Infared peak area ratio determination method of content of PVDF resin in fluorocarbon color coated sheet coating

A resin content, color-coated board technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large application limitations, complicated separation process, large consumption of chemical reagents, etc., and achieve applicability Improvement, strong practicability, and the effect of saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

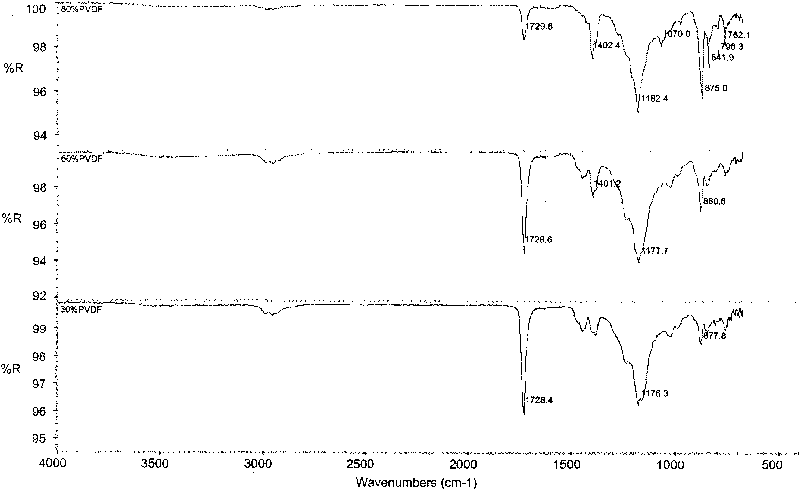

[0033] Embodiment one: a kind of assay method of PVDF resin content of fluorocarbon color-coated plate, its specific operation steps are as follows:

[0034] 1. Reagents and instruments

[0035] PVDF resin (commercially available, solid content is 100%), acrylic resin (commercially available, solid content is 40%), organic solvent (acetone, analytically pure) infrared spectrometer, sample preparation wire rod, stirrer, baking oven

[0036] 2. Sample processing

[0037] Cut the sample into a suitable size for infrared spectrometer measurement.

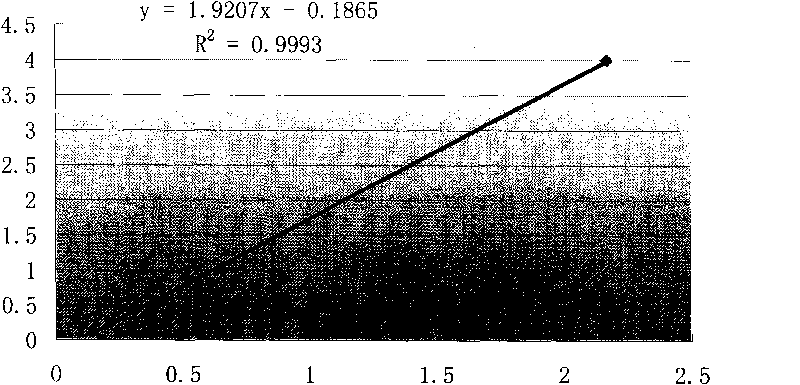

[0038] 3. Preparation of standard working curve

[0039] 1. Preparation of standard samples

[0040]Standard samples were prepared according to the solid content percentages of PVDF resin (solid powder) and acrylic resin (liquid) being 2:8, 4:6, 5:5, 6:4 and 8:2, respectively. When preparing the standard sample, add acetone to adjust the viscosity while fully stirring, so that the viscosity of the sample is suitable for coating. Th...

Embodiment 2

[0052] Embodiment two: a kind of assay method of PVDF resin content of fluorocarbon coil coating, its specific operation steps are as follows:

[0053] 1. Reagents and instruments

[0054] PVDF resin (commercially available, solid content is 100%), acrylic resin (commercially available, solid content is 40%), organic solvent (acetone, analytically pure) infrared spectrometer, sample preparation wire rod, stirrer, baking oven

[0055] 2. Sample processing

[0056] The sample is scraped onto the steel plate by the wire rod method to make a color-coated plate sample, and the coating thickness is controlled at 18 or 20 microns. Then cut into a suitable size for infrared spectrometer measurement

[0057] 3. Preparation of standard working curve

[0058] 1. Preparation of standard samples

[0059] Standard samples were prepared according to the solid content percentages of PVDF resin (solid powder) and acrylic resin (liquid) being 4:6, 5:5, 6:4, 8:2 and 9:1, respectively. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peak area | aaaaa | aaaaa |

| Peak area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com