Wood planing machine with backstop

A backstop, woodworking planer technology, applied in the direction of manufacturing tools, wood processing appliances, processing machines for manufacturing flat surfaces, etc., can solve problems such as damage to planers, threats to the safety of operators, and wood being easily knocked back, so as to improve production. Efficiency, reduce energy consumption, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

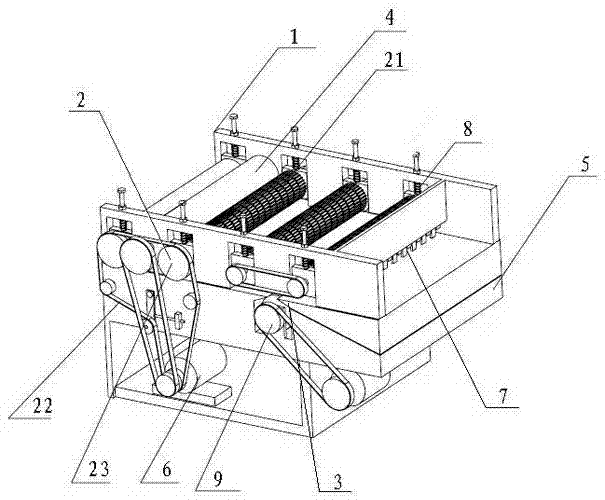

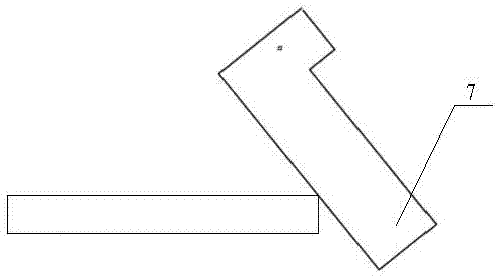

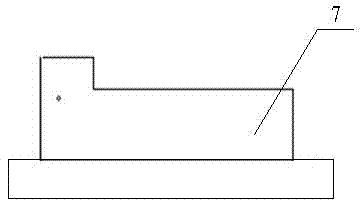

[0031] Such as figure 1 As shown, a woodworking planer with a backstop includes a frame 1, a transmission mechanism 2, a lower planing mechanism 3, an upper planing mechanism 4, a workbench 5, and a drive mechanism 6. The frame 1 is set on the workbench 5 and prop up the transmission mechanism 2, the transmission mechanism 2 transmits the wood placed on the workbench 5, the lower planing mechanism 3 planes the wood conveyed by the transmission mechanism 2 under the drive of the driving mechanism 6, and the upper planing mechanism 4. Under the driving of the driving mechanism 6, the upper end planing is carried out on the wood conveyed by the transmission mechanism 2, and a backstop 7 is arranged between the lower planing mechanism 3 and the frame 1; the backstop is composed of a plurality of backstop pieces; There is a height difference between the two adjacent anti-reverse pieces mentioned above; the worktable 5 includes a fixed table 41 and a movable table 42, the movable ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com