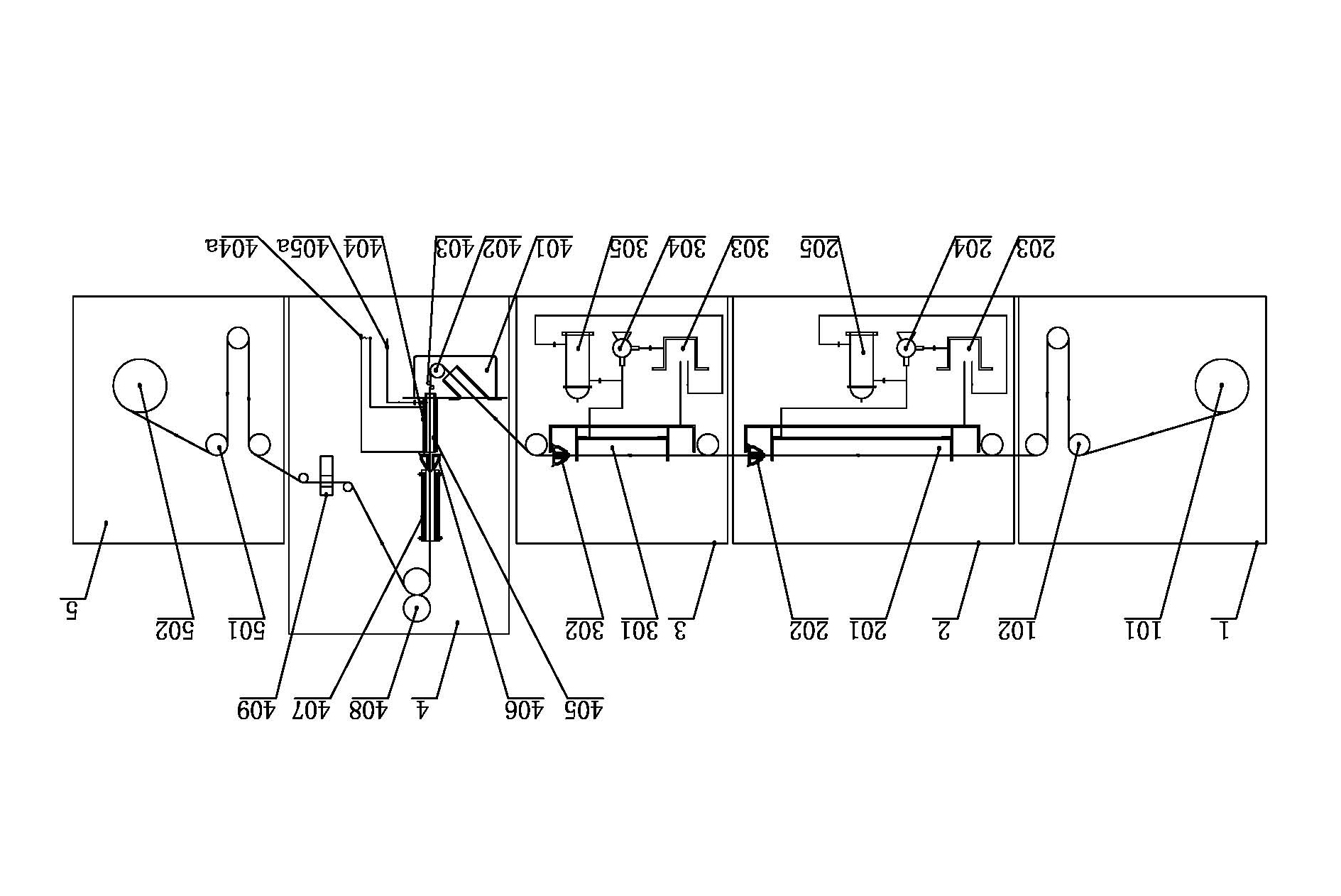

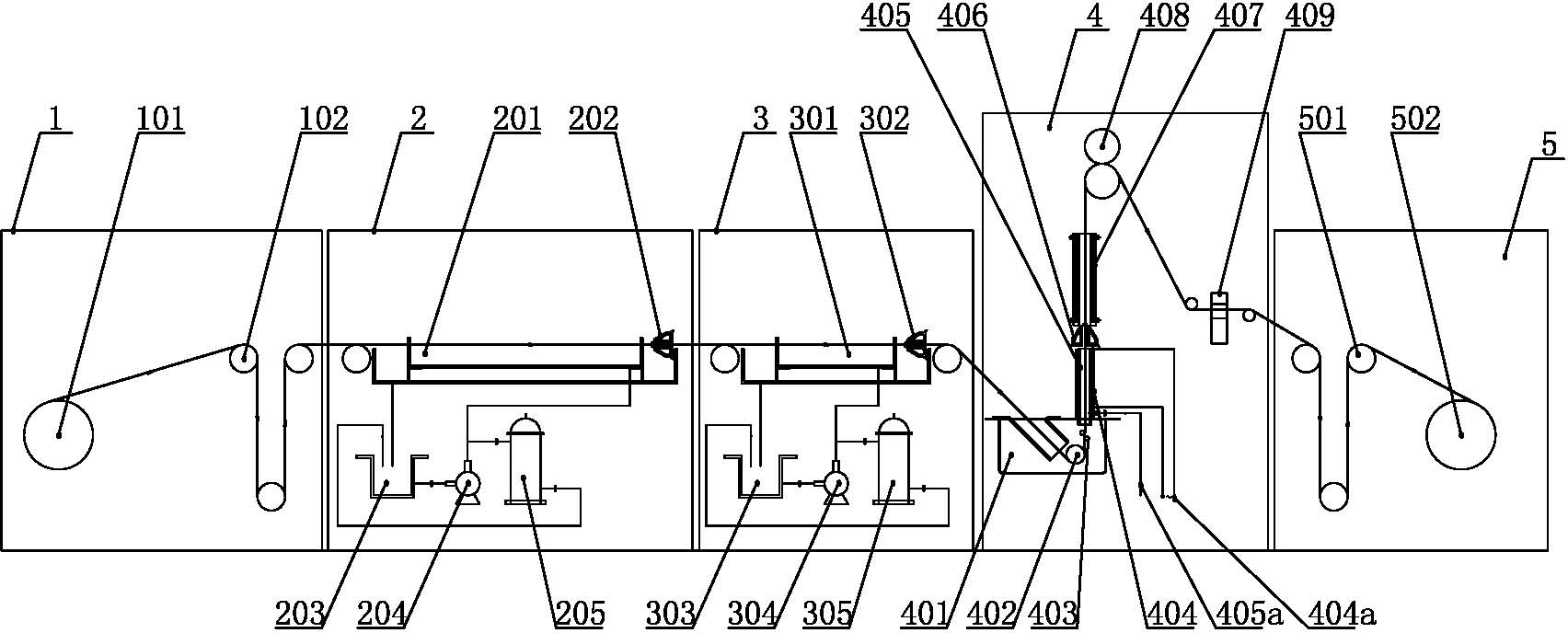

Production system and production method of extremely-soft tin-coated welding strip

A technology for coating tin soldering tape and production system, applied in the field of solar cells, can solve the problems of affecting production efficiency, large amount of cleaning liquid replenishment, and flashing of cleaning liquid, etc., so as to improve production efficiency, reduce heating time, and improve traveling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw material composition and weight content of the cleaning liquid in the cleaning tank are: oxide film dissolving agent: corrosion inhibitor: roughening agent = 1:0.025:0.03; the cleaning tank is equipped with an ultrasonic vibrator with a frequency of 20Kz, and the temperature of the cleaning tank is 20 ℃, the immersion time of the ribbon in the cleaning tank is 10s; the inlet pressure of the water blowing air knife is 0.2MPa, and the outlet wind speed is 20m / s.

[0033] The raw material components and weight content of the flux in the flux tank are, organic acid activator: film forming agent: non-ionic surfactant = 1:0.05:0.02, the inlet pressure of the hot air knife is 0.2MPa, and the outlet wind speed is 20m / s, hot air temperature is 50℃.

[0034] The raw material composition and weight content of the tin liquid in the tin furnace are, lead-containing solder: antioxidant = 1: 0.01, the lead-containing solder is 63Sn37Pb, and the antioxidant is Al.

[0035] The...

Embodiment 2

[0040] The raw material components and weight content of the cleaning liquid in the cleaning tank are: oxide film dissolving agent: corrosion inhibitor: roughening agent = 1:0.035:0.05; the cleaning tank is equipped with an ultrasonic vibrator with a frequency of 30Kz, and the temperature of the cleaning tank is 50 ℃, the immersion time of the ribbon in the cleaning tank is 30s; the inlet pressure of the water blowing air knife is 0.5MPa, and the outlet wind speed is 50m / s.

[0041] The raw material components and weight content of the flux in the flux tank are, organic acid activator: film forming agent: non-ionic surfactant = 1:0.07:0.03, the inlet pressure of the hot air knife is 0.4MPa, and the outlet wind speed is 40m / s, hot air temperature is 100℃.

[0042] The raw material composition and weight content of the tin liquid in the tin furnace are, lead-containing solder: antioxidant = 1:0.03, the lead-containing solder is 60Sn40Pb, and the antioxidant is Mg.

[0043] The ...

Embodiment 3

[0048] The raw material components and weight content of the cleaning liquid in the cleaning tank are: oxide film dissolving agent: corrosion inhibitor: roughening agent = 1: 0.05: 0.08; the cleaning tank is equipped with an ultrasonic vibrator with a frequency of 40Kz, and the temperature of the cleaning tank is 80 ℃, the immersion time of the ribbon in the cleaning tank is 60s; the inlet pressure of the water blowing air knife is 0.8MPa, and the outlet wind speed is 80m / s.

[0049] The raw material components and weight content of the flux in the flux tank are, organic acid activator: film forming agent: non-ionic surfactant = 1: 0.10: 0.05, the inlet pressure of the hot air knife is 0.8MPa, and the outlet wind speed is 80m / s, hot air temperature is 200℃.

[0050] The raw material composition and weight content of the tin liquid in the tin furnace are, lead-containing solder: antioxidant = 1: 0.05, the lead-containing solder is 62Sn36Pb2Ag, and the antioxidant is Ga.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com