Patents

Literature

246results about How to "Reduce supplementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

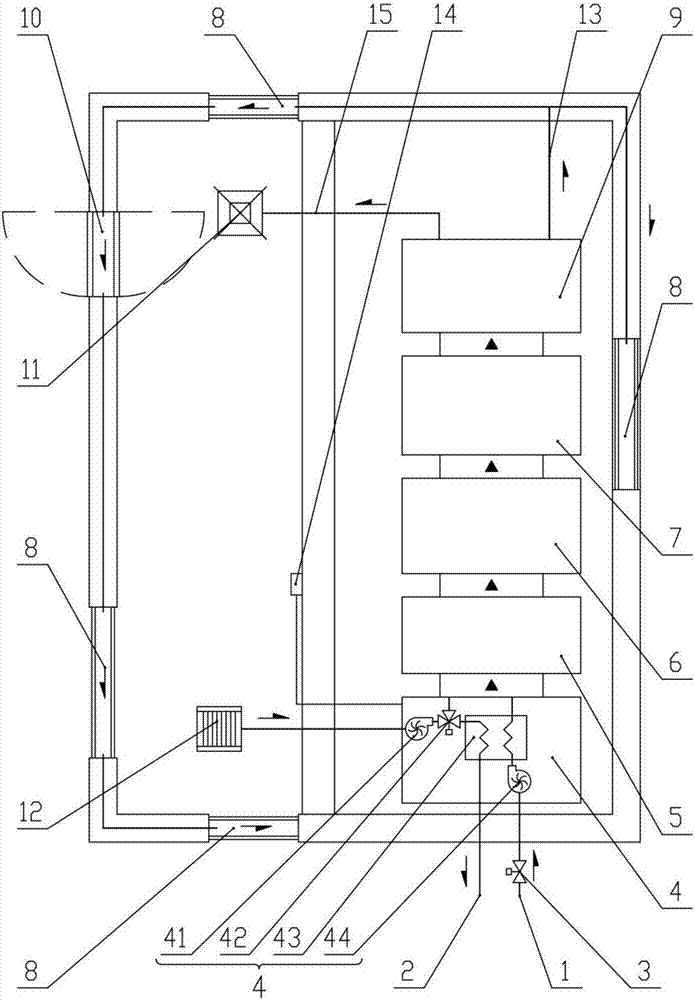

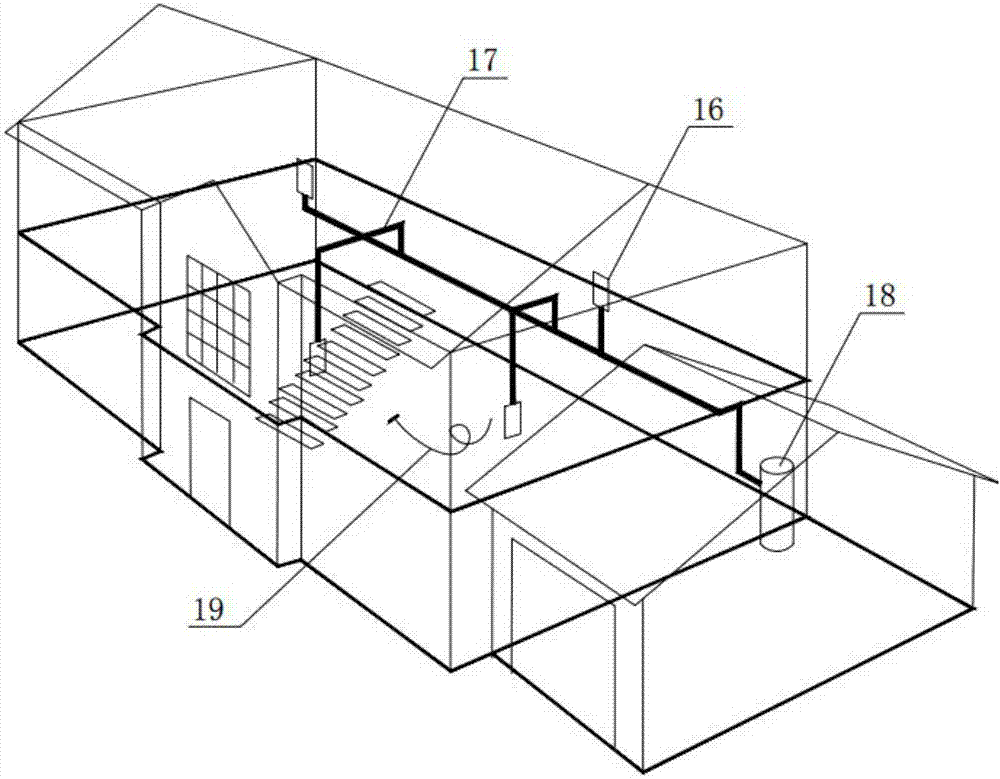

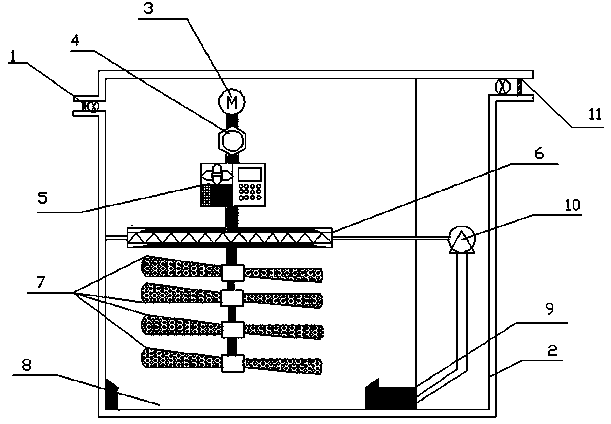

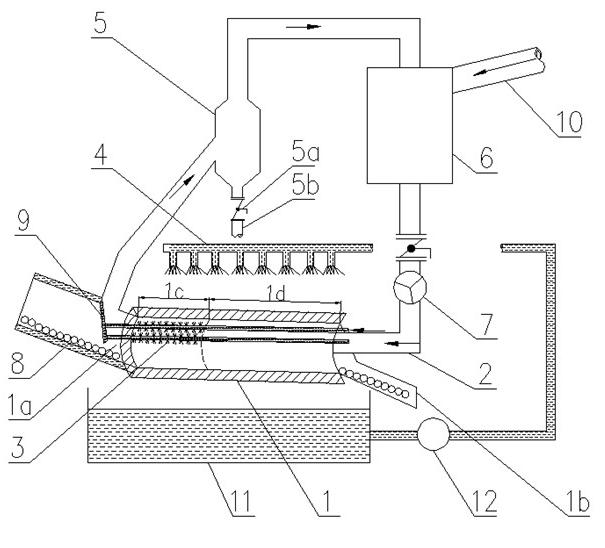

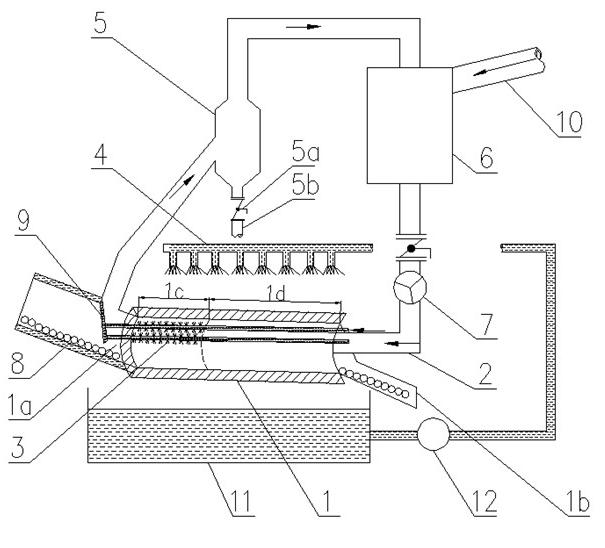

Constant-temperature, constant-humidity and constant-cleanliness silent indoor air system

InactiveCN106895521AAgainst intrusionAvoid damageMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention provides a constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, belongs to the field of indoor intelligent adjustment, and relates to multiple techniques including indoor air pressure control, indoor air purification, an indoor central dedusting system, supercharging and compensation functions for interlayers of double windows and double doors, an outdoor haze isolating system, an indoor air internal-circulation cleaning method, air heat exchange, air heating, refrigeration, dehumidification and the like. According to the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, the pressure of fresh air is made positive through the interlayers of the double doors and the double windows, the air pressure in the interlayers of the double doors and the double windows is made higher than outdoor air pressure, and outdoor air is prevented from invading indoor air; a small primary-efficiency, medium-efficiency and high-efficiency filtering system is used for filtration, various types of automatic adjustment and control including heating, refrigerating, dehumidifying and the like are conducted on air, pollutant dust generated indoors is removed through the central dedusting system, and the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system is an omnidirectional intelligent air control system.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

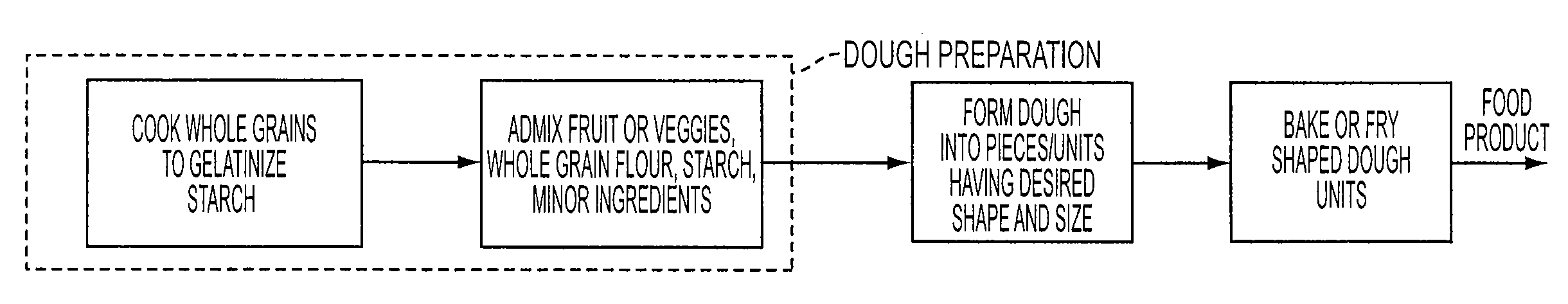

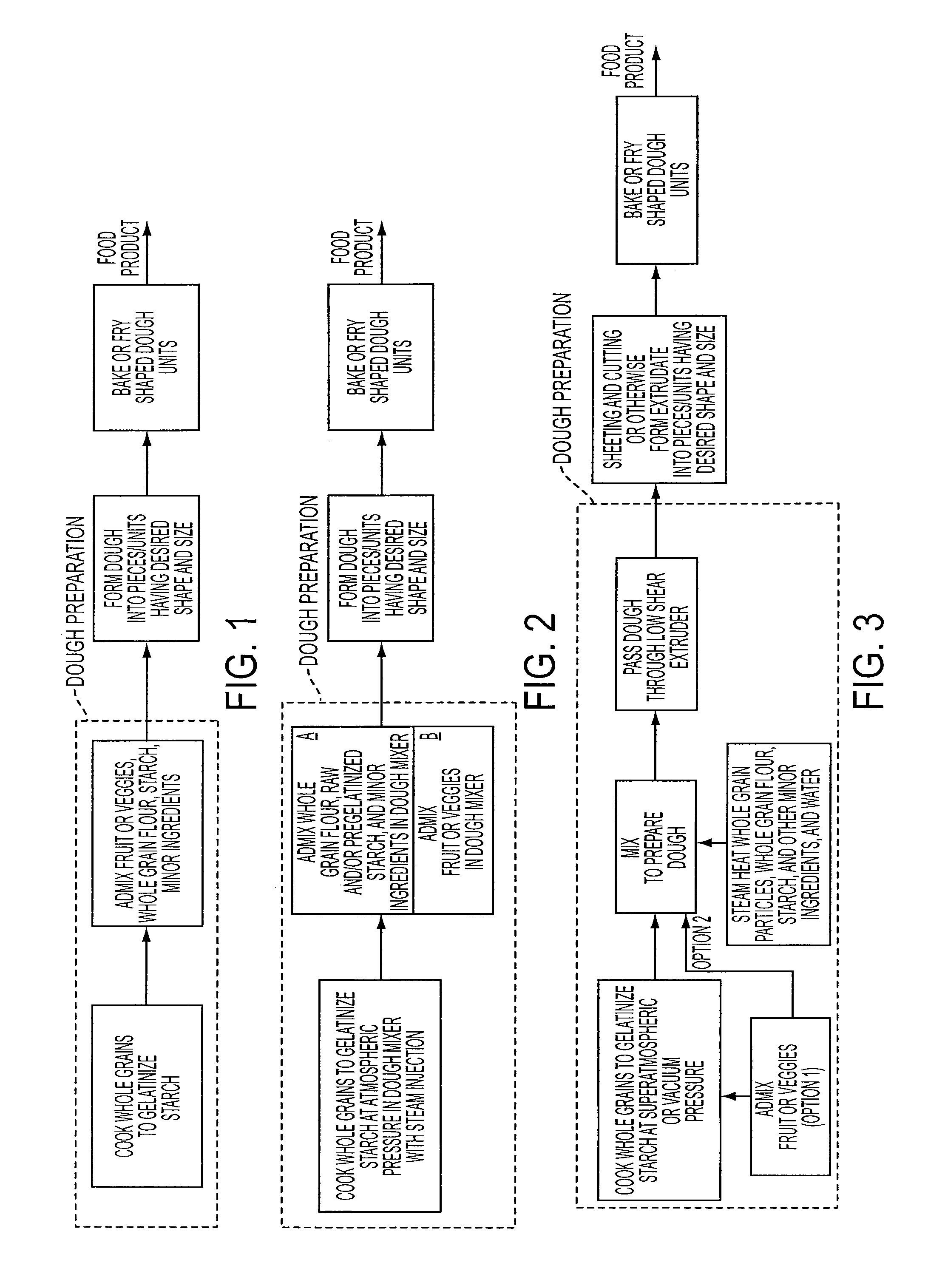

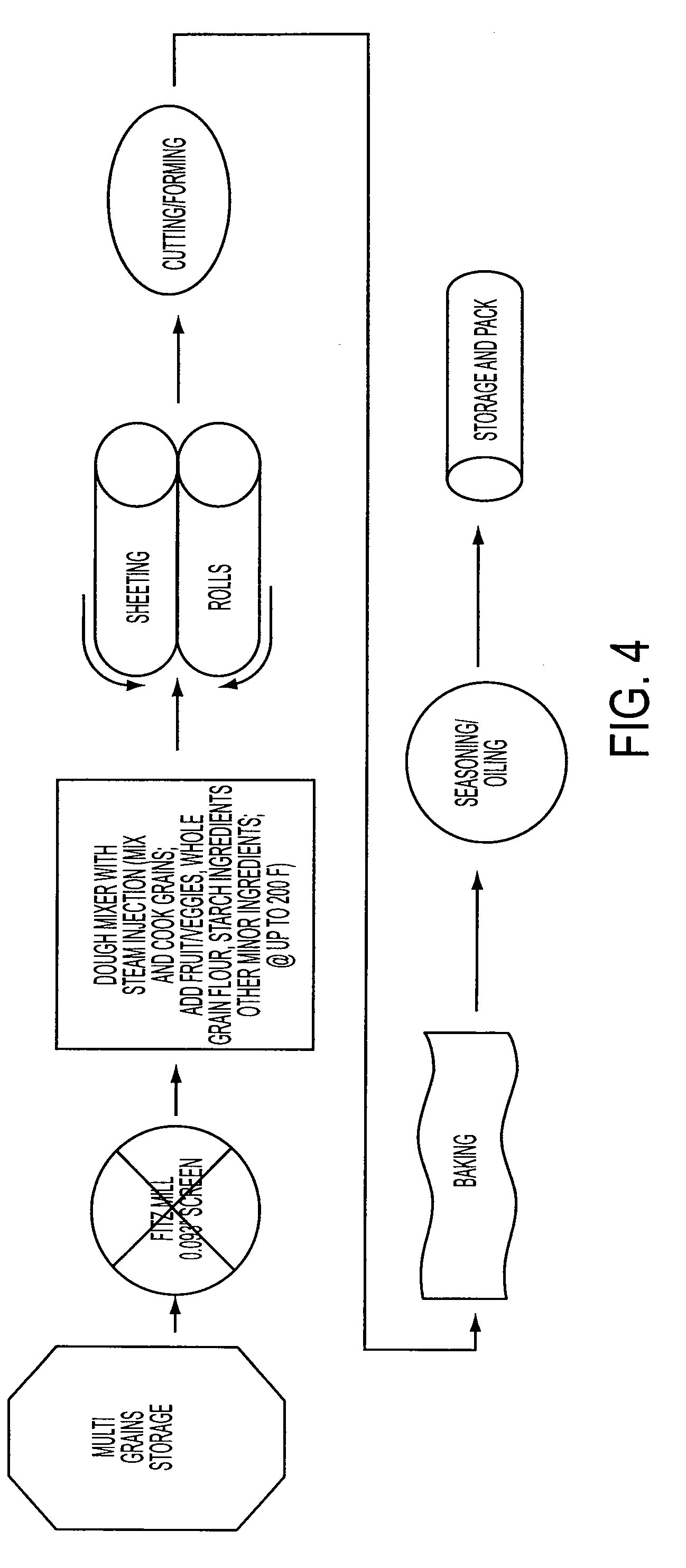

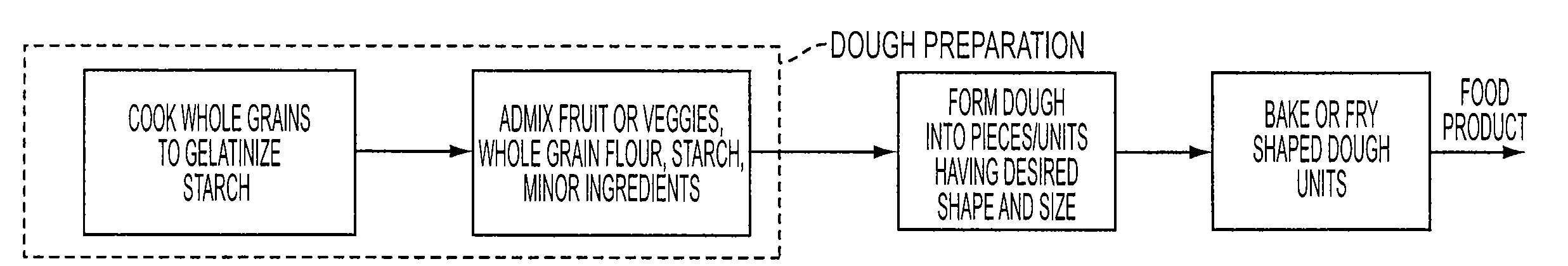

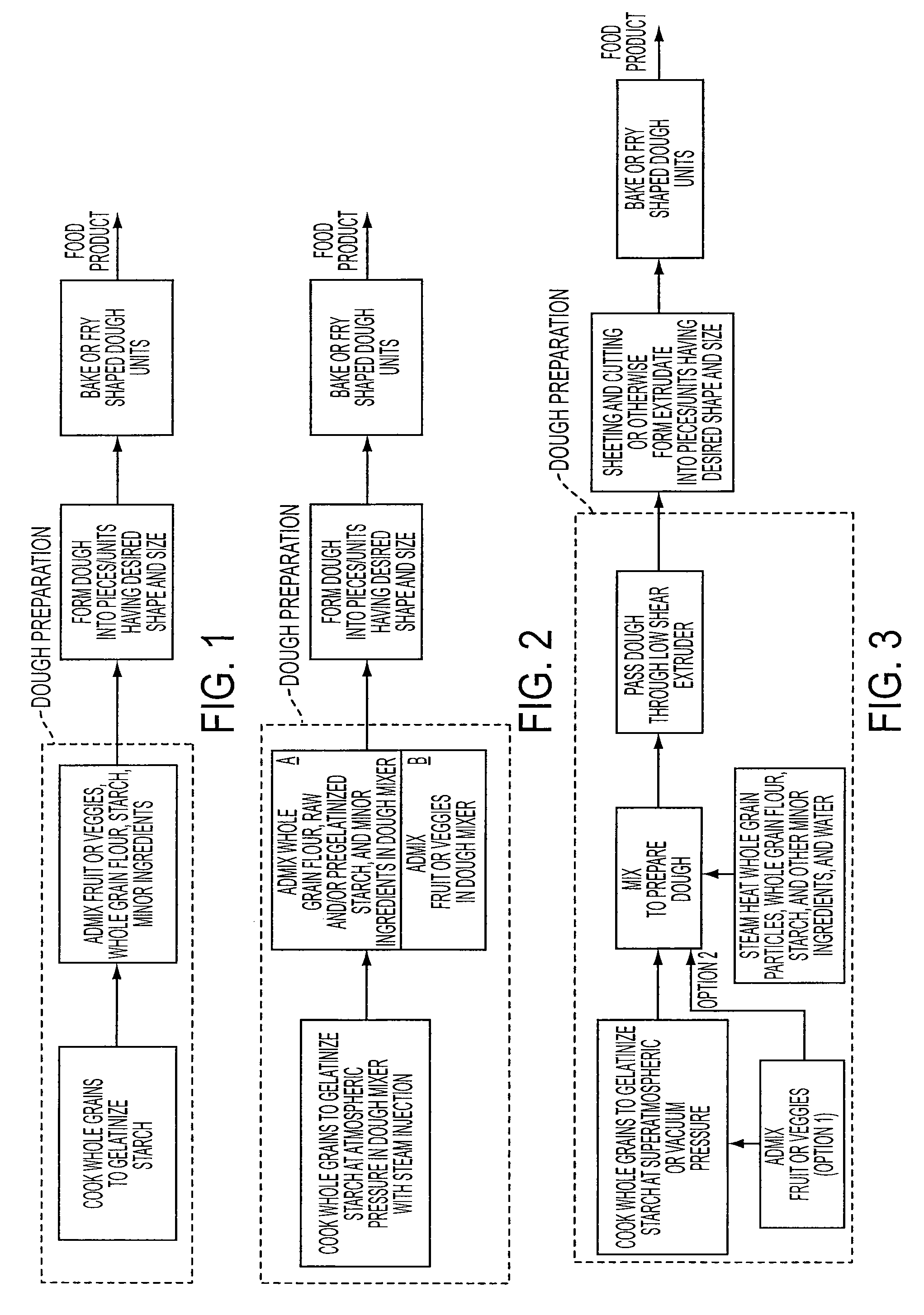

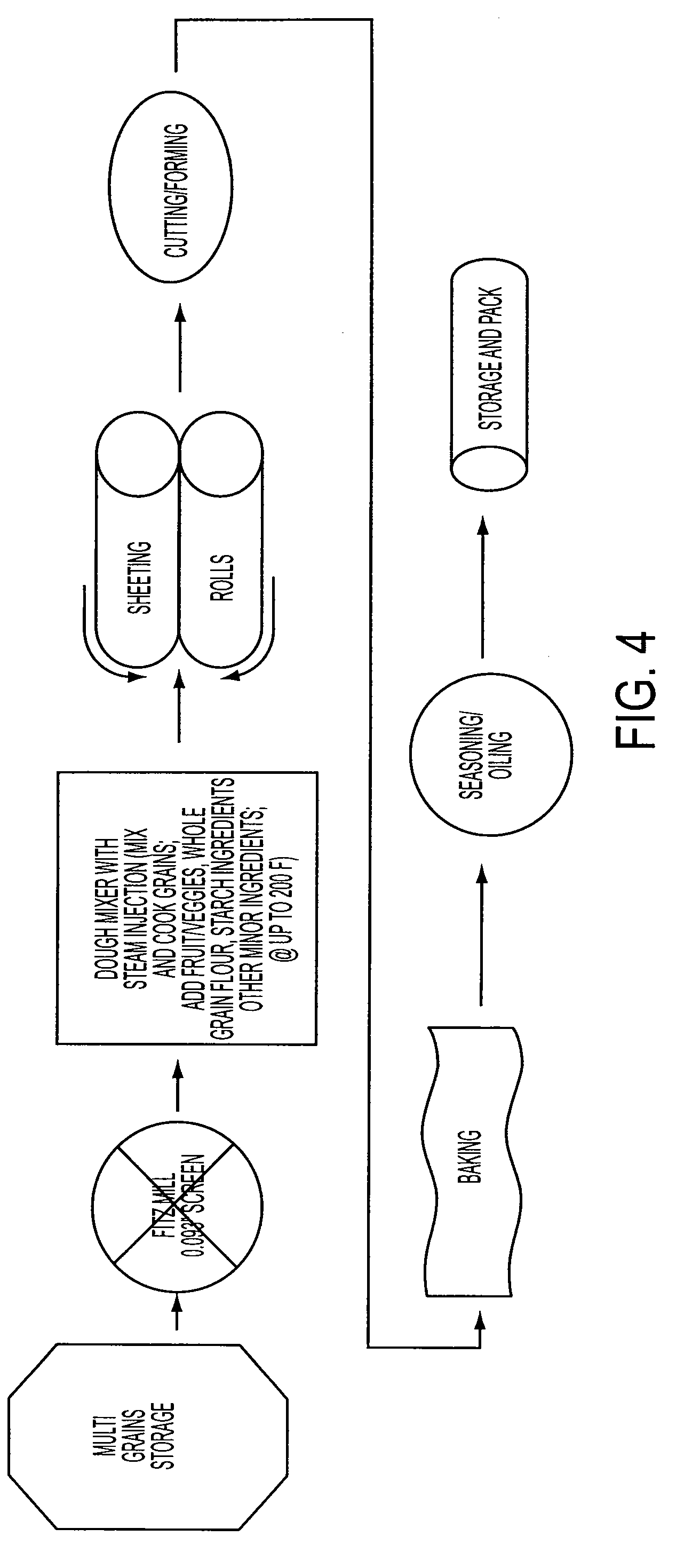

Production of whole grain-containing composite food products

ActiveUS20080003340A1Acceptable machinabilityFood safetyBaking mixturesConfectioneryDietary fiberAdditive ingredient

Shelf-stable whole grain-containing composite food products, such as savory and sweet snacks and cereals, are continuously produced by preparing a dough comprising cooking whole grain cereal grain particles in the presence of water effective to gelatinize starch content of the whole grain cereal particles to provide gelatinized whole grain cereal grain particles, and mixing the gelatinized whole grain cereal grain particles with starch, whole grain flour, optional minor dough ingredients such as leavening agent, and a food component selected from the group consisting of vegetables and fruits, effective to prepare dough. The dough is formed into discrete dough units, which are baked or fried to provide a whole-grain containing composite food product that is nutritious, low fat, multi-flavored, and a good source of dietary fiber.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

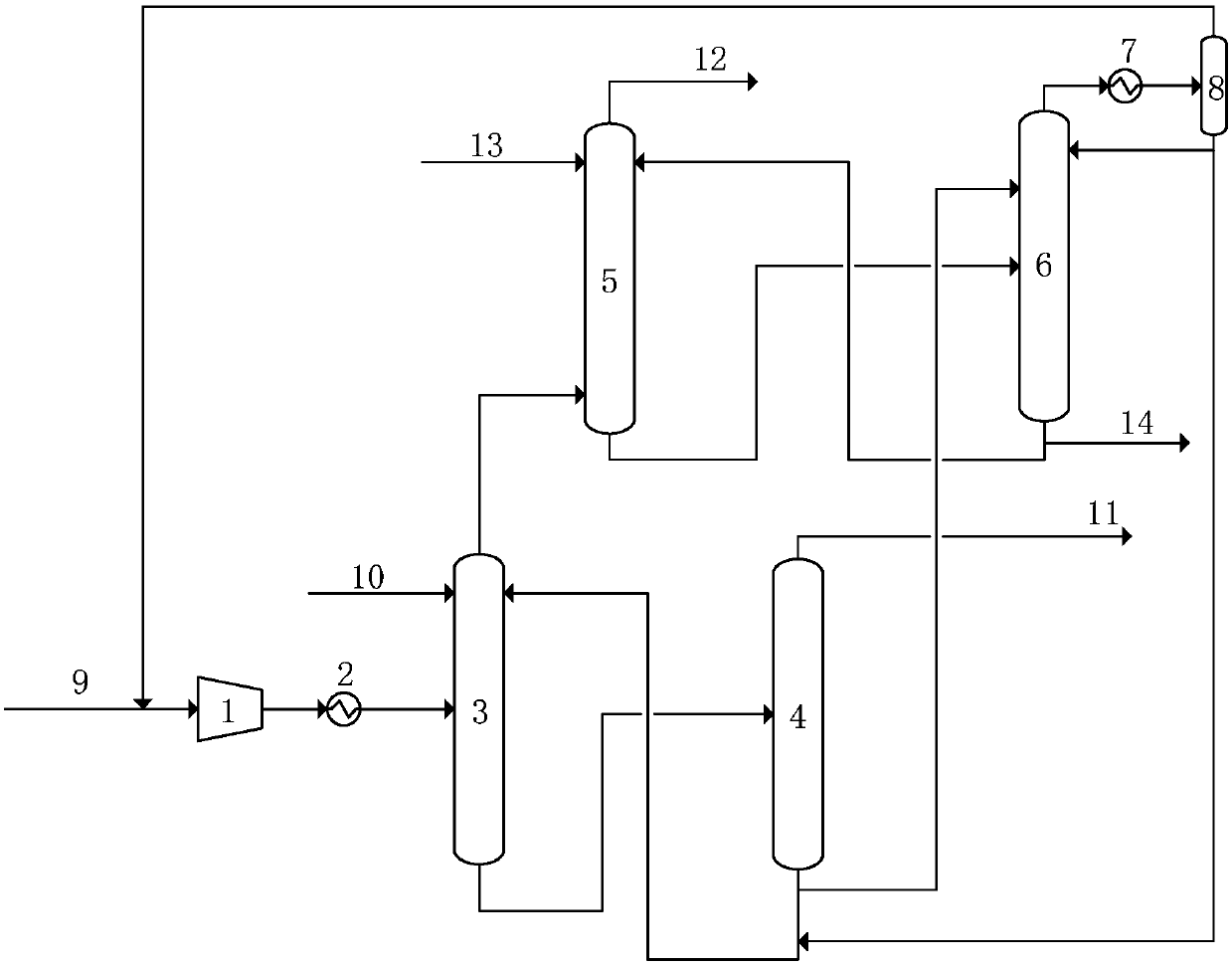

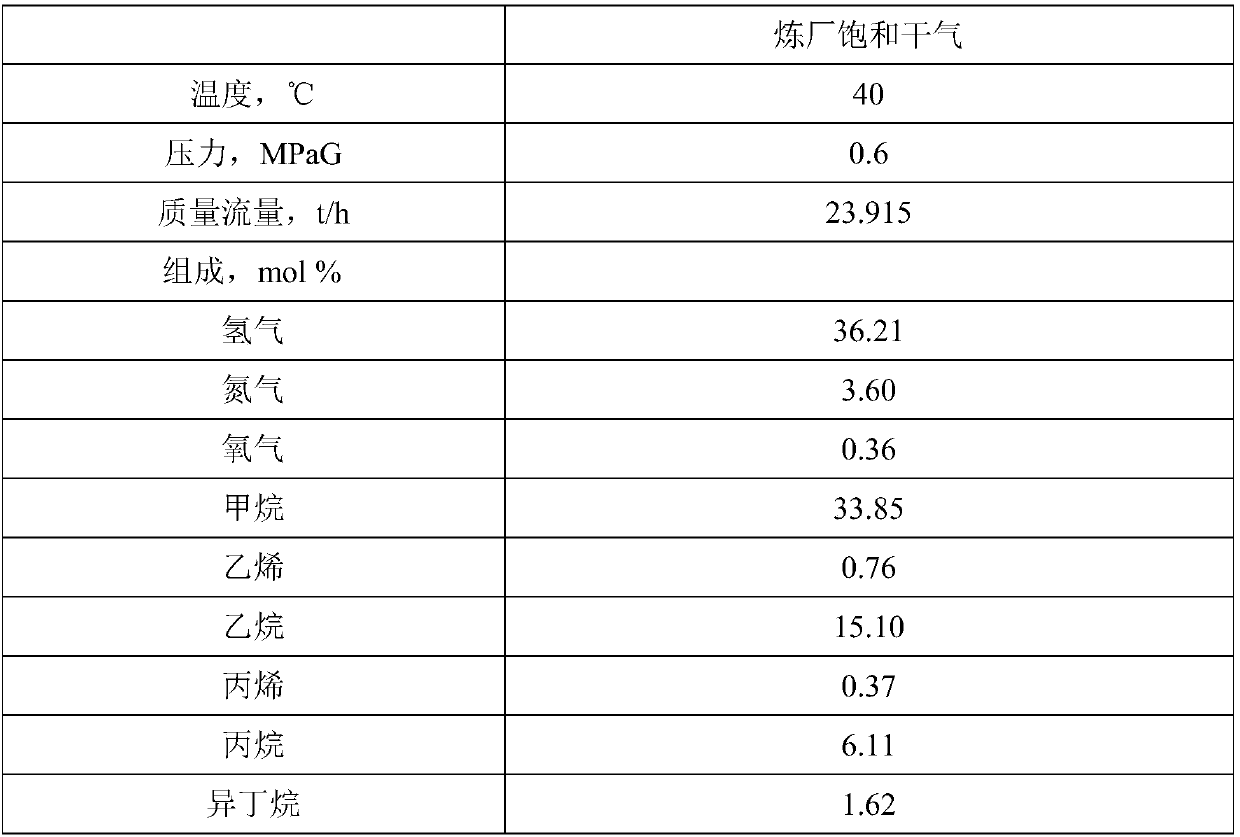

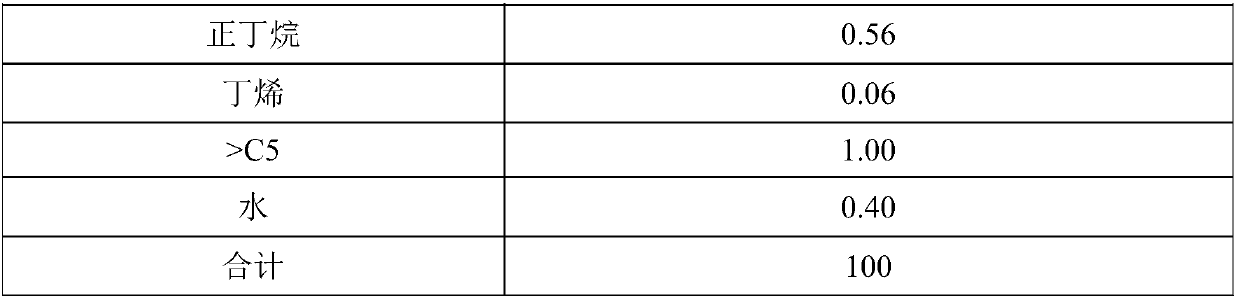

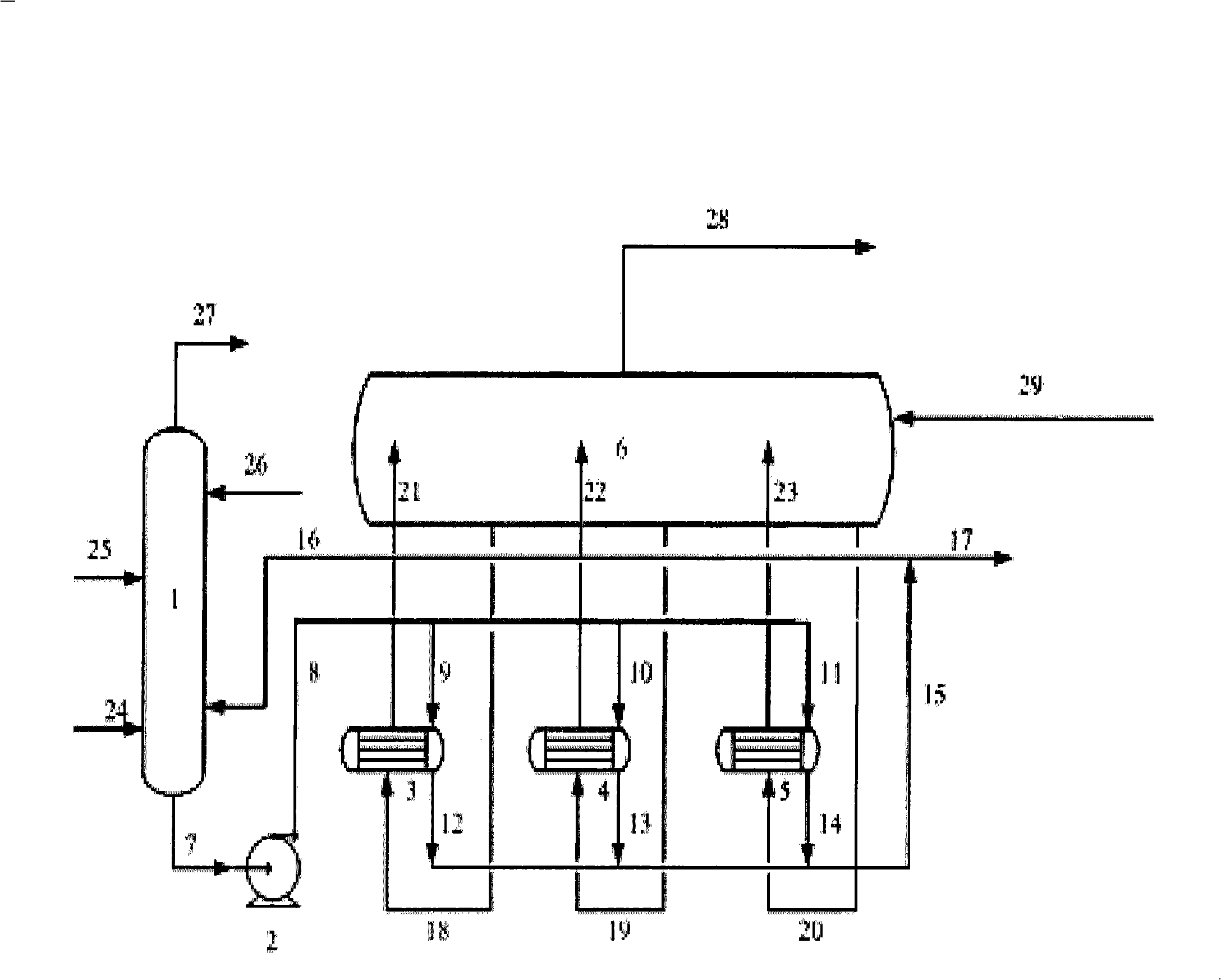

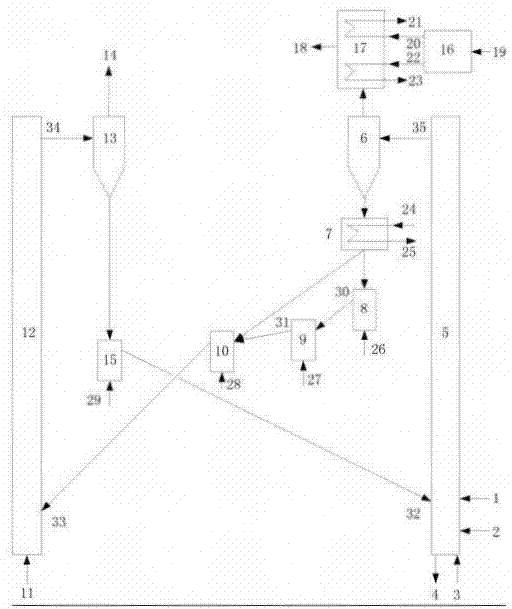

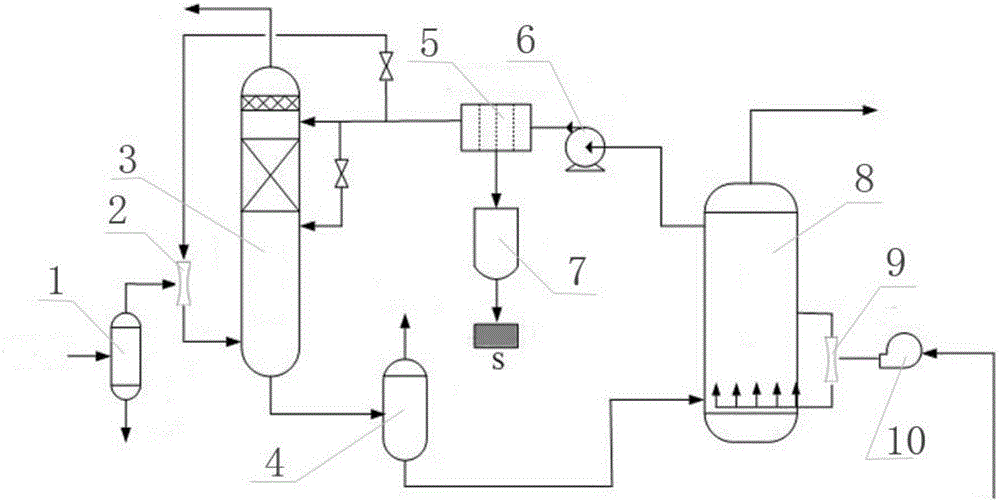

Method and device for recycling saturated dry gas of refinery plant by adopting shallow cold oil absorption technology

InactiveCN109553504AHigh recovery rateReduce energy consumptionHydrocarbonsAbsorption purification/separationDesorptionGas phase

The invention relates to the field of dry gas treatment, the invention discloses a method and a device for recycling a saturated dry gas of a refinery plant by adopting a shallow cold oil absorption technology, the method comprises the following steps: sequentially compressing the saturated dry gas, cooling the saturated dry gas, and feeding the saturated dry gas into a C4 absorption tower for treatment, and respectively sending an obtained gas phase and an obtained liquid phase into a gasoline absorption tower and a C4 desorption tower; recovering a gas phase obtained by treating in the C4 desorption tower to serve as a C2 concentrated gas product, allowing most of an obtained liquid phase to be returned to the C4 absorption tower for recycling, and sending a small part of the obtained liquid phase to a gasoline stabilization tower; and sending the liquid phase treated by the gasoline absorption tower to the gasoline stabilization tower for treatment, allowing most of the obtained liquid phase to be returned to the gasoline absorption tower for recycling and the small part of the obtained liquid phase to serve as an extraction gasoline product, performing condensation and gas-liquid separation treatment in turn on the gas phase obtained by processing in the gasoline stabilization tower, respectively returning the obtained gas phase and the obtained liquid phase to the inlet ofa compressor, and respectively sending the obtained gas phase and the obtained liquid phase to the gasoline stabilization tower and the C4 absorption tower for treatment. The method disclosed by theinvention has the advantages that the material consumption is low, the process is simple, the investment is small, and the recovery rate of the C2 and C3 is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soilless culture organic matrix used for tomato seedling raising and preparation method thereof

InactiveCN101697705AReduce overexploitationAchieve sustainable useAgriculture gas emission reductionCultivating equipmentsRenewable resourceNon-renewable resource

The invention discloses a soilless culture organic matrix and preparation method thereof; wherein the soilless culture organic matrix is formed by evenly mixing corn cob fragments, corn stalk fragments and mushroom residue after respective piling fermentation according to volume ratio of (1.5-2.5): (4-6): (1.5-4.5). The main raw materials of the soilless culture organic matrix provided by the invention adopts waste corn stalk, corn cob and mushroom residue in local agricultural production instead of matrix raw material grass carbon commonly used in the current seedling raising, thus not only greatly saving seedling raising cost but also reducing over-exploitation of non-renewable resources grass carbon, thereby maintaining ecological sustainable development; not only environmental pollution caused by burning is avoided, but also sustainable utilization of resources is realized.

Owner:NORTHWEST A & F UNIV

Artificial culture method and culture medium for fruiting bodies of cordyceps militaris

The invention discloses an artificial culture method and a culture medium for fruiting bodies of cordyceps militaris. Based on the culture medium in a 500mL culture bottle, the culture medium comprises the following components: 20 to 25g of cottonseed hull and 120 to 140mL of nutrient solution, wherein the nutrient solution comprises the following components in part by weight: 2.0 to 3.0 parts of wheat flour, 1.0 to 1.5 parts of soya flour, 3.0 to 4.0 parts of white sugar, 0.1 to 0.2 part of magnesium sulfate, 0.1 to 0.2 part of potassium dihydrogen phosphate, 0.05 to 0.1 part of zinc sulfate, 0.05 to 0.1 part of sodium chloride and 95 to 105 parts of water, and the pH value of the nutrient solution is 6 to 8. The artificial culture method comprises the following steps of: preparation of the culture medium, sub-packaging, sterilization, cooling, inoculation, culture and harvesting of fruiting bodies. The invention has the advantages of simple operation, high efficiency, energy conservation, short culture period, high yield of fruiting bodies, and no pollution or solid wastes.

Owner:LUDONG UNIVERSITY

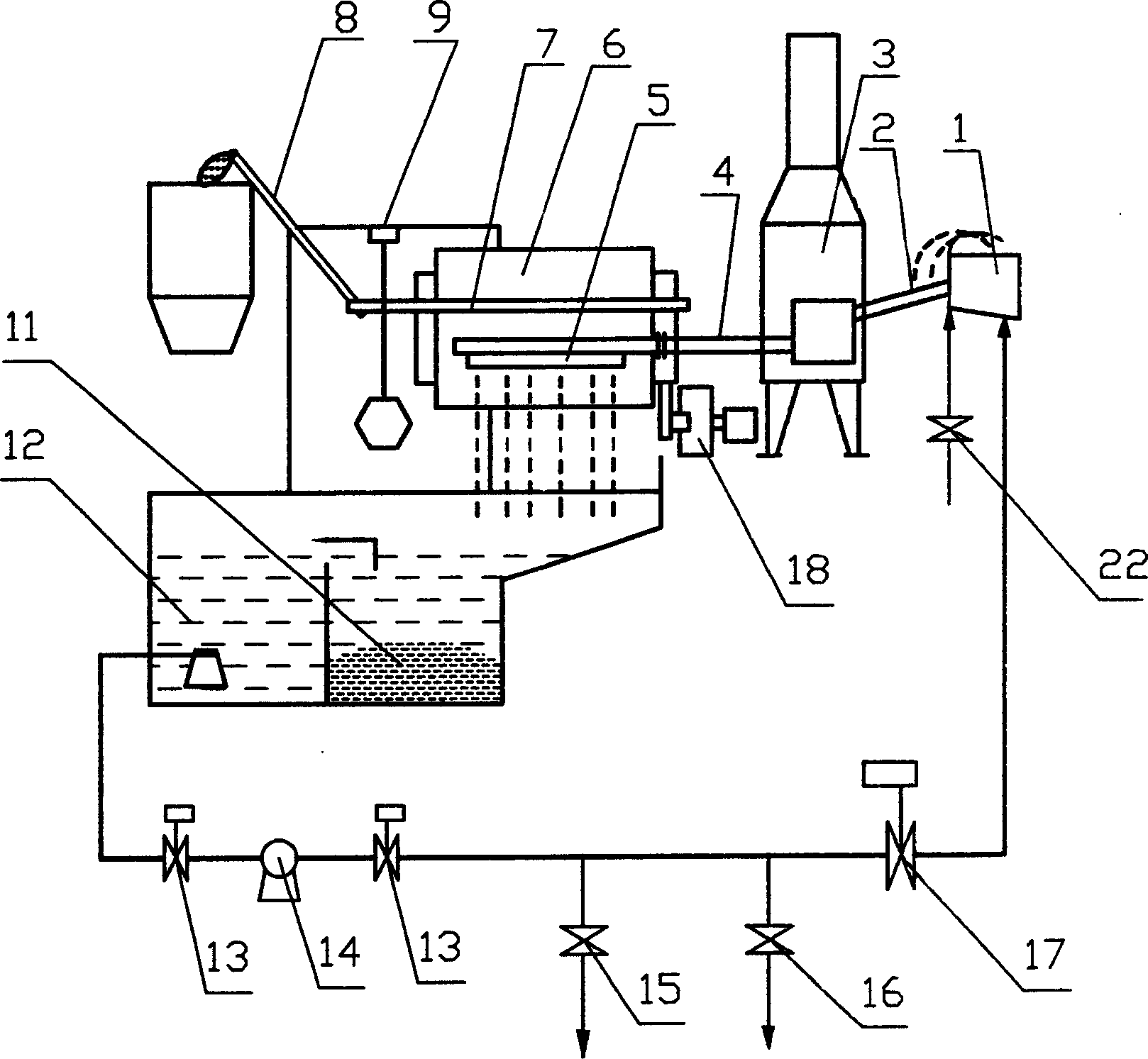

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

Device and technology for wet desulfurization and denitrification of flue gas of coal-fired boiler and treatment of wastewater

ActiveCN105833695AReduce the temperatureIncrease humidityGas treatmentDispersed particle separationFlue gasSupergravity

The invention discloses a device and technology for wet desulfurization and denitrification of flue gas of a coal-fired boiler and treatment of wastewater .The technological process includes the steps that the flue gas enters a wastewater evaporative cooling stage through a draught fan outlet to be cooled and then enters an ozonation stage, the flue gas is fully mixed with ozone to be oxidized and then enters a supergravity device through a supergravity desulfurization and denitrification device inlet, the flue gas is subjected to forcible absorption with desulfurization and denitrification absorption liquid in a packed bed on a rotor, and finally the flue gas is demisted by a demister and then discharged through a flue gas outlet of the supergravity device .Replacement absorbent slurry is subjected to oxidation and denitrification treatment in sequence and then returned to the evaporative cooling stage to perform spraying cooling on the flue gas .By means of the device and the technology, desulfurization and denitrification efficiency is improved, and meanwhile water consumption is low; wastewater generated in desulfurization and denitrification is subjected to innocent treatment, sulfate is collected, and thus the coal-fired flue gas can meet stricter discharge standards.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH +1

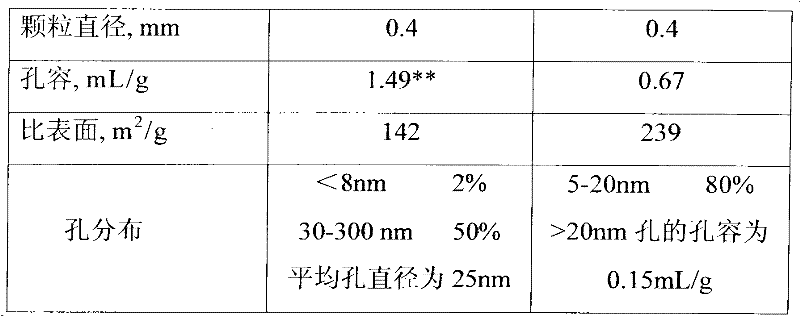

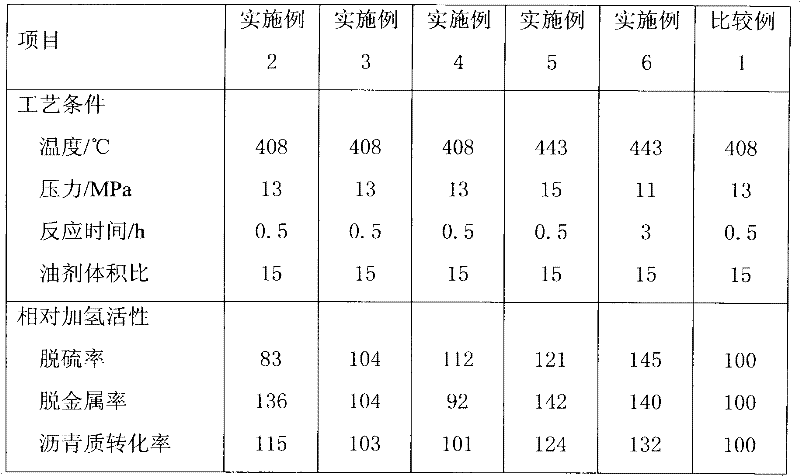

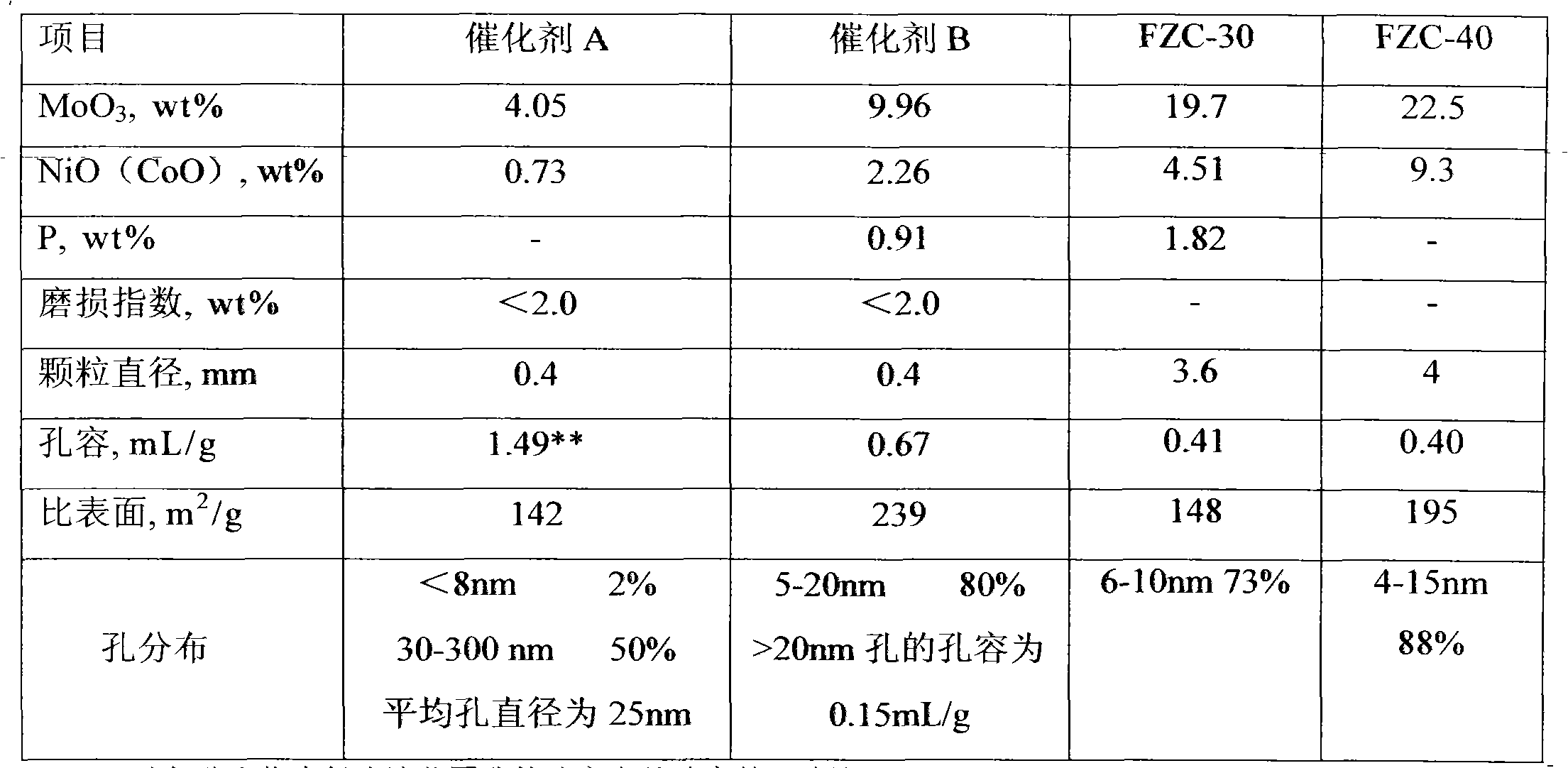

Heavy raw material boiling bed hydrogenation treatment method

ActiveCN102443414ALarge apertureStrong metal capacityHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenSlag

The invention relates to a heavy raw material boiling bed hydrogenation treatment method. A boiling bed hydrogenation treatment reactor is used, the heavy oil raw material oil and hydrogen gas enter a reactor from the bottom, the reaction is carried out under the heavy raw material oil hydrogenation treatment condition, materials after the reaction are discharged out from the reactor from the top, a mixed catalyst of at least two catalysts is used in the boiling bed hydrogenation treatment reactor, and the mixed volume is 1:(0.1-10). One catalyst has the properties that the specific surface is 80 to 200 mm<2> / g, the several-hole diameter can be 15 to 30nm, and holes with the hole diameter being 30 to 300nm account for 35 percent to 60 percent of the total hole volume. The other catalyst has the properties that the specific surface is 180 to 300 mm<2> / g, and holes with the hole diameters being 5 to 20nm at least account for 70 percent of the total hole volume. The method has the advantages that the operation performance of the boiling bed slag oil hydrogenation treatment process can be effectively improved, and the hydrogenation activity level and the operation flexibility are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

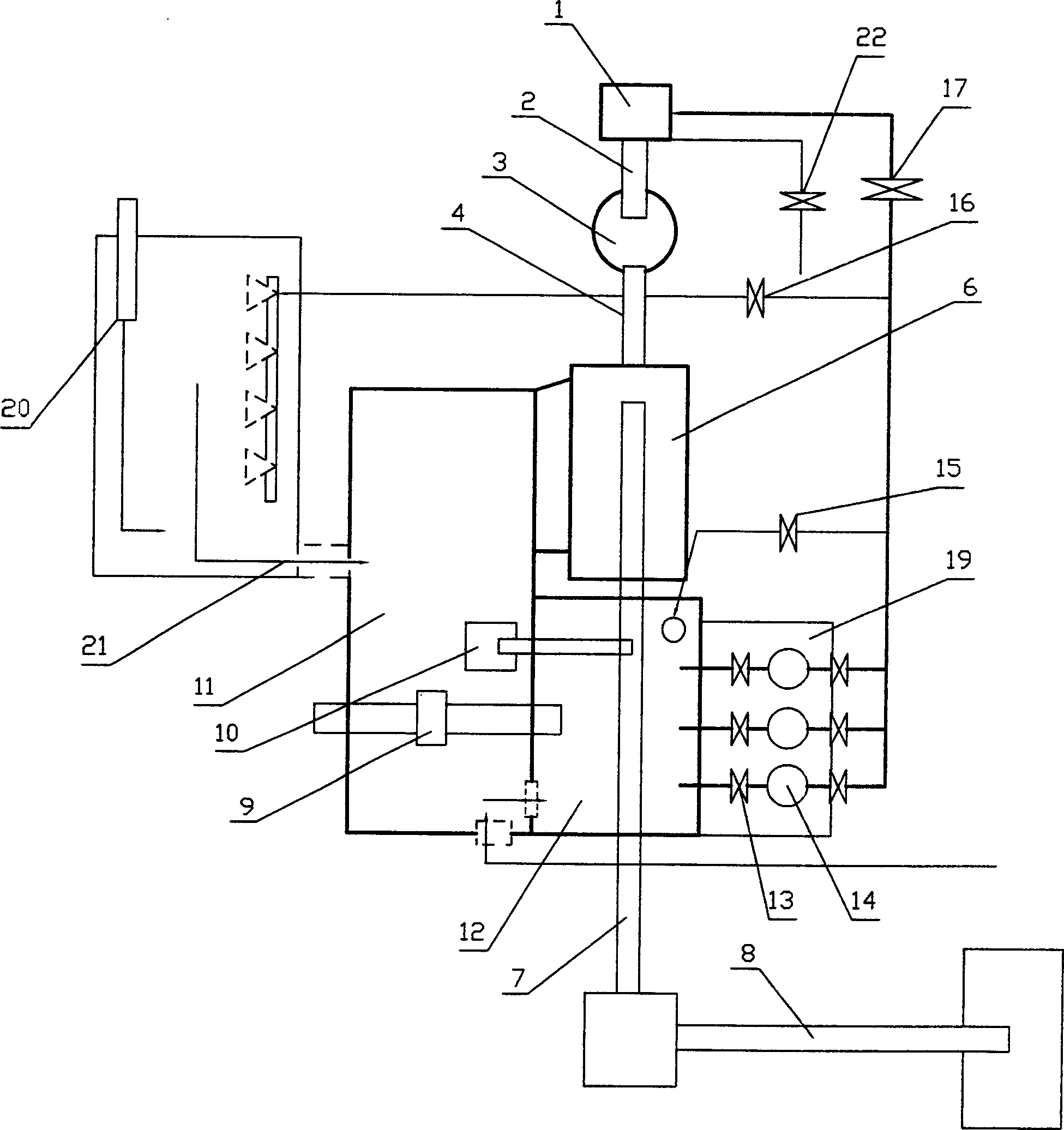

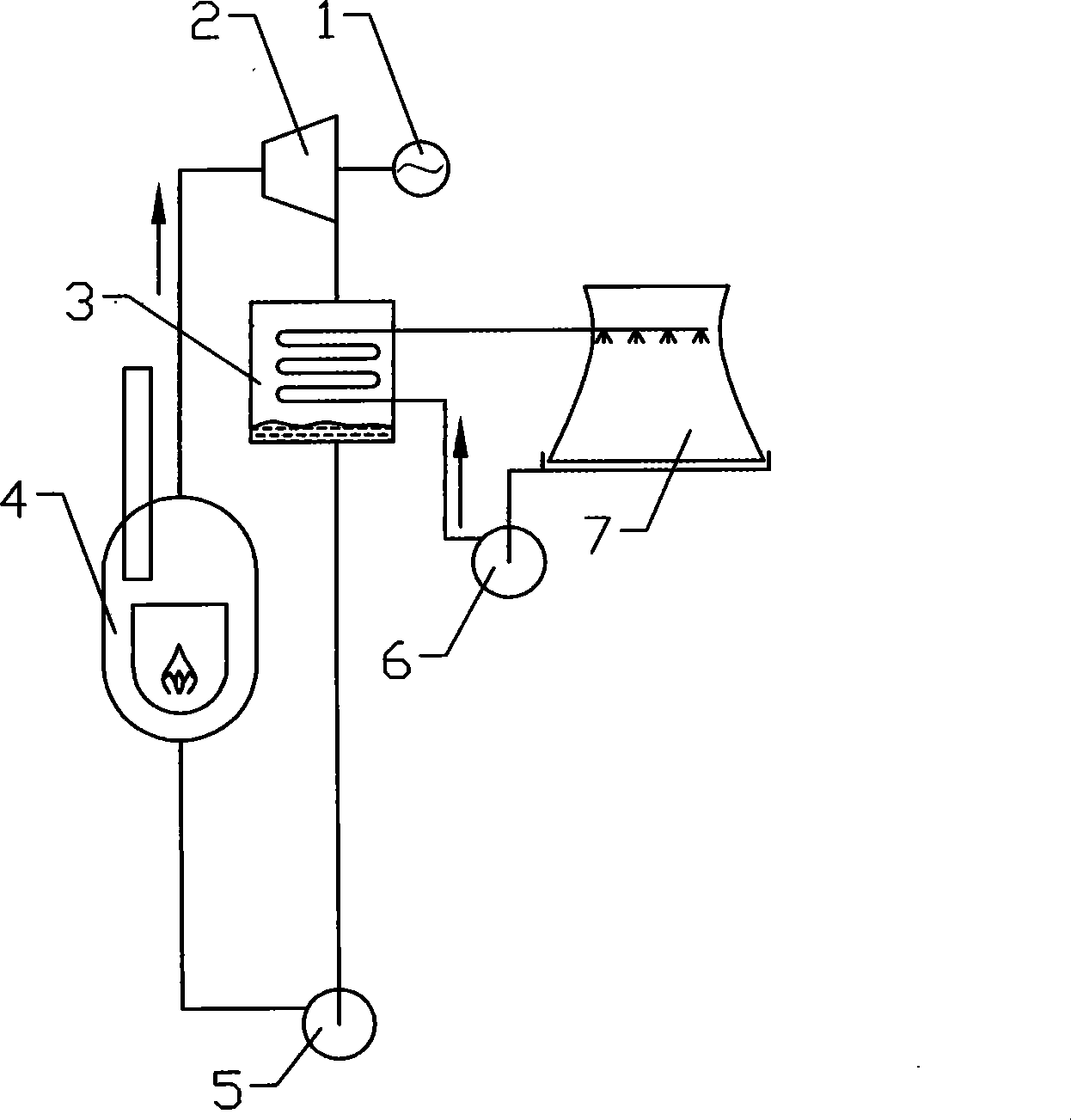

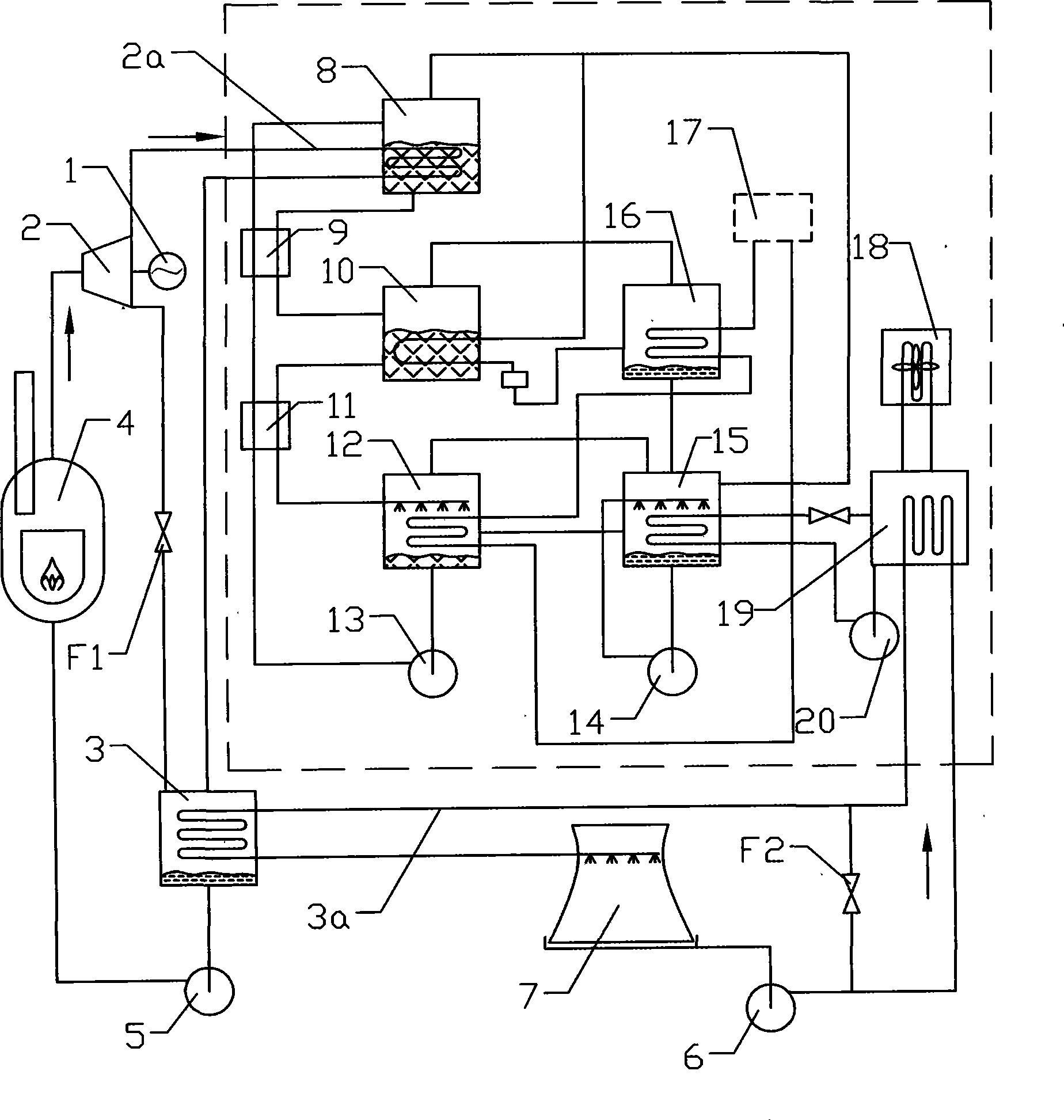

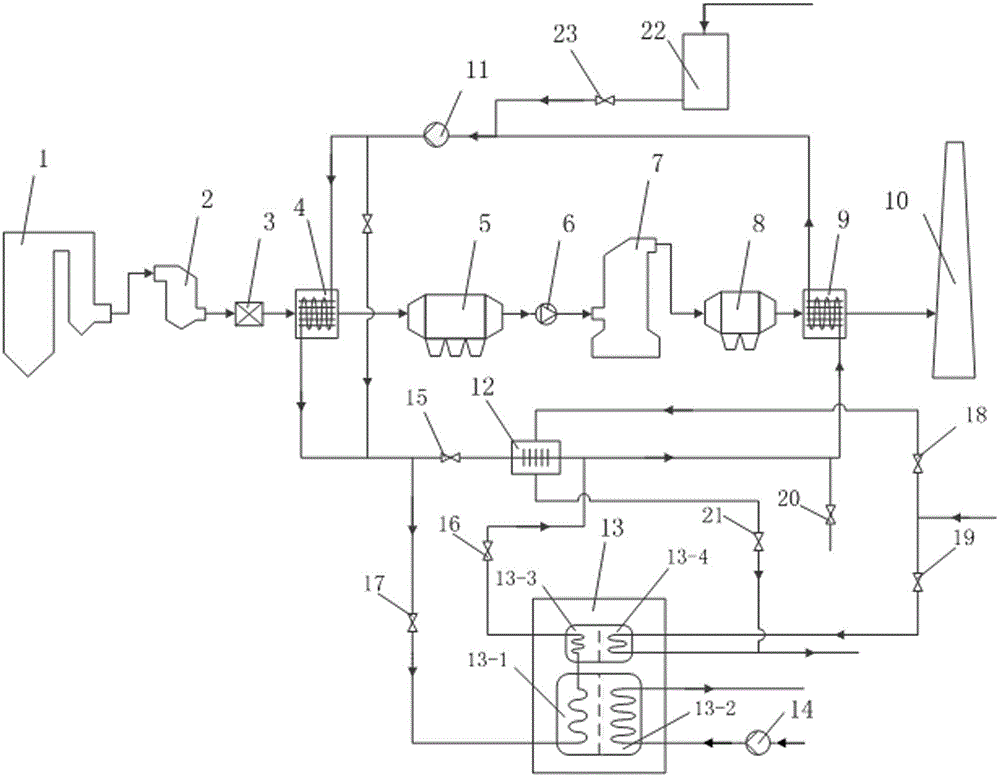

Electric power plant cooling system for enhancing cooling efficiency by utilizing residual heat refrigeration manner

InactiveCN101509716AFlexible adjustmentRealize waste heat utilizationClimate change adaptationSteam useLithium bromideCentral air conditioning

The invention relates to a power plant cooling system which improves the cooling efficiency by a residual heat refrigeration way, in particular to a cooling system which is used for the power plant, carries out the refrigeration by the residual heat of a steam turbine and utilizes the prepared cold water to cool the circular cooling water of the steam turbine further. The cooling system comprises a steam condensed water circulation consisting of a steam turbine, a steam condenser, a condensed water circulation pump and a combustion boiler, and a steam cooled water circulation consisting of a steam condenser, a cooling tower and a cooled water circulation pump. The cooling system is characterized in that a lithium bromide refrigeration unit is added; a high pressure generator of the lithium bromide refrigeration unit is arranged between the steam turbine and the steam condenser so as to lead the steam to become the heat source of the unit; the unit also comprises a refrigerant water tank which can store the cold energy; furthermore, the refrigerant water tank is connected with all air conditioners of the central air conditioning by pipelines; and the refrigerant water tank is arranged between the steam condenser and the cooling water circulation pump so that the refrigerant water is used for supplying the coldness to the central air conditioning or further cooling the circular cooling water of the steam turbine. The cooling system solves the problem that the residual heat of the power plant is cooled and wasted and has the advantages of high cooling efficiency, saving energy, being capable of supplying the cold source for the central air conditioning and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Production of whole grain-containing composite food products

ActiveUS7829128B2Lower requirementReduce fatBaking mixturesConfectioneryDietary fiberAdditive ingredient

Shelf-stable whole grain-containing composite food products, such as savory and sweet snacks and cereals, are continuously produced by preparing a dough comprising cooking whole grain cereal grain particles in the presence of water effective to gelatinize starch content of the whole grain cereal particles to provide gelatinized whole grain cereal grain particles, and mixing the gelatinized whole grain cereal grain particles with starch, whole grain flour, optional minor dough ingredients such as leavening agent, and a food component selected from the group consisting of vegetables and fruits, effective to prepare dough. The dough is formed into discrete dough units, which are baked or fried to provide a whole-grain containing composite food product that is nutritious, low fat, multi-flavored, and a good source of dietary fiber.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

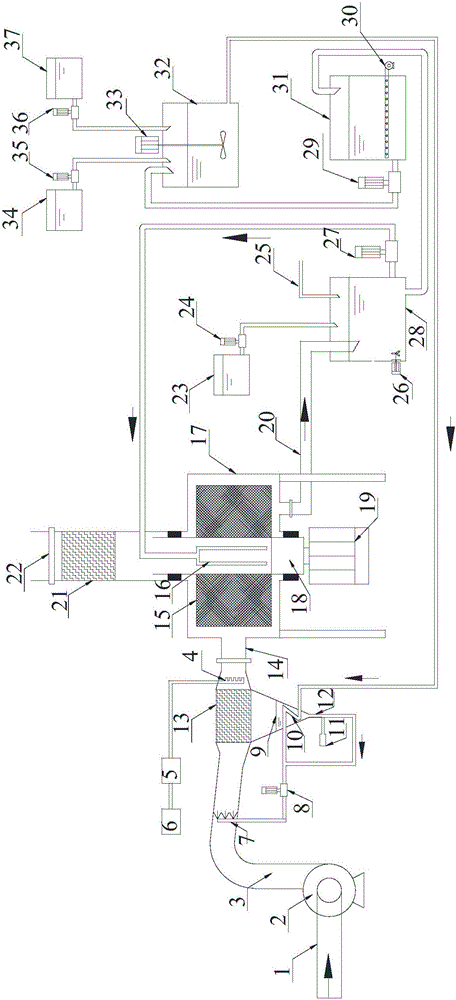

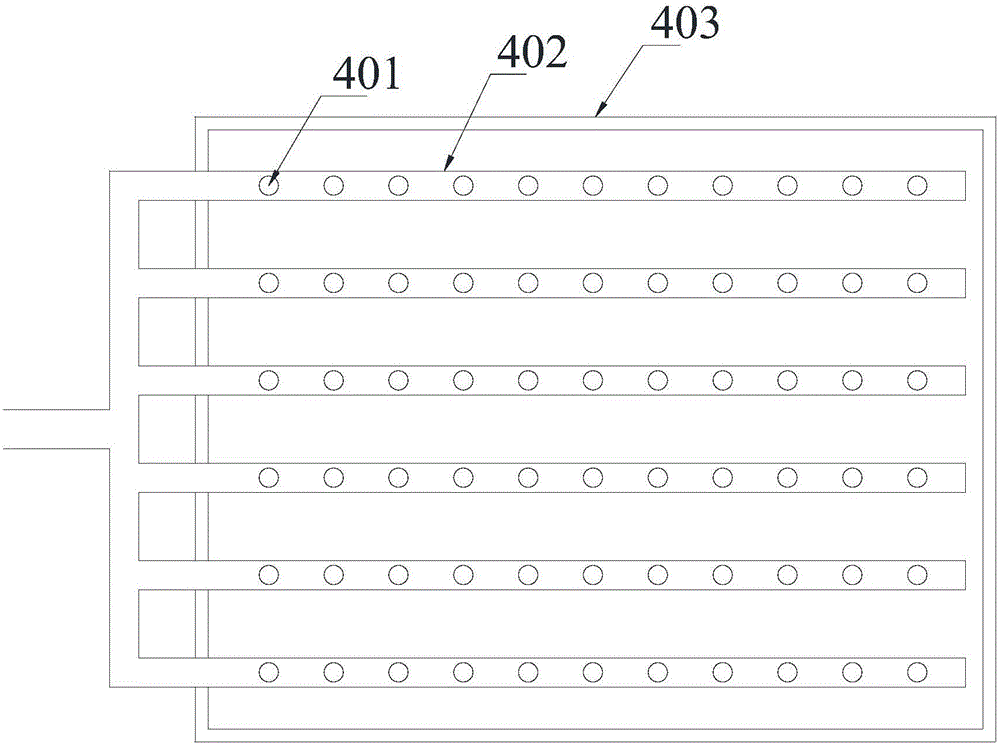

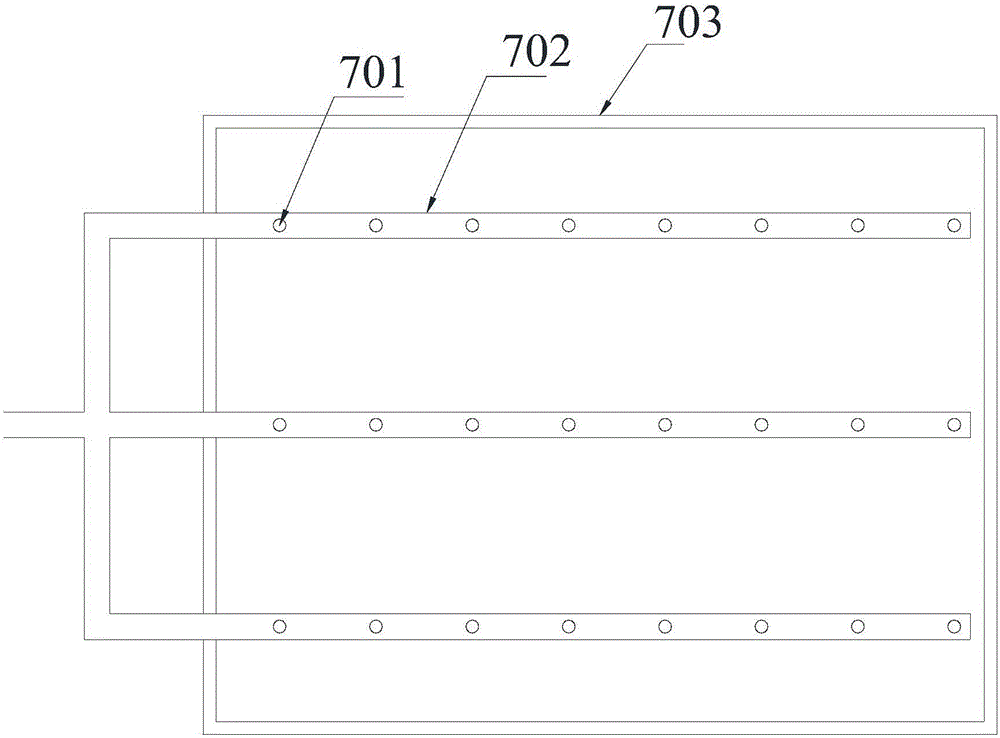

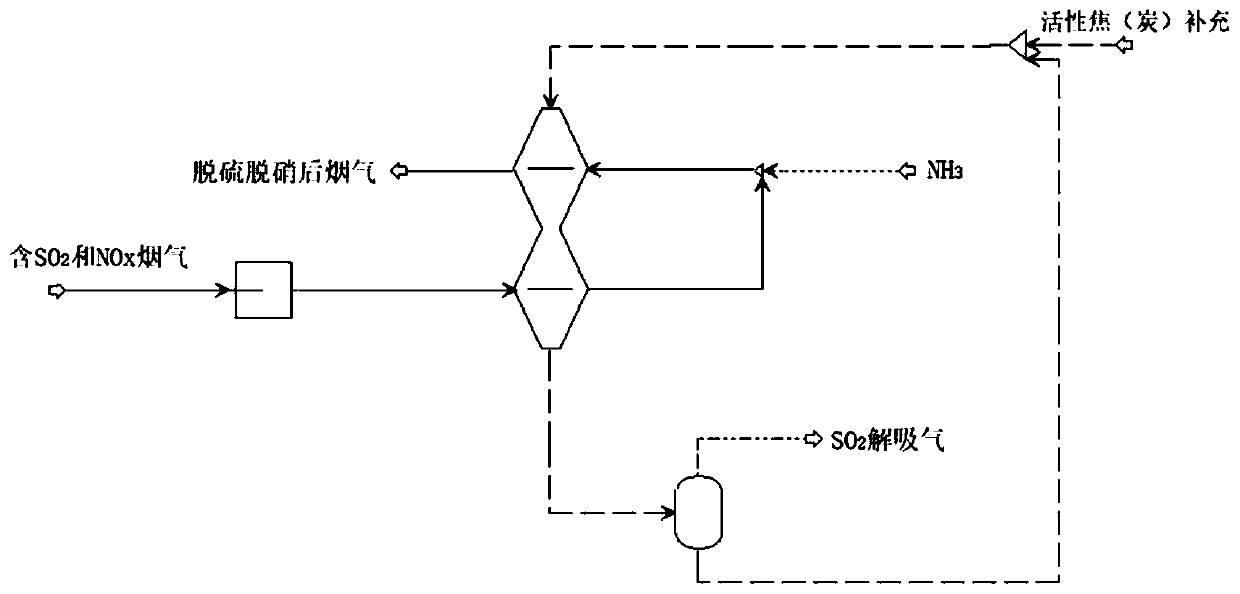

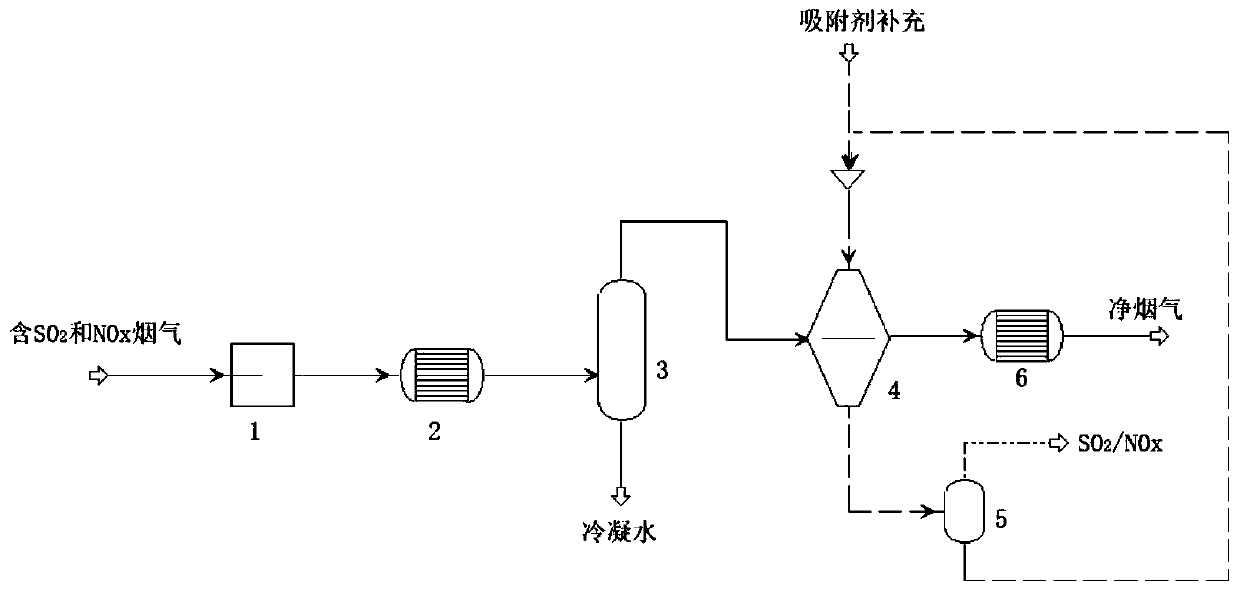

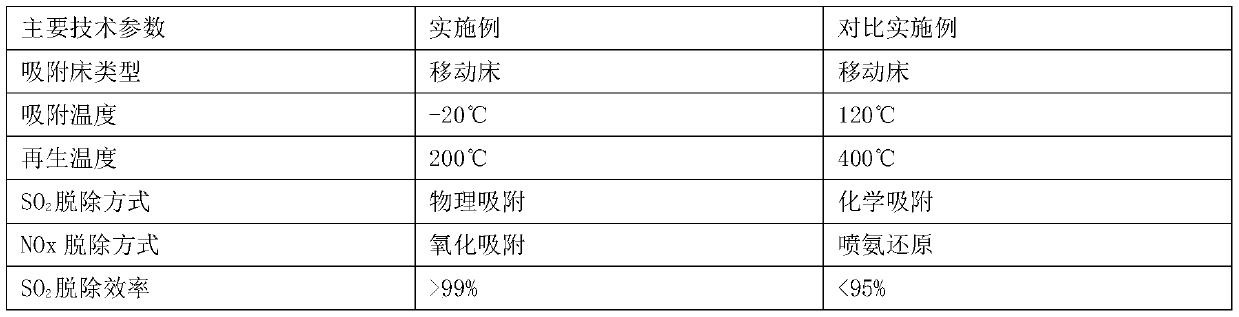

Low-temperature moving bed integrated adsorption desulfurization and denitrification system

PendingCN111495112AReduce lossReduce supplementationGas treatmentDispersed particle separationSorbentFlue gas

The invention discloses a low-temperature moving bed integrated adsorption desulfurization and denitrification system. A flue gas input pipeline containing SO2 and NOx is communicated with an inlet ofa flue gas waste heat recoverer through a flue gas induced draft fan; the outlet of the flue gas waste heat recoverer is communicated with the inlet of the flue gas cooling system; the outlet of theflue gas cooling system is communicated with the flue gas inlet of the low-temperature moving bed adsorption tower; a porous adsorbent outlet in the bottom of the low-temperature moving bed adsorptiontower is communicated with the inlet of the desorption tower, a porous adsorbent outlet of the desorption tower is communicated with a porous adsorbent inlet in the top of the low-temperature movingbed adsorption tower, and the gas outlet of the low-temperature moving bed adsorption tower is communicated with the inlet of a cold energy recoverer; the flue gas cooling system adopts a three-section spray cooling structure, the system can meet the requirement of ultra-clean emission, the desorption temperature is lower, and meanwhile, the adsorbent loss is lower.

Owner:CHINA HUANENG GRP CO LTD +1

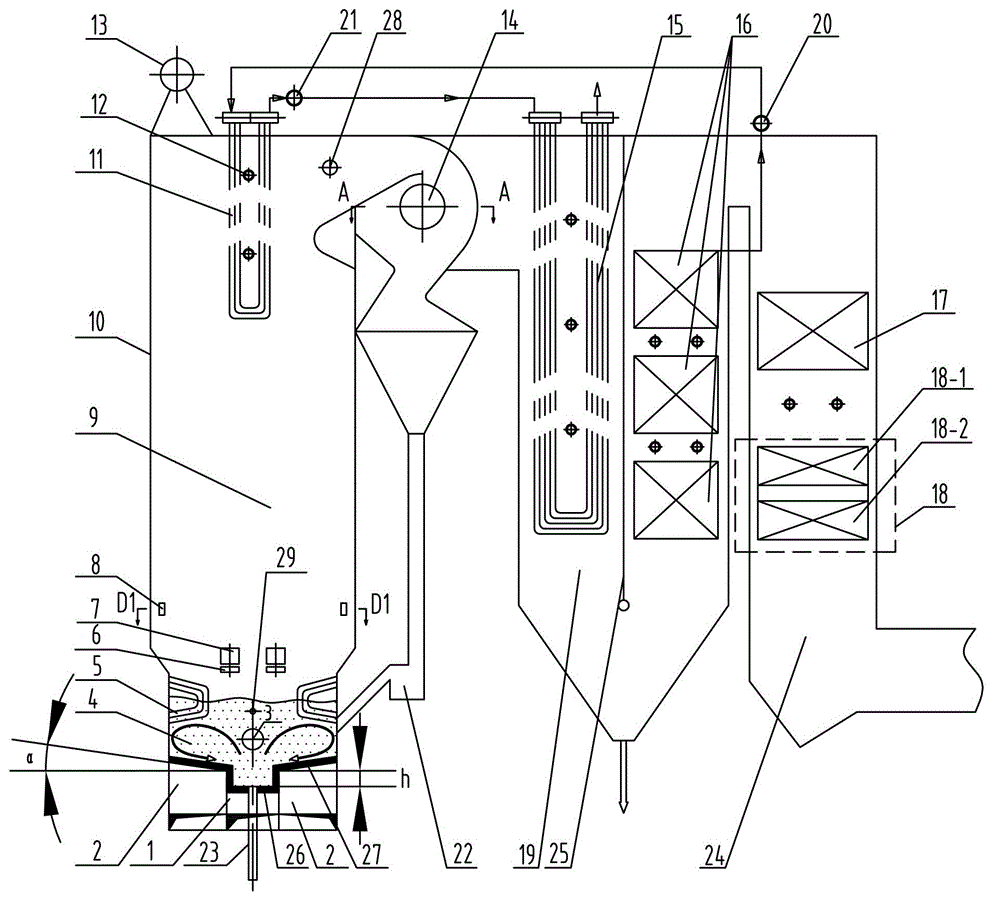

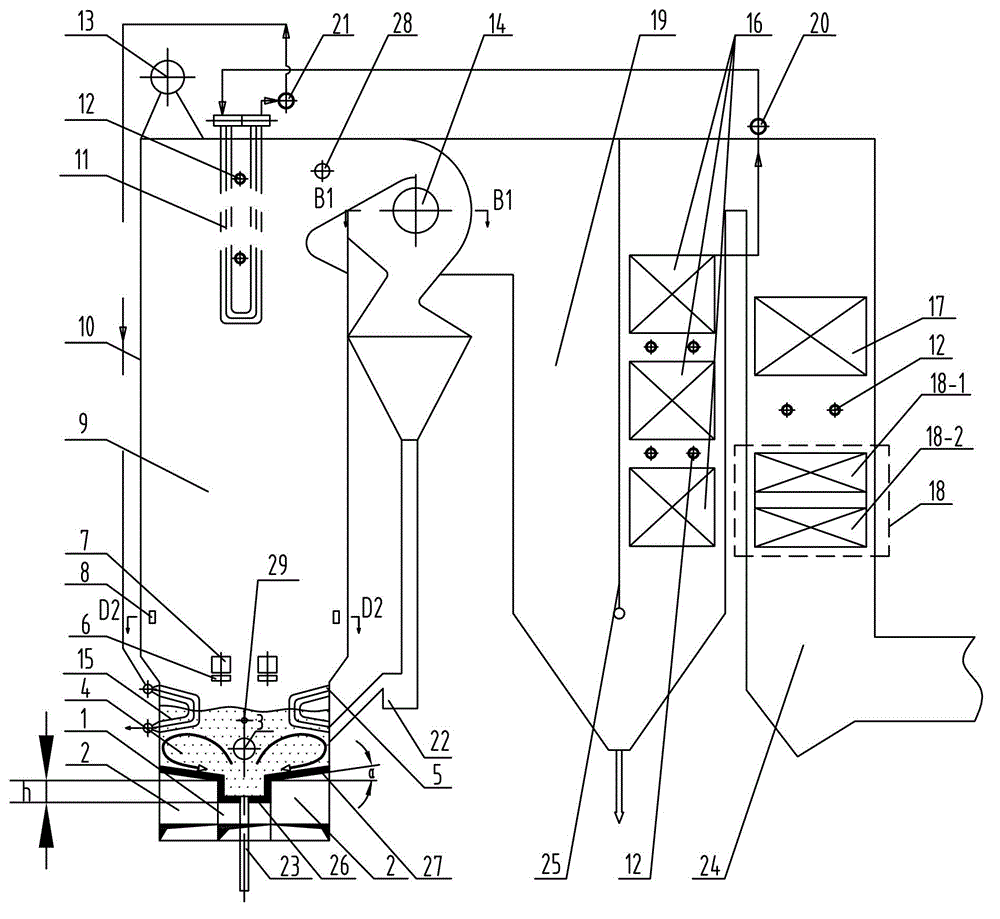

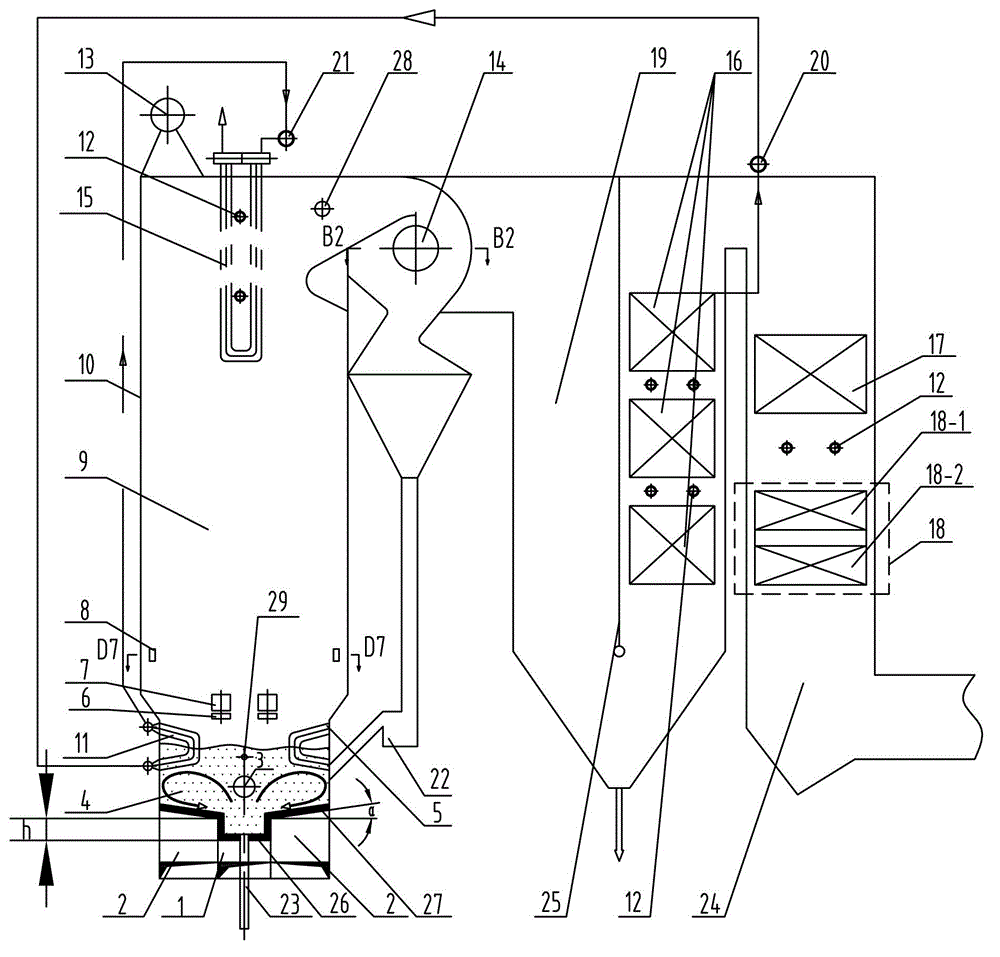

Low-ratio biomass circulating fluidized bed with cooling chamber and pollutant control method thereof

ActiveCN102913900AReduce wearReduce dust accumulationFluidized bed combustionDispersed particle separationSuperheaterCirculating fluidized bed boiler

The invention relates to a low-ratio biomass circulating fluidized bed with a cooling chamber and a pollutant control method thereof and solves the problem that existing grate-fired furnaces and circulating fluidized beds cause grate slag bonding and bed material coking in biomass combustion and especially causes soot formation and high-temperature corrosion in combustion of low ash fusion point biomass. A smoke cooling chamber is disposed behind a cyclone separator and used to lower smoke temperature from 800 DEG C to within 650 DEG C, so that soot formation and corrosion of a superheater are relieved greatly. By in-furnace denitration and limestone desulfuration, denitration efficiency can reach 50-70% when mole ratio of NH3 to NOX is 1.0-1.1, denitration efficiency can reach 70-80% when mole ratio of Ca to S is 2.0-2.5, and emission concentration of SO2 and NOx can be effectively controlled within 100mg / m<3>. The low-ratio biomass circulating fluidized bed with the cooling chamber and the pollutant control method thereof are used to control biomass combustion and pollutants.

Owner:HARBIN INST OF TECH

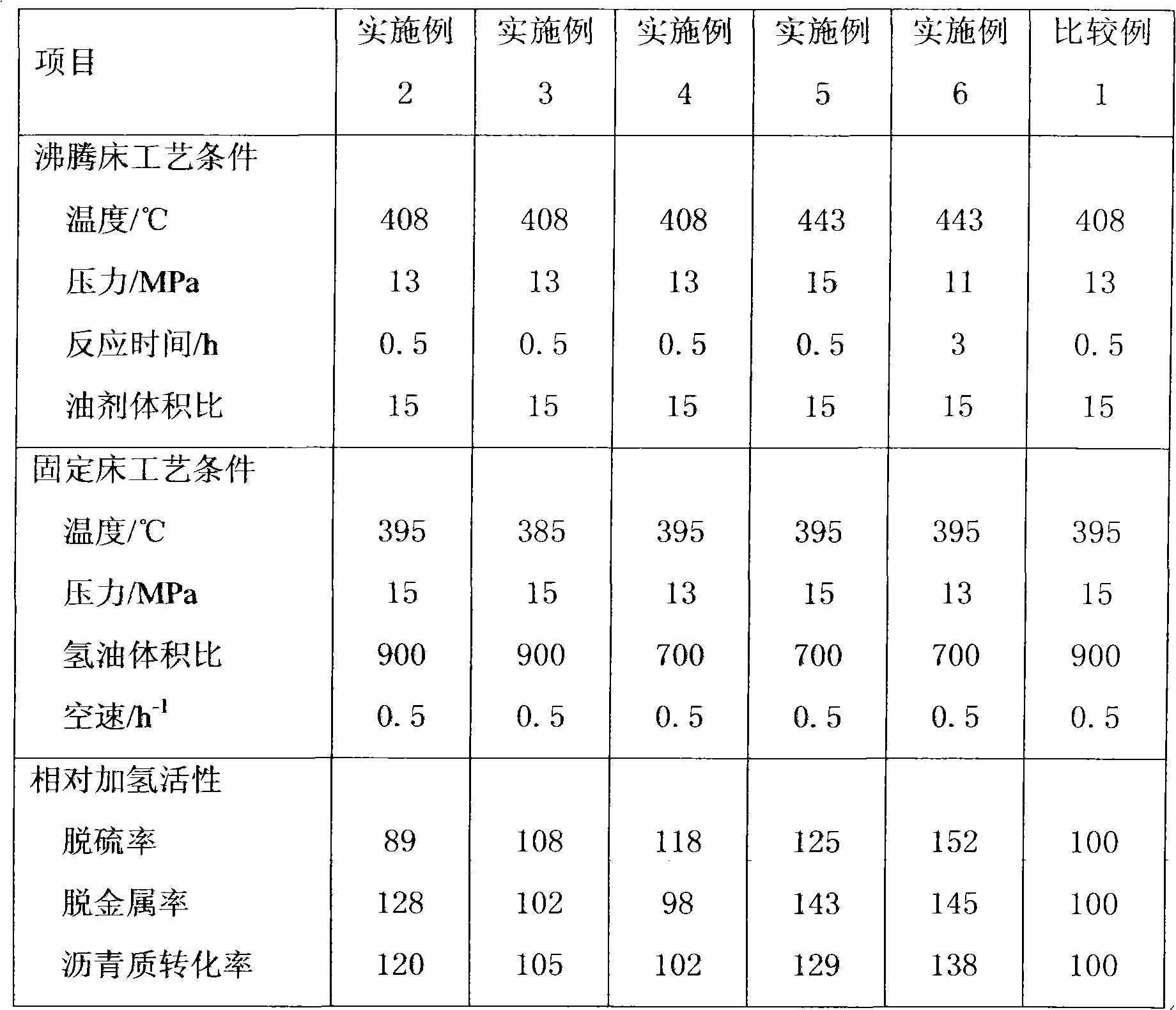

Heavy and inferior raw material hydrotreatment method

ActiveCN102465010ALarge apertureStrong metal capacityTreatment with hydrotreatment processesHydrogenation reactionFixed bed

The invention discloses a heavy and inferior raw material hydrotreatment method. A boiling bed reactor is combined with a fixed bed reactor. Raw oil and hydrogen enter from the bottom of the boiling bed reactor. The hydrogenation reaction is carried out under the fixed bed hydrogenation condition. A material is discharged from the bottom of the fixed bed reactor and enters into a separation system. A mixed catalyst of at least two catalysts with different properties is used in the boiling bed hydrotreatment reactor. In comparison with the prior art, the method provided by the invention can be used to effectively improve the operation performance of boiling bed residuum hydrotreatment and fixed bed hydrotreatment technologies and raise the hydrogenation activity level and flexibility of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

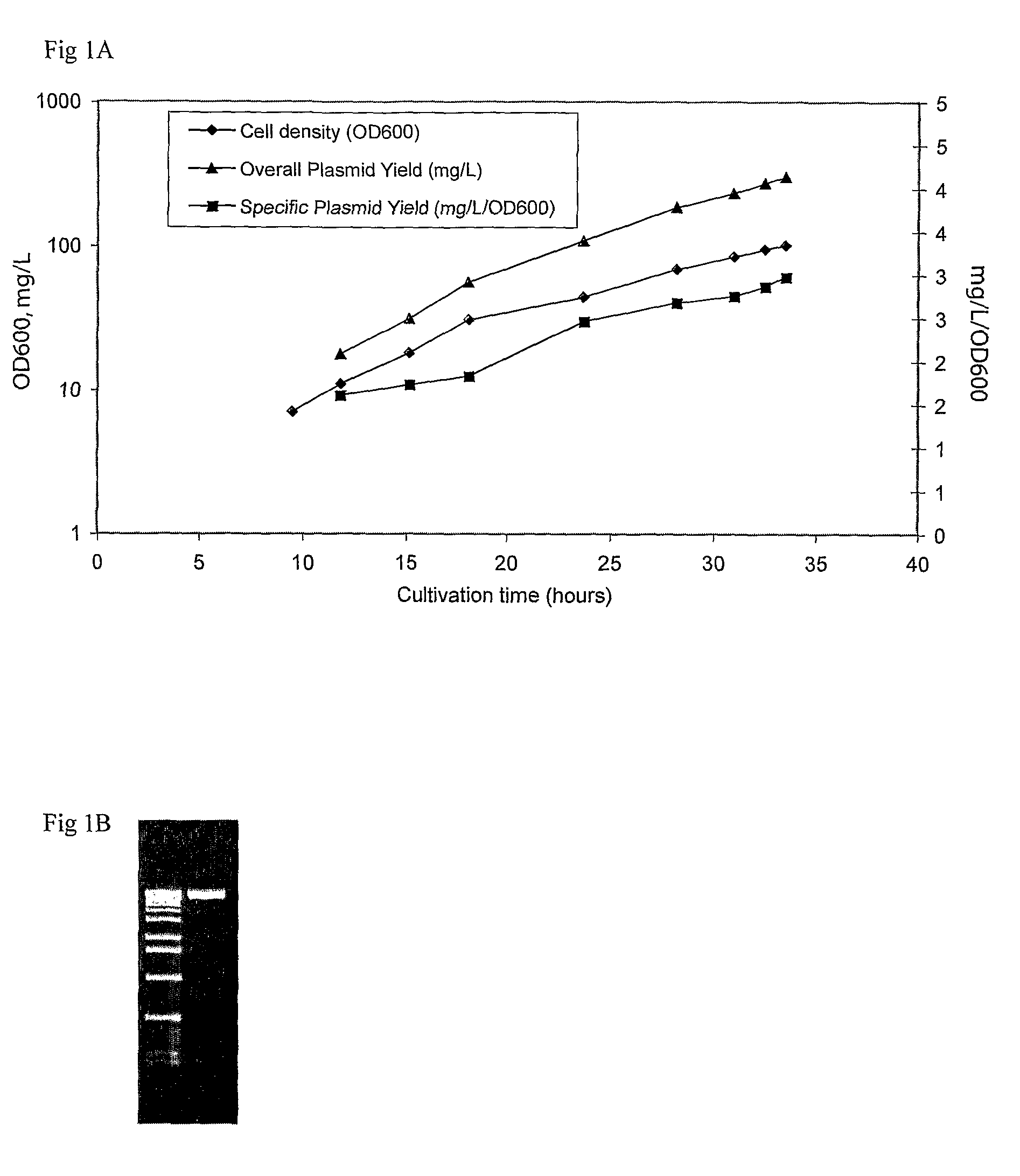

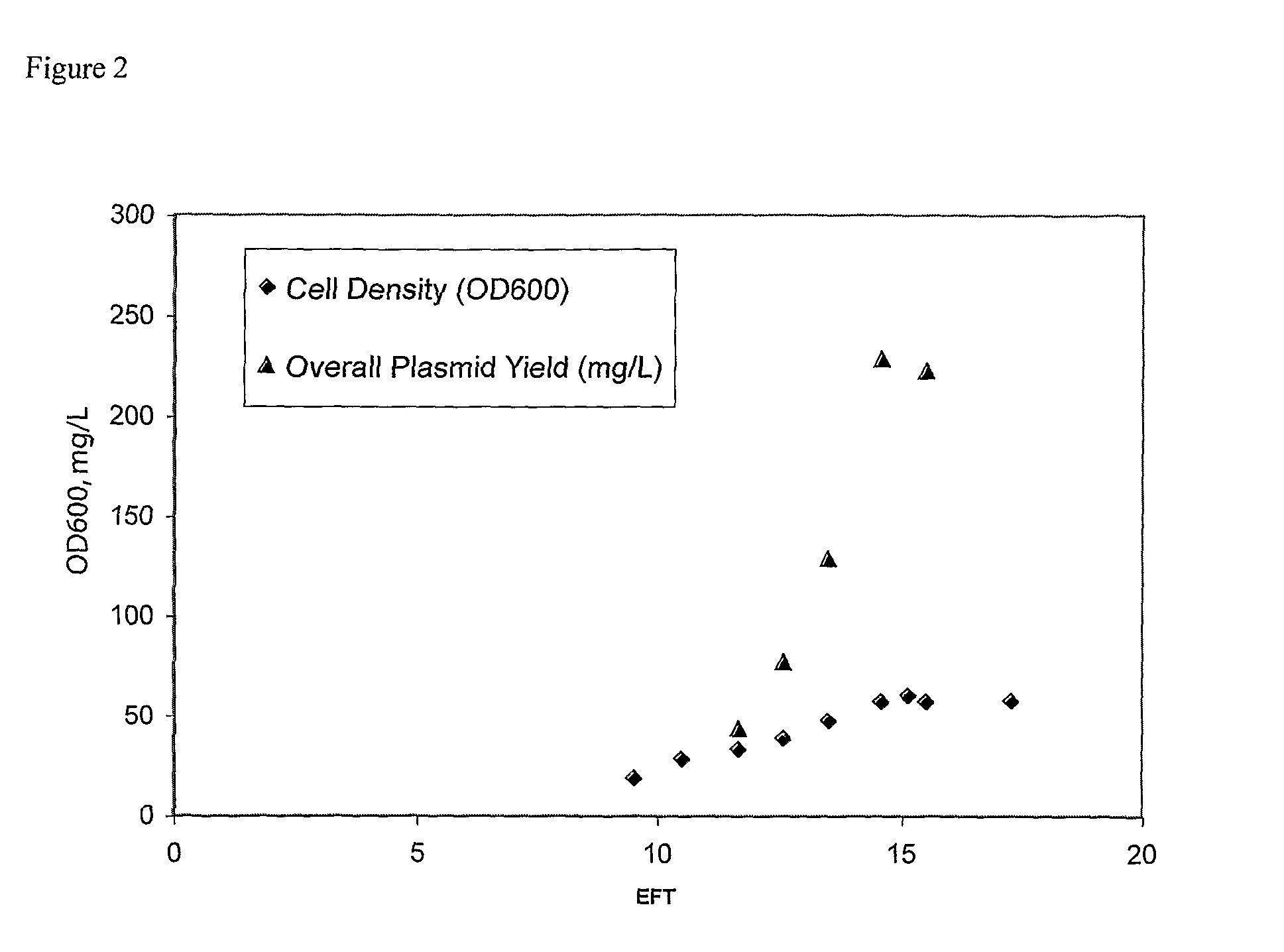

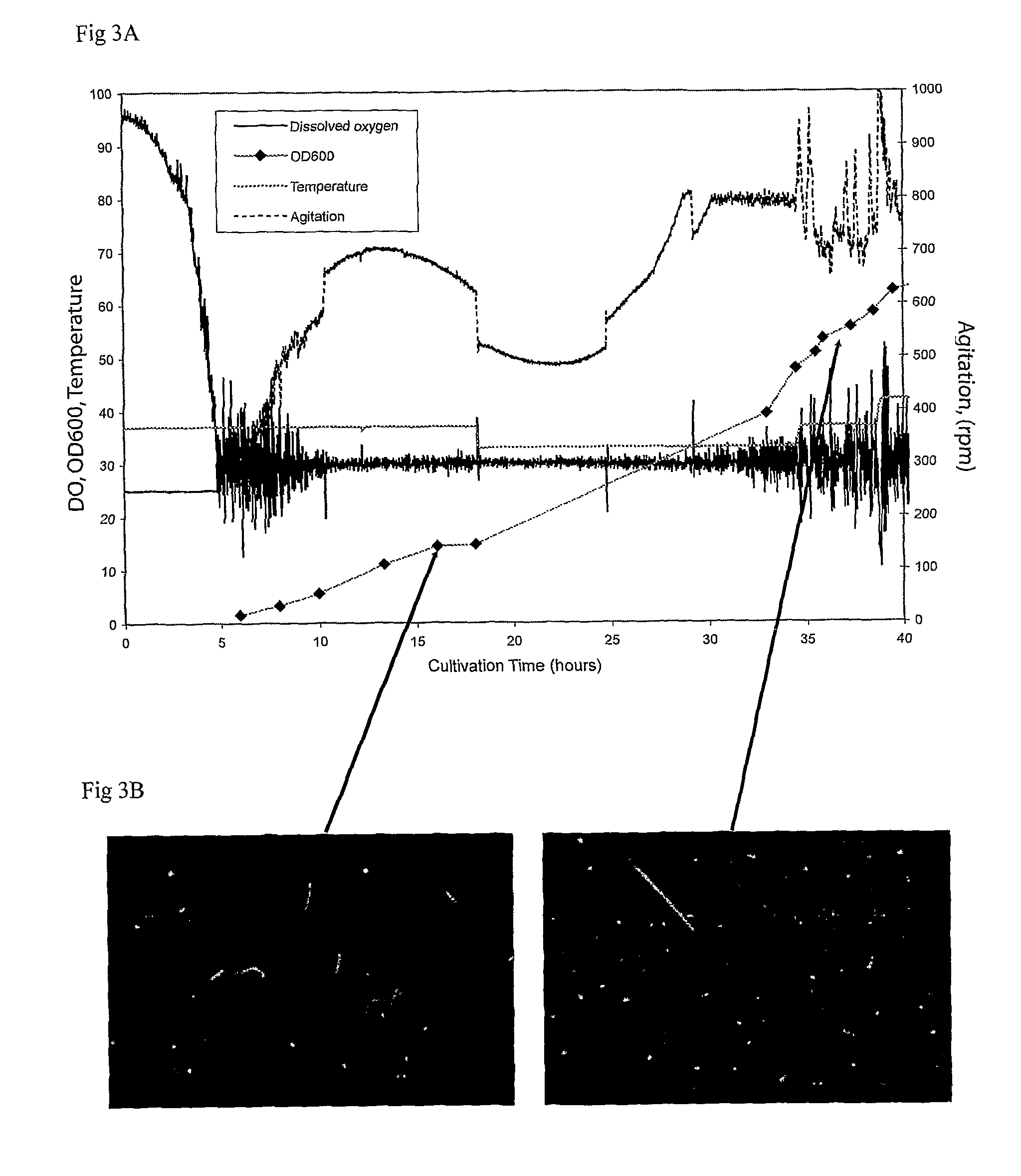

Process for plasmid DNA fermentation

ActiveUS7943377B2Improve plasmid DNA production yieldImprove plasmid DNA qualityGenetic therapy composition manufactureTissue cultureBatch fermentationPlasmid dna

Improvements in plasmid DNA production technology are needed to insure the economic feasibility of future DNA vaccines and DNA therapeutics. General methods are described, by means of which it is possible to dramatically increase plasmid DNA productivity in a fermentor. These processes feature Fed-batch fermentation strategies, combined with novel growth and induction phase temperature shifts.

Owner:ALDEVRON LLC

Soilless cultivation organic substrate used for seedling raising of capsicums and preparation method thereof

InactiveCN101697704AReduce overexploitationAchieve sustainable useAgriculture gas emission reductionCultivating equipmentsRenewable resourceBiology

The invention discloses a soilless cultivation organic substrate and a preparation method thereof. The preparation method comprises the following steps: respectively mixing the broken blocks of maize cobs, the broken blocks of maize stalks and rice hulls evenly after being stacked and fermented in the volume ratio of 3-4:3-5:2-4 and then adding 10-15kg / m3 of puffed chicken dung according to the total volume after being mixed evenly. The soilless cultivation organic substrate provided by the invention adopts the main raw materials of the maize stalks, the maize cobs and the rice hulls which are discarded in the local agricultural production so as to replace the substrate raw material of grass carbon which is commonly used in seedling raising at present, which not only can save the seedling raising cost greatly but also reduces the overexploitation of the unrenewable resource of the grass carbon and maintains the sustainable development of ecology; on the other hand, by utilizing the agricultural wastes reasonably, the income of local farmers is increased, and the wastage of resources is reduced.

Owner:NORTHWEST A & F UNIV

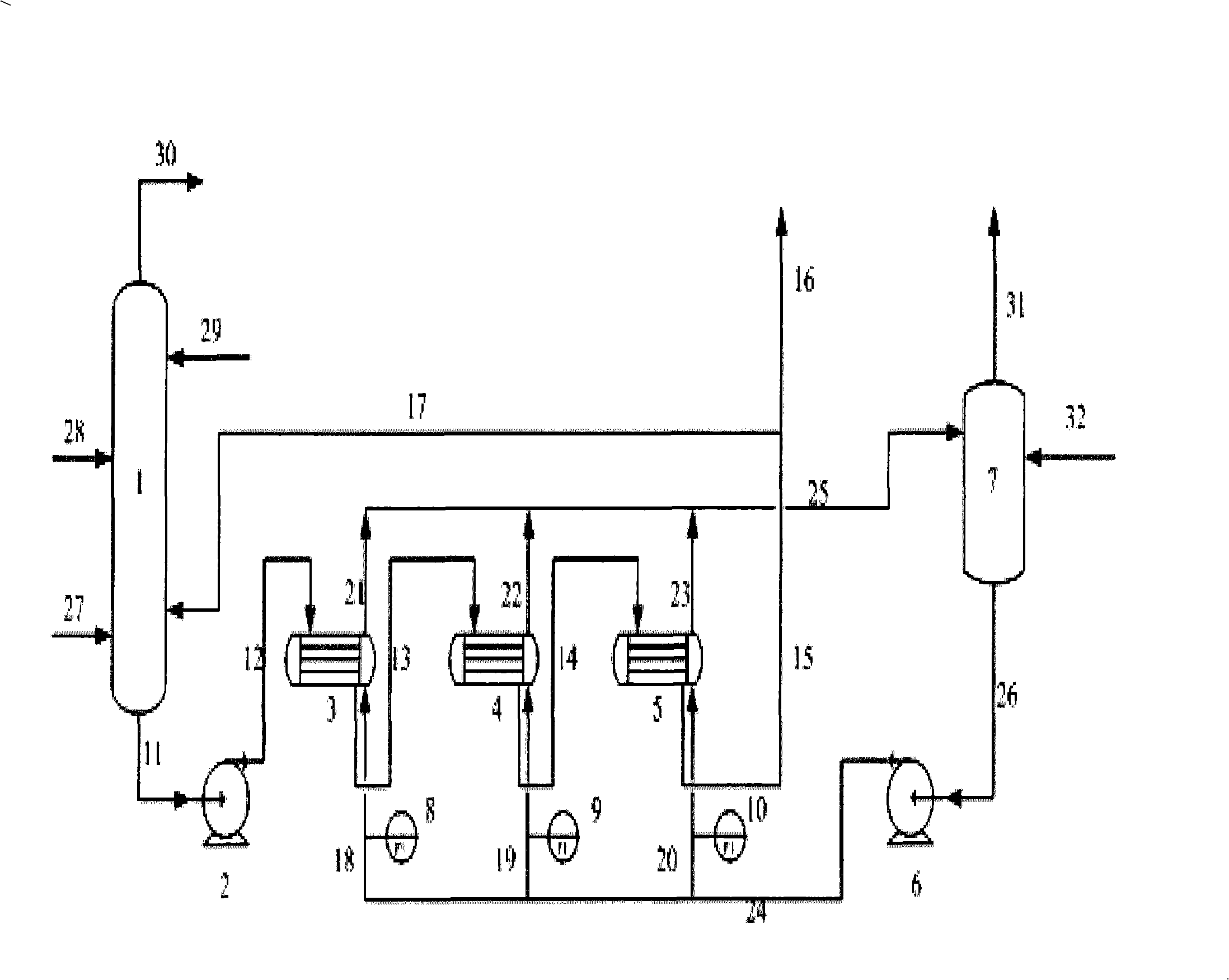

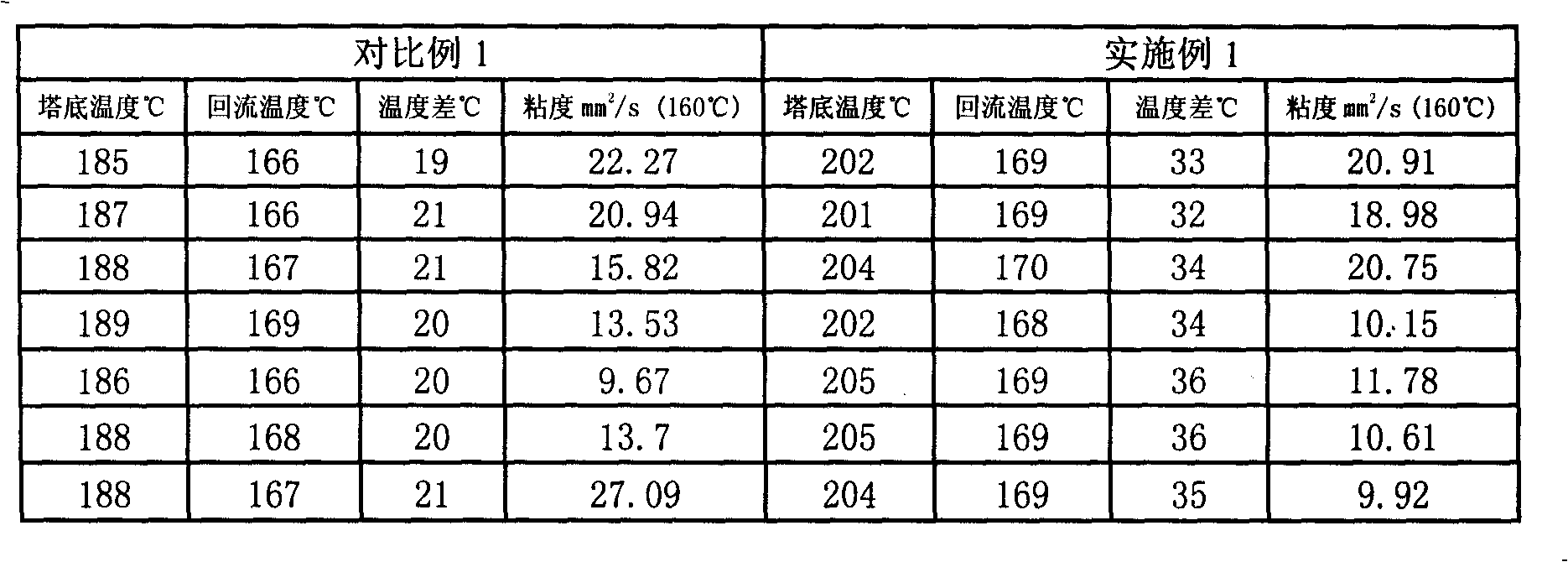

Method for improving ethylene apparatus quench oil tower bottom temperature

ActiveCN101323553AIncrease temperatureSave moneyHydrocarbon by hydrocarbon crackingLighter fuelFresh water

The invention relates to a method for increasing the temperature at a quenching oil tower bottom of an ethene device, which adopts the series of quenching oil heat exchanger and the forced circulation of fresh water; besides, a viscosity reductant and light fuel oil picked out from the middle section of an oil washing tower can be added into quenching oil. Application of the method of the invention can increase the temperature at the bottom of the oil washing tower, increase the generation amount of dilution steam, reduce the direct filling of the steam, ensure the stable operation of the device, save energy and reduce the operation cost of the device.

Owner:PETROCHINA CO LTD

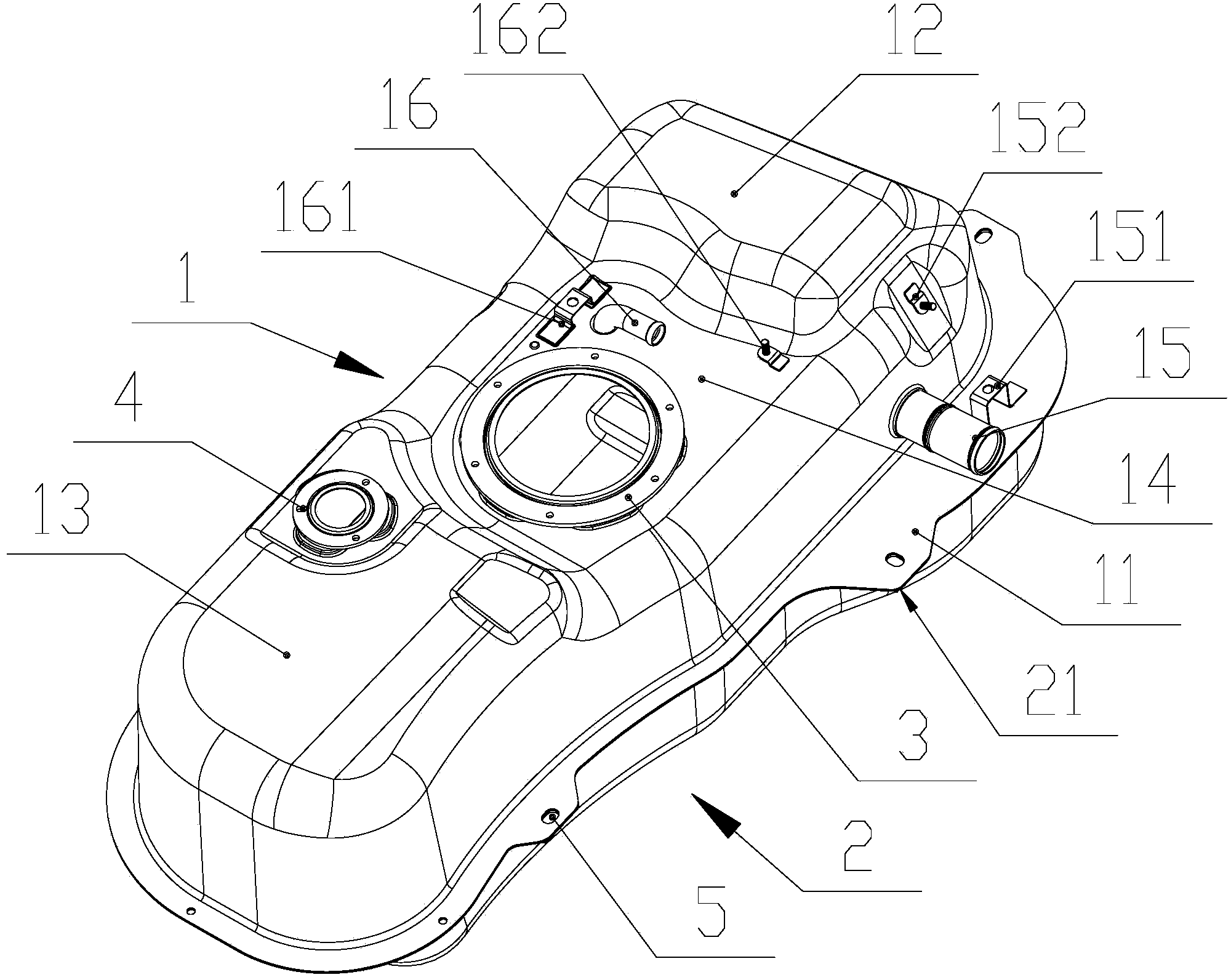

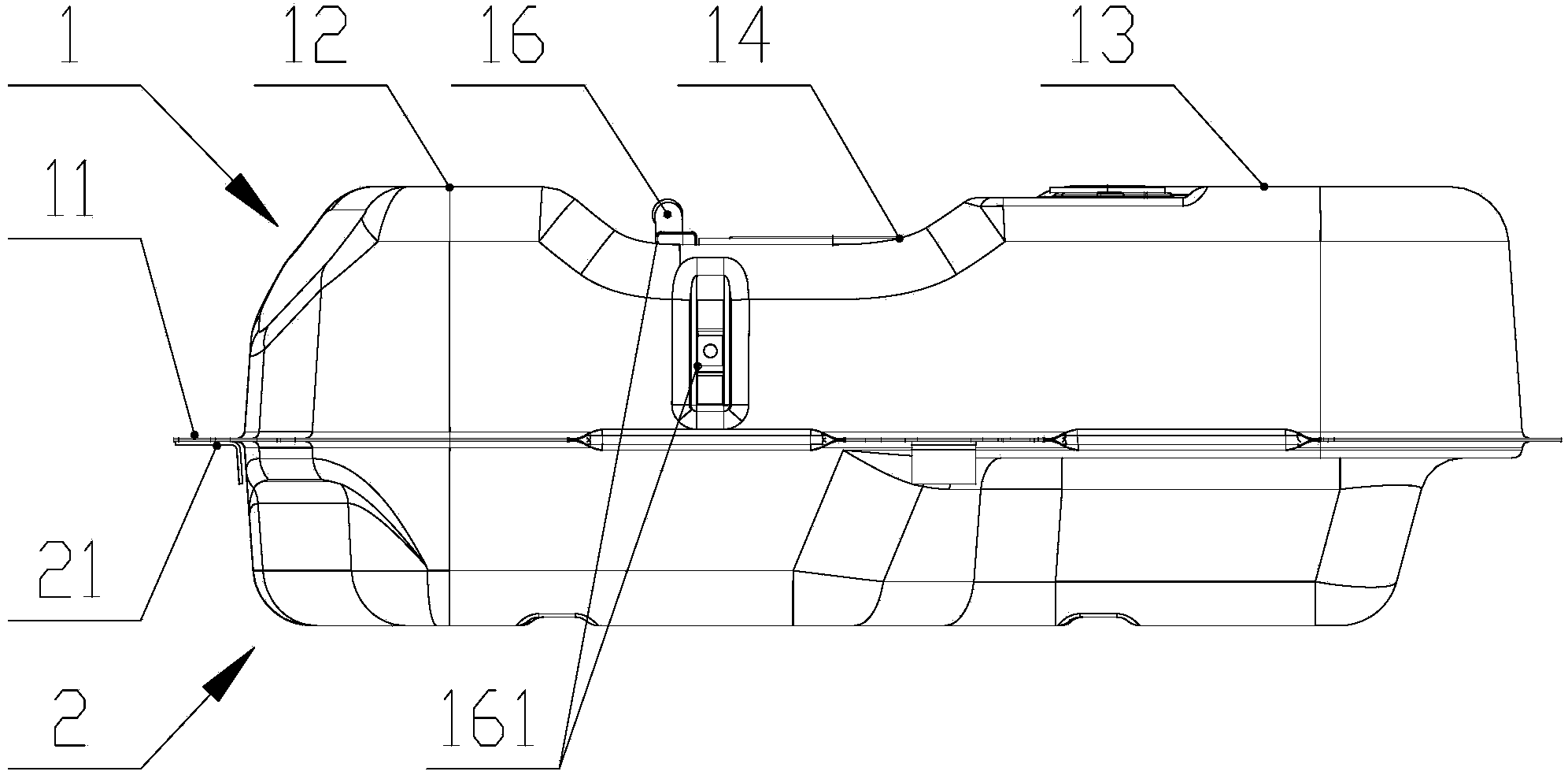

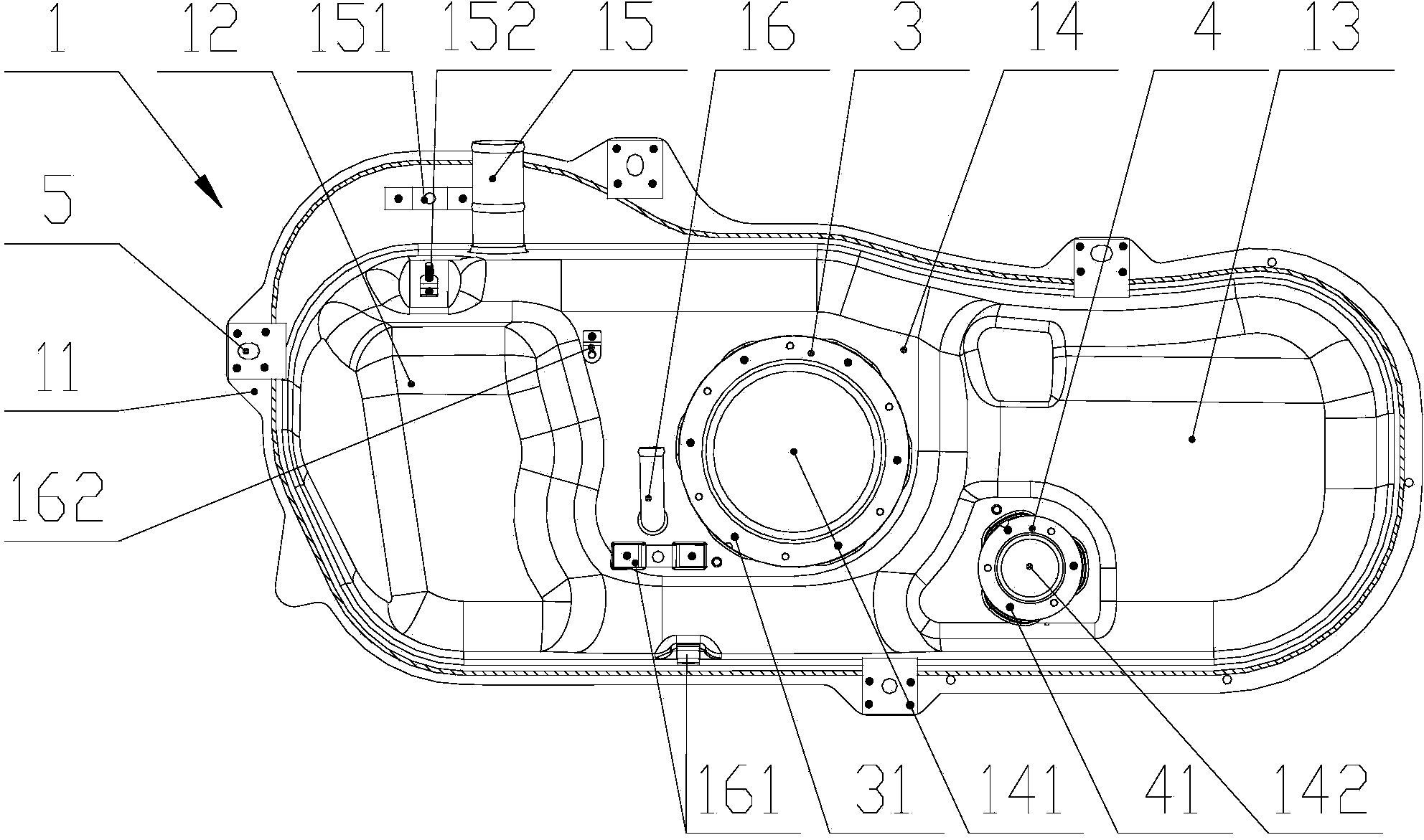

Automobile fuel tank

ActiveCN104175871AMeet air tightness requirementsSmall footprintFuel supplyInterior spaceMetallic materials

The invention discloses an automobile fuel tank which is low in cost. An upper tank body and a lower tank body are connected firmly and stably. The occupied vehicle interior space is small after a fuel pump and a turning-over valve are installed. The fuel tank comprises the upper tank body and the lower tank body arranged on the lower side of the upper tank body. The upper tank body and the lower tank body are made of metal materials respectively. An upper tank-closing ring edge is arranged on the portion, along the edge of the lower side, of the upper tank body. A lower tank-closing ring edge is arranged on the portion, along the edge of the upper side, of the upper tank body. The upper tank-closing ring edge and the lower tank-closing ring edge are matched and welded together in a rolling mode. The upper tank body is a concave casing with the front end and the rear end being protruding faces and the middle portion being a sunken face. The sunken face of the upper tank body is provided with a fuel pump installing flange and a turning-over valve installing flange. The upper tank body is further provided with an oil filling pipe and a ventilation pipe. The cost of the fuel tank is far smaller than that of a plastic fuel tank. The upper tank body and the lower tank body are connected firmly and stably, and influence of vibration is small; due to the sunken face, the tail portion of the installed fuel pump and the tail portion of the turning-over valve are prevented from protruding or protruding excessively.

Owner:重庆双五汽车零部件有限公司

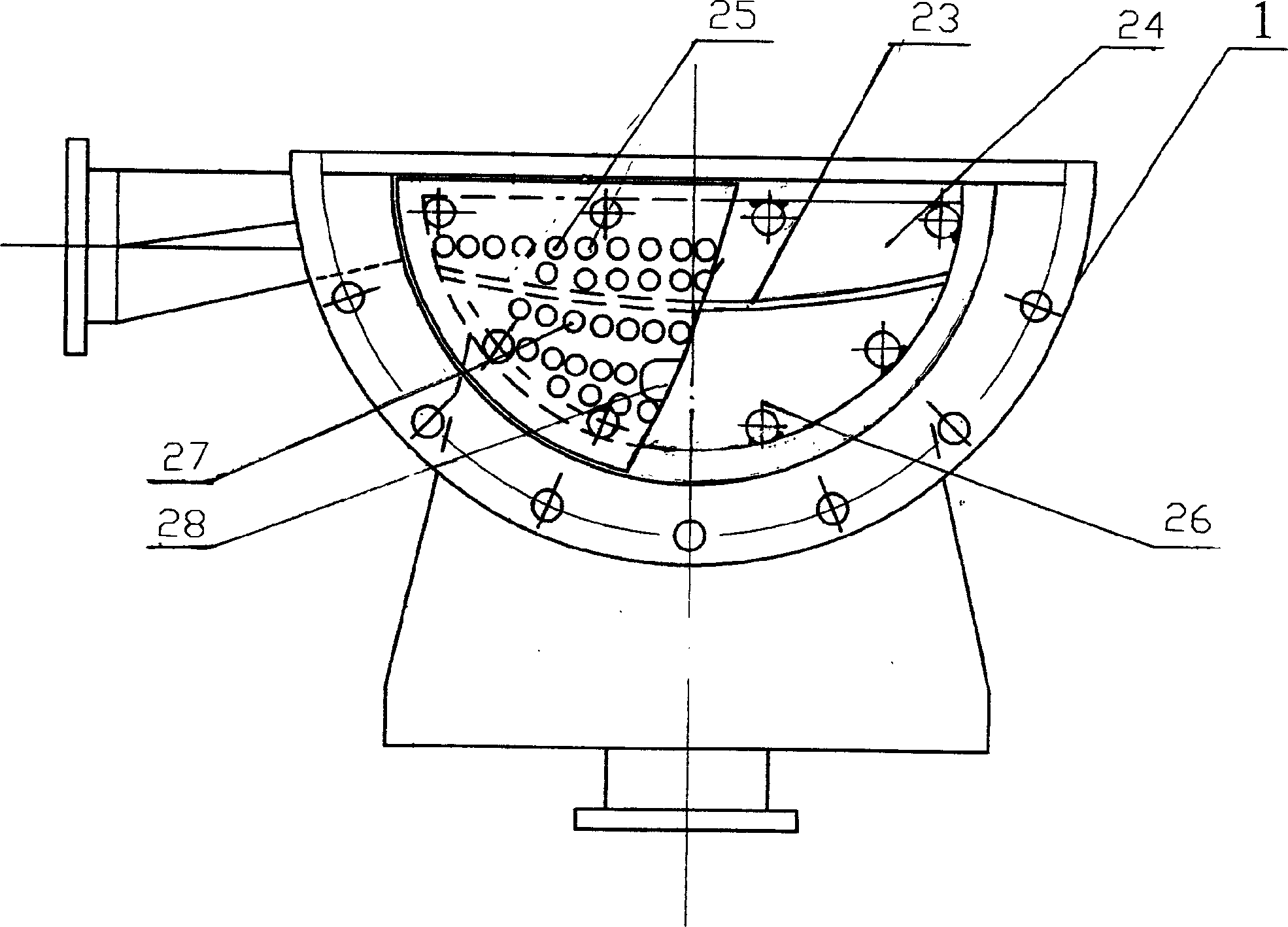

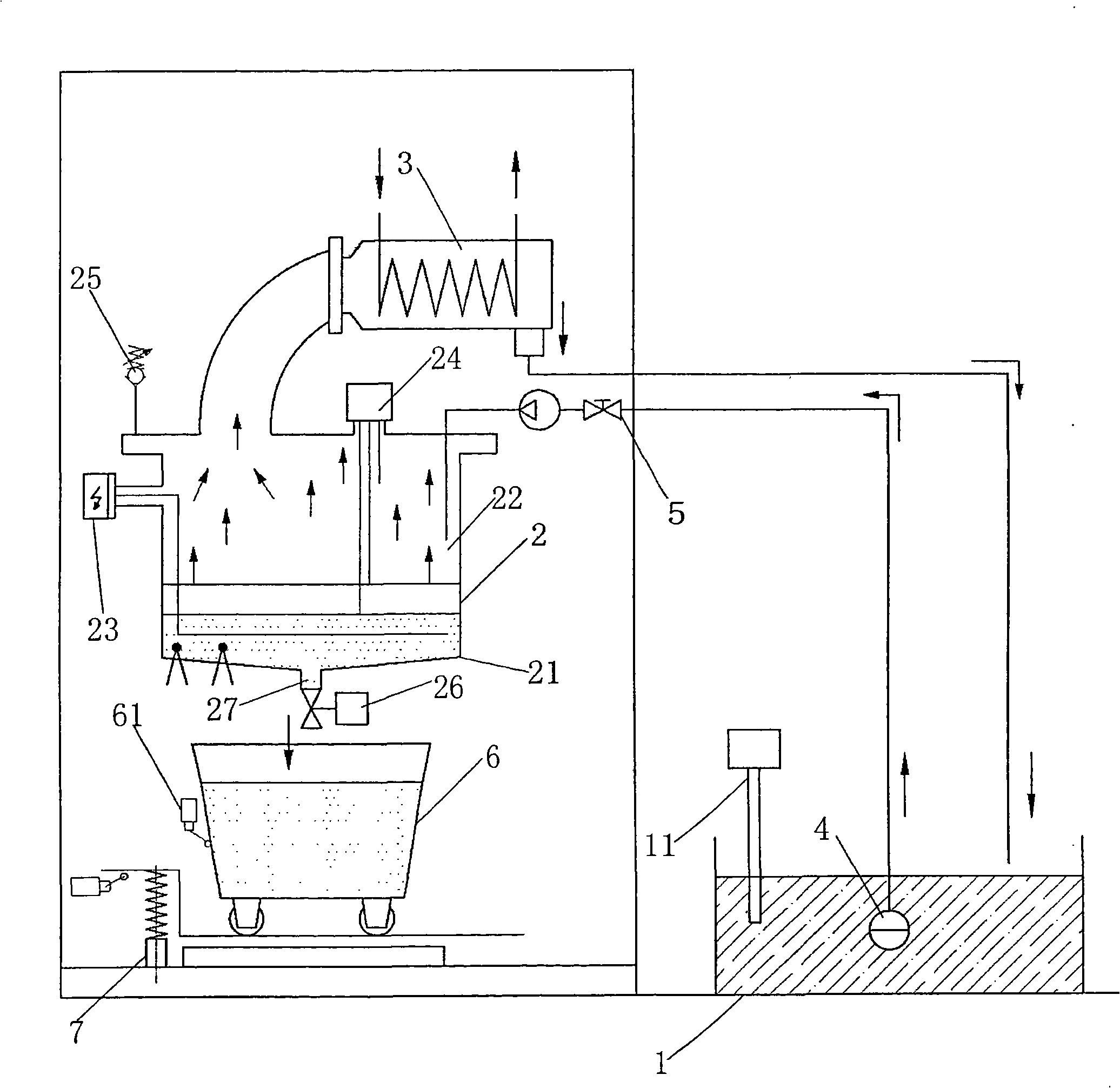

Device for cyclically removing carbon dioxide using calcium-based absorbent with steam activated reactor and method for cyclically removing carbon dioxide using calcium-based absorbent

InactiveCN106975341AImprove thermal economyImprove energy efficiencyGas treatmentDispersed particle separationCycloneNitrogen gas

The invention discloses a device for cyclically removing carbon dioxide using a calcium-based absorbent with a steam activated reactor. The device comprises a fluidized bed carbonation reactor, a fluidized bed calcination decomposition reactor, a fluidized bed steam activated reactor, a fluidized bed dehydration regeneration reactor, a first cyclone separator, a second cyclone separator, a first return feeder, a second return feeder, a circulating material heat exchanger, a CO2 heat exchanger, an air separation unit and pipelines for connecting parts. The activity of CaO inactivated after calcination is regenerated by using the steam activated reactor, and an absorbent pore structure and a reaction surface are substantially regenerated by a hydration-water loss reaction, so that the activity of the calcium-based absorbent can be significantly maintained, the decline in activity of the absorbent is inhibited, and the discharge of an inactivated absorbent and the replenishment amount of a fresh absorbent can be reduced; the heat of temperature flue gas and a recycled material is fully utilized by using the heat exchanger to generate high temperature oxygen, nitrogen and steam, and the thermal economy and energy utilization efficiency of a carbon capture process are improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Energy-saving flue gas pollutant treatment system using waste heat of thermal power plant

ActiveCN104595919AReduce energy costsReduce operating costsHeat pumpsCombustion technology mitigationFlue gasAbsorption heat pump

The invention provides an energy-saving flue gas pollutant treatment system using waste heat of a thermal power plant. The energy-saving flue gas pollutant treatment system comprises a flue gas cooler, a flue gas re-heater and a steam auxiliary heater, wherein an energy-saving branch for utilizing the waste heat of the thermal power plant is further arranged between the flue gas cooler and the flue gas re-heater; the energy-saving branch is provided with a first type absorption heat pump; the first type absorption heat pump comprises an absorber, a condenser, an evaporator and a generator. By virtue of the energy-saving flue gas pollutant treatment system using the waste heat of the thermal power plant, provided by the invention, steam can be greatly saved and supplemented; the loss of circulating water is reduced by the first type absorption heat pump, so that water resources are saved, and the energy consumption and the operation cost of the operation of the pollutant treatment system are greatly reduced.

Owner:ZHEJIANG ZHENENG ENERGY SAVING TECH

Air cleaner and cleaning method thereof

ActiveCN104190182AReasonable designEasy to cleanHuman health protectionUsing liquid separation agentParticulatesReducer

The invention provides an air cleaner which comprises a box body and a partition board, wherein the box body is divided into a cleaning zone and a discharging zone, and a motor, a speed reducer, a liquid dispenser containing an absorption liquid, a plurality of stirring units, a water tank, and a grid used for solid-liquid separation and provided with an air inlet pipeline at the upper part are arranged in the cleaning zone. The air cleaner and a cleaning method thereof are designed reasonably, the secondary pollution is avoided, by the cyclic utilization of the absorption liquid, not only is the supplement problem of the absorption liquid solved, but also the consumption of the absorption liquid is reduced, the operating cost is low, the efficiency is high, the cleaning and the maintenance are easy, the air cleaner is small and small in occupying area, and the air cleaner is convenient to move; through the rotational stirring of stirring blades with through holes, water molecules in the absorption liquid are combined with PM2.5 in industrial waste gas, the combination absorption performed by the grid is facilitated, and the cleaning efficiency is improved to a very large extent.

Owner:福建杰达环保科技有限公司

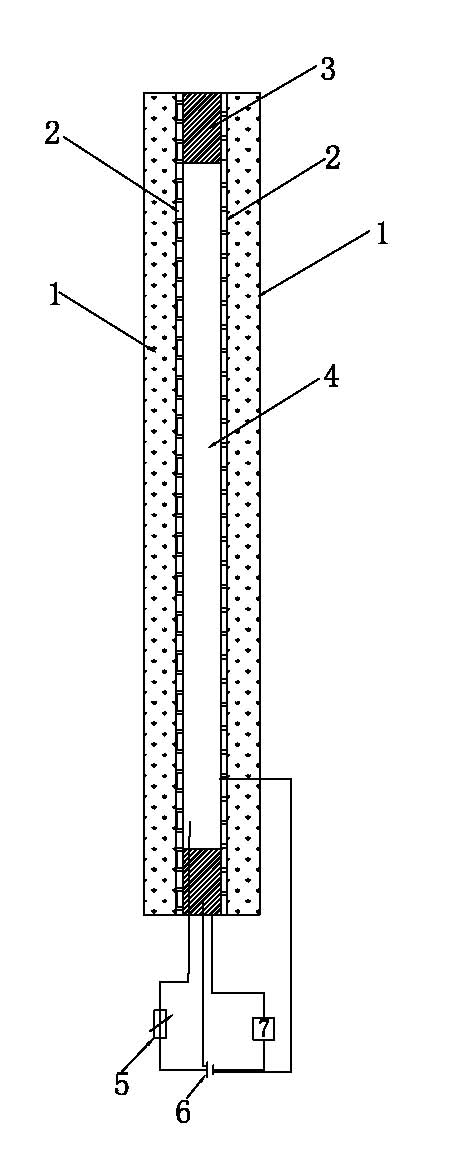

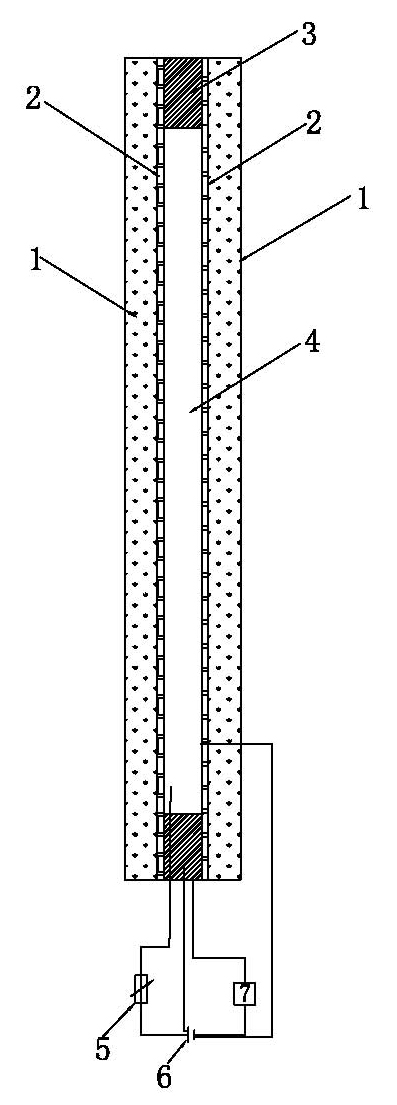

Dimming glass based on solar energy and dimming liquid crystal

InactiveCN102108757ASoft lightGood shading effectBatteries circuit arrangementsLight protection screensSurface layerSolar battery

The invention discloses dimming glass based on solar energy and dimming liquid crystal. The dimming glass is characterized by mainly comprising double transmitting glass surface layers (1), a liquid crystal sheet (4) and a film solar battery (3), wherein the inner surfaces of the double transmitting glass surface layers (1) are respectively bonded with an ethylene-vinyl acetate (EVA) adhesive layer (2); the film solar battery (3) with a frame structure is clamped between two EVA adhesive layers (2) and arranged along the peripheries of the transmitting glass surface layers (1); the liquid crystal sheet (4) is also clamped between the two EVA adhesive layers (2) and is positioned in the frame of the film solar battery (3); the film solar battery (3) is connected with the input end of a storage battery through a control circuit; the output end of the storage battery (6) is electrically connected with the liquid crystal sheet (4); and a dimming resistor (5) is connected in series in a connecting circuit of the storage battery (6) and the liquid crystal sheet (4). The dimming glass has the advantages of adjustable light, energy conservation, environmental friendliness, high strength and low cost.

Owner:JINLING INST OF TECH

Heat treatment spent liquor salt recovery processing method and apparatus

ActiveCN101298636AReduce supplementationNo emissionsWaste water treatment from metallurgical processWater/sewage treatment by heatingSaline waterLiquid waste

The invention relates to a recycle processing method for heat treating waste liquid salts and a device thereof. The recycle processing method for heat treating waste liquid salts comprises following steps: (1) a high liquid level and a low liquid level of a heating slot of salt recycling are set; (2) a mixed liquid of salt and water for cleaning a water slot is pumped into the heating slot of salt recycling, and when the temperature of the mixed liquid of salt and water is raised over 100 DEG C, the water in the mixed liquid evaporates into water vapor which is cooled into water and returned back into a cleaner for recycling; (3) when the liquid level decreases to the low liquid level, a salt discharging valve is opened, and salt solution enters a salt storing slot for cooling and recycling. The specialized device is characterized that the specialized device comprises the cleaning slot (1), a heating device of salt recycling (2) and a condenser (3); a water inlet end of the heating device of salt recycling is connected with the cleaning slot, an air outlet end of the heating device of salt recycling is connected with an air inlet end of the condenser, and the water outlet end of the condenser is connected with the water inlet end of the cleaning slot; a salt discharging port and a valve are arranged in the bottom of a shell, the storing slot of salt recycling is arranged under the shell. The recycle processing method for heat treating waste liquid salts and the device thereof realize non-discharging of sewage and have the advantages of saving water resource, recycling waste salts and lowering cost.

Owner:GUANGDONG STRONG METAL TECH

Gas field sulfur-containing waste gas treatment method

InactiveCN106669402AEasy Oxidation CapacityHas hydrophobic propertiesGas treatmentDispersed particle separationSulfur containingSolution flow

The invention relates to a waste gas treatment process, in particular to a gas field sulfur-containing waste gas treatment method. The method comprises the following steps that raw material gas is treated by a gas-liquid separator to separate out free water; the raw material gas subjected to the free water separation enters an absorption tower in a jet flow manner through a first Venturi tube; a desulfurization solution enters the absorption tower to be mixed with the raw material gas in the second step; bivalent sulfur in the raw material gas in the absorption tower is directly converted into sulfur; purified gas is exhausted from the top of the absorption tower through a defoaming device; after generated sulfur particles pass through a filtering machine or a filter press, sulfur filter cake is obtained; the filter cake enters a sulfur melting kettle to obtain a sulfur product; the desulfurization solution flows into a flash tank after taking reaction in the absorption tower; after flashing, desulfurization rich liquid enters a regeneration tower; the desulfurization rich liquid in the regeneration tower is subjected to oxidation and regeneration, air is subjected to fan pressurization and Venturi tube jet flow to be mixed with the desulfurization rich liquid; the mixed desulfurization solution enters the regeneration tower in a bubbling or aeration mode; after the regeneration, desulfurization barren liquid enters a plate frame filter or the filter press through a solution circulation pump; after being filtered, the desulfurization solution enters the absorption tower to be cyclically used.

Owner:四川沃兹凯兰科技有限公司

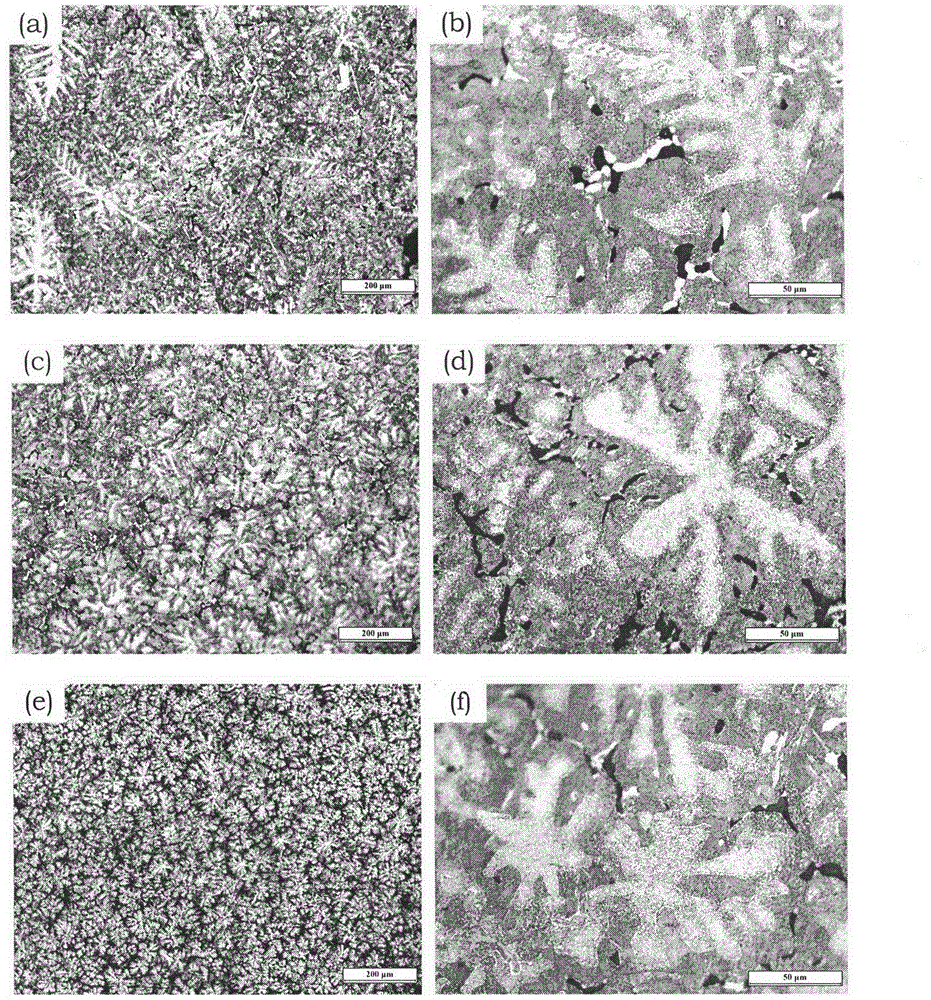

Process method capable of improving comprehensive mechanical property of multielement zinc-aluminum alloy

The invention relates to a multielement zinc-aluminum alloy capable of improving comprehensive mechanical property, belonging to the technical field of zinc-aluminum alloy preparation. The multielement zinc-aluminum alloy is characterized in that the multielement zinc-aluminum alloy is prepared from the following raw materials: industrial aluminum ingot NO.A00, zinc ingot NO.0, electrolytic copper, composite modifier and pure magnesium, wherein the composite modifier contains 20-30% of Ni, 15-25% of Ti, 5-15% of Mn, 5-15% of Cr, 5-10% of Si, 5-10% of Ce, 5-10% of La, 1-6% of Y, 1-6% of Nb, 1-6% of V and the balance of aluminum; the multielement zinc-aluminum alloy is smelted in a medium-frequency induction melting furnace after weighing 27-29% of Al, 2-2.5% of Cu (added in the form of aluminum-copper intermediamidstfrequencye alloy containing 50% of copper ), 0-1.2% of composite modifier, 0.01-0.02% of Mg and the balance of Zn based on percentage by weight. A round-rod-shaped blank iscasted by a common metal type and metal type vibrational casting method, and then processed to a national standard test rod to be subjected to mechanical property testing.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

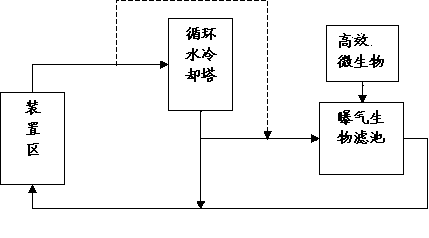

Method for biologically purifying industrial circulating water

The invention relates to a method for biologically purifying industrial circulating water. The method is characterized in that a biodegradation reactor is arranged in a circulating water system; nitrobacteria and denitrifiers are taken as inocula in the biodegradation reactor; at least part of the circulating water enters the biodegradation reactor to be biologically treated; the water from the biodegradation reactor enters the circulating water system; and the denitrifiers contain one or two of kocuriapalustris FSDN-A, arthrobactercreatinolyticus FDN-1 and flavobacteriummizutaii FDN-2. Compared with the prior art, the method has the advantages that the biological treatment method is adopted to treat the nutrient sources needed by microorganisms before the circulating water enters the device, so that the microorganisms brought in by the circulating water in the circulating process are difficult to survive, and then growth and reproduction of the microorganisms in the circulating water system are controlled.

Owner:CHINA PETROLEUM & CHEM CORP +1

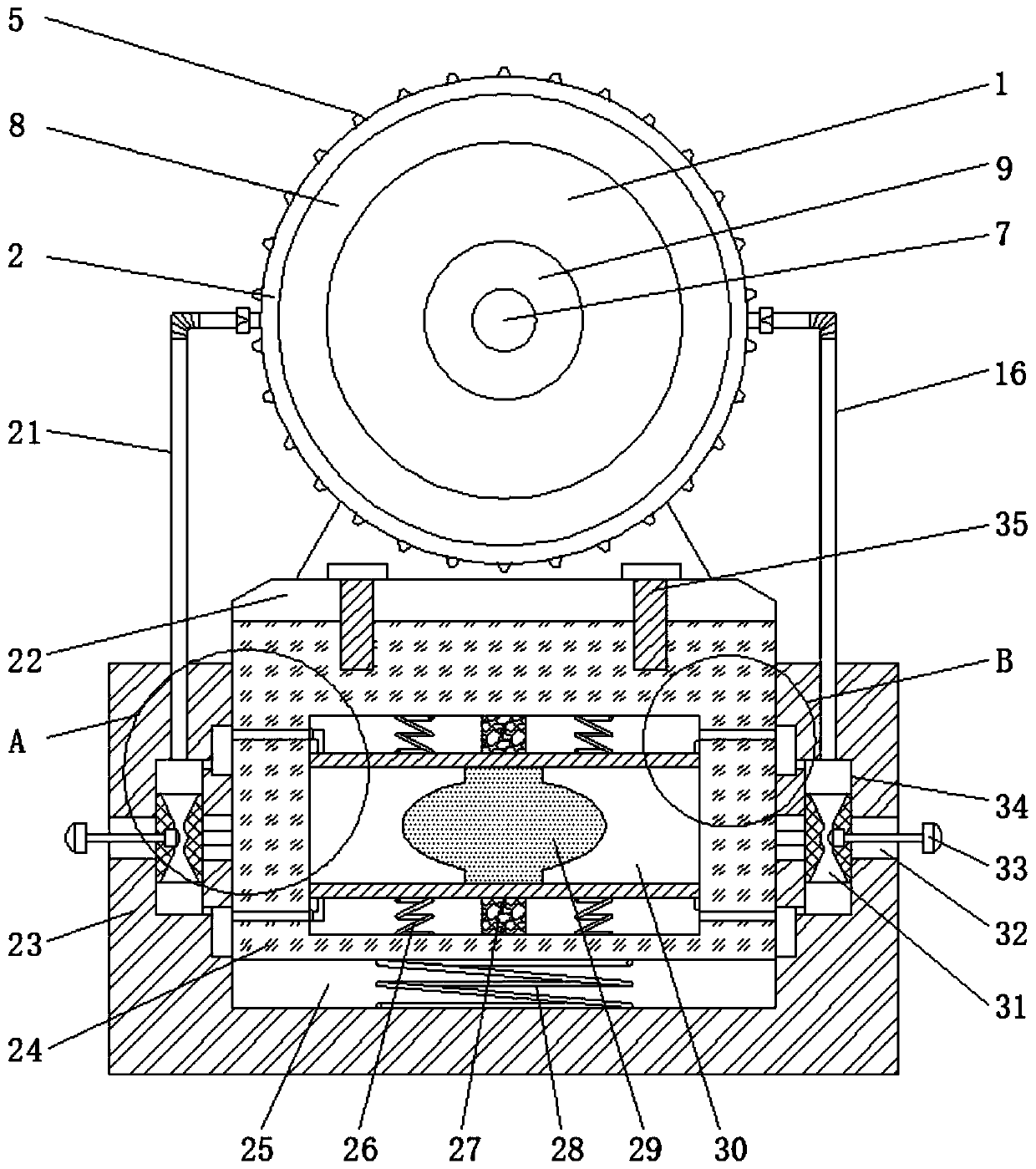

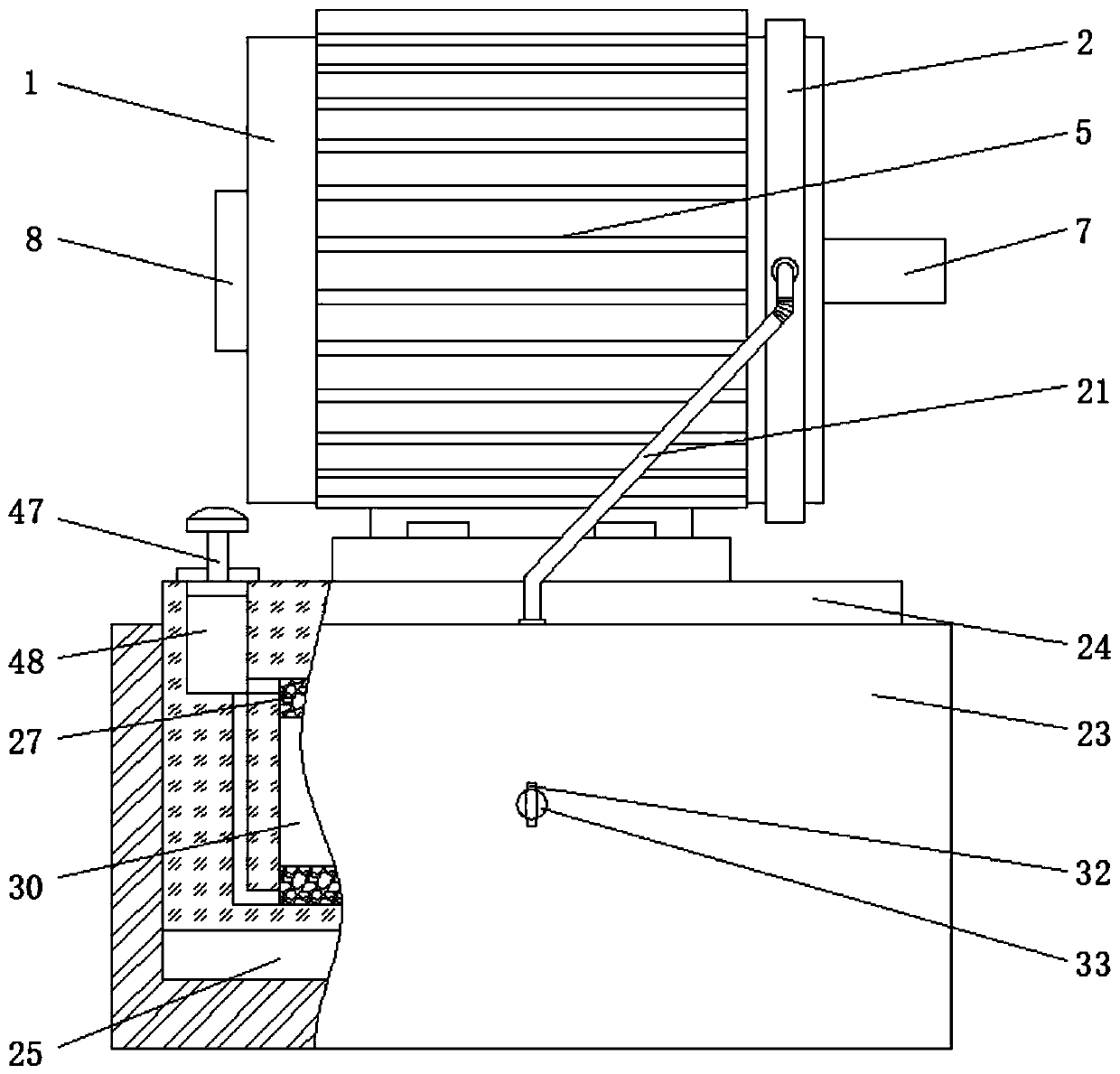

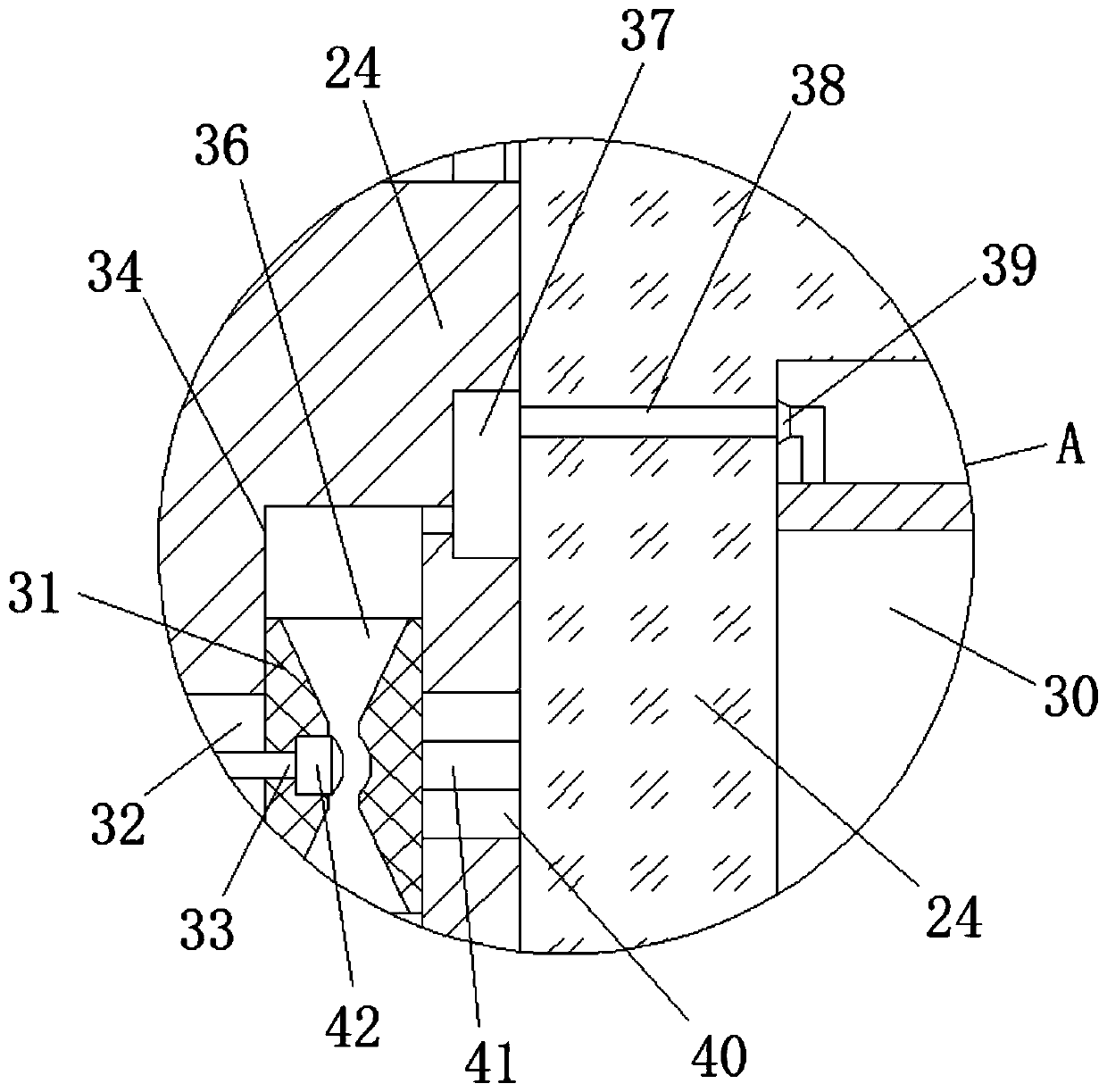

Motor with shock absorption and heat dissipation functions

ActiveCN110868011ARealize the shock absorption effectImprove stabilityCooling/ventillation arrangementSupports/enclosures/casingsOil canEngineering

The invention discloses a motor with shock absorption and heat dissipation functions. The motor comprises a motor body, a heat dissipation mechanism and a shock absorption seat; a cavity is formed inthe top of the shock absorption seat, a shock absorption block is slidably connected to the interior of the cavity, an oil filtering cavity is formed in the center of the interior of the shock absorption block, an oil pressing seat is slidably arranged in the oil filtering cavity, the motor body is arranged above the shock absorption seat, and the heat dissipation mechanism is arranged in the motor body; the motor body comprises a casing, a stator, a rotor, a rotating shaft and a bearing; the heat dissipation mechanism comprises a first oil guide base, a heat conduction pipe and a second oil guide base. Oil can be effectively pushed into a machine body through vibration generated by working of the motor body; heat exchange cooling is conducted on the interior of the machine body through flowing of oil, lubrication on bearings is achieved, mechanical loss is reduced, the service life of the motor body is prolonged, oil pressure of backflow oil can be effectively used as buffering forceto reduce device vibration, the operation stability of the motor body is improved, overall energy consumption is low, linkage performance is high, and the motor is suitable for popularization.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

Method for improving hydrogen peroxide bleaching efficiency of paper pulp

InactiveCN102363929ALow bleaching efficiencyImprove bleaching efficiencyPulp bleachingChemical/chemomechanical pulpEthylene diamineActive agent

The invention discloses a method for improving hydrogen peroxide bleaching efficiency of paper pulp, and belongs to the technical field of pulp preparation and papermaking. According to the method, a urea active agent and a chelating agent are simultaneously added in the alkali hydrogen peroxide bleaching process of chemical mechanical pulp or waste paper ink removed pulp, the consumption of the urea is 2.0 to 20 kilograms per ton of pulp, the consumption of ethylene diamine tetraacetic acid (EDTA) or diethylenetriamine pentaacetic acid (DTPA) serving as the chelating agent is 1 to 10 kilograms per ton of pulp, and hydrogen peroxide, sodium hydroxide and sodium silicate are simultaneously added during bleaching. In the alkali hydrogen peroxide bleaching process of the paper pulp, the urea serving as the active agent is added at the same time of adding the chelating agent, so that the hydrogen peroxide bleaching efficiency can be improved. Compared with a method without adding the urea serving as the active agent during bleaching, the method has the advantages that: the whiteness of the bleached pulp is obviously improved after the urea is added during bleaching, and the physical strength of the bleached pulp is basically as same as that of the pulp when the urea is not added.

Owner:MCC PAPER YINHE

Microbial Products and Uses Thereof to Improve Oil Recovery

This invention relates to compositions and methods of microbial enhanced oil recovery using biochemical-producing microbes. In specific embodiments, the methods of the subject invention comprise applying a bio surfactant-producing bacteria and / or a growth by-product thereof to an oil-producing site. In preferred embodiments, the bacteria is a strain of Bacillus in spore form. In some embodiments, the methods further comprise applying the bacteria with a yeast fermentation product, an alkaline compound, a polymer, a non- biological surfactant, and / or one or more chelating agents. Advantageously, the subject invention can be useful for stimulating the flow of oil from a well, as well as dissolving scale present in an oil-bearing formation.

Owner:LOCUS SOLUTIONS IPCO LLC

Composite greenhouse capable of recycling oxygen, carbon dioxide and the like inside

InactiveCN107926375ATo achieve mutual complementarityReduce manufacturing costClimate change adaptationAgriculture gas emission reductionGreenhouseThermal insulation

The invention provides a compound greenhouse capable of recycling oxygen, carbon dioxide and the like inside. The composite greenhouse is composed of a sun-facing greenhouse body, a shade greenhouse body and a middle wall, wherein the sun-facing greenhouse body is located on the sun-facing side, the shade greenhouse body is located on the shade side; the sun-facing greenhouse body and the shade greenhouse body are connected together through the shared middle wall, the middle wall is provided with two rows of vent holes up and down, and ventilation equipment is installed at the vent holes. Edible mushrooms in the shade greenhouse body generate respiratory heat at night and thus play a role in thermal insulation and temperature increase of the sun-facing greenhouse body, solar radiation heatabsorbed by the sun-facing greenhouse body in the daytime can increase the temperature of the shade greenhouse body, the sun-facing greenhouse body and the shade greenhouse body supplement each otherand can achieve thermal insulation and temperature increase in agricultural production in the greenhouse in winter, and energy is saved. Air fertilizers are supplied, carbon dioxide and oxygen reasonably flow, transform and are reasonably used, metabolism is promoted, the cost is reduced, and the efficiency is greatly improved.

Owner:王永显

Cooling method and system of high-temperature directly reduced iron

InactiveCN102181595APrevent oxidationPrevent burstFluidised-bed furnacesChemical reactionWater vapor

The invention discloses a cooling method and a system of high-temperature directly reduced iron. Under the protection of protective gas, firstly, water mist is directly sprayed to the high-temperature directly reduced iron so that the high-temperature directly reduced iron cools over 620 DEG C, and then water is sprayed or fed to the outer wall of the vessel of the directly reduced iron for cooling purpose, thus indirectly cooling the directly reduced iron. By analyzing the chemical reaction property of iron and steam, the method concludes that the iron above 620 DEG C does not react with steam. Therefore, the method can realize rapid cooling effect by first directly cooling the high-temperature directly reduced iron, and also avoid oxidation of iron by water. Then, the directly reduced iron is cooled to required temperature by a regular indirect cooling method. At the time, yet without direct contact of water with directly reduced iron, the oxidation of iron by water is avoided. The whole cooling process proceeds under the protection of protective gas, thus preventing iron from being oxidized by air. Compared with the method of totally indirect cooling, the method of first direct cooling and second indirect cooling is higher in cooling efficiency, and can also prevent iron from being oxidized for a second time or balls from bursting.

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com