Patents

Literature

61results about How to "Excellent boiling water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous primer used for bicycles

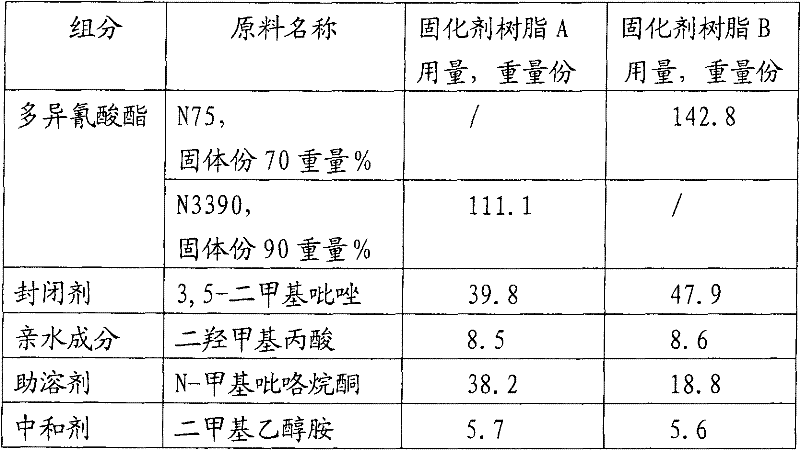

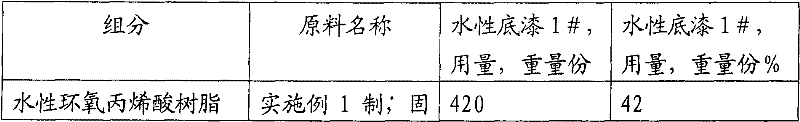

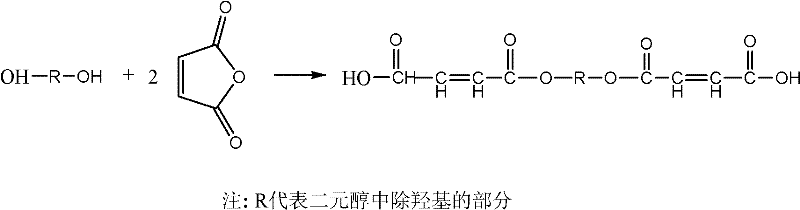

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyderesin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

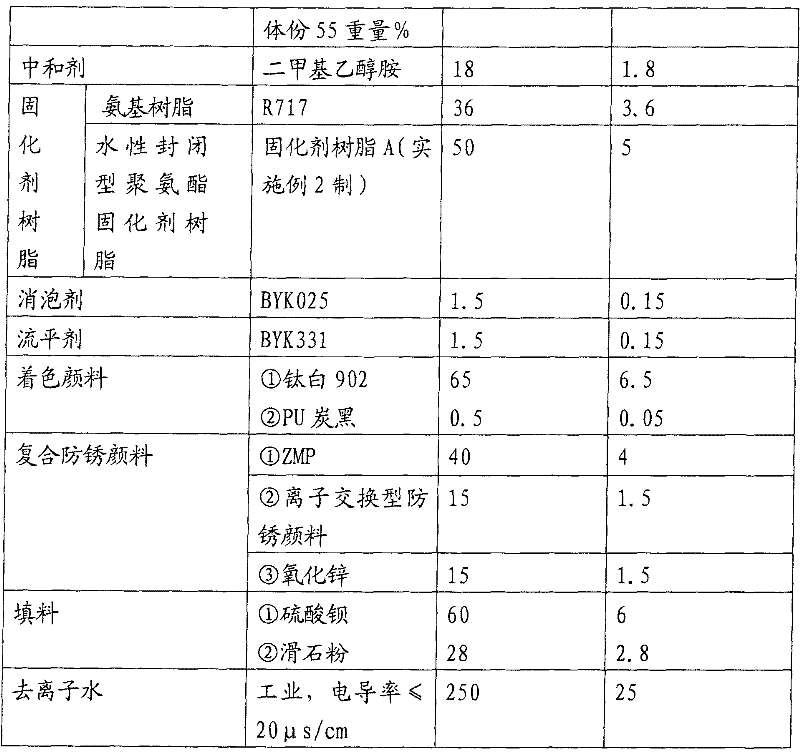

Method for synthesizing unsaturated polyester resin for artificial marble

ActiveCN102212173ACuring at room temperature with gentle exothermCuring shrinkage is smallWater dischargeAlcohol

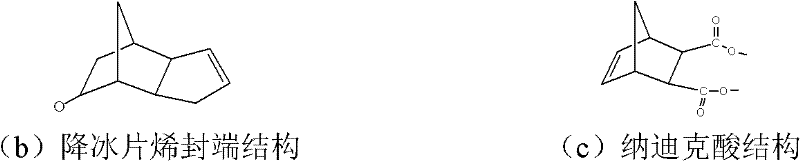

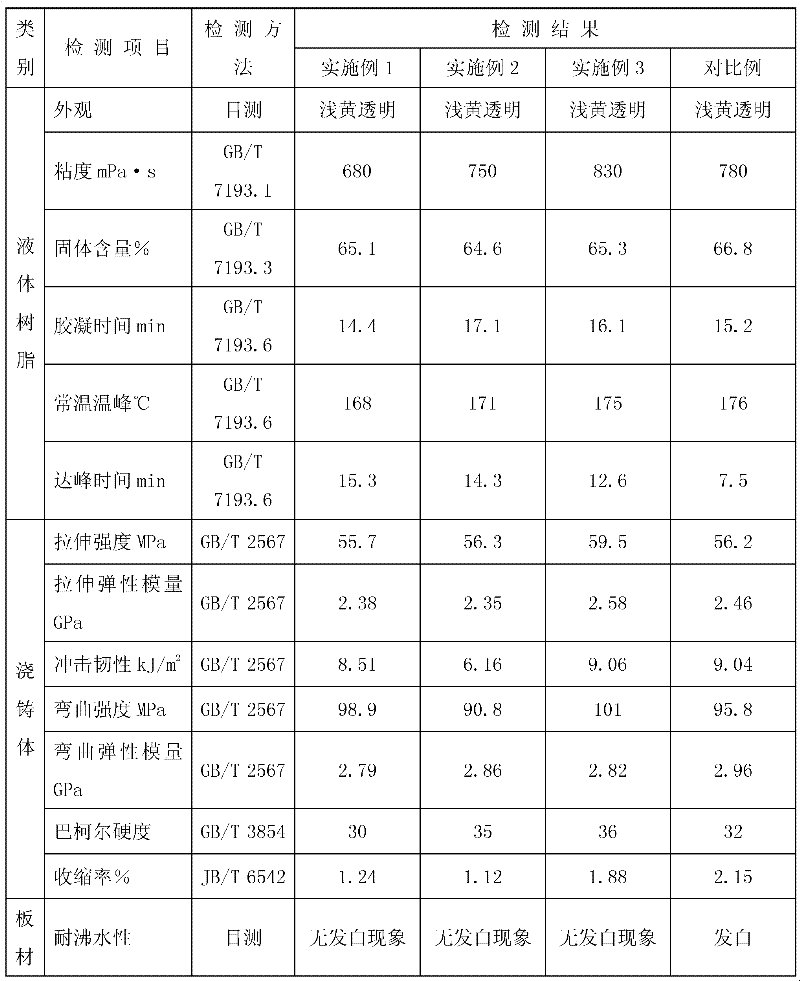

The invention provides a method for synthesizing unsaturated polyester resin for artificial marble, which mainly comprises the following steps of: (A) putting unsaturated dibasic acid, unsaturated dibasic acid anhydride, dicyclopentadiene and partial dihydric alcohol in a reaction kettle, heating and performing reflux reaction under the protection of nitrogen, and then heating and performing reflux reaction until a certain acid value is reached; (B) changing the state of the system to a distillation state, adding the residual dihydric alcohol to perform polycondensation reaction, and evacuating to discharge water forcibly when the water discharge quantity reaches 85% to 90% of a theoretical quantity, so that the reaction continues to be below the certain acid value; and (C) lowering the temperature and adding a polymerization inhibitor, diluting with styrene, and cooling and filtering to obtain the finished unsaturated polyester resin. The method provided by the invention is steady and controllable in the reaction process, fast in polycondensation reaction and small in quantity of generated waste water, and the obtained product has the characteristics of steady and slow curing and heat release at normal temperature, small rate of curing shrinkage, excellent boiling water resistance and the like, and can meet the quality demand of the artificial marble.

Owner:ZHAOQING FUTIAN CHEM IND

Self-crosslinking water-borne wood paint emulsion and synthetic method thereof

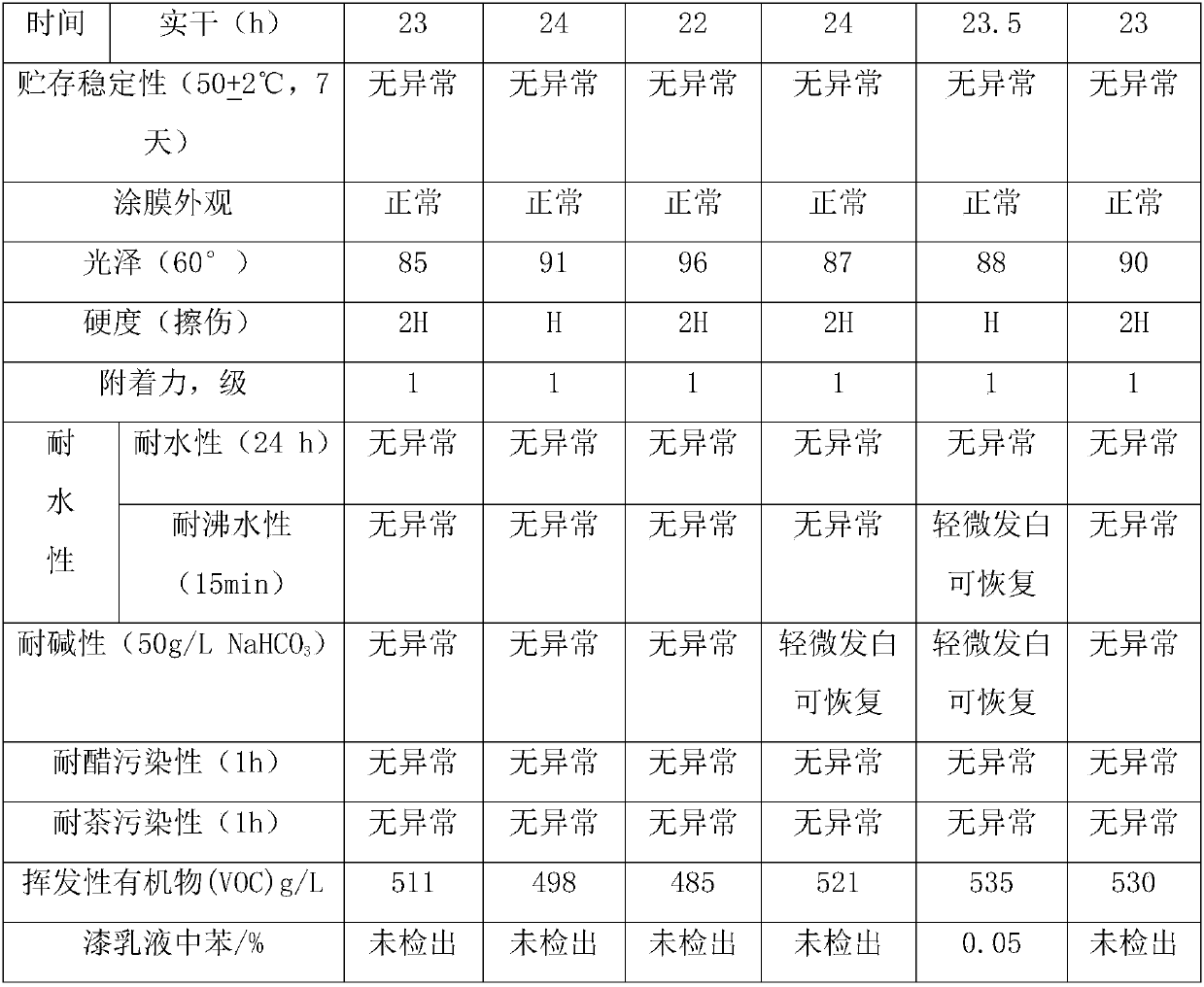

InactiveCN107841222AGood effectIncrease crosslink densityPolyurea/polyurethane coatingsEmulsion paintsSolventIsophorone diisocyanate

The invention provides a self-crosslinking water-borne wood paint emulsion and a synthetic method thereof, relating to the technical field of coatings. The self-crosslinking water-borne wood paint emulsion contains the following raw materials in percentage by weight: 25%-60% of an acrylic emulsion, 2%-6% of isophorone diisocyanate, 2%-7% of glyceryl triacetate, 10%-45% of acrylic monomers, 20%-50%of a waterborne polyurethane resin emulsion, 0.2%-2% of an emulsifying agent, 3%-6% of nano-crystalline cellulose, 0.2%-1.5% of a defoaming agent and the balance of deionized water. By taking the self-crosslinking acrylic emulsion as a main raw material and utilizing the self-crosslinking acrylic monomers, isophorone diisocyanate, the waterborne polyurethane resin emulsion, glyceryl triacetate and nano-crystalline cellulose and other raw materials, the prepared self-crosslinking water-borne wood paint emulsion has relatively high crosslinking density, the hardness, boiling water resistance, solvent resistance, light remaining property, color remaining property and impact resistance of a coating film are relatively excellent, and the content of volatile organic compounds is low, so that the environmental pollution is avoided, and the human healthy is guaranteed.

Owner:GUANGDONG VALSPAR CHEM IND

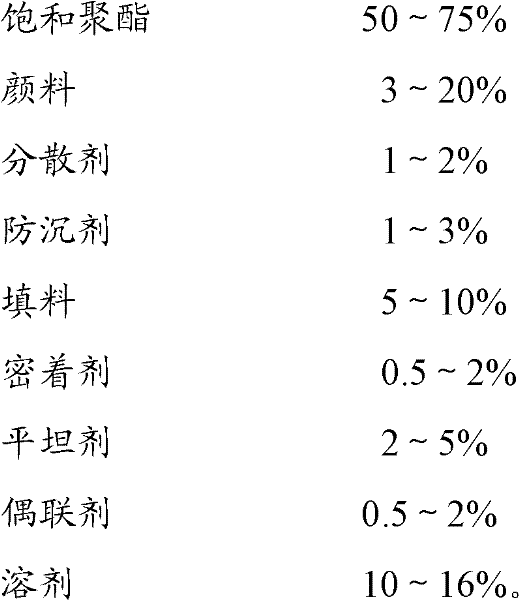

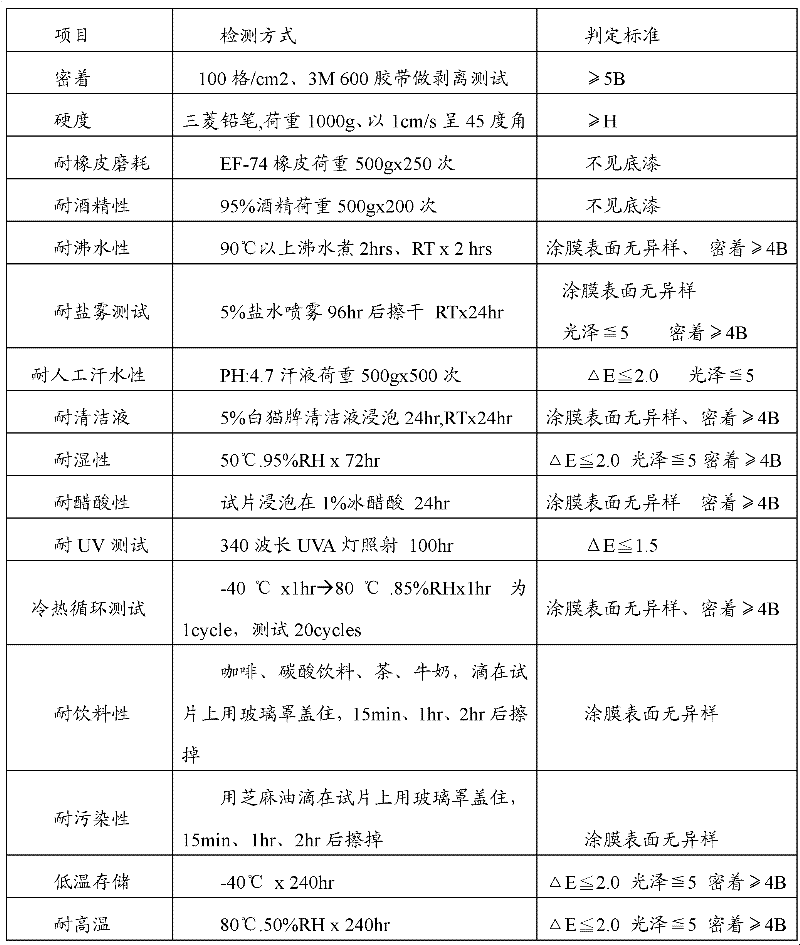

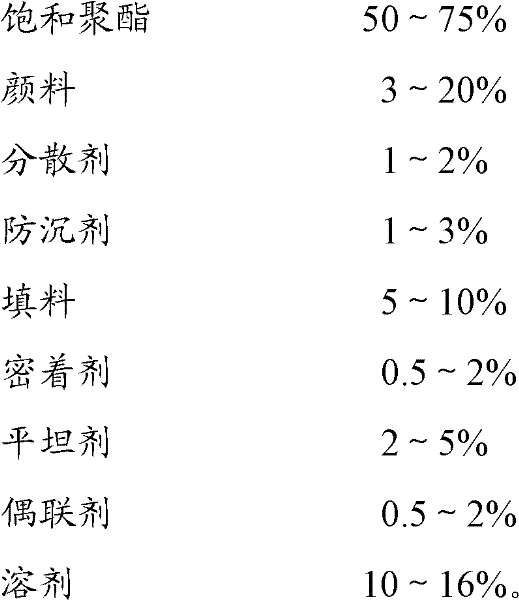

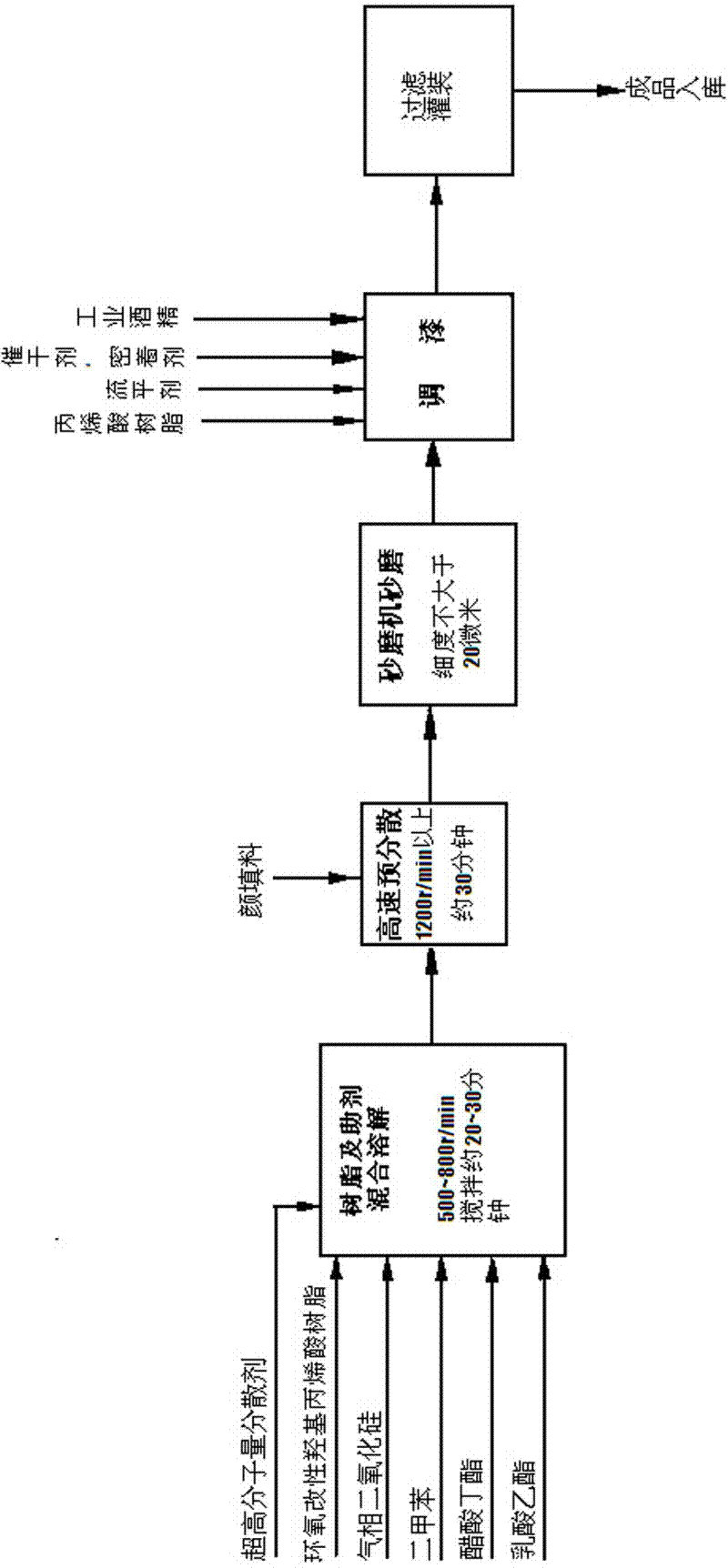

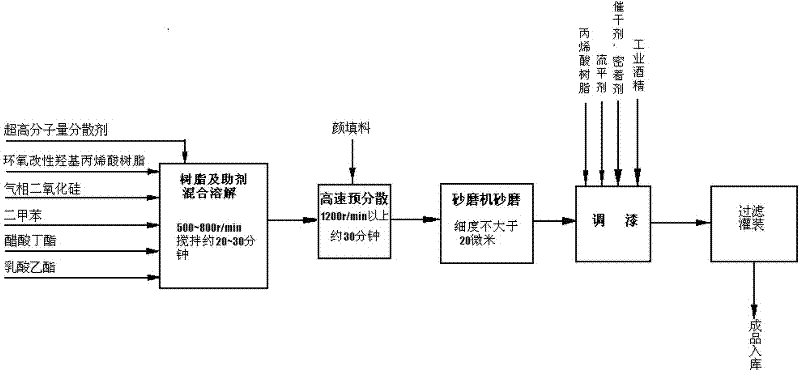

A special solvent-based primer for 3c product magnesium-aluminum alloy materials and preparation method thereof

ActiveCN102268215ANot hard and brittleImprove interlayer adhesionPolyester coatingsPolyesterProduction line

The invention relates to the technical field of solvent priming paints, in particular to a solvent priming paint special for a 3C (China Compulsory Certification) product magnesium-aluminum alloy material and a preparation method thereof. The solvent priming paint comprises substances such as saturated polyester, a pigment, a dispersing agent, an anti-settling agent, a filling, an adhesive agent,a flattening agent, a coupling agent, a solvent and the like, is prepared by performing procedures such as batch mixing, stirring, grinding and the like on different substances in different quantity relative ratios, can meet the requirements of customers on high-low temperature production lines, can be repeatedly coated and remade without causing cracking of a paint film, and has high ply adhesion and particularly high boiling water boiling resistance.

Owner:东莞大宝化工制品有限公司 +1

Environment-friendly flame-retardant straw board

ActiveCN107117927AOvercome the defect of high formaldehyde contentReduce formaldehyde contentChlorideUltra fine

The invention discloses an environment-friendly flame-retardant straw board. The straw board is prepared from the following raw materials in parts by weight: 50 to 100 parts of straw particles, 10 to 200 parts of flame retardant agent, and 1 to 50 parts of binding agent, wherein the flame retardant agent is prepared from the following raw materials: magnesium oxide, magnesium chloride, magnesium sulfate, nano stibium oxide and ultra-fine micro-silica powder; the binding agent is inorganic binding agent and is prepared from the following raw materials: aluminum sol, water glass, polyvinyl alcohol and deionized water. According to the environment-friendly flame-retardant straw board, by combining with the inorganic flame retardant agent and the inorganic binding agent with excellent performance, straw is used as a main raw material, so that the obtained straw board is flame-retardant without being carbonized and deformed at a high temperature of 1200 DEG C or more, and the production of harmful fume and gas is avoided; moreover, heat conduction on the straw board is avoided under a high temperature condition, and the straw board is not swelled once encountering the water, and the comprehensive performance is very excellent.

Owner:石植

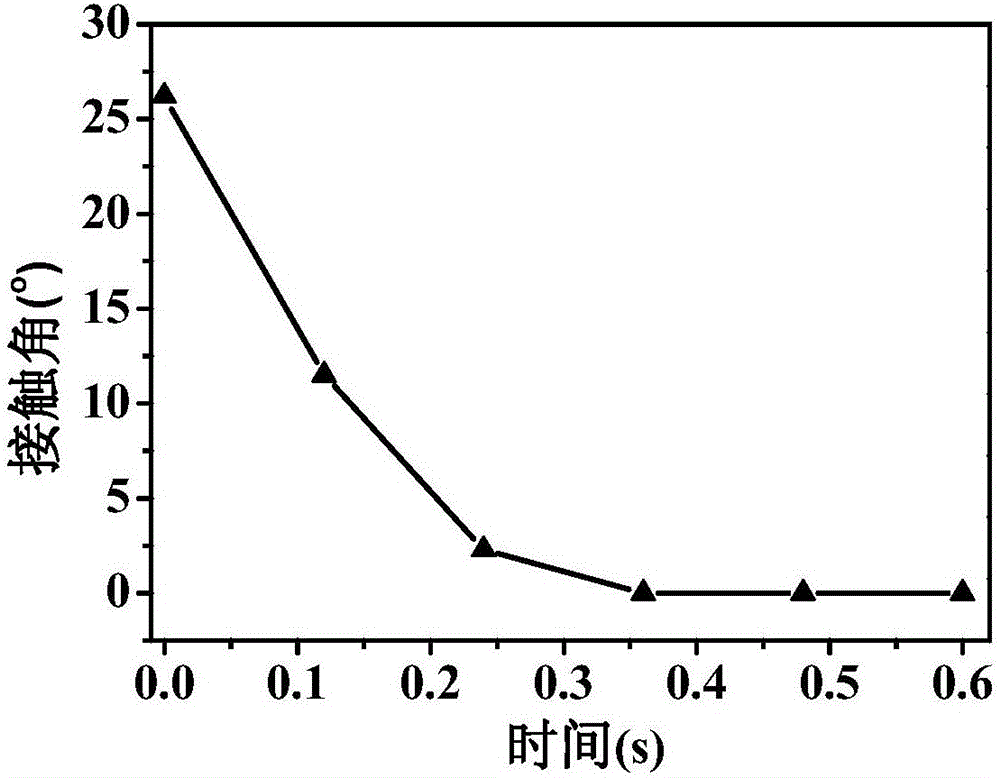

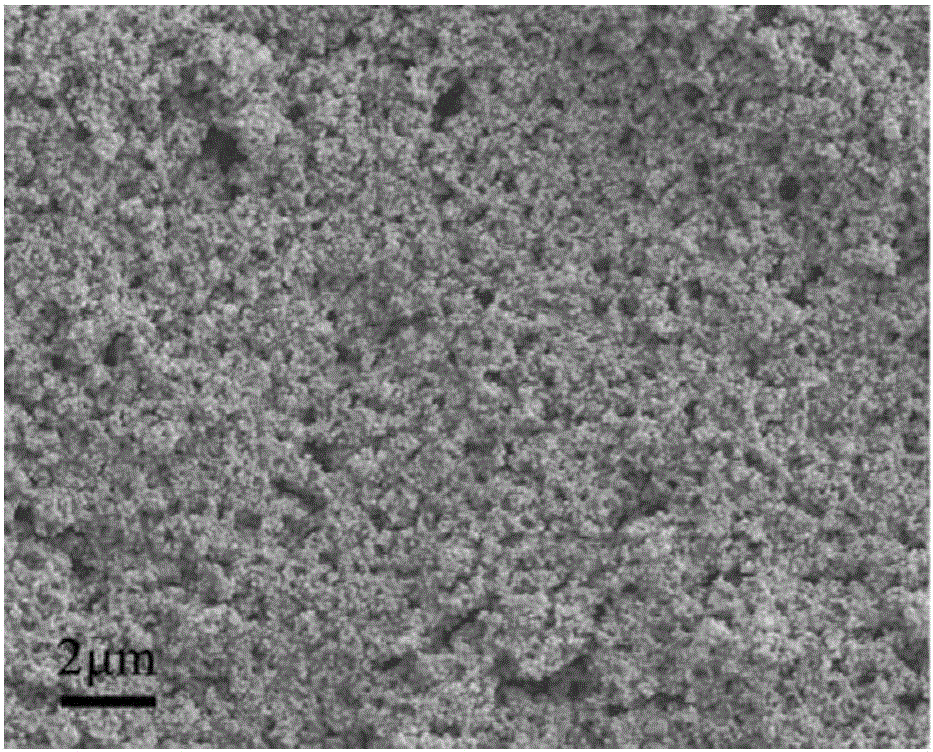

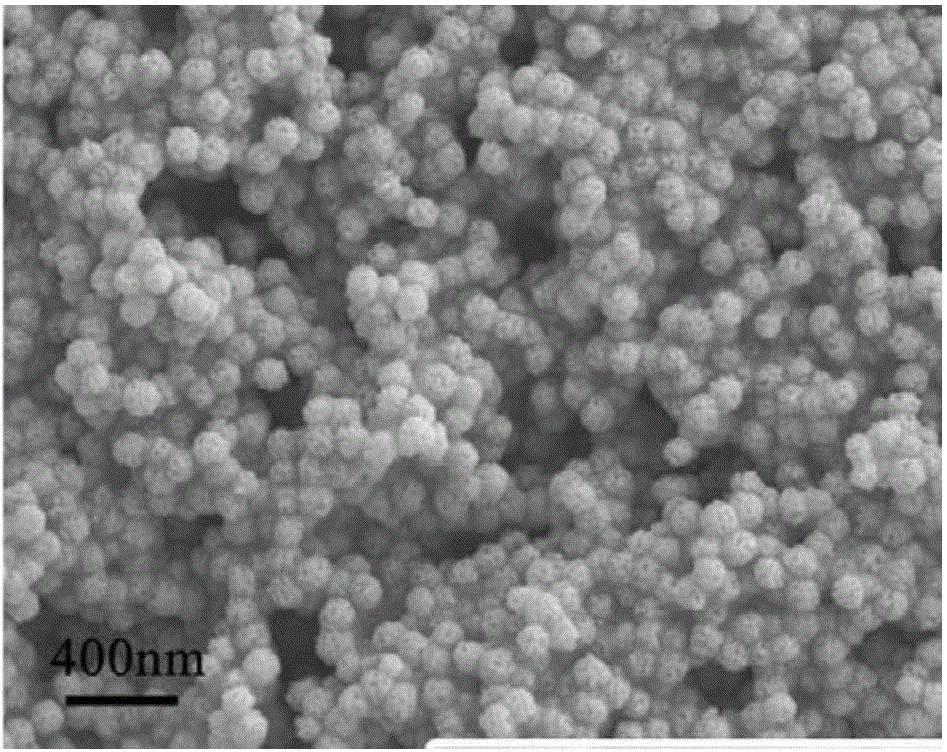

Ultraviolet cured organic/inorganic hybrid super-hydrophilic coating and method for preparing same

InactiveCN106479333AImprove superhydrophilicityImprove acid resistancePolyether coatingsCross-linkUltraviolet

The invention discloses an ultraviolet cured organic / inorganic hybrid super-hydrophilic coating and a method for preparing the same. The method includes carrying out sulfhydryl-alkene reaction on mercaptan compounds and acrylic ester compounds under the catalytic effects of amine catalysts to prepare hydrophilic oligomers; uniformly mixing the hydrophilic oligomers, mesoporous silicon dioxide, cross-linking agents and photoinitiators in methanol with one another to obtain solution; spraying the uniformly mixed solution on the surfaces of base materials and forming the organic / inorganic hybrid super-hydrophilic coating on the surfaces of the base materials by means of ultraviolet curing. Two ends of each mercaptan compound carry sulfhydryl, each of two ends of each acrylic ester compound carry C=C double bonds, and each of two ends of each hydrophilic oligomer carry C=C double bonds. The ultraviolet cured organic / inorganic hybrid super-hydrophilic coating and the method have the advantages that the method includes simple processes, water contact angles of the organic / inorganic hybrid super-hydrophilic coating prepared by the aid of the method can be reduced and are smaller than 5 degrees in 0.24 s, and the ultraviolet cured organic / inorganic hybrid super-hydrophilic coating is excellent in acid resistance, boiling water resistance and mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

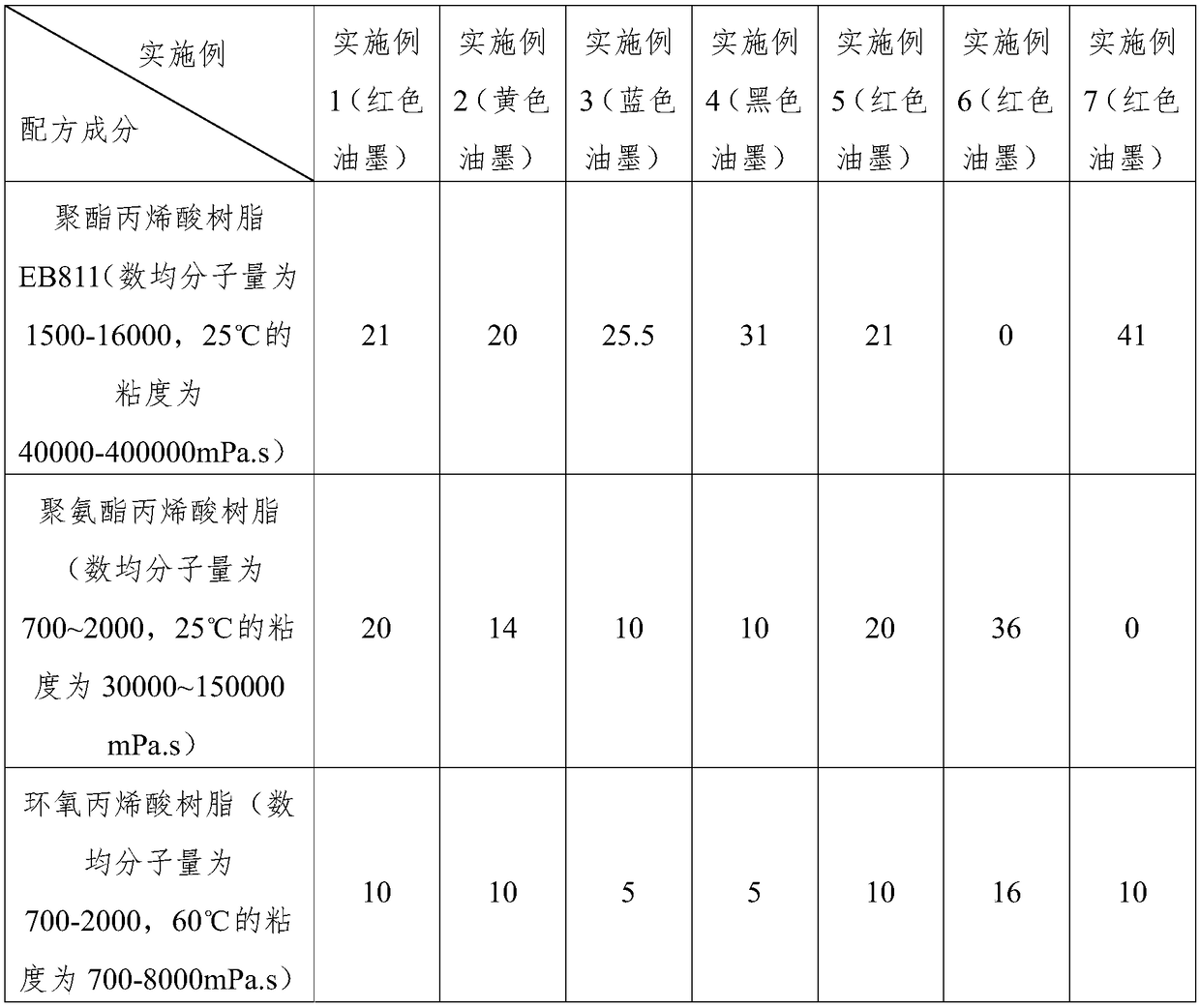

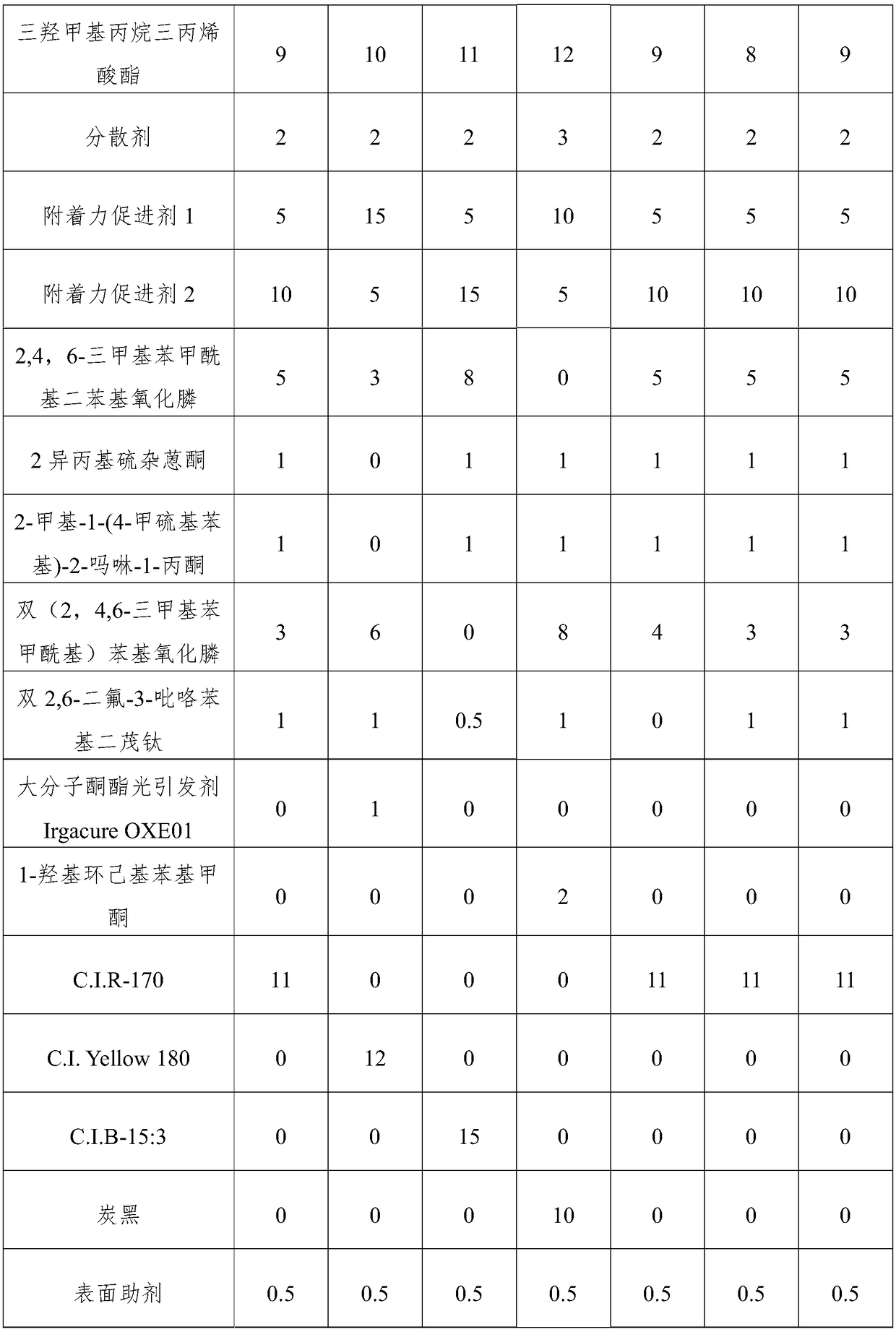

UV-LED curing transfer printing ink and preparation method and application

The invention provides UV-LED curing transfer printing ink in order to solving the problem that existing transfer printing ink is poor in adhesive force. The UV-LED curing transfer printing ink is prepared from, by mass, 40-60 parts of crylic acid prepolymer, 5-25 parts of adhesion promoter, 5-15 parts of monomers, 5-15 parts of photoinitiator, 5-25 parts of pigment and 0.3-3 parts of surface aid.Meanwhile, the invention discloses a preparation method and application of the UV-LED curing transfer printing ink. The adhesive force of the UV-LED curing transfer printing ink on all kinds of basematerials is good, the alcohol resistance and boiling water resistance are excellent, the durability at high temperature and high humidity is good, the scratch resistance is prominent, and the workingtime is short.

Owner:清远慧谷新材料技术有限公司

Method for preparing resin for high water resistant waterborne glass ink

The invention discloses a preparation method of a water-based glass ink-used resin with high water resistance, which comprises the following steps: step A. under the protection of nitrogen, dehydrated polyether dihydric alcohol, modified epoxy polyester polyol and IPDI react with each other at certain temperature; during the reaction course, the end of the reaction is judged by measuring the content of NCO; when the reaction ends, an emulsifying hydrophilc agent is added to react for a period of time and then the temperature is reduced; step B. after aqueous alkali is added for neutralization, a diluting solvent is added for dilution so as to reduce the viscosity of the solution after neutralization; then, emulsification is carried out at normal temperature, the chain is extended by a chain extender and the diluting solvent is removed in vacuum to obtain a water-based polyurethane dispersoid; and step C. core-shell copolymerization is carried out after high-speed emulsification by adding polymerized monomers into the water-based polyurethane dispersoid, and then the acroleic emulsion resin modified by the polyurethane is obtained after the temperature is reduced.

Owner:王兆进

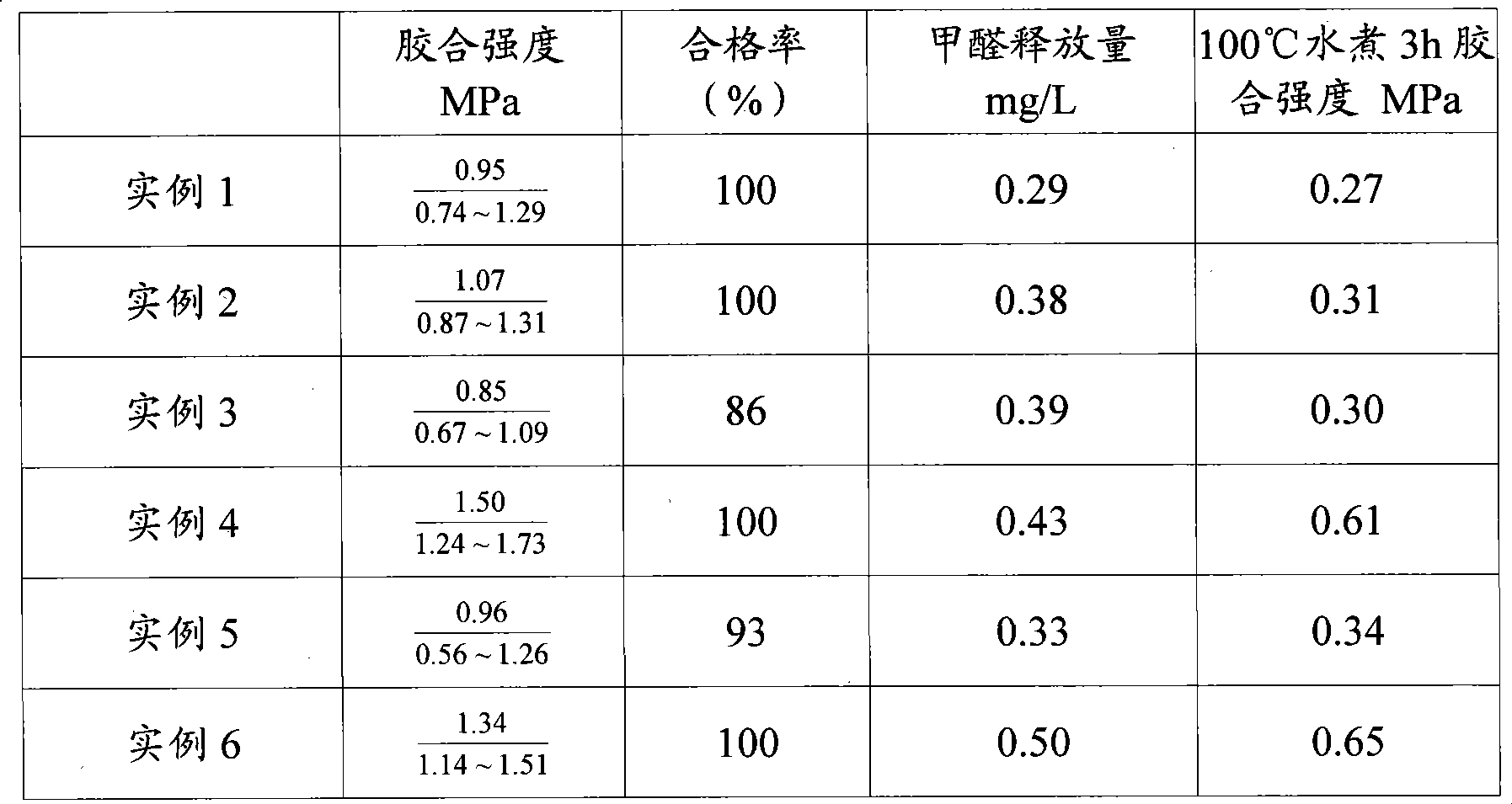

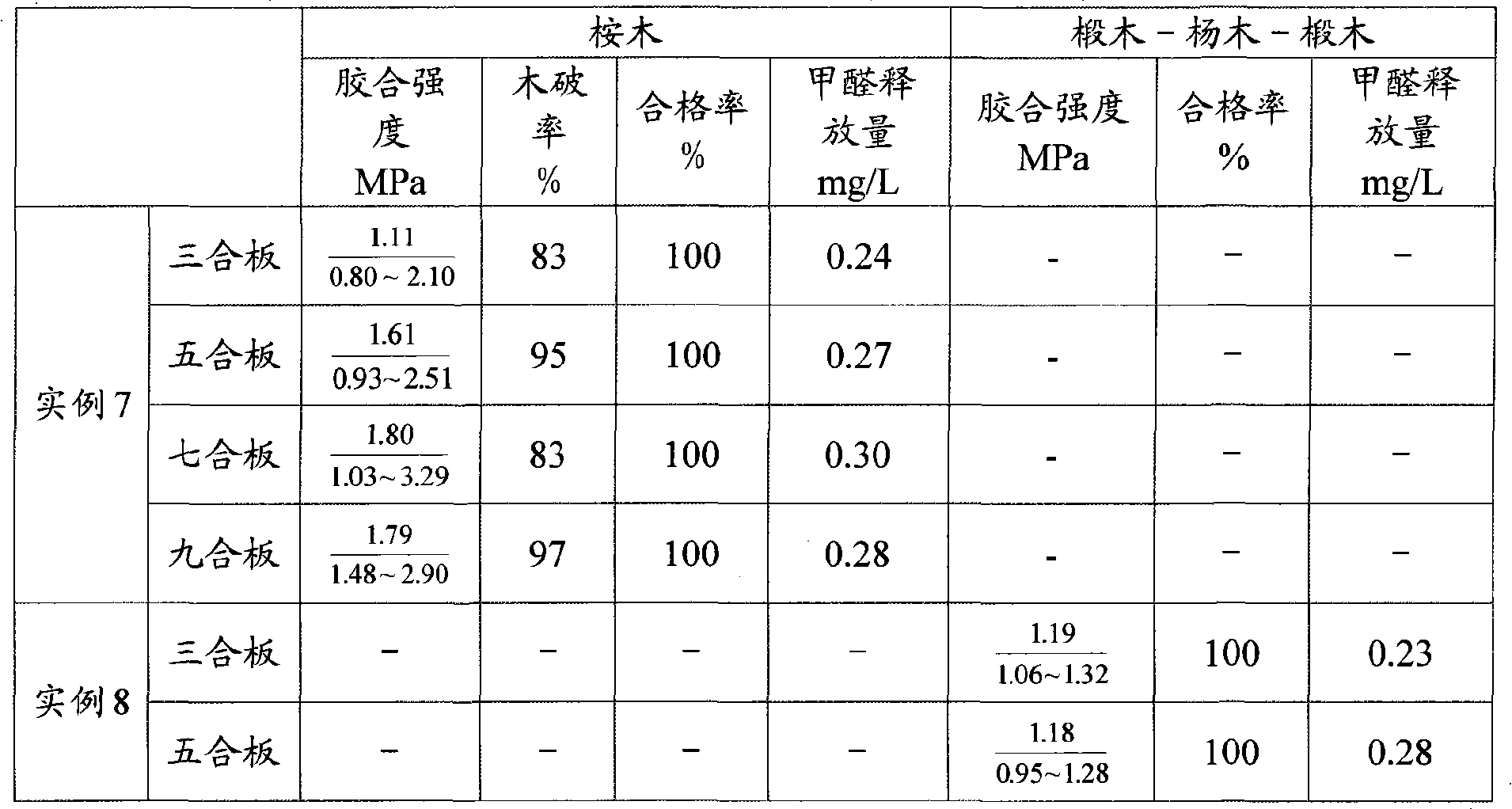

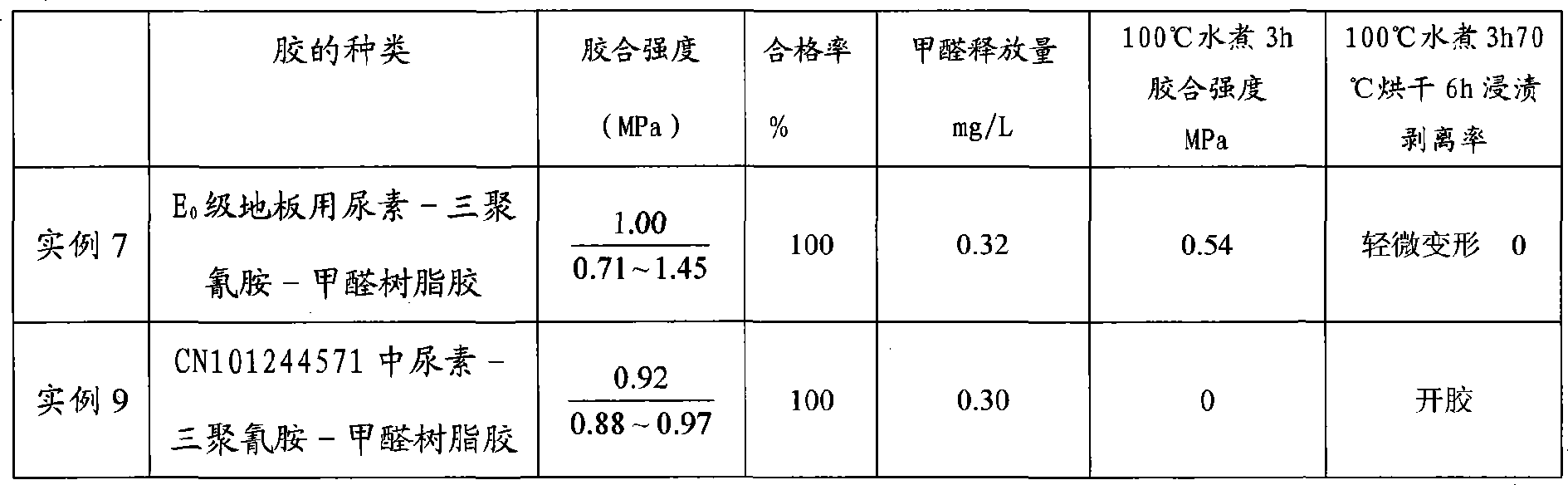

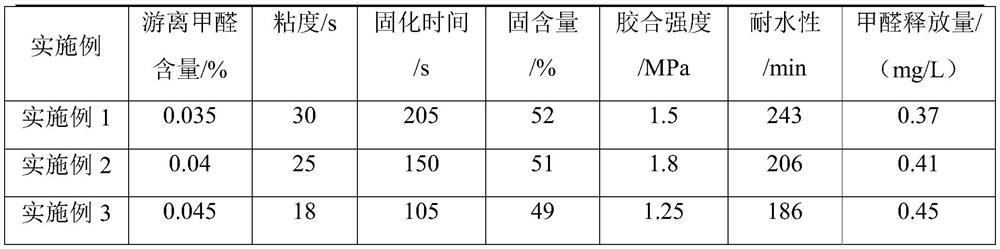

Preparation of urea-melamine-formaldehyde resin adhesive for E0 floor

InactiveCN101481593AReduce the content of ether linkagesReduce releaseAldehyde/ketone condensation polymer adhesivesUreaUrea melamine formaldehyde

The invention discloses a method for preparing a urea-melamine-formaldehyde resin adhesive for an E0-level floor. In the first step, formaldehyde solution, melamine and urea are mixed, the pH value of the mixture is regulated, the temperature is raised to 80-95 DEG C, and the reaction lasts 40-60 minutes, wherein, the mol ratio between formaldehyde and the total amount of the urea and the melamine is 2.05-2.12 : 1; in the second step, the pH value is regulated to be 5.0-6.0, and the reaction is underway till the turbidity point; in the third step, the pH value is regulated to be 6.0-6.9, the urea and the melamine are added, and the mol ratio between the formaldehyde and the total amount of the urea and the melamine which are added in the first step and the second step is 1.48-1.74 : 1, and the reaction lasts 30-70 min at a temperature of 90 DEG C; in the fourth step, the pH value is regulated to be 7.5-9.0, the melamine is added, and the reaction lasts 20-80 min at a temperature of 80-90 DEG C; and in the fifth step, the urea is added, the mol ratio between the formaldehyde and the total amount of all the urea and all the melamine is 1.02-1.30 : 1, and the material is cooled and discharged after the reaction is finished. A veneer formed by pressing the resin adhesive has good boiled-water resistance and low formaldehyde release, and the reaction is gentle and also easy to control.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

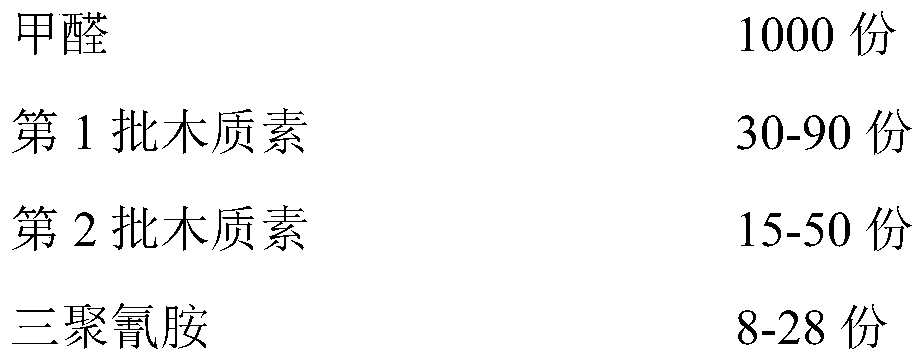

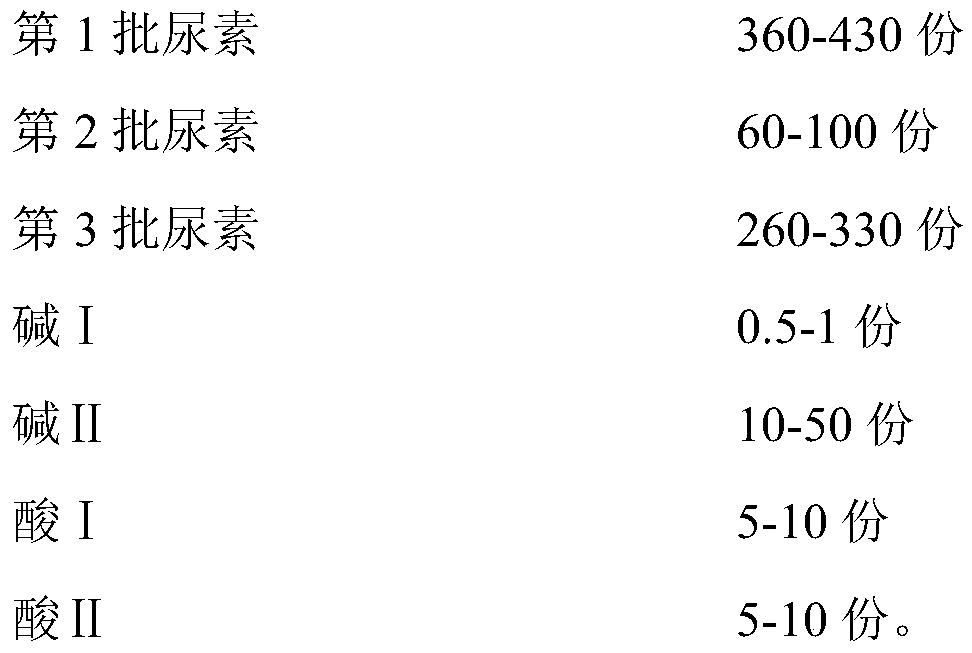

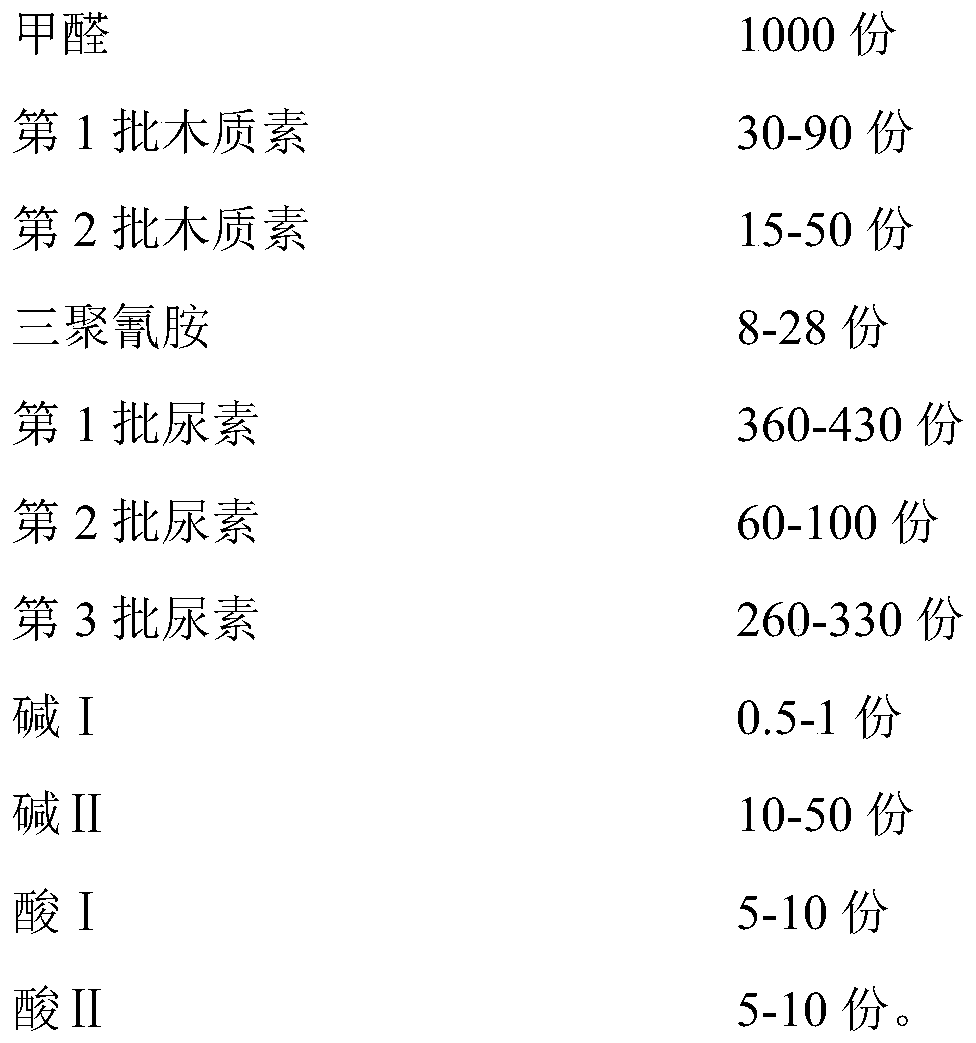

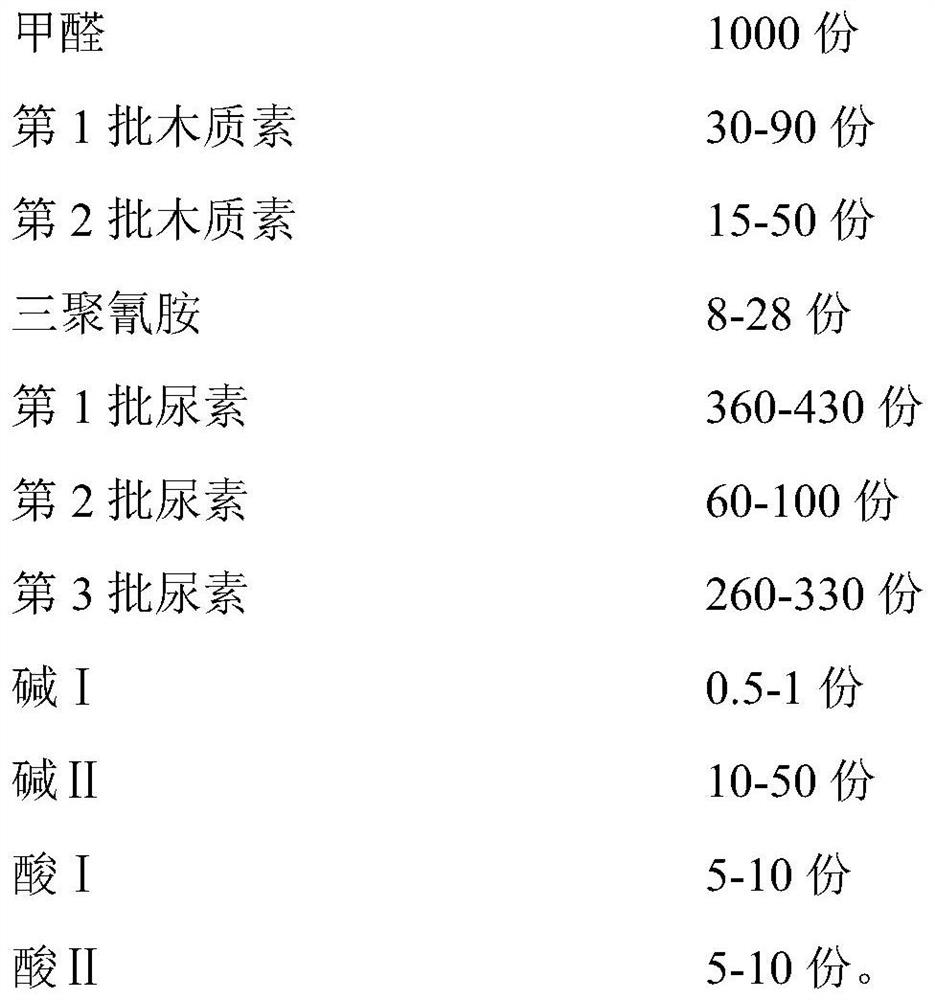

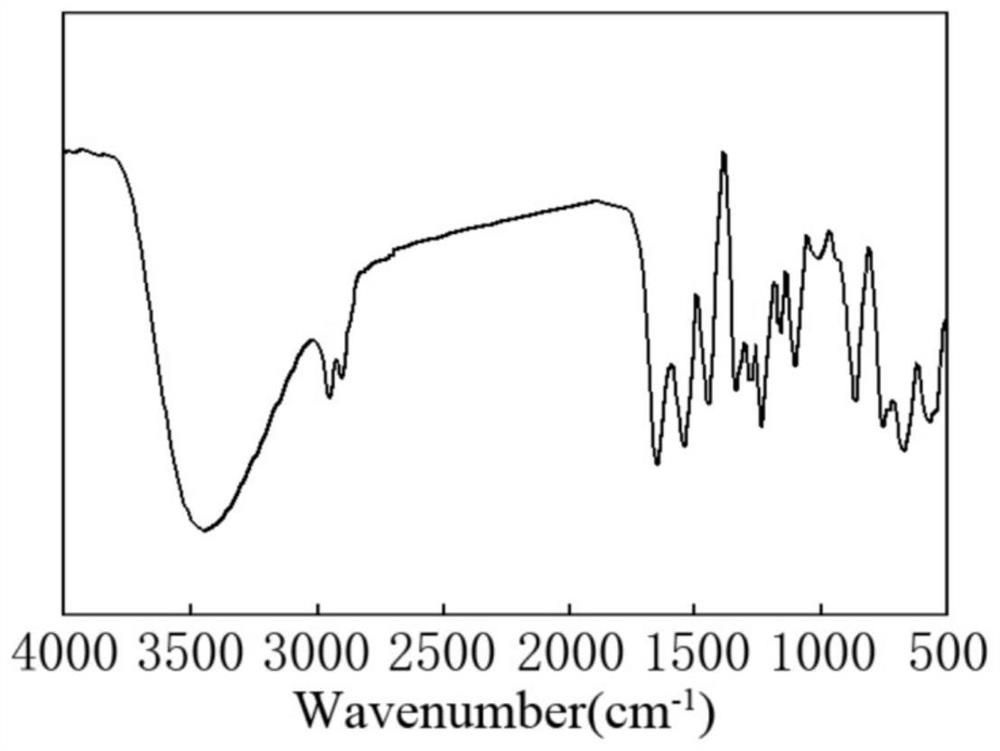

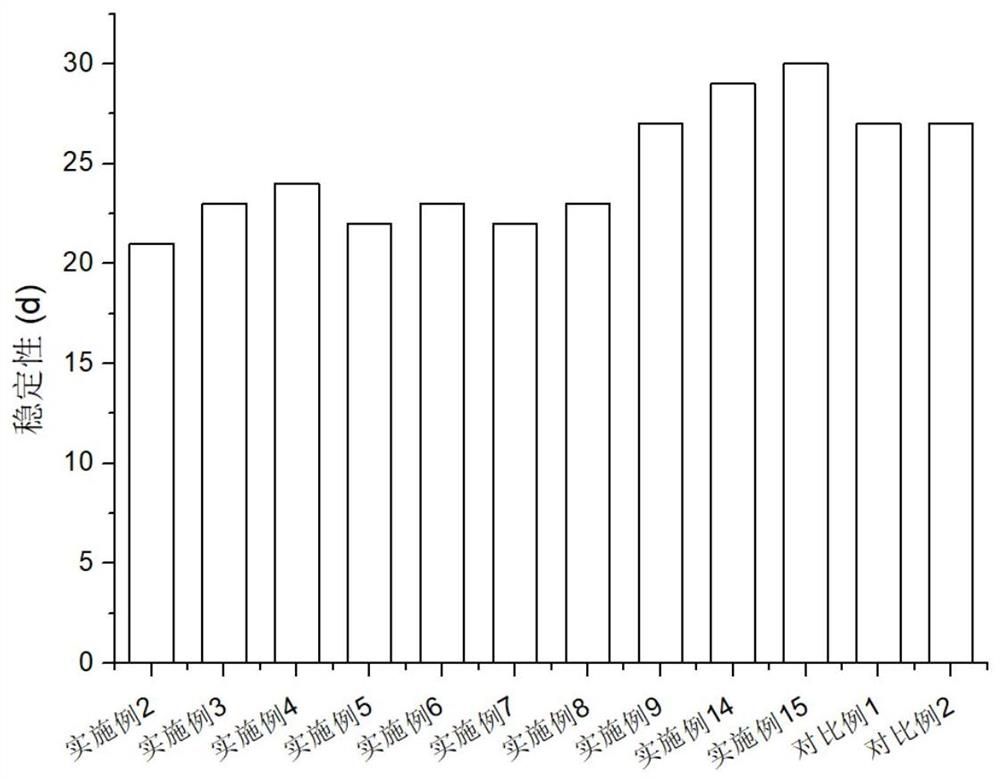

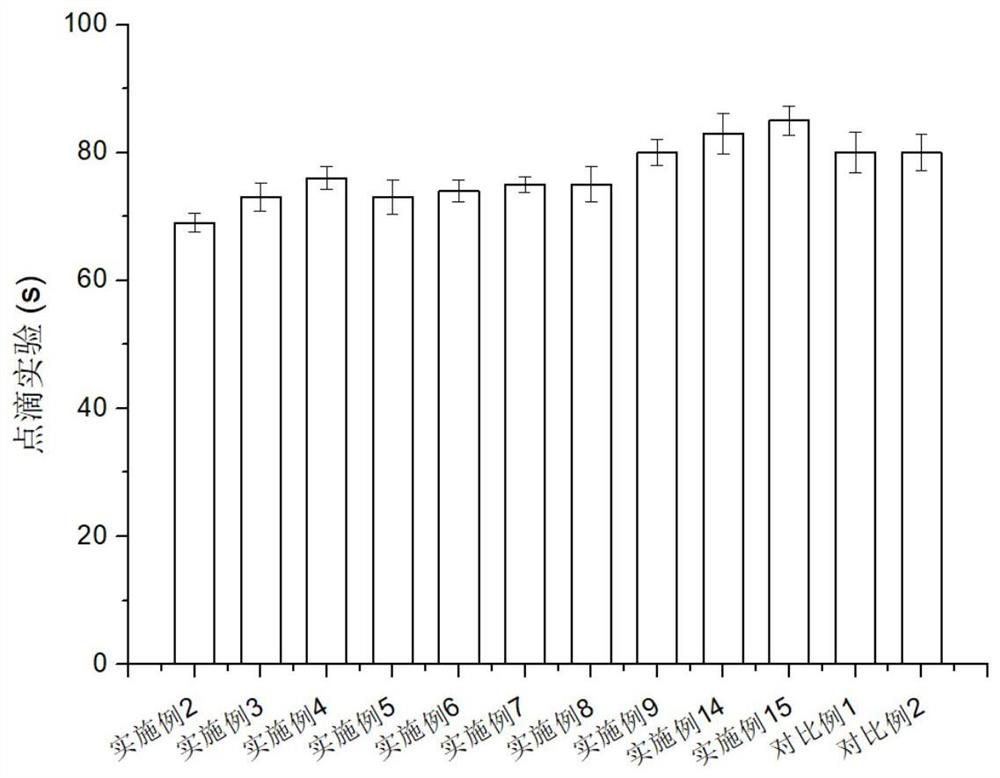

Lignin modified urea-formaldehyde resin adhesive and preparation method and application thereof

ActiveCN109868101ALow free formaldehyde contentReduce contentAldehyde/ketone condensation polymer adhesivesQuality controlUltimate tensile strength

The invention discloses a lignin modified urea-formaldehyde resin adhesive and a preparation method and application thereof. 1000 parts of formaldehyde, 45-140 parts of lignin, 8-28 parts of melamine,680-860 parts of urea, 10.5-51 parts of alkali and 10-20 parts of acid are used as raw materials, the lignin is added in two batches, the urea is added in three batches, and the lignin modified urea-formaldehyde resin adhesive is prepared by one-time addition reaction and three-time polycondensation reaction. The prepared adhesive has good initial adhesion, fast curing speed, high bonding strength, low content of free formaldehyde and good boiling water resistance. The adhesive can be used as a plywood adhesive, and the formaldehyde emission of the prepared plywood can reach the E0 standard,and the bonding strength meets the standard of a class II plywood. The lignin modified urea-formaldehyde resin adhesive has the advantages of simple preparation process, good stability, simple, fast and feasible quality control method, and low raw material cost, and is suitable for popularization and application.

Owner:广西高林林业股份有限公司

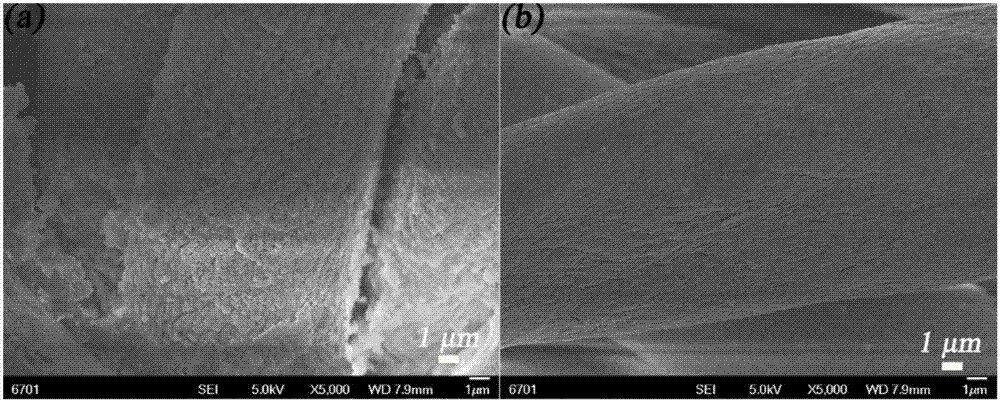

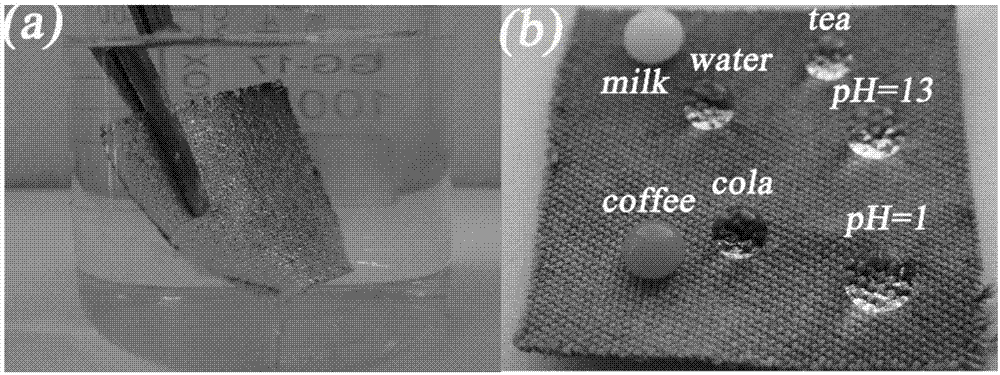

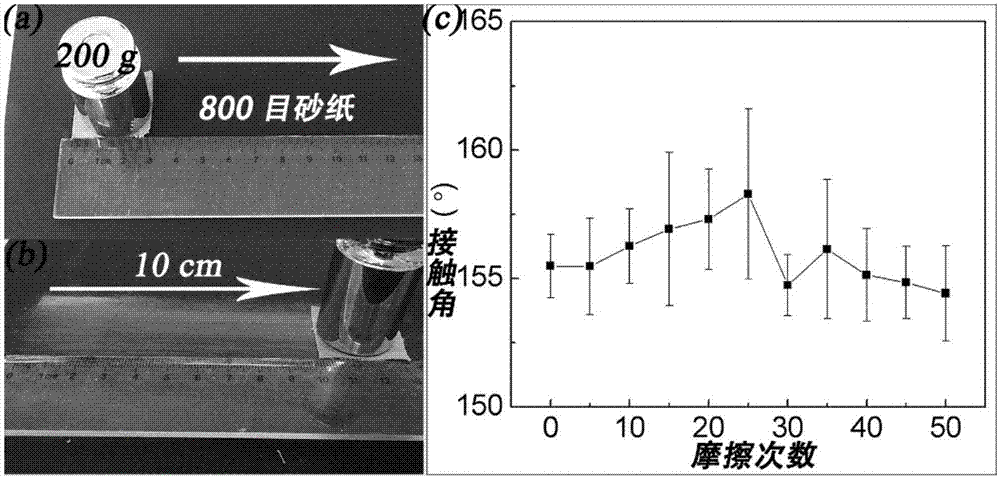

Preparation method of boiling water-resistant super-hydrophobic fabric for oil-water separation

ActiveCN107287903ASimple processRaw materials are easy to getLiquid repellent fibresNon-miscible liquid separationOil waterEngineering

The invention belongs to the technical field of super-hydrophobic materials and particularly relates to a preparation method of a boiling water-resistant super-hydrophobic fabric for oil-water separation. The preparation method comprises the step of preparing the super-hydrophobic fabric by virtue of a one-pot method. The super-hydrophobic fabric has good stability, all contact angles with water are larger than 150 degrees, roll angles are smaller than 10 degrees, and the super-hydrophobic fabric has good anti-infiltration capacity to common water system liquid in life and can preserve the super-hydrophobic performance after being put into boiling water for a long time. The preparation method has the beneficial effect that a preparation process is simple, the raw materials are easily available, and the super-hydrophobic fabric is non-toxic, environmentally friendly, low in cost, strong in stability, applicable to large-area preparation and applicable, applied to daily life and also applicable to the fields of oil-water separation and the like.

Owner:HUBEI UNIV

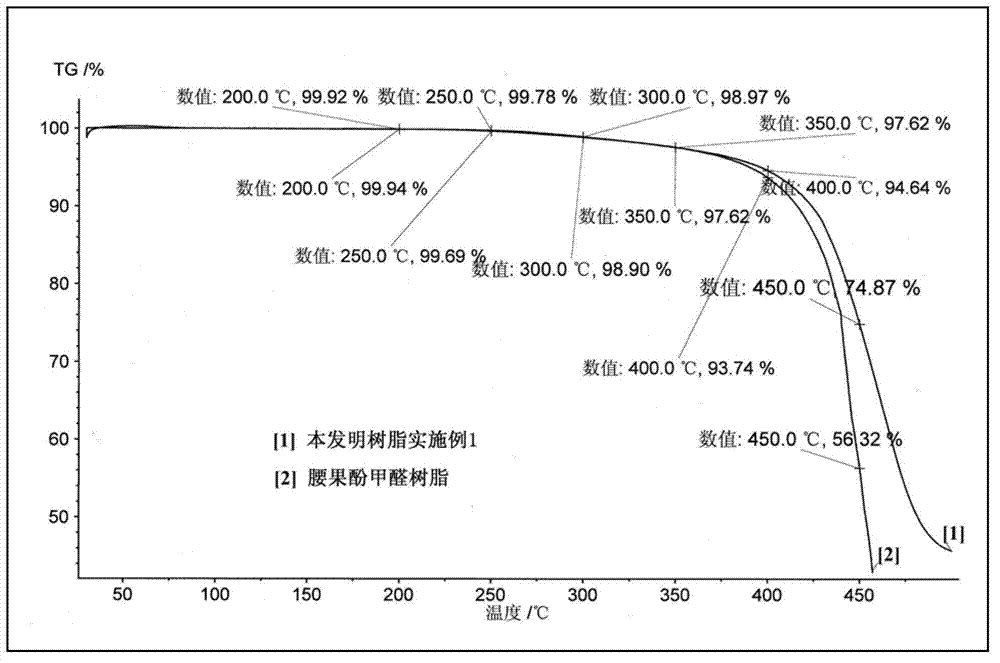

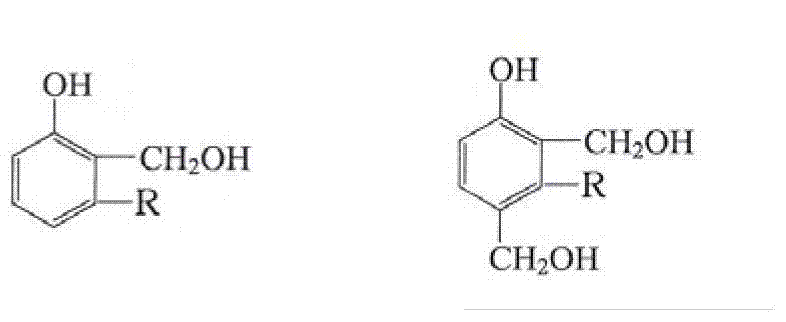

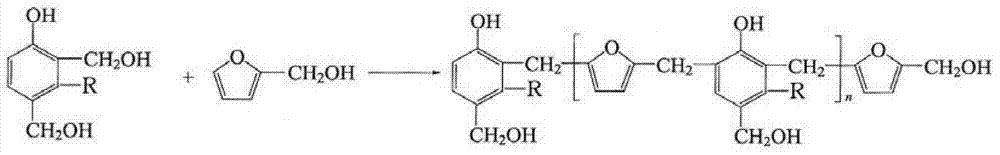

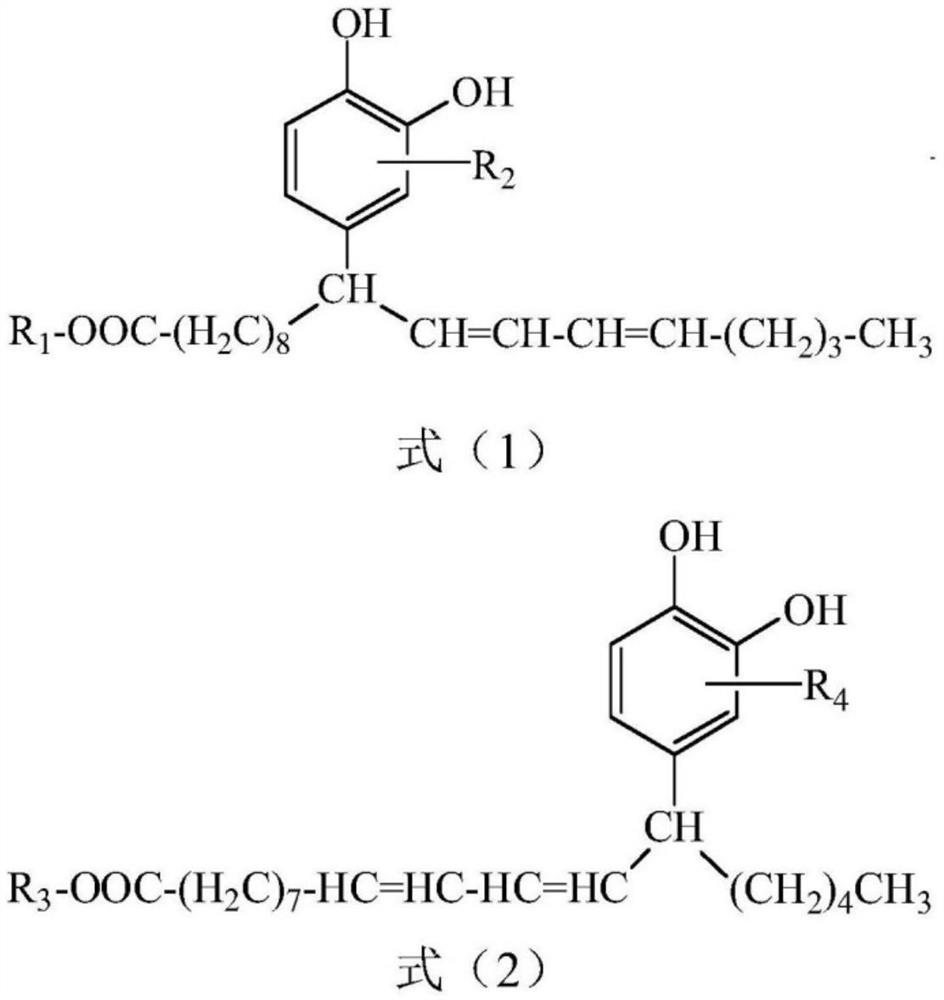

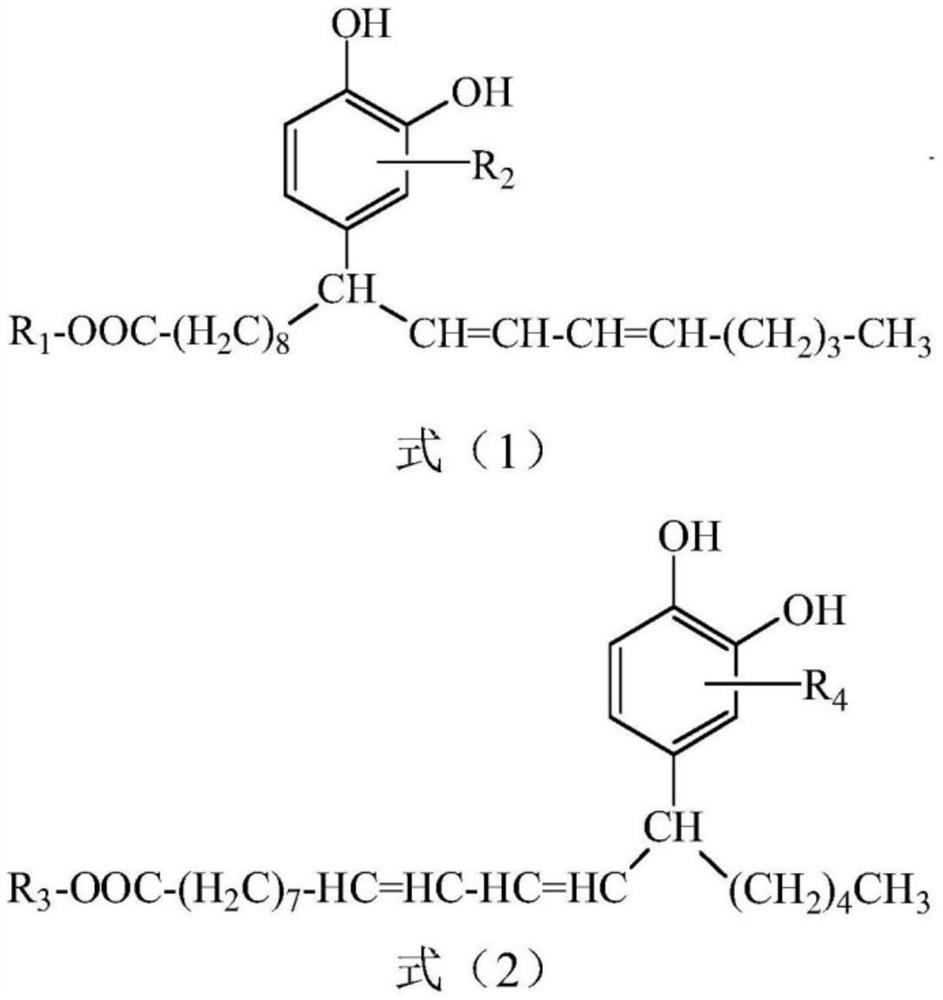

Preparation method of furan-modified cashew phenolic resin

ActiveCN103289035AImprove boiling water resistanceExcellent resistance to boiling waterHeat transfer tubeSeawater

The invention provides a preparation method of furan-modified cashew phenolic resin. The preparation method comprises the following steps of: selecting the following raw materials in parts by weight: 100-140 parts of cardanol, 32-54 parts of formaldehyde, 10-23 parts of furfuryl alcohol, 80-120 parts of dimethyl benzene and 8-10 parts of catalyst; adding the cardanol, the formaldehyde and the catalyst into a reaction kettle in proportion, reacting for 1 hour to 2 hours at 70 DEG C-80 DEG C; adding the furfuryl alcohol, and reacting for 1 hour to 2 hours at 90 DEG C-100 DEG C; adding the 80-120 parts of dimethyl benzene, heating up, separating the water by adopting an oil-water separating device until the temperature reaches 155 DEG C-160 DEG C, and performing heat preservation for 1 hour to 2 hours to obtain the furan-modified cashew phenolic resin. The preparation method of the furan-modified cashew phenolic resin has the beneficial effects of remarkably improving boiling water resistance and heat resistance of the resin, having a practical application meaning in corrosion resistance and scaling prevention of a distillation-process seawater desalting heat transfer tube as well as steam blowing resistance of a heat exchanger tube bundle of a petrifaction system, and being applicable to paint base preparation of industrial heavy-duty anticorrosive coating.

Owner:天津市中海科技有限公司

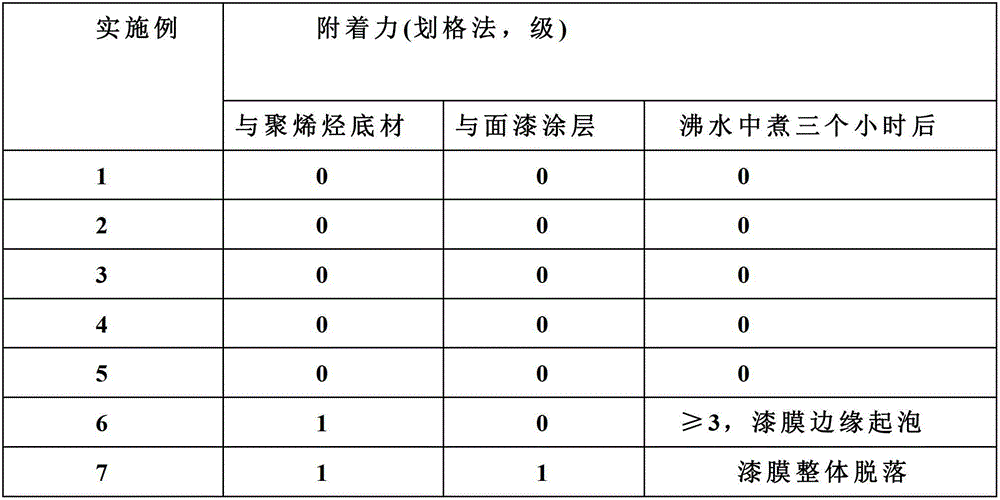

Modified polypropylene special resin and preparation method thereof

ActiveCN102746472AEasy to industrializeGood adhesionPolyurea/polyurethane coatingsGraft polymer adhesivesPolypropylenePolyolefin

The present invention discloses a modified polypropylene special resin, which is characterized by mainly comprising the following components: chlorinated polyolefin, a butadiene rubber, a vinyl monomer, and a terpene resin, wherein a weight ratio is 1:0-0.5:0.1-2:0.003-0.15. According to the modified polypropylene special resin, a long chain of the chlorinated polyolefin is adopted as a skeleton, and a tertiary carbon position or a secondary carbon position on the chlorinated polyolefin is grafted with the vinyl monomer and / or the butadiene rubber or / and the terpene resin. The modified polypropylene special resin of the present invention has good adhesion and good boiling water resistance, and a preparation method for the resin is simple, and is easy to industrialize.

Owner:SUZHOU XINGYE MATERIALS TECH

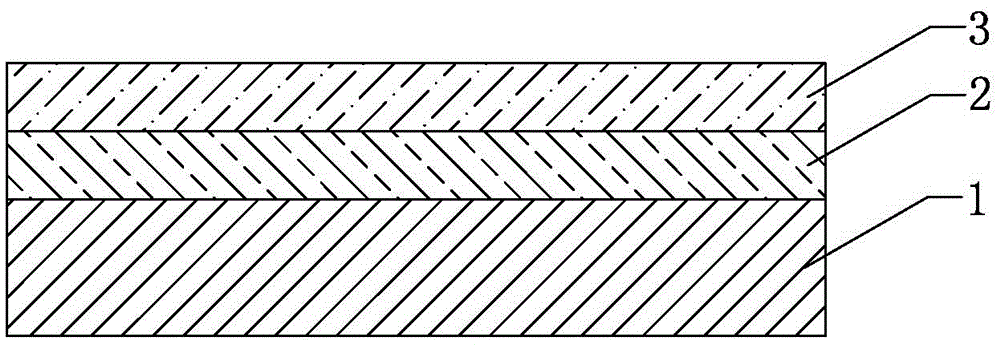

Glossy impregnated paper and manufacturing method thereof

ActiveCN105648843AHigh surface glossSimple structureSpecial paperPaper coatingAdhesivePulp and paper industry

The invention relates to the technical field of impregnated paper, and specifically to glossy impregnated paper and a manufacturing method thereof. The glossy impregnated paper comprises a raw paper layer, a wood-grain-printed layer attached to the upper surface of the raw paper layer, and a glossy surface adhesive layer attached to the upper surface of the wood-grain-printed layer. The wood-grain-printed layer and the glossy surface adhesive layer are arranged on the raw paper layer, so the manufactured impregnated paper is high in surface gloss and simple in structure. The method is low in cost and high in practicality.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

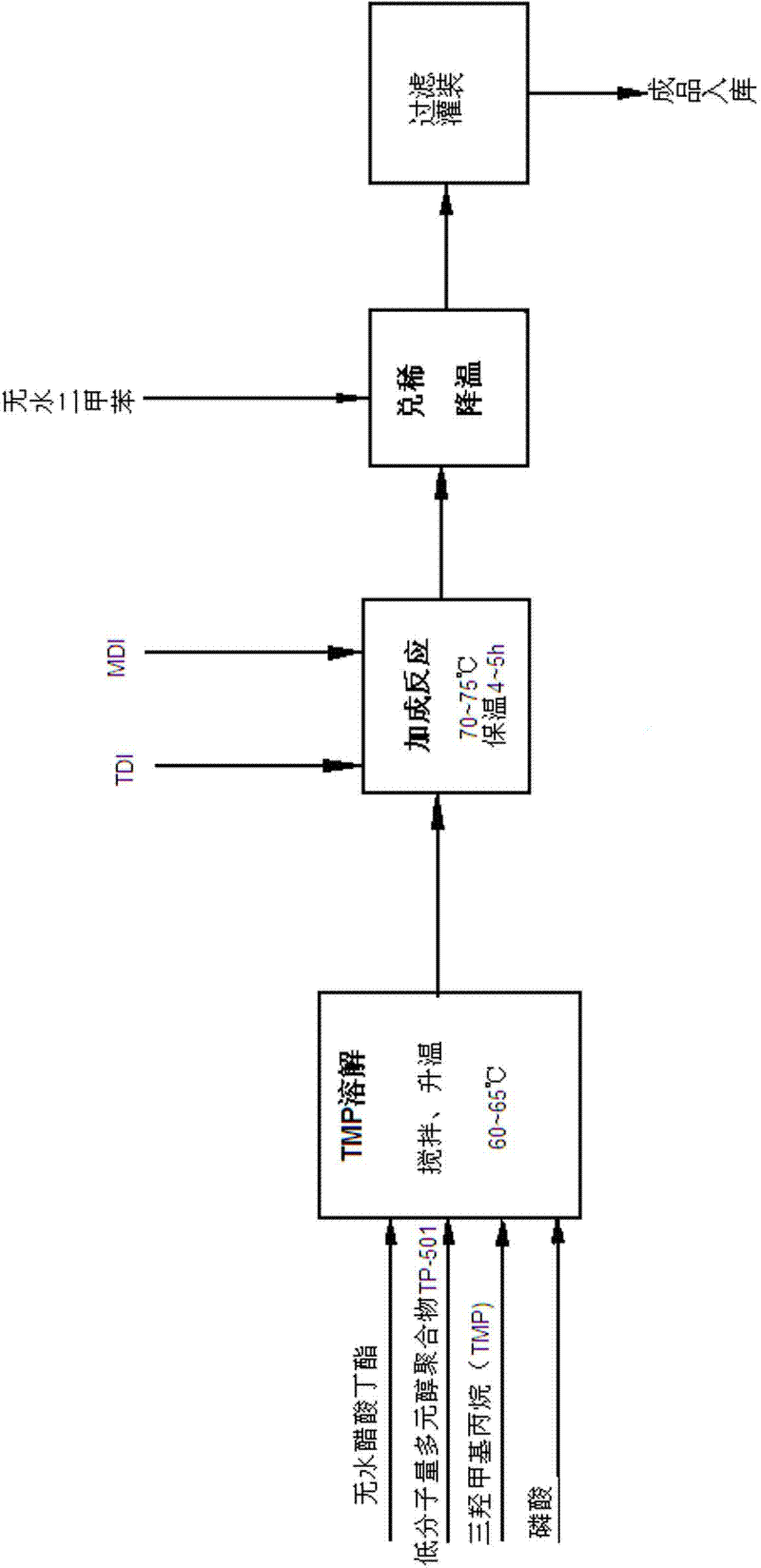

Acrylic polyurethane hot-dip galvanized substrate coating and preparation method thereof

ActiveCN102286242AExcellent adhesion strengthExcellent resistance to boiling waterAnti-corrosive paintsPolyurea/polyurethane coatingsPolyamideIron oxide

The invention discloses acrylic polyurethane hot galvanizing substrate paint and a preparation method thereof. The acrylic polyurethane hot galvanizing substrate paint is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A comprises epoxy modified hydroxyl acrylic resin, aerosil, organic bentonite or polyamide wax powder, hyper dispersants, xylol-butyl acetate-ethylene glycol methyl ether acetate mixed solvents, non-floating type aluminum silver paste and mica iron oxide pigment, coloring pigment, fluorine modified acrylic flowing agents, driers, organic siloxane adherence promoters and industrial alcohol, the ingredient B comprises low-molecular-weight polyalcohol polymers (TP hydroxyl value 500), trimethylolpropane (TMP), toluene diisocynate (TDI) and 4, 4'-diphenylmethane diisocyanate (MDI), and mixed solvents of xylol and butyl aetate are used as addition product carriers. The prepared products have excellent adhesive strength on hot galvanizing substrates.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Low-temperature-resistant flame-retardant PC (polycarbonate) composite material and preparation method thereof

The invention discloses a low-temperature-resistant flame-retardant PC (polycarbonate) composite material and a preparation method thereof. The low-temperature-resistant flame-retardant PC composite material is composed of the following components in percentage by mass: 70-85% of PC resin, 5-10% of polyolefin elastomer graft, 2-5% of low temperature resistance modifier, 5-10% of composite flame retardant, 1-3% of stabilizer, 0.1-0.5% of antioxidant and 0.1-1.5% of dispersing agent. Compared with the prior art, the PC composite material disclosed by the invention has the advantages of excellent low-temperature impact toughness, excellent flame retardancy, higher PC notch sensitivity, higher chemical resistance, higher boiling water resistance and the like. The flame retardancy can satisfy the requirements of Grade UL94V-0, no halogen and environmental protection. The PC composite material can be widely used in the fields of automobiles, electronic and electric appliances, illumination, physical equipment and the like. The production technique disclosed by the invention is simple, and has wide application and industrialization prospects.

Owner:QINGDAO WANLI TECH

Water-based polyurethane emulsion with high water resistance and ethanol resistance and preparation method thereof

ActiveCN109721707AImprove water resistanceImprove ethanol resistancePolyurea/polyurethane coatingsWater basedEmulsion

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a water-based polyurethane emulsion with high water resistance and ethanol resistance and a preparation method thereof. The invention provides the preparation method of the water-based polyurethane emulsion with high water resistance and ethanol resistance. The preparation method comprises the following steps: a) carrying out a first reaction on poly(propylene carbonate) polyol, diisocyanate, castor oil and a hydrophilic chain extender under the action of a catalyst to obtain a first product;b) adding a silane coupling agent into the first product to carry out a second reaction to obtain a second product; and c) adding a neutralizer into the second product to carry out a neutralization reaction, then adding deionized water for emulsifying, and then adding a non-hydrophilic chain extender to carry out a third reaction to obtain the water-based polyurethane emulsion. Experimental results show that a coating film formed by the water-based polyurethane emulsion disclosed by the invention has excellent boiling water resistance and ethanol resistance.

Owner:GUANGDONG UNIV OF TECH

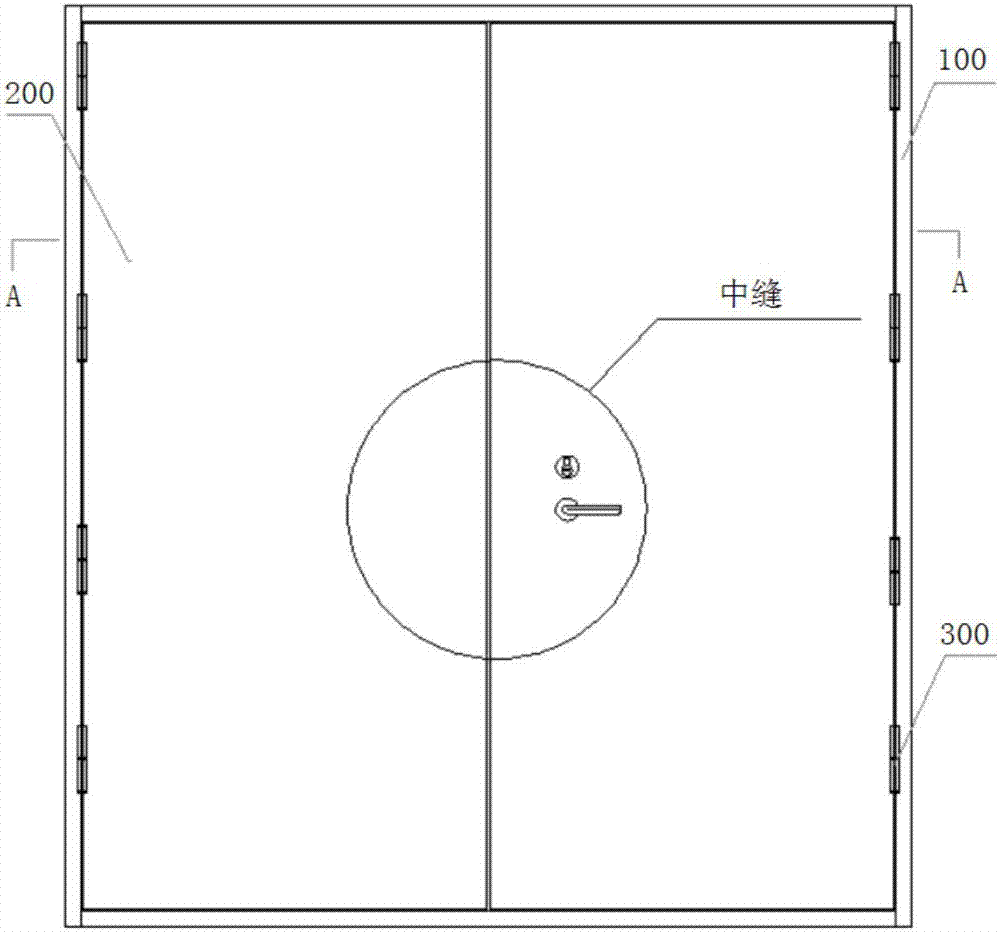

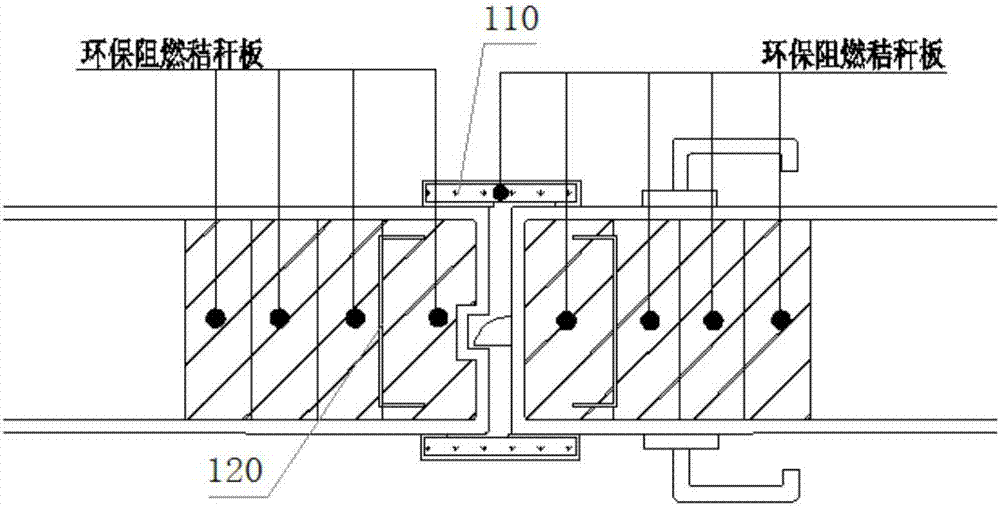

Fireproof door middle seam provided with flame-retardant straw fire prevention boards

ActiveCN107130894AGuaranteed stabilityImprove rigidityFireproof doorsFlat articlesEngineeringFire prevention

The invention discloses a fireproof door middle seam provided with flame-retardant straw fire prevention boards. The fireproof door middle seam comprises a door frame, door leaves and hinges, wherein the door leaves are connected with the door frame by the hinges; a face exposed to fire and a face unexposed to fire are respectively formed at the two sides of each door leaf; a middle seam is formed by the contact surfaces of the left door leaf and the right door leaf; the left door leaf and the right door leaf are respectively formed by two parts, wherein the four flame-retardant straw fire prevention boards are arranged in the parts at the sides close to the middle seam, and the other parts connected with the flame-retardant straw fire prevention boards are made from steel section; a seam cover plate is also arranged in the fireproof door middle seam and is formed by cutting the flame-retardant straw fire prevention board. The fireproof door middle seam creatively overcomes the defect that a middle seam of the traditional steel or wooden fireproof door is easily deformed in the event of high temperature of a fire; the flame-retardant straw fire prevention boards are set as the parts, close to the middle seam, of the door leaves and the seam cover plate, so that the effects of fire prevention, flame retardance and smoke suppression are effectively achieved; the fireproof door middle seam guarantees the stability of a framework structure of the fireproof door when the fireproof door is in a fire; the middle seam is non-deformable and fireproof.

Owner:石植

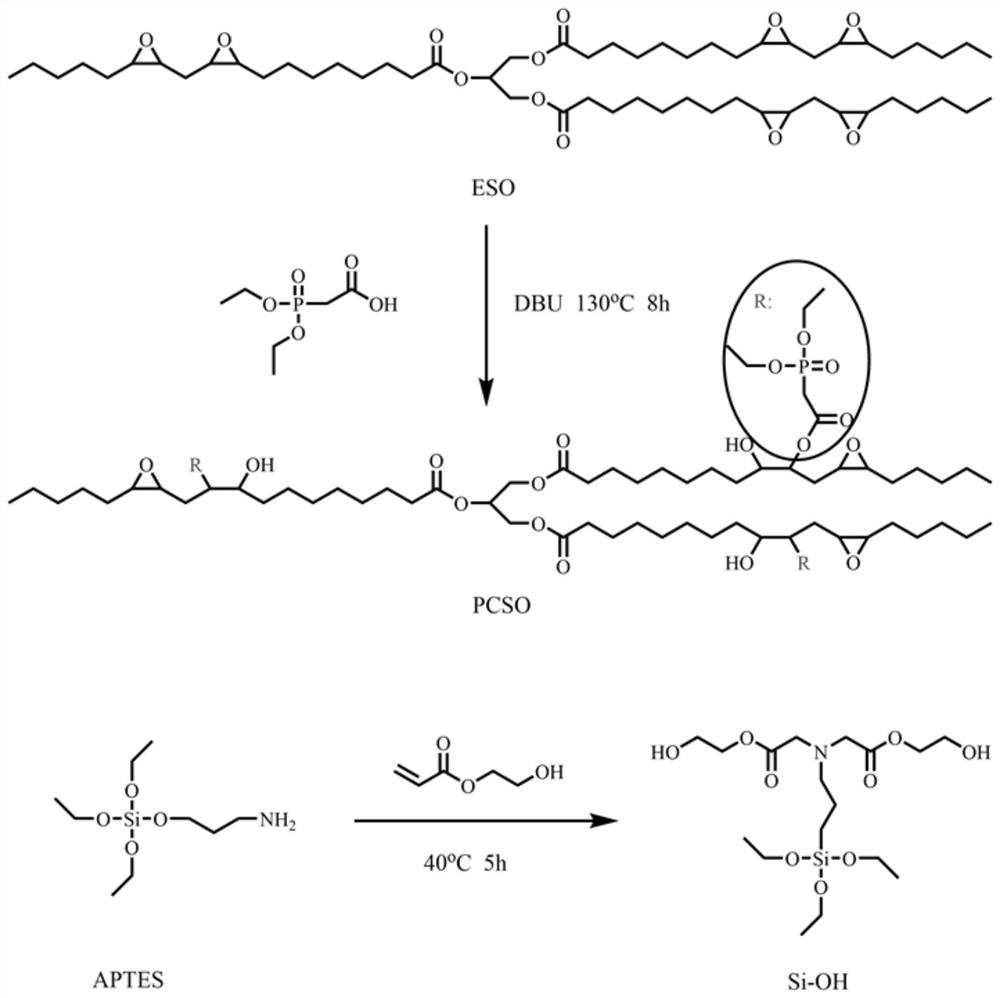

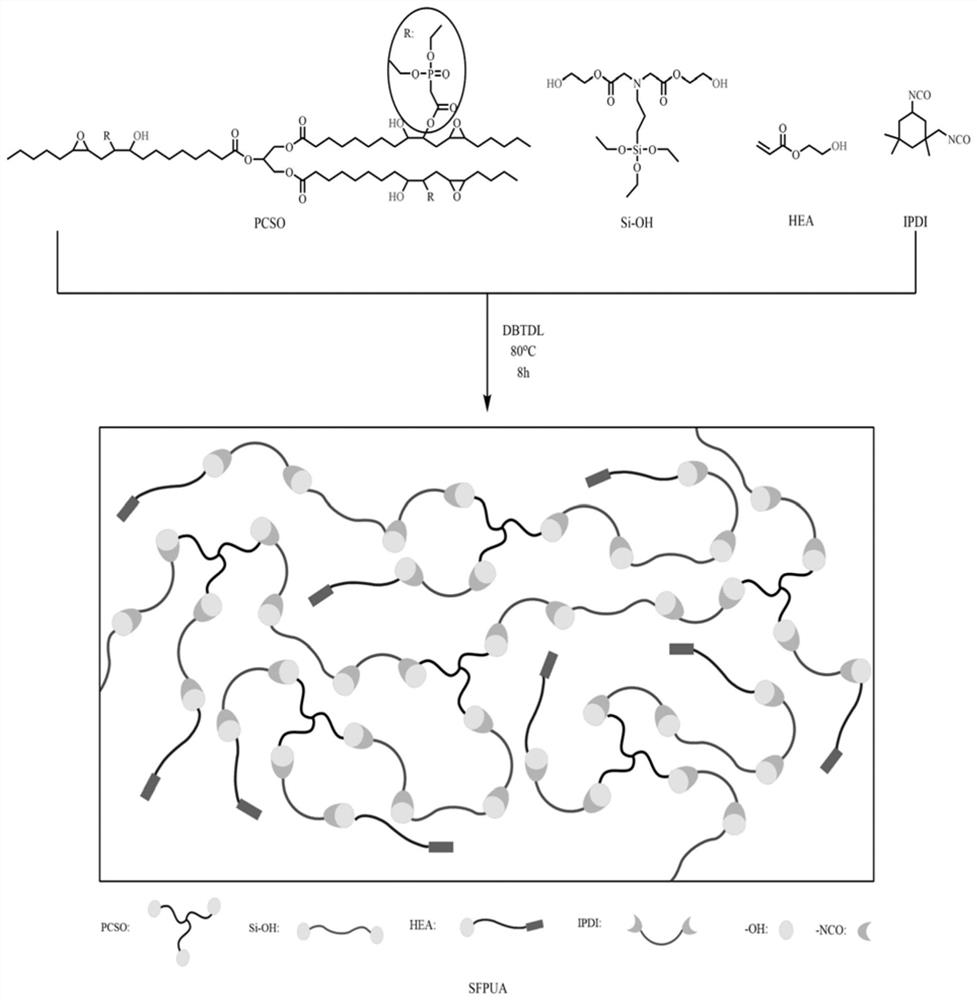

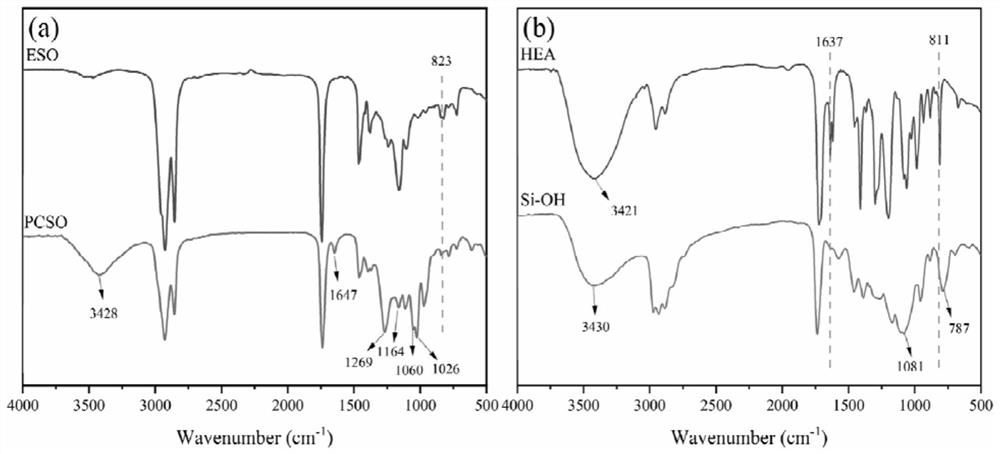

Vegetable oil-based flame-retardant polyurethane acrylate prepolymer as well as preparation method and application thereof

ActiveCN113307931AHigh reactivityImprove flame retardant performanceFireproof paintsAdditive manufacturing apparatusPolymer scienceVegetable oil

The invention belongs to the technical field of UV (ultraviolet) curing materials, and particularly relates to a vegetable oil-based flame-retardant polyurethane acrylate prepolymer as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting epoxy vegetable oil with diethyl phosphorus acetic acid to prepare bio-based phosphorus-containing polyol, reacting amino siloxane with hydroxyl acrylate to prepare a silicon-containing monomer, and reacting the hydroxyl acrylate, the bio-based phosphorus-containing polyol, the silicon-containing monomer and diisocyanate to prepare the vegetable oil-based flame-retardant polyurethane acrylate prepolymer. According to the invention, green and environment-friendly phosphorus and silicon elements are introduced into the molecular chain of the vegetable oil-based polyurethane acrylate prepolymer, so that the cured film has good flame retardant property, the defect that the traditional vegetable oil-based high polymer material is easy to burn can be overcome, and the application range of the bio-based high polymer material can be expanded.

Owner:SOUTH CHINA AGRI UNIV

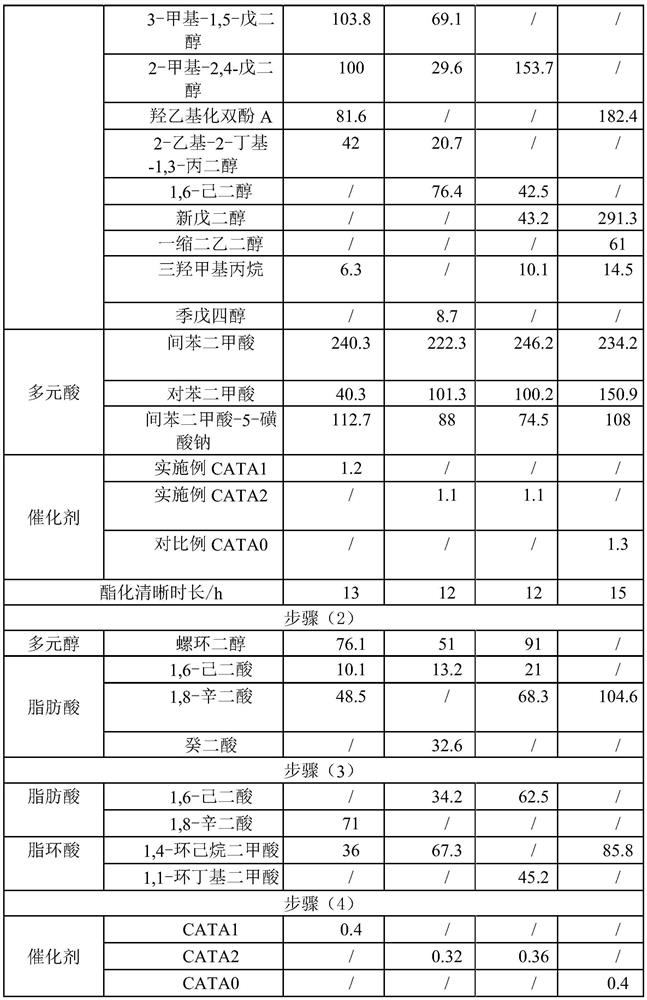

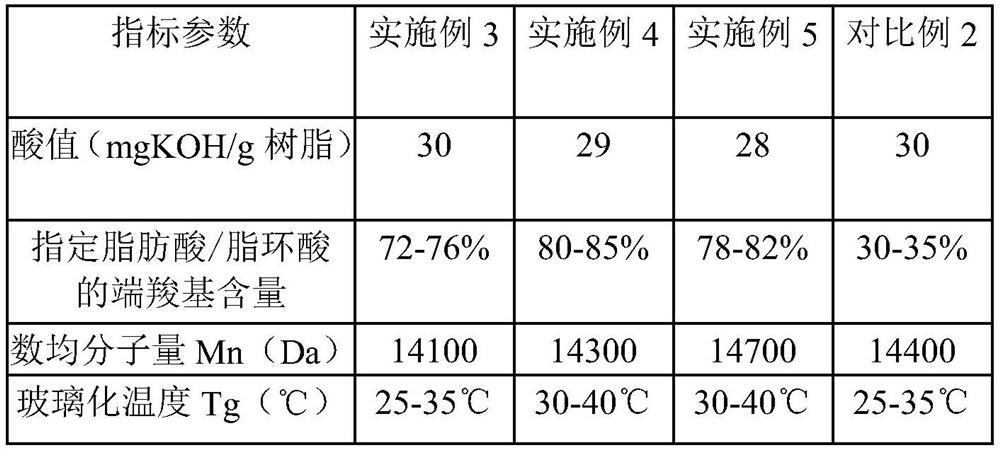

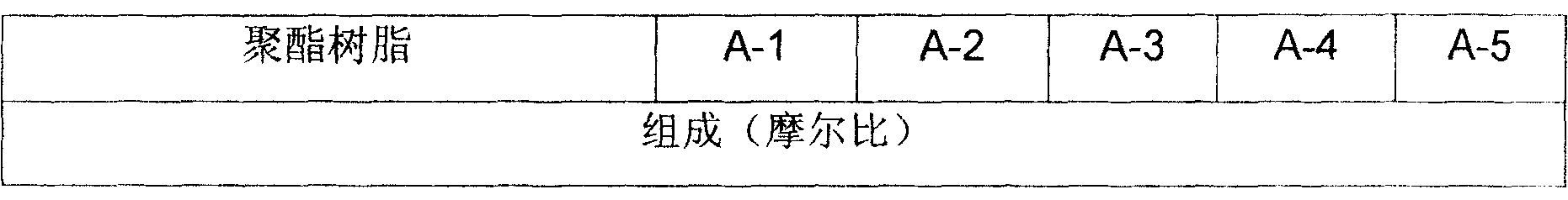

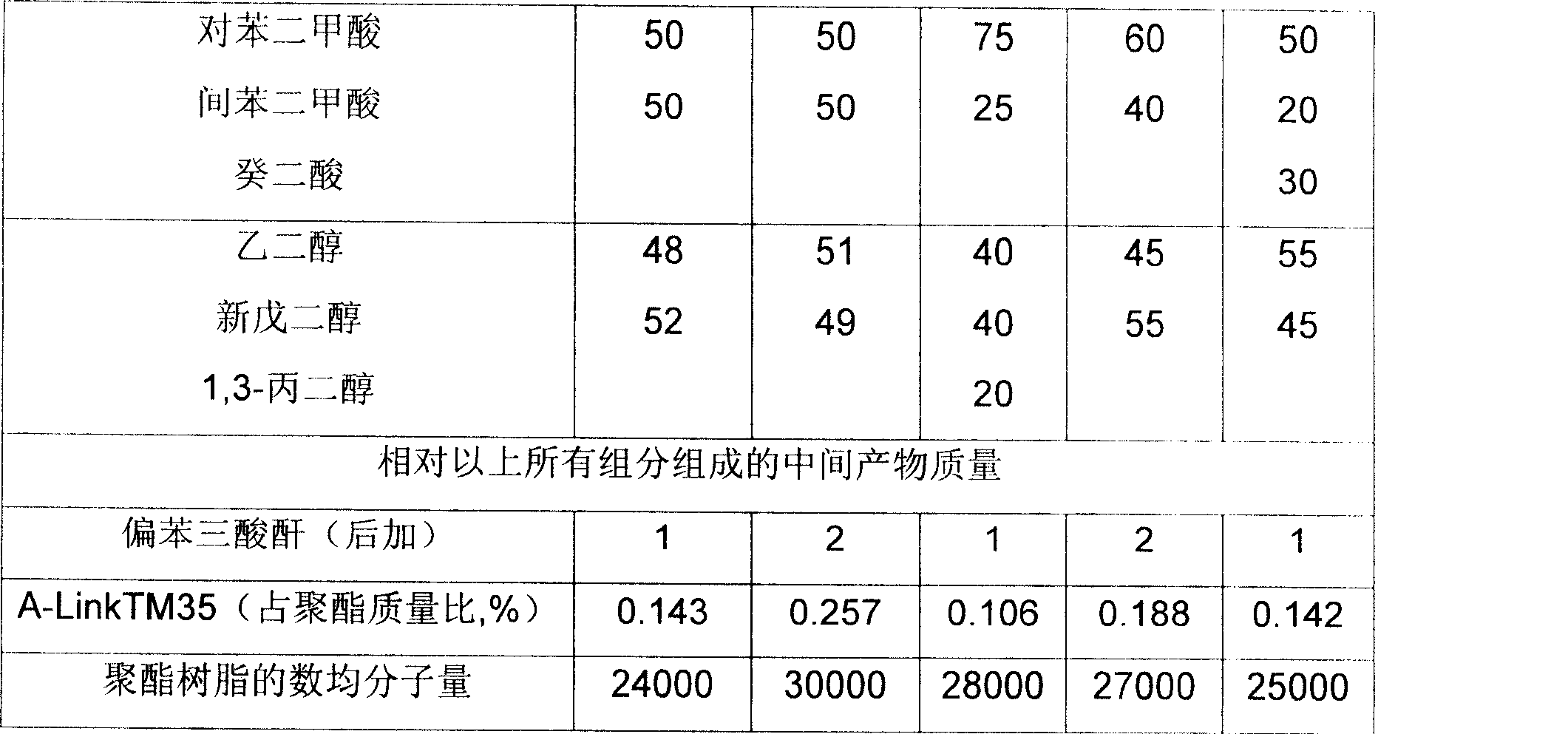

A water-based polyester copolymer and preparation method and application thereof

ActiveCN112654658ABoth processabilityResistant to retortPolyester coatingsPolymer sciencePtru catalyst

The invention belongs to the technical field of coatings, and discloses awater-based polyester copolymer and a preparation method and application thereof.The water-based polyester copolymer is mainly prepared from the following components: polyol, polyacid and an environmentally friendly catalyst. The polyol includes spiro diols and diols with no less than 5 carbon atoms in the main chain. The polyacid includes aromatic polyacid, sulfonic acid group-containing dibasic acid (ester), fatty acid and alicyclic acid; the environmental protection catalyst is prepared by complexing reaction of titanate, silicate and amine compound; 70-100% of the total carboxyl end groups in the water-based polyester copolymer are derived from fatty acid and / or alicyclic acid end carboxyl groups. After the water-based polyester copolymer is used in the preparation of water-based coatings, the cured coating has excellent processability, boiling water resistance and stability.

Owner:GUANGZHOU KINTE IND

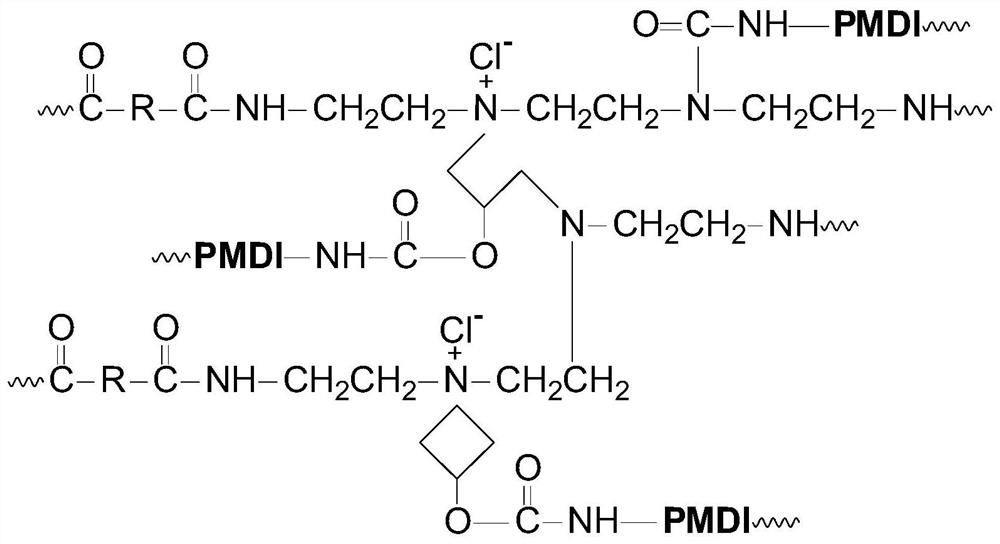

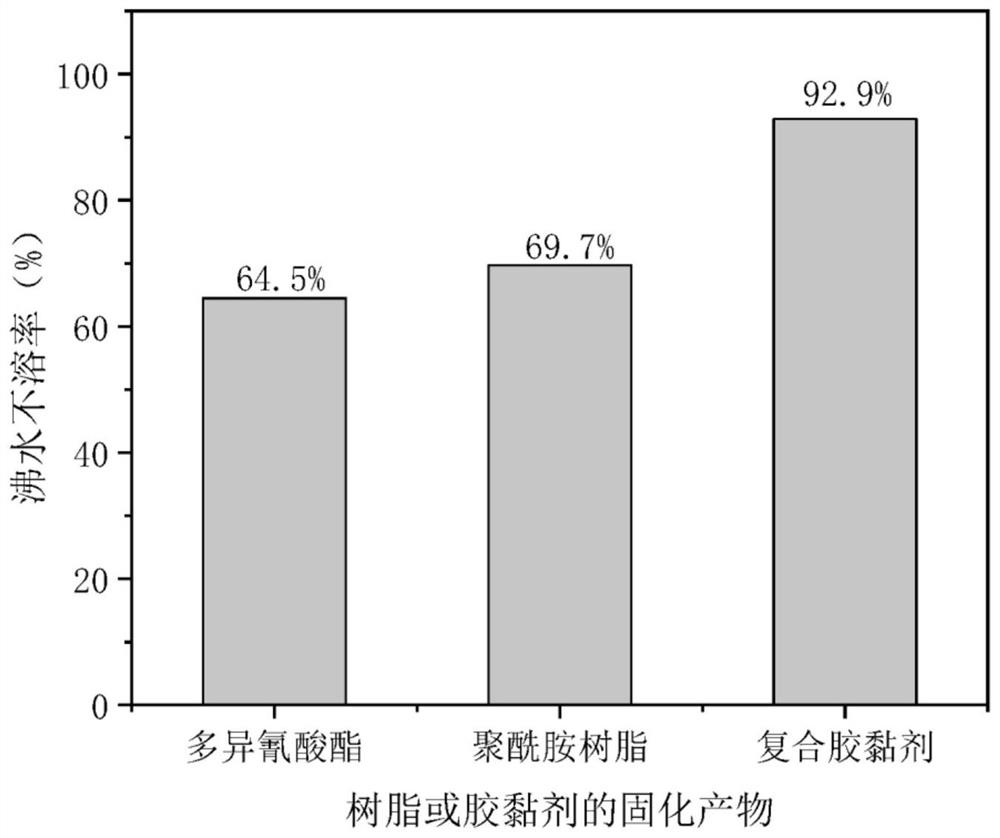

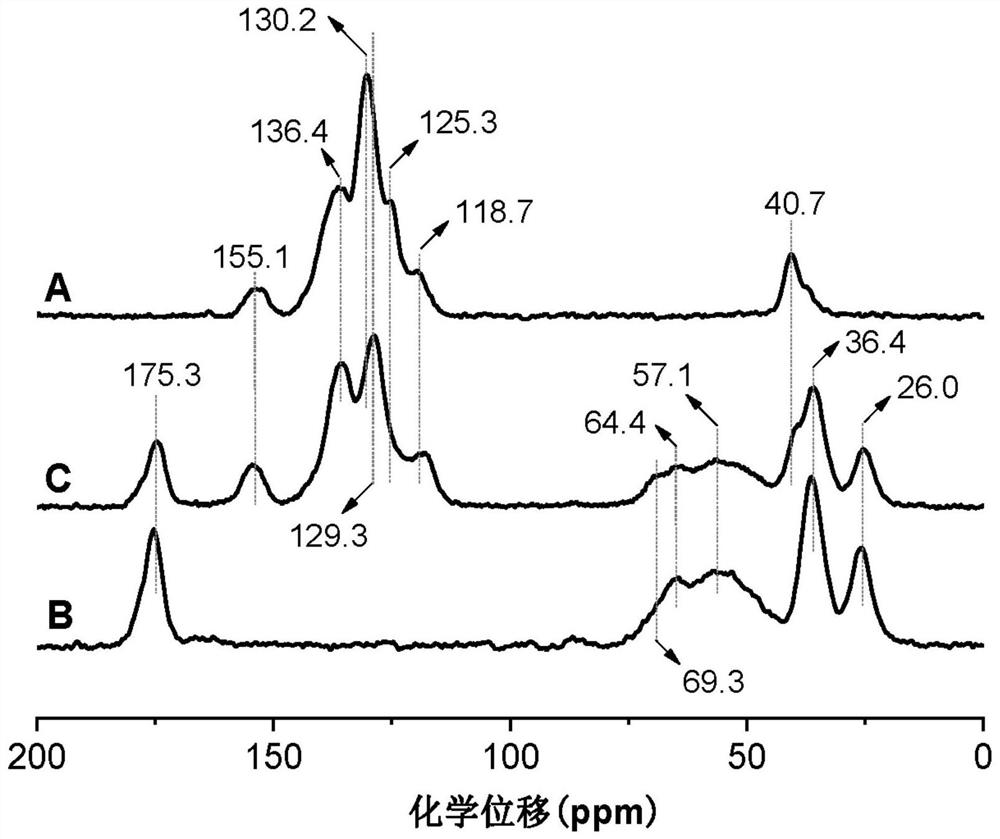

Waterproof polyamide-based adhesive and preparation method thereof

ActiveCN112322243AReduce the degree of polymerizationGood emulsificationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a waterproof polyamide-based adhesive and a preparation method thereof, and relates to an adhesive and a preparation method thereof. The invention aims to solve the technical problems of high cost and non-ideal water resistance of the formaldehyde-free adhesive for an artificial board. A method for preparing a dispersing agent comprises the following steps: stirring and heating adipic acid or an adipic acid / organic binary anhydride mixture and a polyamine compound, adding water, adding epoxy chloropropane, heating, and reacting to obtain the dispersing agent. The adhesive is prepared by uniformly stirring a polyamide-based aqueous cross-linking dispersant, water, polymethylene polyphenyl polyisocyanate (PMDI) and an inorganic filler at room temperature in parts by weight. According to the polyamide-based water-based polymer composite adhesive, the PMDI dosage can be reduced by 33%, the adhesive cost is reduced, the working life is long, and formaldehyde and an organic solvent are not used in the preparation process. The product can effectively solve the problem of high cost of the existing formaldehyde-free soybean adhesive for artificial boards, and has theadvantages of excellent boiling water resistance and environment friendliness. The invention belongs to the technical field of adhesives.

Owner:NORTHEAST FORESTRY UNIVERSITY

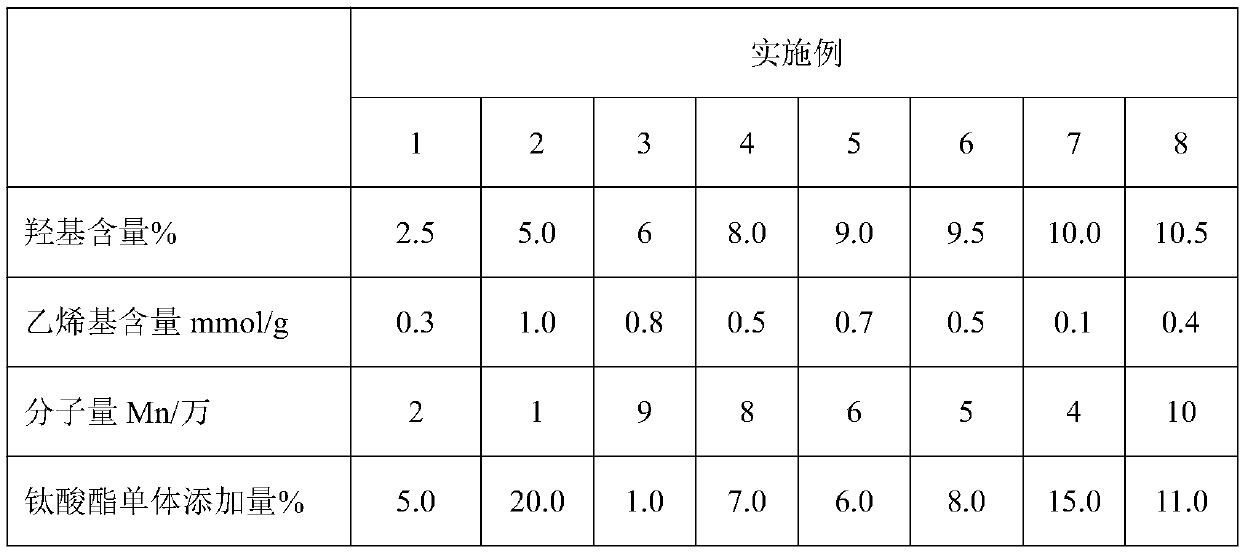

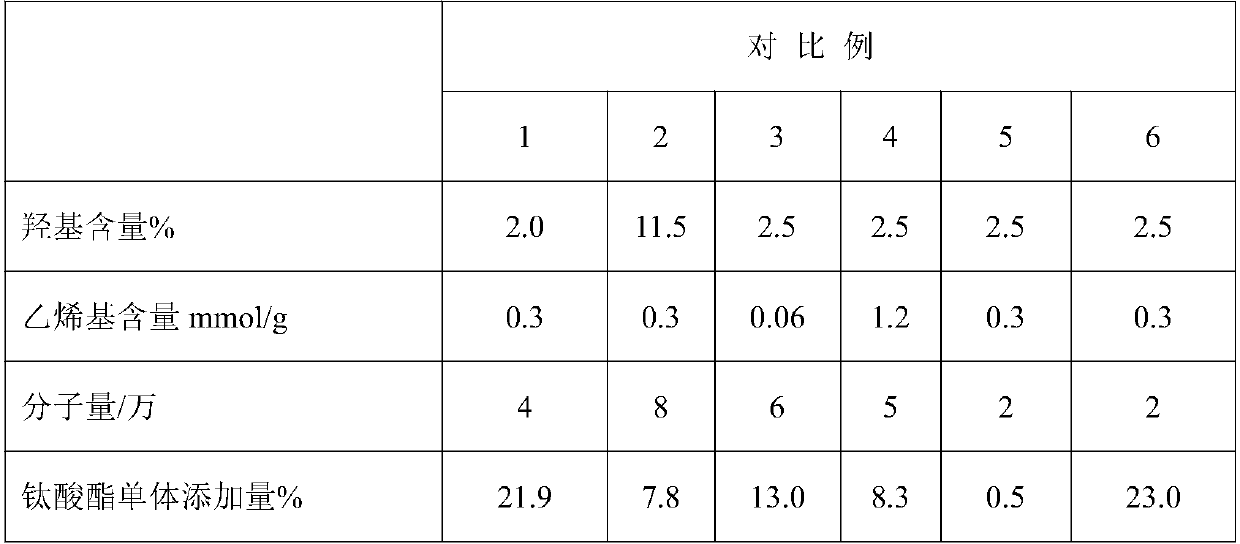

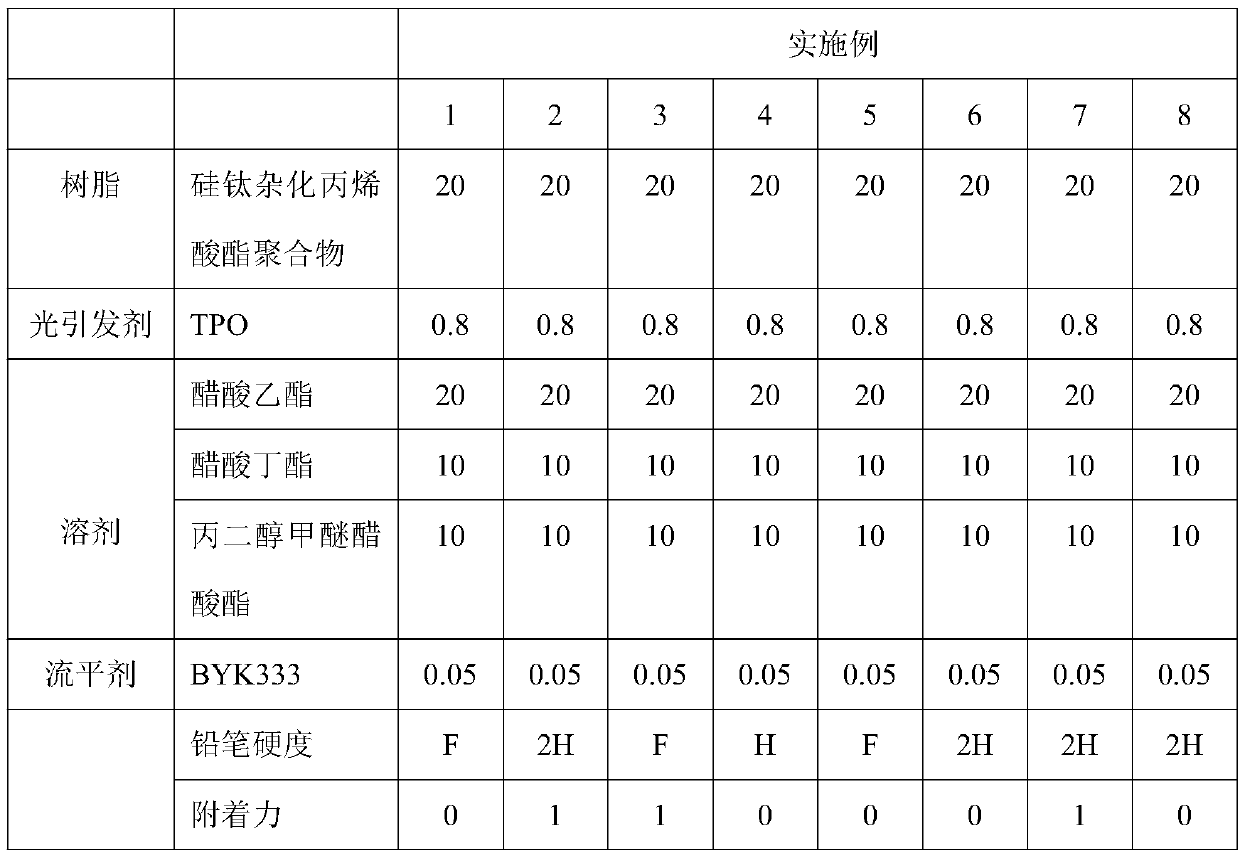

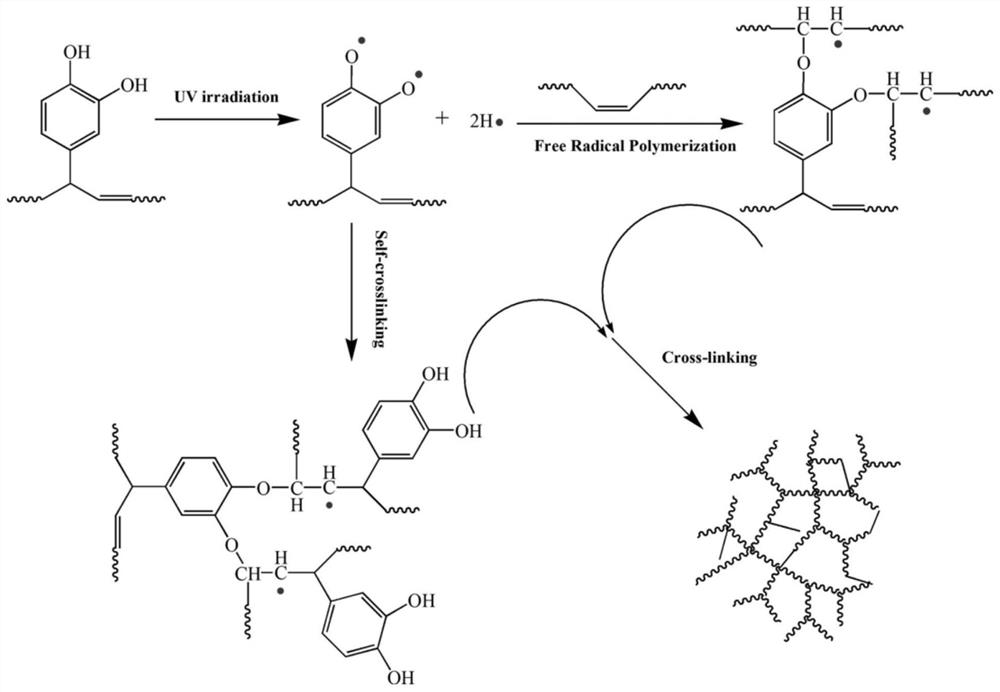

Silicon-titanium hybrid acrylate polymer and double-cured paint prepared therefrom

ActiveCN110003383AImprove hydrophilicityImprove adhesionCoatingsGlycidyl methacrylateHydroxybenzoate Ethers

The invention belongs to the technical field of polymer polymerization, and discloses a silicon-titanium hybrid acrylate polymer and double-cured paint prepared therefrom. The silicon-titanium hybridacrylate polymer is obtained by the following steps: adding an acrylate monomer, a silane coupling agent, a hydroxyl group-containing acrylate monomer and a carboxyl group-containing acrylate monomerinto an initiator for free radical polymerization to obtain a carboxyl group-containing prepolymer; then adding p-hydroxyanisole and triphenylphosphine, and using glycidyl methacrylate to react with acarboxyl group in the main chain of the carboxyl group-containing prepolymer to introduce a double bond and obtain an organosilicon hybrid acrylate prepolymer; and then adding a titanate monomer, andstirring at room temperature with humidity being not more than 30%. The invention provides silicon-titanium hybrid acrylate which is capable of double curing. The paint has both excellent continuousanti-fog property and boiling water resistance after being cured into a film.

Owner:广州五行材料科技有限公司

Aqueous coating material for exterior wall painting

The present invention discloses an aqueous coating material for exterior wall painting. The aqueous coating material comprises 35-50 wt% of a film-forming substance, 1-6 wt% of a color filler, 25-45 wt% of water, and the balance of an auxiliary agent, wherein the film-forming substance preparation steps comprise: mixing isophorone diisocyanate and PPG according to a weight ratio of 1:3-12), carrying out a first reaction for 2-5 h at a temperature of 60-90 DEG C under catalysis of dibutyltin dilaurate having the amount of 2-5% wt% of the isophorone diisocyanate, adding N-methyl pyrrolidone, 2,2-dihydroxymethyl propionic acid, an epoxy resin and diglycolamine, carrying out a second reaction for 1-4 h at a temperature of 80-85 DEG C, carrying out rotary evaporation, and drying for 1-10 h at a temperature of 45-55 DEG C to obtain the film-forming substance. According to the present invention, the aqueous coating material has characteristics of rapid drying, good hardness, good boiling water resistance, good room temperature water resistance, good alkali resistance, and good dry heat resistance, and is suitable for external wall painting.

Owner:河南兰堡湾涂料科技有限公司

A kind of manufacturing process of environmental protection flame retardant straw board

ActiveCN107127841BNo emissionsOvercome the defect of high formaldehyde contentWood treatment detailsLaminationManufacturing technologyCarbonization

The invention discloses a manufacturing technology of an environment-friendly anti-flaming straw board. The manufacturing technology comprises the following steps that (1) crop straws are impurity-removed and smashed; (2) measurement and sub-package are conducted; (3) pavement and mould-entering are conducted; (4) pre-pressing formation is conducted; (5) sizing and cold-pressing are conducted; (6) mould-locking is conducted; (7) maintenance and mould-releasing are conducted; (8) drying is conducted; (9) final trimming of a semi-finished product is conducted; (10) sanding is conducted; and (11) packaging and storehouse-entering are conducted. The manufacturing technology adopts a normal-temperature cold-pressing technology, the method is simple, high-temperature heating is not needed, and gluing can be completed in a normal-temperature state; a slab is dried only in a drying step by adopting a microwave technology, solid fuel is not consumed, no chimney exists in a factory, and the whole process is green and environmentally friendly; and in addition, the straws are principal raw materials matched with an inorganic flame retardant and an inorganic binder which have excellent performances, the obtained straw board cannot be carbonized and deformed in the anti-flaming process at a high temperature of above 1200 DEG C, no harmful smoke and gas is generated, the straw board does not conduct heat at a high temperature and does not swell when encountering water, and the comprehensive performance is quite excellent.

Owner:石植

Full-bio-based ultraviolet-curable coating as well as preparation method and application thereof

The invention discloses a full-bio-based ultraviolet-curable coating as well as a preparation method and application thereof. The full-bio-based ultraviolet-curable coating provided by the invention is mainly composed of a tung oil-based urushiol-like compound, drying oil, epoxy vegetable oil and a composite photoinitiator, is a coating prepared from an imitated natural paint system, contains various photocuring groups such as phenolic hydroxyl groups, double bonds and epoxy groups, and can be subjected to a cross-linking curing reaction under photo-initiation. The full-bio-based ultraviolet-curable coating is high in curing rate, a light curable film formed after curing has extremely high cross-linking degree and good mechanical property, and meanwhile, the light curable film is high in adhesive force and good in heat resistance, acid resistance, alkali resistance and boiling water resistance. The coating can be widely applied to the industrial fields of wood coatings, musical instrument coatings, toy coatings, art coatings, anti-corrosive coatings, automobile coatings, coil coatings, building coatings, industrial coatings and the like.

Owner:SOUTH CHINA AGRI UNIV +1

Single-component reaction type hot melt adhesives and steel plate composite material using the same

InactiveCN101255326BImprove impact resistanceExcellent boiling water resistanceEpoxy resin adhesivesMetal layered productsEpoxyPolyvinyl chloride

Owner:NANTONG GAOMENG NEW MATERIAL

Metal base material corrosion-resistant coating and preparation method thereof

InactiveCN102391779BWeather resistantAnti-corrosionAnti-corrosive paintsEpoxy resin coatingsVinyl esterBis epoxide

The invention discloses metal base material corrosion-resistant coating and a preparation method thereof. The metal base material corrosion-resistant coating comprises the following components in parts by weight: 25 to 30 pats of epoxy modified organic silicon resin, 15 to 20 parts of modified vinyl resin, 1 to 2 parts of nano material, 1 to 3 parts of corrosion-resistant particulate filler, 15 to 18.5 percent of pigment and filler, 1 to 2 parts of antisettling agent, 0.3 to 0.5 part of dispersing agent, 0.5 to 0.8 part of stabilizing agent, 3 to 4 parts of aid and 23 to 26 parts of solvent, wherein the modified vinyl resin comprises according to the weight percentage 50 to 70 % of phenolic aldehyde epoxy vinyl ester resin and 30 to 50 % of flexible vinyl ester resin. The metal base material corrosion-resistant coating is prepared by multiple flows of weighing the raw materials in parts by weight, mixing the raw materials according to certain sequence, dispersing, grinding and the like. The metal base material corrosion-resistant coating has high temperature tolerance, wet resistance, corrosion resistance, weldability and constructability and can be applied in the technical fieldsof processing of various different metals.

Owner:资阳赛特化工有限公司

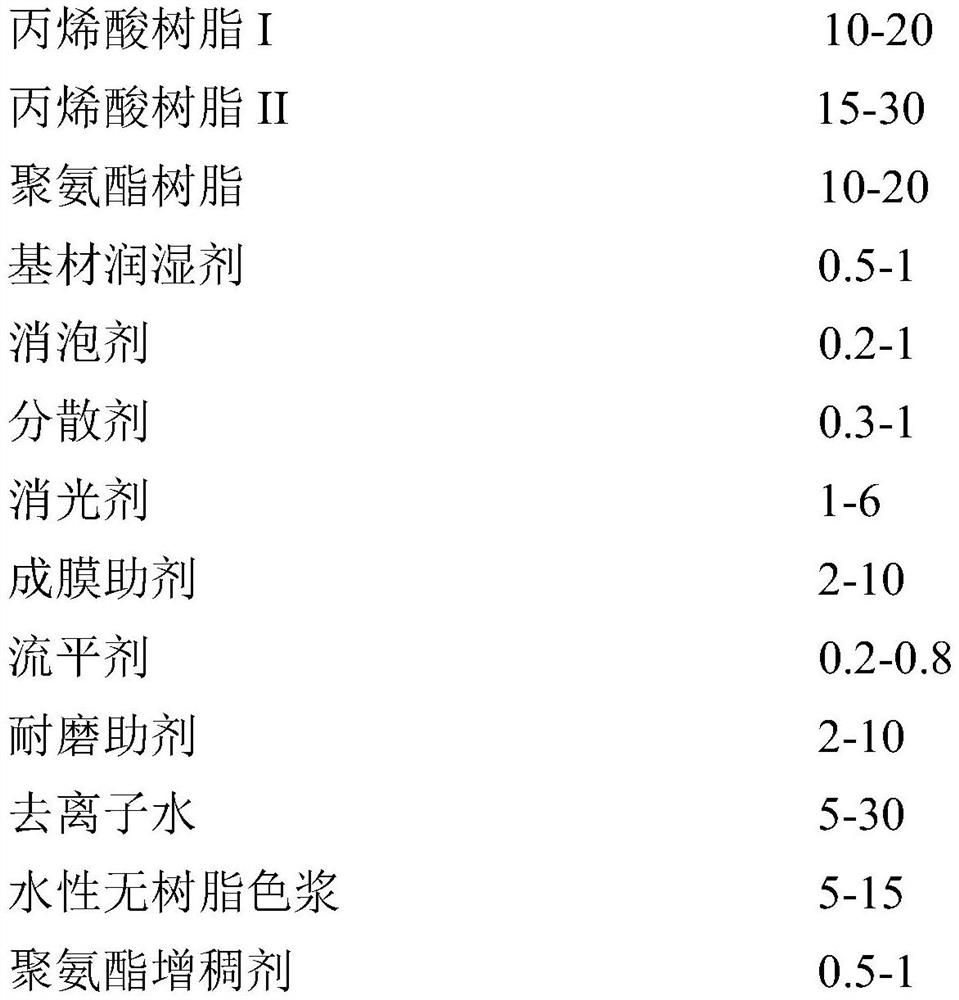

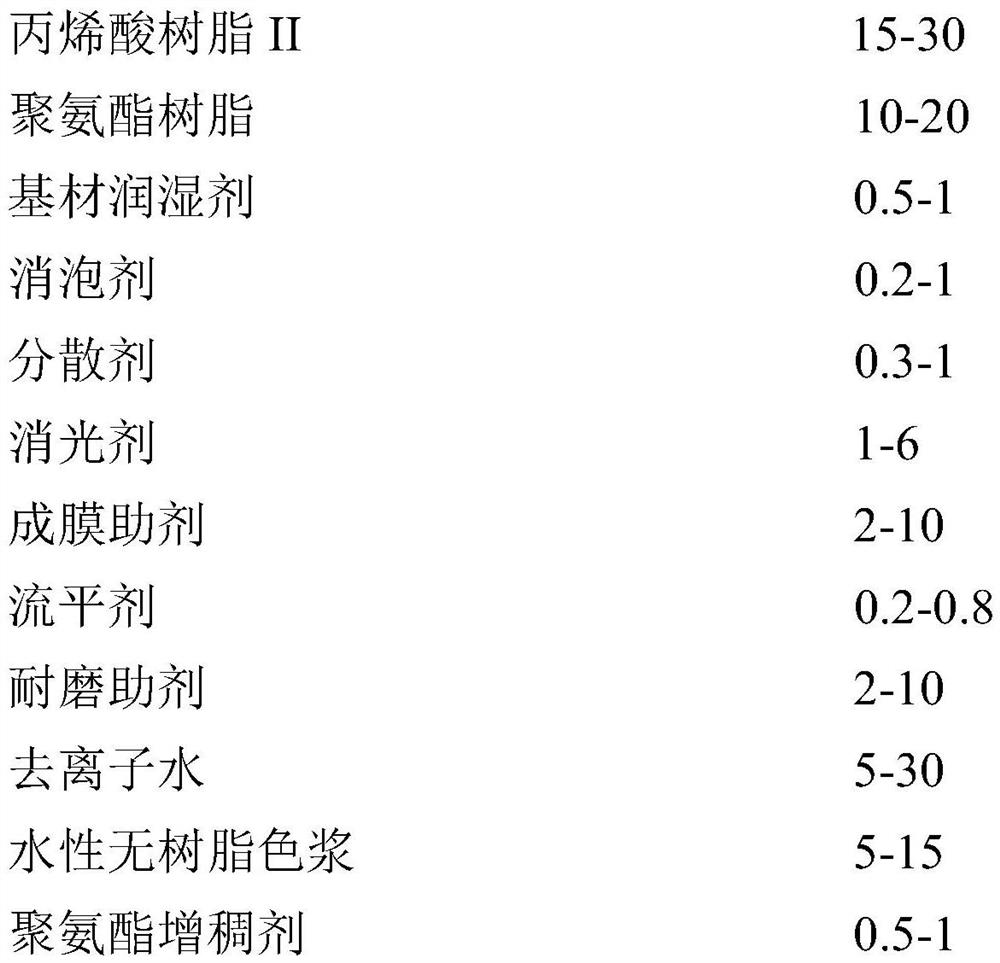

Wool felt-resistant two-component water-based paint and preparation method thereof

InactiveCN112080195AStrong defect abilityColor adjustablePolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a wool felt-resistant two-component water-based paint and a preparation method thereof. The raw materials comprise component A: acrylic resin I, acrylic resin II, polyurethane resin, a base material wetting agent, an antifoaming agent, a dispersing agent, a delustering agent, a coalescing agent, a leveling agent, a wear-resistant additive, deionized water, water-based resin-free color paste and a thickener; and component B: aliphatic isocyanate. The preparation method comprises the following steps: uniformly dispersing the acrylic resin I, the acrylic resin II and the polyurethane resin, adding the base material wetting agent, the defoamer, the dispersant, the coalescing agent and the deionized water, uniformly dispersing, adding the delustering agent, dispersing until the fineness is qualified, adding the leveling agent, the deionized water, the wear-resistant aid, the thickener and the color paste, and uniformly dispersing; and discharging to obtain the component A, and uniformly mixing the component A with the component B aliphatic isocyanate to obtain the wool felt-resistant double-component water-based paint. The preparation method is simple, and the coating has excellent wear resistance, chemical resistance and the like.

Owner:卡秀万辉(无锡)高新材料有限公司

A kind of lignin modified urea-formaldehyde resin adhesive and its preparation method and application

ActiveCN109868101BLow free formaldehyde contentReduce contentAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention discloses a lignin-modified urea-formaldehyde resin adhesive and its preparation method and application. 1000 parts of formaldehyde, 45-140 parts of lignin, 8-28 parts of melamine, 680-860 parts of urea, 10.5-51 parts of alkali and 10 ‑20 parts of acid as raw material, add lignin in two batches, add urea in three batches, prepare lignin-modified urea-formaldehyde resin adhesive through one addition reaction and three polycondensation reactions, and the prepared adhesive has good initial tack , fast curing speed, high bonding strength, low content of free formaldehyde, good boiling water resistance, can be used as glue for plywood, and the formaldehyde emission of the prepared plywood reaches E 0 Grade standard, the bonding strength reaches the standard of Class II plywood. The lignin-modified urea-formaldehyde resin adhesive of the invention has simple preparation process, good stability, simple, fast and feasible quality control method, low raw material cost, and is suitable for popularization and application.

Owner:广西高林林业股份有限公司

Aluminum alloy radiator and preparation method thereof

ActiveCN114351131AImprove stabilityImprove corrosion resistanceMetallic material coating processesHeat exchange apparatusPotassium dichromateSalt water

The invention discloses an aluminum alloy radiator and a preparation method thereof, belongs to the technical field of aluminum alloy surface treatment, and discloses an aluminum alloy radiator attached with a protective film, and the protective film contains a Mannich base compound. The metal compound prepared from the Mannich base compound and the metal reagent is used in the conversion liquid to prepare the aluminum alloy radiator attached with the protective film, and the conversion liquid is good in stability and can be stably stored for more than 20 days under the condition that the pH value is adjusted to 5; the prepared protective film is high in adhesion amount, and the weight of the protective film is 75 mg / cm < 2 > or above; the corrosion resistance is good, and the corrosion resistance is more than 50s in a 3% potassium dichromate solution; the boiling water resistance is good, and the salt water soaking resistance is good.

Owner:HANGZHOU ANYU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com