Device for cyclically removing carbon dioxide using calcium-based absorbent with steam activated reactor and method for cyclically removing carbon dioxide using calcium-based absorbent

A calcium-based absorbent and carbon dioxide technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of capture performance degradation, absorbent deactivation, etc., and achieve the effect of improving thermal economy and energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

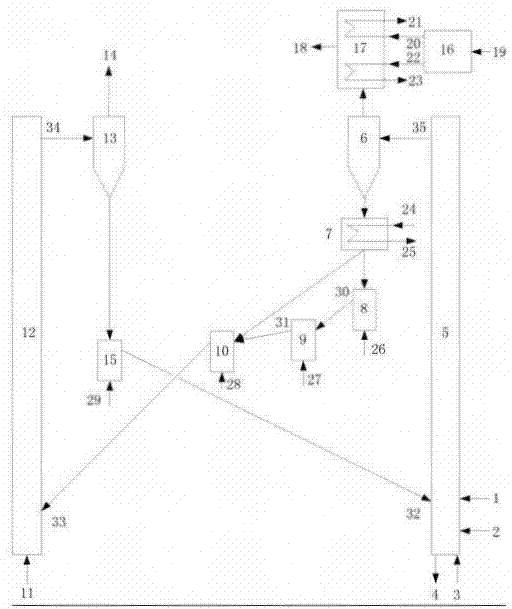

[0039] Air 19 is sent into air separation unit 16 and is separated into nitrogen 20 and oxygen 22; Nitrogen 20 passes through CO 2 The heat exchanger is heated to high-temperature nitrogen gas 21 and sent to the fluidized bed dehydration regeneration reactor 9 as a fluidized medium, and at the same time, it is used for the dehydration reaction Ca(OH) 2 →CaO+H 2 O for heat; oxygen 22 by CO 2 The heat exchanger is preheated to send high-temperature oxygen 23 into the fluidized bed calcining decomposition reactor 5 bottom oxygen inlet 3 as a fluidizing medium, and at the same time provide an oxidant for the pure oxygen combustion of carbon-based fuels;

[0040] The temperature of the fluidized bed calcination decomposition reactor 5 is 800-1000°C, fresh calcium-based absorbent and carbon-based fuel are respectively fed into the fresh absorbent inlet 1 and carbon-based fuel inlet 2 in the middle and lower part of the reactor, and the carbon-based fuel and high-temperature oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com