Energy-saving heat pump and co-generation coupled heating system and coupled heating method

A coupling system and combined heat and power technology, applied in the energy field, can solve the problems of heating loads that cannot be expanded and waste heat, etc., and achieve the effects of saving investment, operation and maintenance workload, saving floor space, and improving thermal economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

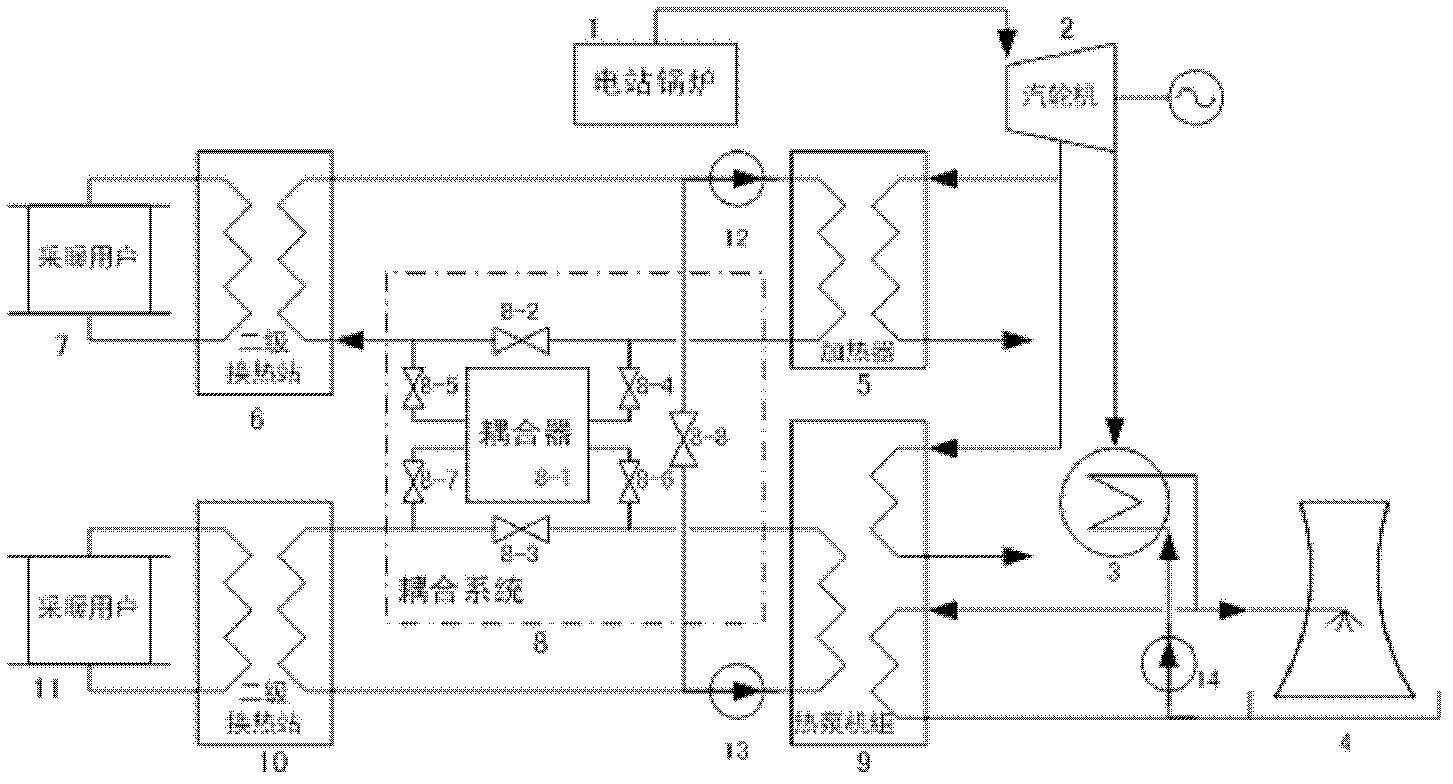

[0019] figure 1 It is a schematic diagram of the structural form of a heat pump and cogeneration coupled heating system. The system adopts the realization form of dual heat network heating, including steam turbines, steam turbine condensing equipment, steam turbine circulating cooling equipment, steam absorption heat pumps, and heat network heaters. , secondary heat exchange station and corresponding pipelines and ancillary equipment.

[0020] Boiler 1 is connected to steam turbine 2 through pipelines, and the exhaust steam of steam turbine 2 is connected to steam turbine condensing equipment 3; the circulating water outlet of steam turbine condensing equipment 3 is connected to circulating water cooling equipment 4 and steam absorption heat pump unit 9 through pipelines, and the circulation cooling The circulating water return water of equipment 4 and heat pump unit 9 is connected to steam turbine condensing equipment 3 via circulating water pump 14; The return water of the ...

Embodiment 2

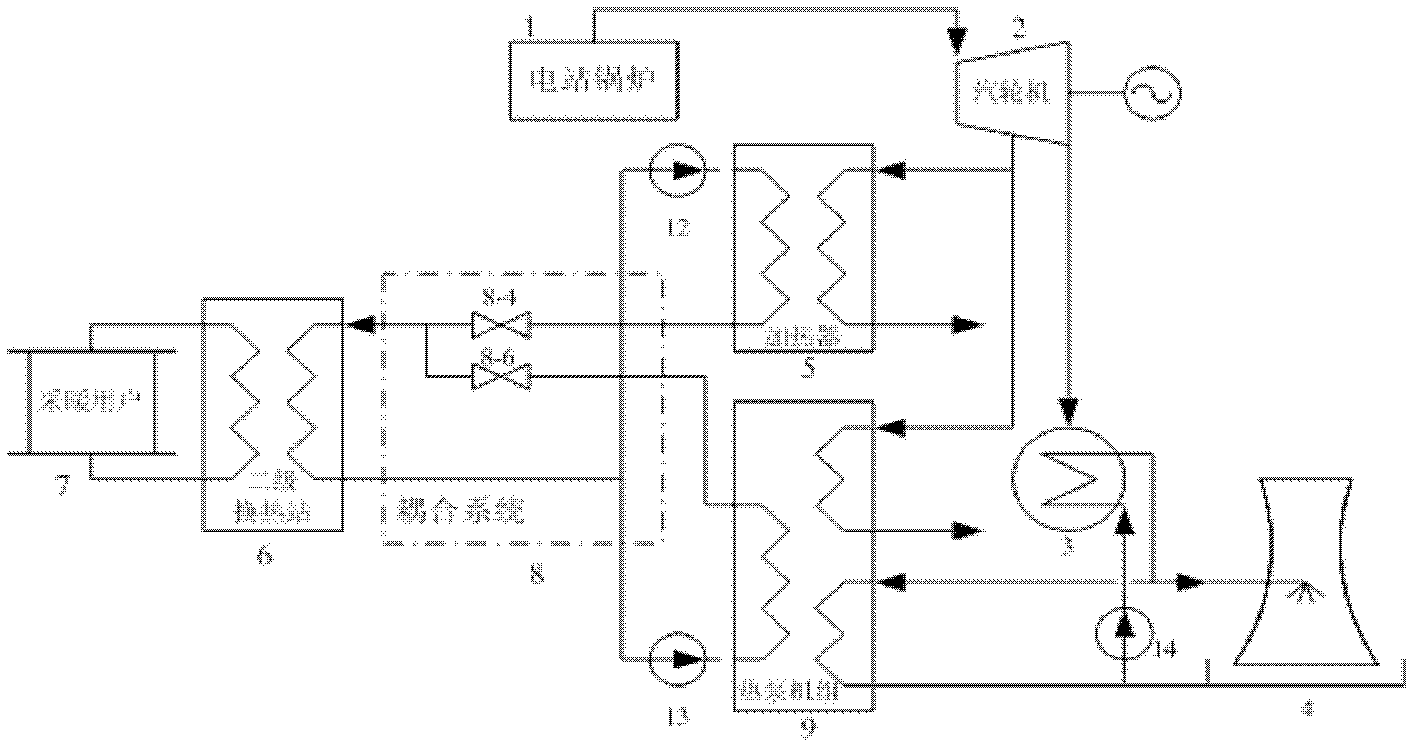

[0024] figure 2 Shown is a schematic diagram of the structural form of the heat pump and cogeneration coupled heating system of the simplified coupled system. The system adopts the realization form of single heating network heating, including steam turbine, steam turbine condensing equipment, steam turbine circulating cooling equipment, steam absorption heat pump, heating network heater, heat exchange station and corresponding pipelines and auxiliary equipment. In the figure, the structure of the coupling system is that the heater-side inlet valve 8-4 connected to the heat network heater 5 and the heat pump-side inlet valve 8-6 connected to the heat pump unit are jointly connected to the coupling system, and are connected to each two through the coupling system. stage heat exchange station, the heat network return water pipe is connected to the inlet end of the first heat network circulating water pump 12 and the second heat network circulating water pump 13; figure 1 same. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com