Waterborne coil coating polyester rear face paint and preparation method thereof

A technology of coil coating and back coating, applied in the field of coatings, can solve the problems of difficult to meet the requirements of volatile organic content standards, poor adhesion and pressure resistance, low solid content, etc., and achieve good hardness, good pressure resistance, and solid with high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prepare described waterborne coil coating polyester back paint by following weight distribution ratio:

[0068] Polyester resin: 35 parts;

[0069] Titanium dioxide R-996: 30 parts;

[0070] Nickel-cadmium yellow: 5 parts;

[0071] Amino resin CYMEL327: 8 parts;

[0072] Dispersant BYK180: 0.3 parts;

[0073] Anti-sedimentation agent A-300: 0.2 parts;

[0074] Defoamer BYK011: 1 part;

[0075] Adhesion promoter ADP9999: 1 part;

[0076] Acid catalyst N-2500: 0.4 parts;

[0077] Wax additive: 0.2 parts;

[0078] Leveling agent BYK381: 0.2 parts;

[0079] Matting powder: 0.5 parts;

[0080] Ethylene glycol butyl ether: 4 parts;

[0081] Isopropanol: 2 parts;

[0082] Water: 35 parts.

[0083] Step 1: After the polyester resin is neutralized with an amine neutralizer, such as N,N-dimethylethanolamine, it is mixed with a dispersant, a pigment, an anti-sedimentation agent and the first part of water, and ground to obtain a slurry, which is controlled during grind...

Embodiment 2

[0086] Prepare described waterborne coil coating polyester back paint by following weight distribution ratio:

[0087] Polyester resin: 35 parts;

[0088] Titanium dioxide R-996: 30 parts;

[0089] Molybdenum cadmium yellow: 5 parts;

[0090] Amino resin CYMEL303: 8 parts;

[0091] Dispersant EFKA4585: 0.3 part;

[0092] Anti-sedimentation agent R-974: 0.2 parts;

[0093] Defoamer BYK024: 1 part;

[0094] Adhesion promoter RHEAD9997: 1 part;

[0095] Acid catalyst N-155: 0.4 parts;

[0096] Wax additive: 0.2 parts;

[0097] Leveling agent Tego500: 0.2 parts;

[0098] Matting powder: 0.5 parts;

[0099] Ethylene glycol butyl ether: 4 parts;

[0100] Isopropanol: 2 parts;

[0101] Water: 35 parts

[0102] The steps of the preparation method of Example 2 are the same as those of Example 1.

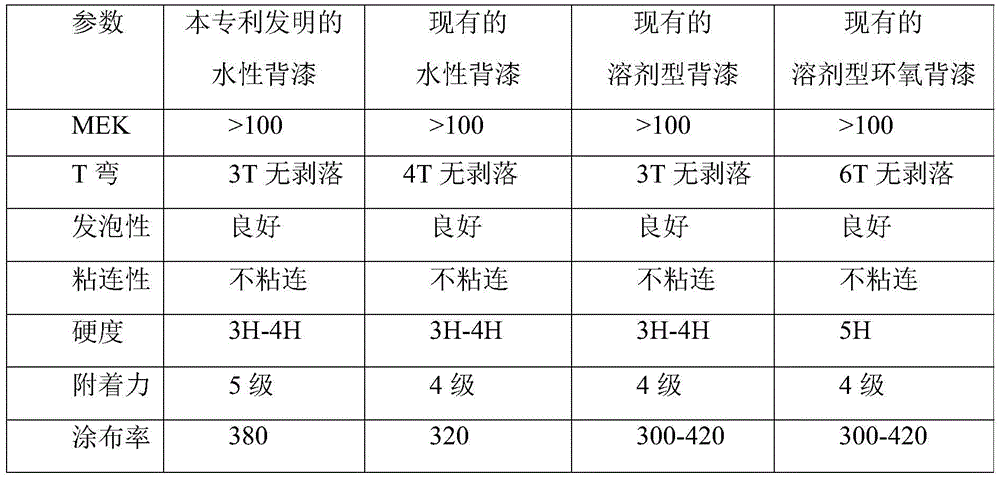

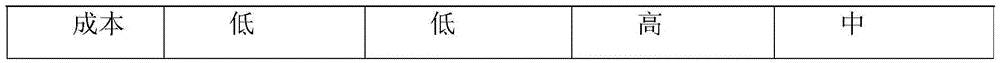

[0103] The prepared waterborne coil coating polyester back paint of embodiment 1, 2 all meets the performance index of following table 1, and with existing waterborne acrylic bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com