Full-bio-based ultraviolet-curable coating as well as preparation method and application thereof

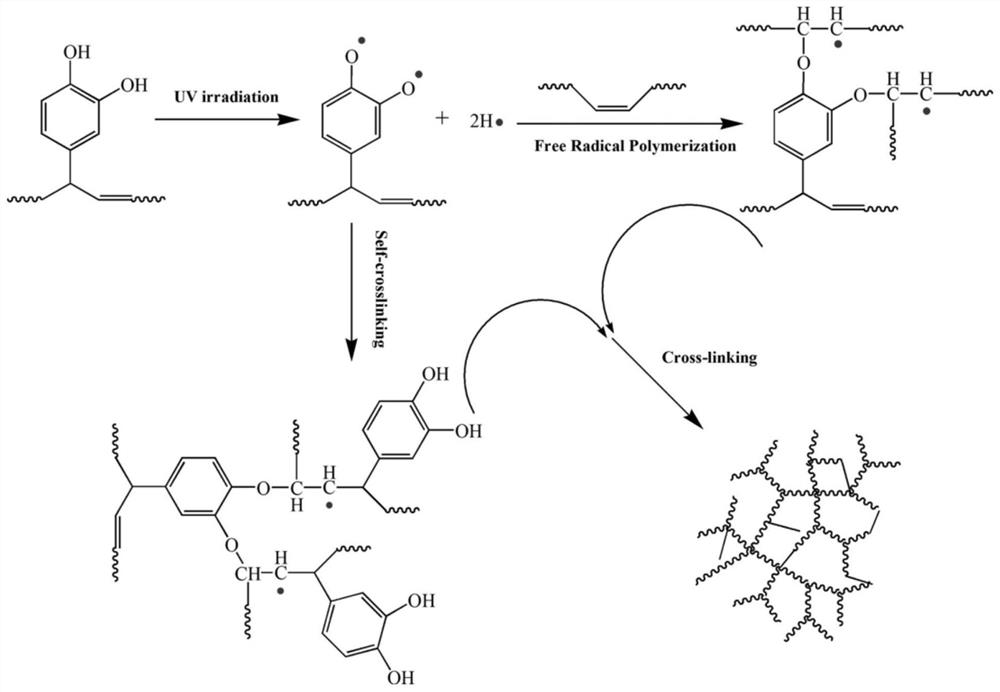

A technology for curing coatings and ultraviolet light, applied in coatings and other directions, can solve the problems of volume shrinkage, curing depth, limited light penetration, restricted development, etc., to overcome the effect of oxygen inhibition, protect the environment, and improve added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The tung oil-based urushiol-like compound, tung oil, epoxy castor oil, and composite photoinitiator are mixed in proportion, stirred and dispersed evenly, and a fully bio-based UV-curable coating is obtained. in:

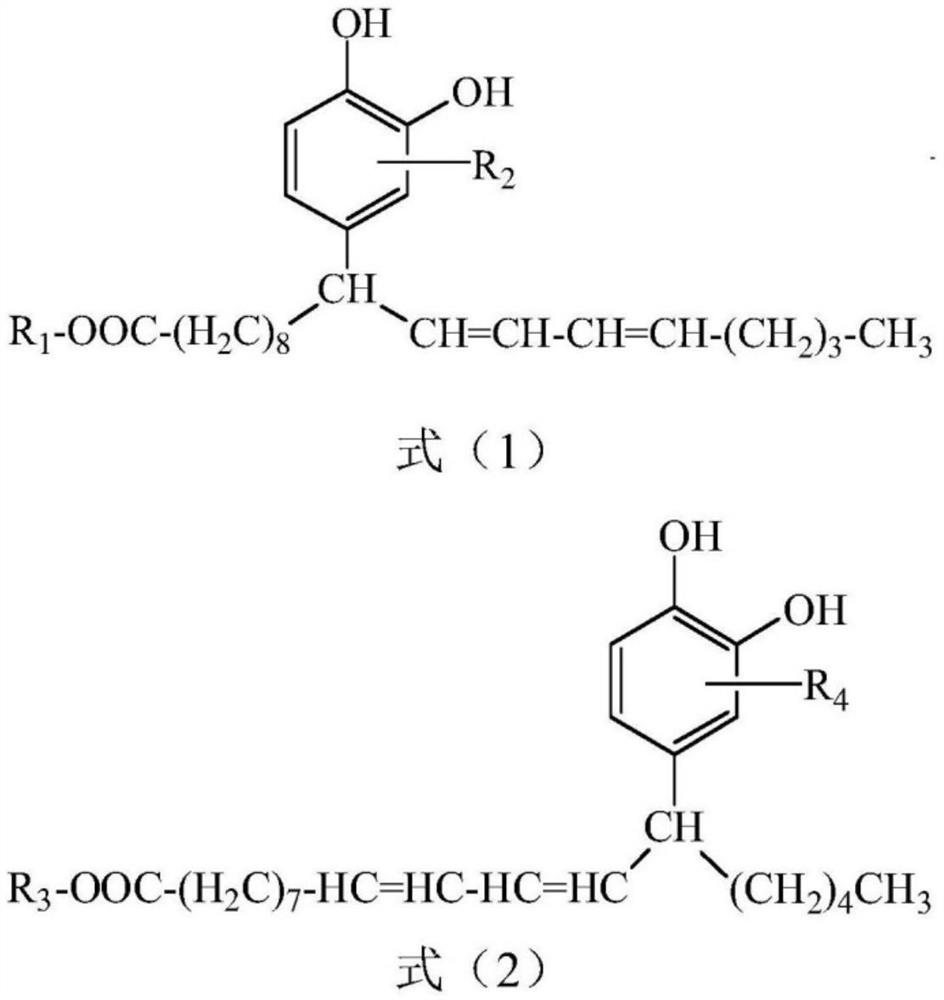

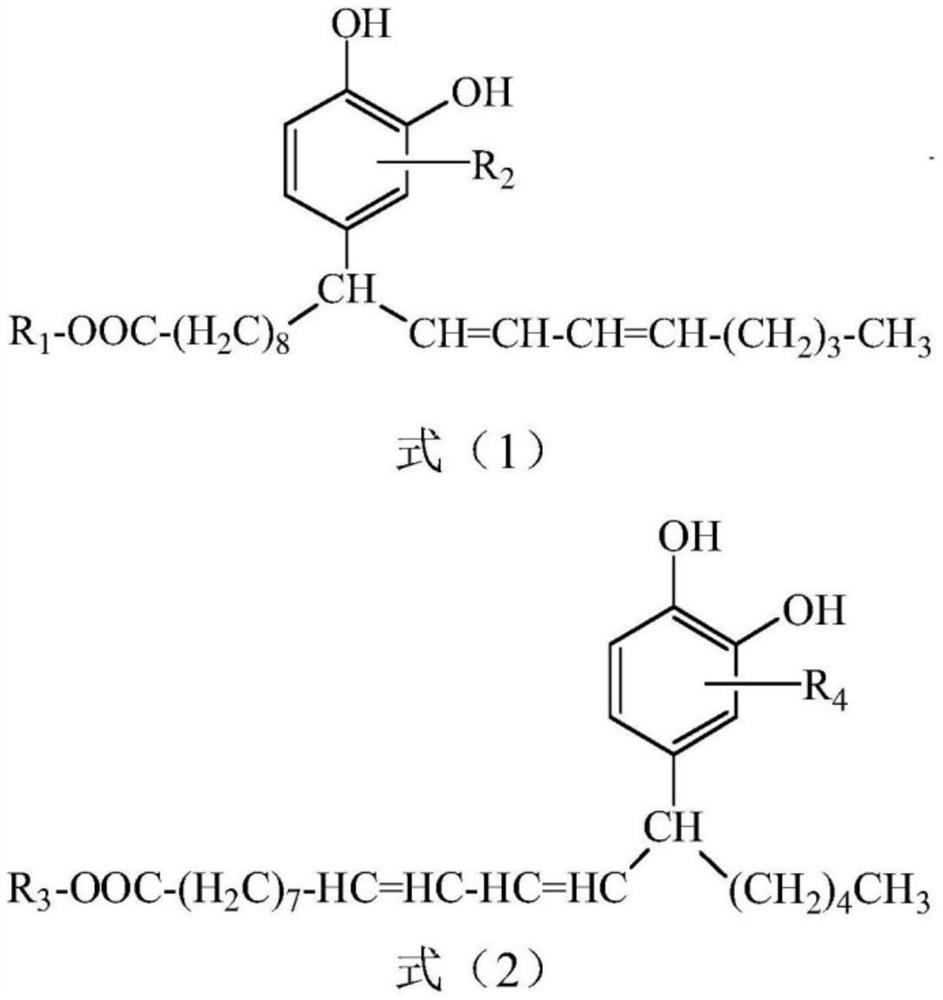

[0037] Tung oil-based urushiol-like compounds were prepared from tung oil and catechol through photocatalytic reaction.

[0038] In terms of mass percentage, the dosages of tung oil-based urushiol-like compounds, tung oil, epoxy castor oil and composite photoinitiator are 10%, 60%, 25% and 5% in sequence.

[0039] The composite photoinitiator is a mixture composed of photoinitiator 184 and diazonium salt at a mass ratio of 1:9.

Embodiment 2

[0041] The tung oil-based urushiol-like compound, linseed oil, epoxy tung oil, and composite photoinitiator are mixed in proportion, stirred and dispersed evenly, and a fully bio-based UV-curable coating is obtained. in:

[0042] Tung oil-based urushiol-like compounds are prepared from tung oil acid and catechol through photocatalytic reaction.

[0043] In terms of mass percentage, the dosages of tung oil-based urushiol-like compounds, linseed oil, epoxy tung oil and composite photoinitiator are 60%, 10%, 20% and 10% in sequence.

[0044] The composite photoinitiator is a mixture composed of photoinitiator 1173 and triarylsulfonium salt in a mass ratio of 9:1.

Embodiment 3

[0046] The tung oil-based urushiol-like compound, tung oil, epoxy linseed oil, and composite photoinitiator are mixed in proportion, stirred and dispersed evenly, and a fully bio-based UV-curable coating is obtained. in:

[0047] Tung oil-based urushiol-like compounds were prepared from tung oil and catechol through photocatalytic reaction.

[0048] In terms of mass percentage, the amounts of tung oil-based urushiol-like compounds, tung oil, epoxy linseed oil and composite photoinitiator are 35%, 20%, 40% and 5% in sequence.

[0049] The composite photoinitiator is a mixture composed of photoinitiator 907 and diaryliodonium salt in a mass ratio of 5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com