Patents

Literature

202 results about "Coil coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coil coating is the continuous and highly automated industrial process for efficiently coating coils of metal. Because the metal is treated before it is cut and formed, the entire surface is cleaned and treated, providing tightly-bonded finishes. (Formed parts can have many holes, recessed areas, valleys, and hidden areas that make it difficult to clean and uniformly paint.) Coil coated metal (often called prepainted metal) is often considered more durable and more corrosion-resistant than most post painted metal.

Enhanced scratch resistance of articles containing a combination of nano-crystalline metal oxide particles, polymeric dispersing agents, and surface active materials

InactiveUS20060063911A1Improve scratch resistanceEasy to measureMaterial nanotechnologyIndividual molecule manipulationMetal coatingNanoparticle

A film forming composition comprises a resin, a plurality of nanoparticles, a surface active material and a polymeric dispersant. The film forming composition is substantially transparent and is adapted to be combined with a substrate to enhance abrasion resistance. The film forming composition may be used with wood objects including furniture, doors, floors, for architectural surfaces, for automotive articles and finishes, for metal coatings and coil coatings, for plastic articles, and for wipe-on protective treatments.

Owner:ALTANA CHEM CORP +1

Waterborne coil coating polyester rear face paint and preparation method thereof

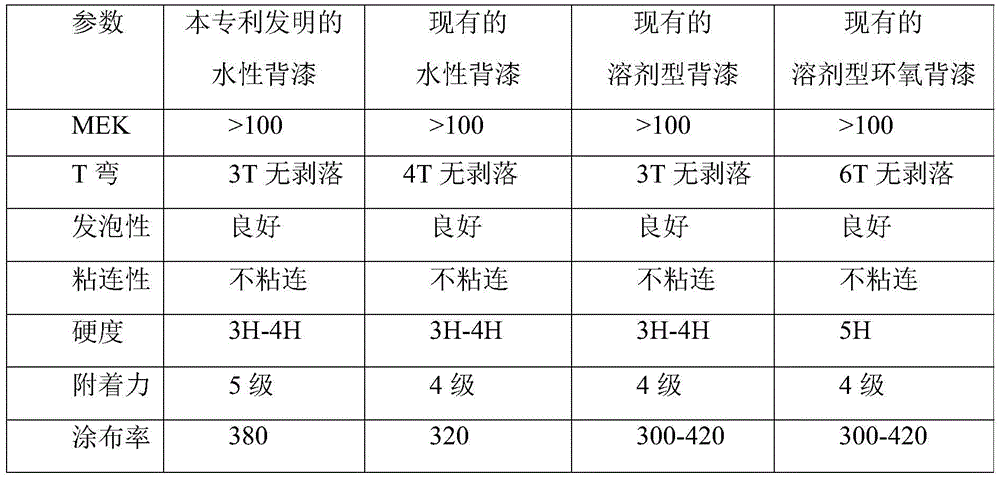

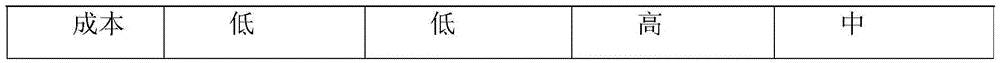

The invention discloses waterborne coil coating polyester rear face paint and a preparation method thereof. The rear face paint comprises, by weight, 30-40 parts of polyester resin, 30-35 parts of pigment filler, 7-10 parts of amino resin, 0-0.5 part of dispersant, 0.1-0.5 part of an anti-settling agent, 0.5-1.2 parts of an antifoaming agent, 0.5-3 parts of adhesion promoter, 0.1-0.5 part of an acid catalyst, 0.1-0.5 part of a wax auxiliary agent, 0.1-0.3 part of a flatting agent, 0.1-2 parts of extinction powder, 4-6 parts of butyl cellosolve, 2-4 part of isopropanol and 35-40 parts of water. The invention further discloses the preparation method of the rear face paint. According to the waterborne coil coating polyester rear face paint and the preparation method thereof, water serves as a dispersion medium, so that the rear face paint has the advantages of being environmentally friendly, low in cost, excellent in scratch resistance, corrosion resistance and solvent resistance, not sticky, good in foaming performance and the like, and the rear face paint is equivalent to solvent type polyester rear face paint in performance; waterborne rust resistance is achieved, and corrosion resistance is more excellent.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

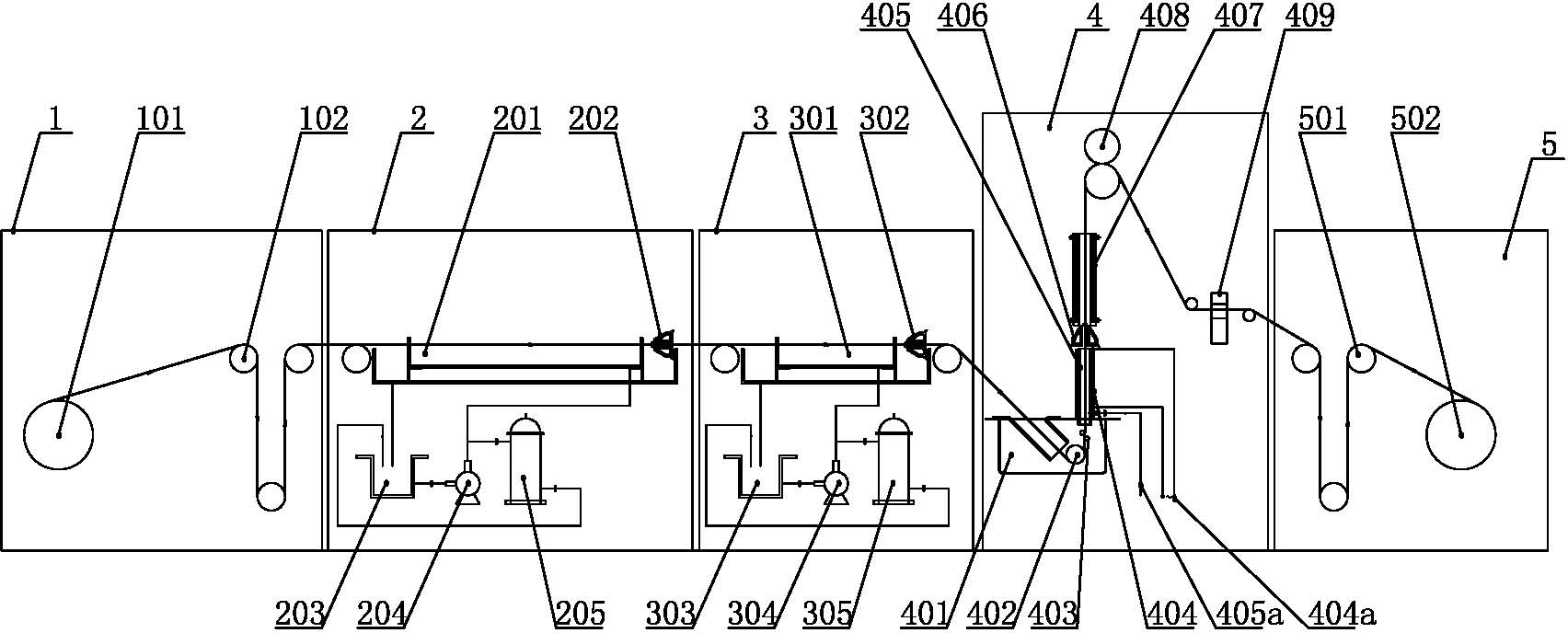

Production system and production method of extremely-soft tin-coated welding strip

ActiveCN102383084AAvoid Yield Strength IncreasesPrevent oxidationHot-dipping/immersion processesCoating systemEngineering

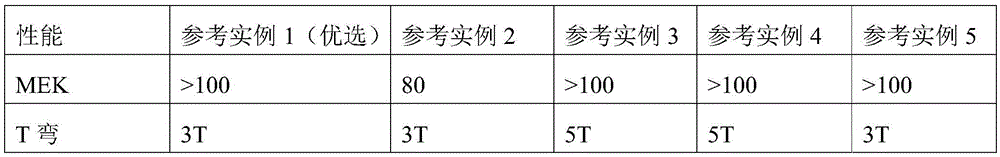

The invention relates to a production system and a production method of an extremely-soft tin-coated welding strip, and belongs to the technical field of solar cells. The welding strip of the system orderly passes through an roll-charging system, a cleaning system, a flux coating system, a tin coating system, and a rolling system; the tin coating system comprises a tin furnace, and an induction heating device, a cooling air knife, a cooling water jacket, and a transmission roller couple which are orderly disposed above the tin furnace; a soaking roller is disposed in the tin furnace; the welding strip is winded on the soaking roller, and then moves upward to enter the induction heating device; the induction heating device comprises a ceramic protecting pipe and an induction heating coil coating the outer wall of the ceramic protecting pipe; the induction heating coil is connected with a high frequency induction heating power supply; a nitrogen pipe interface for injecting nitrogen into a inner cavity is disposed on a lower pipe wall of the ceramic protecting pipe; the lower end port of the ceramic protecting pipe is soaked below the liquid level of the tin furnace; the welding strip enters the rolling system through a thickness measuring device from the transmission roller couple. The increase of yield strength due to the plastic deformation of the copper strip in high-temperature liquid tin liquor is avoided.

Owner:江苏太阳科技股份有限公司

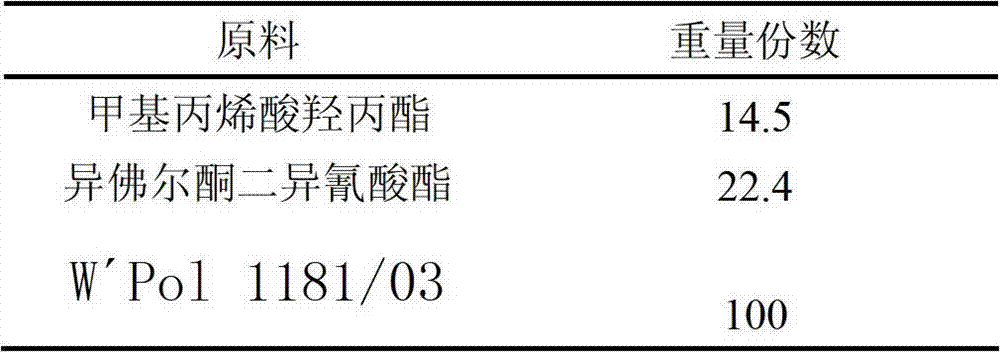

Preparation method and application of core-shell polyurethane/acrylic acid composite emulsion

The invention relates to a preparation method and application of core-shell polyurethane / acrylic acid composite emulsion. The preparation method includes steps of (1), pre-polymerizing hydroxyl acrylate and isocyanate which are equal in equivalent weights for 1-5 hours, adding macromolecular polyhydric alcohol with the equivalent weight equal to that of the hydroxyl acrylate or the isocyanate into the mixture to react for 1-5 hours to obtain prepolymer with double bonds; (2), stirring and mixing the prepolymer synthesized in the step (1) with acrylic acid or methacrylic acid, olefin monomers, hydroxyl acrylate monomers, initiators and chain transfer agents; (3), using co-solvents accounting for 5-20wt% of the total mass of mixed monomers for bottoming, dripping the mixed monomers at the temperature ranging from 80 DEG C to 150 DEG C for 2-5 hours, keeping the temperature unchanged for 4 hours after finishing dripping; (4), reducing the temperature of the mixture to be 90 DEG C, and adding neutralizers for neutralizing the mixture; and (5), reducing the temperature of the mixture to be 60 DEG C, and adding water into the mixture to realize self-emulsification to obtain the core-shell polyurethane / acrylic acid composite emulsion with the solid contents of 42-45wt%. The obtained emulsion is combined with crosslinking components, and is applicable to producing low-VOC (volatile organic compound) water-base coil coatings.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

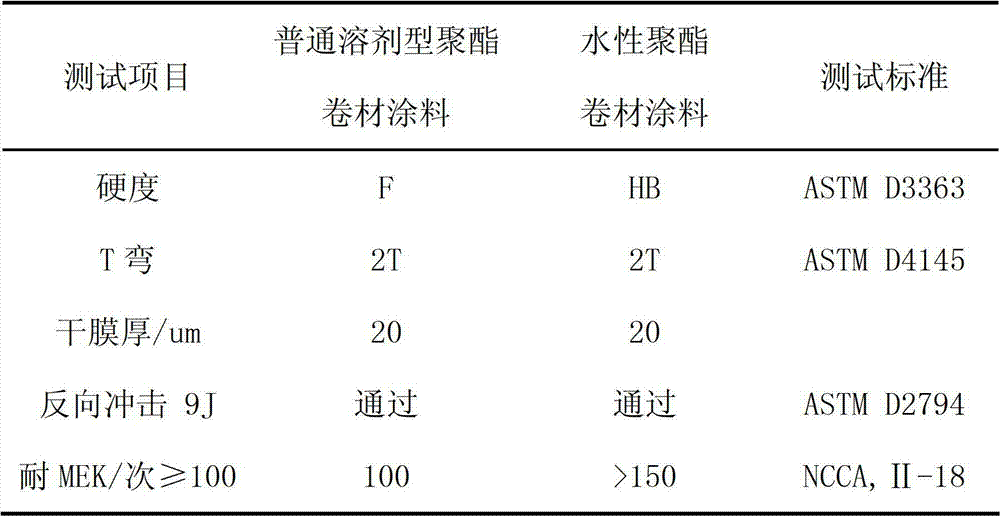

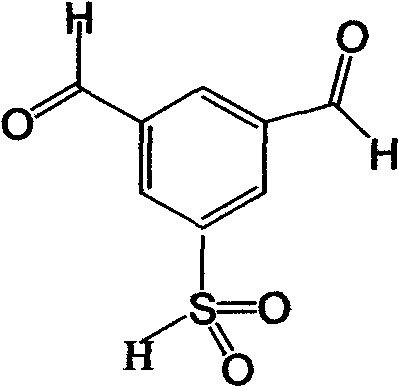

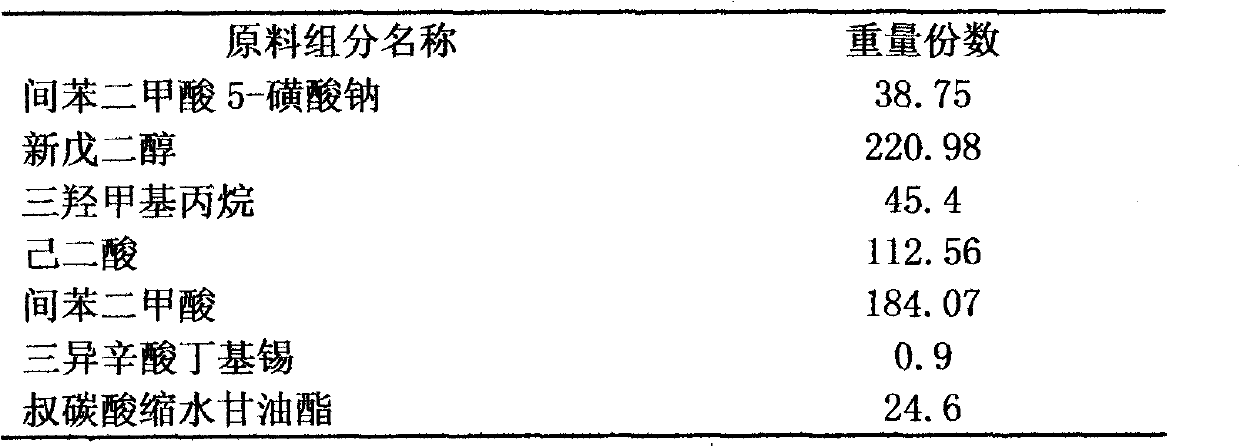

Preparation method of waterborne polyester resin used in coil coatings and application thereof

ActiveCN102887993AReduce usageEmission reductionMagnetic paintsPolyester coatingsWater basedHydrophilic monomer

Disclosed are a preparation method of waterborne polyester resin used in coil coatings and an application thereof. The preparation method comprises the following steps of: (1) performing prepolymerization between a certain amount of alcohol and a carboxyl group containing hydrophilic monomer under the action of a catalyst at 170-240 DEG C, wherein the OH / COOH ratio is 2-20; (2) adding other raw materials of alcohol and acid after the acid value is less than 3mgKOH / g, slowly heating up, and insulating at 180-230 DEG C for 3-8 hours; (3) refluxing by the use of 5-30 wt% of a hydrocarbon solvent to remove small molecular water after the acid value is less than 90mgKOH / g; (4) cooling to below 150 DEG C, adding a small molecular monomer containing an epoxy group, and stop heating after the acid value is less than 2mgKOH / g; and (5) adding a hydrophilic solvent and water to obtain the waterborne polyester resin. The combination of the obtained waterborne polyester resin, a crosslinking component and a painting base stock is suitable for the production of a low-VOC water-based top-coat which is used on metal coils.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

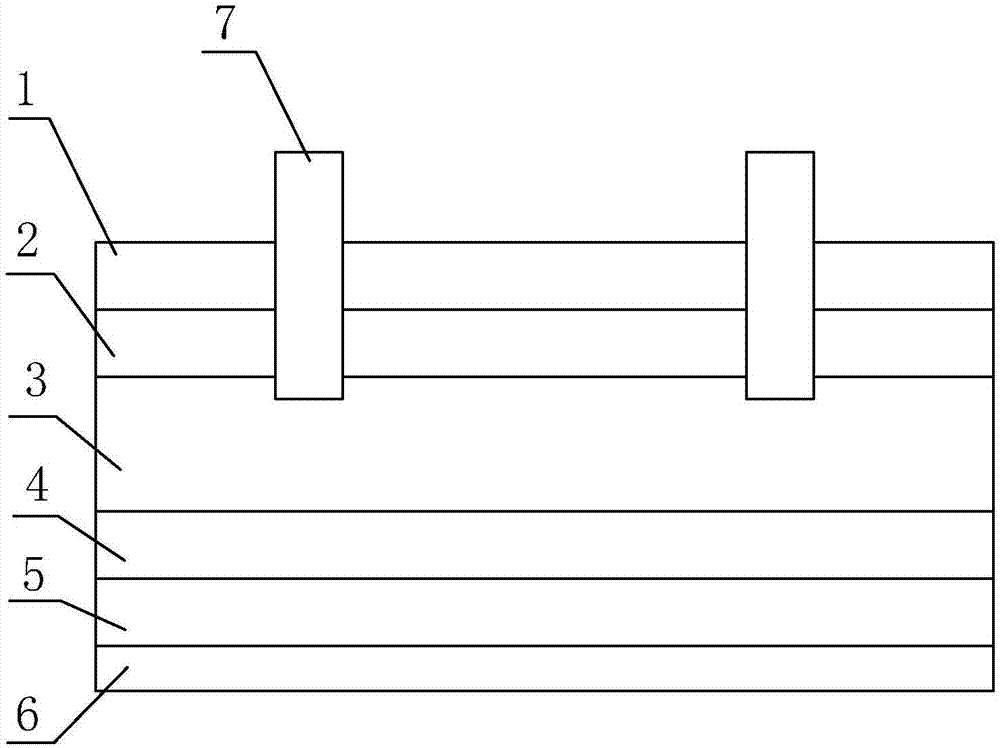

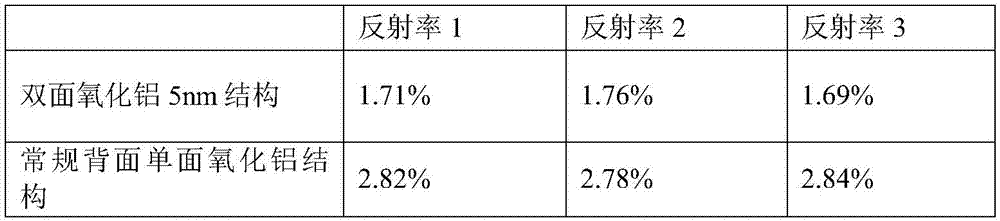

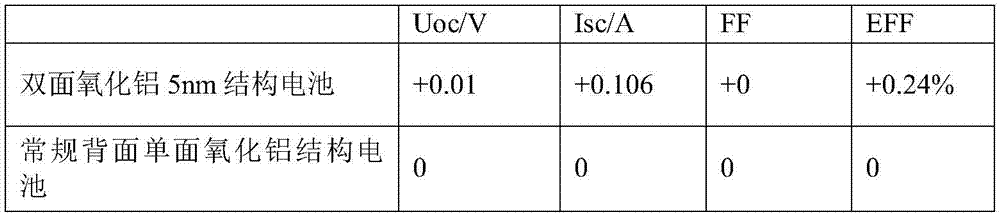

Double-faced alumina P-type PERC solar cell and making method

ActiveCN107887453ASolve the appearanceSolve the problem of blackening of EL edgeFinal product manufacturePhotovoltaic energy generationScreen printingSolar cell

The invention relates to the field of solar cells, and discloses a double-faced alumina P-type PERC solar cell and a making method. The cell comprises a silicon wafer and two positive electrodes; thefront surface of the silicon wafer is sequentially provided with a front silicon nitride film and a front alumina film; and the back surface of the silicon wafer is sequentially provided with a back alumina film, a back silicon nitride film and a back electrode / field. The making method comprises steps of 1) cleaning and etching, 2) PN junction making through diffusion, 3) etching, 4) front siliconnitride film coating, 5) double-faced alumina film coating, 6) back silicon nitride film coating, 7) laser slotting, and 8) screen printing and sintering. The back surface and the front surface of the silicon wafer are coated with the alumina films, the problems of frontal appearance color difference and blackening of an EL edge caused by coil coating when the back alumina is made in the conventional P-type PERC cell can be solved, the alumina film layer can be uniformly deposited on the front surface, the reflectivity is reduced, and the conversion efficiency is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

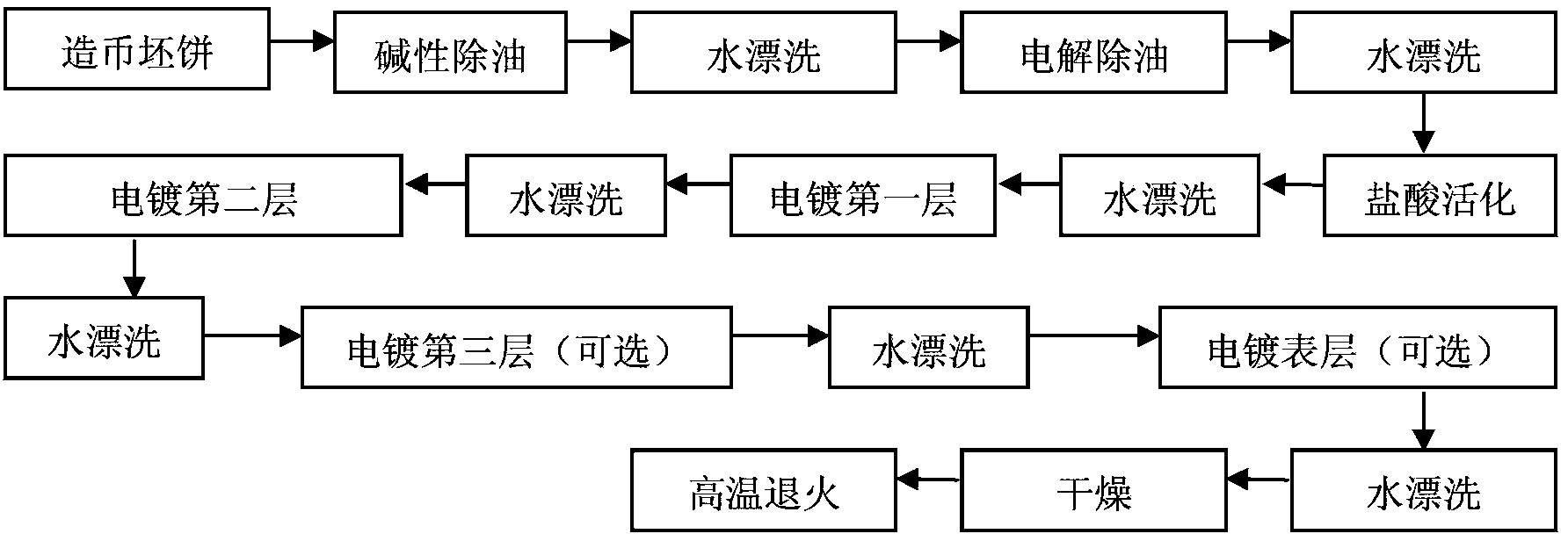

Electroplating liquid of multi-layer cyanide-free electroplated copper-tin alloy coating, electroplating technology and coin thereof

ActiveCN103668359AAvoid the risk of mutual contaminationReduce management costsCoinsCyanidePyrophosphate

The invention relates to the technical field of coinage, and particularly relates to electroplating liquid of a multi-layer cyanide-free electroplated copper-tin alloy coating, an electroplating technology and a coin produced by the technology. The pyrophosphate electroplating solution of a multi-layer cyanide-free electroplated copper-tin alloy coating provided by the invention comprises a cyanide-free brass tin major brightening agent consisting of solutes brightener A and brightener B, wherein the concentration of the brightener A in the major brightening agent is 1-10g / L, and the concentration of the brightener B in the major brightening agent is 0.05-0.5g / L. By adopting the pyrophosphate electroplating solution and the electroplating technology of the multi-layer cyanide-free electroplated copper-tin alloy coating, a coin product of which the coating thickness is over 20 microns and the coating is uniform and dense can be obtained. After high-temperature thermal treatment, the coil coating is of a single-layer structure; the content of tin in the single-layer coating is 11-14% by weight; the coating appearance is in uniform golden yellow color without chromatic aberration, and the problem acknowledged by the electroplating section at present that a single-layer cyanide-free electroplated alloy coating is relatively thin is solved.

Owner:SHANGHAI MINT +1

Coil coating finishing paint and preparation thereof

InactiveCN101343502AIncreased durabilityGood adhesionPolyester coatingsFoaming agentWeather resistance

The invention discloses a coiled material coating finish paint, the components of the finish paint are as follows: polyester resin, amine resin, pigment, titanium white powder, dispersing agent, anti-foaming agent, leveling agent, adhesive force accelerating agent, solidified accelerating agent, solvent, matt powder and wax powder. The invention also discloses a preparation method of the coiled material coating finish paint. The coiled material coating finish paint of the invention has the advantages that the paint has splendid decorative quality, and the utilization has protectionability and durability; the paint also has excellent stamping and processing resistant performances and superior adhesivity to the bottom layer and the surface coating layer; the paint has excellent wear resistance, light resistance and weatherability, and the paint also has good adhesive force, anti-scratching property, good deep-processing resistant property and good light retention and color retention; the preparation method is simple, and and the large-scale production is easy.

Owner:WUXI HUHUANG PAINT

Insulating coil coating and preparation method thereof

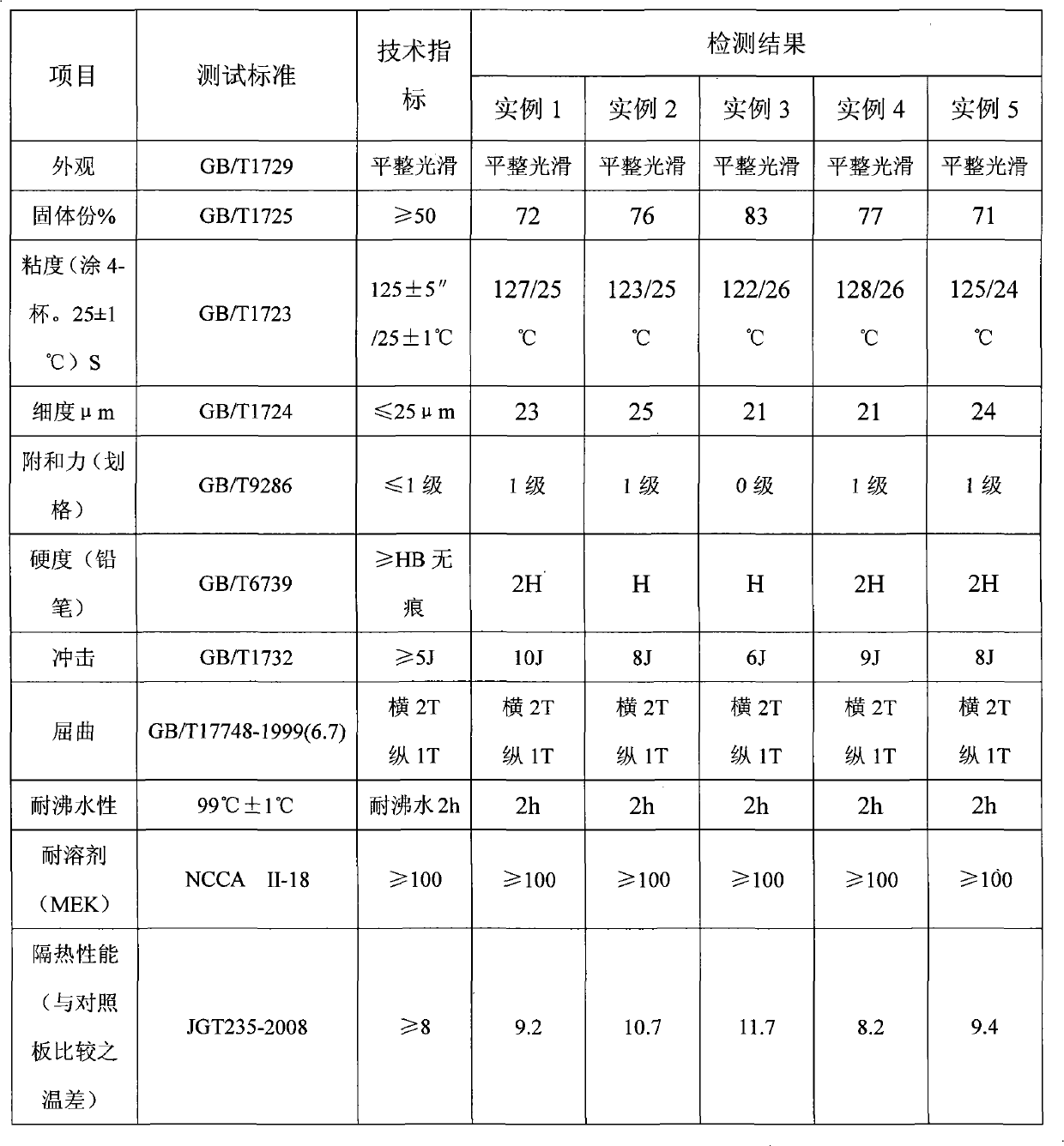

InactiveCN101906264AHigh emissivityGood heat insulationPolyester coatingsReflecting/signal paintsSolventDefoaming Agents

The invention relates to an insulating coil coating and a preparation method thereof, in particular to the building insulating coil coating which is applicable to precoating a metal coiled material production line and has high solar thermal reflectivity and better weathering resistance. The insulating coil coating is composed of saturated polyester resin, amino resin, a dispersant, solar heat reflection composite pigment, a functional potassium titanate whisker, a filling material, a solvent and other additives, wherein the additives comprise an adhesion promoter, a levelling agent, a defoaming agent and a catalyst. The efficient insulating coil coating of the invention has the advantages of efficient heat insulation, ultrathin coating, corrosion resistance, weatherability and the like.

Owner:SOUTH CHINA UNIV OF TECH

Precoated coil coating for adhering polyester film and using method thereof

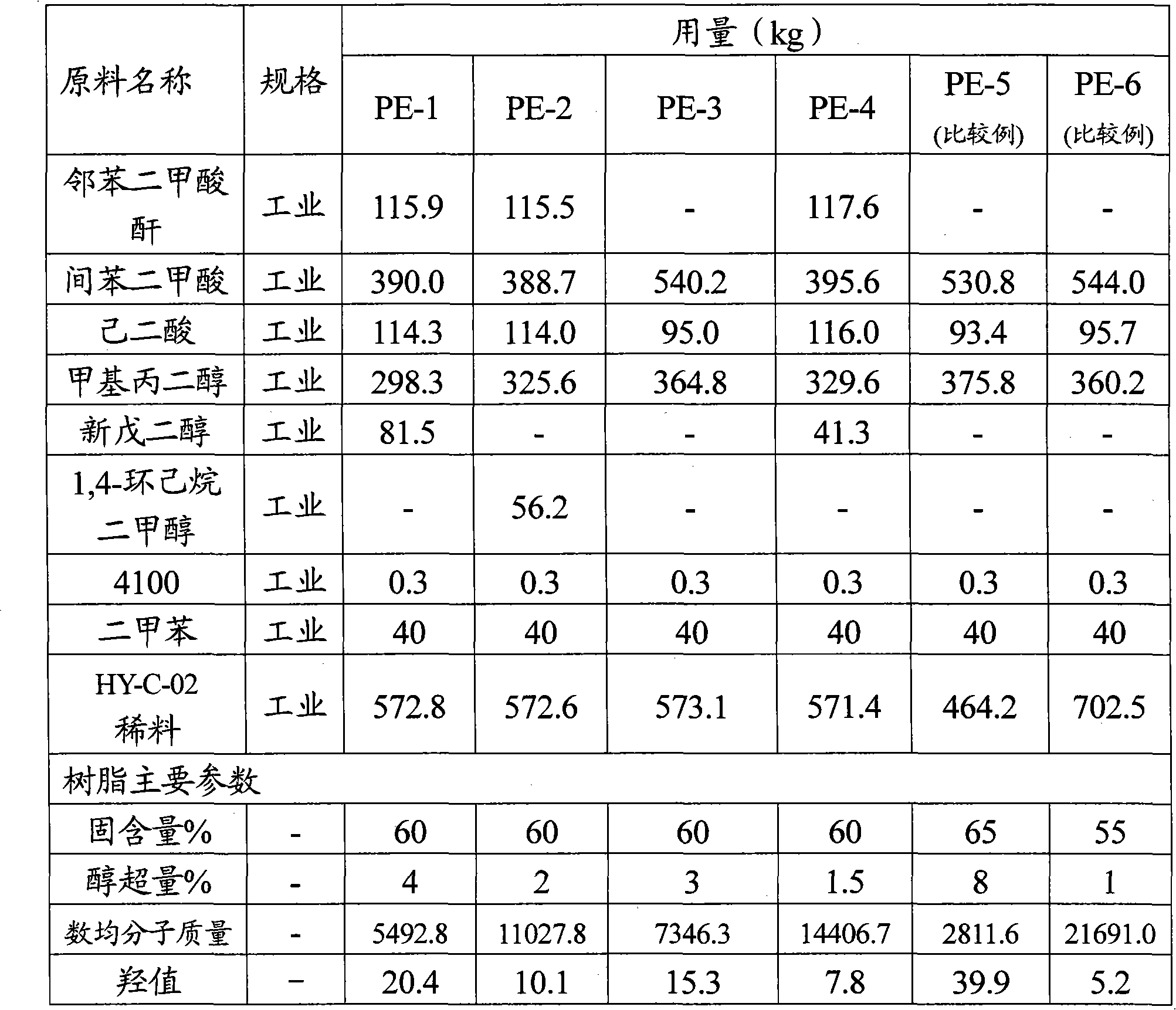

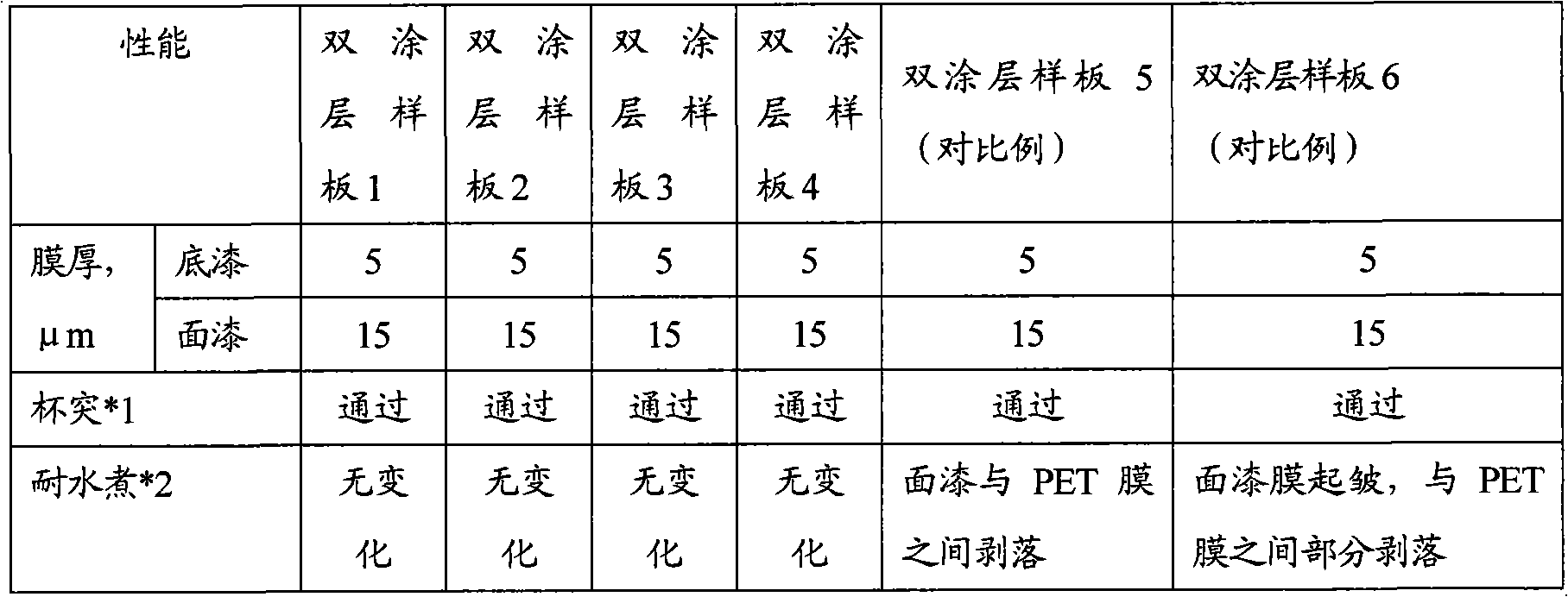

ActiveCN101602914AImprove adhesionFirmly attachedLiquid surface applicatorsPolyester coatingsPolyester resinSolvent

The invention relates to precoated coil coating for adhering a polyester film and a using method thereof. The precoated coil coating comprises the following compositions in percentage by mass: 20 to 35 percent of film-forming resin in solid, 0.5 to 5 percent of an auxiliary agent, 20 to 35 percent of pigment and filling, and 25 to 50 percent of solvent, wherein the film-forming resin consists of 70 to 95 percent of polyester resin which is provided with hydroxy functional group and has number average molecular weight of between 3,500 and 20,000 and a hydroxyl value of between 6 and 35, and 5 to 30 percent of crosslinked resin. The using method is to directly coat the precoated coil coating for adhering the polyester film on a steel plate which is treated by chemical transforming solution and laminate and adhere the polyester film on site, or directly coat the precoated coil coating on a precoated coil which is precoated with priming coat, bake and cure the coil, and laminate and adhere the polyester film on site. The polyester film laminated precoated coil prepared by the precoated coil coating has excellent adhesive force, cup drawing and water boiling resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

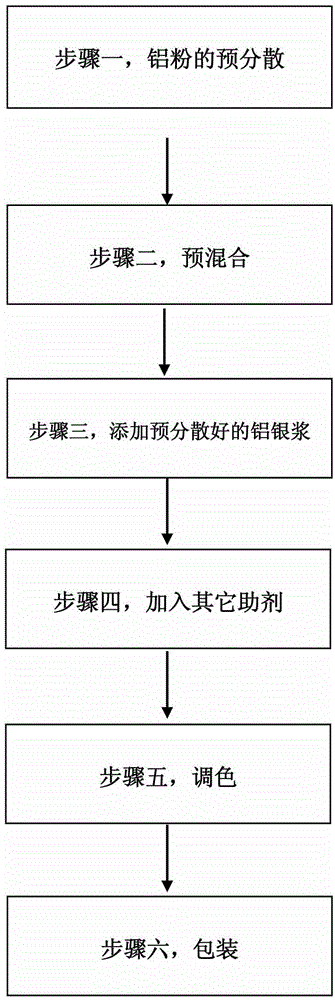

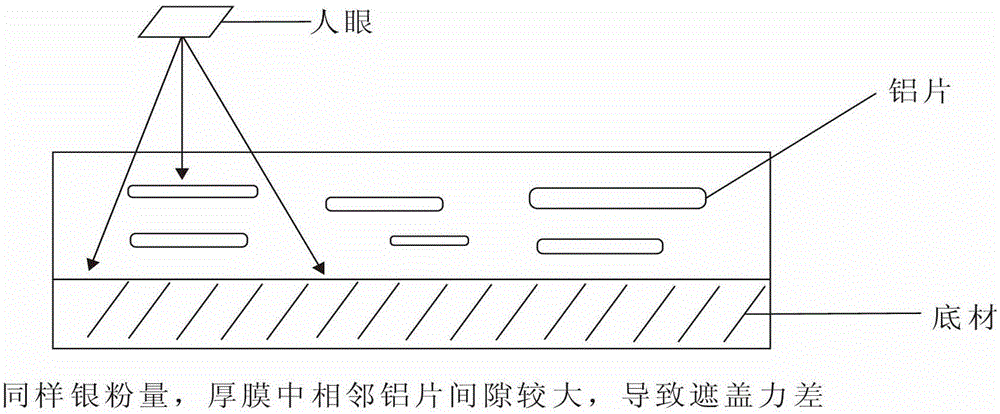

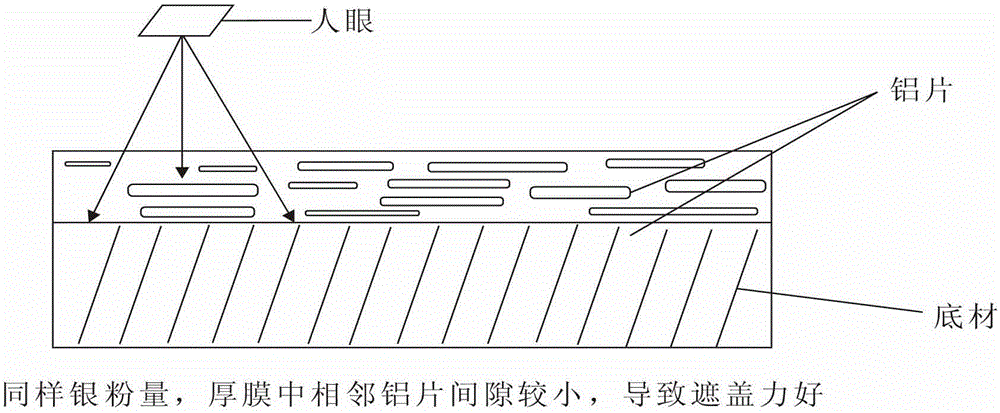

Coil coating having special anode oxidation effect and special for aluminum plate coiled material and preparation method of coil coating

ActiveCN105199558AReduce pollutionReduce manufacturing costPaints with free metalsPolyester coatingsAl powderPtru catalyst

The invention discloses coil coating having a special anode oxidation effect and special for an aluminum plate coiled material. The coil coating is characterized by being prepared from the following components in percent by weight: 2 to 10 percent of solvent, 0.5 to 1 percent of dispersing agent, 0.5 to 1 percent of catalyst, 5 to 10 percent of amino, 0.3 to 0.5 percent of defoaming agent, 0.3 to 0.6 percent of flatting agent, 1 to 2 percent of directional alignment agent, 0.5 to 1 percent of anti-static agent, 15 to 25 percent of nanoscale processed aluminum powder, 40 to 50 percent of polyester resin, 10 to 20 percent of fluorine-modified polyester resin and appropriate nanoscale color mixing color concentrate. After the coil coating disclosed by the invention is used on the aluminum plate coiled material, a surface effect which is equivalent to an anode oxidation effect can be generated.

Owner:连州市格雷特化工有限公司

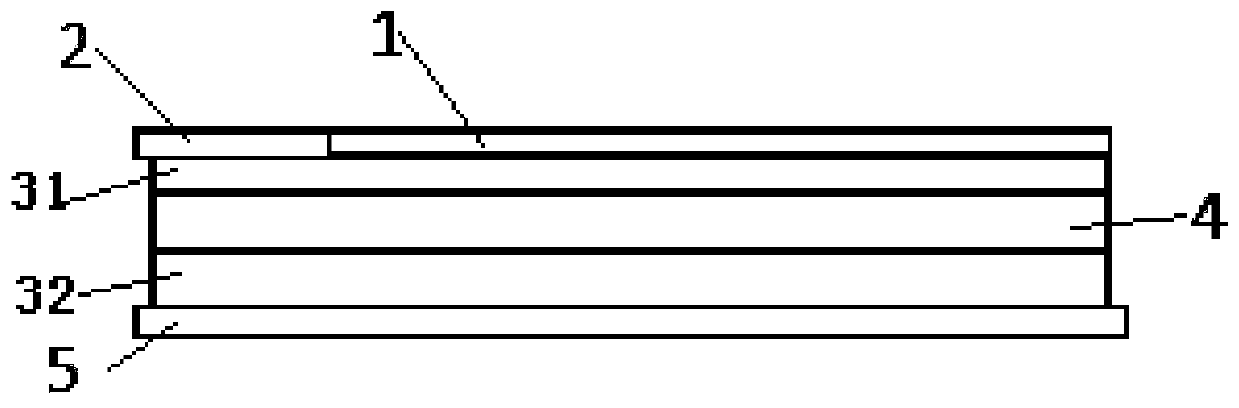

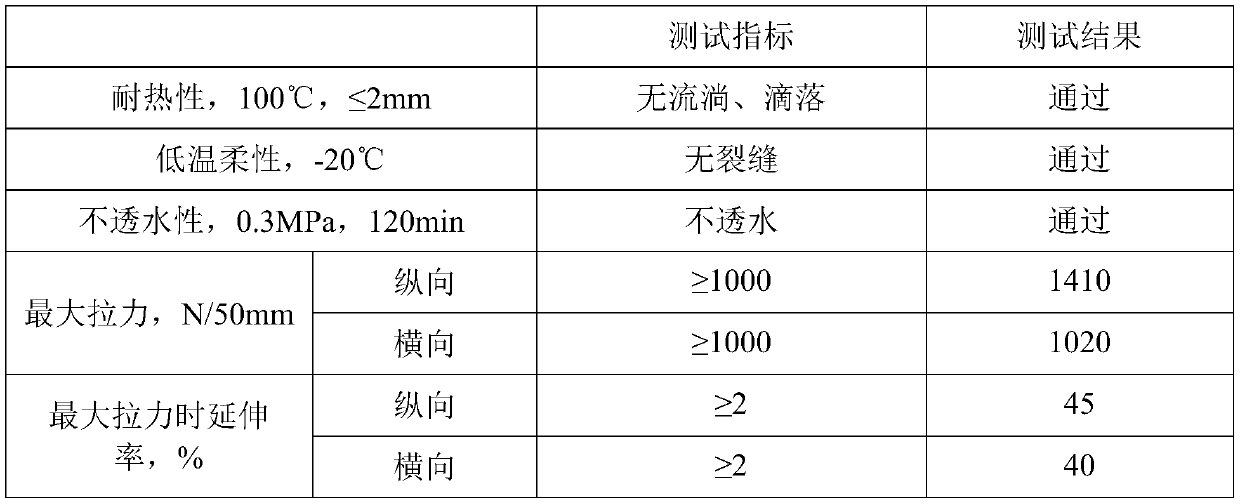

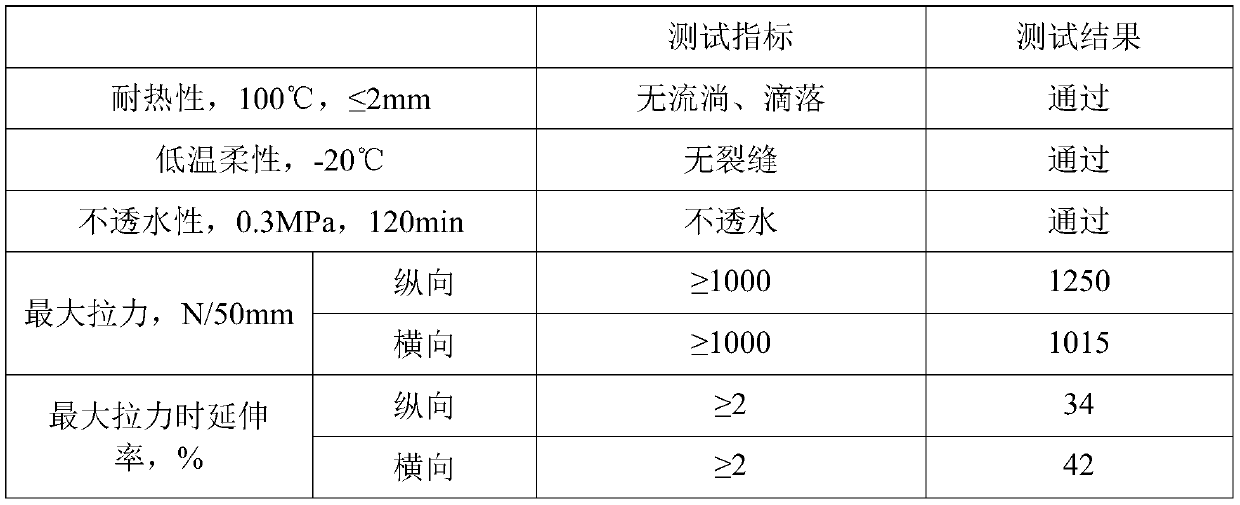

Self-adhesion modified asphalt waterproofing coil coating material, preparation method thereof and passive special self-adhesion asphalt waterproofing coil for buildings

ActiveCN110746930AImprove compactnessExtend your lifeNon-macromolecular adhesive additivesRoof covering using flexible materialsBituminous waterproofingPhosphoric acid

The invention discloses a self-adhesion modified asphalt waterproofing coil coating material, a preparation method thereof and a passive special self-adhesion asphalt waterproofing coil for buildings.The raw materials for preparing the self-adhesion modified asphalt waterproofing coil coating material include the following components: mixed asphalt, polyethylene wax, a stabilizer, a linear SBS modifier, a powder SBR modifier, tackifying resin and inorganic filler, wherein the mixed asphalt is a mixture of petroleum asphalt and softening oil, and the stabilizer is a mixture of polyphosphoric acid and a phosphotriester. The self-adhesion asphalt waterproofing coil has a longitudinal-transverse tensile value of >= 1000 N and elongation of >= 2%, and the modified asphalt is special-made modified asphalt, and is characterized by good compactness and high temperature resistance; and compared with ordinary self-adhesion modified asphalt, the modified asphalt is delicate, and has no bubbles and resistance to a high temperature of 100 DEG C.

Owner:四川东方雨虹建筑材料有限公司

Low temperature curing color coil suede coating

InactiveCN101857767AHigh reactivityProduce a suede effectPolyester coatingsMulticolor effect coatingsLacquerLow temperature curing

The invention relates to a low temperature curing color coil coating, in particular to a low temperature curing color coil suede coating which comprises paint and a curing agent, wherein the paint and the curing agent are stored individually. The formula of the paint comprises the following components by weight proportion: 50% to 70% of saturated polyester resin, 5% to 8% of completely methylated melamine-formaldehyde resin, 1% to 2% of ethylenediamine surface active agent, 0.5% to 0.8% of closed p-toluenesulfonic acid catalyst, 5% to 20% of rutile titanium pigment, 5% to 19% of pigment, 3% to 5% of propylene glycol aether acetate, 2% to 5% of dibasic acid dimethyl ester, 5% to 10% of aromatic hydrocarbon solvent, 0.3% to 0.8% of dispersant and 0.3% to 0.8% of polytetrafluoroethylene wax.

Owner:JIANGSU LANLING COATING TECHN RES INST

Waterborne nano coil coating and preparation method thereof

The invention belongs to a waterborne nano coil coating and a preparation method thereof. Firstly, an inorganic material with no toxic property, foreign smell and combustion characteristic is used as a basic powder material of a coil coating, a waterborne acrylic emulsion, waterborne epoxy resin, water-soluble functional auxiliaries and other film forming matters are compounded, updated and modified by using a nanotechnology and nano materials, and gaps of large micro materials in a coating structure are filled by using various nano powder materials after the hydration of the coil coating is effectively finished, so that the coating generates a coating function enhancing effect under the synergistic action of multi-effect combination of the nano materials and micro materials, the defect that the performance of the waterborne coil coating prepared by a micrometer technology is lowered is overcome effectively, and the technical performance of the waterborne coil coating is remarkably enhanced. By using the waterborne nano coil coating and the preparation method thereof, the production efficiency is increased, the fire risks and industrial pollution of the traditional solvent type coil coating are eliminated, and meanwhile, the aim of safe, environment-friendly, low-consumption and efficient production is achieved.

Owner:北京中科捷达纳米应用科技有限公司

Initial solids mixture for a later organic coating application

InactiveUS20020088373A1Less riskLess-uneven propertyPigmenting treatmentConductive materialBoron carbideLanthanide

An initial solids mixture for a later organic coating, such as pigmented coatings, films, priming coats, etc., e.g., for a coil coating method in which an initial solids mixture is applied to a substrate, e.g., broad strip, and this is thereby pre-coated, wherein the initial solids mixture includes, as additive particles, boron carbide and / or silicon carbide and / or compounds of transition elements or lanthanides, the electrical conductivity of which is selected to be in the metallic range (sigma>102 1 / OMEGAcm and sigma<107 1 / OMEGAcm), during the later coating, the additive particles have a continuous physical connection in at least one spatial direction.

Owner:DAIMLER AG

Coil coating with imitated velvet effect and preparation method thereof

InactiveCN101705045AMeet any processing and forming requirementsAchieve chemical resistancePolyester coatingsEthylenediamineCyclohexanone

The invention relates to a coil coating with imitated velvet effect and a preparation method thereof and the coil coating is a colour paint coating used for colour steel and colour aluminum for architectural decoration. According to the technical scheme provided by the invention, the coil coating with imitated velvet effect comprises the following components in parts by weight: 35-40 parts of branched saturated polyester resin, 0.3-1.5 parts of macromolecular block copolymer, 5-30 parts of coloring pigment, 5-25 parts of filler, 3-5 parts of 100# aromatic solvent, 1-3 parts of cyclohexanone, 1-3 parts of dibasic ester, 5-20 parts of polyester polyol resin, 1-3 parts of enclosed type polyurethane curing agent, 2-5 parts of methylated melamine resin, 0.6-1.8 parts of enclosed type p-toluenesulfonic acid, 0.5-1.5 parts of polyethylene wax, 0.15-1.5 parts of triethylamine or ethylenediamine and 0.3-1.5 parts of fluorine modified acrylic leveling agent. The paint capability of the coating of the invention can fully reach all kinds of requirements of forming and can also meet the requirements of good look, newfangled, personality, and the like.

Owner:无锡银星涂层板有限公司

Dendritic hyper-branched polymer, preparation method and application thereof

InactiveCN101538345AIncrease the degree of branchingWide variety of sourcesCoatingsPolymer sciencePhotoinitiator

The invention discloses a dendritic hyper-branched polymer, a preparation method and application thereof. The homo-polymerized or co-polymerized dendritic hyper-branched polymer is obtained by taking poly-alkenyl monomers or poly-alkenyl monomers and mono-alkenyl monomers as raw materials to carry out polymerization in the presence of radical initiator and chain transfer agent. The invention comprises the following components by the weight percentage: 69% to 92% of poly-alkenyl monomers or poly-alkenyl monomers and mono-alkenyl monomers, 0.05% to 2% of radical initiator and 7% to 30% of chain transfer agent. In the invention, the monomer conversion rate of polymers is 40% to 90%, and the number average molecular weight of polymers is 2,000 to 6,000. Compared with the prior art, the invention has the advantages of various material sources, high product branching coefficient and short production period, therefore, the invention is applicable to industrialized production on a large scale. The photo-curable coatings which are obtained by mixing the dendritic hyper-branched polymer of the invention, photo initiator and photo-initiation additive are applicable to coil coatings, board coatings, and film coatings for electronic products.

Owner:SHANGHAI HUAYI GRP CO

Low gloss coil powder coating composition for coil coating

InactiveUS20070142570A1Good coating performanceHigh exterior durabilityPowdery paintsPolyester coatingsPliabilityHigh velocity

The present invention provides a powder coating composition obtainable by homogeneous mixing of at least two separately produced powder coating compositions as powder coating bases, especially suitable for the coil coating technology, that means, for coating applications also under high speed, e.g., at coating speeds of about >50 m / min providing coatings with a high flexibility for post forming. In spite of substitution of TGIC, the powder coating composition of this invention are coating compositions having a good storage stability and giving coatings with any desired gloss level as well as good coating properties, particularly, high exterior durability and stable flexibility and the compositions are suitable for the coil coating technology, that means, for coating applications also under high speed.

Owner:DUPONT POWDER COATINGS FRANCE

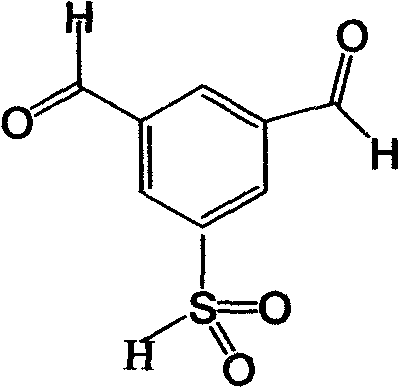

Storage-stable PU powder coating compositions and their use for flexible, low-haze polyurethane coatings

InactiveCN101200617ALiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterPolyurethane coating

Owner:GOLDSCHMIDT CHEM CORP

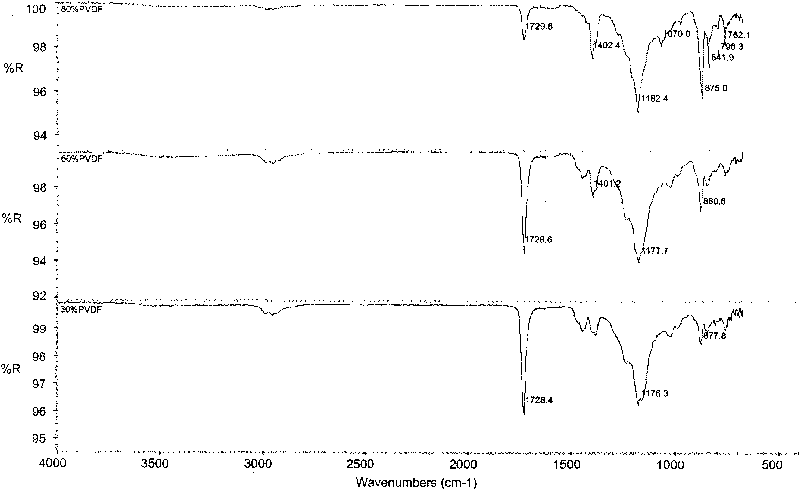

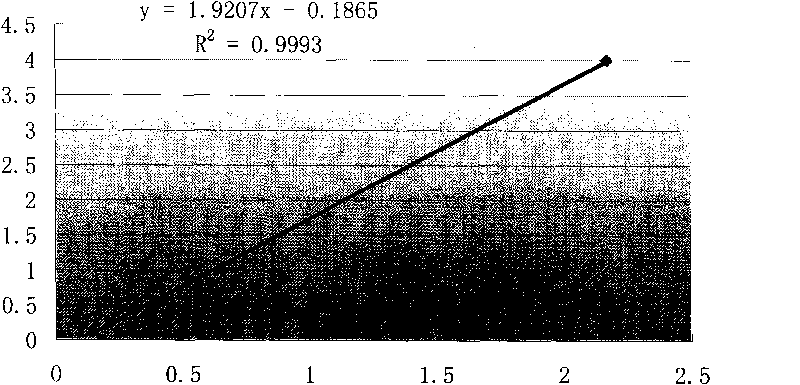

Infared peak area ratio determination method of content of PVDF resin in fluorocarbon color coated sheet coating

InactiveCN101750279AReduce usageShorten test timeMaterial analysis by optical meansOrganic solventAcrylic resin

The invention relates to an infared peak area ratio determination method of the content of PVDF resin in a fluorocarbon color coated sheet coating, comprising the following steps: 1. preparing a series of fluorocarbon coil coatings with known PVDF resin content; 2. scraping the fluorocarbon coil coatings prepared in step 1 on a steel plate by a coil bar method to obtain color coated sheet samples, and drying the samples; 3. directly collecting infrared spectrum charts for the series samples produced in step 2 on an infrared spectrometer by an ART sampling method; 4. calculating the peak area A of 1696-1764cm-1 and 860-900cm-1 of each sample and the ratio of the two peak area, and taking the peak area ratio of each sample and PVDF resin content / acrylic resin content as a horizontal coordinate and a vertical coordinate to obtain a standard working curve; and 5. collecting the infrared spectrum chart of the fluorocarbon color coated sheet to be detected, calculating the peak area ratio of the sample and calculating on the working curve to obtain the PVDF resin content of the sample. The method leaves out the pretreatment step of the sample, and does not need to use organic solvent, thus achieving the purposes of green analysis and rapid detection.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Initial solids mixture for a later organic coating application

InactiveUS20050017221A1Less riskLess-uneven propertyConductive materialOrganic conductorsLanthanideBoron carbide

An initial solids mixture for a later organic coating, such as pigmented coatings, films, priming coats, etc., e.g., for a coil coating method in which an initial solids mixture is applied to a substrate, e.g., broad strip, and this is thereby pre-coated, wherein the initial solids mixture includes, as additive particles, boron carbide and / or silicon carbide and / or compounds of transition elements or lanthanides, the electrical conductivity of which is selected to be in the metallic range (σ>102 1 / Ωcm and σ<107 1 / Ωcm), during the later coating, the additive particles have a continuous physical connection in at least one spatial direction.

Owner:DAIMLER AG

Polyvinylidene fluoride dispersion

InactiveUS20130122309A1Group 5/15 element organic compoundsSynthetic resin layered productsOrganic solventPolyvinylidene difluoride

The invention relates to a polyvinylidene fluoride (PVDF) solvent dispersion composition containing PVDF (such as KYNAR 500) that is free of fluorosurfactants, an organic solvent, and low levels of dispersants. A pigmented version of this dispersion is also covered. The dispersion is useful for producing tough, chemical-resistant coatings, especially on metallic substrates, including for use as a coil coating or an architectural coating.

Owner:ARKEMA INC

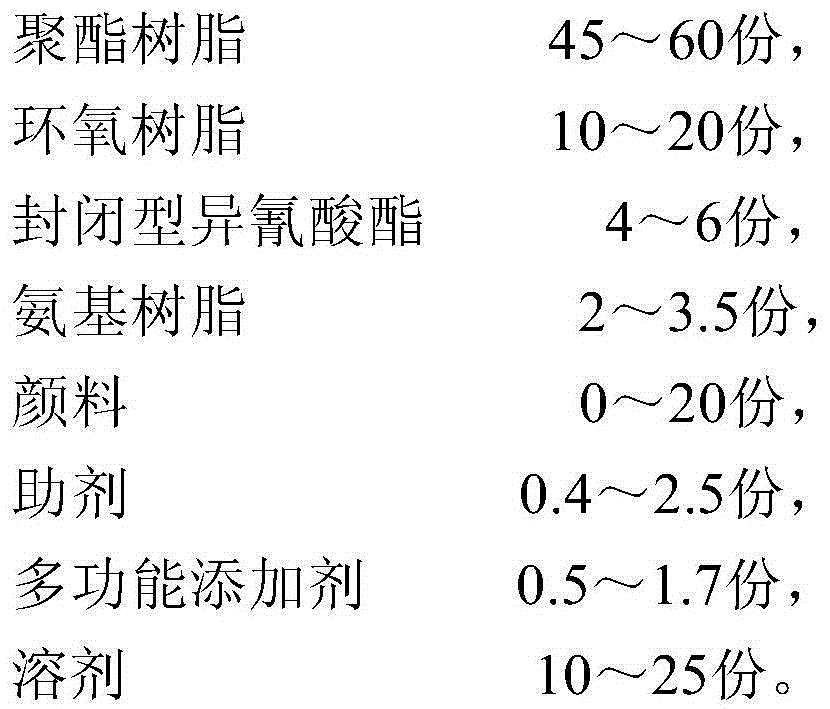

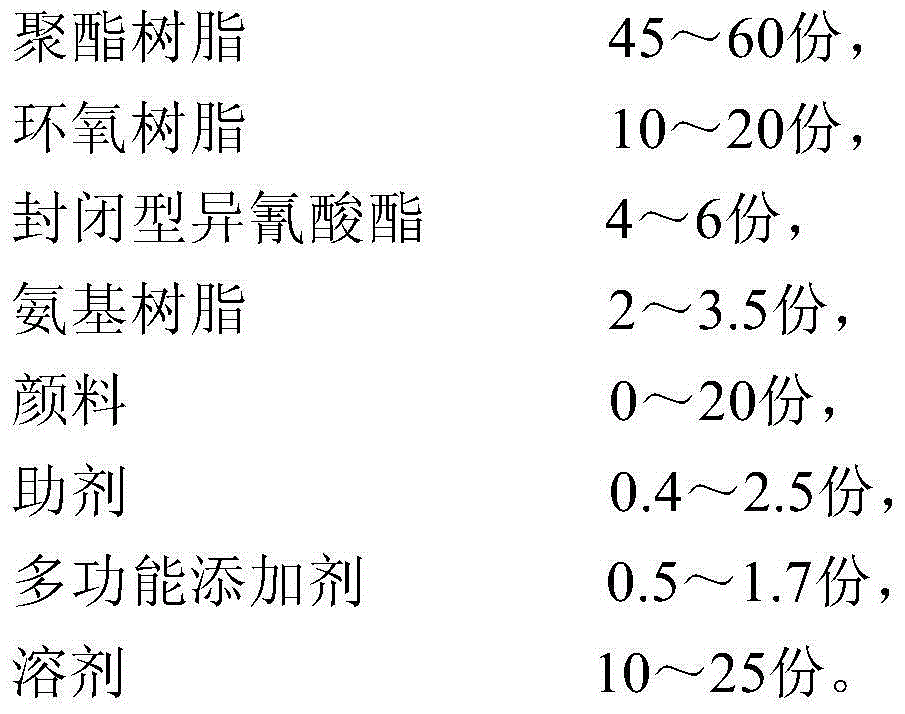

Coil coating bonded with PVC film and preparation method thereof

ActiveCN105567058AImprove corrosion resistanceImprove boiling resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses a coil coating bonded with a PVC film. The coil coating bonded with the PVC film is prepared from the following raw materials by weight: 45 to 60 parts of polyester resin, 10 to 20 parts of epoxy resin, 4 to 6 parts of enclosed isocyanate, 2 to 3.5 parts of amino resin, 0 to 20 parts of pigment, 0.5 to 1.7 parts of a silanol compound, 0.4 to 2.5 parts of an auxiliary agent and 10 to 25 parts of a solvent. The coil coating bonded with the PVC film has excellent anticorrosion performance and boiling resistance. The coil coating is applicable to coiled material (colorful coated steel plate) production process, can be directly bonded with the PVC film and has excellent mechanical performance and adhesion. The coil coating can present more and richer colors after addition of different pigments as needed.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

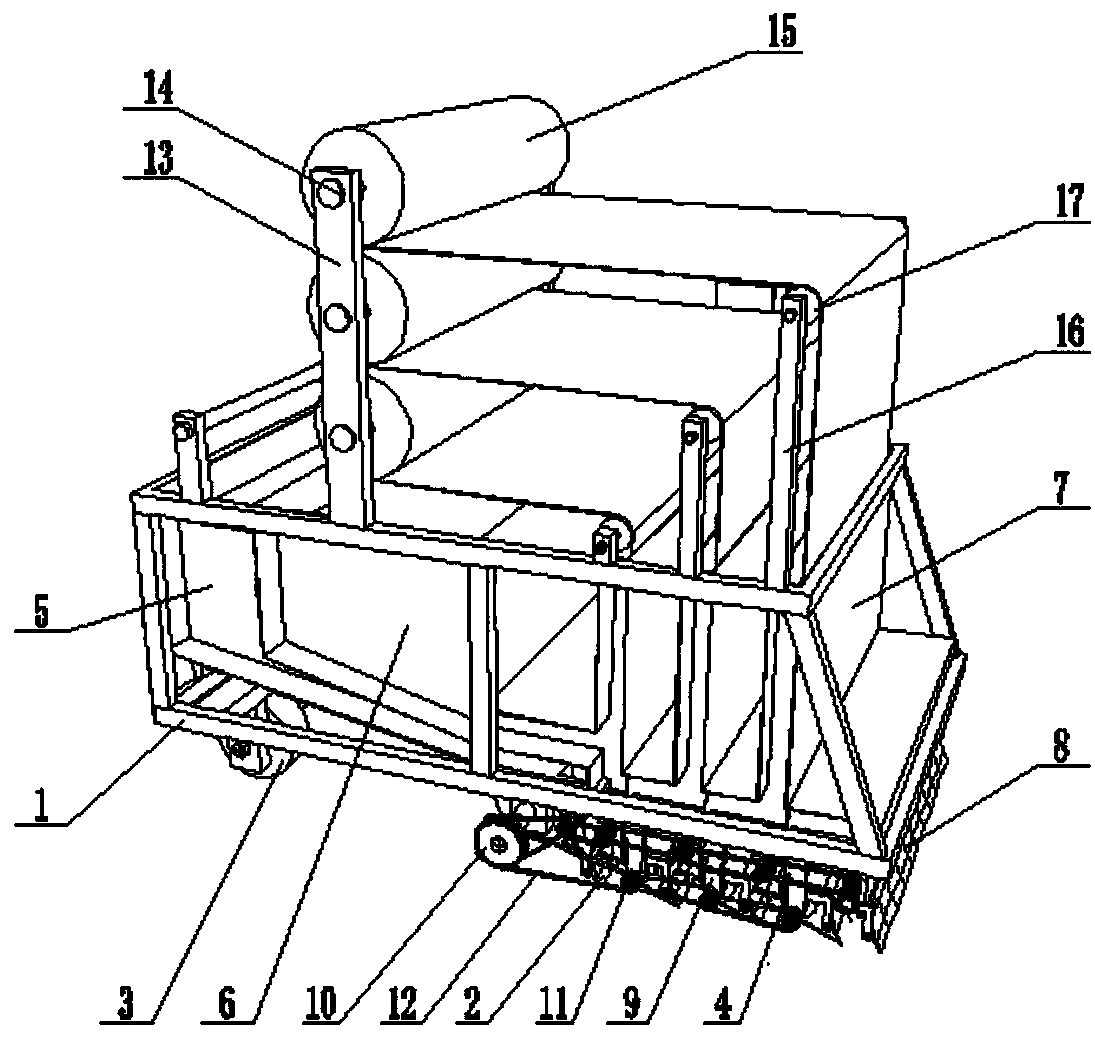

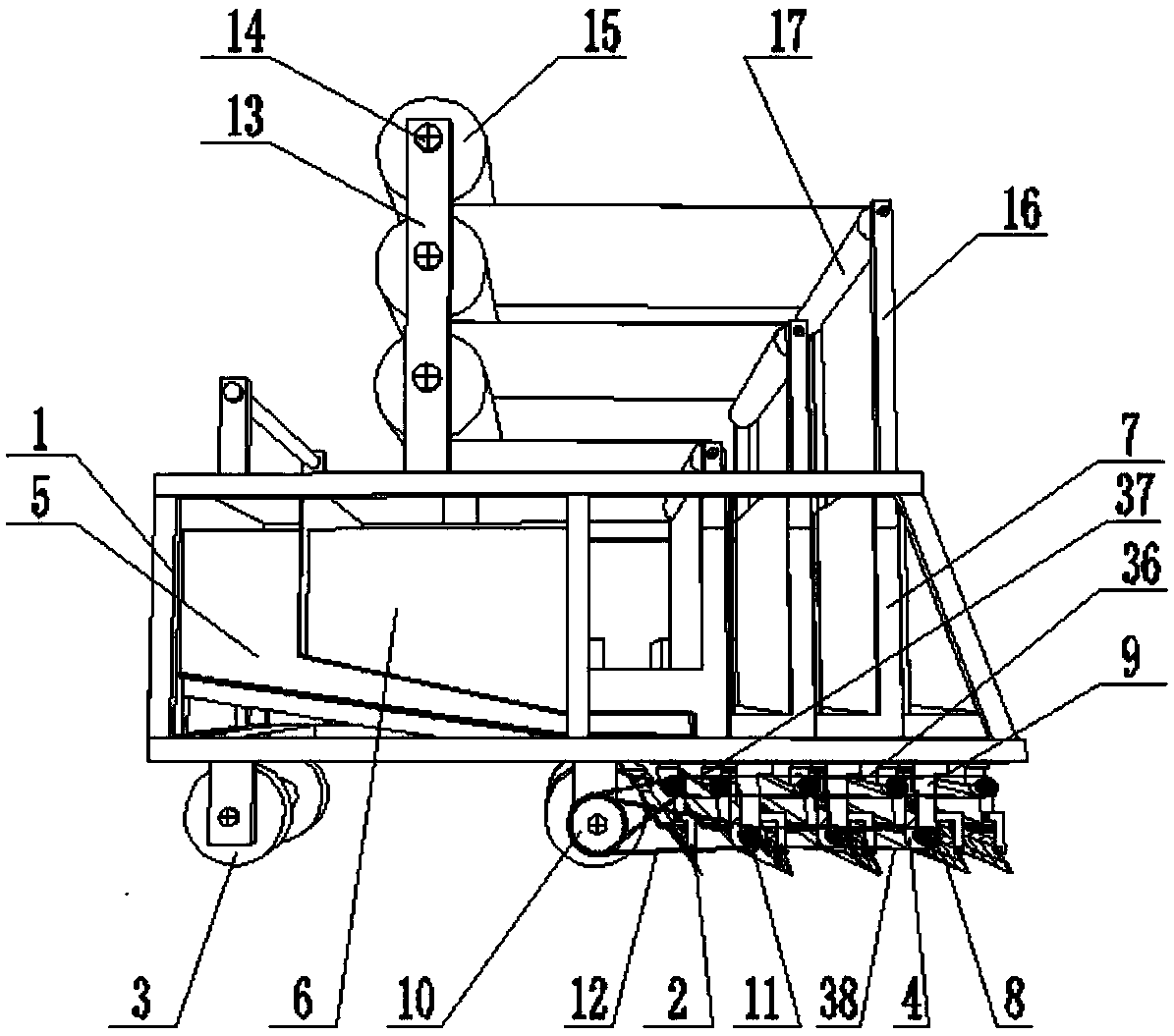

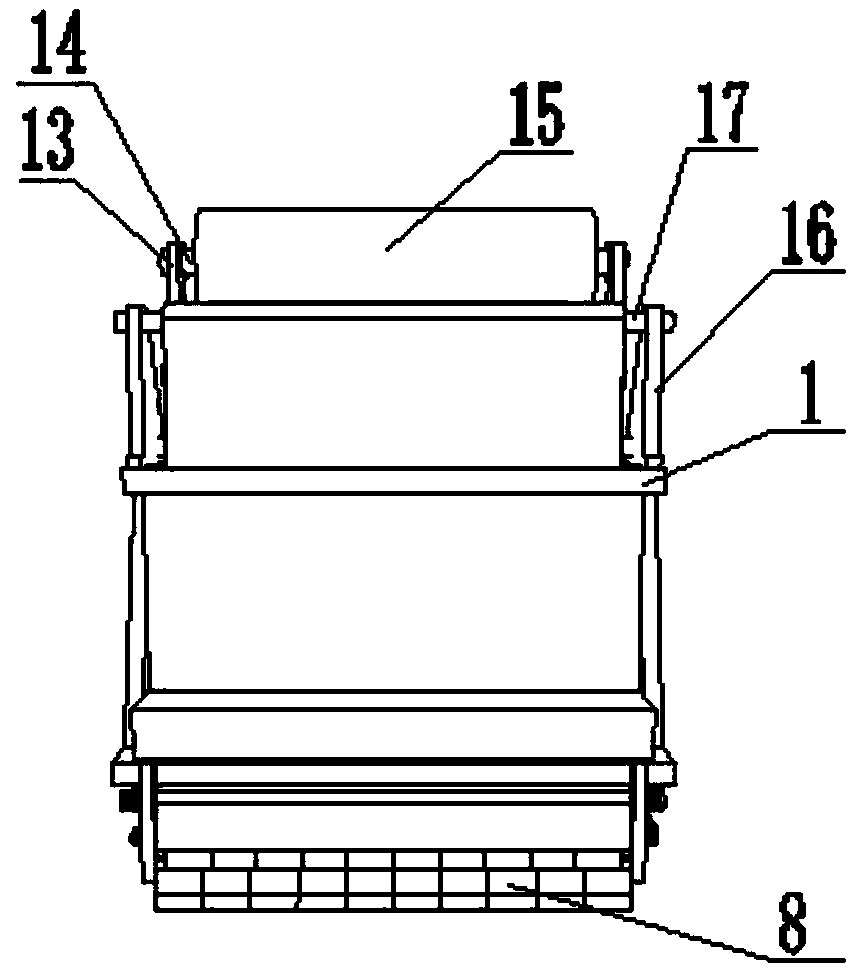

Coil coating body vehicle for site operation of multilayer composite waterproof layer

The invention discloses a coil coating body vehicle for site operation of a multilayer composite waterproof layer. The coil coating body vehicle comprises a coating stock bin, a tire base feeding device and a coating device. The coating stock bin, the tire base feeding device and the coating device are all arranged on the coil coating body vehicle. Both the tire base feeding device and the coatingdevice communicate with the coating stock bin. According to the technical scheme, coating is put into the coating stock bin, a tire base is put into a leaching bin, the multilayer composite waterproof layer formed by the coating and the tire base are laid on interarea through the coating device, so that the multilayer composite waterproof layer can be laid synchronously and molded once, and accordingly construction efficiency is improved and labor intensity is lowered. Outer edge line speeds of a driving wheel and a driven wheel are in accordance so as to ensure the generating speed of the multilayer composite waterproof layer and the laying speed to keep consistent. Moreover, gravity center of the coating stock bin is between a first pair of wheels and a last pair of wheels so that the stability of the construction of the coil coating body vehicle is improved.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

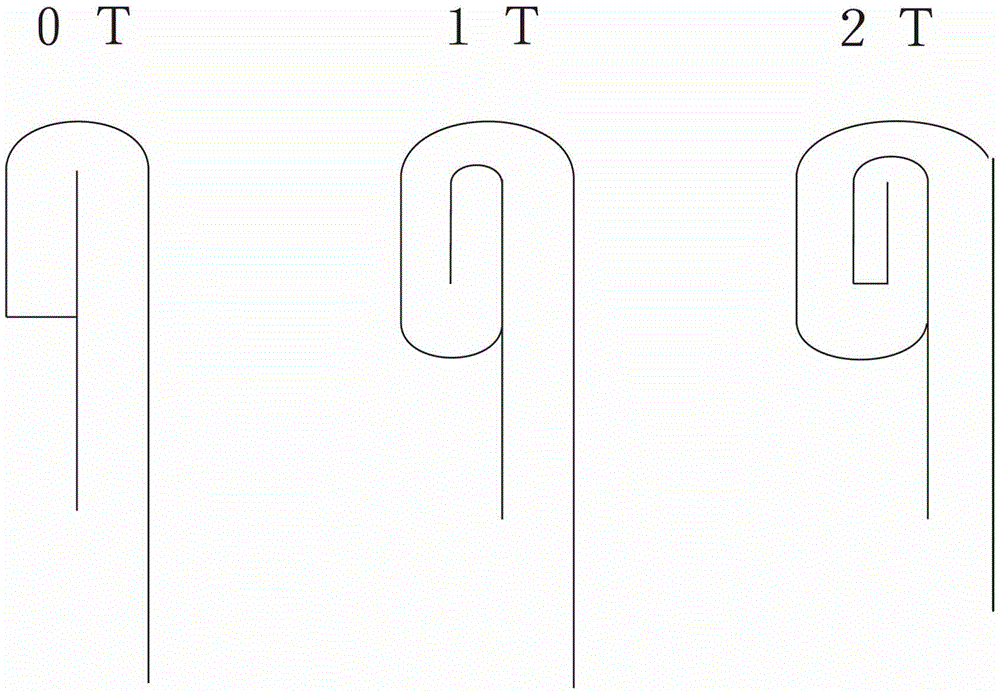

Polyester coil coating formulation

InactiveUS20100076154A1Outstanding of hardnessEasy to combineMixingPolyester coatingsCross-linkPolyester

In a curable coil coating composition comprising a mixture of: (a) a curable polyester that is a liquid at room temperature, (b) a cross-linking agent; and (c) a solvent; the improvement comprising preparing the polyester from a composition comprising a mixture of 1,3- and 1,4-cyclohexane dimethanol wherein the molar ratio of the 1, 3 isomer to the 1, 4 isomer is from about 60:40 to about 5:95. Cured coil coatings prepared from these compositions exhibit an excellent combination of flexibility and hardness.

Owner:DOW GLOBAL TECH LLC

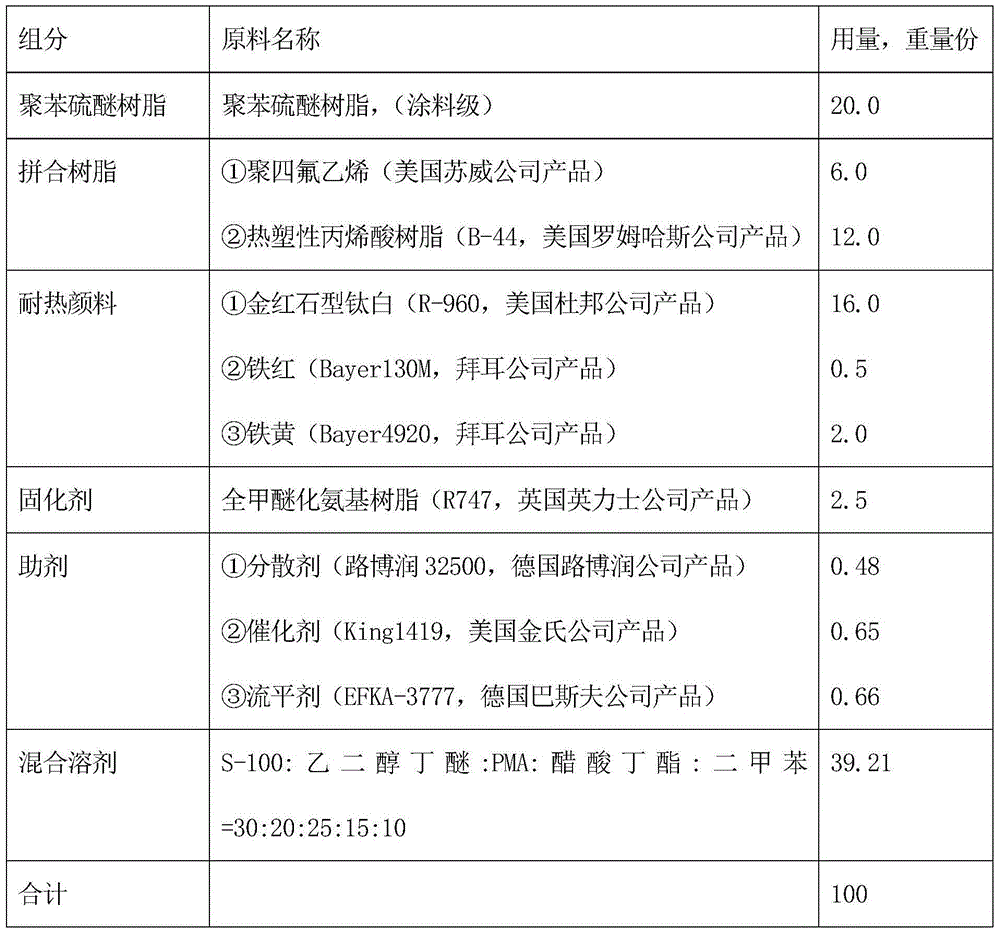

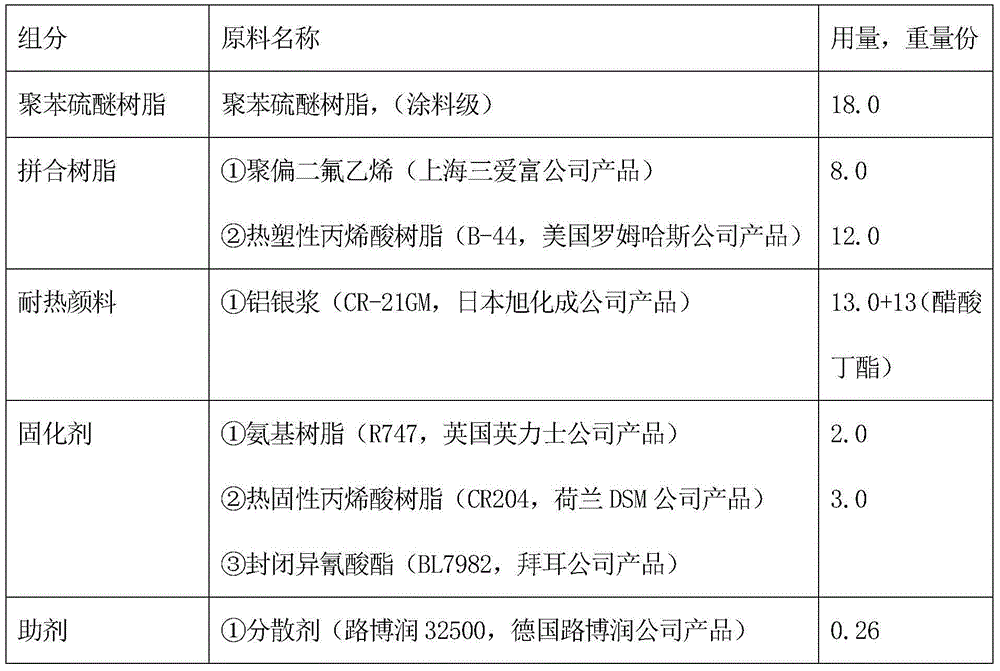

Polyphenylene sulfide coil coating

ActiveCN104312425AStay acid resistantMaintain alkaline propertiesPolyether coatingsAcrylic resinWater boil

The invention relates to a polyphenylene sulfide coil coating which comprises the following components in parts by weight: 9-30 parts of polyphenylene sulfide resin, 9-30 parts of combined resin, 2-6 parts of a curing agent, 10-19 parts of thermal resistant pigment, 45-57 parts of a mixed solvent and 0.5-1.5 parts of an additive, wherein the sum of the components is 100 parts by weight; the polyphenylene sulfide resin is of a coating grade or polyphenylene sulfide oligomer; the combined resin is one or more of polyphenyl ether, polyether-ether-ketone, polytetrafluoroethylene, thermoplastic acrylic resin and polyvinylidene fluorine; the curing agent is full-methyl etherification amino resin, a sealed hexamethylene diisocyanate tripolymer, thermosetting acrylic resin and full-methyl etherification amino resin, or a mixture of the thermosetting acrylic resin and the sealed hexamethylene diisocyanate tripolymer, wherein the mass ratio of the thermosetting acrylic resin and the sealed hexamethylene diisocyanate tripolymer is (1-2):1. The properties such as the acid and alkali resistance and the water boiling resistance of the coil coating are far better than those of resistant medium requirements on ordinary coil coating products of the national standard.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Enhanced scratch resistance of articles containing a combination of nano-crystalline metal oxide particles, polymeric dispersing agents, and surface active materials

InactiveCN1964796AReduce surface tensionMaterial nanotechnologyIndividual molecule manipulationMetal coatingNanoparticle

A film forming composition comprises a resin, a plurality of nanoparticles, a surface active material and a polymeric dispersant. The film forming composition is substantially transparent and is adapted to be combined with a substrate to enhance abrasion resistance. The film forming composition may be used with wood objects including furniture, doors, floors, for architectural surfaces, for automotive articles and finishes, for metal coatings and coil coatings, for plastic articles, and for wipe-on protective treatments.

Owner:NANOCO TECH LTD +1

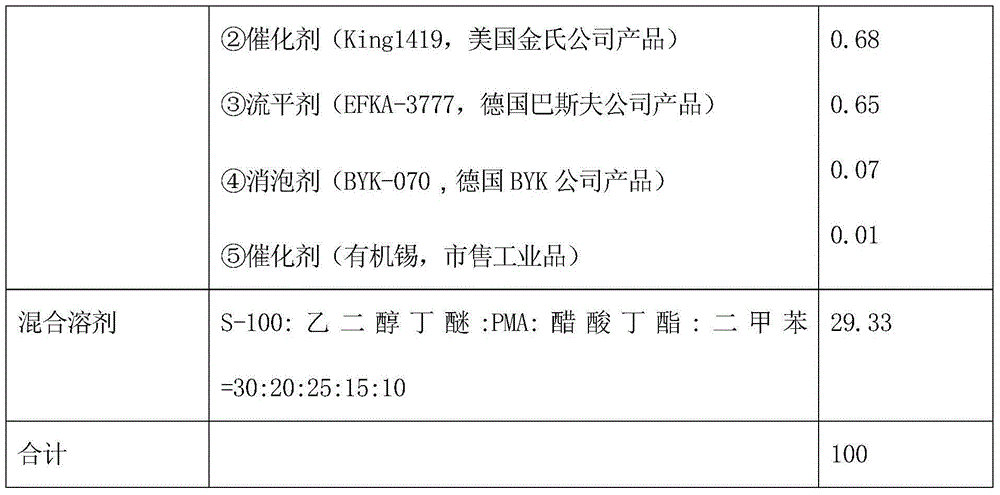

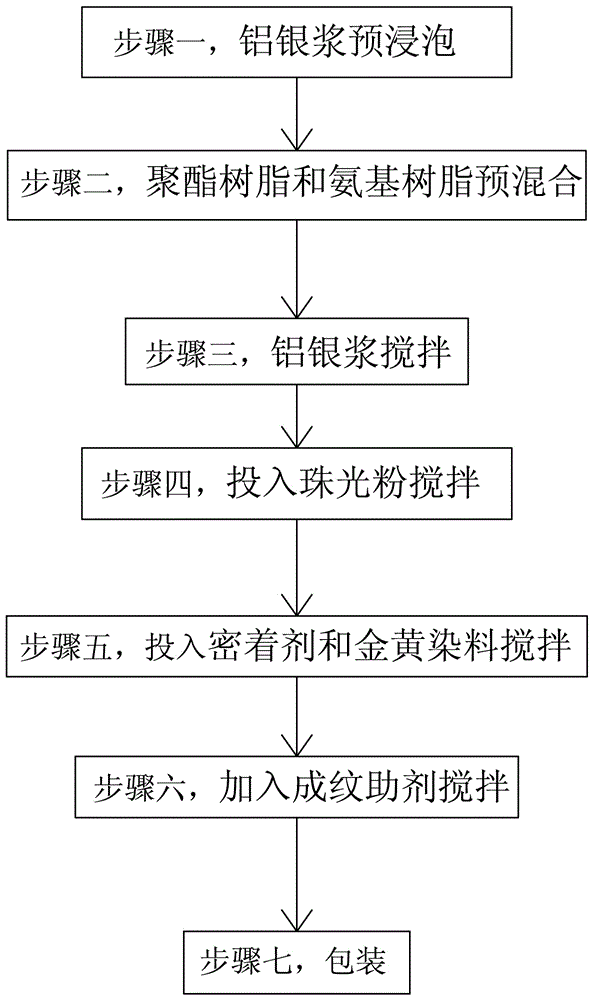

Aluminum plate coil coating and preparation method thereof

InactiveCN106147545AMeet the construction requirements of decorative bending performanceBright colorPolyester coatingsSilver pasteYELLOW DYE

The present invention relates to an aluminum plate and coil coating and a preparation method thereof, comprising the following components and their weight percentages: polyester resin: 70-80%; aluminum silver paste: 5-9%; amino resin: 5-9%; solvent : 5‑8%; Golden dye: 1‑3%; Pearlescent powder: 1‑3%; Texture aid: 1‑3%; Adhesive agent: 1%‑2%. Coil coating, the coating has bright colors, strong flashing feeling, and has a three-dimensional concave-convex coating effect; moreover, the coil coating forms a golden flashing diamond three-dimensional shell pattern paint effect, and it adopts high-solid and low-viscosity linear polyester resin , itself has good flexibility, which can meet the construction requirements of aluminum plate decorative bending performance.

Owner:连州市格雷特化工有限公司

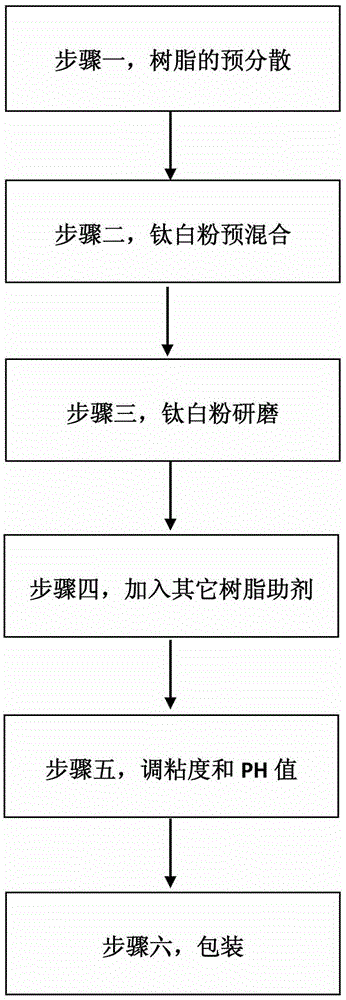

Water-based white polyester coil coating special for aluminum ceiling finish paint and preparation method of water-based white polyester coil coating

InactiveCN105385314ABendableReduce pollutionEpoxy resin coatingsPolyester coatingsEpoxyPtru catalyst

The invention discloses water-based white polyester coil coating special for aluminum ceiling finish paint and a preparation method of the water-based white polyester coil coating. The coil coating is prepared from, by weight, 5%-20% of deionized water, 2%-4% of solvent, 1%-2% of dispersing agent, 0.5%-1% of catalyst, 5%-10% of amino resin, 1%-2% of adherence promoter, 0.3%-0.5% of antifoaming agent, 0.3%-0.6% of flatting agent, 20%-40% of titanium dioxide, 5%-10% of water-based polyester modified epoxy, 30%-50% of water-based organosilicone modified polyester resin and 1%-3% of modifier. The flexibility of the coil coating can meet the construction requirement of an aluminum ceiling, and the advantage of being environment friendly is achieved. The easy-to-implement preparation method of the water-based white polyester coil coating for the aluminum ceiling finish paint is further disclosed.

Owner:佛山市沃特布恩新型材料有限公司

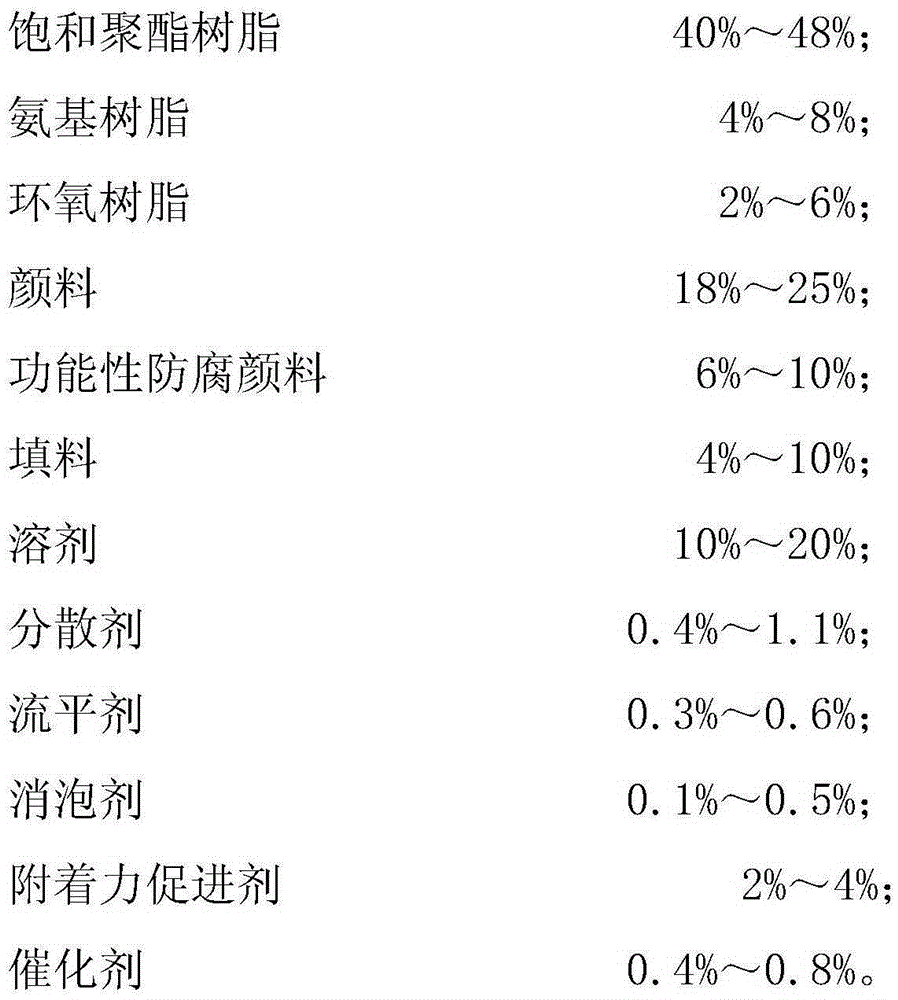

Low-temperature curing primer-topcoat coil coating back paint and preparation method thereof

InactiveCN105419575AMeet the hardness and toughnessCorrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses low-temperature curing primer-topcoat coil coating back paint and a preparation method thereof. The low-temperature curing primer-topcoat coil coating back paint is prepared from the following components in mass ratio by stirring and mixing under the rotating-speed stirring condition: 40-48% of saturated polyester resin, 4-8% of amino resin, 2-6% of epoxy resin, 18-25% of pigment, 6-10% of functional anticorrosion pigment, 6-10% of filler, 10-20% of a solvent, 0.4-1.1% of a dispersing agent, 0.3-0.6% of a leveling agent, 0.1-0.5% of a defoaming agent, 2-4% of an adhesion promoter and 0.4-0.8% of a catalyst. The low-temperature curing primer-topcoat coil coating back paint product has low curing temperature and can meet hardness, toughness, corrosion resistance, acid resistance, alkali resistance, heat resistance and processability required by a galvanized steel sheet, and a single coating has excellent adhesive force, machinability and anti-corrosion property. The low-temperature curing primer-topcoat coil coating back paint product is simple in preparation technology, is applicable to being coated on the surfaces of a hot galvanized steel sheet, an electro-galvanized steel sheet and a cold-rolled steel sheet, so as to form a colorful coating protective film, and is also applicable to continuous roller painting of a continuous coating high-speed production line.

Owner:陕西宝塔山油漆股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com