Preparation method of urea-melamine-formaldehyde resin glue for e0 floor

A technology of melamine and formaldehyde resin, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of complex operation and high cost, reduce formaldehyde release, prevent hydrolysis speed, reduce The effect of the content of ether linkages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Step 1: Add 250g of formaldehyde solution, 7.5g of the first batch of melamine, and 84g of the first batch of urea into a 500ml four-neck flask, add to the reactor, adjust the pH value to 7.5, raise the temperature to 80°C-90°C, and react for 40min.

[0029] The second step: adjust the pH value to 5.0, and react to the required viscosity at 90°C.

[0030] The third step: adjust the pH value to 6.5, add the second batch of melamine 7.5g and the second batch of urea 29g, react at 90°C for 50min.

[0031] Step 4: Adjust the pH value to 7.5, add the third batch of melamine 45g, and react at 80°C for 40min.

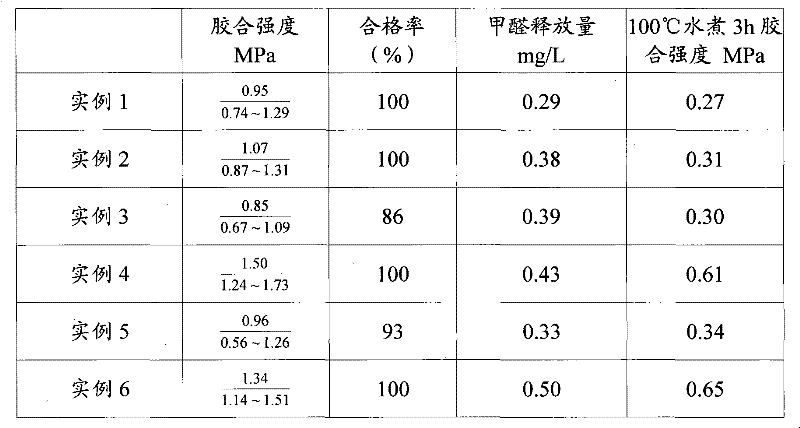

[0032]Step 5: Lower the temperature to 70°C, add the third batch of urea 29g, continue the reaction at 50°C for 30min, cool and discharge. Test their performance respectively, and the results are listed in attached table 1. and with 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are shown in attached table 2.

example 2

[0034] Step 1: Add 250g of formaldehyde solution, the first batch of 7.5g of melamine, and the first batch of 84g of urea into a 500ml four-necked flask into the reactor, adjust the pH value to 8.0, raise the temperature to 85°C, and react for 45min.

[0035] The second step: adjust the pH value to 5.5, and react to the required viscosity at 90°C.

[0036] The third step: adjust the pH value to 6.5, add the second batch of melamine 7.5g and the second batch of urea 24g, react at 90°C for 50min.

[0037] Step 4: Adjust the pH value to 8.0, add the third batch of melamine 45g, and react at 90°C for 40min.

[0038] Step 5: Lower the temperature to 70°C, add the third batch of urea 24g, continue the reaction at 60°C for 30min, cool and discharge. Test their performance respectively, and the results are listed in attached table 1. and with 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are shown in attached table 2.

example 3

[0040] Step 1: Add 250g of formaldehyde solution, 9g of the first batch of melamine, and 84g of the first batch of urea into a 500ml four-neck flask, add the reactor, adjust the pH value to 9.0, raise the temperature to 90°C, and react for 50min.

[0041] The second step: adjust the pH value to 5.8, and react to the required viscosity at 90°C.

[0042] The third step: adjust the pH value to 6.9, add the second batch of melamine 9g and the second batch of urea 29g, react at 90°C for 50min.

[0043] Step 4: Adjust the pH value to 9.0, add the third batch of melamine 52g, and react at 90°C for 40min.

[0044] Step 5: Lower the temperature to 70°C, add the third batch of urea 29g, continue the reaction at 60°C for 30min, then cool and discharge. Test their performance respectively, and the results are listed in attached table 1. and with 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are shown in attached table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com