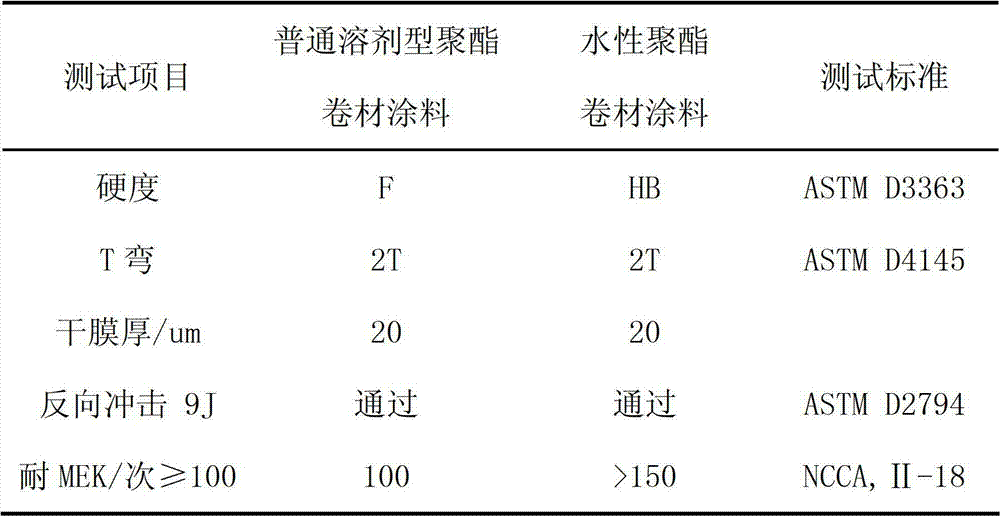

Preparation method and application of core-shell polyurethane/acrylic acid composite emulsion

A composite emulsion, acrylic technology, applied in the direction of coating, to achieve the effect of saving energy, reducing VOC emissions and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

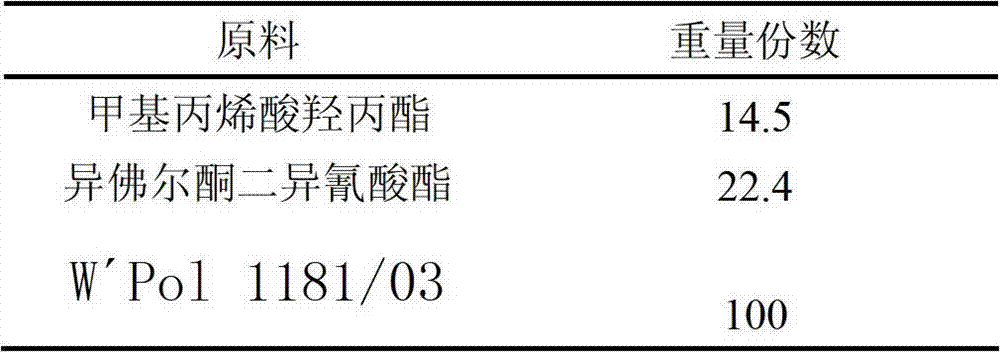

[0033] Add hydroxypropyl methacrylate and IPDI in a 1000ml three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. Slowly heat under continuous stirring, the temperature rises to 70°C and keep warm for 3 hours, then add W'Pol 1181 / 03 (product of WorléeCryl Company), keep warm for 3 hours, then cool down and discharge to obtain transparent prepolymer 1.

Embodiment 2

[0035] The preparation process is the same as that in Example 1, but the isophordione diisocyanate (IPDI) in the formula is replaced with an equivalent amount of toluene diisocyanate (TDI). A transparent prepolymer 2 was obtained.

Embodiment 3

[0037] The preparation process is the same as in Example 1, but the W'Pol 1181 / 03 in the formula is replaced by equivalent Capa3201 (product of Pestorp Company). A transparent prepolymer 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com