Panel planer and thicknesser for wooden packaging box production

A packaging box, single-sided technology, used in planers, wood processing appliances, processing machines for manufacturing flat surfaces, etc., can solve the problems of large wood chips and large pollution in the production workshop, and achieve the effect of reducing pollution and improving synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

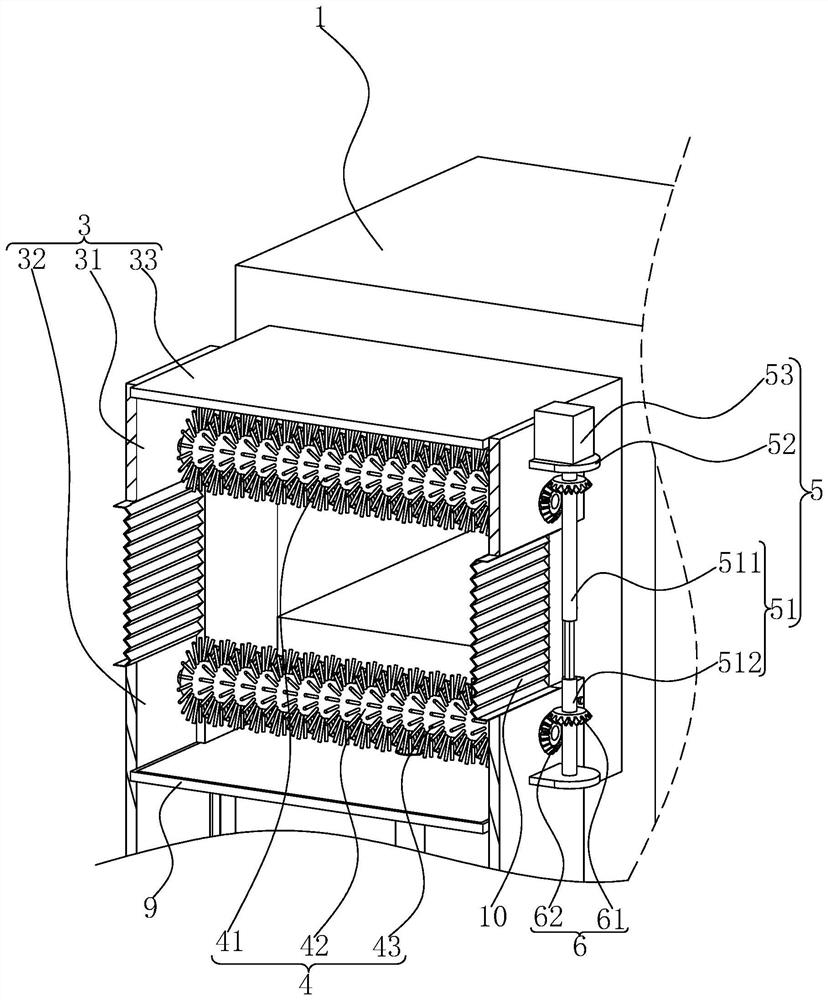

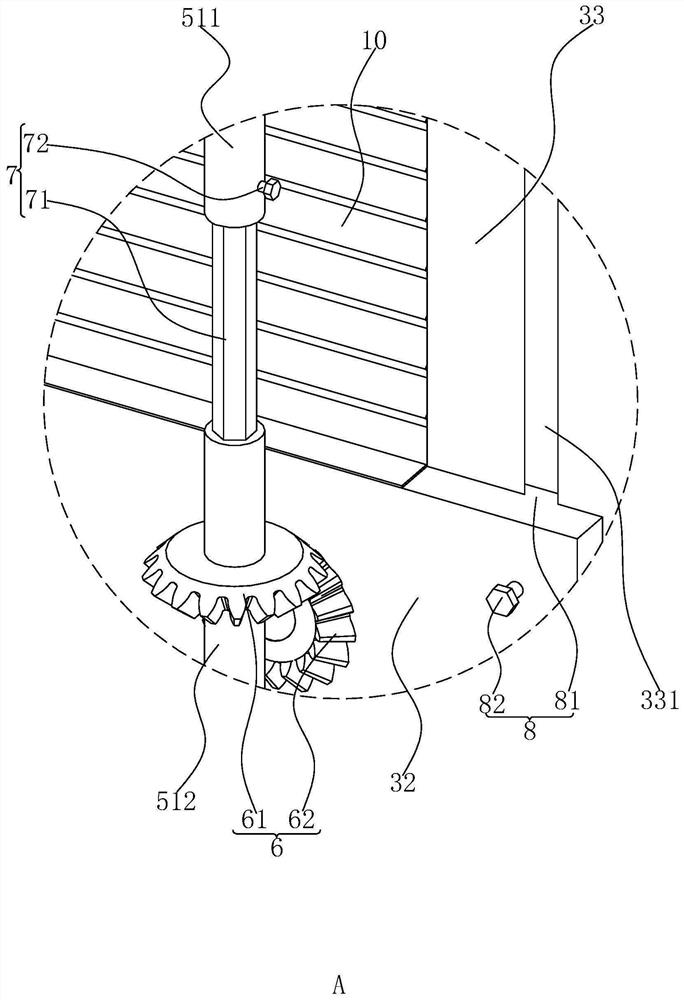

[0031] The following is attached Figure 1-3 The application is described in further detail.

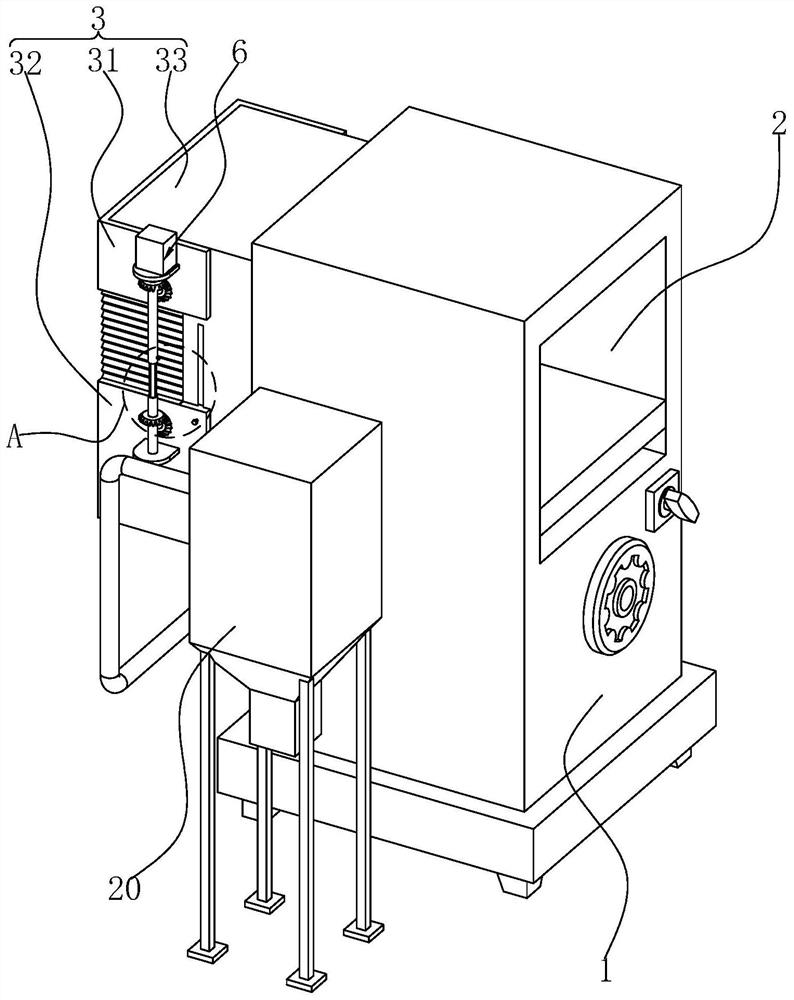

[0032] The embodiment of the present application discloses a single-sided woodworking planer for the production of wooden packaging boxes. refer to figure 1 and figure 2 A single-sided woodworking planer for the production of wooden packaging boxes includes a body 1, a planing device 2 and a sawdust collection device 3, the body 1 is vertically arranged, the bottom of the body 1 is fixedly connected to the ground, and the planing device 2 is arranged on the body 1, the planing device 2 is fixedly connected with the machine body 1, and the sawdust collection device 3 is arranged at the discharge port of the planing device 2. When using a single-sided woodworking planer, start the machine body 1, feed the planks from the feed port of the planing device 2, use the planing device 2 to plan the planks, and the wood chips produced by planing enter the collection cylinder 33 for collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com