Patents

Literature

31 results about "WOOD TREATERS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel wood flour and rice hull powder mixed type thermoplastic wood-plastic composite material and preparation method thereof

The invention discloses a novel wood flour and rice hull powder mixed type thermoplastic wood-plastic composite material and a preparation method of the composite material. The composite material is prepared by adopting wood flour, rice hull powder and HDPE (high-density polyethylene) resin in combination with certain surface conditioning agent and a processing auxiliary agent and utilizing the polymer interface chemistry principle and plastic filling modification characteristic through mixing in a high-speed mixer and granulating with a extruder. The processed sectional material takes inexpensive and rich rice hull powder as a main raw material, has appearance like wood, better dimensional stability than wood, no crack, warping or knot, higher hardness than plastic and good physical mechanical performance, can be re-processed by an universal wood processing method, and is waterproof, anti-corrosive, vermin-proof, aging-resistant, repeatedly recyclable and environment-friendly.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

Comprehensive utilization of phenol-containing wastewater

InactiveCN102241802AEfficient use ofAldehyde/ketone condensation polymer adhesivesWater/sewage treatment by neutralisationThermoplasticWastewater

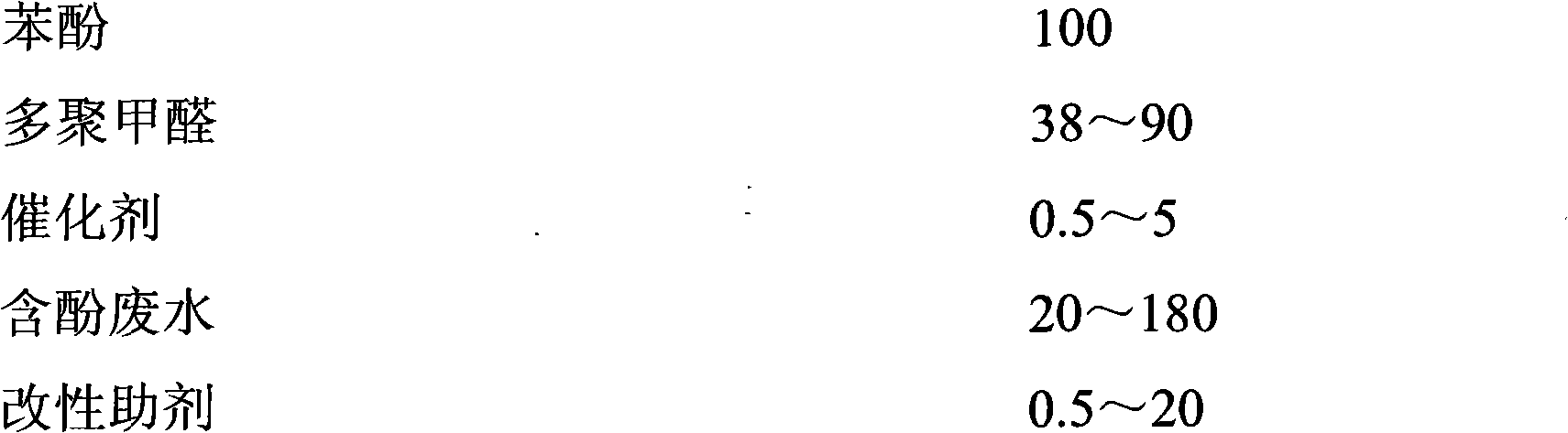

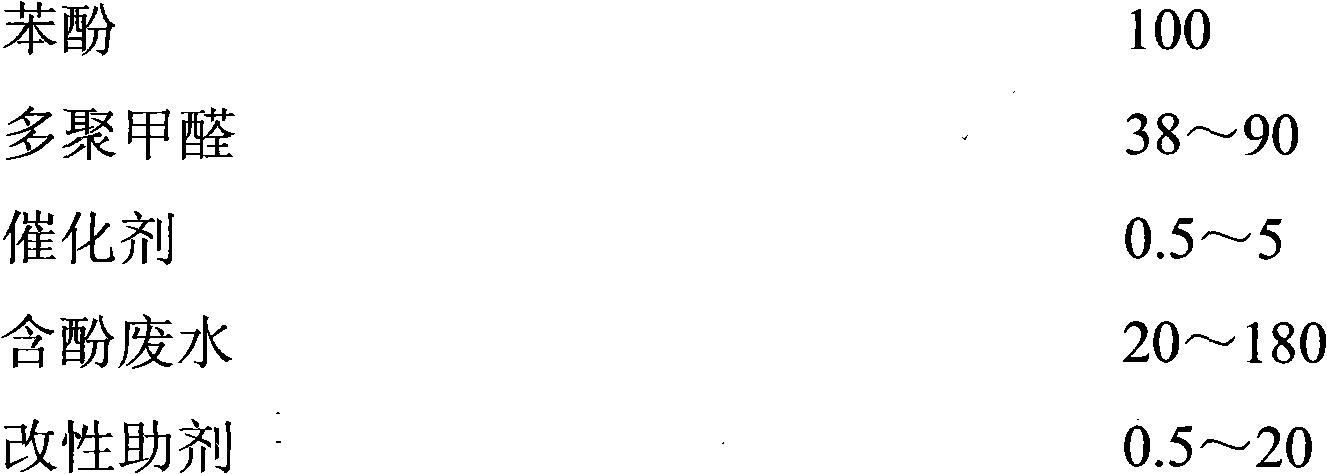

The invention relates to a method for treating phenol-containing wastewater by regulating the pH value of the phenol-containing wastewater generated in phenolic resin (comprising thermoplastic and thermoset phenolic aldehyde) production and synthesizing into thermoset liquid phenolic resin having different purposes. The thermoset liquid phenolic resin can be applied to producing rockwool glue, wood glue, expandable phenolic resin, grinding materials, coatings and the like; the wastewater is comprehensively utilized; and the zero emission of the phenol-containing wastewater generated in the phenolic resin production is realized. The thermoset liquid phenolic resin is prepared from the following raw materials in part by mass: 100 parts of phenol, 38 to 90 parts of paraformaldehyde, 0.5 to 5 parts of catalyst, 20 to 180 parts of phenol-containing wastewater and 0.5 to 20 parts of modification aid.

Owner:BEIJING UNIV OF CHEM TECH

One part woodworking adhesive composition

InactiveUS6872278B2Improve shelf life stabilityImprove relationshipMonocarboxylic acid ester polymer adhesivesSynthetic resin layered productsEmulsionPolymer science

An adhesive composition that includes a) an emulsion that includes a multi-stage polymer that includes a first stage polymer having a Tg from −20° C. to 90° C. and including from about 0.5% by weight to about 3% by weight latent crosslinking monomer based on the first stage monomer weight, and a second stage polymer having a Tg from 40° C. to 140° C., the second stage polymer being different from the first stage polymer, b) formaldehyde-based crosslinking agent, and c) catalyst, the composition being capable of passing the DIN EN 204 Test Method.

Owner:HB FULLER CO

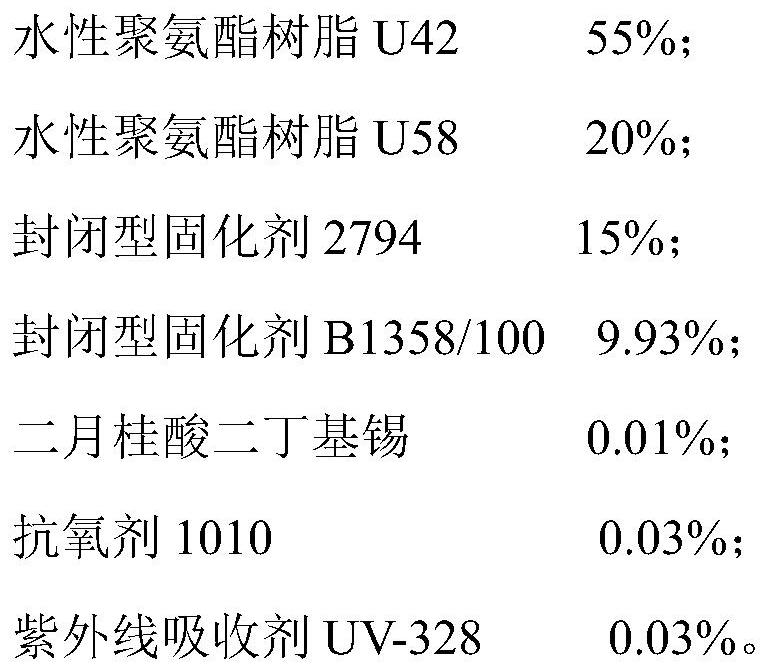

Latent single-component polyurethane hot melt adhesive, preparation method thereof and adhesive film

ActiveCN111100592AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

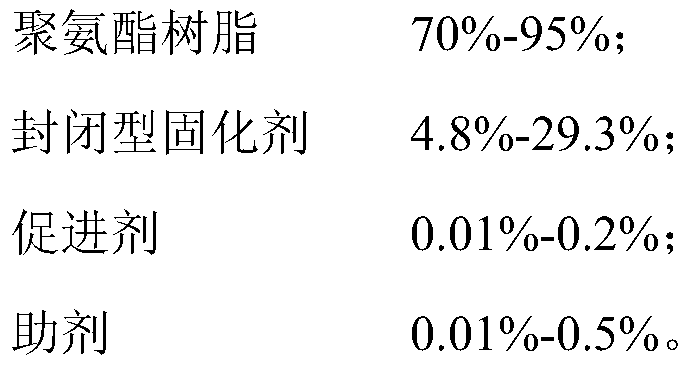

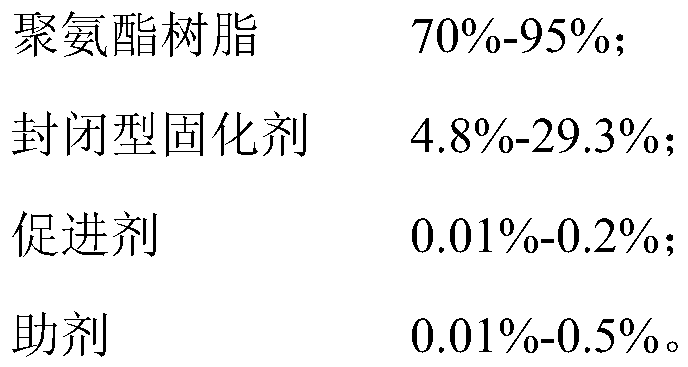

The invention relates to the field of polymer adhesives, in particular to a latent single-component polyurethane hot melt adhesive, a preparation method thereof and an adhesive film. The latent single-component polyurethane hot melt adhesive comprises the following components (by weight): 70%-95% of polyurethane resin, 4.8%-29.3% of a closed curing agent, 0.01%-0.2% of an accelerant, and 0.01%-0.5% of an auxiliary agent. The latent single-component polyurethane hot melt adhesive disclosed by the invention has good bonding strength, heat resistance, hydrolysis resistance and the like; the preparation method is simple in process, low in cost and high in preparation efficiency, and has a prospect in industrial production; a latent single-component polyurethane adhesive film obtained by curingthe latent single-component polyurethane hot melt adhesive has good initial adhesion, excellent final adhesion and storage stability; and the product can be widely used in woodworking, textile, outdoor clothing, automobiles, electronics, household appliances and other industries.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

Quick-drying high-strength carpenter's glue and preparation method thereof

InactiveCN107488421AFast dryingGood water resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionSurface-active agents

The invention provides quick-drying high-strength carpenter's glue which is prepared from 10.0 to 50.0% of deionized water, 20.0 to 70.0% of polyvinyl acetate emulsion, 3.0 to 10.0% of polyvinyl alcohol, 0.1 to 5.0% of organic silicon modifier, 0.5 to 5.0% of plasticizer, 0.1 to 2.0% of thickener, 1.0 to 6.0% of antifreezing agent, 0.20 to 1.0% of preservative, 0.10 to 0.5% of defoamer, 0.1 to 1.0% of surface active agent, 0.1 to 2.0% of coalescing agent, 0 to 20.0% of waterborne polyurethane and 0 to 5.0% of filler. A preparation method comprises the steps of adding deionized water, polyvinyl alcohol powder, thickener and plasticizer into a reaction kettle, introducing steam to warm, then adding a half of the defoamer, cooling to 55 DEG C, adding the rest half of the defoamer, then adding the polyvinyl acetate emulsion, adding the waterborne polyurethane, the organic silicon modifier and the filler, evenly stirring, then adding the surface active agent, the coalescing agent and the preservative, standing to defoam and filling to obtain the carpenter's glue. The quick-drying high-strength carpenter's glue has the advantages of quick drying speed, good cold and water resistance, high adhesive strength and good creep resistance.

Owner:NINGBO PASCO UNITED IND

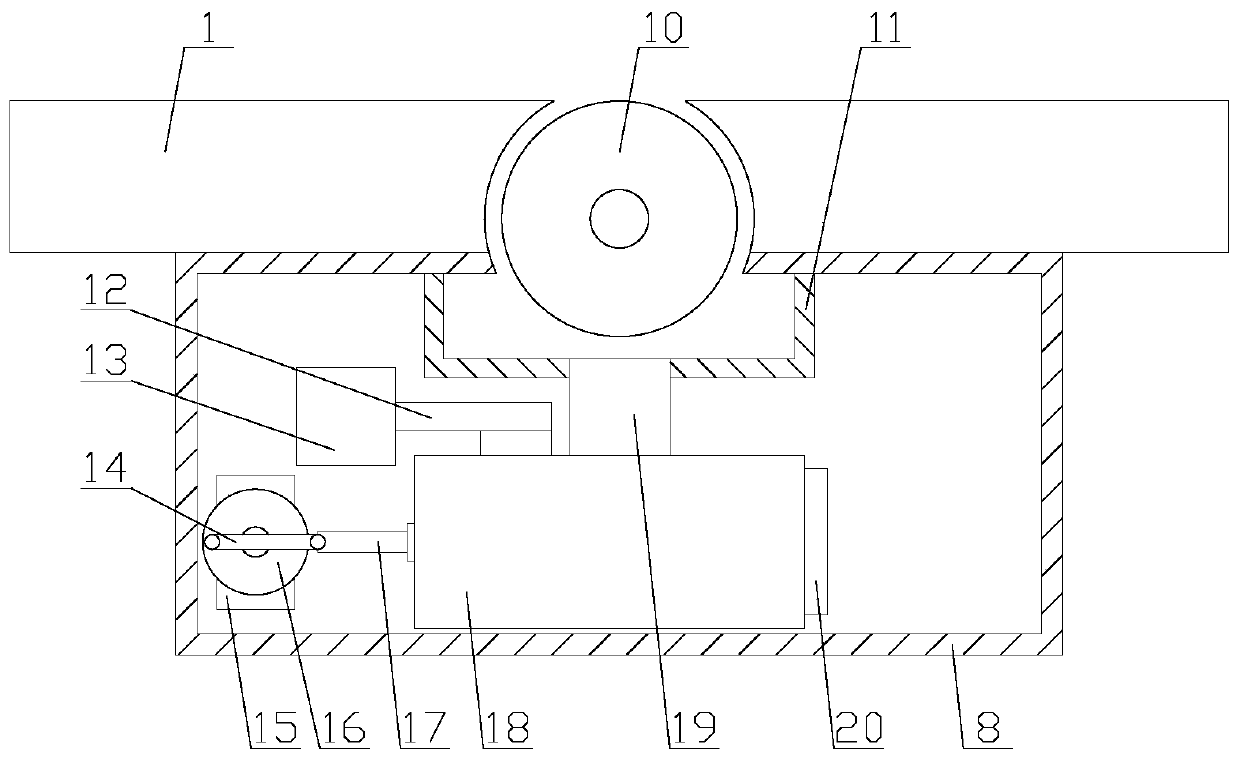

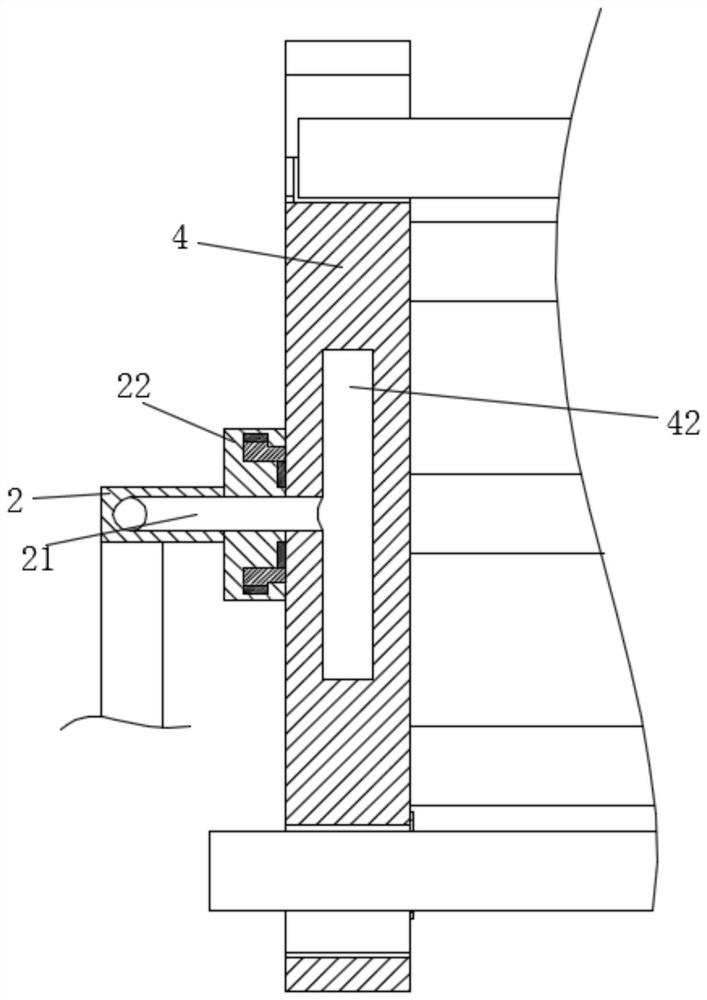

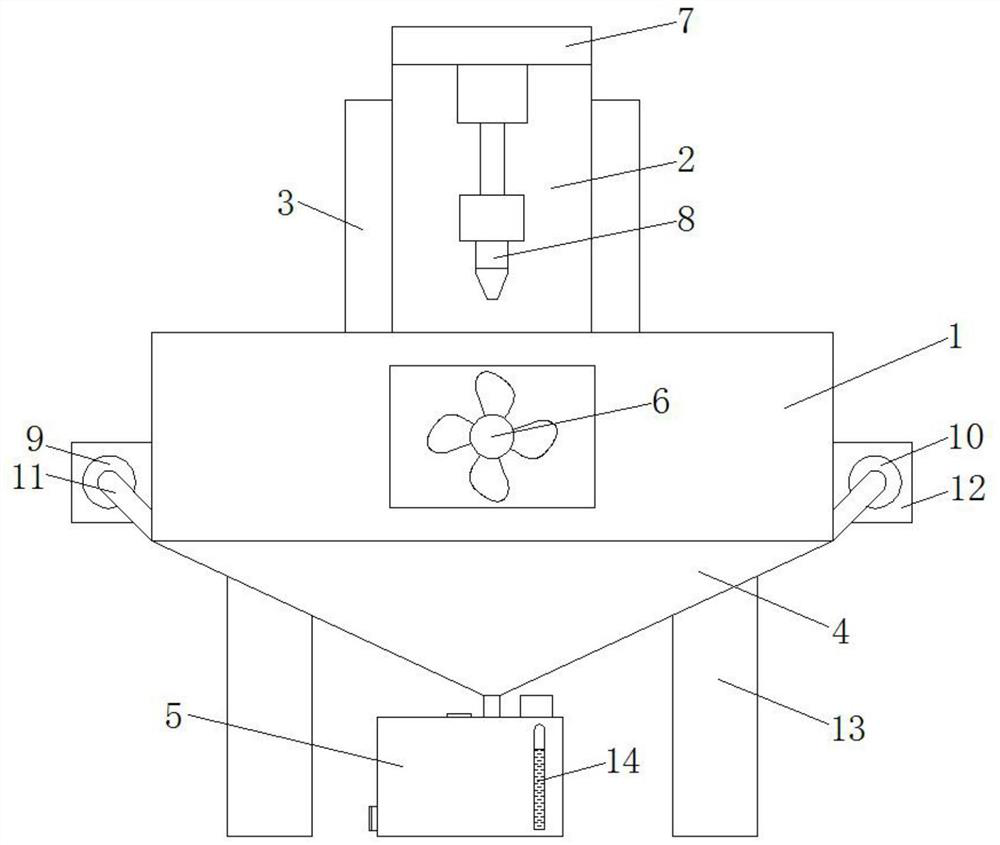

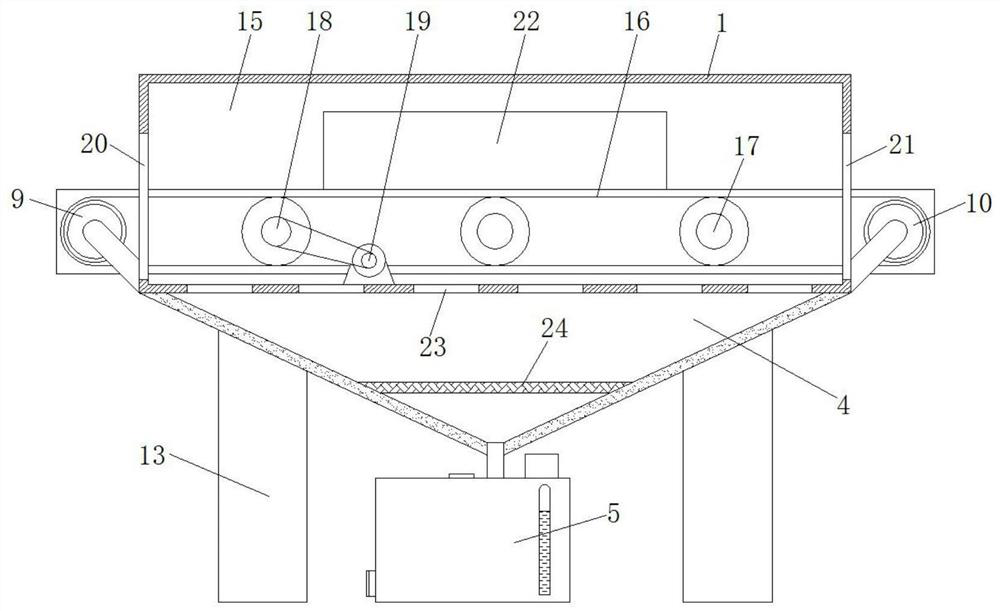

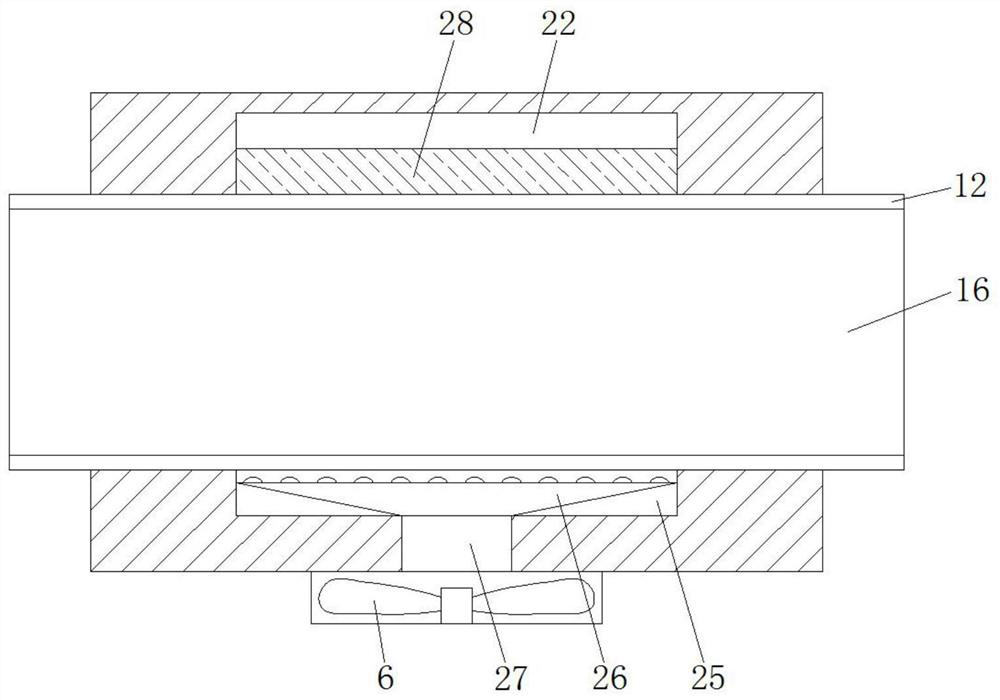

Wood planer with high processing accuracy and wood dust recycling function

InactiveCN110757589AImprove securityImprove environmental performanceWood feeding arangementsBark-zones/chip/dust/waste removalWOOD TREATERSElectric machine

The invention relates to a wood planer with high processing accuracy and a wood dust recycling function. The wood planer with the high processing accuracy and the wood dust recycling function comprises an operation table, a planer tool and a base, and further comprises a positioning mechanism and a cleaning mechanism, wherein the positioning mechanism comprises a lifting rod, a positioning roller,a first motor, a distance sensor, two air cylinders and two fixed components; the cleaning mechanism comprises a dust suction hood, a collection box, a conveying pipe, a driving component, a second transmission rod, a supporting casting pipe, an extrusion plate, cleaning bars, an exhaust pump, an exhaust pipe and a filter screen; each fixed component comprises a fixed casing pipe and a fixed rod;and the driving component comprises a second motor, a rotary table, and a first transmission rod. According to the wood planer with the high processing accuracy and the wood dust recycling function,the positioning mechanism can be used for controlling the speed of wood movement and the pressure on wood, so that the precision of processing the wood by the planer is improved; and the cleaning mechanism can be used for collecting wood dust generated when the planer works, and thus, the environmental protection performance of the planer is improved.

Owner:何桂华

Woodworking binder

InactiveCN105802557AReasonable formula designSimple production processStarch adhesivesMacromolecular adhesive additivesPolymer scienceAcrylonitrile

The invention discloses a woodworking binder. The woodworking binder is prepared from E-51 epoxy resin, liquid butadiene-acrylonitrile rubber, a curing agent, modified tree ash, styrene, polyisobutylene, di-(2-ethylhexyl)-4, 5-epoxytetrahydrophthalate, acrylate, sodium persulfate, pure acrylic emulsion, corn starch, sodium dodecyl sulfate and water according to an appropriate weight part ratio. The woodworking binder has a reasonable formula design, can be prepared by simple processes, can be dried fast, does not produce foam, has large bonding strength and has good water resistance.

Owner:SHIFANG MIDEE WOOD IND

Wood-plastic material replacing solid wood plate

InactiveCN102924946ASolve processability problemsEasy to processPlastic materialsMaterials processing

The invention discloses a wood-plastic material replacing a solid wood plate. The wood-plastic material consists of the following components in percentage by weight: 20-45% of polypropylene reworked material, 51-70% of crop straw powder, 0.2-2.0% of lubricant, 3-15% of cladding agent, 1.0-8.0% of coupling agent, 1.0-5.0% of moisture absorbent, 0.5-2.0% of anti-aging agent and 0.1-5.5% of other auxiliaries. The extrusion plate special wood-plastic material replacing a solid wood plate disclosed by the invention solves the problems of material processability and material strength; the material can be applied to the extrusion production of various high-strength plates; the product has a beautiful appearance much like the wood appearance as well as the natural smell of wood, and the strength is much higher than that of a common solid wood plate; meanwhile, the wood-plastic material can be cut at will according to the woodwork requirements without the problems of deformation caused by water soaking and the like; and the service life is remarkably prolonged, and the cost is low.

Owner:KECHUANG POLYMER SUZHOU

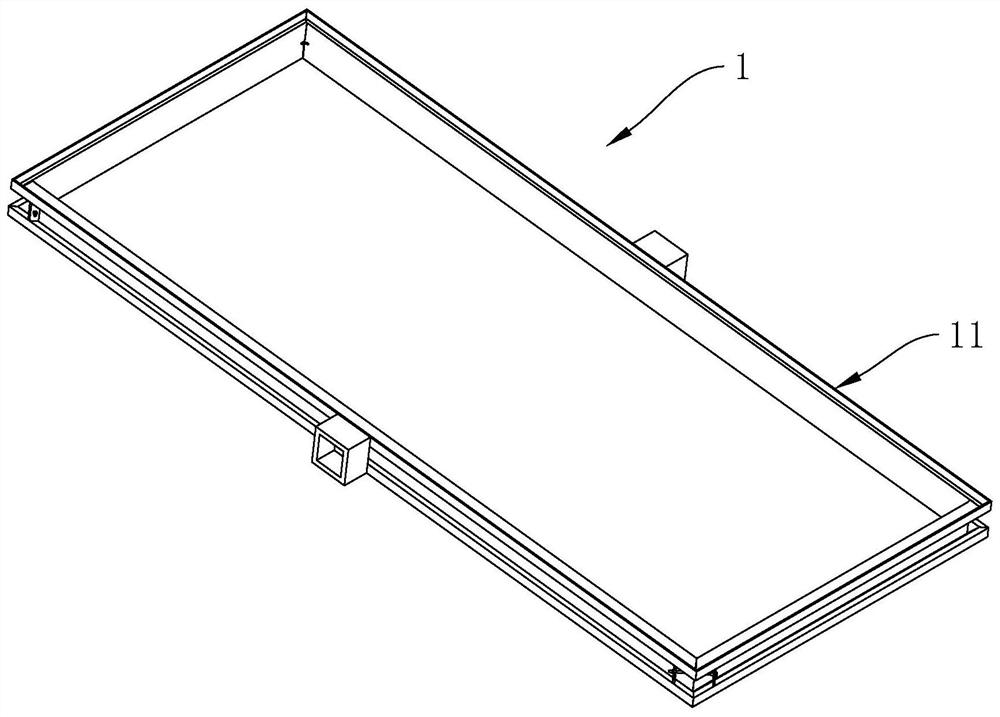

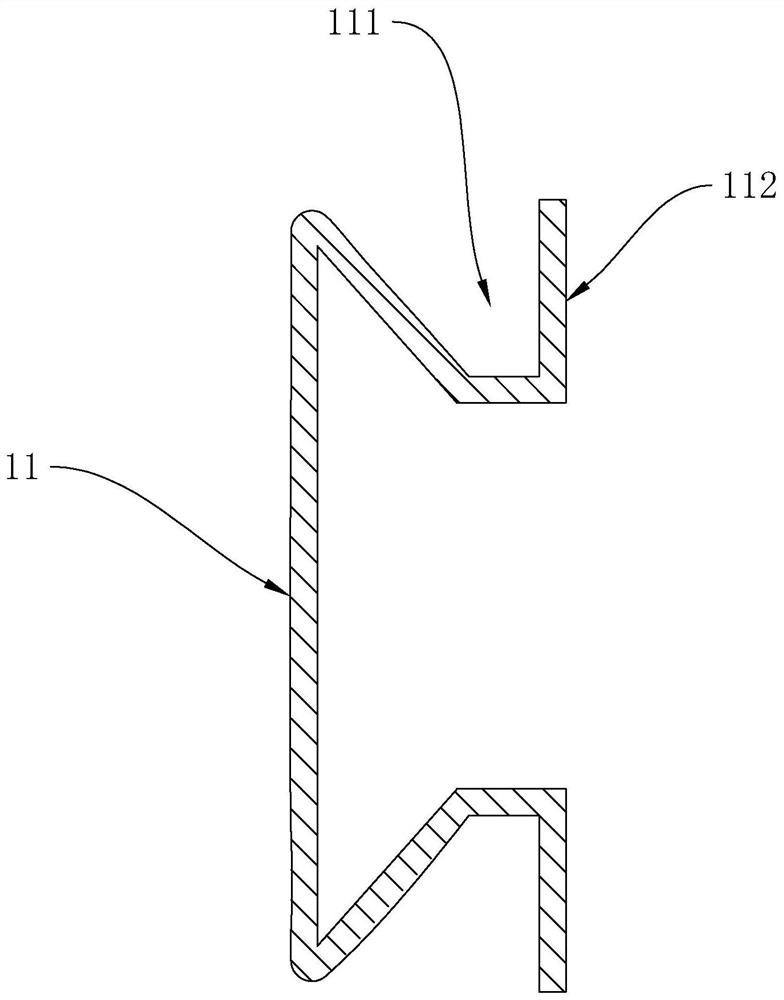

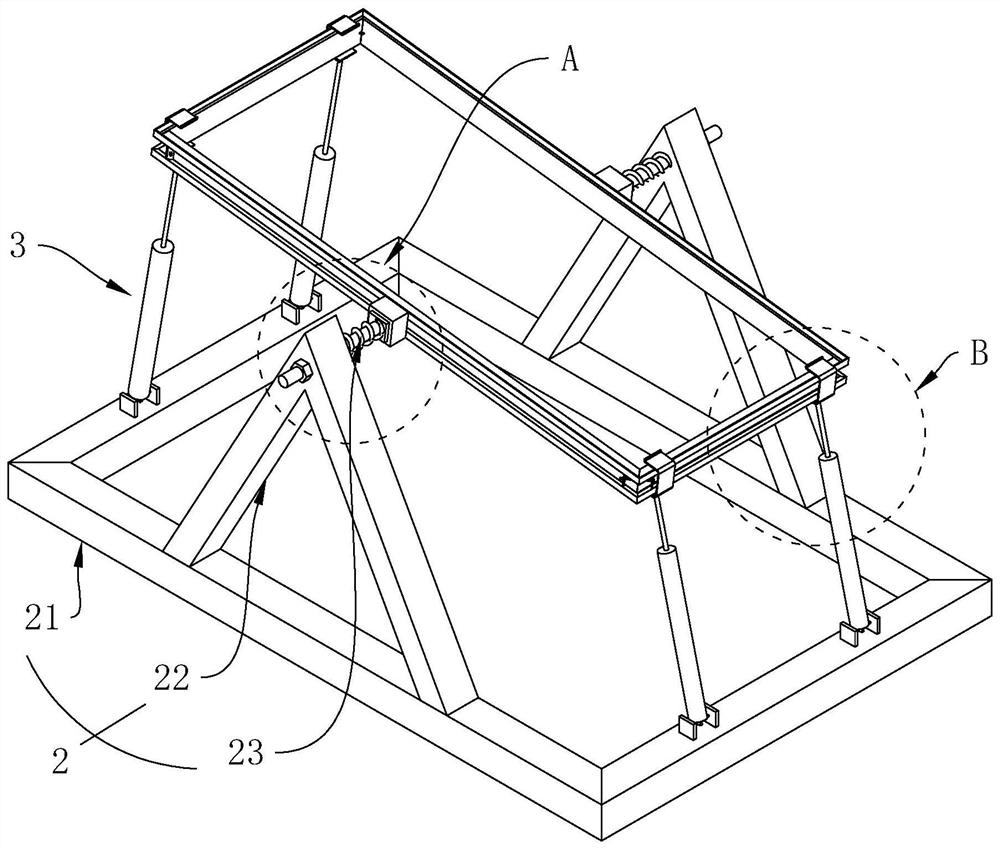

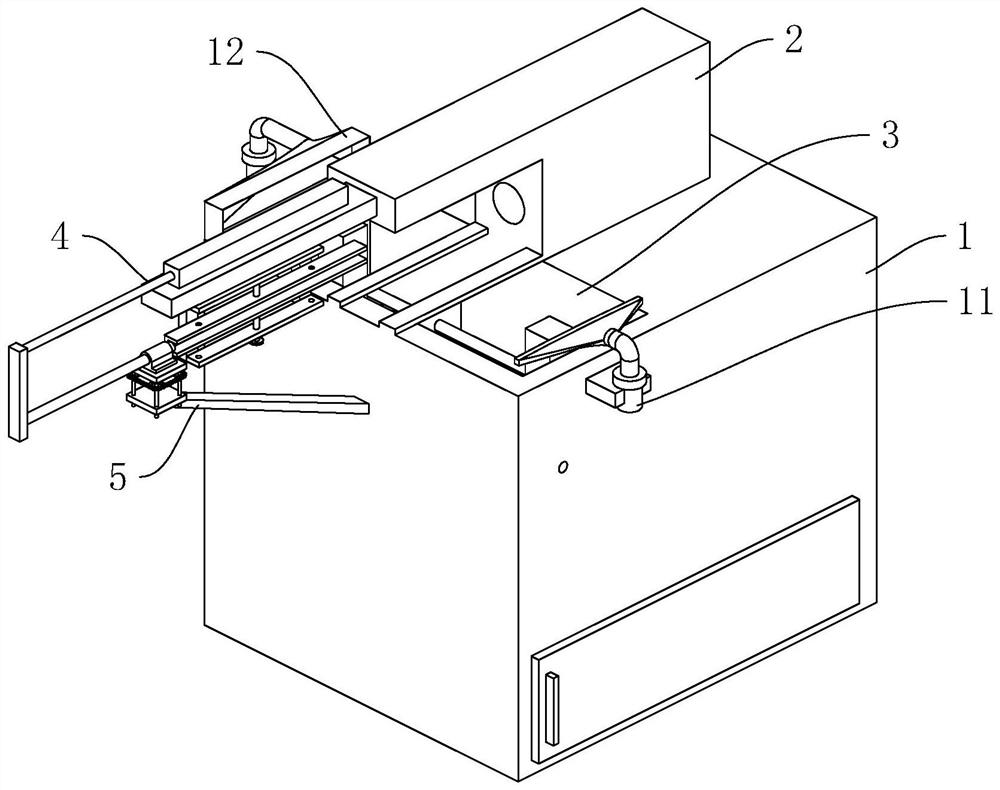

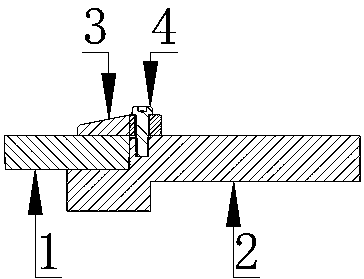

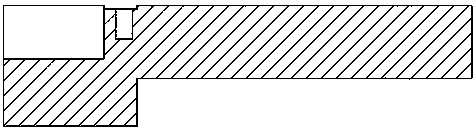

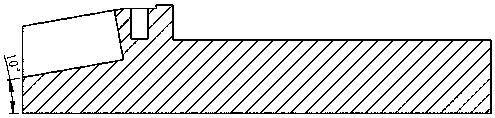

A plywood film coating process and auxiliary device

The present application relates to a plywood film covering process and auxiliary device, and relates to the field of plywood production, which includes the following steps: Step 1, making a limit frame according to the size of the plywood; Step 2, installing the plywood in the limit frame; Step 3 1. Apply wood glue on the surface of the plywood, and then cover the decorative film; step 4, scrape off the air bubbles and excess wood glue between the decorative film and the plywood; step 5, separate the plywood and the limit frame, and cover the film The finished plywood is allowed to air dry. The present application has the effect of improving that the wood glue will flow to the side of the plywood after being scraped out.

Owner:漳州市桥头木业有限公司

Flame-retardant floor coating

InactiveCN104341945AEasy to prepare and useExtended service lifeFireproof paintsPaints with biocidesScrapSaw dust

The invention discloses a flame-retardant floor coating comprising wood powder and urea resin cold-pressing glue, wherein the weight ratio of the wood powder to the urea resin cold-pressing glue is 1.5:8. The wood powder can be saw dust or crushed waste wood, wherein the crushed waste wood can be forest branches, woodworking wastes and the like. The coating disclosed by the invention or floor blocks made of the coating have the characteristics of flame retardance, water tightness, moth prevention, good wear resistance, sound insulation, long service life, low production cost and the like.

Owner:QINGDAO YIQUN PANT GRP

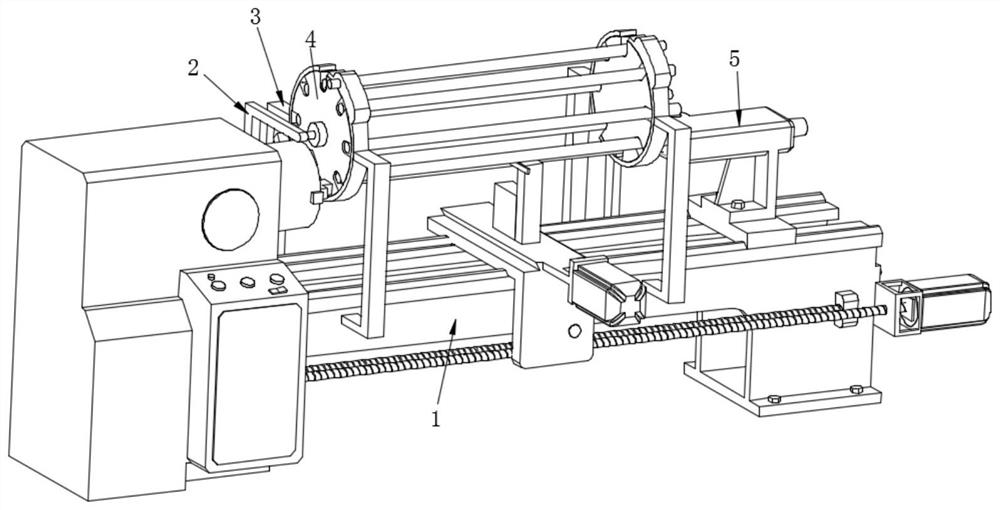

CNC lathe for woodworking

ActiveCN111890480BImplementation orientationImplement targeted collectionWood-turning machinesBark-zones/chip/dust/waste removalWOOD TREATERSWorking environment

The application discloses a numerically controlled lathe for woodworking, which relates to the field of numerically controlled lathes. It includes a machine base and a body mounted on the machine base. The blower on the side and the dust cover, the outer wall of the machine base is provided with a suction fan, the dust cover is connected to the inlet end of the suction fan, and the suction fan is provided with a sewage pipe connected to the inside of the waste tank. This application has the following advantages and effects: by adding a blower and a vacuum cover on the machine base, the guidance and directional collection of the splashed sawdust can be realized, the pollution of the sawdust to the working environment can be reduced, and at the same time, a relatively clean working environment can be provided for the workers to protect their health and safety. Lung health.

Owner:台州一鼎数控机床有限公司

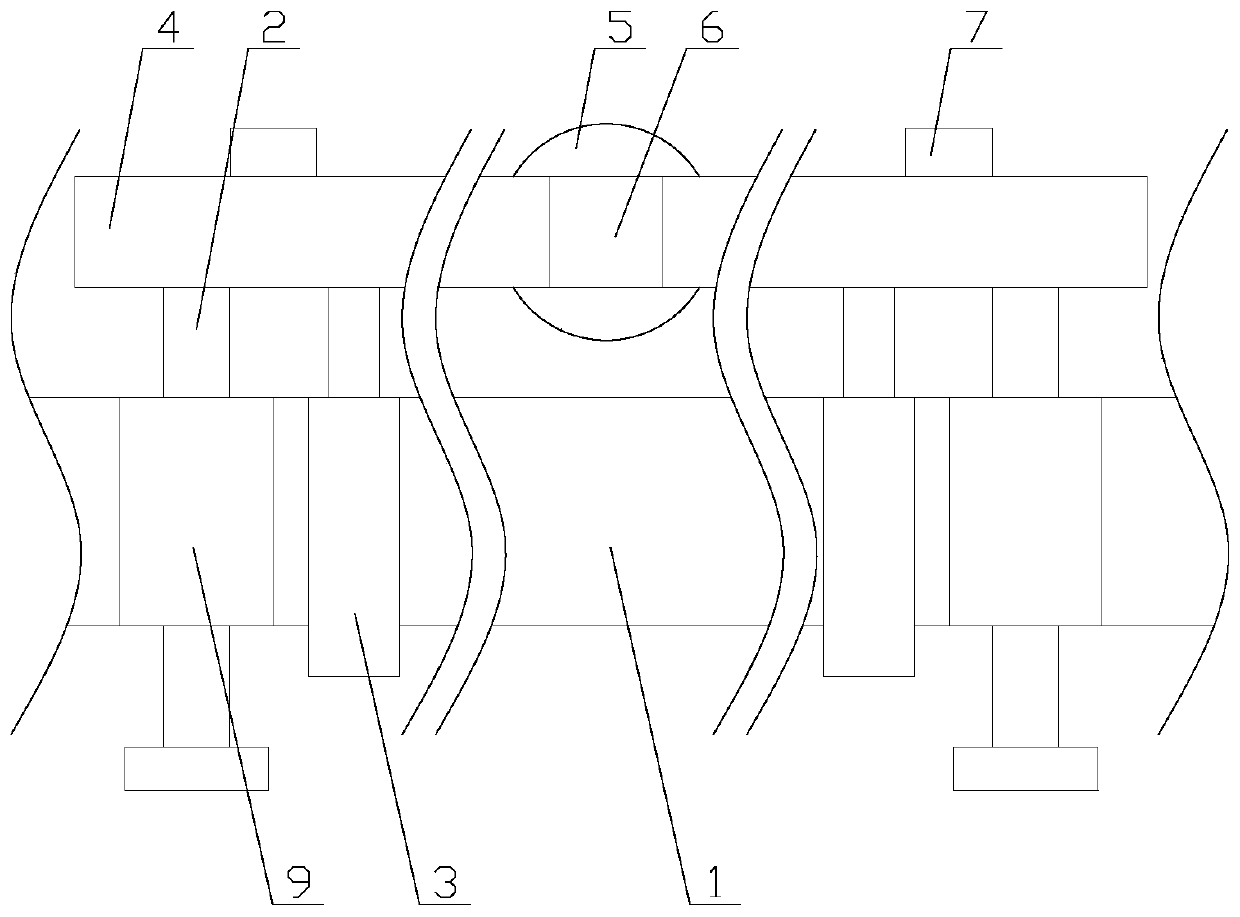

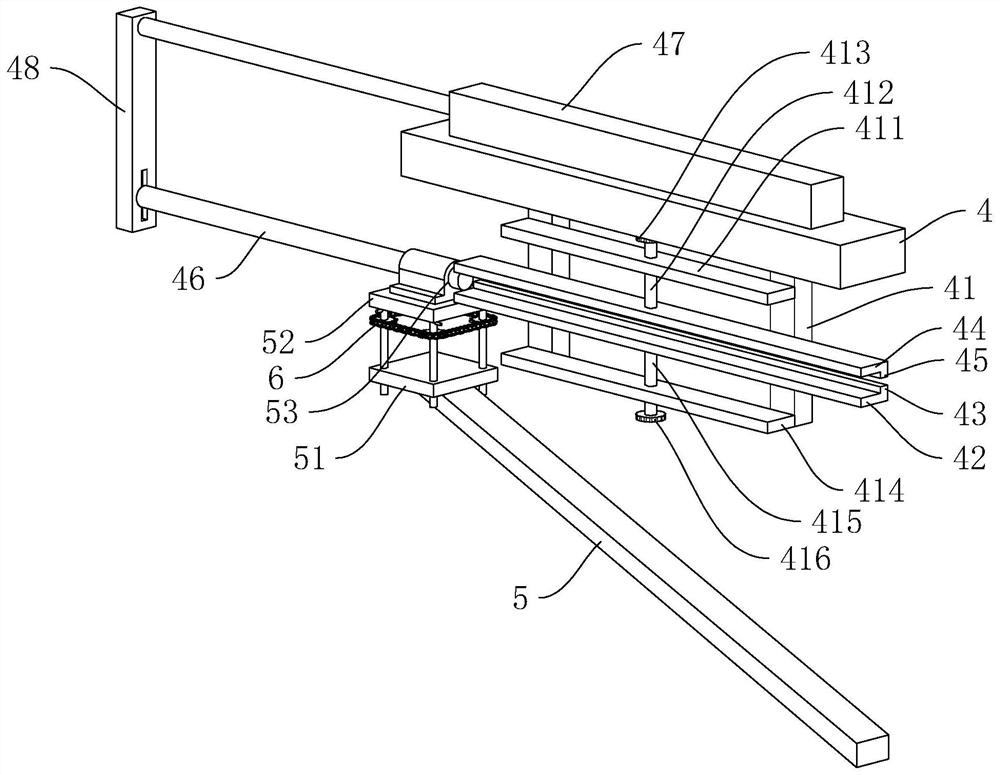

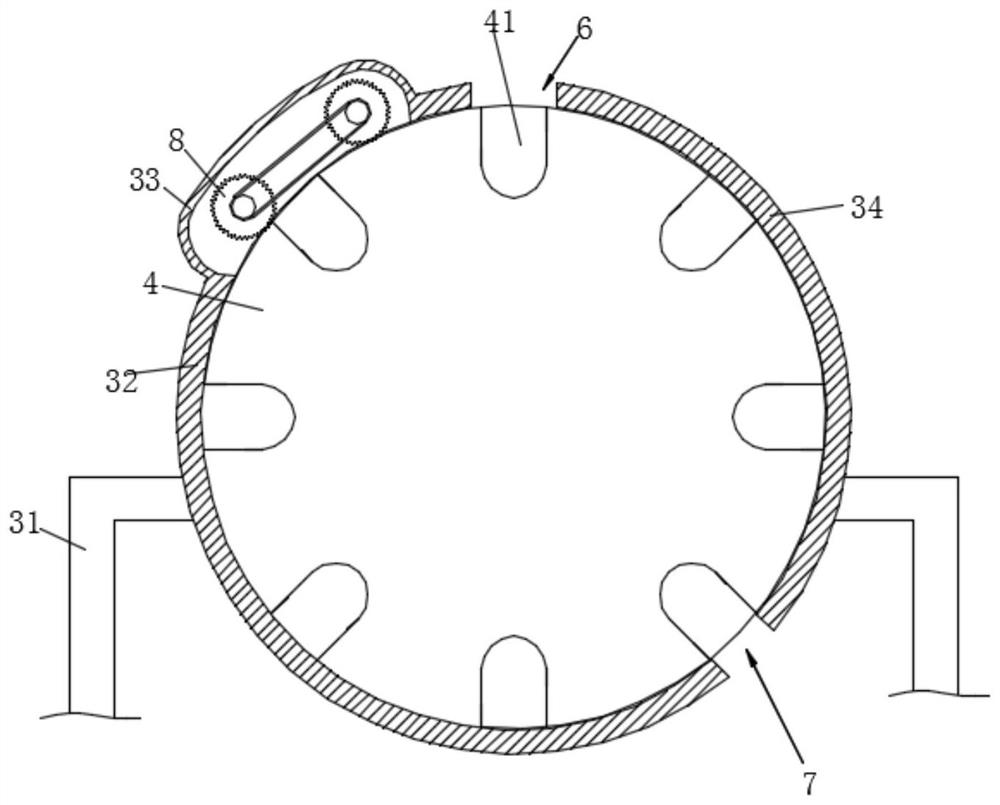

Feeding and discharging device for wood lathe

ActiveCN114407142AGuaranteed concentricityAvoid misalignmentWood-turning machinesWOOD TREATERSAgricultural engineering

The invention discloses a feeding and discharging device for a wood lathe, and belongs to the technical field of wood processing, the feeding and discharging device comprises two rotatable turntables arranged at two ends of a workbench, each turntable is correspondingly provided with a fixing device for supporting the turntable, and a plurality of U-shaped grooves which are uniformly distributed and used for mounting wood are formed in the turntables; a positioning device for positioning a workpiece is arranged in the U-shaped groove; the fixing device comprises a first ring body and a second ring body, notches are formed between the first ring body and the second ring body, and the two notches are a feeding port and a discharging port respectively. Compared with the prior art, tedious manual feeding is not needed, the feeding time can be saved, and the working efficiency is improved.

Owner:XUZHOU FENG ZHAN MACHINERY

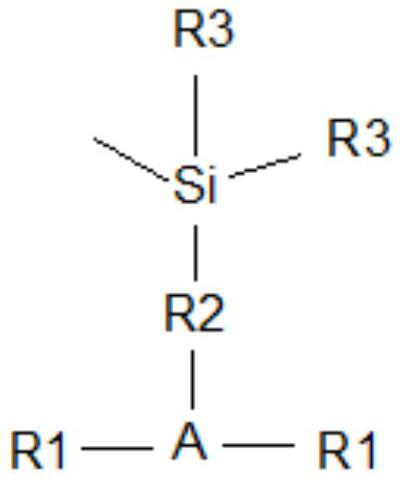

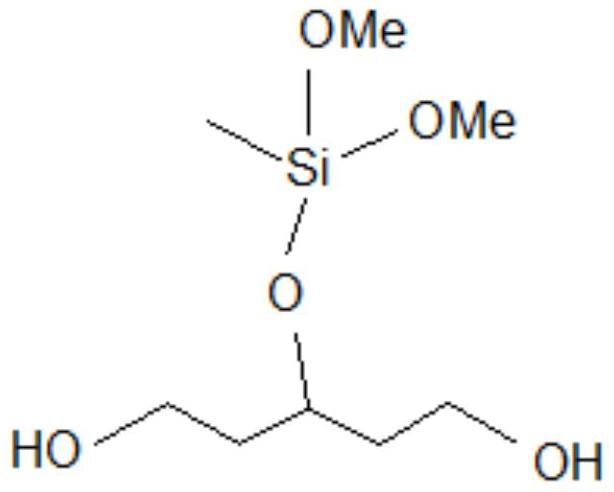

Special modified polyvinyl acetate emulsion adhesive and preparation method thereof

PendingCN114437652AWith environmental protection requirementsHigh bond shear strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemical industryAdhesive cement

The invention discloses a special modified polyvinyl acetate emulsion adhesive and a preparation method of the special modified polyvinyl acetate emulsion adhesive. The raw materials comprise, by weight, 40%-50% of water, 40%-50% of vinyl acetate, 2%-5% of polyvinyl alcohol, 3%-9% of butyl ether acetate, diethylene glycol formate and propylene carbonate, 0.1%-0.2% of persulfate, 0.05%-0.1% of a defoaming agent and 0.1%-0.2% of a preservative. According to the special modified polyvinyl acetate adhesive disclosed by the invention, three special plasticizers, namely butyl ether acetate, diethylene glycol formate and propylene carbonate, are added, so that the adhesive has special performance, an adhesive film is soft and tough after being dried, and adhesion between glass and wood can be completed. And the adhesive shear strength is equivalent to that of the similar polyvinyl acetate emulsion adhesive on the market, and is determined according to the chemical industry standard (HG / T2727-2010) of the polyvinyl acetate emulsion woodworking adhesive.

Owner:沈阳爱克浩博化工有限公司

A kind of reactive polyurethane hot melt adhesive and preparation method thereof

ActiveCN108997965BGood adhesionImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a reactive polyurethane hot-melt adhesive, which is composed of the following raw materials in parts by weight: 30-60 parts of polyether polyol, 20-40 parts of polyester polyol, 10-20 parts of polyisocyanate, hydroxyl-terminated acrylate ‑Carbonate copolymer resin 0.5-20 parts, water resistance enhancing additive 0.5-4 parts, catalyst 0.05-0.5 parts. The invention also provides a preparation method of the reactive polyurethane hot-melt adhesive. The reactive polyurethane hot-melt adhesive prepared by the present invention has excellent adhesion to plastics, metals, wood, glass, etc., and has good adhesion to low surface energy materials such as PP and PE, and has good heat resistance. The resistance to water or moisture is particularly superior, and it can be used in fields that require good adhesion to low surface energy materials and may be exposed to heat, water or moisture for a long time. It is suitable for automobile manufacturing, woodworking appliances, construction engineering, Electronic appliances and other fields have broad market prospects.

Owner:CHENGDU GUIBAO SCI & TECH +1

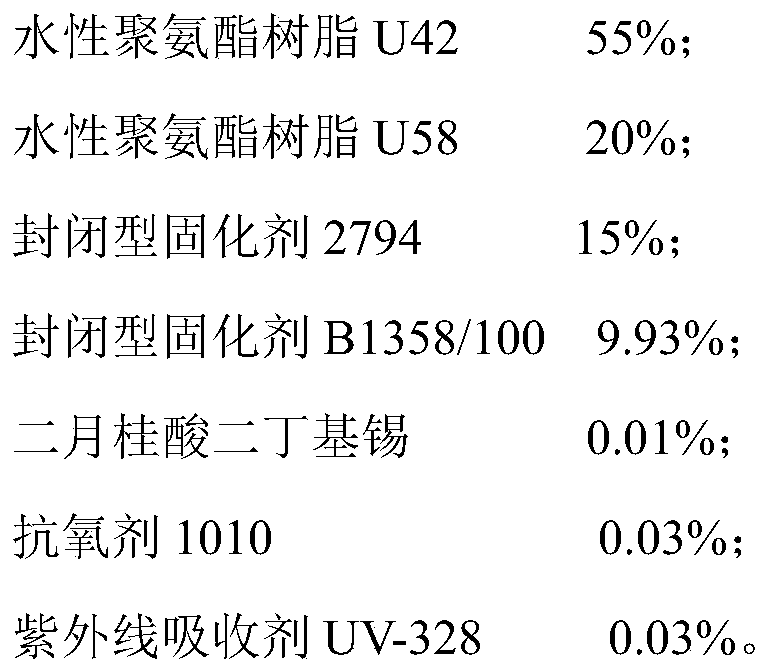

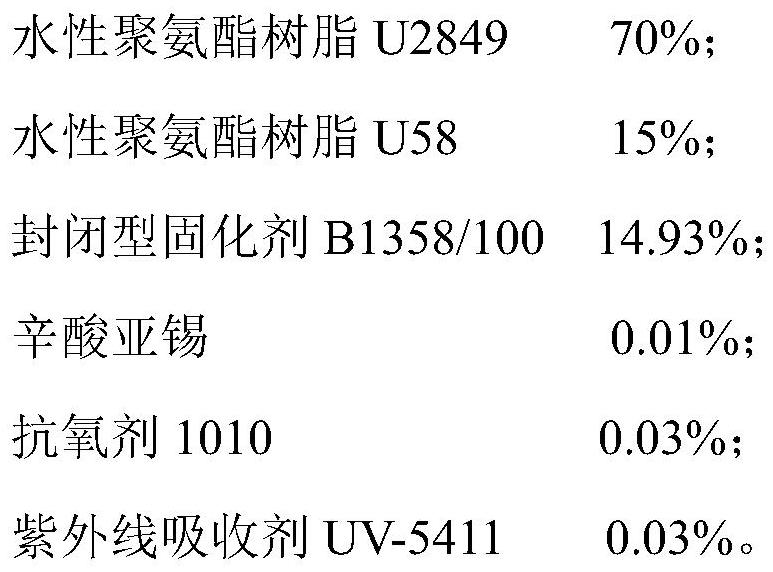

A kind of latent one-component polyurethane hot-melt adhesive and its preparation method and adhesive film

ActiveCN111100592BHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to the field of polymer adhesives, in particular to a latent single-component polyurethane hot-melt adhesive and a preparation method and adhesive film thereof. The latent one-component polyurethane hot melt adhesive of the present invention comprises the following components by weight percentage: polyurethane resin 70%-95%; closed curing agent 4.8%-29.3%; accelerator 0.01%-0.2%; agent 0.01%-0.5%. The latent type one-component polyurethane hot-melt adhesive of the present invention has good bonding strength, heat resistance, hydrolysis resistance and other properties; the preparation method is simple in process, low in cost, high in preparation efficiency, and has prospects in industrial production; The latent one-component polyurethane film obtained by curing one-component polyurethane hot melt adhesive has good initial tack, excellent final tack and storage stability; it can be widely used in woodworking, textile, outdoor clothing, automobile, electronics, Appliances and other industries.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

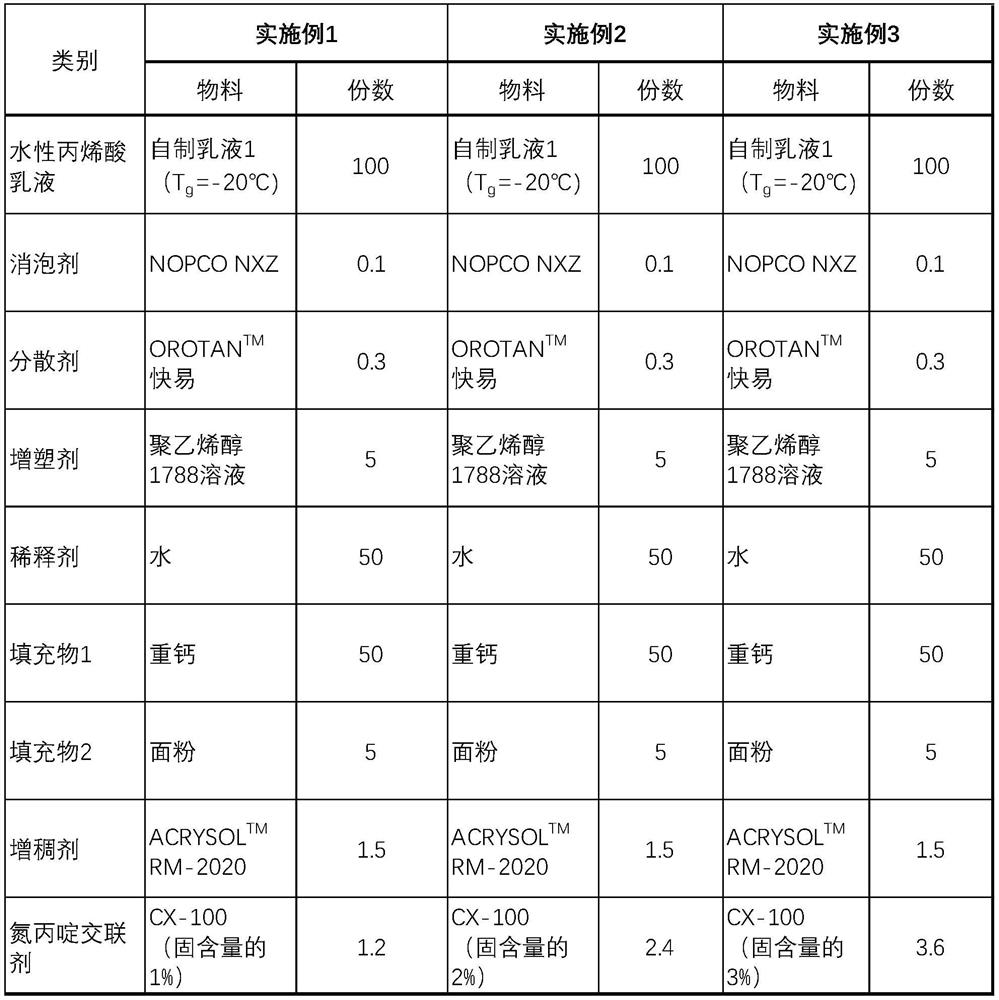

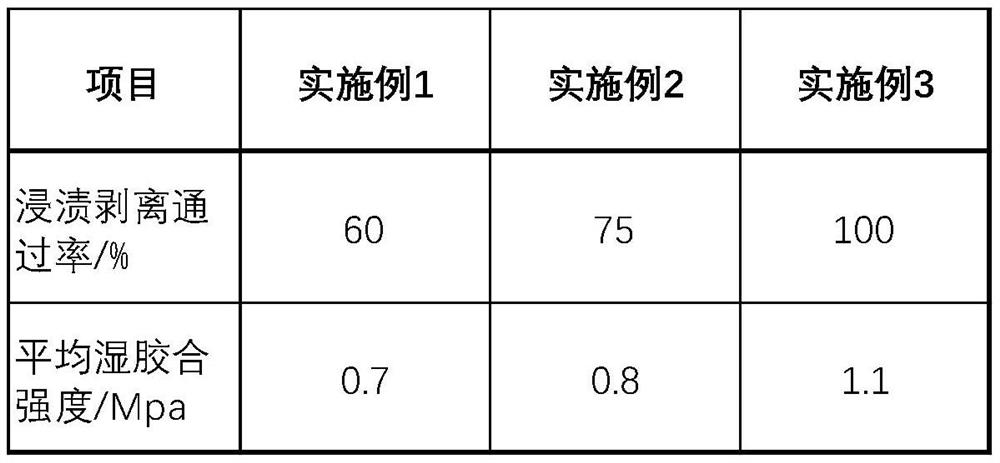

Two-component formaldehyde-free adhesive composition for artificial board

InactiveCN113444477AQuick responsePromote cross-linking reactionNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceWOOD TREATERS

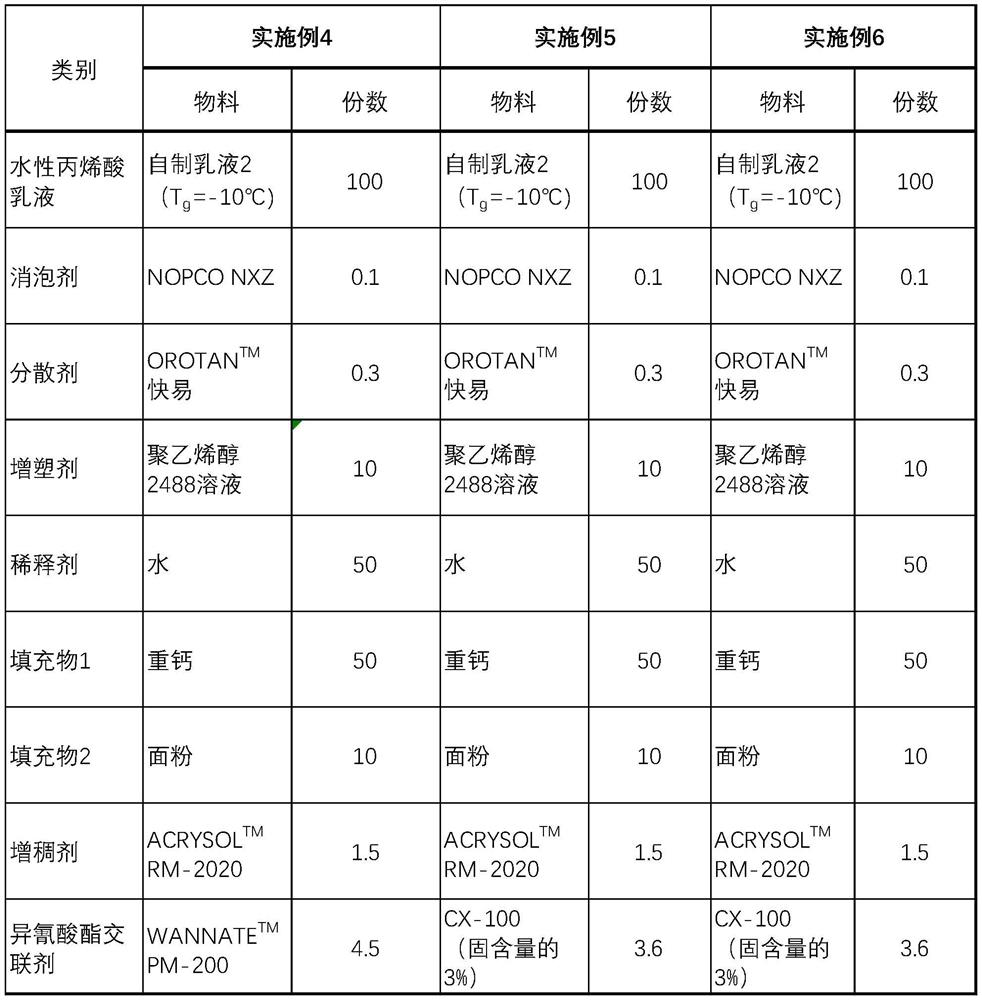

The invention discloses a two-component formaldehyde-free adhesive composition for an artificial board, which is a two-component formaldehyde-free adhesive composition based on a water-based polymerized acrylic resin emulsion and an aziridine cross-linking agent, and the two-component formaldehyde-free adhesive composition comprises the water-based polymerized acrylic resin emulsion, the aziridine cross-linking agent, a filler and other auxiliaries. In order to accelerate the thermocuring efficiency of the adhesive and shorten the hot pressing time of an artificial board, the aziridine cross-linking agent is used, and the thermocuring water-based formaldehyde-free woodworking adhesive is formed on the basis of combining the excellent water resistance and bonding performance of the water-based polyacrylic resin emulsion.

Owner:JIANGSU AKST NEW MATERIALS CO LTD

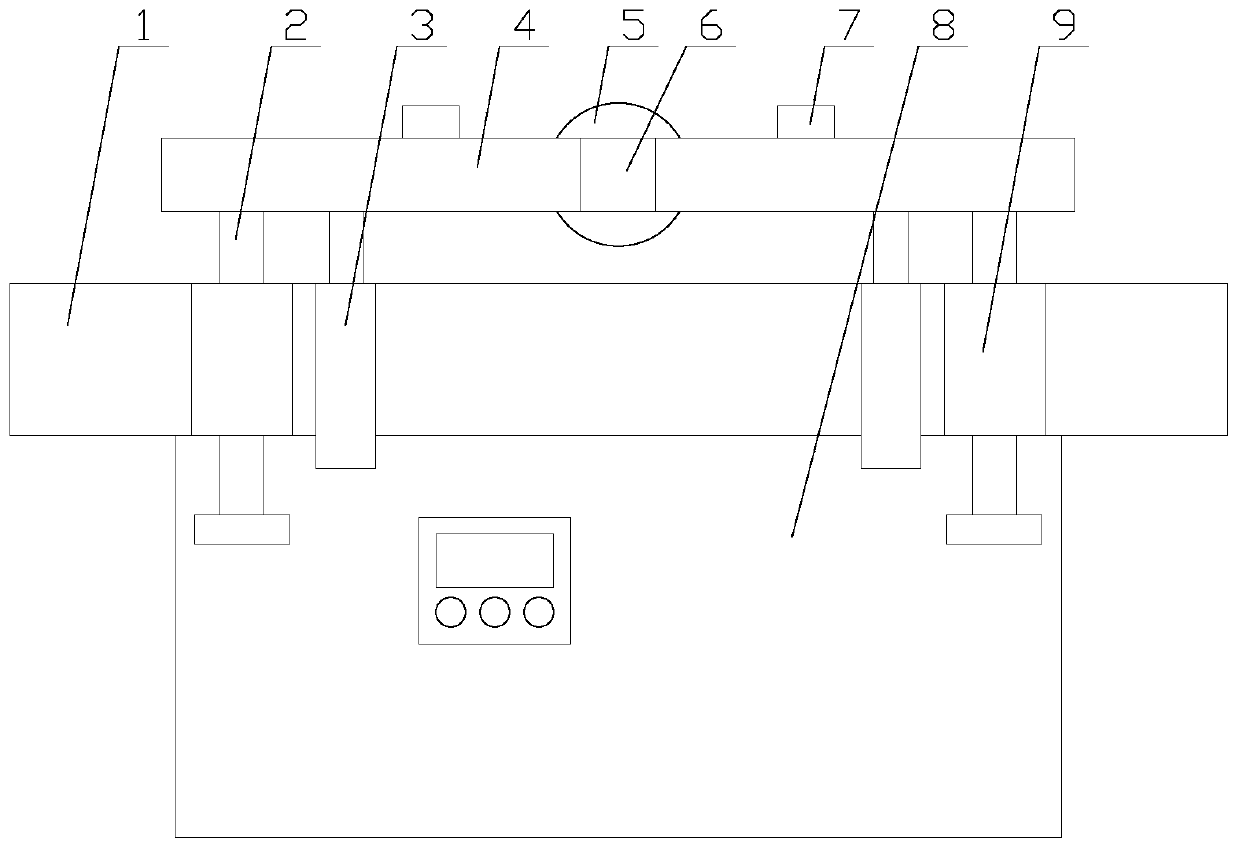

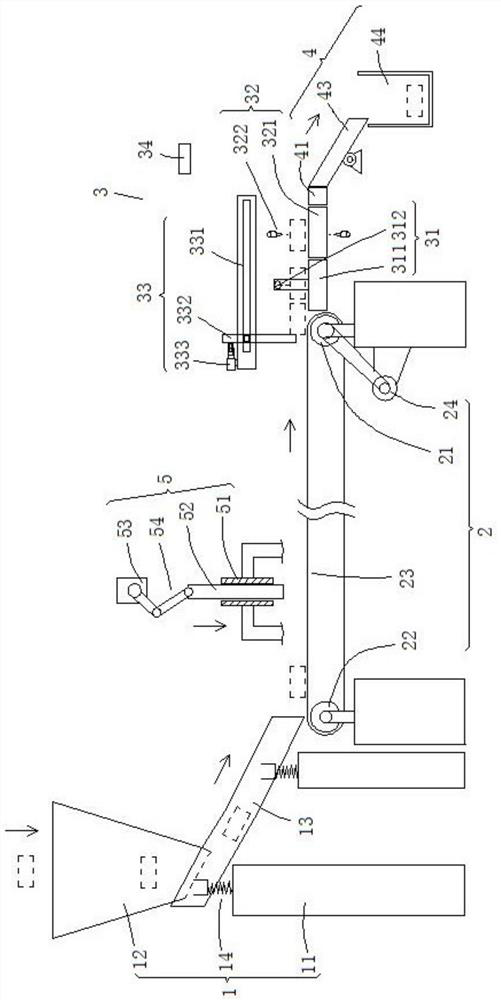

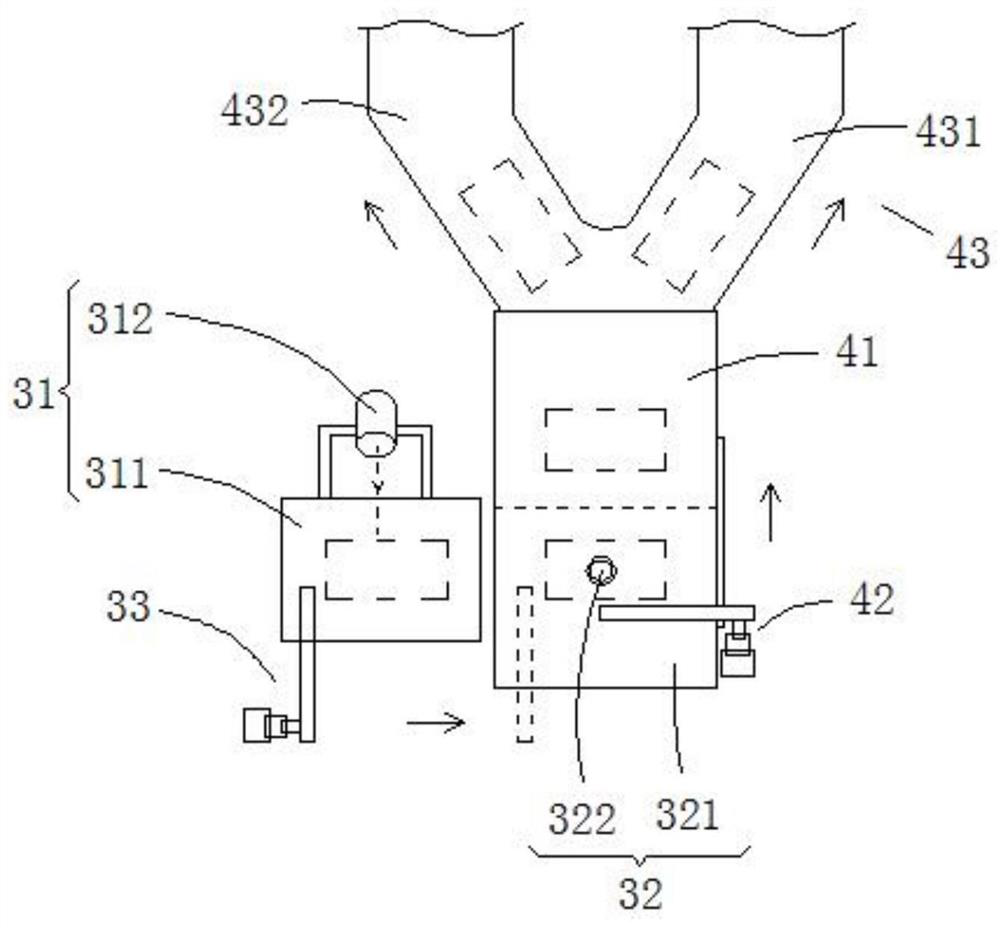

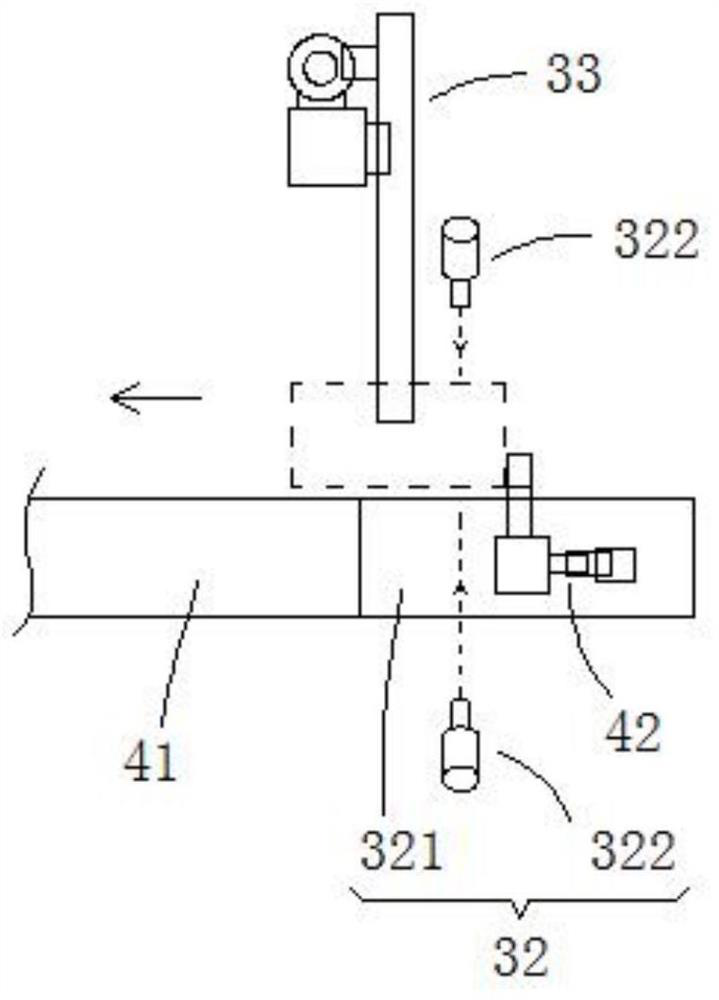

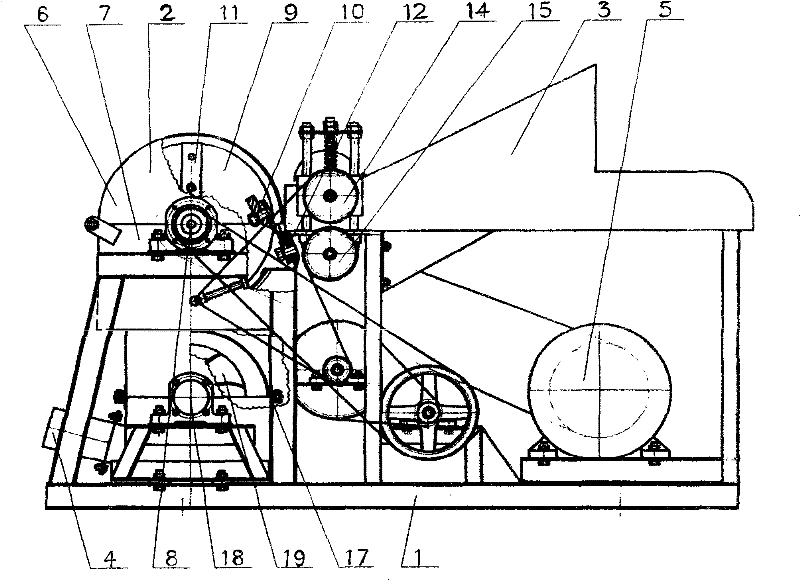

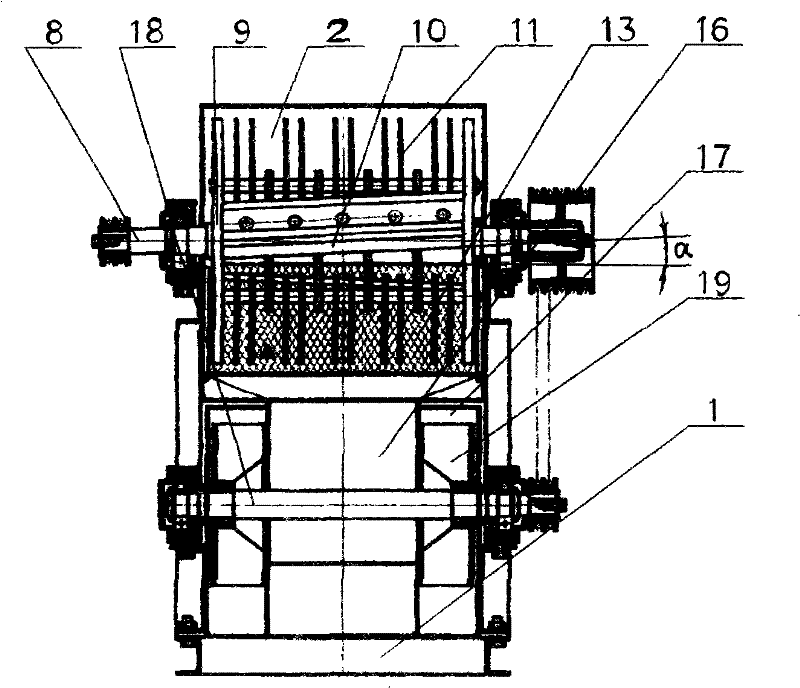

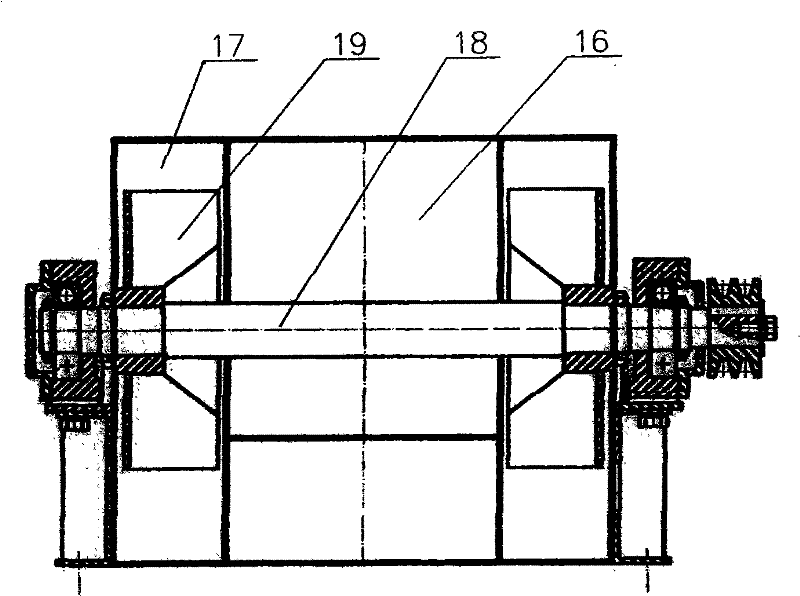

Feed wheel sorting device for woodworking feeder

ActiveCN111229620BFast quality inspectionThe detection process is fastSortingAgricultural scienceWOOD TREATERS

The invention provides a feeding wheel sorting device of a woodworking feeder, and belongs to the technical field of material sorting. The feeding wheel sorting device comprises a feeding mechanism, aconveying mechanism, a detecting mechanism and a sorting mechanism, wherein a feed inlet and a discharge outlet are formed in the feeding mechanism and used for accommodating feeding wheels; the feedend of the conveying mechanism is in butt joint with the discharge outlet of the feeding mechanism and used for receiving and conveying the feeding wheels output by the feeding mechanism; the detecting mechanism is in butt joint with the discharge end of the conveying mechanism and used for detecting the feeding wheels output by the conveying mechanism; and the sorting mechanism is in butt jointwith the discharge end of the detecting mechanism and used for sorting the feeding wheels detected by the detecting mechanism, and the feeding wheels sequentially pass through the feeding mechanism, the conveying mechanism, the detecting mechanism and the sorting mechanism. The feeding wheel sorting device of the woodworking feeder has the technical effects of high quality detection and sorting speed for the feeding wheels, high operating efficiency and capability of effectively reducing labor intensity of workers.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dual-edge dual-way cutting numerical control wood turning tool

PendingCN107839042AExtend your lifeEasy to cutWood turning toolsWood boring toolsTool bitNumerical control

The invention discloses a dual-edge dual-way cutting numerical control wood turning tool. The dual-edge dual-way cutting numerical control wood turning tool mainly comprises a tool bar and a replaceable tool bit. The tool bar is formed by special tempered carbon steel. The tool bit is designed to be a forward and reverse dual-way symmetrical cutting edge. A main cutting edge and an auxiliary cutting edge are spaced. The tip of the auxiliary cutting edge is 0.1-0.2 mm closer to the machined surface compared with the tip of the main cutting edge, and the width of the auxiliary cutting edge is 1-3 mm. The tool cutting edge angle is 75-90 degrees, the tool minor cutting edge angle is zero, the edge inclination angle is zero or negative and is implemented through the inclination angle of the installation position of the tool bit in the tool bar, the anterior angle is about 45 degrees, the relief angle is 10-15 degrees, and the end relief angle is 1-2 degrees. The surface of a tool bit matrix is coated with one or more composite hard abrasion-resistant coatings through a vapor deposition method. The dual-edge dual-way cutting numerical control wood turning tool provided by the inventionperforms cutting easily, is low in cost and long in service life, and is used for the procedures of blank forming, outer circle turning, end face turning and the like of soft non-metal materials suchas wood and plastics.

Owner:CHENGDU UNIV

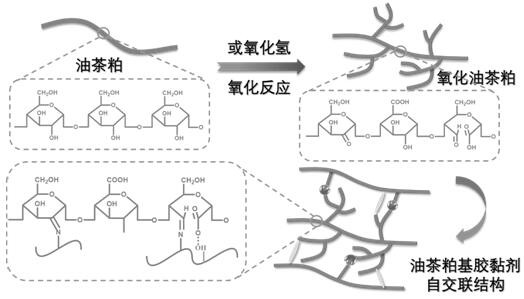

Oil-tea meal-based formaldehyde-free self-mildew-proof water-resistant adhesive

PendingCN114656896AImprove water-resistant bonding strengthReduce usageProtein adhesivesGlue/gelatin preparationCamellia oleiferaAdhesive

The invention relates to the technical field of woodworking adhesives for artificial boards, and particularly discloses an oil-tea-meal-based formaldehyde-free self-mildew-proof water-resistant adhesive and a preparation method of the oil-tea-meal-based formaldehyde-free self-mildew-proof water-resistant adhesive. The aldehyde-free adhesive is prepared by reacting the oil-tea meal with the soybean meal, the reinforcing agent and the cross-linking agent through modification methods such as liquefaction and oxidation. The oil-tea meal-based adhesive provided by the invention solves the problems that the existing biomass adhesive is poor in water resistance, is easily corroded by microorganisms, and causes no pollution to the environment due to the use of a large amount of chemical cross-linking agents. Effective components such as polysaccharide and tea saponin in the oil-tea meal are fully utilized, the modified oil-tea meal partially replaces soybean meal, a self-crosslinking network structure is formed in a system, the use of a chemical crosslinking agent is reduced while the water-resistant bonding strength of the adhesive is improved, VOC emission is reduced, the adhesive has excellent self-mildew-proof performance, and the service life of the adhesive is prolonged. The woodworking adhesive for the artificial board is formaldehyde-free, low in cost, high in performance and easy to realize industrial production.

Owner:BEIJING FORESTRY UNIVERSITY

Ultralow VOC (volatile organic compound) vegetable protein adhesive for I-class plywood and preparation method of ultralow VOC vegetable protein adhesive

PendingCN114752348ASolve problems such as serious pollutionReduce releaseNon-macromolecular adhesive additivesProtein adhesivesWOOD TREATERSAdhesive

The invention relates to the technical field of woodworking adhesives for artificial boards, and particularly discloses an ultra-low VOC (volatile organic compound) vegetable protein adhesive for class-I plywood, namely a preparation method of a reactive inorganic cross-linking agent hybrid modified vegetable protein adhesive. The adhesive is prepared from modified oil-tea meal, soybean meal, a reactive inorganic cross-linking agent, a reinforcing agent, an organic cross-linking agent, a dispersion medium and the like. The adhesive provided by the invention is innovatively and thoroughly used for solving the problems of serious indoor VOC pollution and the like caused by low water-resistant strength (only meeting the strength requirement of national standard II-type plates) and addition of a large amount of chemical cross-linking agents in the existing known vegetable protein adhesive. A reaction type inorganic cross-linking agent reacts with various plant protein peptide chains to generate a covalent bond network interpenetrating structure complex, so that the water-resistant bonding strength reaches the national standard I-class plate strength requirement in a breakthrough manner for the first time, and the green plant protein adhesive which is low in cost, ultrahigh in water-resistant strength, ultralow in VOC indoor pollution and high in mildew resistance is realized.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of processing method of imitation ostrich pattern leather

ActiveCN109207657BLow costPracticalLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingWOOD TREATERSFuraldehyde

The invention discloses a processing method of ostrich texture simulated leather. The processing method is characterized by comprising the following steps of flatly spreading a delimed and softened pelt on a pin board, wherein a grain side of the pelt is upward, and a flesh side is in contact with wood screws; afterwards, uniformly brushing a pattern fixing agent on a part, which is convex on thepin board, of the pelt, wherein the pattern fixing agent is at least brushed for 1 time; and after the brushing of the pattern fixing agent is finished, standing for at least 5min, and carrying out acid pickling, tanning, after-tanning wet processing and coating operation according to normal operation, thus obtaining an ostrich texture leather finished product. Distances among wood screws on the pin board are 2cm to 6cm; and the heights at which the wood screws protrude the plane of the pin board are 0.5cm to 3cm. The pattern fixing agent is an aldehyde solution with the pH (potential of Hydrogen) of 8.0 to 9.5; and the aldehyde solution is prepared from any one of formaldehyde with a mass friction of 40%, glutaraldehyde with a mass friction of 50%, modified glutaraldehyde with a mass friction of 45%, acetaldehyde with a mass fiction of 60% or furaldehyde with a mass friction of 50%. The delimed and softened pelt is any one of a cattle hide, a buffalo hide, a dzo hide or a yak hide. The method is simple, low in cost, high in operability, and moreover, easy in style change, and is used for producing ostrich skin pattern simulated leather with different characteristics.

Owner:SICHUAN UNIV

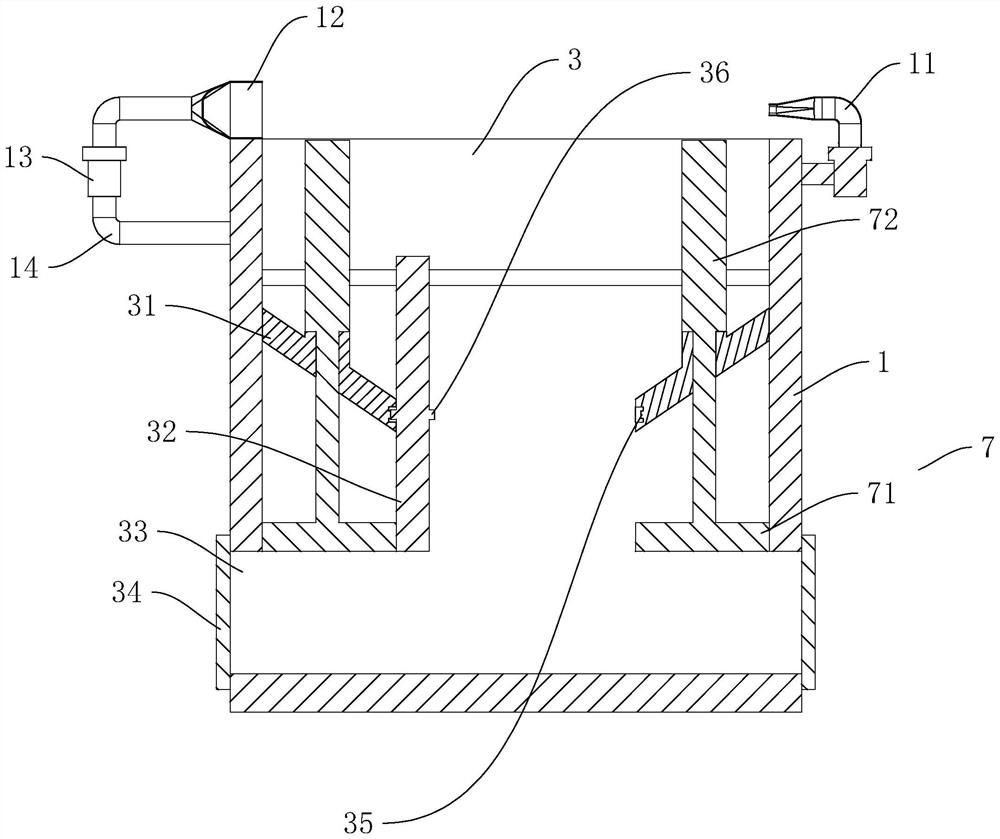

Vertical single-spindle wood milling machine with dust collecting device and using method thereof

InactiveCN112497365AEasy to transportReduce the hassle of handlingCombination devicesProfiling/shaping machinesWOOD TREATERSWood machining

The invention discloses a vertical single-spindle wood milling machine with a dust collecting device, and relates to the technical field of wood working equipment. The vertical single-spindle wood milling machine comprises a working box, a milling machine body and a fixing mechanism. The working box is fixedly installed on a working floor through stand columns. Meanwhile, an inner cavity is formedin the working box, and a conveying belt is arranged in the inner cavity. The conveying belt conducts conveying motion, so that wood conveying is more convenient, and the trouble of wood carrying isreduced. Meanwhile, a side hole is formed in the rear side wall of the inner cavity, the side hole is communicated with a collecting groove, an air collecting cover is fixedly installed at the position, corresponding to the side hole, of the front side wall, and the air collecting cover is communicated with a fan through a guide pipe. In the wood working process, wood chips generated by wood working are blown into the side hole through a guide plate by the fan, then the wood chips are guided into the collecting groove from a vertical hole to be treated, the phenomenon that the wood chips scatter about or splash is avoided, the wood chips are collected more efficiently, environment contamination caused by the wood chips is reduced, and the body health of operators is guaranteed.

Owner:湖北永吉智能家居有限公司

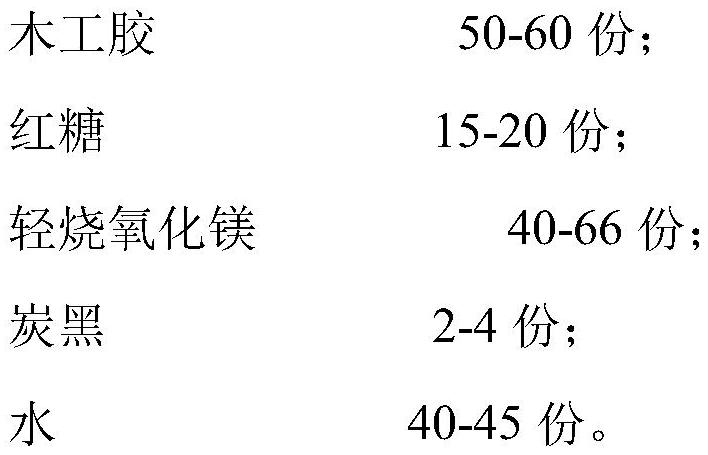

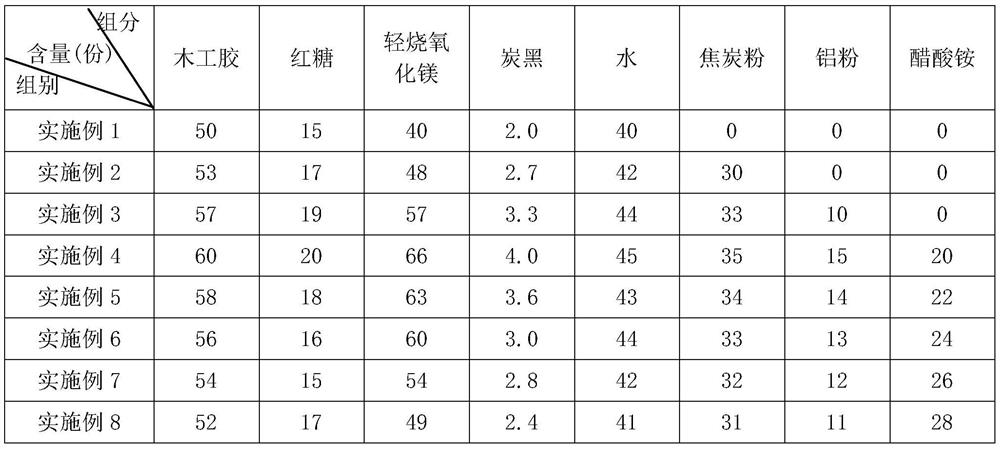

Anti-oxidation coating for working lining of iron ditch and preparation method thereof

The invention discloses an anti-oxidation coating for iron ditch working lining and a preparation method thereof, and relates to the technical field of preparation of blast furnace iron ditch protective materials. Its formula includes the following weight components: 50-60 parts of wood glue, 15-20 parts of brown sugar, Lightly burned magnesia 40-66 parts, carbon black 2-4 parts; water 40-45 parts. The preparation method of the anti-oxidation coating for the working lining of the iron ditch includes the following steps: S1. dissolving ammonium acetate in water to form an ammonium acetate aqueous solution; S2. stirring the wood glue at a speed of v=120r / min, and stirring in sequence Add brown sugar, lightly burned magnesia, aluminum powder, coke powder and carbon black to form a primary mixture; S3. add the ammonium acetate aqueous solution prepared in the S1 step while stirring to the primary mixture obtained in the S2 step, and stir Uniformly obtained finished paint. The invention has the technical effect of reducing the oxidation degree of carbon in the pouring material of the working lining of the iron trench, thereby improving the working performance of the lining of the iron trench and prolonging the service life of the lining of the iron trench.

Owner:武汉市科达耐火有限责任公司

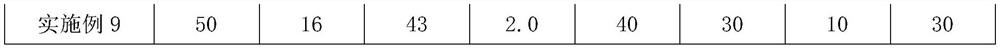

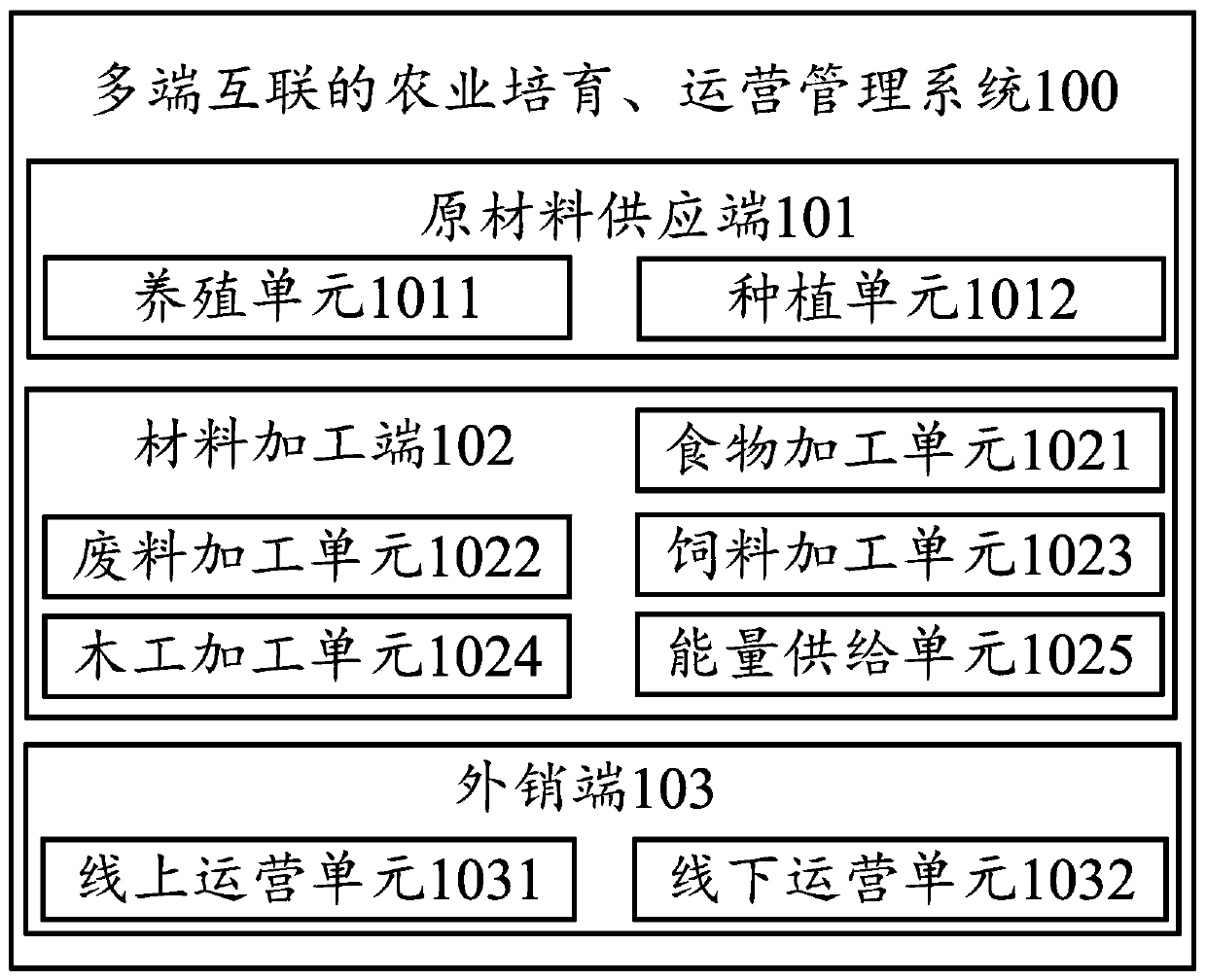

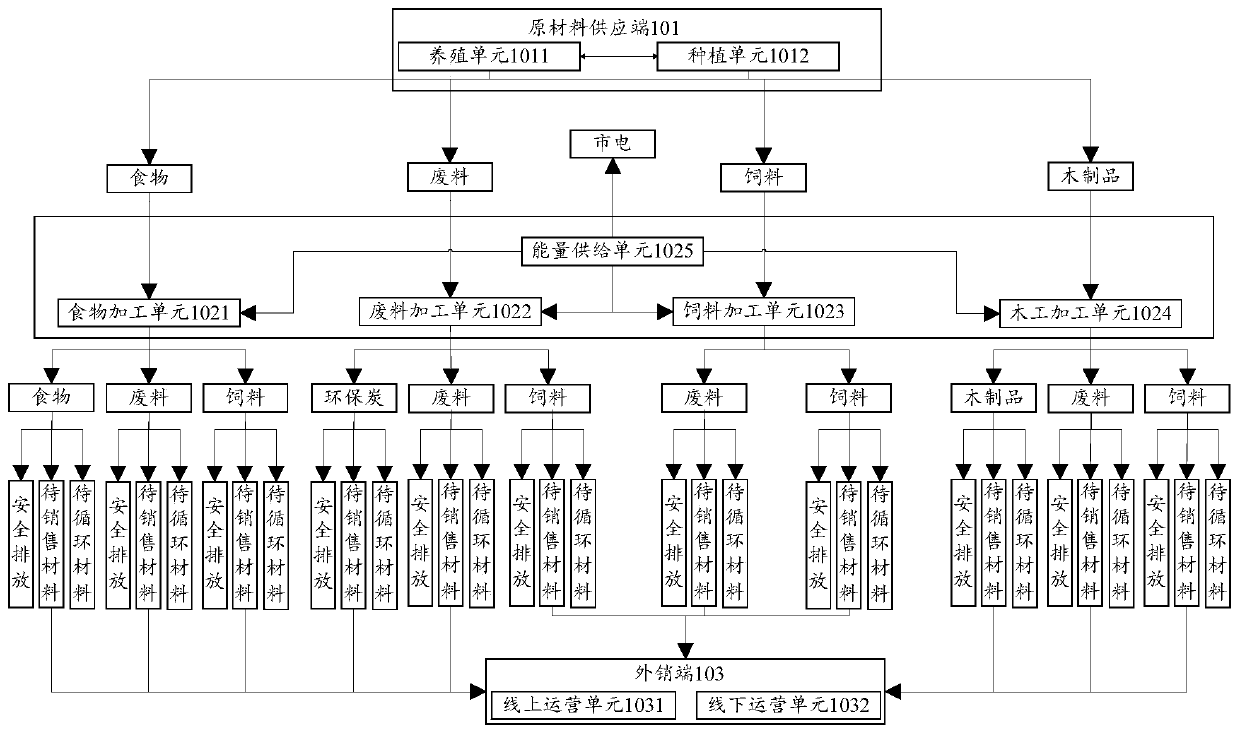

Multi-terminal interconnected agricultural cultivation and operation management system and method

InactiveCN110570325AThe production is convenientEasy to reuseData processing applicationsWaste processingEnergy supply

The invention provides a multi-terminal interconnected agricultural cultivation and operation management system and method. The system comprises a raw material supply end, a material processing end and an outer pin end. The raw material supply end, the material processing end and the outer pin end are communicated with one another. The raw material supply end comprises a breeding unit and a planting unit, the material processing end comprises a food processing unit, a waste processing unit, a feed processing unit, a woodworking processing unit and an energy supply unit, and the export end comprises an online operation unit and an offline operation unit. According to the method, all links in cultivation and product operation of the breeding industry and the planting industry can be associated with one another, reutilization of waste is achieved, generation of an ecological circulation chain is also facilitated, and environmental pollution is effectively avoided.

Owner:李春来

Durable organic kitchenware cutter production process based on laser cladding and powder steel

InactiveCN113996760AHigh hardnessHigh dimensional accuracyFoundry mouldsFoundry coresWOOD TREATERSManufactured material

The invention discloses a durable organic kitchenware cutter production process based on laser cladding and powdered steel. The durable organic kitchenware cutter production process comprises cutter blank manufacturing and cutter blank forging, wherein the cutter blank manufacturing steps comprise: 1, pressing a cutter body wax mold body, taking out a wax cylinder from a heat preservation groove, and mounting the wax cylinder on a double-station hydraulic wax mold injection molding machine. According to the invention, through the manufacturing process, the woodworking cutter body which is high in hardness, high in toughness, resistant to high temperature and high in cutter body casting size precision can be manufactured while a large number of machine tool equipment and machining time are saved, metal raw materials are greatly saved, internal impurities can be forged out in cooperation with repeated hammer pressing and forging and borax, the impurities in the casting can be separated out through the rotation of the stirring rod, and finally, the casting is formed through a small air hammer type forging machine, wherein the cutter manufactured through the forging and pressing mode is pure in component and few in impurity, and a first-class cutter can be manufactured.

Owner:深圳市波尔顿科技有限公司

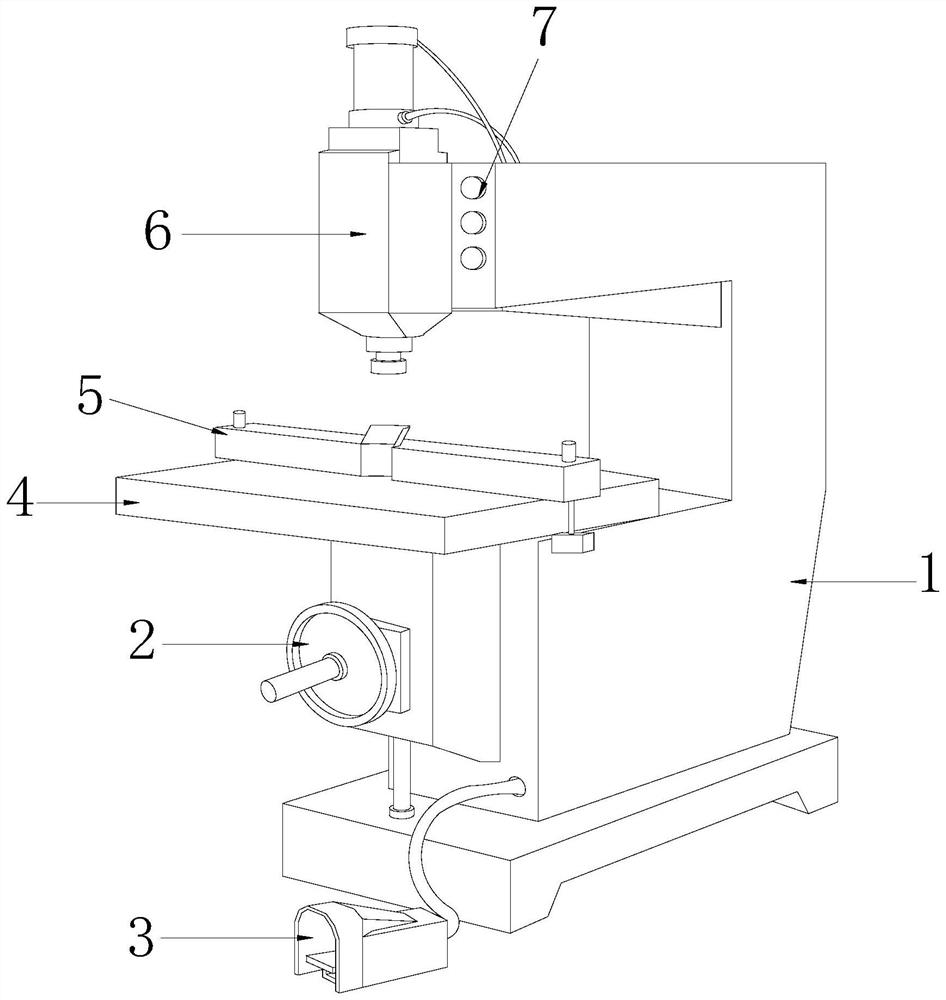

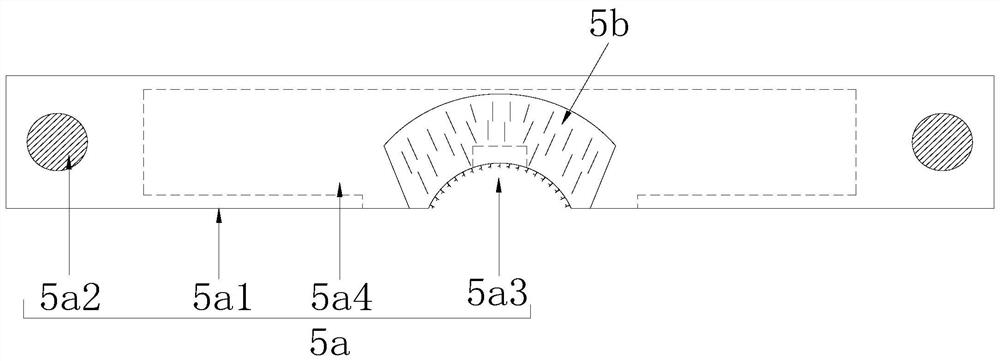

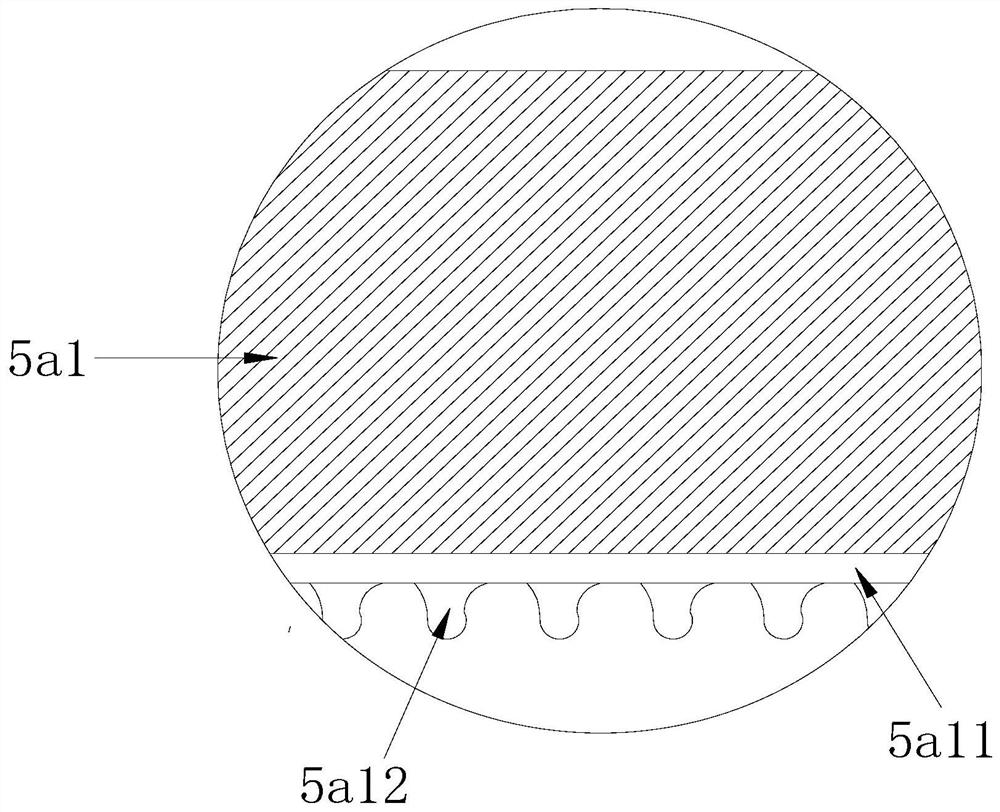

Wood milling machine

InactiveCN112720711AAvoid indentationAvoid wear and tearStationary drilling machinesProfiling/shaping machinesWOOD TREATERSMechanical engineering

The invention discloses a wood milling machine. The wood milling machine structurally comprises a main body, an adjusting disk, a pedal plate, a workbench, a pressure stabilizing device, a drilling and milling machine head and a control panel. The wood milling machine has the beneficial effects that through cooperation of a pressing mechanism, friction particles arranged on the lower surface of a frame body and a sealing layer, the surface of a wood plate is protected when pressed by external force, so that the phenomenon of indentation or wear on the surface of the wood plate due to the pressing effect of the external force when the pressing mechanism is in contact with the wood plate is avoided; and meanwhile, through cooperation with a positioning arc groove, wood chips attached to the outer surface of the drilling and milling machine head are subjected to adsorption treatment, so that the phenomenon that the drilling and milling machine head is blocked due to the fact that a large number of tiny wood chips are attached to the outer surface of the drilling and milling machine head is avoided. According to the wood milling machine, through the arranged straightening mechanism, when the drilling and milling machine head drills the surface of the wood plate, the drilling and milling machine head is effectively straightened to move downwards through the structure installation of a structure protection plate, so that the phenomenon of hole deviation during downward pressing and drilling is avoided.

Owner:李惠明

Preparation method of high-strength water-resistant polyvinyl acetate woodworking adhesive

PendingCN113736396ANumber of protectionImprove water resistanceMonocarboxylic acid ester polymer adhesivesPolymer sciencePolyvinyl alcohol

The invention discloses a preparation method of a high-strength water-resistant polyvinyl acetate woodworking adhesive. According to the method, sodium hypochlorite is introduced to oxidize starch to generate carboxyl, aldehyde, keto-carbonyl and other groups; under an acidic condition, carboxyl, aldehyde group and the like can be subjected to esterification reaction and aldolization reaction with hydroxyl on polyvinyl alcohol (PVA) to generate hydrophobic groups such as ester group and the like, so that grafting modification of PVA is realized, the number of hydroxyl on a PVA molecular chain segment is reduced, and a partial cross-linked network structure is formed with PVA, so that the bonding strength is enhanced. The polyvinyl acetate prepared by the invention takes water as a dispersion medium, is convenient to use, has no pollution to the environment, and has higher water resistance and strength compared with the traditional polyvinyl acetate with the same solid content. Volatile matters do not cause harm to human bodies and the environment, and the production environment is safe.

Owner:顶立新材料科技股份有限公司

Double-use plant material cutting grinder

InactiveCN101786034BReduce energy consumptionStable suctionCuttersGrain treatmentsWOOD TREATERSAgricultural engineering

The invention relates to processing machinery for producing edible fungi culture materials, in particular to a double-use plant material cutting grinder. The grinder comprises a frame, a cutting-grinding chamber arranged on the frame, a feeding hopper, a material outlet, a power device and a variable-speed transmission mechanism, wherein a public blanking hopper is directly arranged below the cutting-grinding chamber, namely at the bottom of a filter screen; a centrifugal material-sucking fan device is arranged in the public blanking hopper; the centrifugal material-sucking fan device consists of a pair of air impellers arranged on two sides of the same centrifugal fan main shaft ; and an air outlet of the centrifugal material-sucking fan device is communicated with the material outlet. The grinder can cut and grind straw of various plant materials, weeds, branches, woodwork shavings and other soft / hard raw materials, and helps to directly and smoothly suck out raw material particles even with high water content, thereby achieving the effects of reducing energy consumption, simplifying process and improving production efficiency.

Owner:翁赐和

Production technique for environment-friendly wood plywood

InactiveCN104647484AFlat surfaceAvoid deformationOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAdhesive cementWOOD TREATERS

The invention discloses a production technique for an environment-friendly wood plywood. The production technique for the environment-friendly wood plywood includes steps that (1) pre-processing log; (2) planning and burring to form square plates; (3) preparing adhesive for latter use; (4) using the square plates as an upper panel, a lower panel and a middle core plate, bonding adhesive, hot pressing to form a base plate, and sanding to obtain a finished product. The production technique for the environment-friendly wood plywood uses slab and short and small material as the raw material of the plate core, the slab and short and small material are combined through special adhesive, and the produced core plate is large, flat in surface, difficult to deform and low in production cost. When preparing adhesive solution, flour, wood powder, bentonite and the like are added to decompose free formaldehyde, and the environment protection is realized. The production technique greatly improves the outturn percentage, simplifies the technique, improves the product use intensity and quality and has broad market prospect.

Owner:QINGDAO RENJIE IND & TRADE

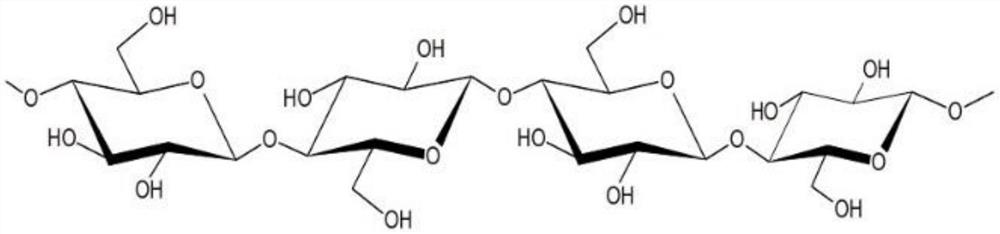

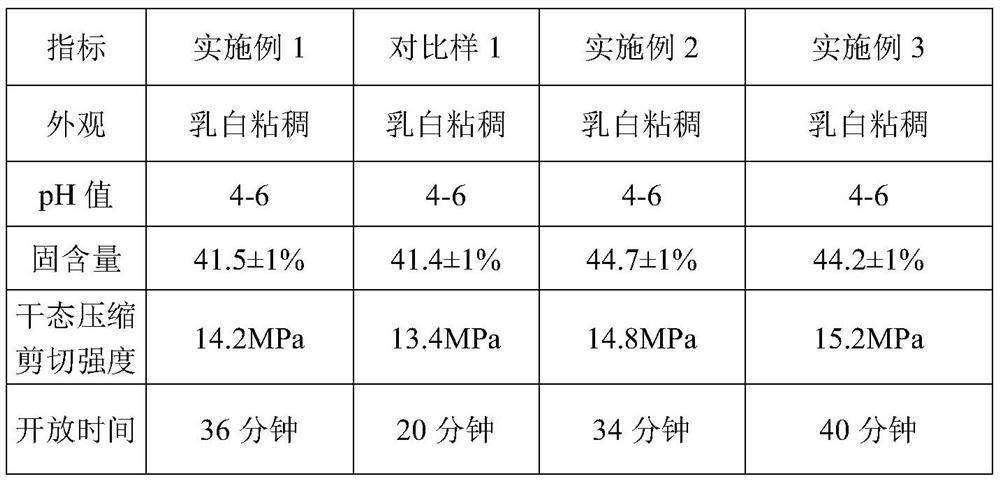

A woodworking adhesive with long open time based on maltose syrup modified polyvinyl acetate emulsion

ActiveCN109355039BEffective intervalHas water retentionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention belongs to the technical field of adhesives, and relates to a long-open-time woodworking adhesive based on maltose syrup modified polyvinyl acetate emulsion. When the adhesive is prepared, firstly, polyvinyl alcohol and maltose syrup serve as a protective colloid, vinyl acetate serves as a monomer, ammonium persulfate serves as an initiator, the polyvinyl acetate emulsion is preparedby a seed emulsion polymerization process, and secondly, edible seaweed powder is added into copolymer emulsion. According to the polyvinyl acetate woodworking adhesive, water serves as a dispersionmedium, use is convenient, environments cannot be polluted, and the woodworking adhesive has the advantage of long open time as compared with a traditional polyvinyl acetate woodworking adhesive withthe same solid content.

Owner:TAIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com