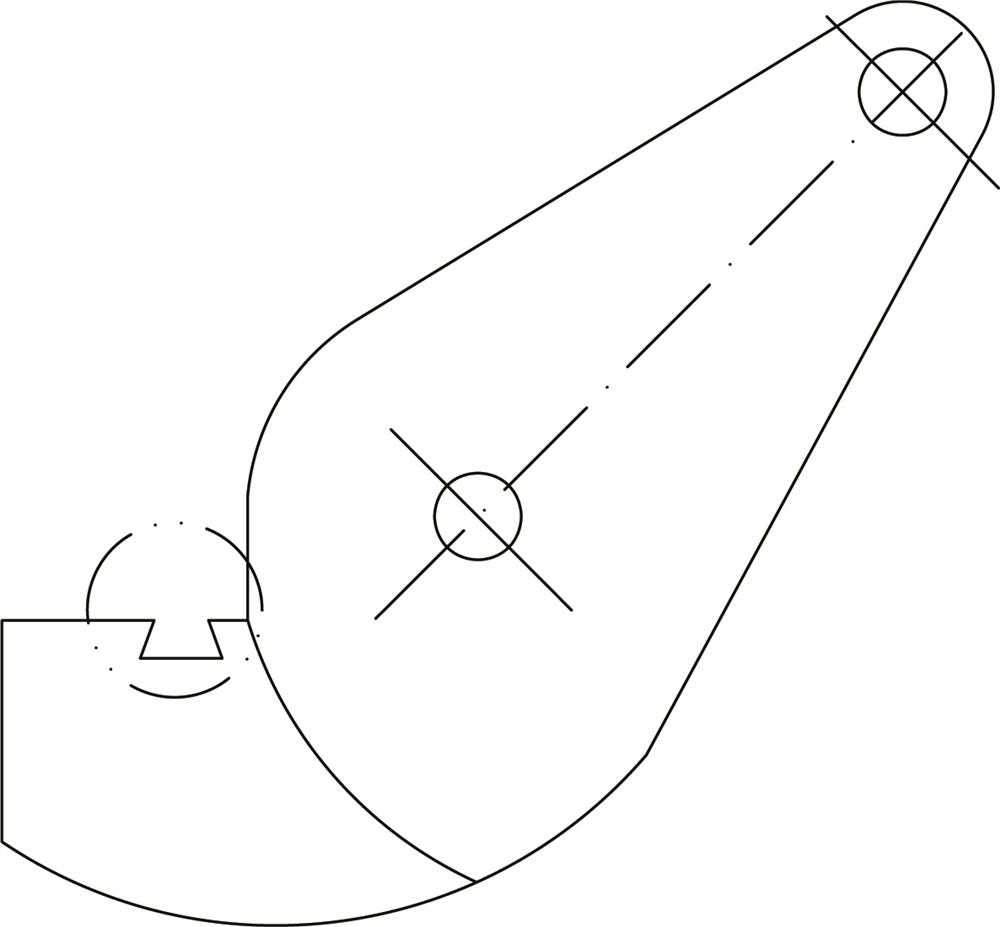

Numerical control planing and polishing combined machining method for special-shaped blades of super-huge type water ring vacuum pump impeller and equipment

ActiveCN112247498AImprove processing qualityAchieve precise positioningPositioning apparatusMetal-working holdersNumerical controlImpeller

The invention discloses a numerical control planing and polishing combined machining method for special-shaped blades of a super-huge type water ring vacuum pump impeller and equipment. The numericalcontrol planing and polishing combined machining method comprises the steps that firstly, a special-shaped blade blank is clamped through a blade convex surface positioning clamp, a machining numerical control program is written into a gantry numerical control planer, a thin-wall complex spline molded line variable-thickness blade convex surface is machined by using a circular planer tool, and thecircular planer tool is replaced with a polishing wheel to polish the thin-wall complex spline molded line variable-thickness blade convex surface; and the special-shaped blade blank is clamped by using a blade concave surface positioning clamp, a numerical control program is written into a gantry numerical control planer, a thin-wall complex spline molded line variable-thickness blade concave surface is machined by using the circular planer tool, the circular planer tool is replaced with the polishing wheel to polish the thin-wall complex spline molded line variable-thickness blade concave surface therefore the numerical control planing and polishing combined machining process of the special-shaped blade blank is completed, the machined special-shaped blade blank is cut through a laser cutting machine, and of the multiple special-shaped blades are obtained.

Owner:ZIBO WATER RING VACUUM PUMP FACTORY +1

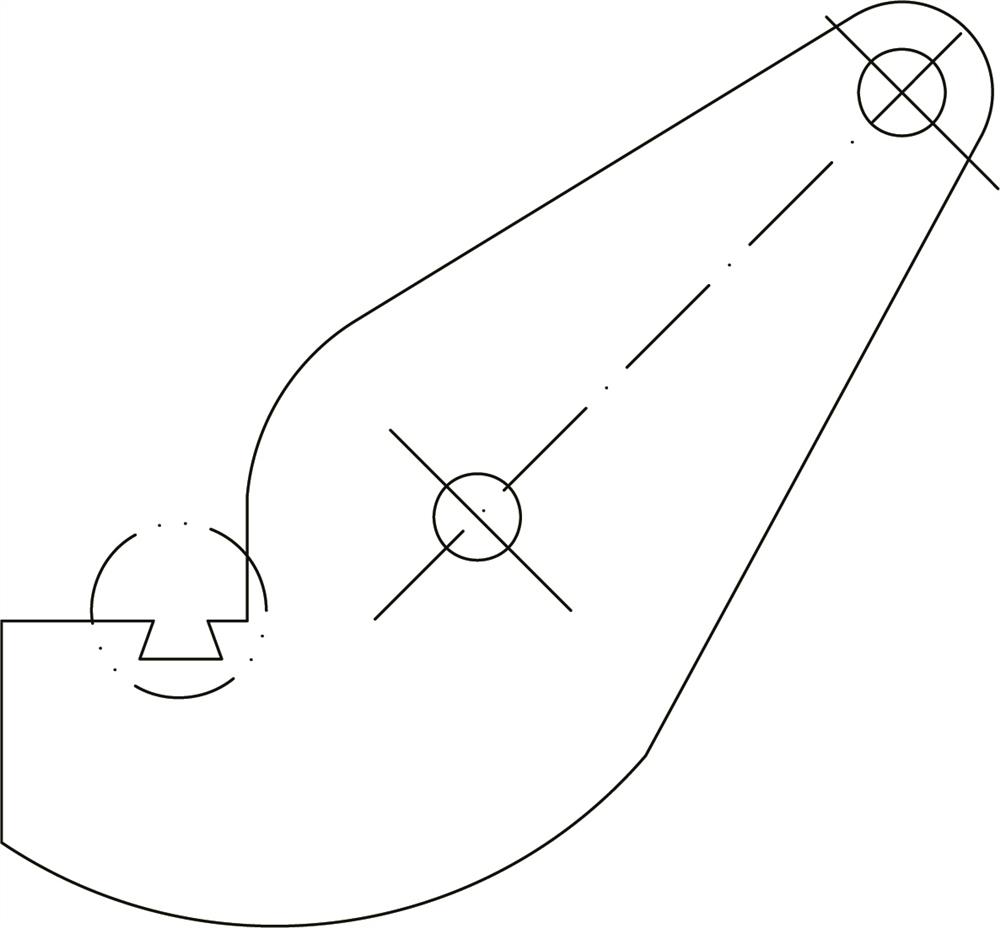

Machining device and method for dovetail groove of jaw plate of seamless steel tube cold-drawing machine

ActiveCN111940806AReasonable designProcess stabilityPlaning/slotting machinesVertical planeAcute angle

The invention discloses a machining device and method for a dovetail groove of a jaw plate of a seamless steel tube cold-drawing machine. The machining device comprises a bearing frame arranged on oneside face of a horizontal planer workbench, two supporting plates, a supporting cross beam, an adjusting screw, and a positioning plate; the two supporting plates are arranged in parallel; each supporting plate is in a right-angle sector shape; the upper part of one side edge of each supporting plate is a circular arc; the lower part of one side edge of each supporting plate is a vertical plane;the other side edge of each supporting plate is an inclined plane forming an acute angle with the side edge, and the degree of the acute angle is 11-20 degrees; the supporting cross beam is arranged between the upper parts of two supporting plates; the two ends of the supporting cross beam are connected to inner side surfaces of the right-angled parts of the two supporting plates; an adjusting screw hole is formed in the middle of the supporting cross beam; the adjusting screw is arranged in an adjusting screw hole in the middle of the supporting cross beam; and the positioning plate is vertically connected to the lower parts of the fan-shaped cambered surfaces of the two supporting plates and is fixed to the side face of a workbench of the horizontal planer through bolts. The machining device realizes accurate and rapid correction and positioning of planing machining to the jaw plate dovetail groove, synchronously optimizes and perfects the dovetail groove planing machining process and can meet the technical requirement for jaw plate dovetail groove machining.

Owner:宝武特种冶金有限公司

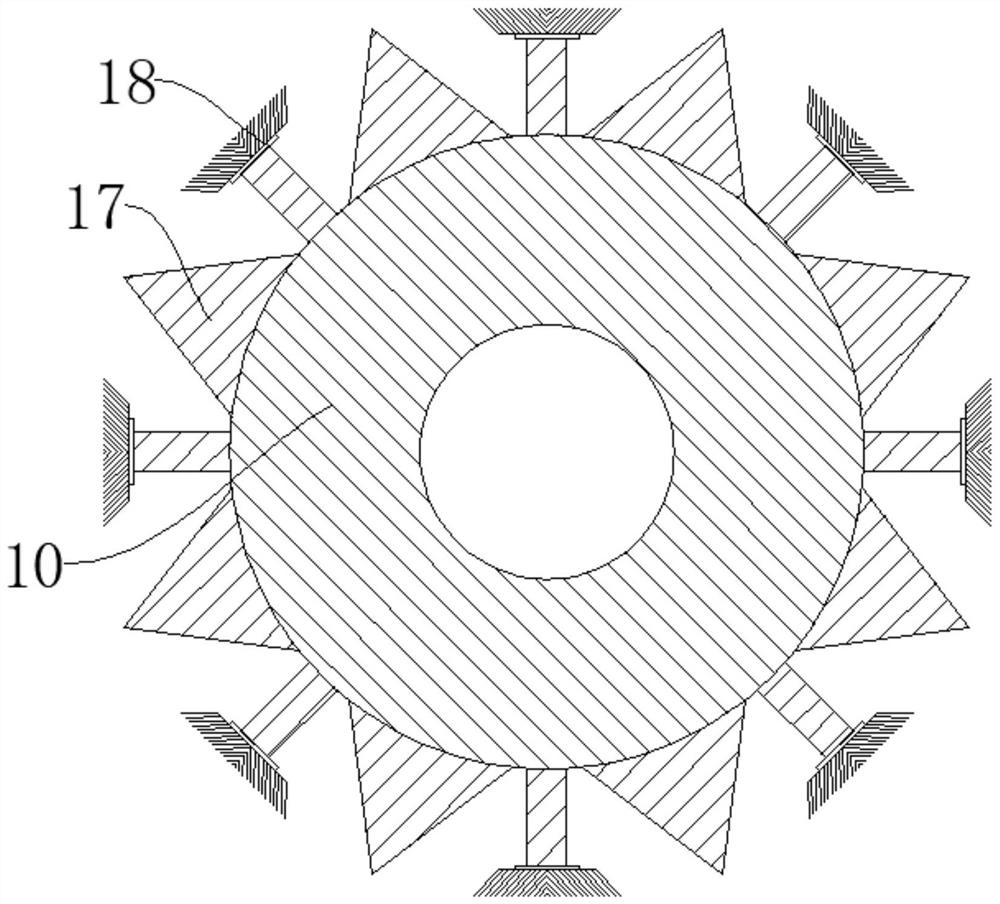

Multifunctional wood planing machine

InactiveCN112917604AReduce pollutionQuality improvementFlat surfacing machinesBark-zones/chip/dust/waste removalAgricultural engineeringWorking environment

The invention discloses a multifunctional wood planing machine. The machine comprises a frame body, sliding strips are respectively fixed to the front end and the rear end of the top of the frame body, the tops of the sliding strips are connected with moving plates in a sliding mode, a supporting rod is fixed between the two moving plates, the surface of the supporting rod is connected with a planing machine In a sliding mode, the planing machine comprises a cylindrical planing tool rest, a center shaft of the planing tool rest is hollow, two groove parts are symmetrically arranged on the planing tool rest, planing edges are mounted on one sides of the edges of the groove parts, guide edges are arranged on first curved surfaces of the groove parts, chip grooves are formed in second curved surfaces of the groove parts, the chip grooves communicate with a middle shaft of the planing tool rest, each guide edge comprises a front end and a rear end, and the rear ends of the guide edges are close to the chip grooves. According to the machine, the groove parts, the chip grooves and the hollow middle shaft are arranged on the planing tool rest, so that wood chips are collected in time and in a centralized mode, pollution of the wood chips to the environment is reduced, and the quality of the working environment is improved.

Owner:蔡雪

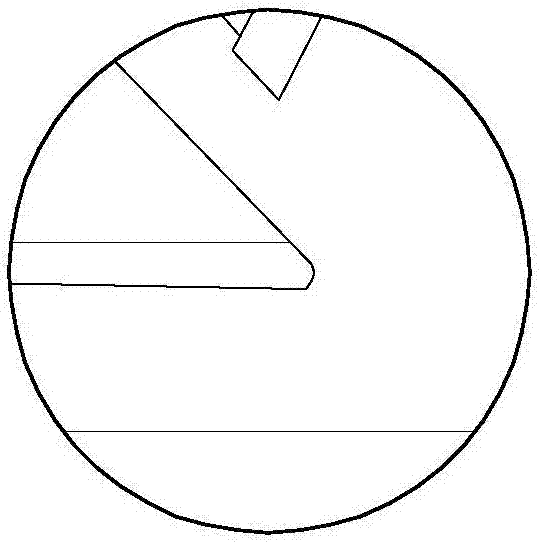

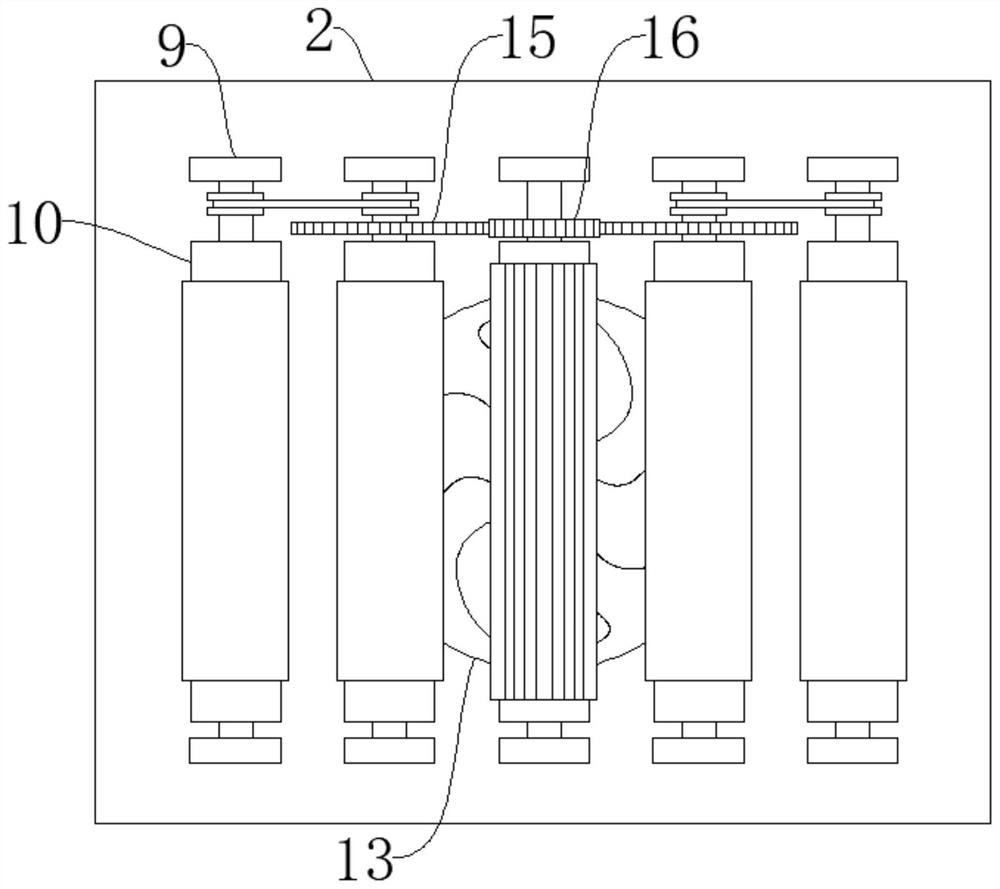

Adjustable multi-section blade structure for automatic planer

InactiveUS20210008752A1Reduce cutting loadMaintain precisionRotary cutting toolsSmoothing machinesClassical mechanicsStructural engineering

An adjustable multi-section blade structure for an automatic planer includes a cutter shaft, a plurality of cutter holders, a plurality of cutters, and a blade calibration tool. The cutter shaft is a long cylinder. The cutter shaft has an outer annular surface and an axis. The cutter holders are arranged at substantially equiangular intervals around the outer annular surface of the cutter shaft. The cutter holders each have a fixing surface, a bearing surface, and an arcuate groove. The cutters are spaced apart from each other and disposed on the fixing surface. In addition to reducing the cutting load, the precision of the blade can be calibrated through the blade calibration tool to achieve an energy-saving effect.

Owner:CHUANG BOR YANN

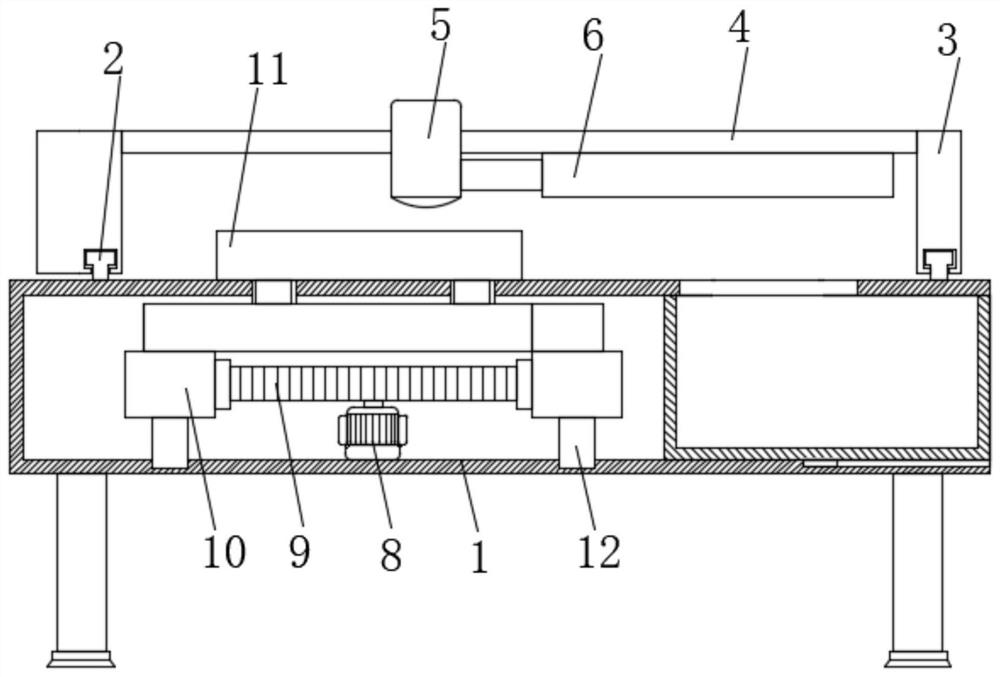

Double-sided planer with oppositely arranged planer tools

PendingCN112720707AIncrease profitSave electricityWood feeding arangementsBark-zones/chip/dust/waste removalSanderElectric machinery

The invention provides a double-sided planer with oppositely arranged planer tools. The double-sided planer comprises a base, a fixed planer body is arranged at the left end of the base, a fixed support is arranged at the right end of the base, a sliding rail is arranged at the position, between the fixed planer body and the fixed support, of the base, a movable planer body is arranged on the sliding rail, and the movable planer body is connected with the fixed support through an adjusting screw rod. The adjusting screw rod is connected with a motor through a chain, a planer tool A and a planer tool B are arranged on the two corresponding faces of the fixed planer body and the movable planer body respectively, the planer tool A and the planer tool B are arranged correspondingly, and the center lines of the planer tool A and the planer tool B are located on the same plane. The double-sided planer with oppositely arranged planer tools is simple in structure and low in manufacturing cost, the front face and the back face of a machined planed plate are flat and free of defects, the utilization rate of the machined plate is increased, the production cost is reduced, the planing effect on a stock board is good, the utilization rate of a sander is reduced, the electricity and labor cost is reduced for enterprises, and dust pollution to the environment is reduced.

Owner:烟台三奇智能科技有限公司

Planing machine for furniture wood

InactiveCN112571526AReduce workloadImprove practicalityWood feeding arangementsSmoothing machinesWood machiningElectric machinery

The invention relates to the technical field of furniture wood processing, in particular to a planing machine for furniture wood. According to the machine, a lifting support is enabled to move downwards by rotating a first lead screw and through threaded transmission, a mounting seat is driven to move downwards to enable a conveying belt to press the wood placed at the top end of a front workbench, a first motor is turned on, by means of transmission of a first speed reducer, a first roller and the conveying belt are driven to rotate, and the conveying belt conveys the wood, so that the workload of operators is reduced, and the practicability is improved. The machine comprises a base, a mounting plate, a rotary planer tool, the front workbench, a rear workbench and a guide plate; and the device further comprises a pressing support, two sets of sliding supports, the first lead screw, the lifting support, the mounting seat, the first roller, a second roller, a third roller, the conveyingbelt, the first motor and the first speed reducer, wherein the pressing support is mounted at the rear end of the base, and two sets of sliding rails are arranged on the pressing support.

Owner:山东珍木园家居有限公司

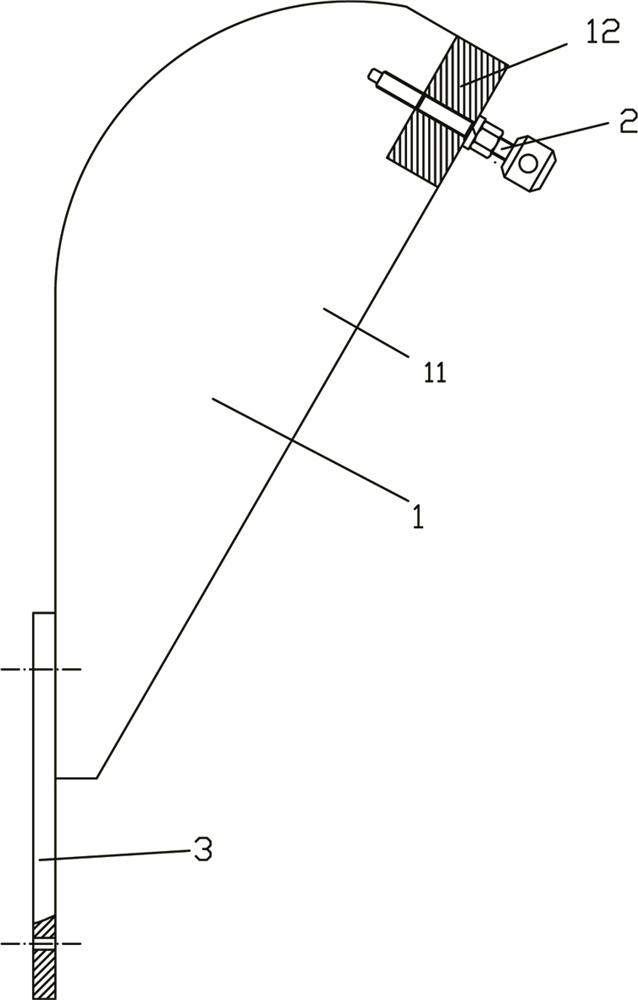

Inclined planer capable of easily discharging chips

PendingCN113770435AIncrease cutting forceRealize the rationalization of forcePlaning/slotting machinesEngineeringStructural engineering

An inclined planer capable of easily discharging chips comprises a base and a planer tool seat connected with a planer tool. The inclined planer is characterized in that the base is provided with a planer tool body which is not less than 15 degrees and inclines in the planer tool feeding direction, and the planer tool body is movably connected with the planer tool seat through lead screws arranged on the two sides of the planer tool body; and the planer tool seat is hinged to a balance traction table through paired rigid connecting rods and paired elastic connecting rods, the elastic connecting rods are lower than the rigid connecting rods, and the balance traction table is movably connected with the lead screws. The inclined planer tool body is adopted, the balance traction table is connected with the planer tool seat through the elastic connecting rods and the rigid connecting rods, stress rationalization of a planer tool frame is achieved, the cutting force of the planer tool is improved through the resultant force action of inclined gravity, the equipment size is not additionally increased, and chip removal is facilitated.

Owner:余锦波

Wood planing machine equipment with adjustable planing head

The invention relates to the technical field of wood planing machines, and discloses wood planing machine equipment with an adjustable planing head. The equipment comprises the planing head and a working platform, a driving shaft is rotatably connected to the interior of the planing head, a first gear is rotatably connected to the middle of the driving shaft, and a first notch is slidably connected to the surface of the first gear; and a first long plate is fixedly connected to the surface of the first notch, and a second gear is fixedly connected to the right side of the first long plate. According to the wood planing machine equipment with the adjustable planing head, a third long rod is pressed to slide in a fourth notch, the third long rod drives a second gear on a second long rod to slide in a third notch, the second gear is fixedly connected with a first long plate, a small fan-shaped part of an inclination device is fixedly connected with the working platform, and a large fan-shaped part of the inclination device is fixedly connected with the first long plate; and the second gear drives the first long plate to slide along the L-shaped third notch, and the first long plate drives the planing head to do inclined motion, so that the effect of adjusting the inclination angle between the planing head and the wood is achieved.

Owner:吴清华

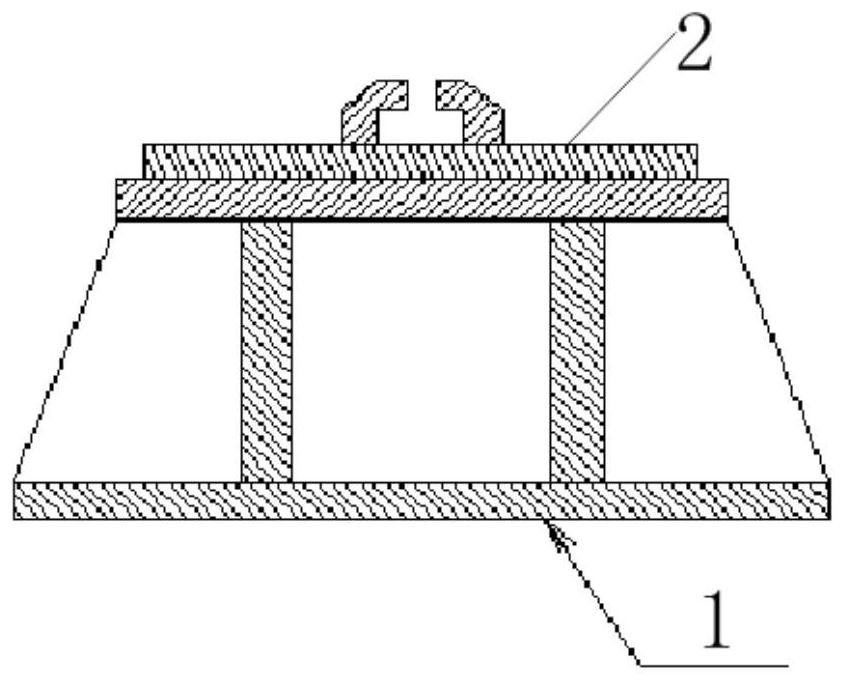

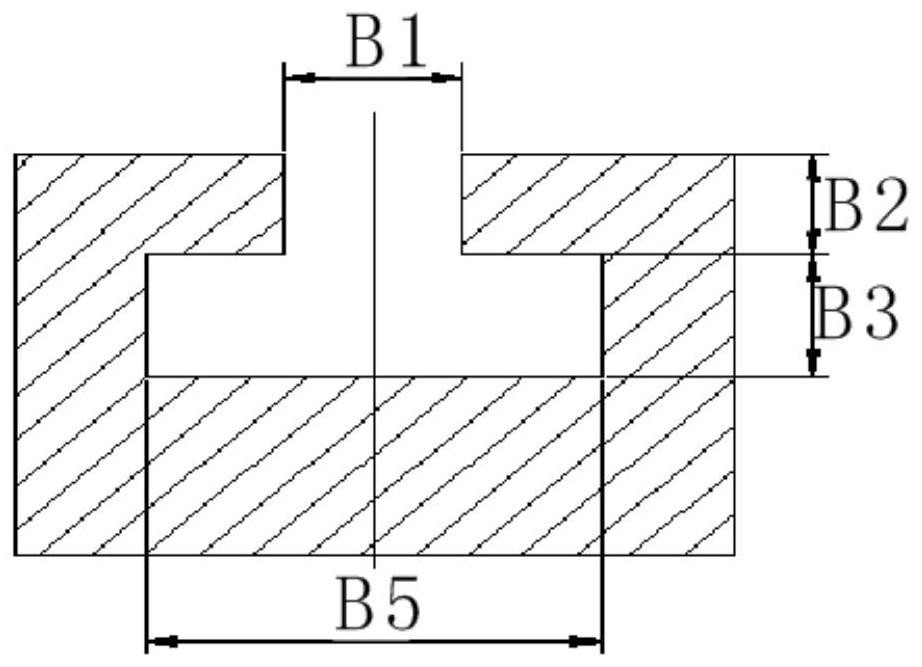

A processing method for ultra-long and narrow T-slots

Owner:HUBEI JIANGSHAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com