Double-sided planer for vertical planing

A double-sided planer and planing technology, which is used in the manufacture of flat surface processing machines, workpiece feeding devices, wood processing appliances, etc. Great cleaning difficulty, improved dust removal effect, and improved practicality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

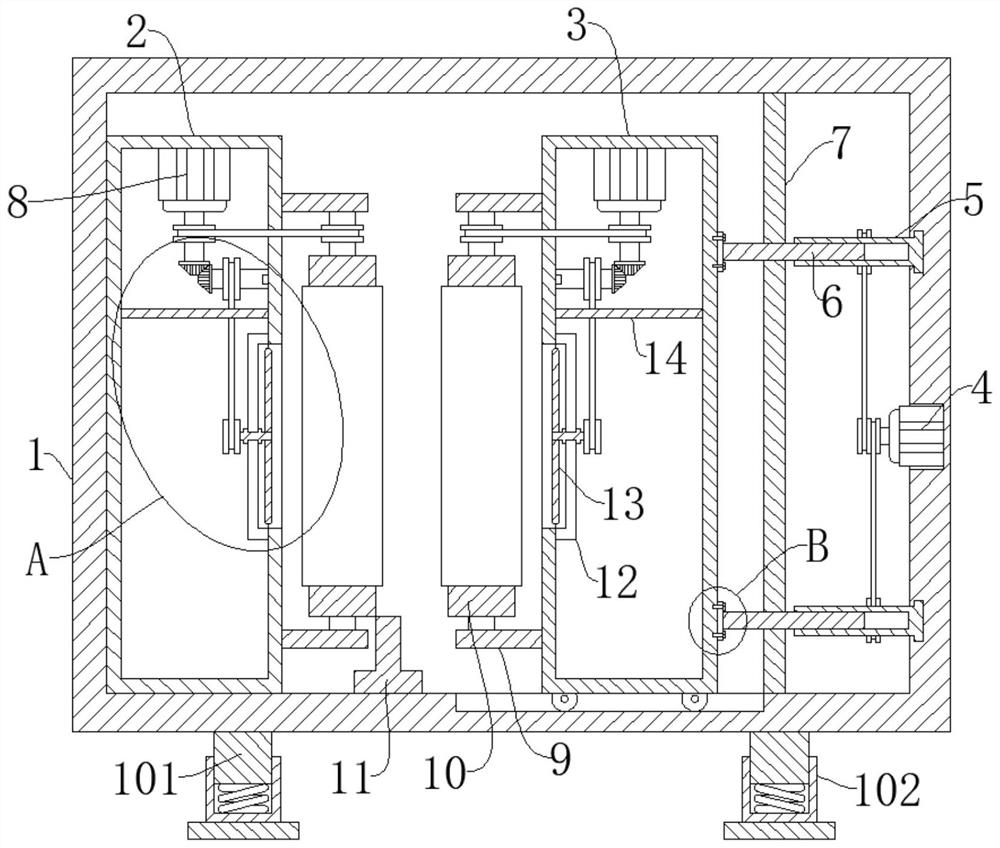

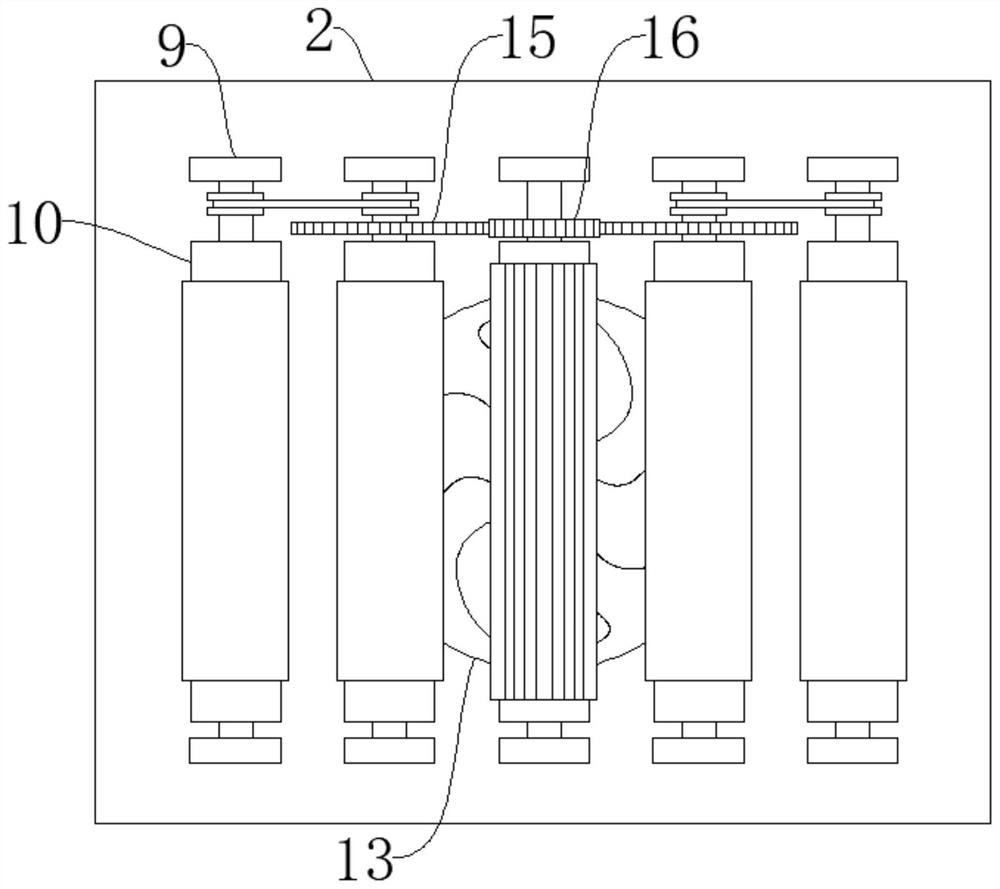

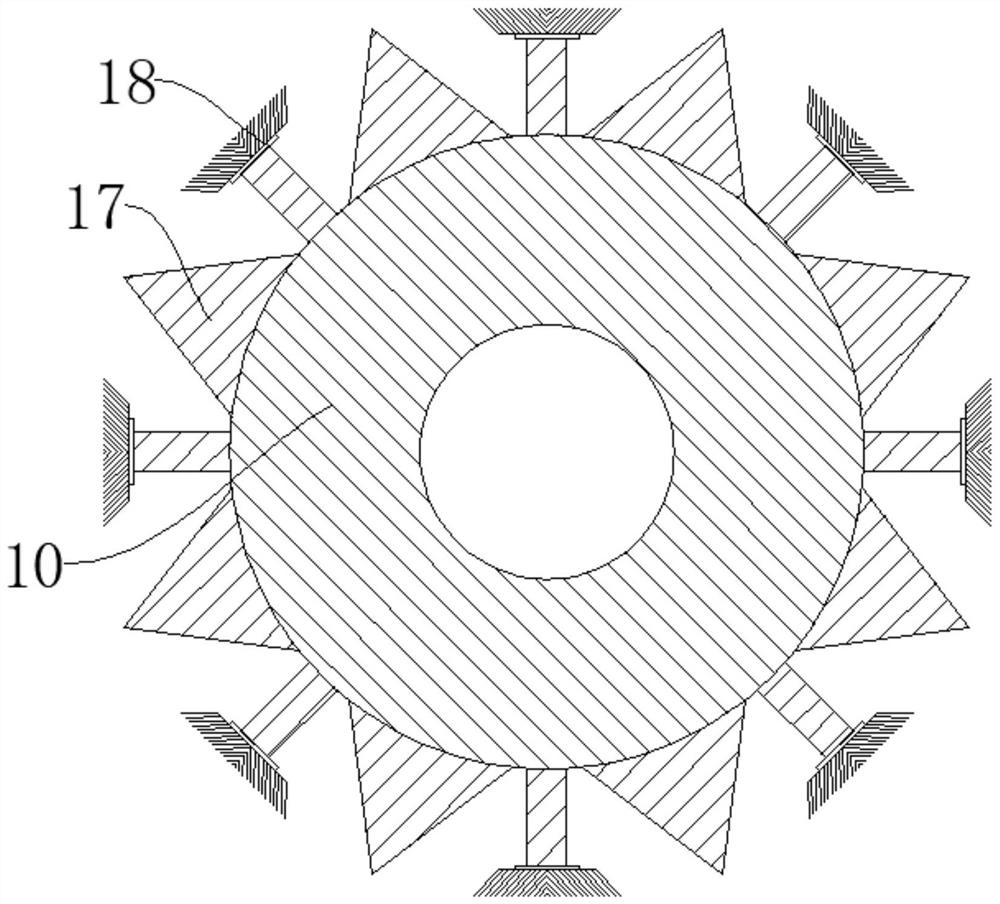

[0029] refer to Figure 1-8 , a double-sided planer for vertical planing, comprising a fixed frame 1, a fixed box 2, and a movable box 3, the fixed box 2 is fixedly connected to one side of the fixed frame 1, and the lower end of the side of the fixed frame 1 away from the fixed box 2 is provided There is a chute, the mobile box 3 is slidingly connected in the chute by rollers, the upper and lower ends of the inner side of the fixed box 2 and the mobile box 3 are fixedly connected with multiple sets of matching support blocks 9, and each two support blocks 9 are rotated A transmission roller 10 is connected, a plurality of planers 17 are fixedly connected to the surface of the middle transmission roller 10, a cleaning brush 18 is fixedly connected between every two planers 17, and a pinion 16 is fixedly connected to the middle transmission roller 10, which is connected with the planer. 17 Adjacent conveying rollers 10 are fixedly connected with a large gear 15, and the pinion ...

Embodiment 2

[0032] refer to figure 1 and Figure 6 , a double-sided planer for vertical planing, which is basically the same as Embodiment 1, and furthermore: the drive mechanism includes a first motor 8, a first output shaft, a second output shaft 20, and the first output shaft is fixedly connected to the second output shaft. On the output end of a motor 8, a first driving wheel is sleeved on the first output shaft, the first driving wheel and one of the first driven wheels are connected by a belt, and the end of the first output shaft away from the first motor 8 is fixedly connected There is a first bevel gear 22, a second bevel gear 21 meshed with the first bevel gear 22 is fixedly connected to the second output shaft 20, and a second driving wheel is sleeved on the second output shaft 20, when the transmission roller 10 clamps After the plate is tightened, start the first motor 8 at this time, the first motor 8 drives the first output shaft to rotate, the first output shaft drives th...

Embodiment 3

[0034] refer to figure 1 and Figure 6 , a double-sided planer for vertical planing, which is basically the same as Embodiment 1, and furthermore: the collection mechanism includes a support frame 12, an impeller 13, and one end of the fixed box 2 and the mobile box 3 near the planer 17 is provided with a collection The support frame 12 is fixedly connected to the collection port, and the impeller 13 is rotatably connected to the support frame 12. One end of the impeller 13 away from the planer 17 is fixedly connected with a second driven wheel, and the second driving wheel on the second output shaft 20 is connected with the second The driven wheels are connected by a belt. When the second bevel gear 21 drives the second output shaft 20 to rotate, the second output shaft 20 drives the second driving wheel to rotate, and the second driving wheel drives the second driven wheel to rotate through the belt. , so that the second driven wheel drives the impeller 13 to rotate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com