Oil-tea meal-based formaldehyde-free self-mildew-proof water-resistant adhesive

A technology of camellia oleifera meal and adhesive, applied in the direction of adhesive, adhesive type, protein adhesive, etc., can solve the problems of complex protein process, difficult to promote production, environmental pollution, etc., achieve rich sources and reduce VOC release , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

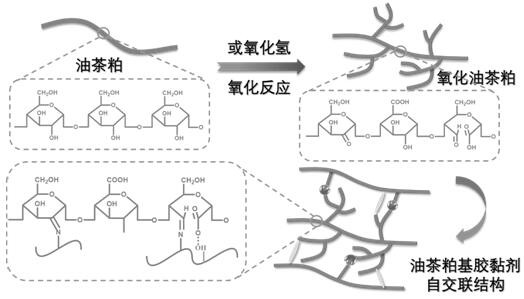

Method used

Image

Examples

Embodiment 1

[0033] The specific steps for the preparation of a formaldehyde-free self-mildew-proof and water-resistant adhesive based on camellia oil meal are as follows:

[0034] (1) Mix 8 g of melamine, 4 g of KOH, 50 g of water and 40 g of camellia oleifera meal, add it to a 250 mL three-necked flask equipped with a stirrer, and raise the water bath to 60°C under stirring at 350 rpm, and react for 20 min. , continue to stir the solution at room temperature to obtain liquefied camellia meal;

[0035] (2) Add 0.2 g of copper sulfate and 5 g of potassium peroxide to the liquefied camellia oil solution, stir for 1 h, cool to room temperature, and adjust the pH to 7 to obtain oxidized modified camellia oil;

[0036] (3) Add 2g of polymethylenediamine to 100g of water and stir for 20min;

[0037] (4) Continue to add 15 g of modified camellia oil to the system, stir at 50 °C for 40 min, and then add 10 g of epichlorohydrin;

[0038] (5) Finally, 15 g of soybean meal was added, and stirring ...

Embodiment 2

[0040] The specific steps for the preparation of a formaldehyde-free self-mildew-proof and water-resistant adhesive based on camellia oil meal are as follows:

[0041] (1) Mix 8 g of urea, 6 g of NaOH, 60 g of water and 50 g of camellia oleifera meal, add it to a 250 mL three-necked flask equipped with a stirrer, raise the water bath to 80 °C under stirring at 400 rpm, and react for 40 min. Continue to stir the solution at normal temperature to obtain liquefied camellia meal;

[0042] (2) Add 1 g of aluminum sulfate and 25 g of calcium peroxide to the liquefied camellia oil solution, stir for 1.5 h, cool to room temperature, and adjust the pH to 8 to obtain oxidatively modified camellia oil;

[0043] (3) Add 3g polyethyleneimine to 100g water and stir for 30min;

[0044] (4) Continue to add 25 g of modified camellia oil to the system, stir at 80°C for 40 min, and then add 8 g of 1,6-hexanediol diglycidyl ether;

[0045] (5) Finally, add 5 g of soybean meal and continue stirrin...

Embodiment 3

[0047] The specific steps for the preparation of a formaldehyde-free self-mildew-proof and water-resistant adhesive based on camellia oil meal are as follows:

[0048] (1) Mix 5 g of melamine, 4 g of KOH, 50 g of water and 20 g of camellia oleifera meal, add it to a 250 mL three-necked flask equipped with a stirrer, raise the water bath to 40 °C under stirring at 350 rpm, and react for 15 min. Continue to stir the solution at normal temperature to obtain liquefied camellia meal;

[0049] (2) Add 0.2 g of sodium sulfate and 5 g of hydrogen peroxide to the liquefied camellia oleifera meal solution and stir for 1 h, cool to room temperature, and adjust the pH to 6.5 to obtain oxidized modified camellia oleifera meal;

[0050] (3) Add 1g polyethyleneimine to 50g water and stir for 20min;

[0051] (4) Continue to add 10 g of modified camellia meal to the system, stir at 45°C for 20 min, and then add 8 g of epichlorohydrin;

[0052] (5) Finally, add 20 g of soybean meal and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com