Patents

Literature

350results about How to "Save investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image-processing device and method for enhancing the luminance and the image quality of display panels

InactiveUS20060146351A1Increase brightnessGood effectDigitally marking record carriersStatic indicating devicesImaging processingImaging quality

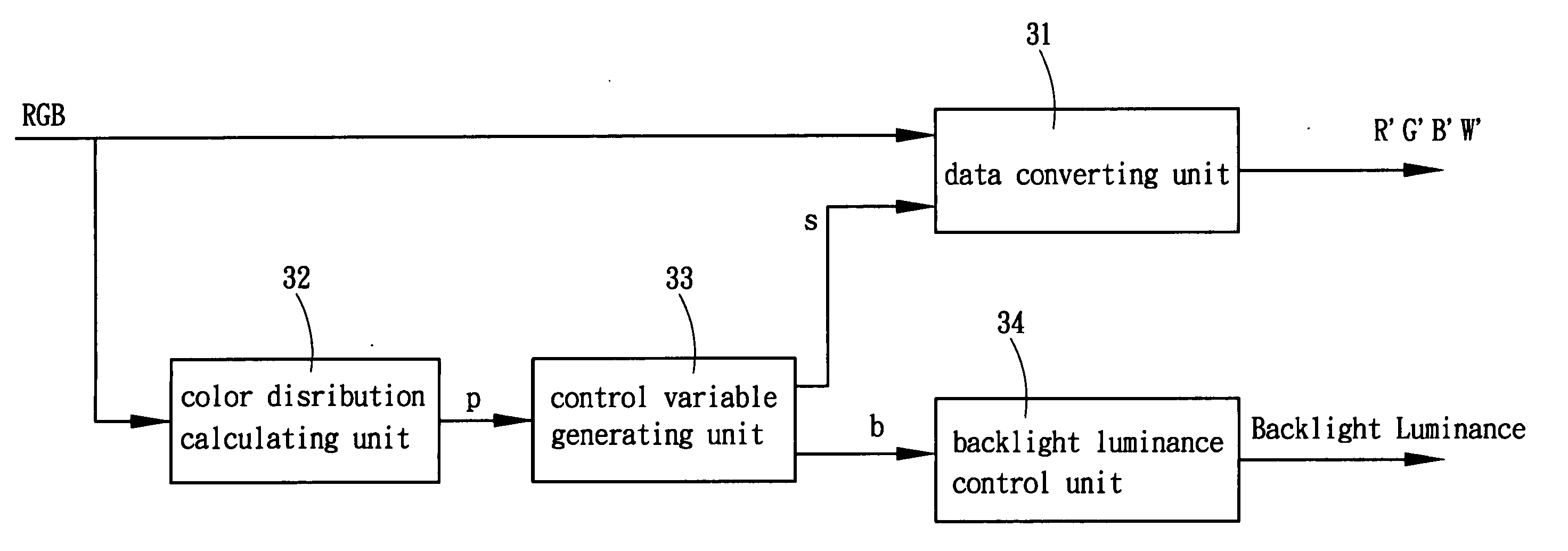

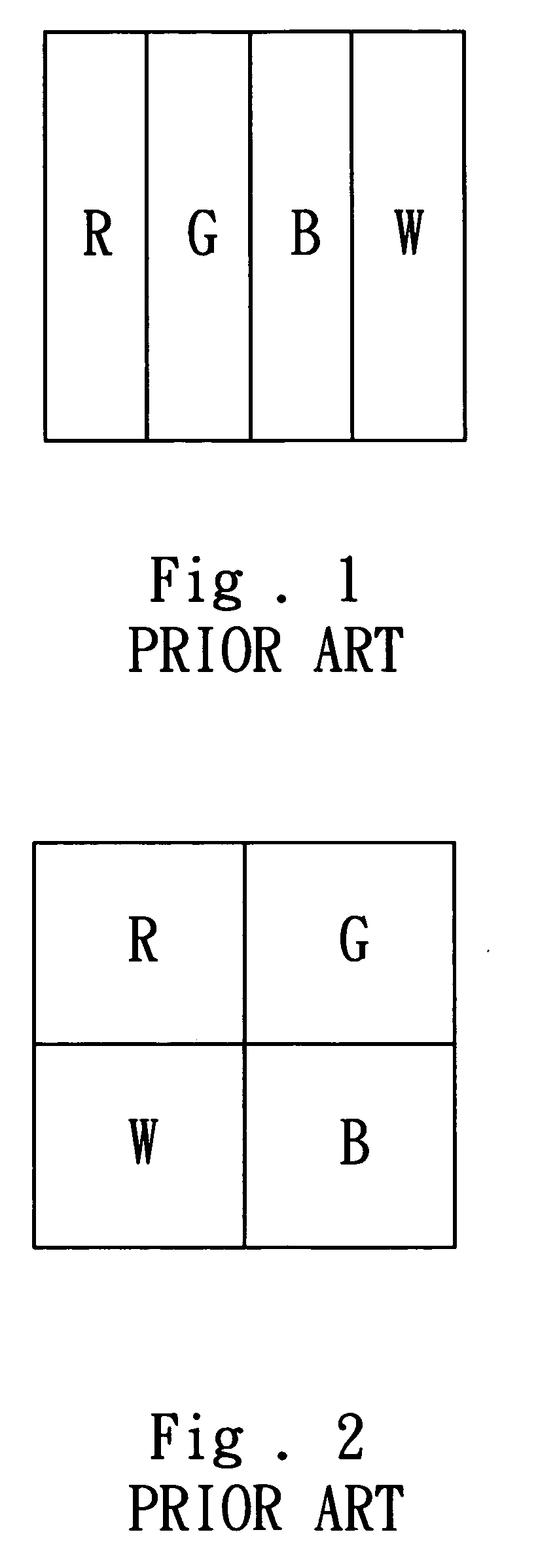

An image-processing device and method for enhancing the luminance and the image quality of display panels, the device and method includes a color distribution calculating unit which classifies the original image-color data, and then calculates the ratio of the color data in block B2 to all input image-color data. A control-variable generating unit determines the value of the converting-control variable and the value of the backlight luminance-control variable according to the ratio. The converting-control variable will be output to a numerical converting unit so as to convert the original image-color (RGB) data to the new image-color (R′G′B′W′) data. The backlight luminance-control variable will be output to a backlight luminance-control unit so as to control the backlight luminance.

Owner:WINTEK CORP

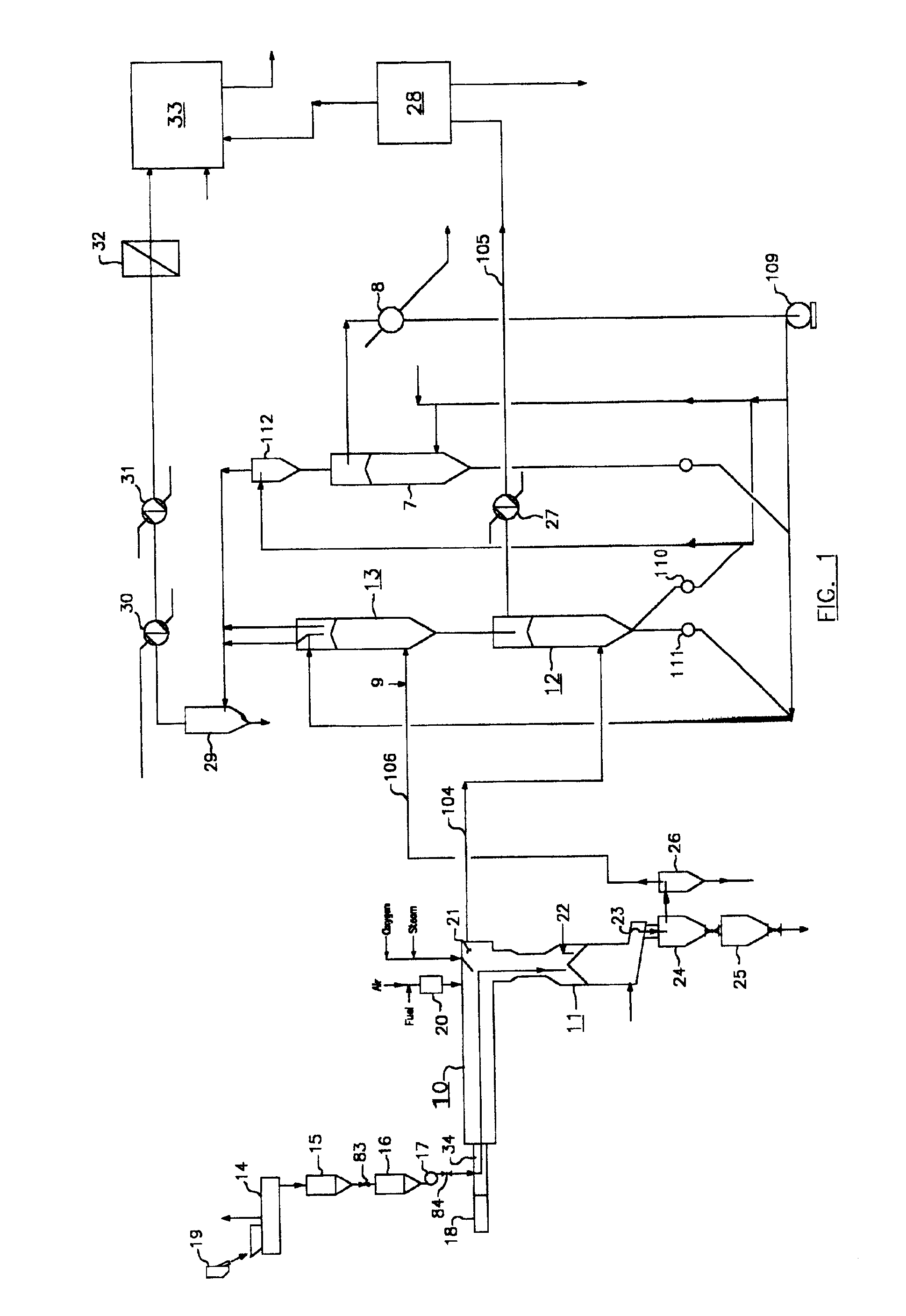

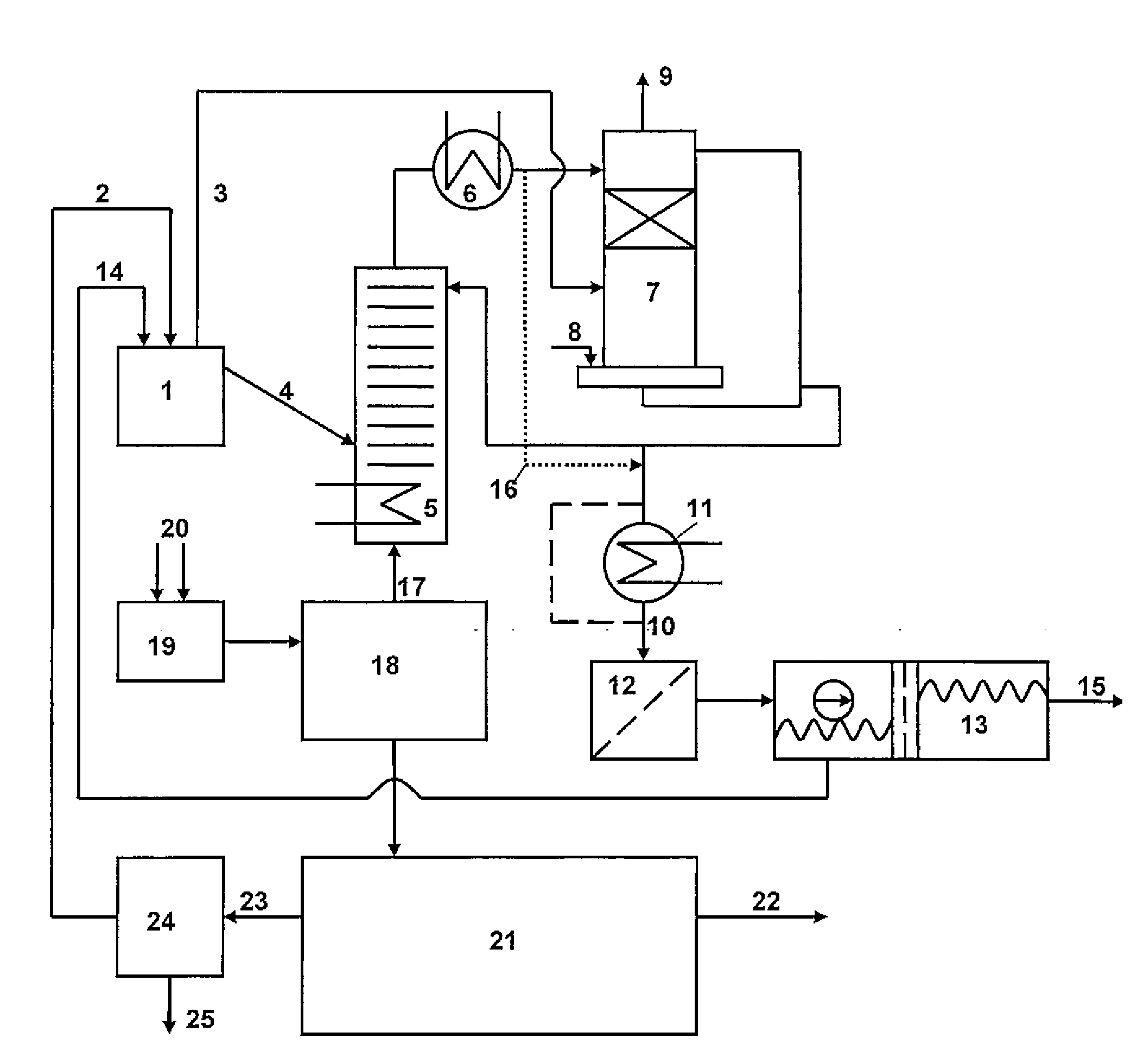

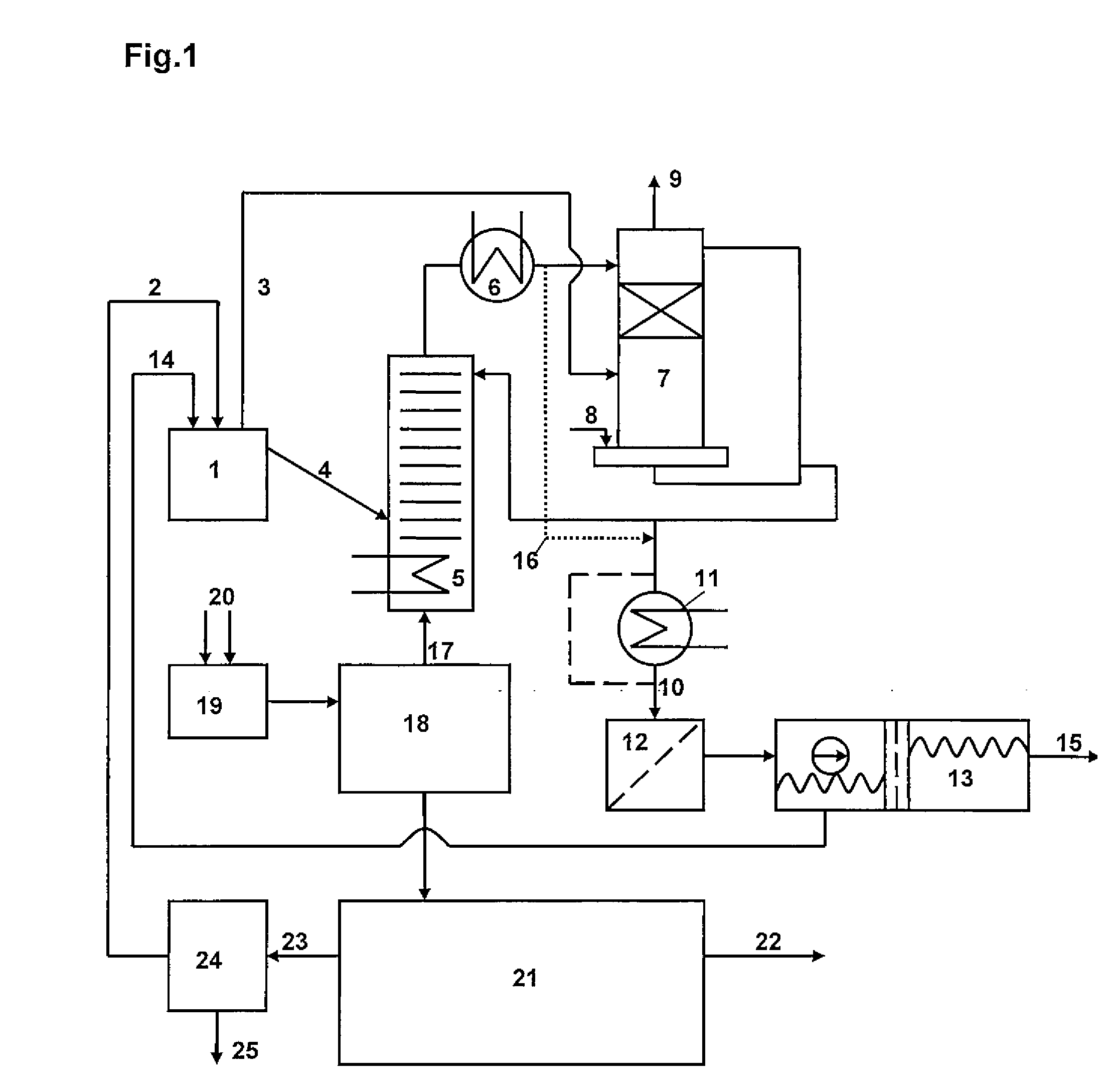

Method for producing clean energy from coal

InactiveUS6911058B2Produce energyImprove efficiencyThermal non-catalytic crackingMuffle furnacesActivated carbonGas turbines

Owner:CALDERON SYNGAS CO

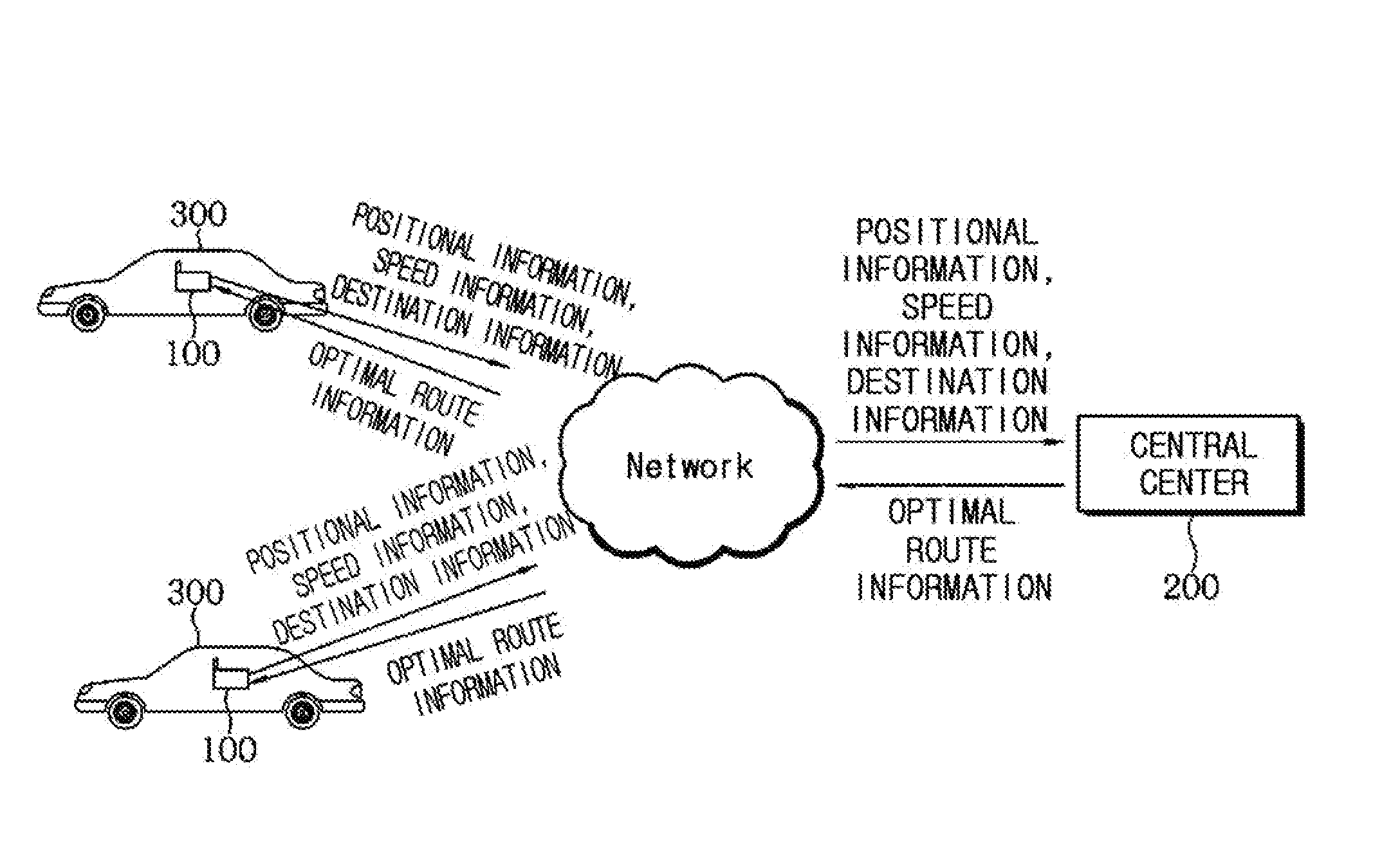

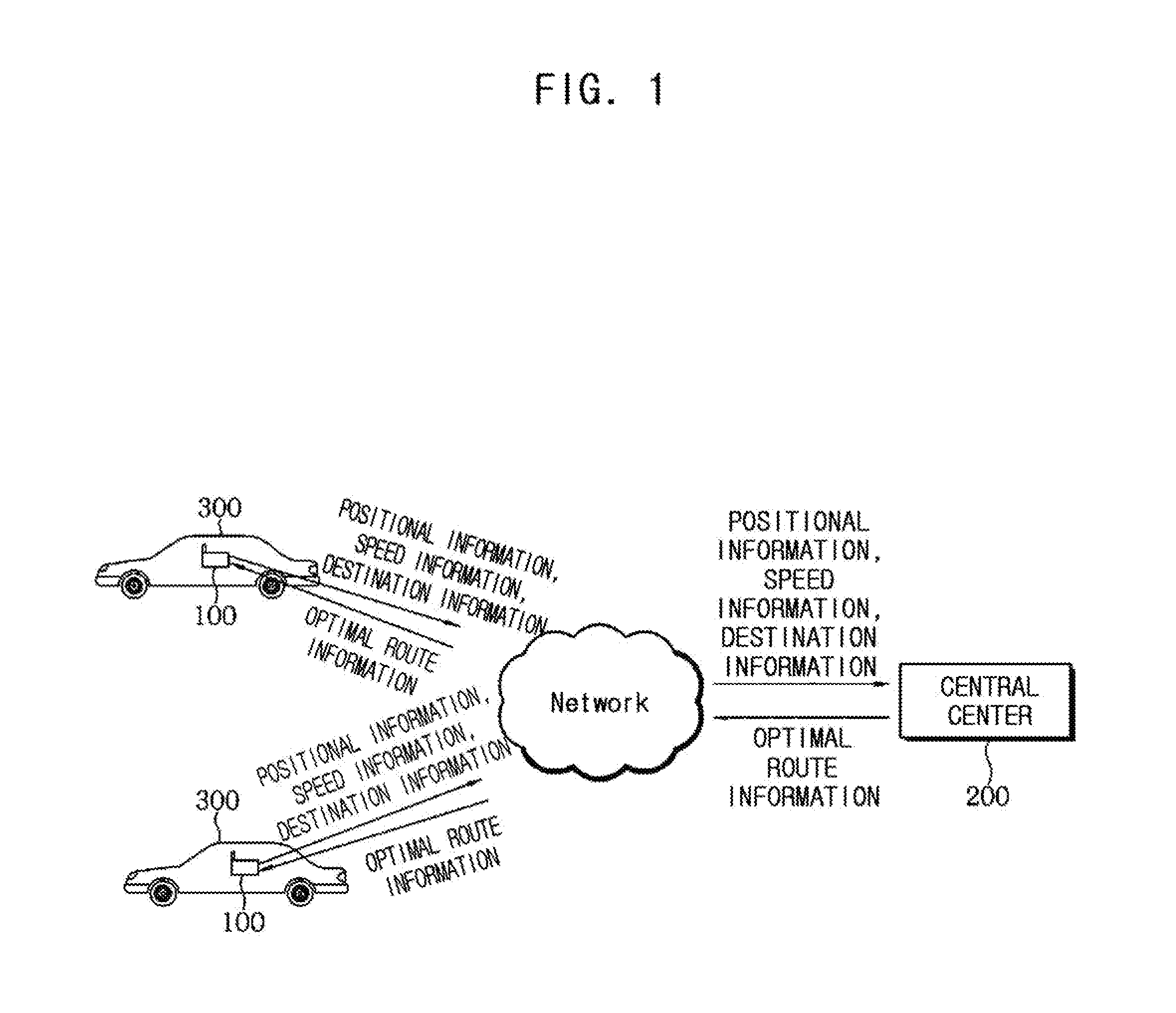

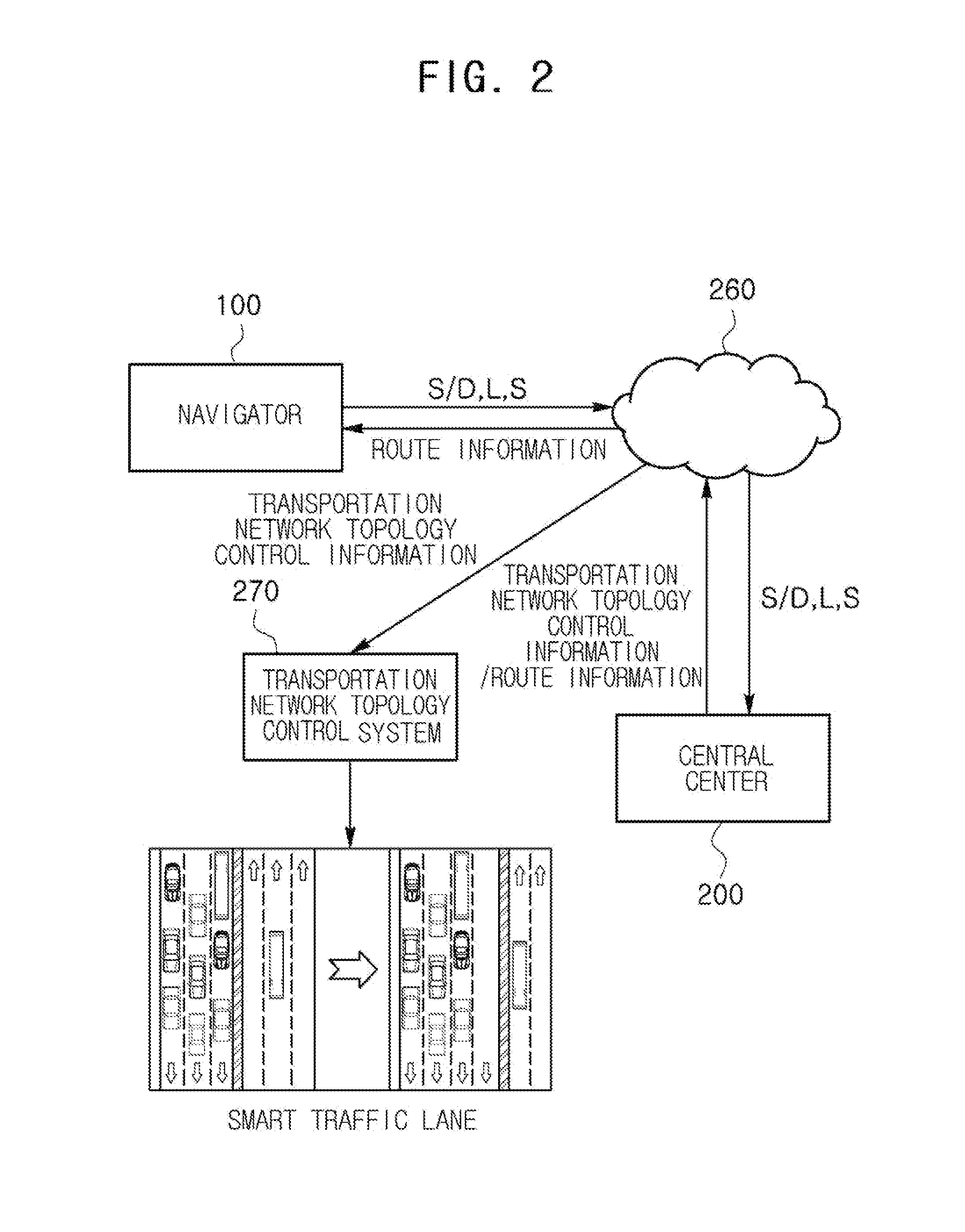

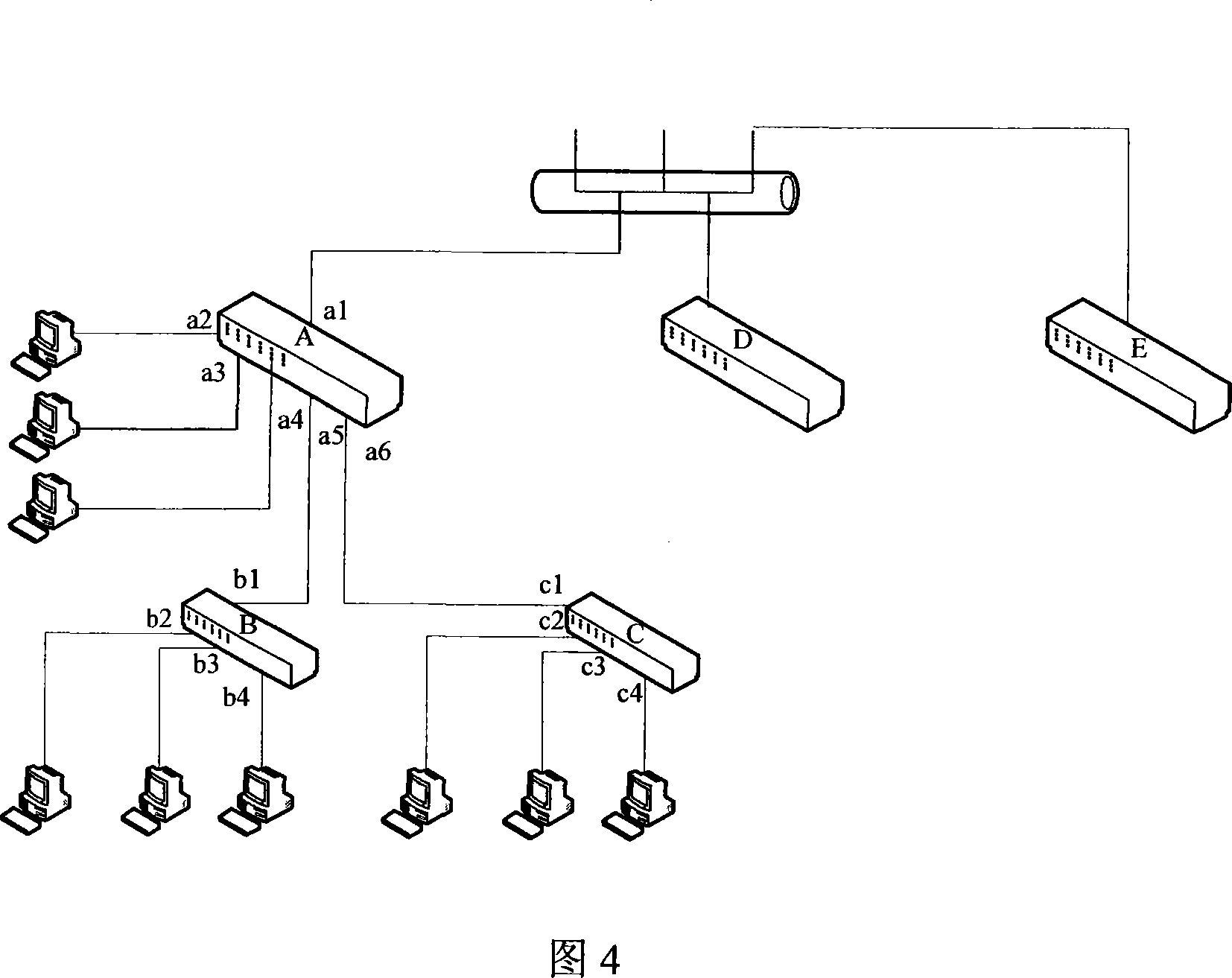

Real-time transportation network topology control-combined traffic flow control and dynamic route guidance system using in-vehicle navigator with bidirectional communication and parking guidance and reservation system using the same

ActiveUS20150219463A1Save investmentMaintenance savingControlling traffic signalsAnalogue computers for vehiclesGuidance systemStructure of Management Information

Provided are a real-time traffic flow control and dynamic route guidance system, a parking guidance system using the same, and a method thereof capable of guiding a vehicle distribution. and a transportation flow by collecting positional information, destination information, a vehicle moving speed, and the like from each vehicle in real time at one or a plurality of central centers by using an in-vehicle navigator with bidirectional communication and a GPS to dynamically calculate and provide an optimal route of an individual vehicle so as to make a flow of the entire transportation network smooth and perform a control for a transportation network structure through various kinds of traffic control devices installed on roads.

Owner:KOREA UNIV RES & BUSINESS FOUND

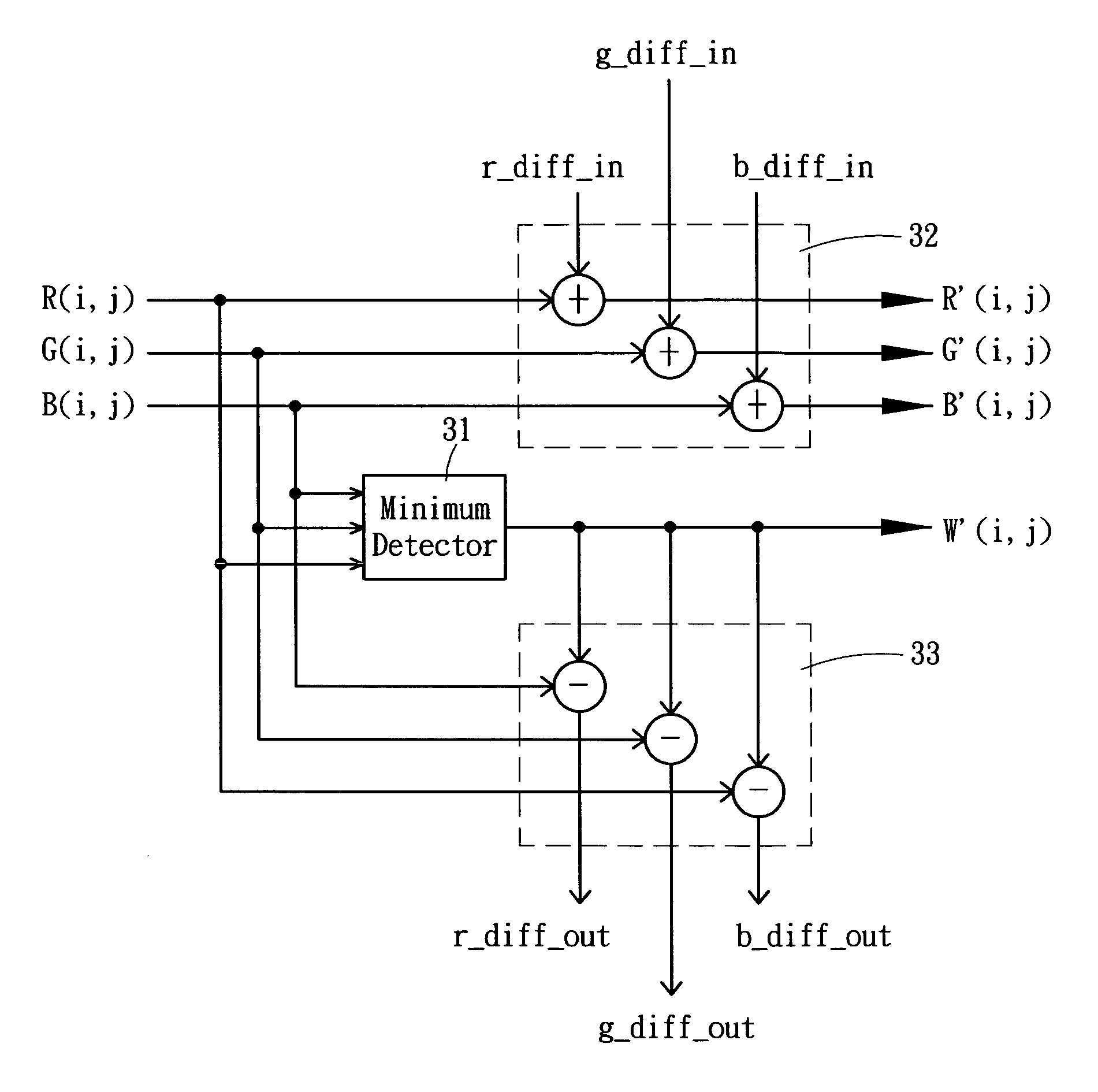

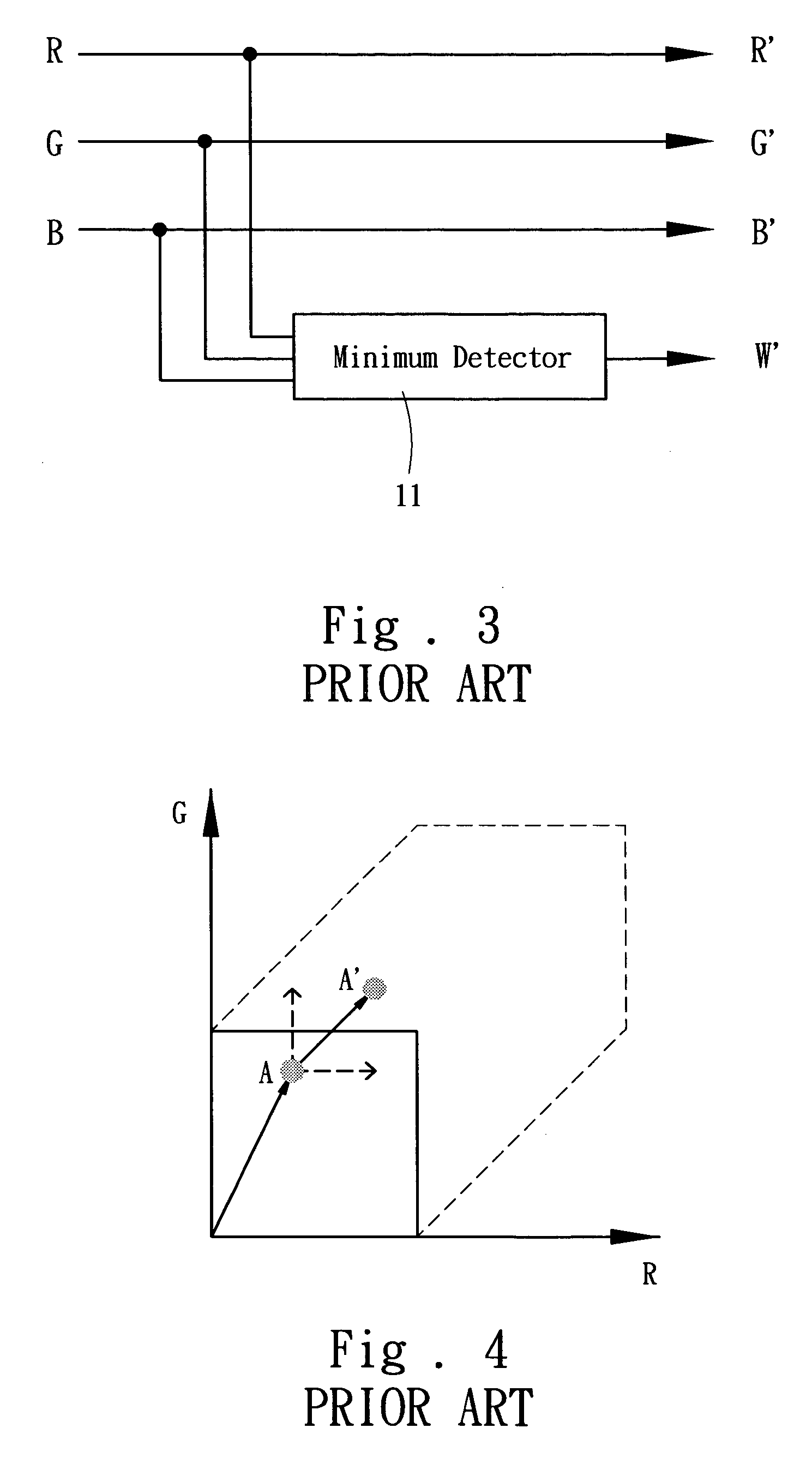

Method and apparatus for four-color data converting

InactiveUS20060274212A1Increase brightnessGood effectColor signal processing circuitsBrightness and chrominance signal processing circuitsHueData value

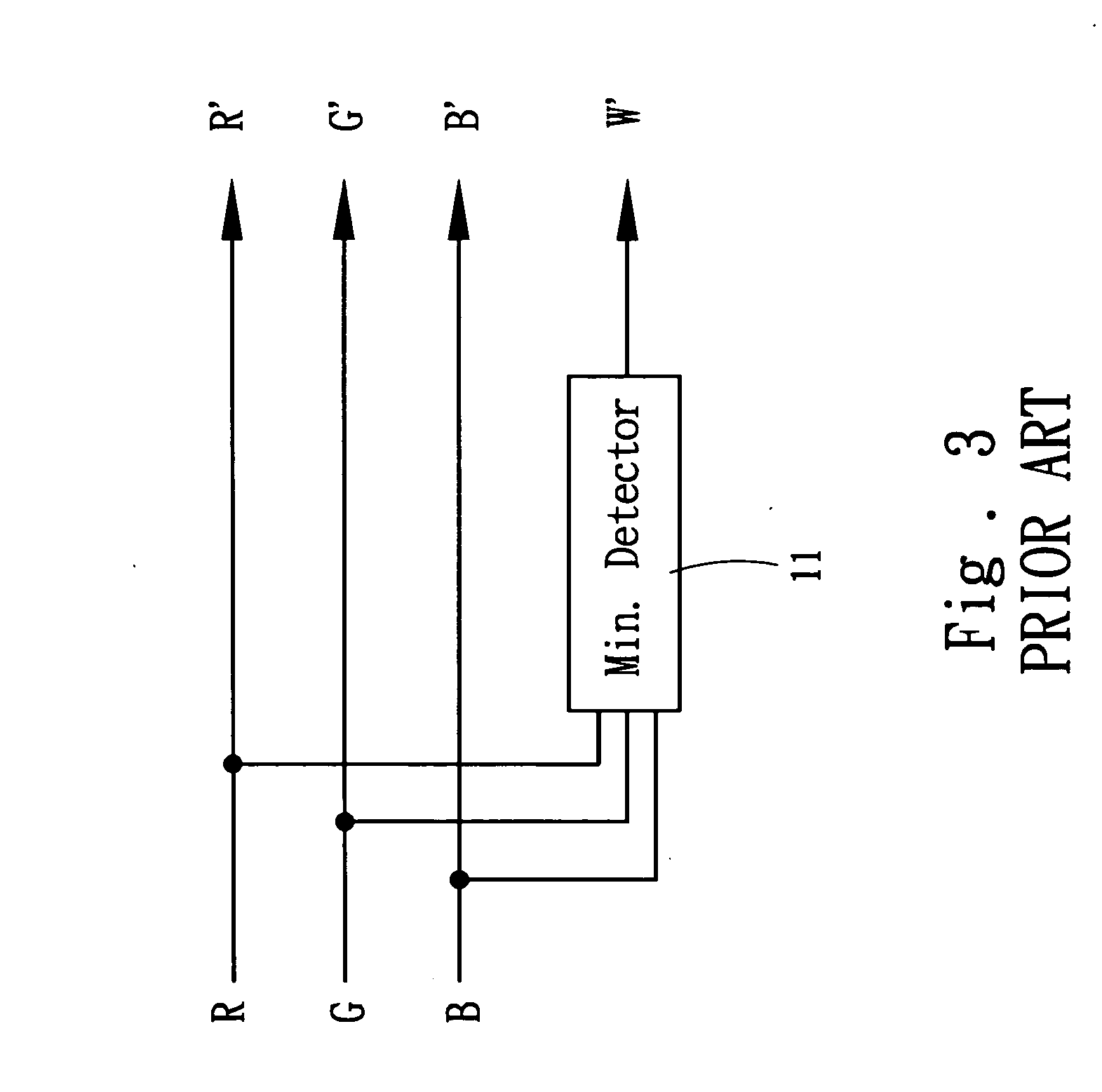

A data converting for red, green, blue, and white four colors, after a pixel extracts a minimum value of red, green, and blue by using a minimum-value extractor to be the white light data value of the pixel converted to red, green, blue, and white four-color system; and then calculates a difference values among colors red, green, and blue of the pixel. The difference values of three colors are added to the neighboring pixels or sub-pixels such that at the same time when the red, green, blue, and white four-color system increases the luminance of the image color, the hue and saturation of the image color can be compensated adequately so that the image color can be very close to the situation of the original red, green, and blue three-color system.

Owner:WINTEK CORP

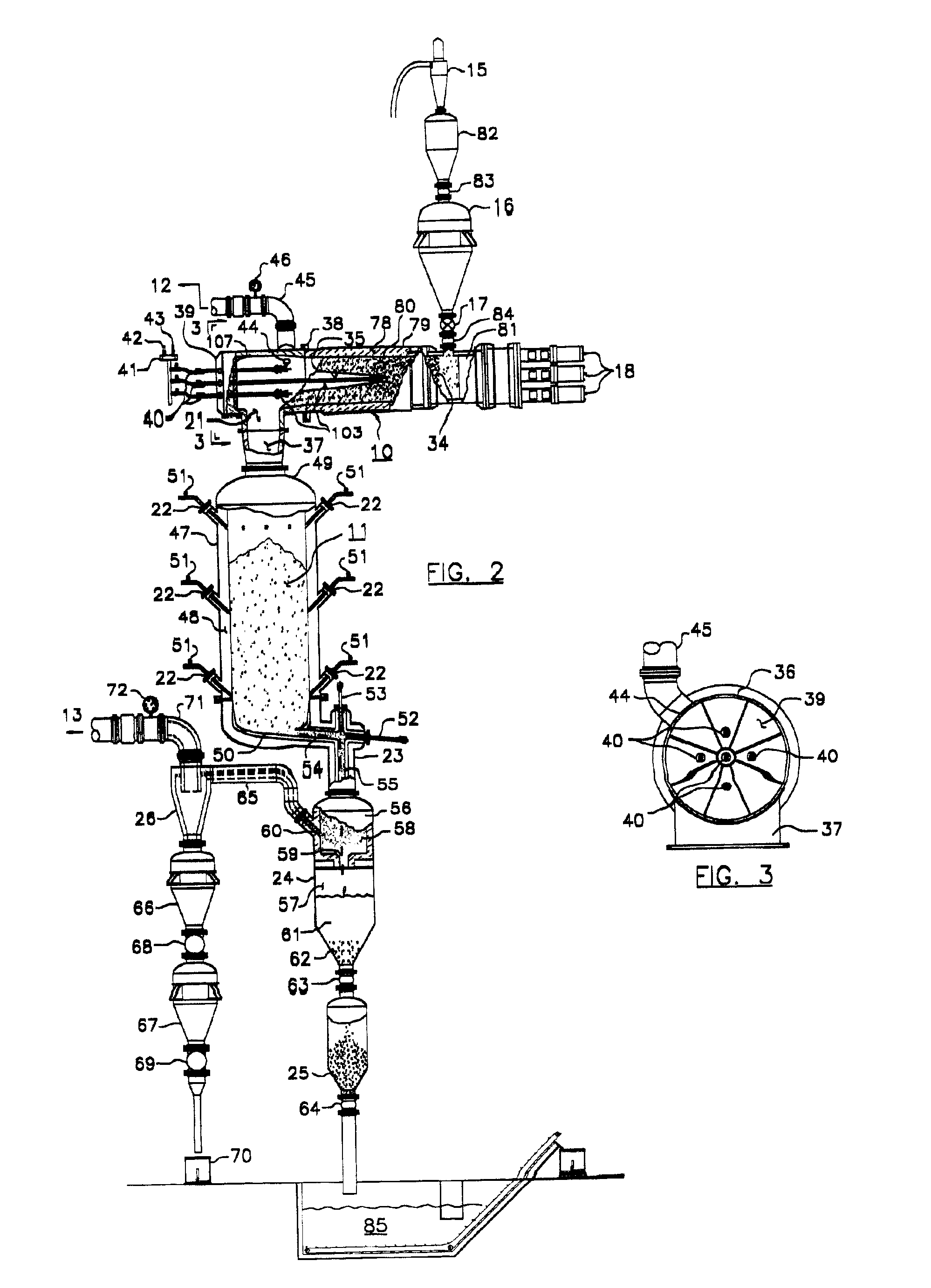

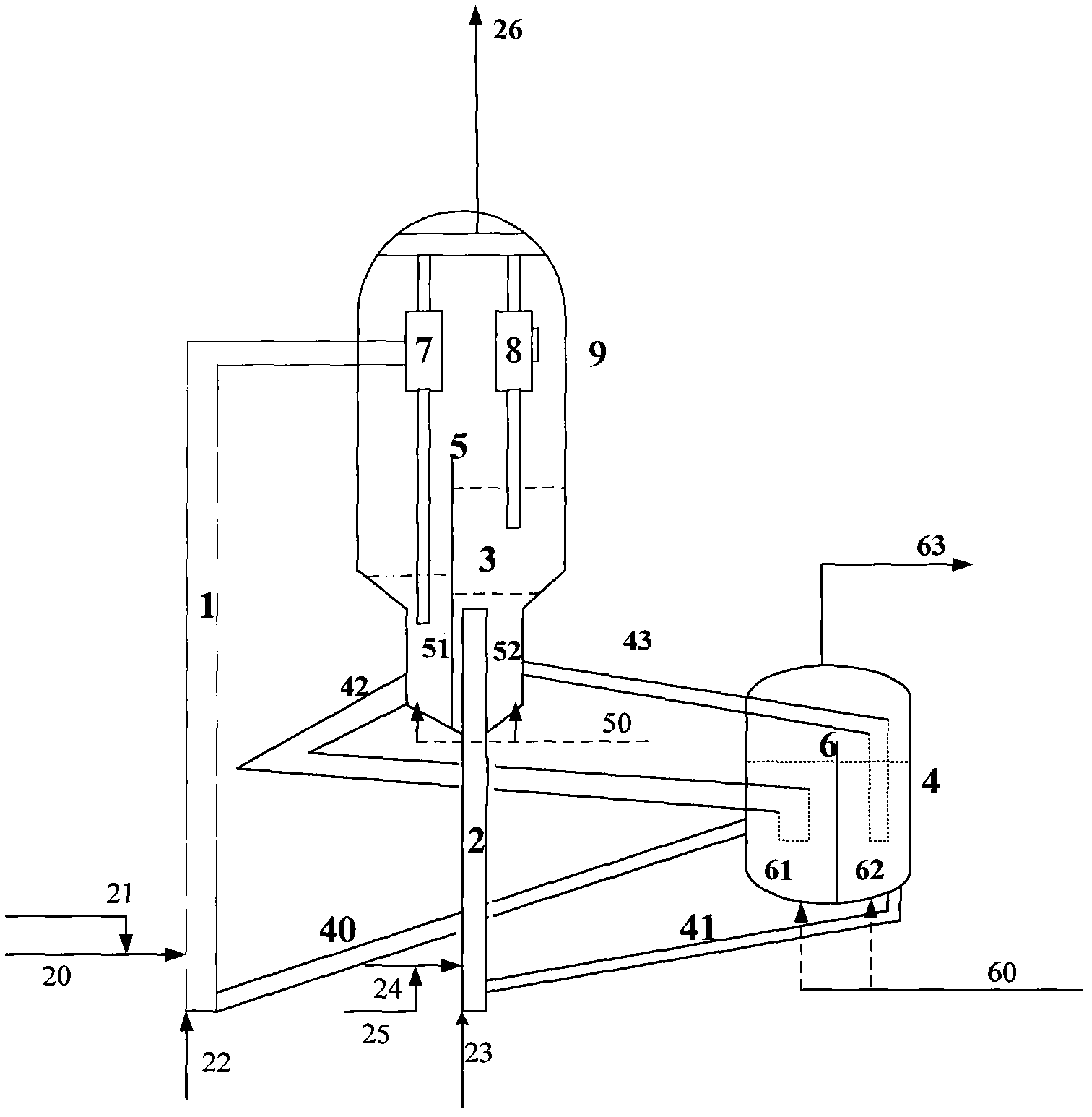

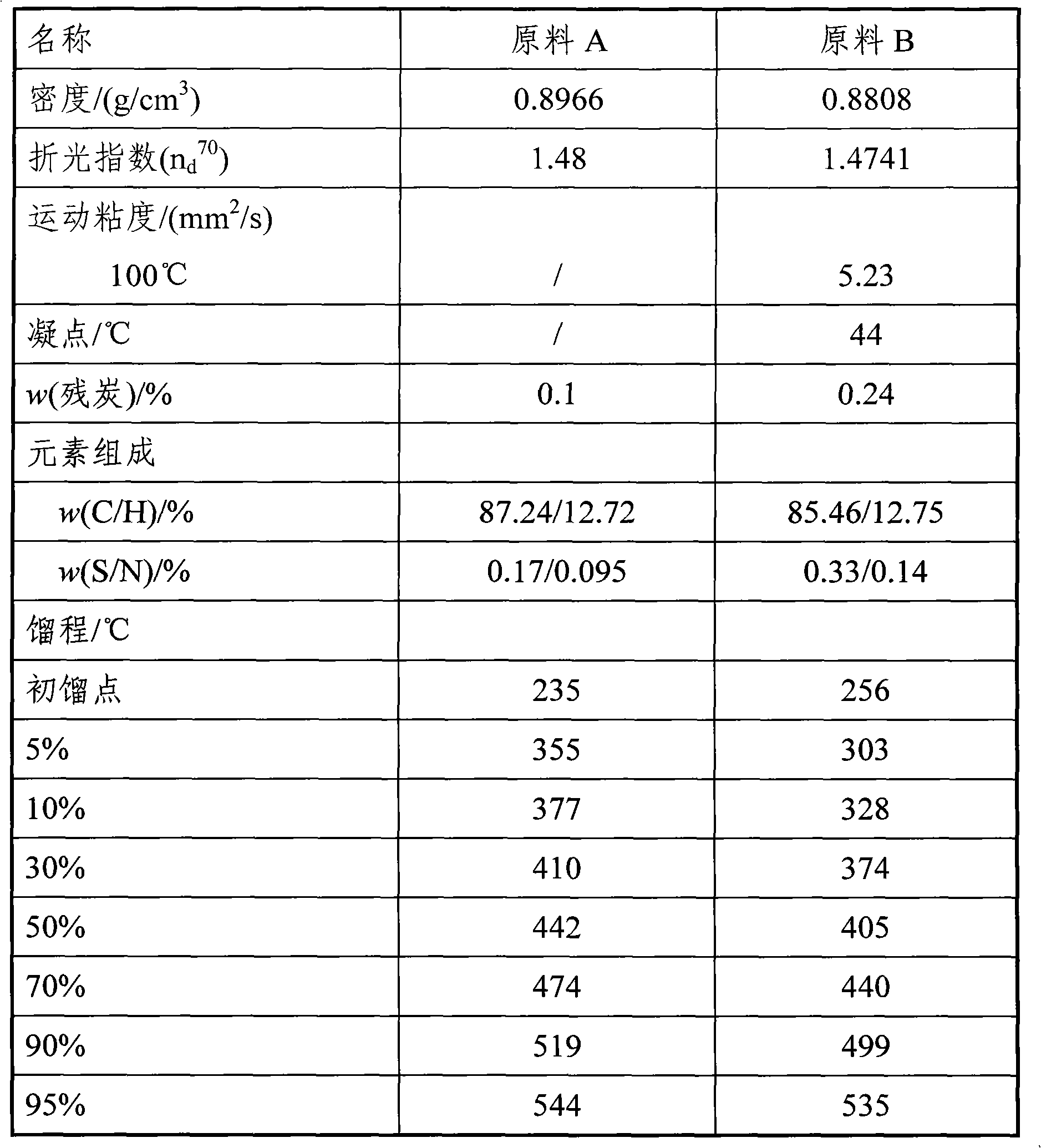

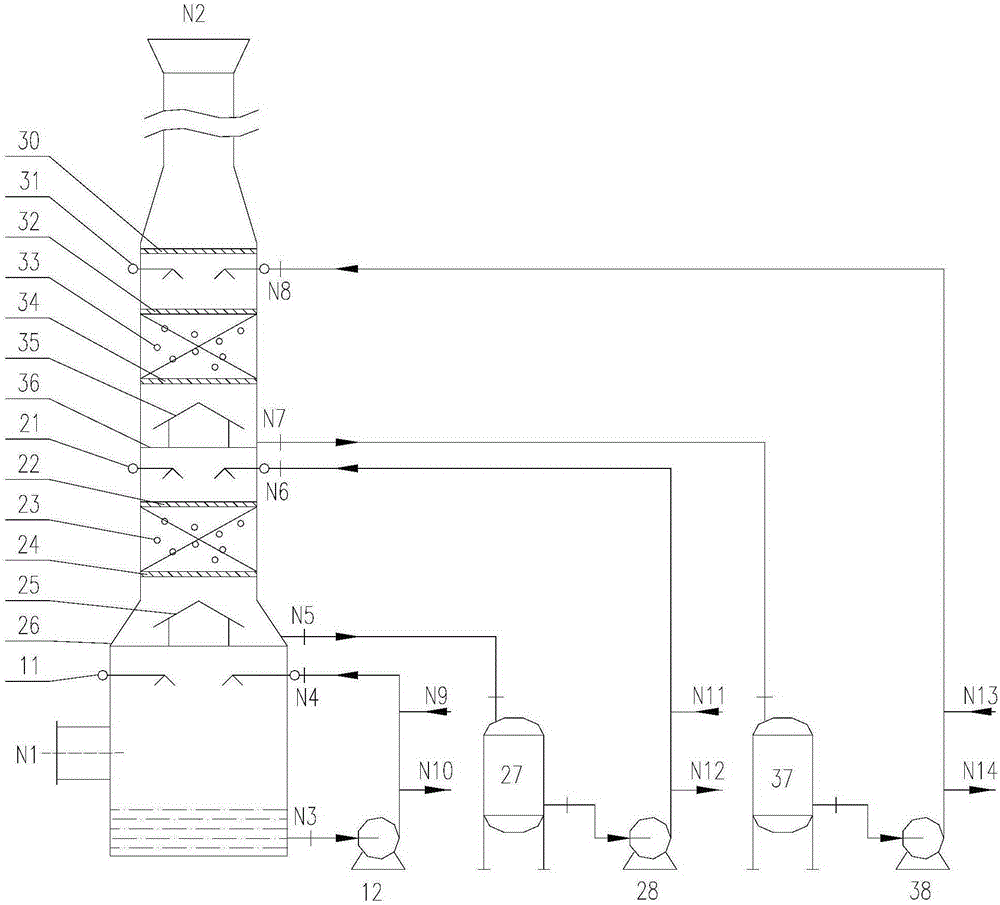

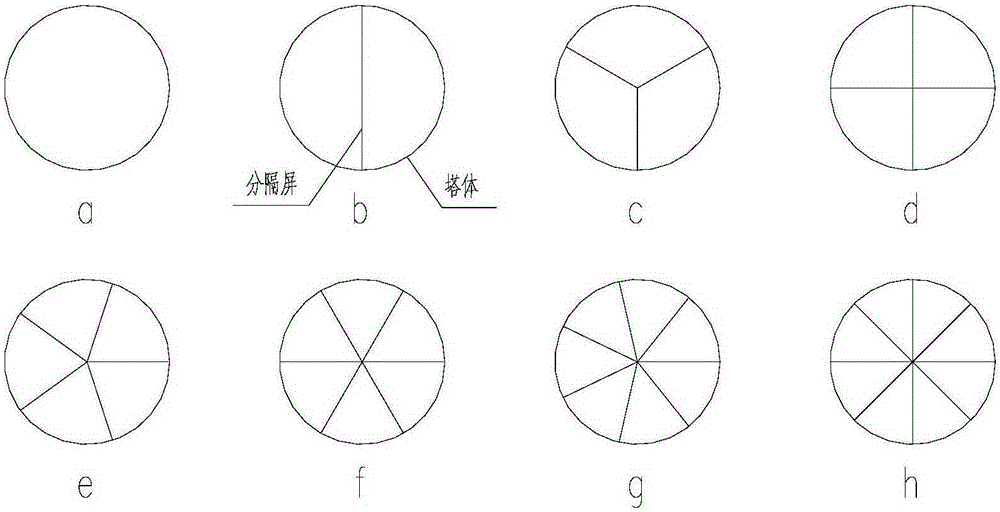

Catalytic cracking method and catalytic cracking device for producing propylene

ActiveCN102690682AHigh yieldImprove conversion rateTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionButeneFluidized bed

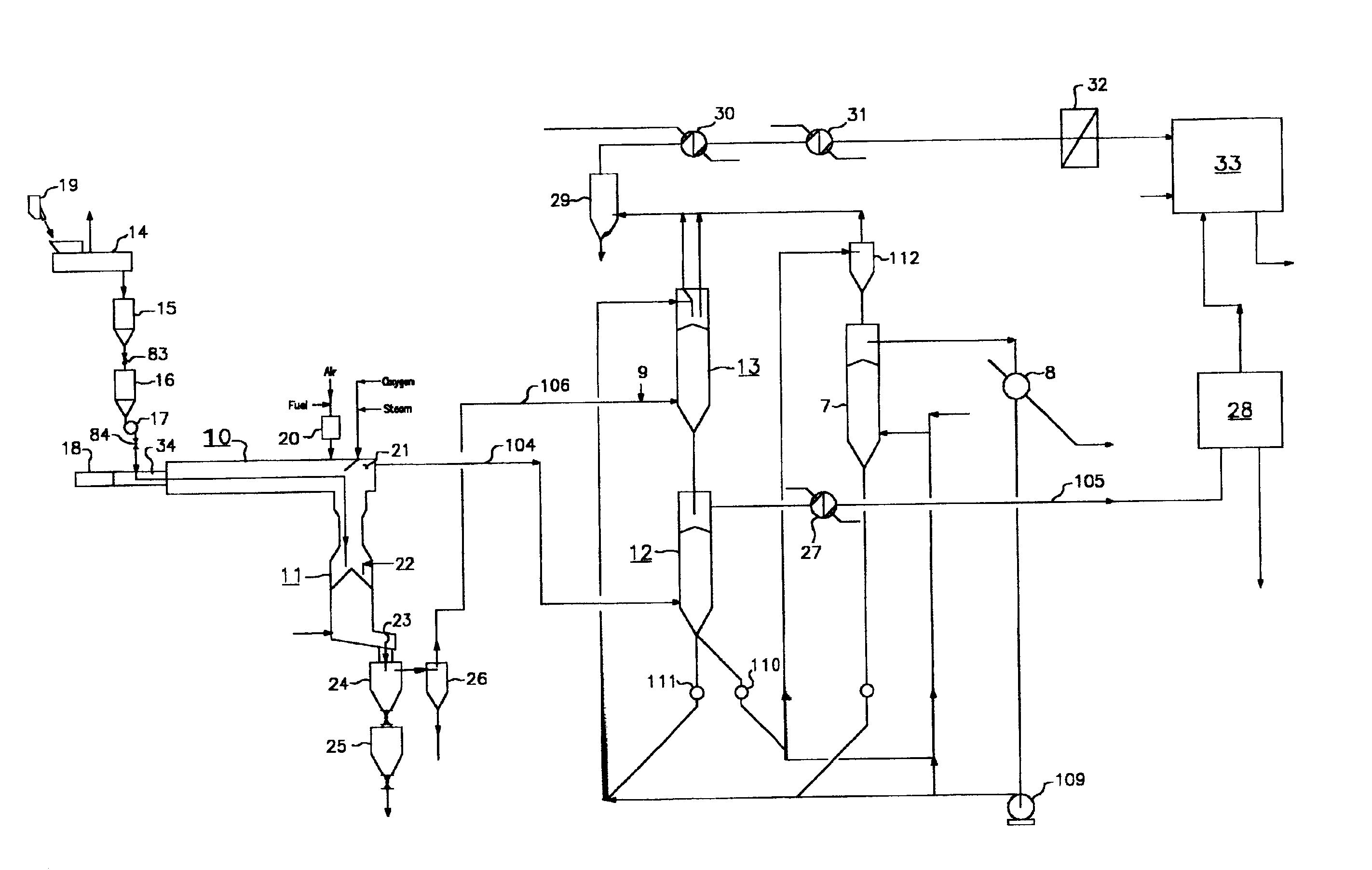

The invention discloses a catalytic cracking method and a catalytic cracking device for producing propylene. The catalytic cracking method comprises the following steps that one or more heavy raw materials and a first catalytic cracking catalyst comprising a main active component of Y-type zeolite undergo a contact reaction in a first riser reactor; one or more light hydrocarbons and a second catalytic cracking catalyst comprising a main active component of shape-selective zeolite having aperture sizes less than 0.7nm undergo a contact reaction in a second riser reactor; and reacted oil gas and the catalysts are introduced into a fluidized bed reactor connected to the second riser reactor in series and then undergo a reaction. A stripper of the catalytic cracking device is divided into two independent stripping zones by a separator plate, wherein one of the two independent stripping zones and a combined reactor composed of one riser and a fluidized bed form one reaction and stripping route; and the other one of the two independent stripping zones and the other riser form the other one reaction and stripping route. The catalytic cracking method has high propylene and butene yields. The catalytic cracking device has a simple structure and can respectively realize a reaction and regeneration in a device by two catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

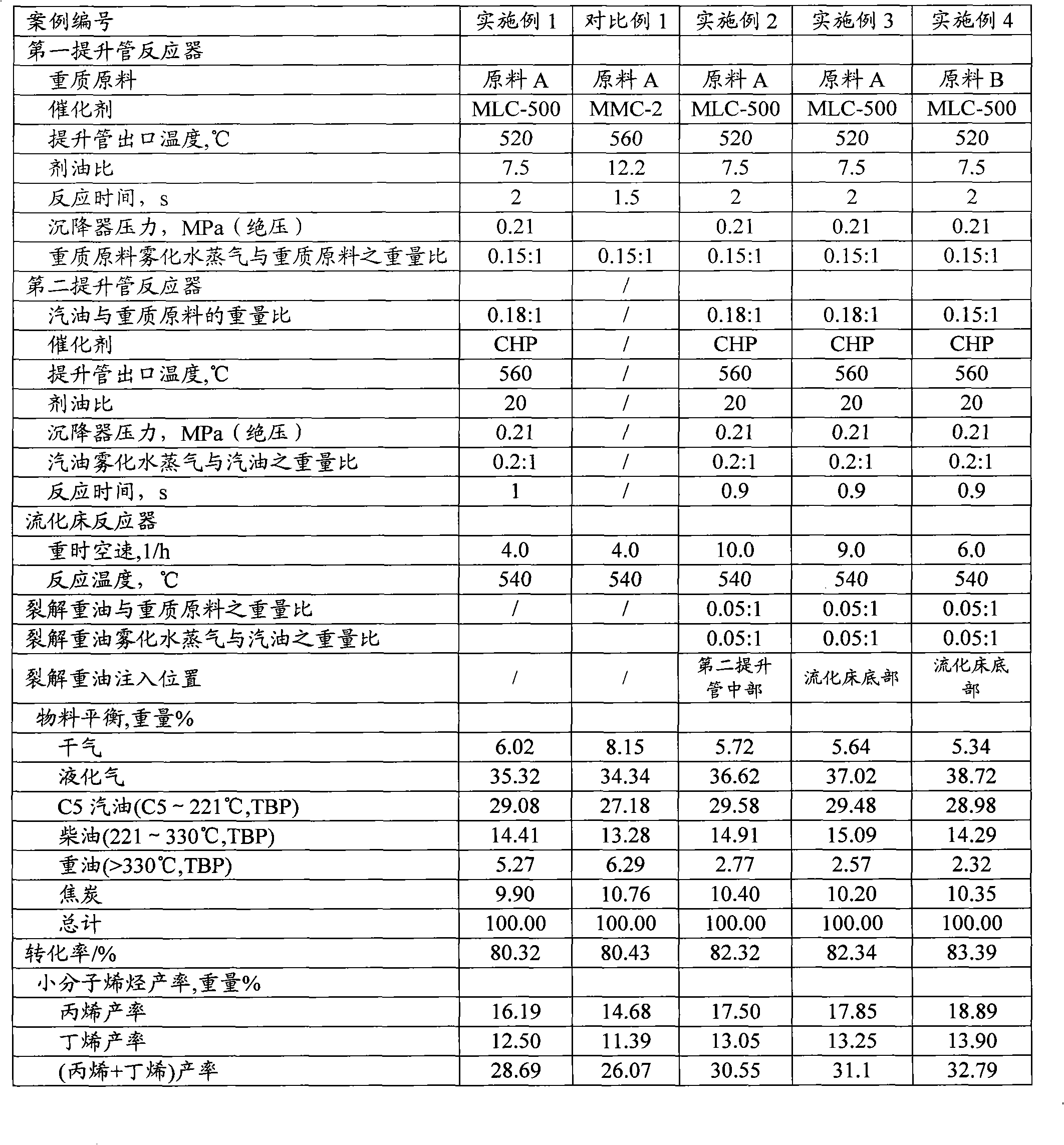

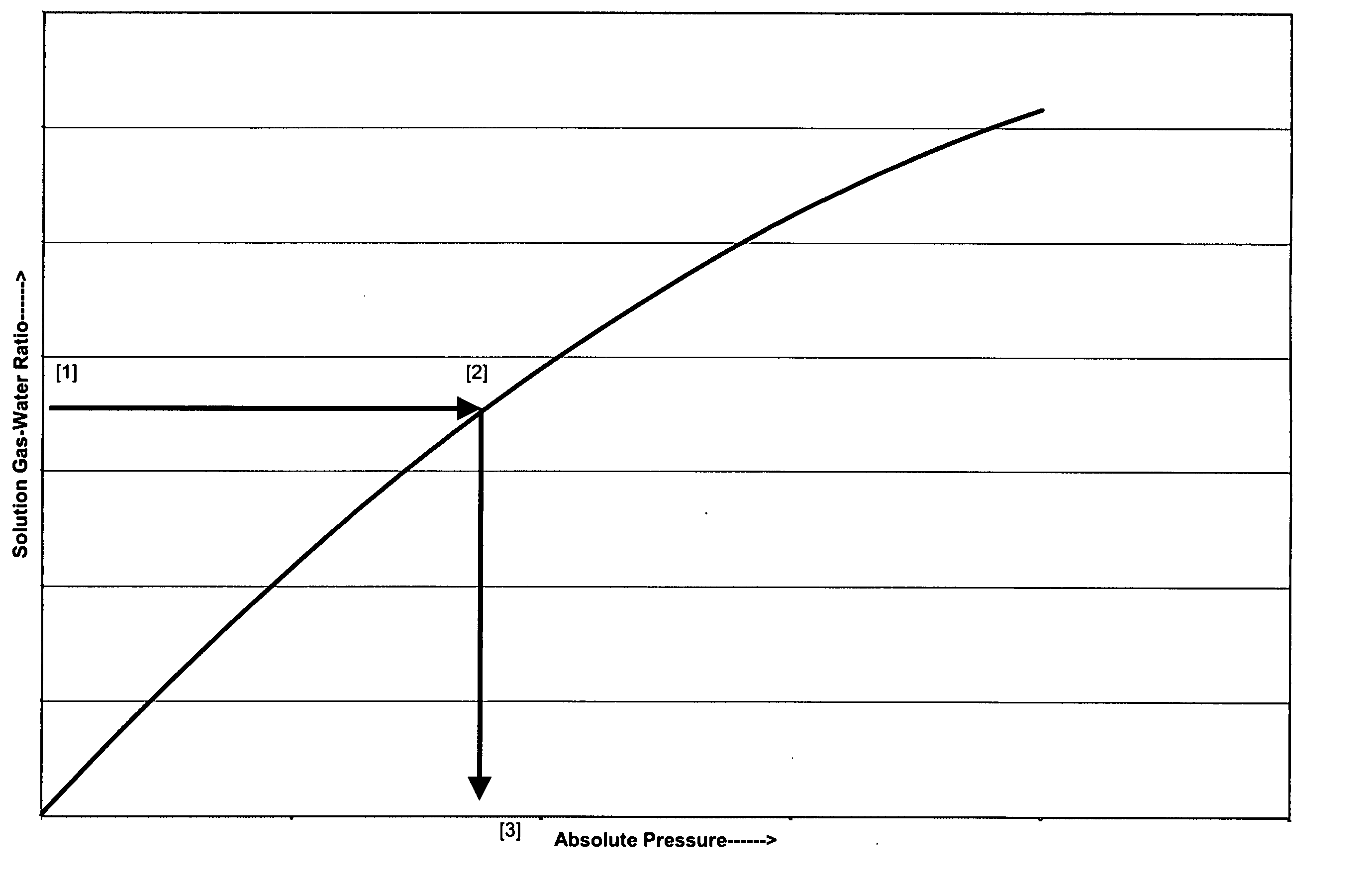

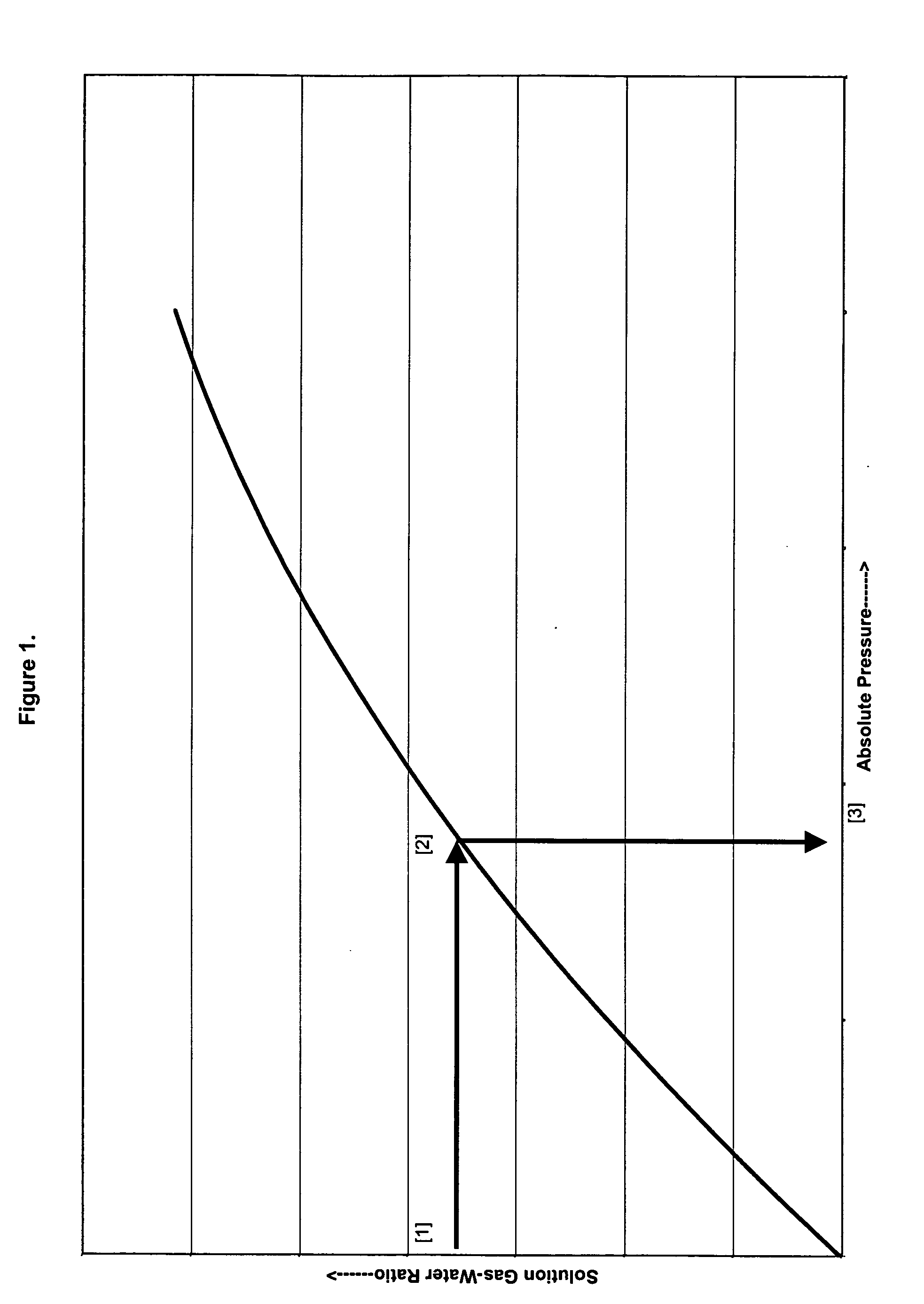

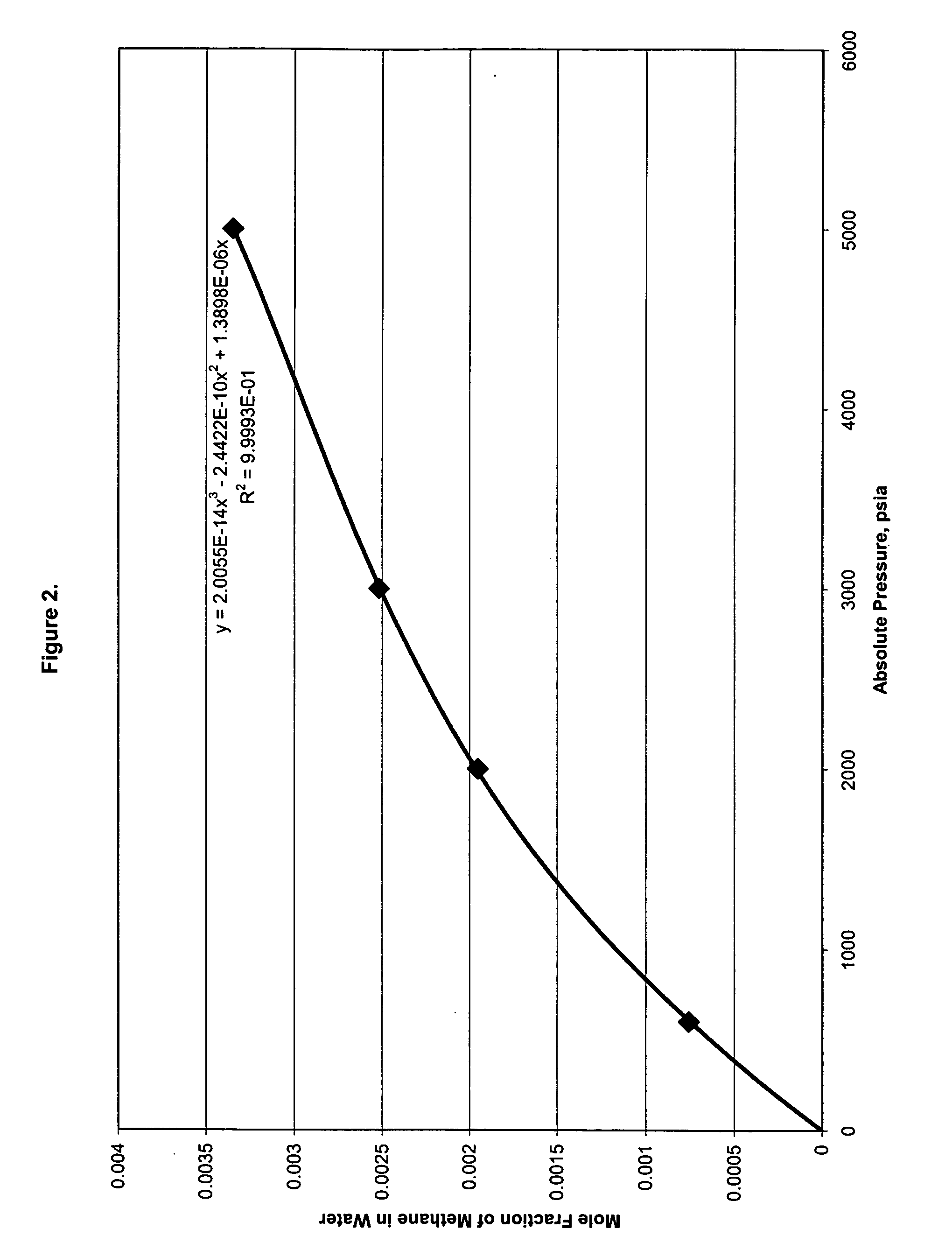

Methods of evaluating undersaturated coalbed methane reservoirs

InactiveUS20050194133A1Quickly and easily and accurately and relatively inexpensively determinedGood estimateSurveyFluid removalDesorptionFormation water

The evaluation and assessment of geologic formations comprising undersaturated coalbed methane reservoirs. In some embodiments, the present invention provides for inductively quantifying critical desorption pressure of the solid in an undersaturated coalbed methane reservoir from an unrelated substance, the formation water. By using these techniques, the characterization of undersaturated coalbed methane reservoirs may be more quickly and economically made based upon a methane content characteristic such as critical desorption pressure, gas content, and in some embodiments gas content as calculated from isotherm evaluation, estimates of dewatering for production, and ratios of critical desorption pressure to initial reservoir pressure, among other possible characteristics. The features of the invention may further have applicability in combination with conventional reservoir analysis, such as coring, logging, reservoir isotherm evaluation, or other techniques.

Owner:YATES HLDG

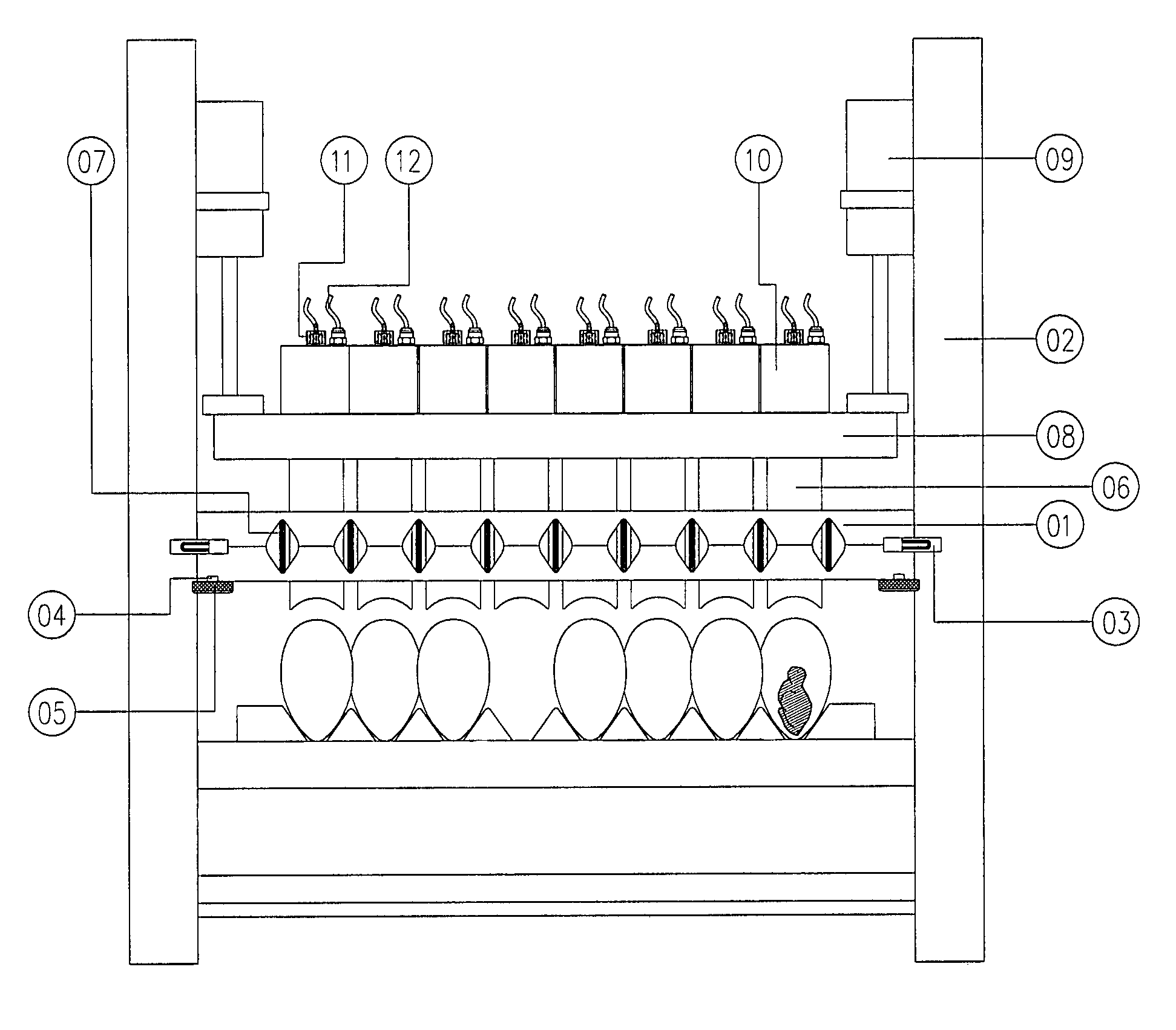

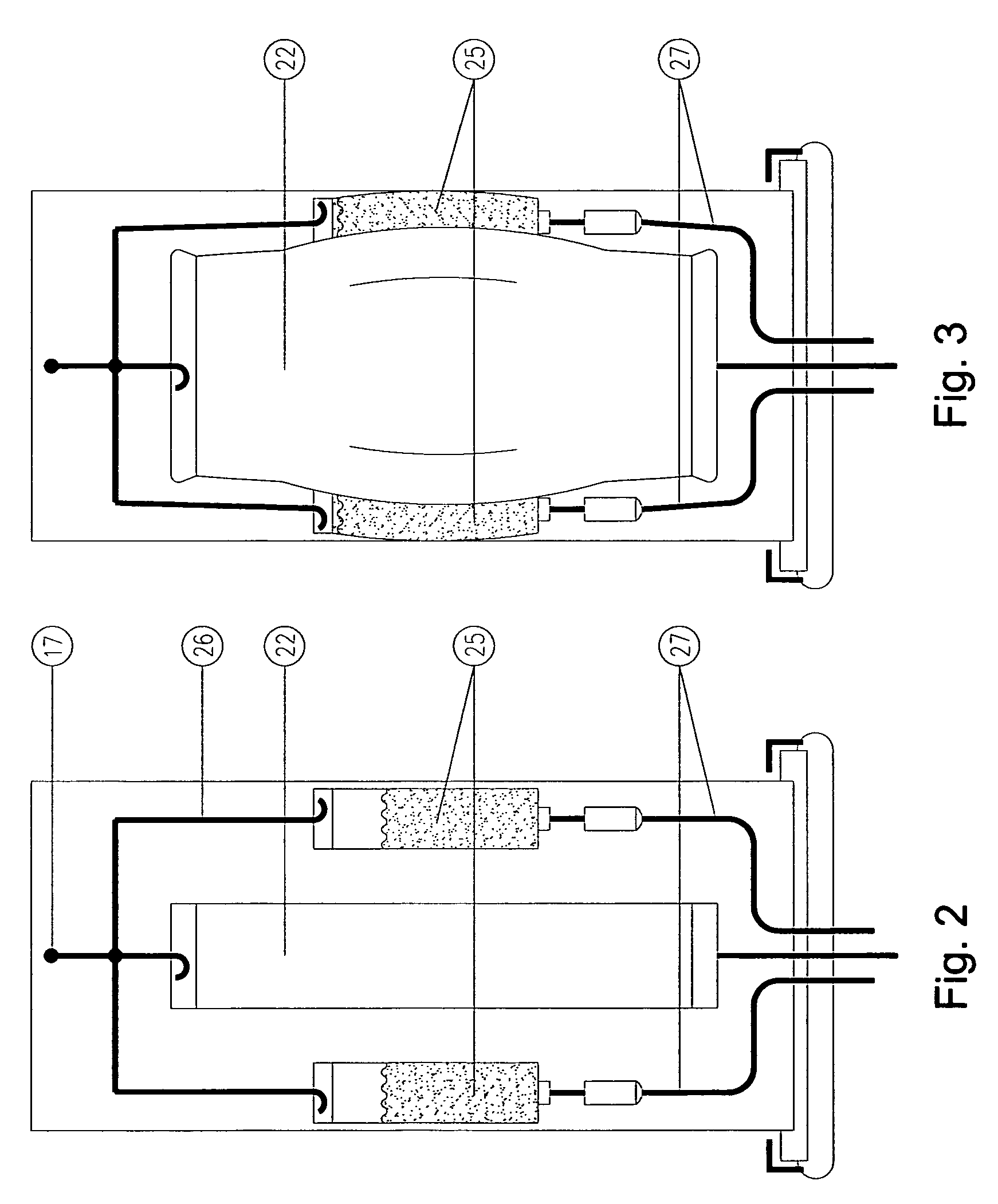

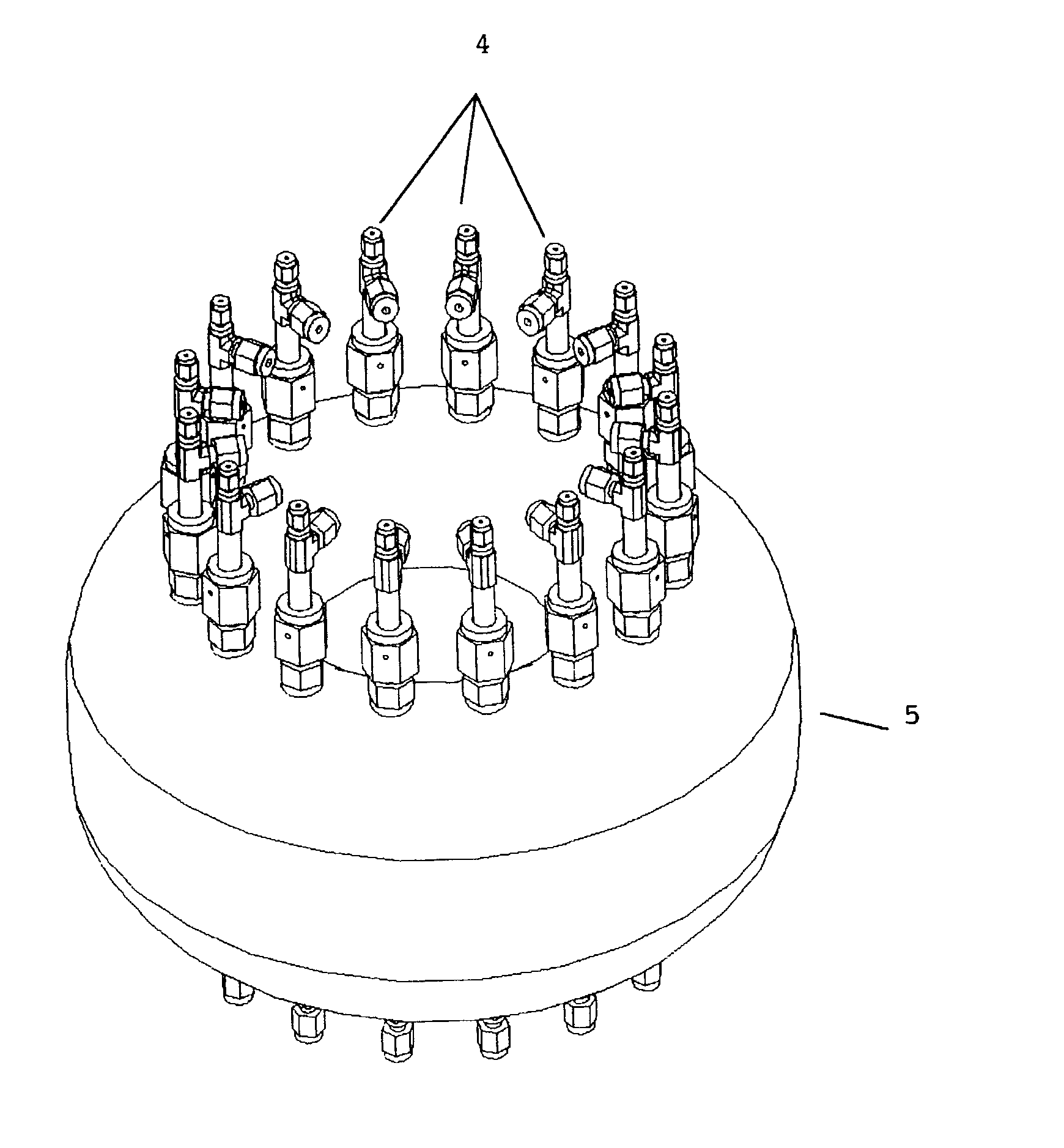

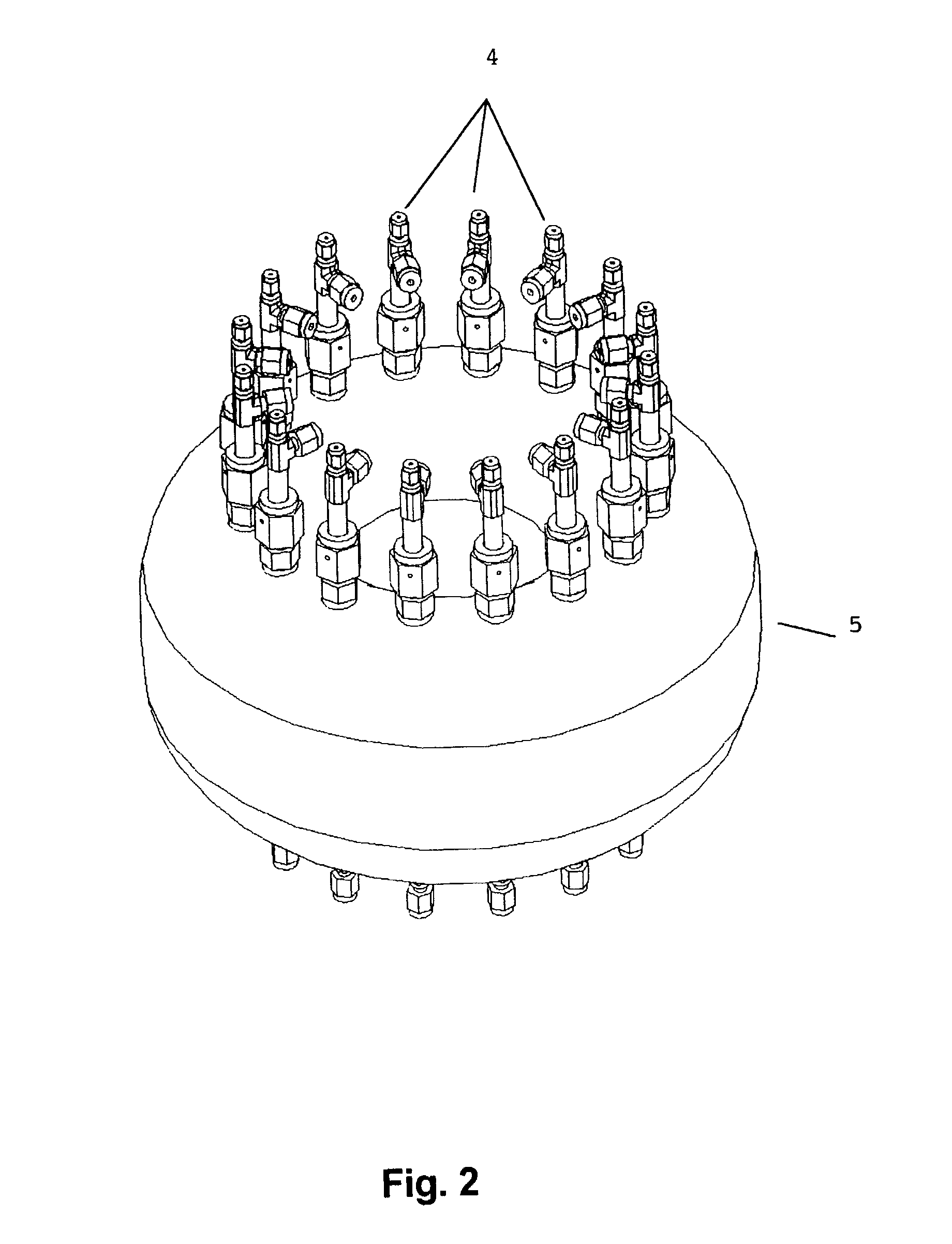

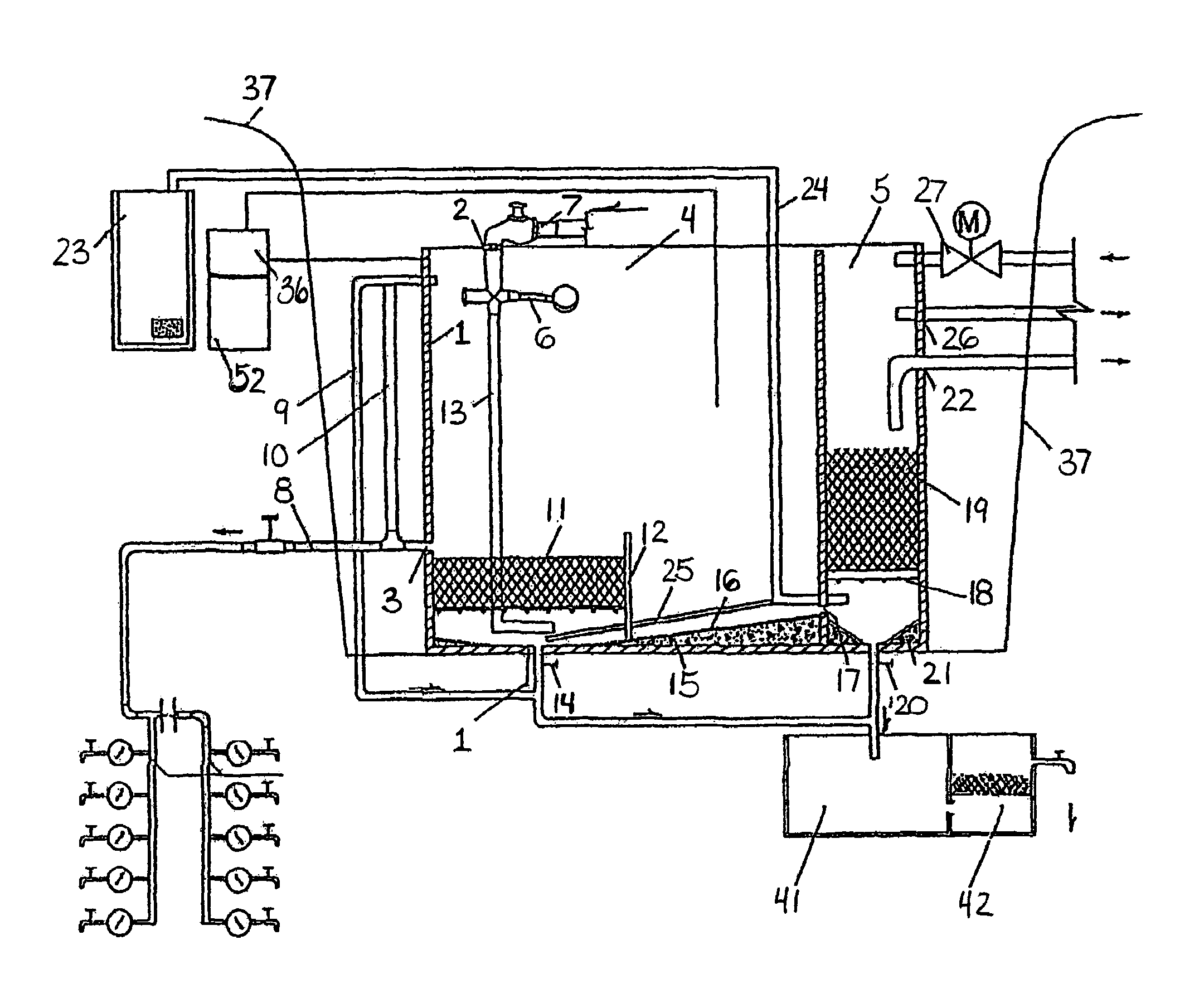

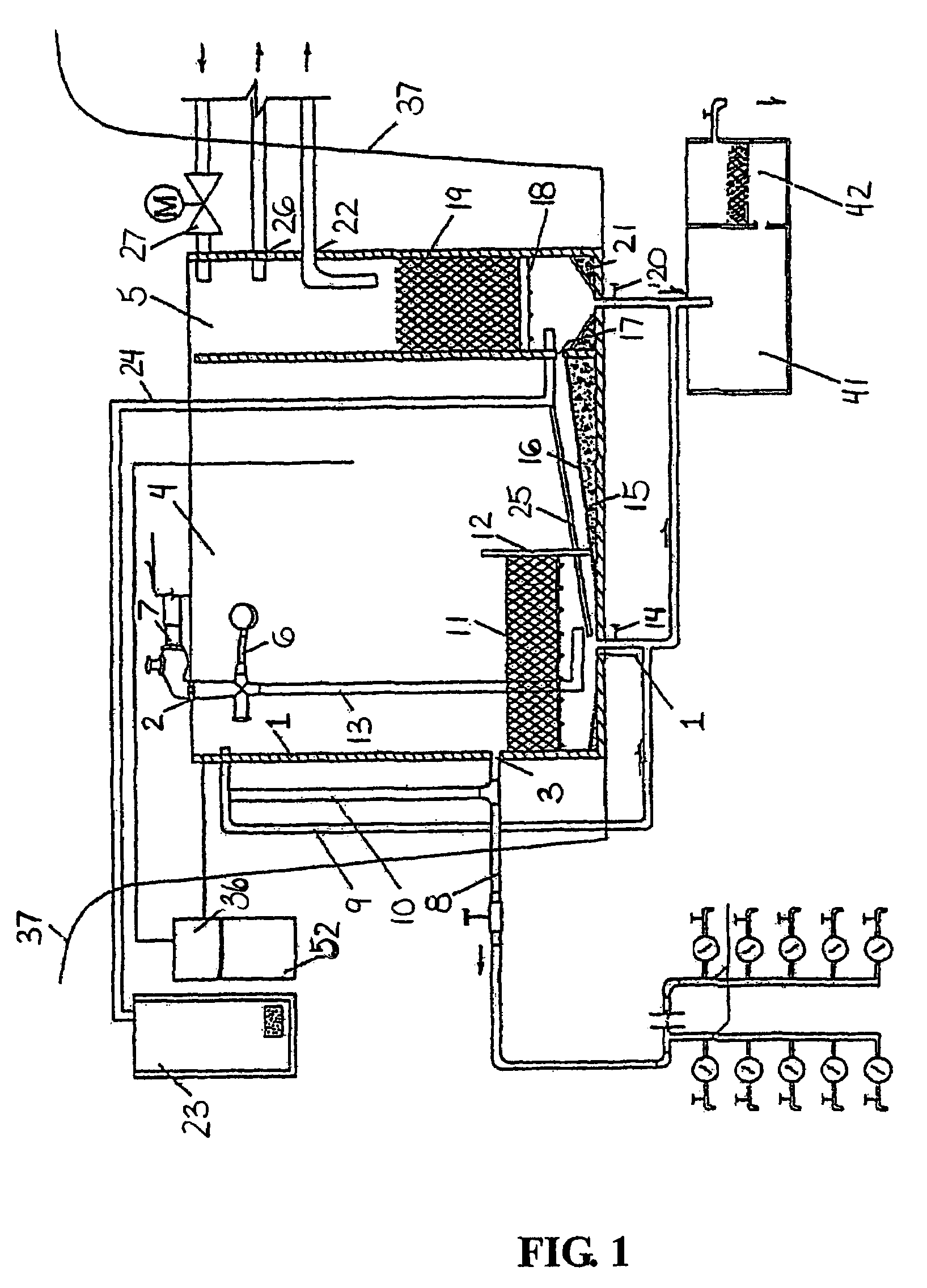

Egg vaccination apparatus

ActiveUS7721674B2Minimizing of movementMinimize the possibilityEar treatmentCannulasVaccinationCritical level

An automatic vaccinator of eggs, consisting of a system for applying vaccine with a vaccine chamber in which vaccine bags are hung and with an air bag that, when expanded, forces the vaccine from the bags and through tubing to a distribution manifold and the injectors, so that the vaccine is delivered to the eggs, is disclosed. A pressure sensor is installed in the distribution manifold and connected to a regulator, measuring the pressure in the distribution manifold at the point farthest from the vaccine chamber and controlling the pressure in the air bag to maintain a uniform quantity of vaccine being injected into the eggs and turning off the vaccinator if the pressure falls below a critical level, signaling that the vaccine bags are empty. The mechanical unit includes a system to support, align and secure the injectors over the egg tray, composed of two plates that work independently, a support plate and an alignment plate.

Owner:MERIAL INC

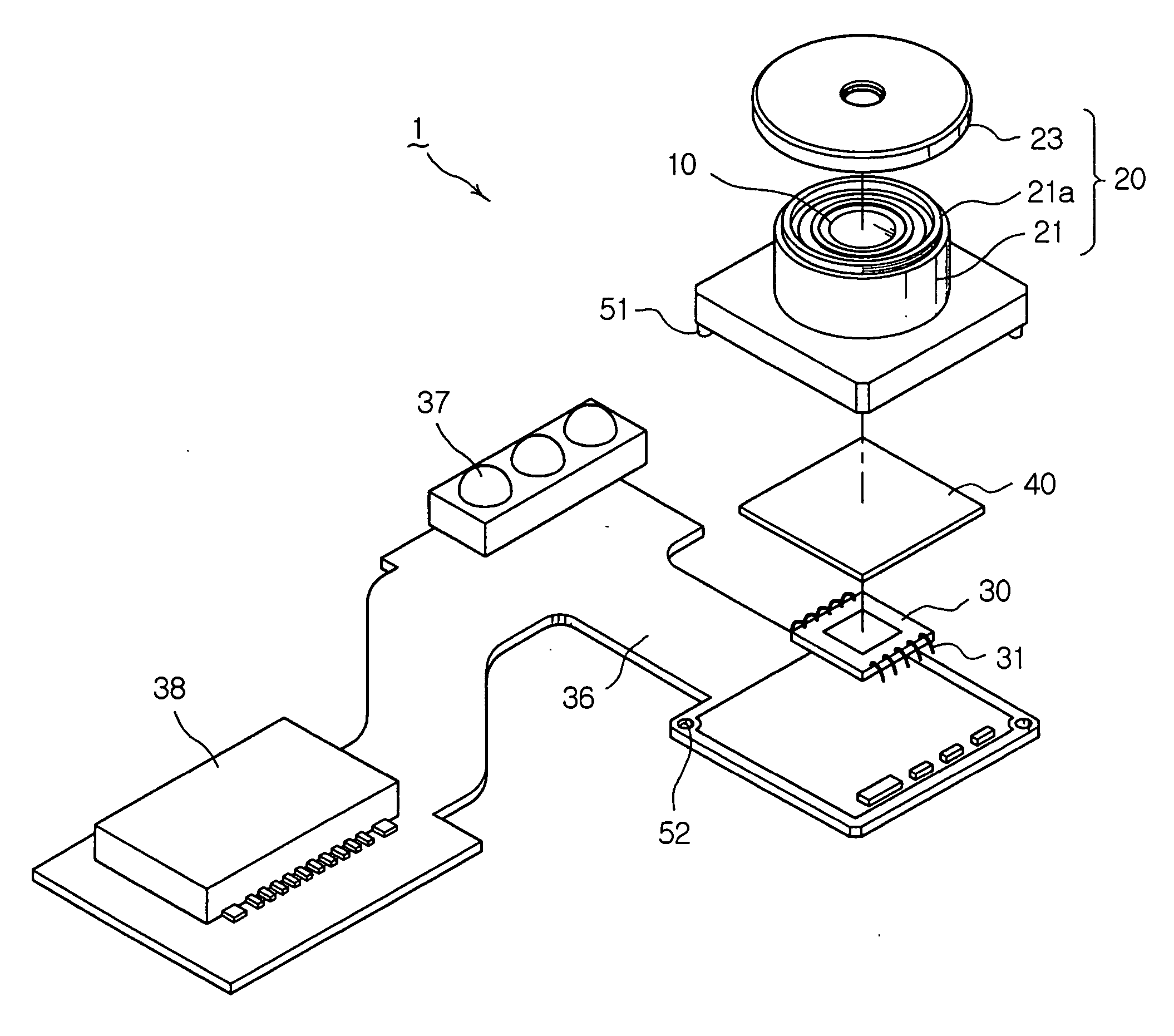

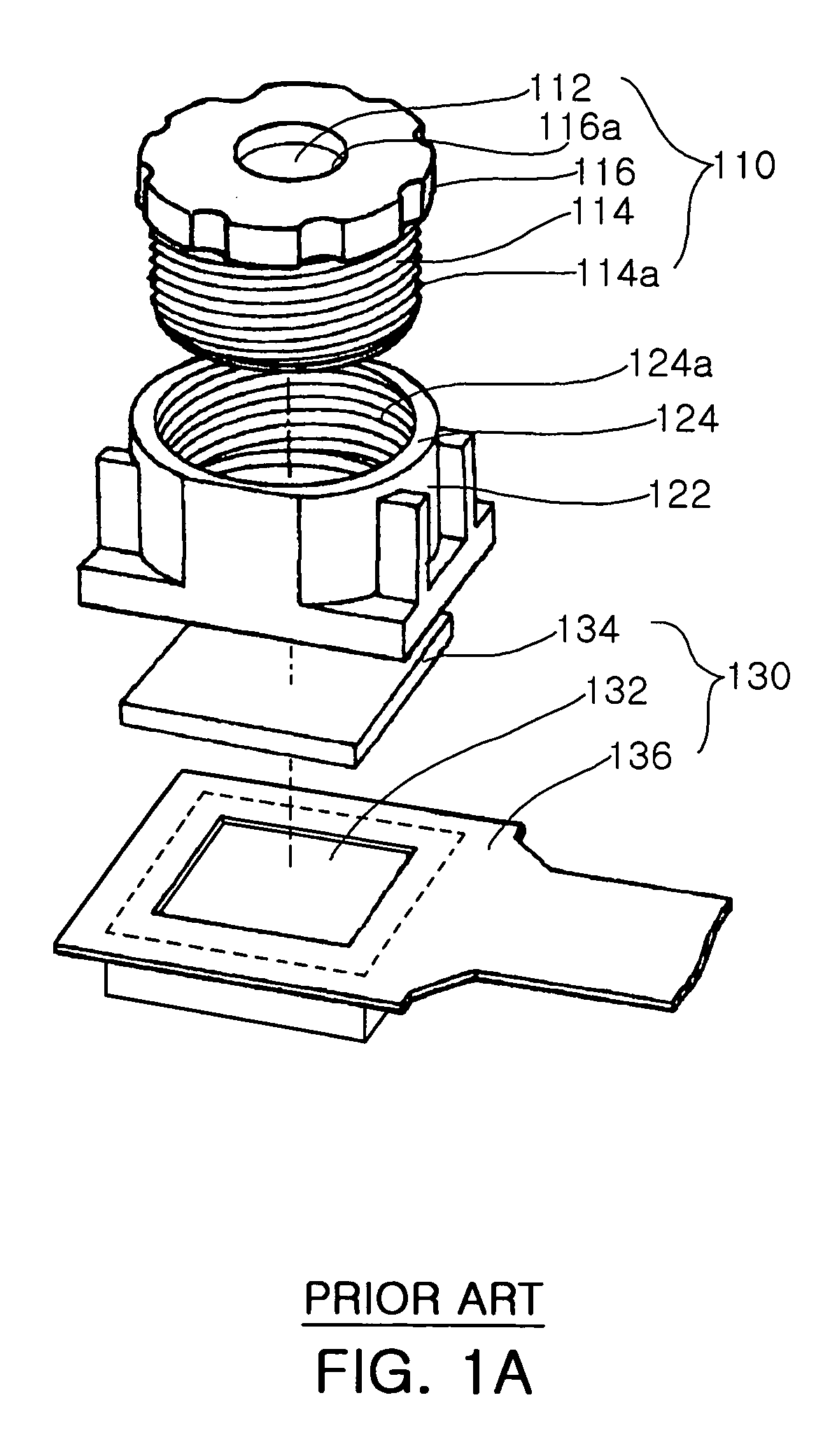

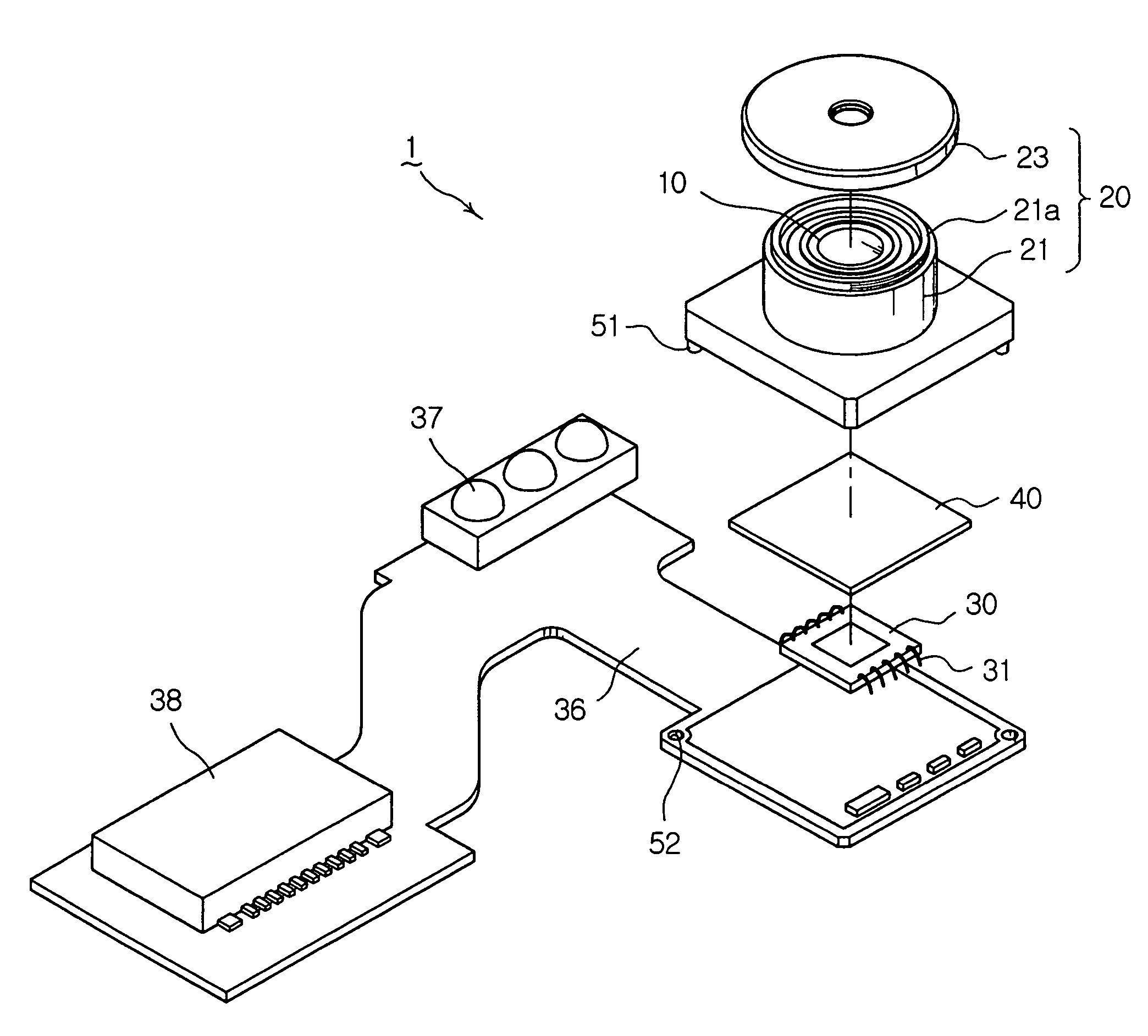

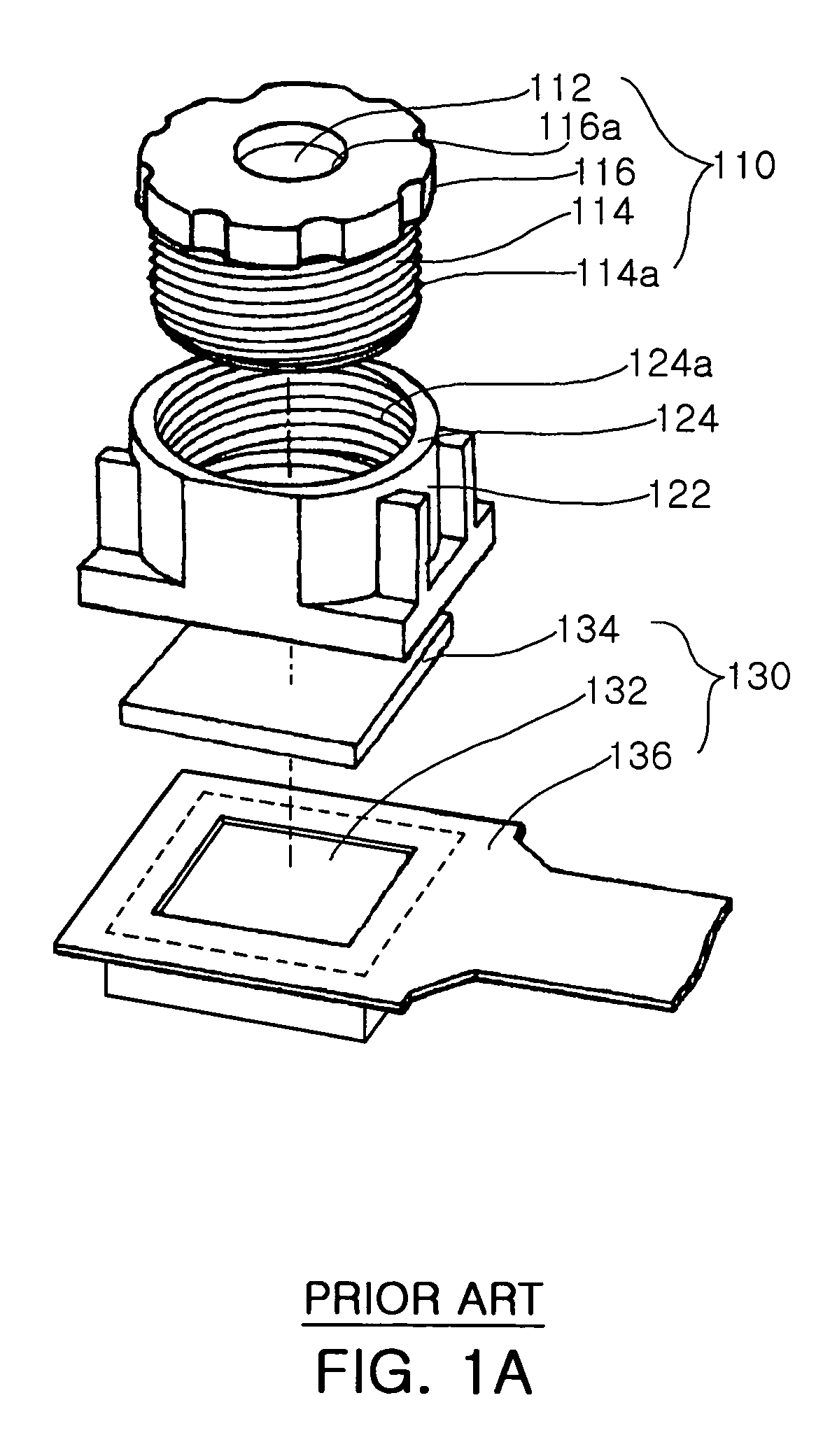

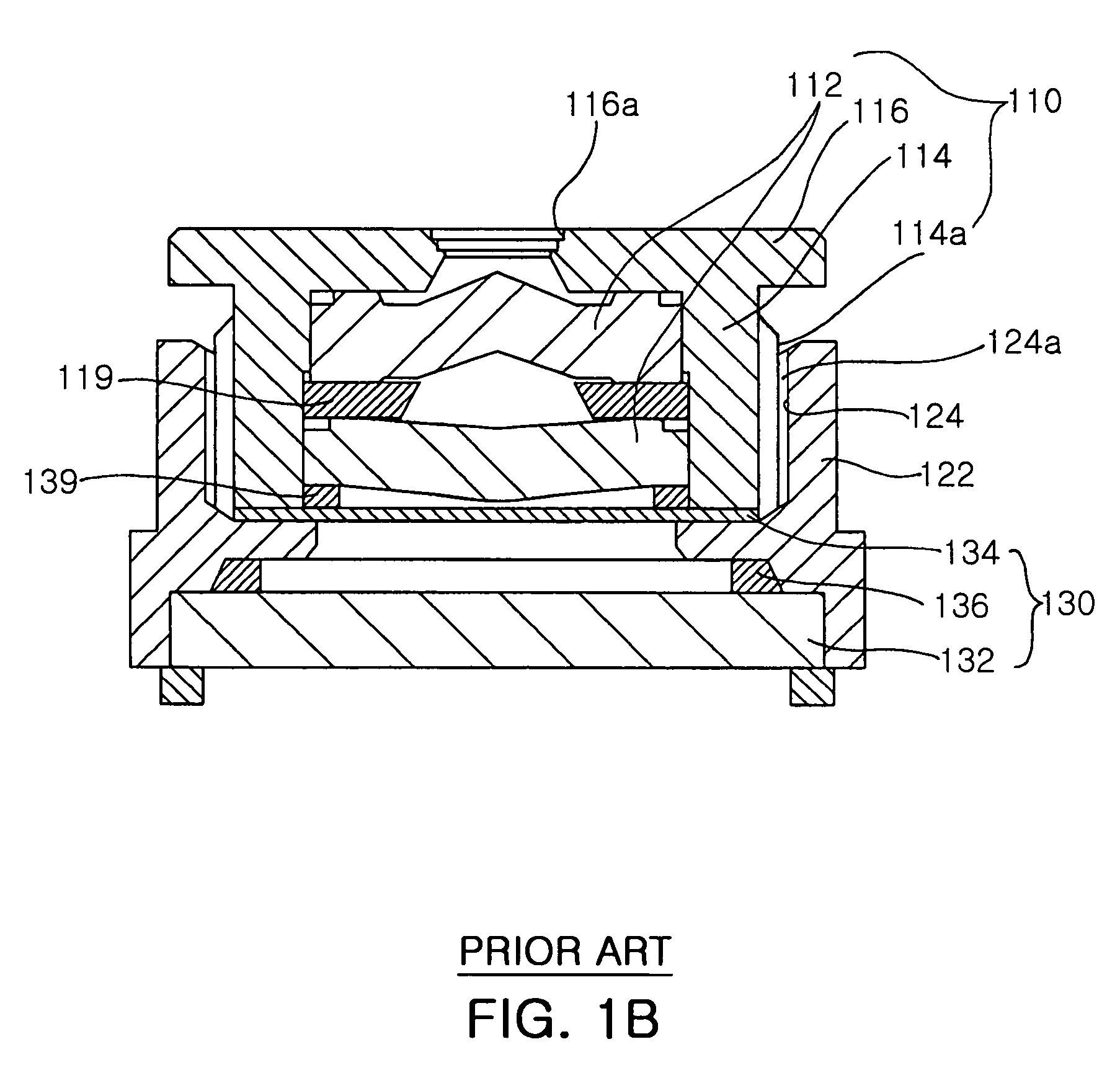

Nonadjustable focusing type camera module

InactiveUS20060228103A1Reduce manufacturing costMinimized volumeTelevision system detailsSolid-state devicesOptical axisImage formation

The invention relates to a nonadjustable focusing type camera module. The camera module includes a lens assembly including at least one lens, a lens accommodating part mounted on an upper surface of a substrate, and including a barrel having an inner space in which the lens assembly is arrange along an optical axis, and an upper cap having an incident hole formed in the front center and fixed to the upper side of the barrel to apply pressure to the lens assembly along the optical axis, an image sensor having an image forming plane on which a light passed through the lens is focused and electrically connected to the substrate to transmit the focused image, and a filter disposed between the lens assembly and the image sensor. Components accommodating a lens and installed on a substrate are integrally formed, thereby simplifying a mold, reducing time for design.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

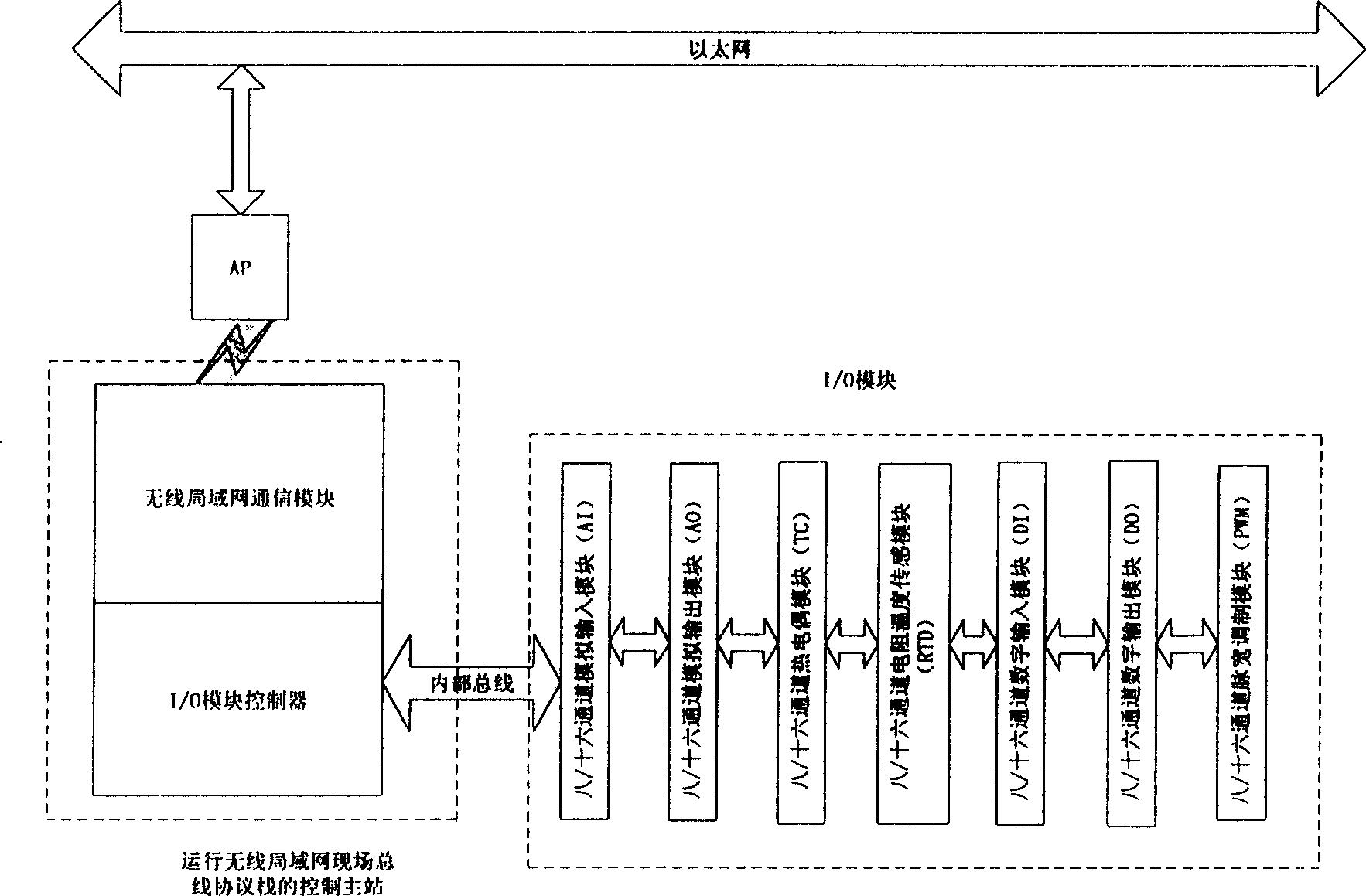

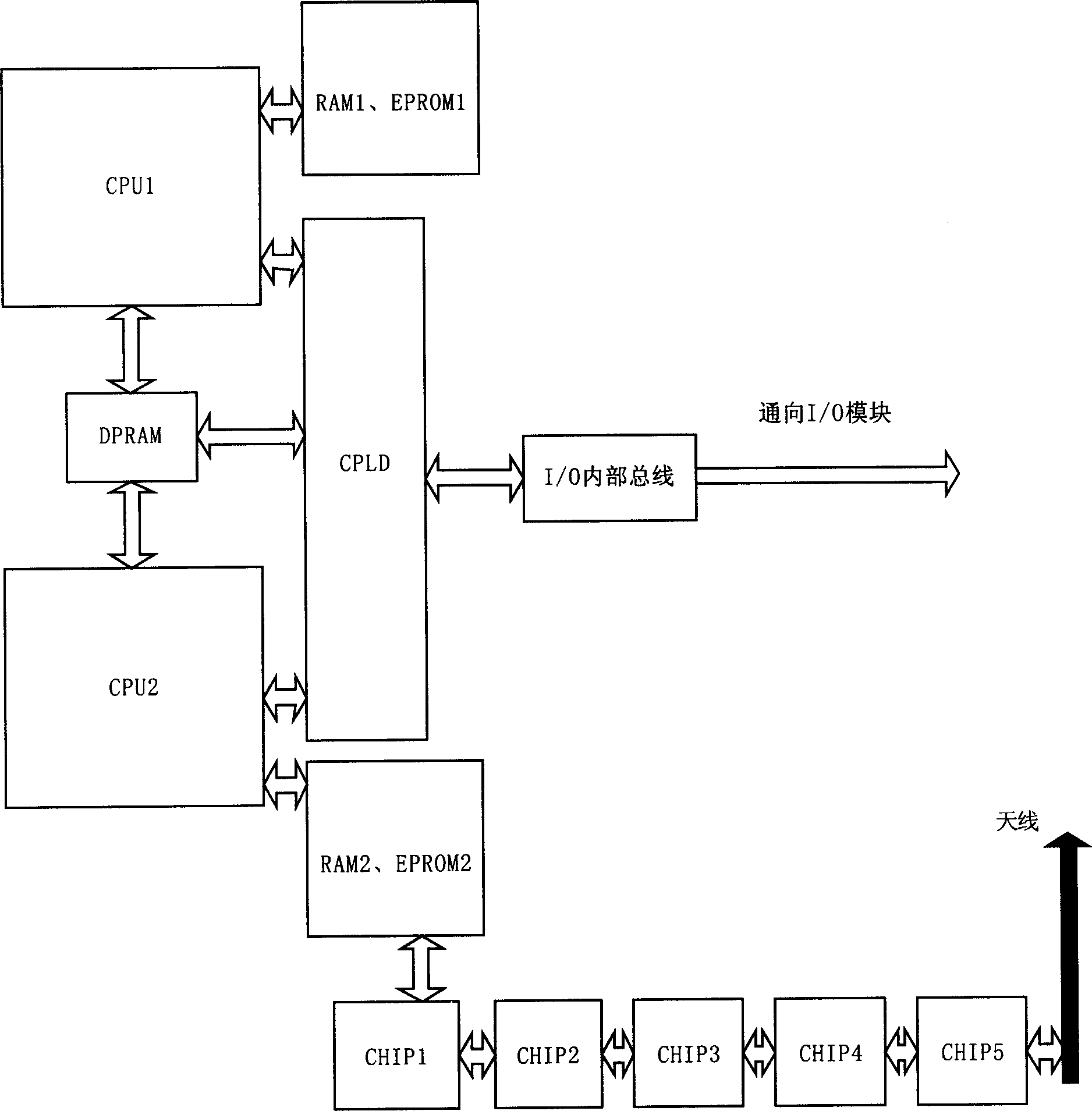

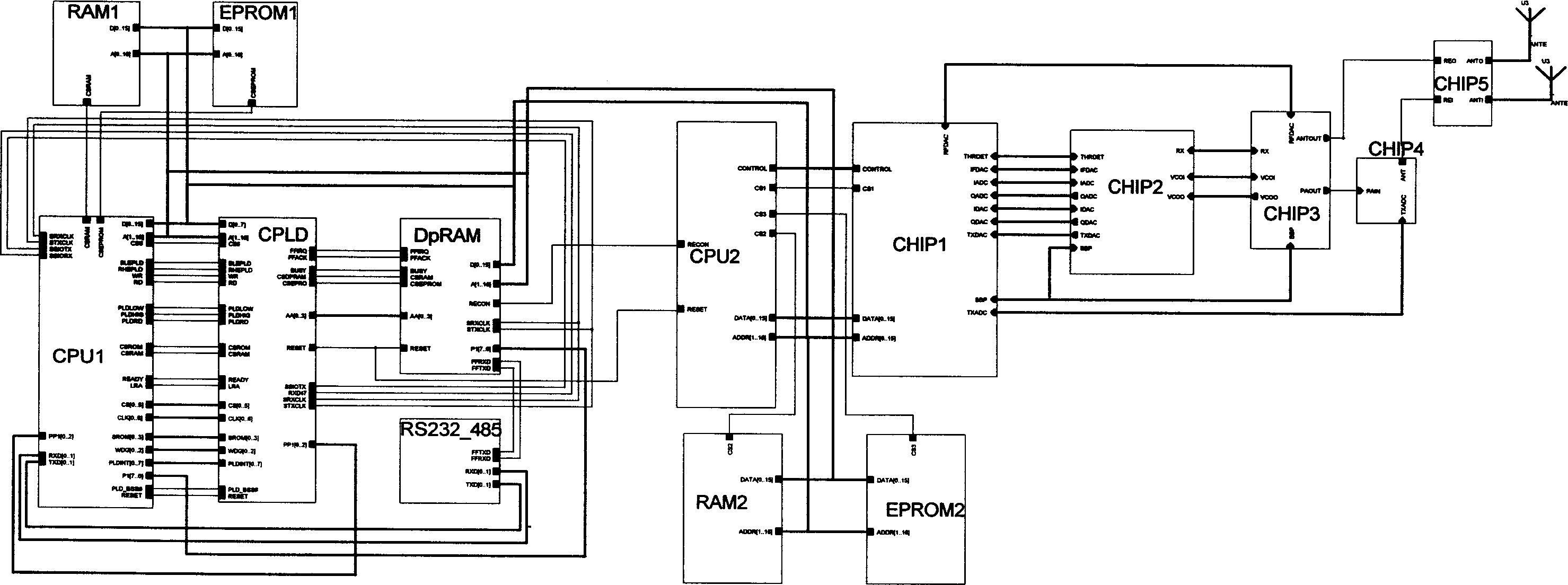

Wireless local area network on-site bus network control station

InactiveCN1567114ASupport hot swapSupport plug and play technologyTotal factory controlElectric digital data processingAutomatic controlDistributed structure

This invention relates to auto-control field, which in detail is used to a wireless LAN on-site bus net control station. It comprises main control station and I / O module, wherein, its main control station runs the wireless LAN on-site bus agreements and accomplishes the distribution I / O control through I / O module controller and receives and transmits data to Ethernet through wireless LAN transmission module. The I / O module is to accomplish the collection and conversion of the on-site signals. It is based on intelligence control device of the wireless Ethernet and turns the DCS total distributed system structure into new type of total distribution structure to completely distribute the control into the on site by network control station. This invention especially applies to old industry control system reconstruction to make it possible for old enterprises to enter the new time of on-site bus.

Owner:无锡中科泛在信息技术研发中心有限公司

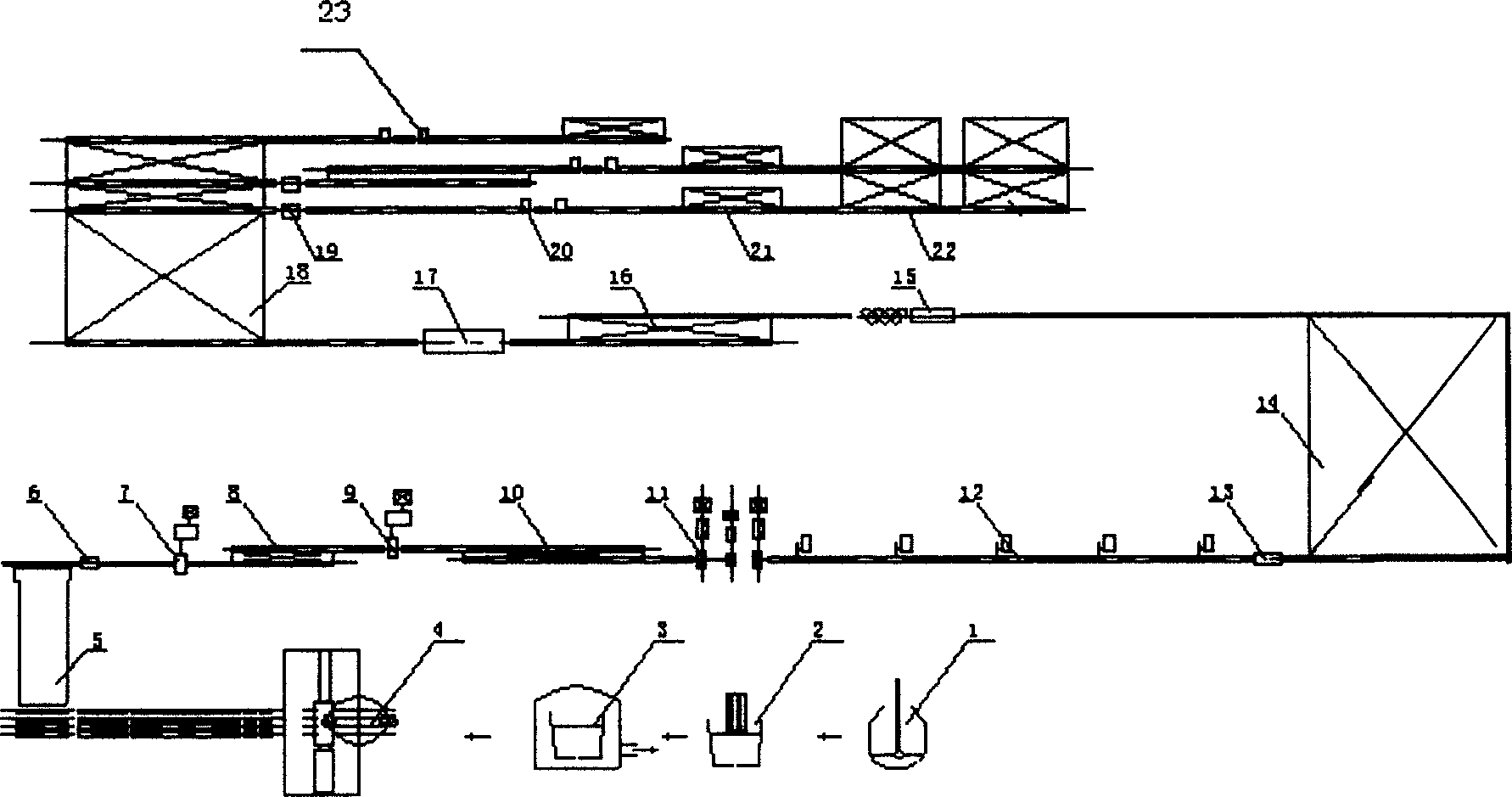

Short flow path manufacturing method of heavy rail

InactiveCN1589983AImprove pure qualityEliminate white spot defectsMetal rolling arrangementsEngineeringMolten steel

A short-flow technology for manufacturing the heavy rails with 50 m in length includes such steps as refining molten steel, conticasting, step heating, shaping rolling, fine rolling, sawing by needed size, prebending-cooling, straightening, and inspection. Its advantages are short technological flow, high quality of product and low cost.

Owner:ANGANG STEEL CO LTD

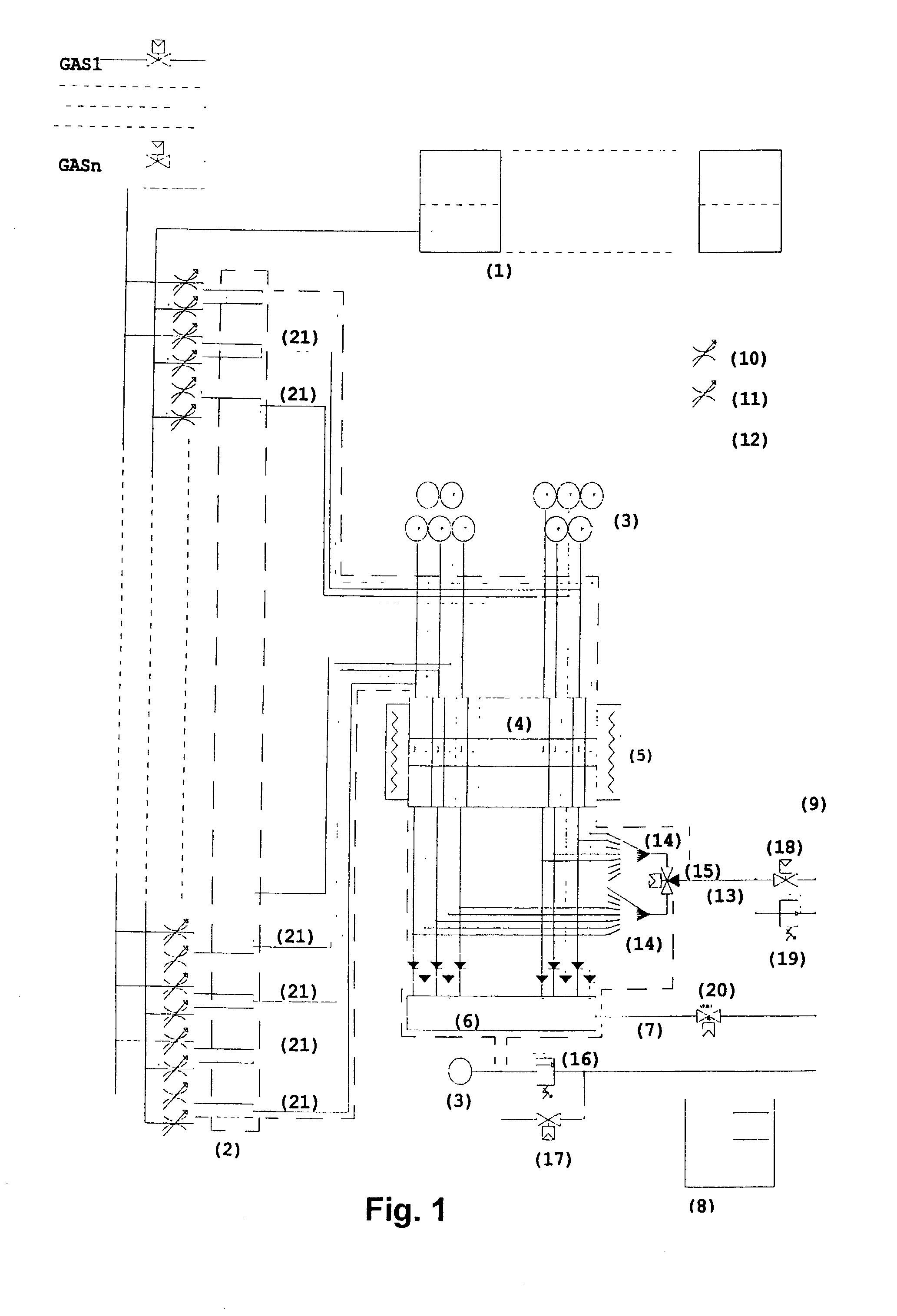

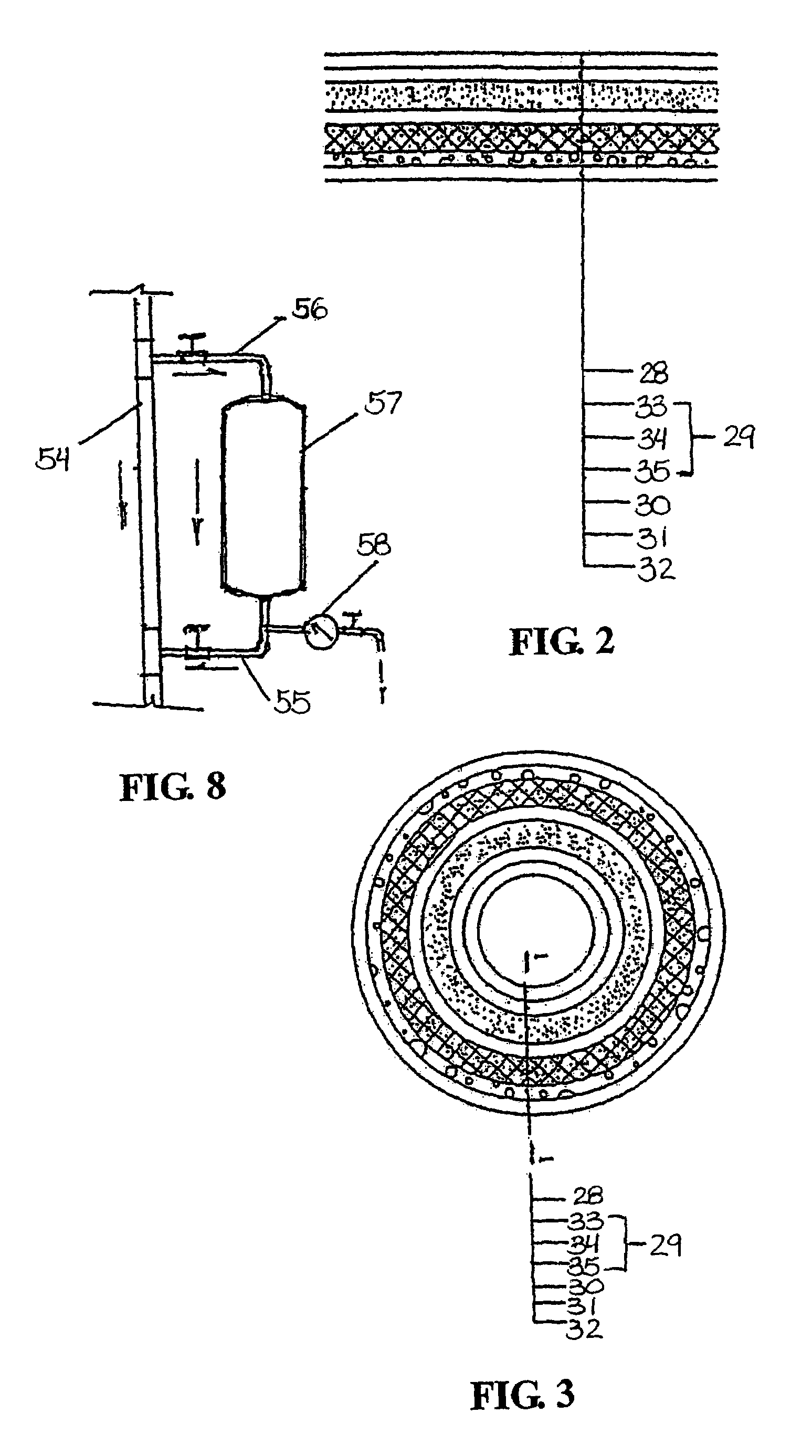

Catalytic testing device and method for its use in material testing

InactiveUS20030040116A1Quick and accurate decisionWide rangeSequential/parallel process reactionsTemperatue controlMaterials testingEngineering

A catalytic testing device comprising a reaction block comprising a set of reaction chambers, each chamber comprising a fluid inlet and outlet connected to an outgoing fluid duct connected to analysis means, fluid feed means capable of performing regulated dosing of flows of the fluid at the required pressure independently in each of the reaction chambers, automatic and dynamic pressure control means, capable of performing pressure regulation in each reaction chamber, which comprise a non-return valve in the outgoing fluid duct between the outlets of the reaction chambers and a common regulating tank that receives the outgoing fluid from the chambers, a pressure sensor provided in a first outlet duct and an automatic needle valve provided in a second outlet duct from the tank.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

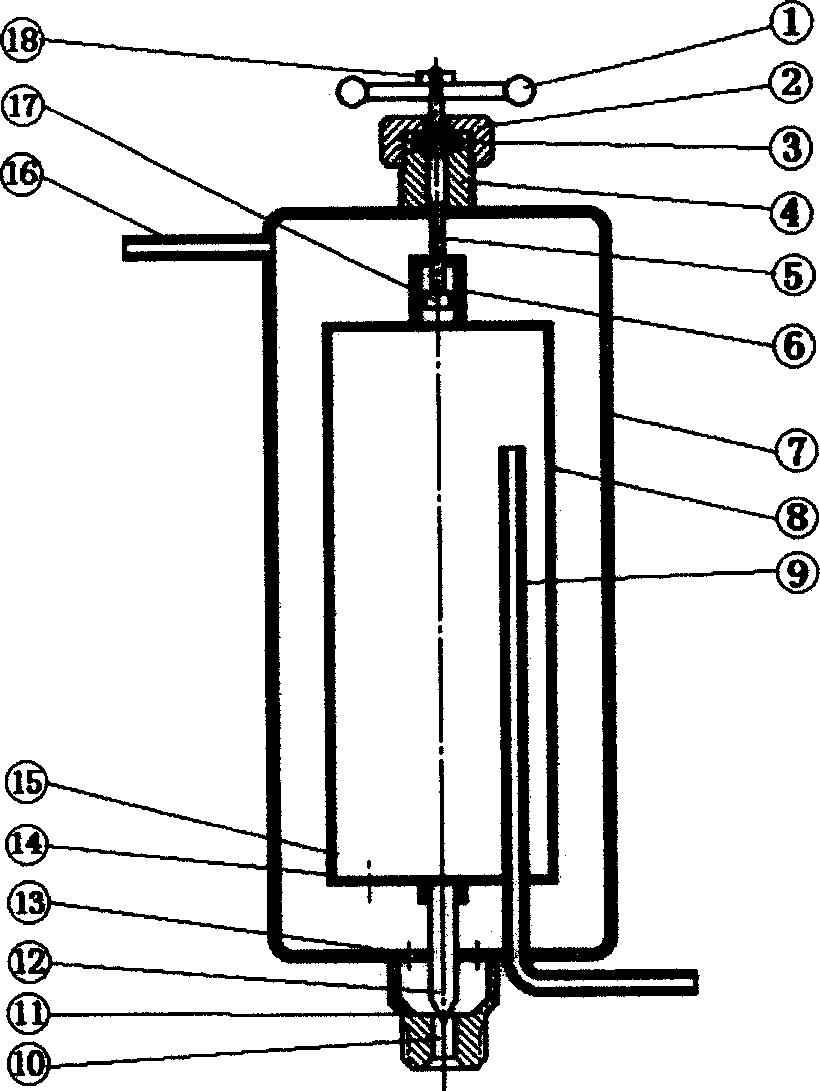

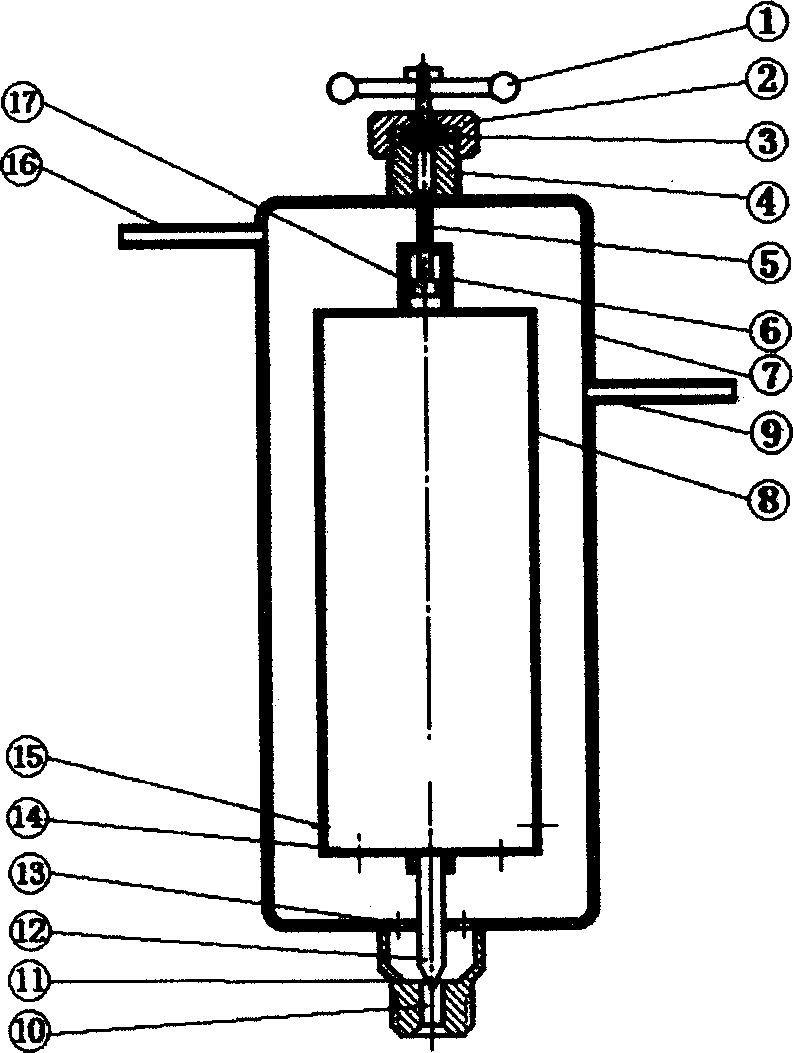

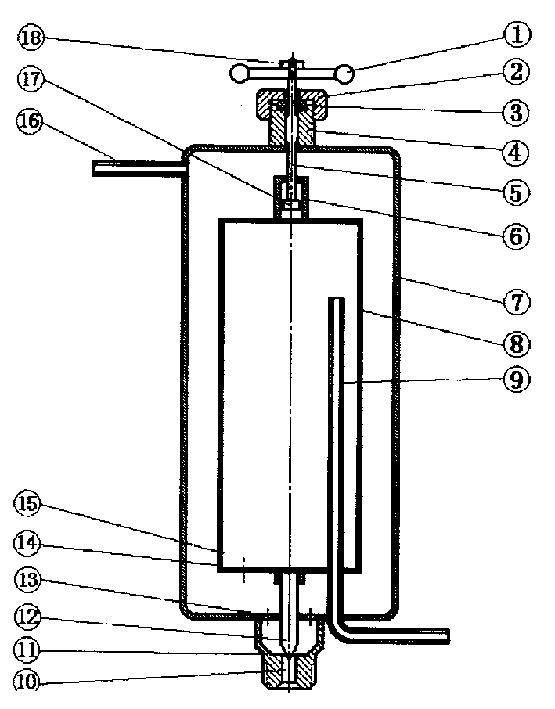

Integrated gas/liquid separating device with automatically controlled liquid level

InactiveCN1457915ASimple structureSmall footprintLiquid degasificationVapor–liquid separatorIntegrated design

The integrated gas / liquid separator with automatically controlled liquid level consists of mainly regulating hand wheel, sealing screw nut, sealing ring, regulating screw sleeve, outer cylinder, floating cylinder, material feeding pipe, liquid draining valve body, liquid draining valve needle rod and gas exhaust pipe. The integrated design of gas / liquid separation and liquid level control results in simple structure, convenient use and no limitation in use pressure, and is especially gas / liquid phase separation in petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

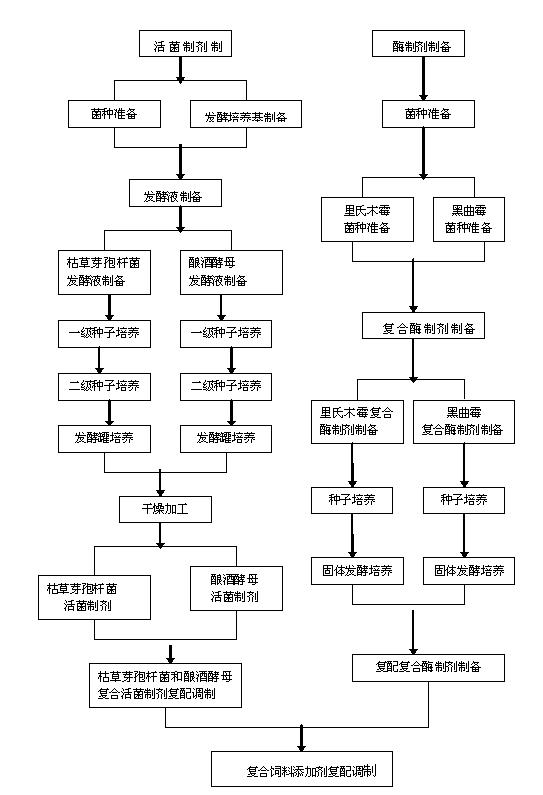

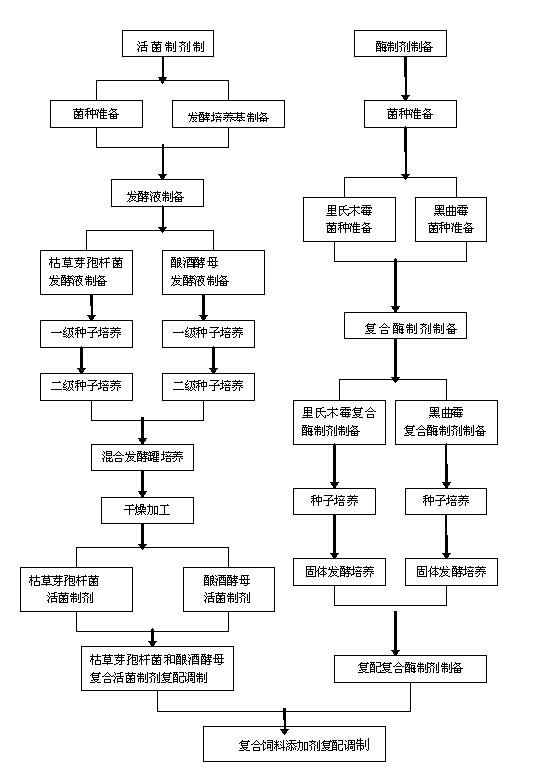

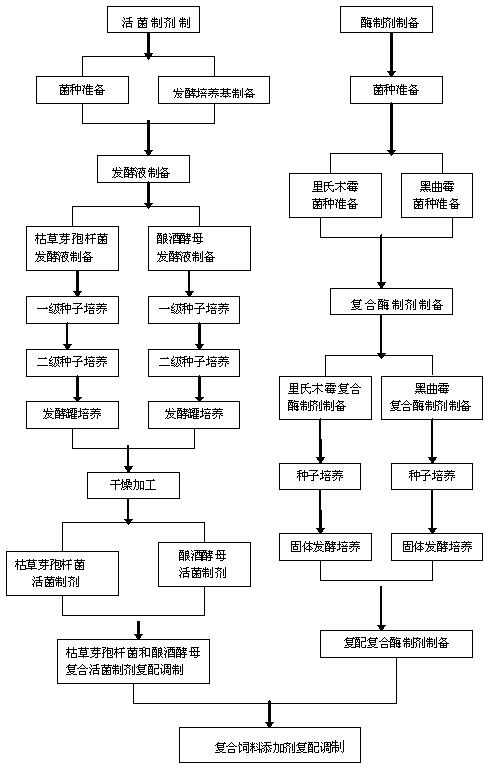

Bio-enzyme and microorganism containing compound feed additive and preparation process thereof

InactiveCN102599351AImprove feed utilizationIncrease production capacityAnimal feeding stuffAmylaseTrichoderma reesei

The invention discloses a bio-enzyme and microorganism containing compound feed additive and a preparation process thereof, which solve the problems of high production cost and less viable count of beneficial microorganisms in the prior art. The bio-enzyme and microorganism containing compound feed additive is characterized in that the additive is prepared by compounding a viable organism preparation (prepared by carrying out liquid fermentation and low-temperature drying on bacillus subtilis and brewer's yeast) with an enzyme preparation (prepared by carrying out solid fermentation and drying on trichoderma reesei and Aspergillus niger); and the viable count of beneficial microorganisms in each gram of the product is greater than 8*10<9> cfu / g, the cellulase activity (refer to the quantity of cellulose degraded by each gram of the product per minute) is greater than 500 mg, the alpha-amylase activity (refer to the quantity of starch hydrolyzed by each gram of the product per minute) is greater than 3000 mg, and the protease activity (refer to the mount of an amino acid generated by caseins hydrolyzed by each gram of the product per minute) is greater than 400 mg. The bio-enzyme and microorganism containing compound feed additive disclosed by the invention has the advantages that: the feed utilization rate of livestock can be improved in a short term, the intestinal digestive flora of livestock is improved and balanced, the breeding cost is reduced, and the feed conversion rate and the animal production performance are improved; and meanwhile, the additive is simple in preparation process, low in production cost, and suitable for industrialized production.

Owner:LIAONING SHENNONG BIOLOGICAL ENG

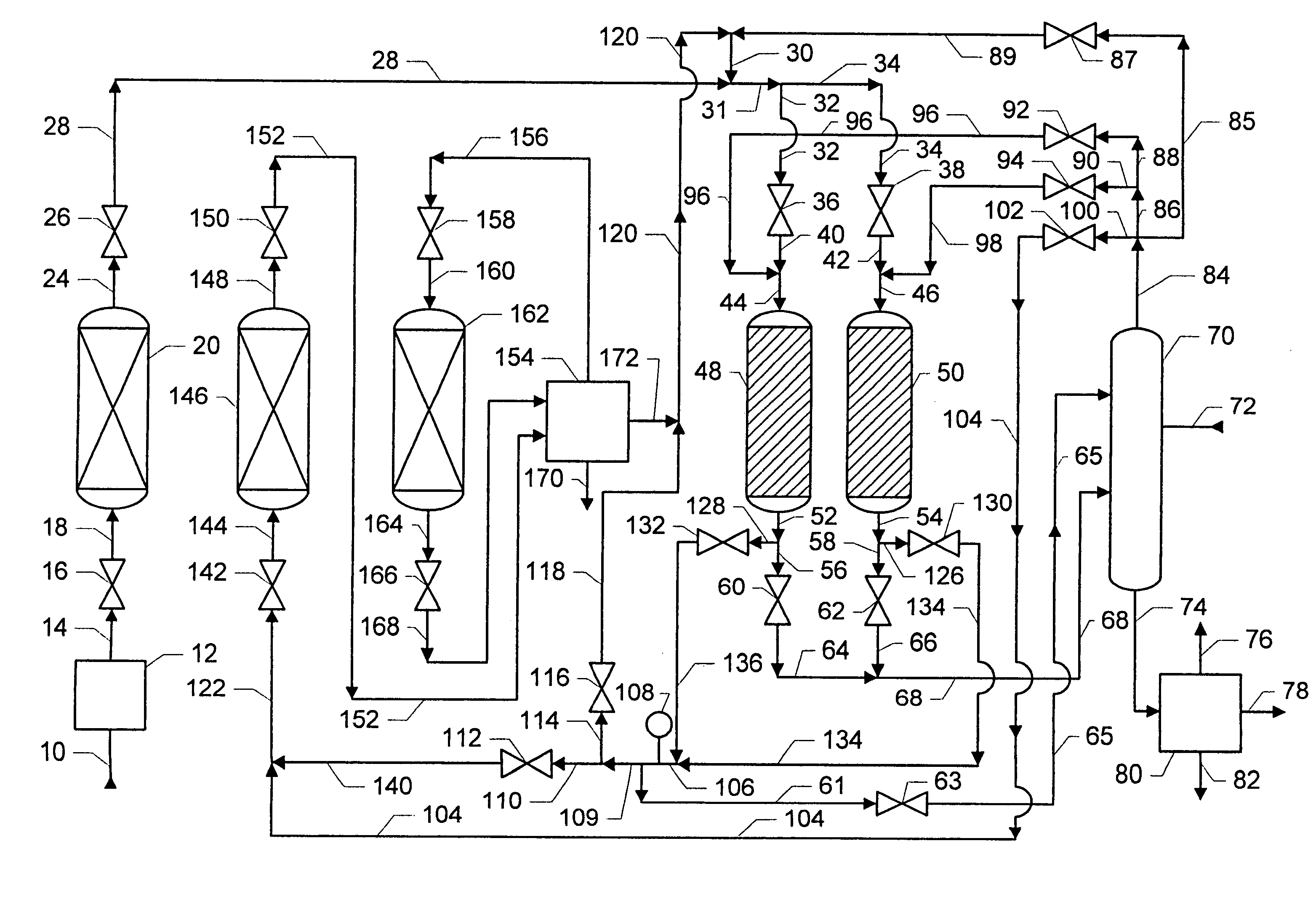

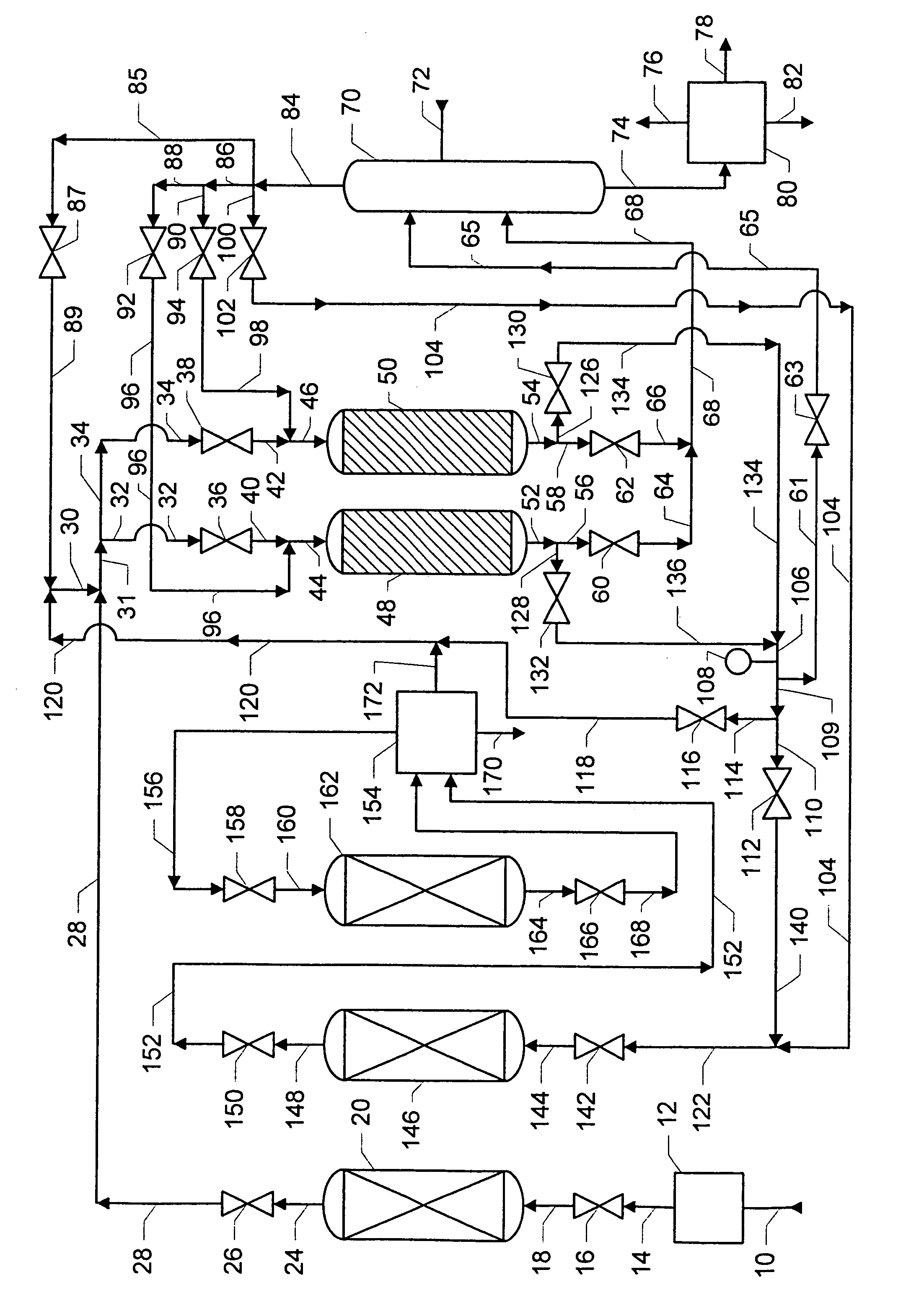

Alkylaromatic process with catalyst regeneration

InactiveUS6979394B2Save expenseSave investmentHydrocarbonsChemical recyclingAlkyl transferAlkylation

A process for producing a product aromatic compound is disclosed which uses an on-stream alkylation reactor and an off-stream alkylation reactor, and in which at least a portion of the feed aromatic compound in the effluent stream of off-stream alkylation reactor undergoing regeneration is passed to the on-stream alkylation reactor. An embodiment of this process that uses on-stream and off-stream aromatic byproducts removal zones is also disclosed.

Owner:UOP LLC

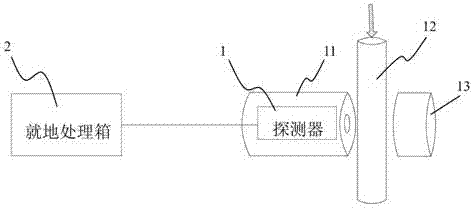

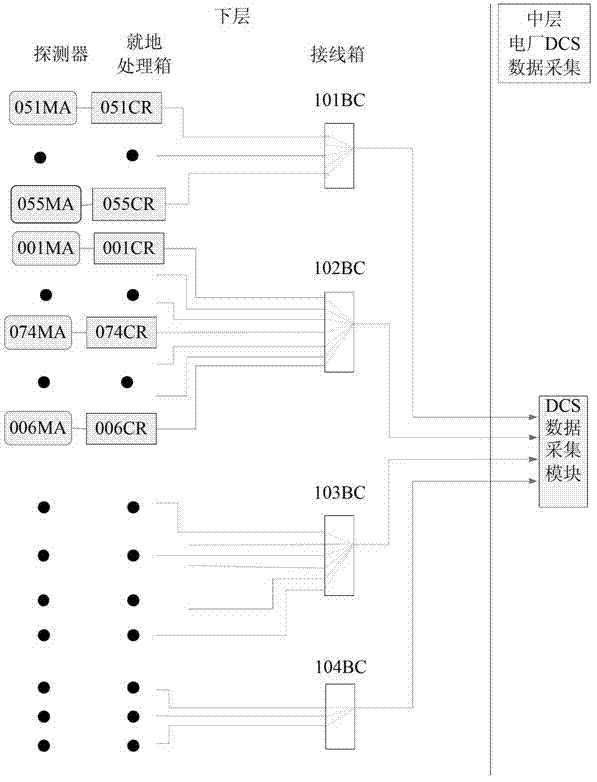

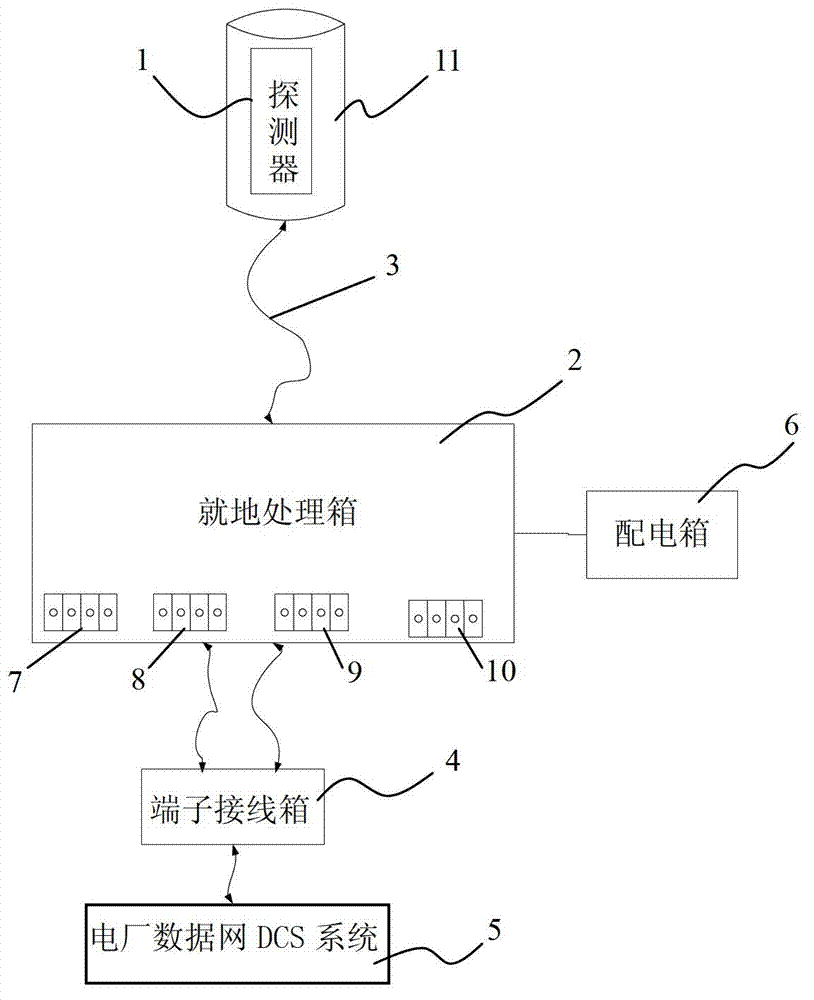

Nuclear power plant digital radiation monitoring system

InactiveCN102930907AImprove securityIncrease the level of automationNuclear energy generationNuclear monitoringAutomatic controlNuclear power

The invention belongs to the technical field of nuclear radiation measurement and automatic control, and particularly relates to a nuclear power plant digital radiation monitoring system. The system comprises multiple radiation monitoring channels; each radiation monitoring channel is connected with a data network digital control system of a nuclear power plant; the radiation monitoring channel comprises a detector; the detector is connected with an on-site processing box through a cable; the on-site processing box is provided with an RS485 communication port, an RS232 communication port, an analog input / output port and an on-off input / output port; and the ports of the on-site processing box are connected with the data network digital control system of the nuclear power plant through a terminal junction box. Through the nuclear power plant digital radiation monitoring system provided by the invention, the automatic level of the radiation monitoring equipment is improved, the equipment investment and the field workload are saved, the analysis of operators to the radiation data is facilitated, and the operation safety of the power plant is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

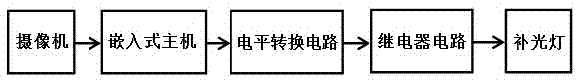

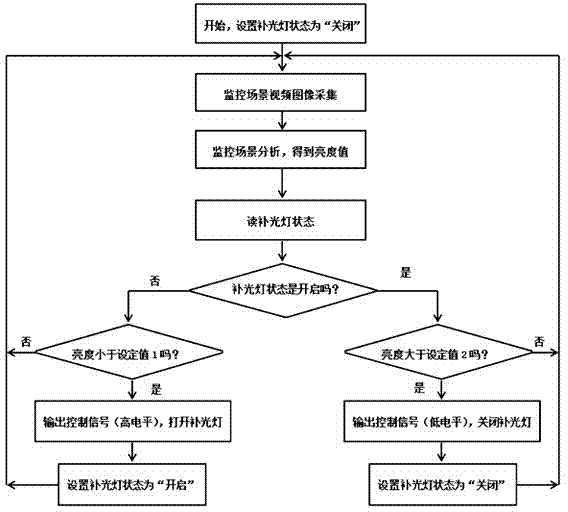

Fill light lamp automatic control method based on video analysis

InactiveCN103491313AAchieving Adaptive ControlBrightness value is accurateTelevision system detailsColor television detailsAutomatic controlLight pollution

The invention discloses a fill light lamp automatic control method based on video analysis. The fill light lamp automatic control method based on the video analysis achieves the automatic control over a fill light lamp according to the changing of brightness values in a monitoring area. The fill light lamp automatic control method based on the video analysis achieves the self-adaptive control over the fill light lamp according to the changing of ambient brightness, avoids electric energy waste and light pollution to the environment by the fill light lamp, avoids the phenomena that the definition of monitoring video images declines due to insufficient light and the fill light lamp may flicker, saves equipment investment, shortens mounting construction cycles, and improves the reliability of system working.

Owner:ANHUI SANLIAN APPLIED TRAFFIC TECH

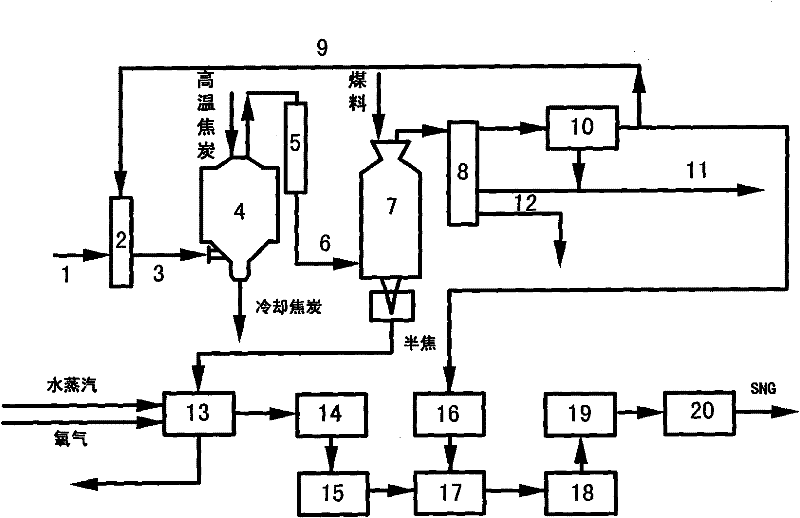

Method for preparing natural gas by dry quenching co-production coal

InactiveCN101747918AAvoid pollutionAchieve emissionsCoke quenchingDirect heating destructive distillationMethanationQuenching

The invention provides a method for preparing natural gas by dry quenching co-production coal. In the method, reducing gas is taken as heat-carrying gas, refrigerant and a pyrolytic process thereof are adopted to recover a great quantity of sensible heat of high-temperature coke so as to couple the dry-method coke quenching process and the coal pyrolytic process of high-temperature metallurgical coke, thus cancelling a gas and air supply system, a combustion control system and a waste gas discharging system in the original pyrolytic process, avoiding pyrolytic combustion process, saving a great quantity of energy, and realizing smoke-free, NOX-free, SOX-free and CO2-free discharging. Meanwhile, gasification gas produced by pyrolytic gas and semi-coke gasification is used for producing andsynthetizing natural gas in a methanation manner so as to realize clean conversion of coal. In addition, the method cancels N2 preparation equipment and waste heat boiler systems in dry quenching, thus simplifying the operation and maintenance process and greatly lowering investment and operation cost.

Owner:山西中元煤洁净技术有限公司

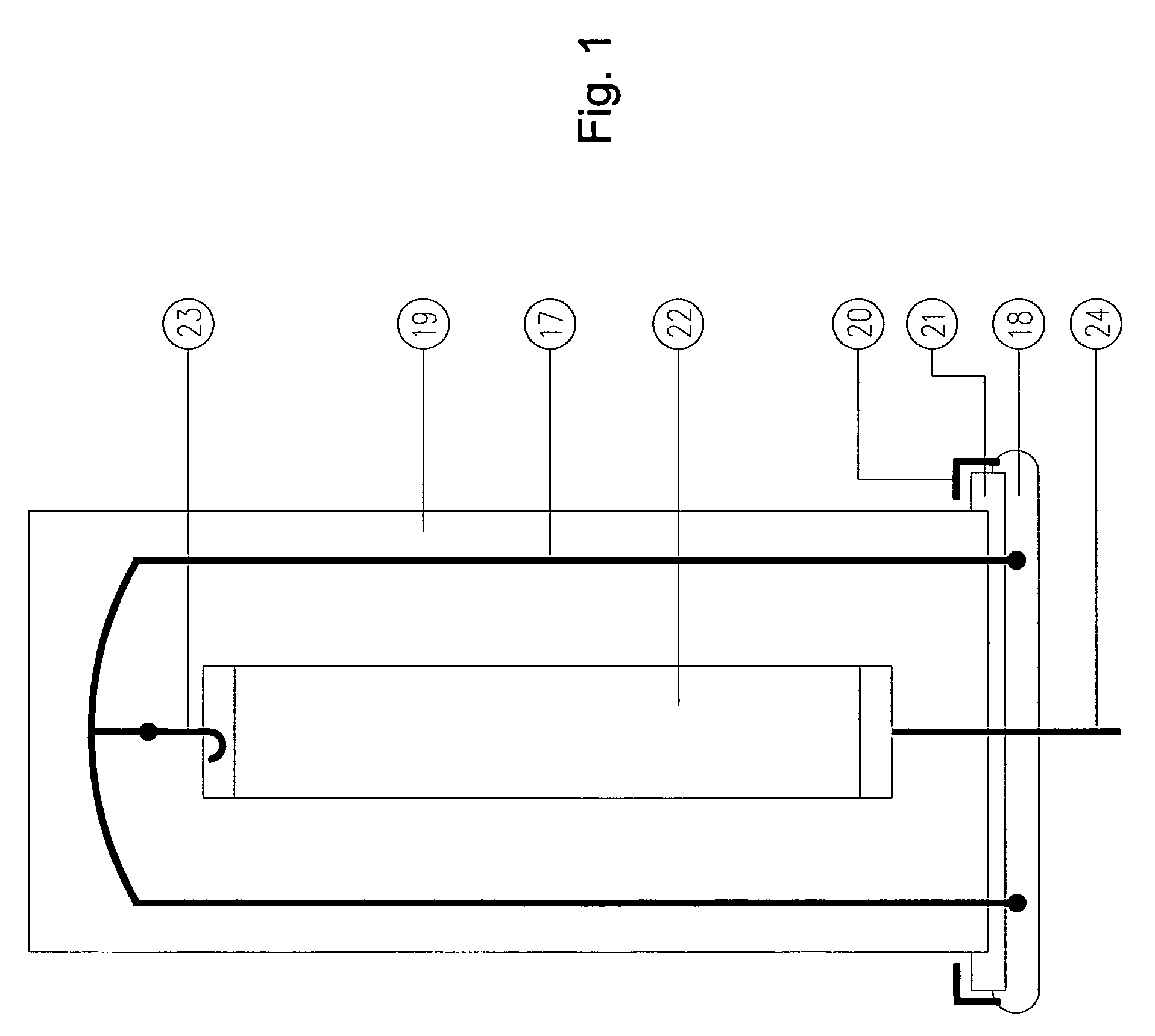

Water supply system and multifunctional water supply tank

InactiveUS7163619B2Easy to useQuality improvementTreatment involving filtrationSolid sorbent liquid separationTap waterPotable water

The invention discloses a multifunctional water supply tank with pressure-stabilized water storage and quality-distinguished supply of service and potable water, which includes a service water storage room with a water inlet and a water outlet, a potable water storage room communicated with the service water storage room and containing purifying agents, a potable water outlet, and a water outlet communicated with a solar water heater, the present invention solves the problems of insufficient water pressure of tap water pipe network and the secondary water contamination during water supply by the pipe network, meanwhile it heats and preserves the temperature of the water supply tank cover and the water supply pipe walls, and separates pure water from service water, solar heated water, and purified potable water for separate metering and utilization.

Owner:WANG ZERONG

Multistage spraying fluidization tail gas washing tower

InactiveCN105214464AEasy to follow upReduce consumptionDispersed particle separationChemical/physical/physico-chemical processesThermodynamicsMechanical engineering

The invention discloses a multistage spraying fluidization tail gas washing tower. A tail gas inlet is formed in the bottom of the washing tower, and a tail gas outlet is formed in the top end of the washing tower. The washing tower comprises at least two stages of independent circulation spraying sections, wherein at least one stage of independent circulation spraying section is filled with light sphere packing, so that the fluidization independent circulation spraying sections are formed. The independent circulation spraying sections conduct spraying through an independent circulation spraying system. The multistage spraying fluidization tail gas washing tower can treat multi-component tail gas and has the advantages of being high in washing efficiency, not prone to blockage, convenient to wash, capable of reducing cost and wide in application prospect.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

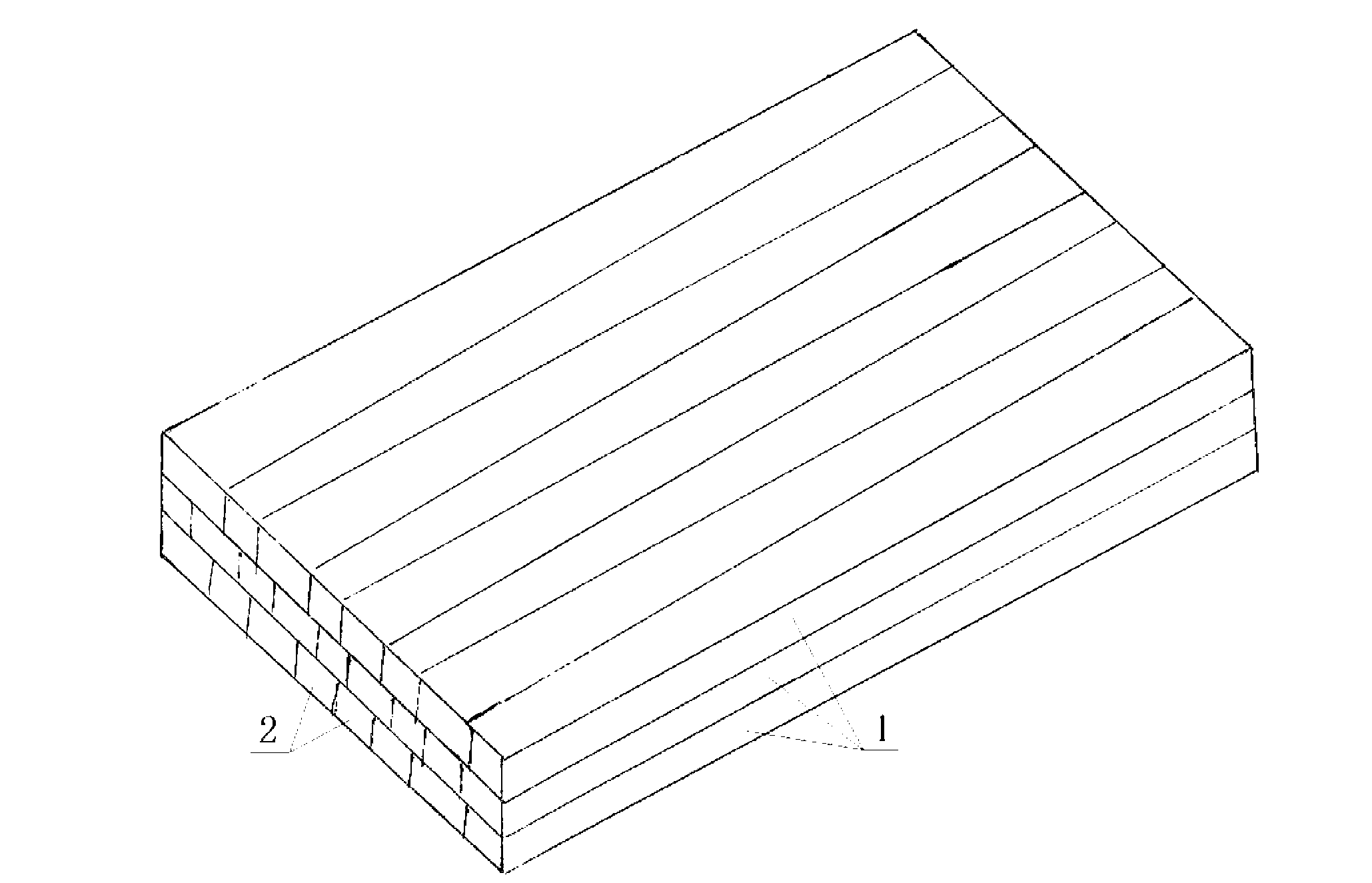

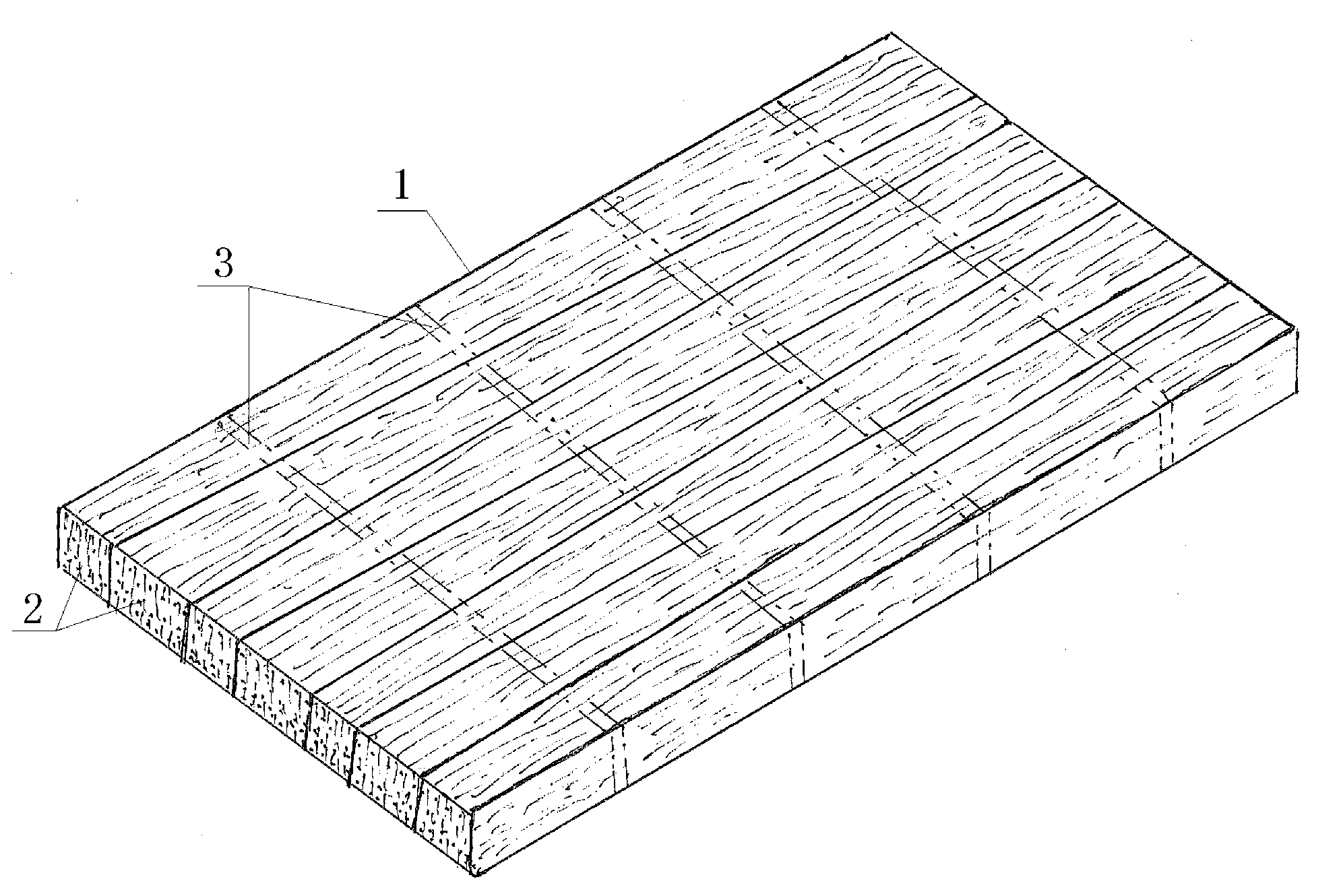

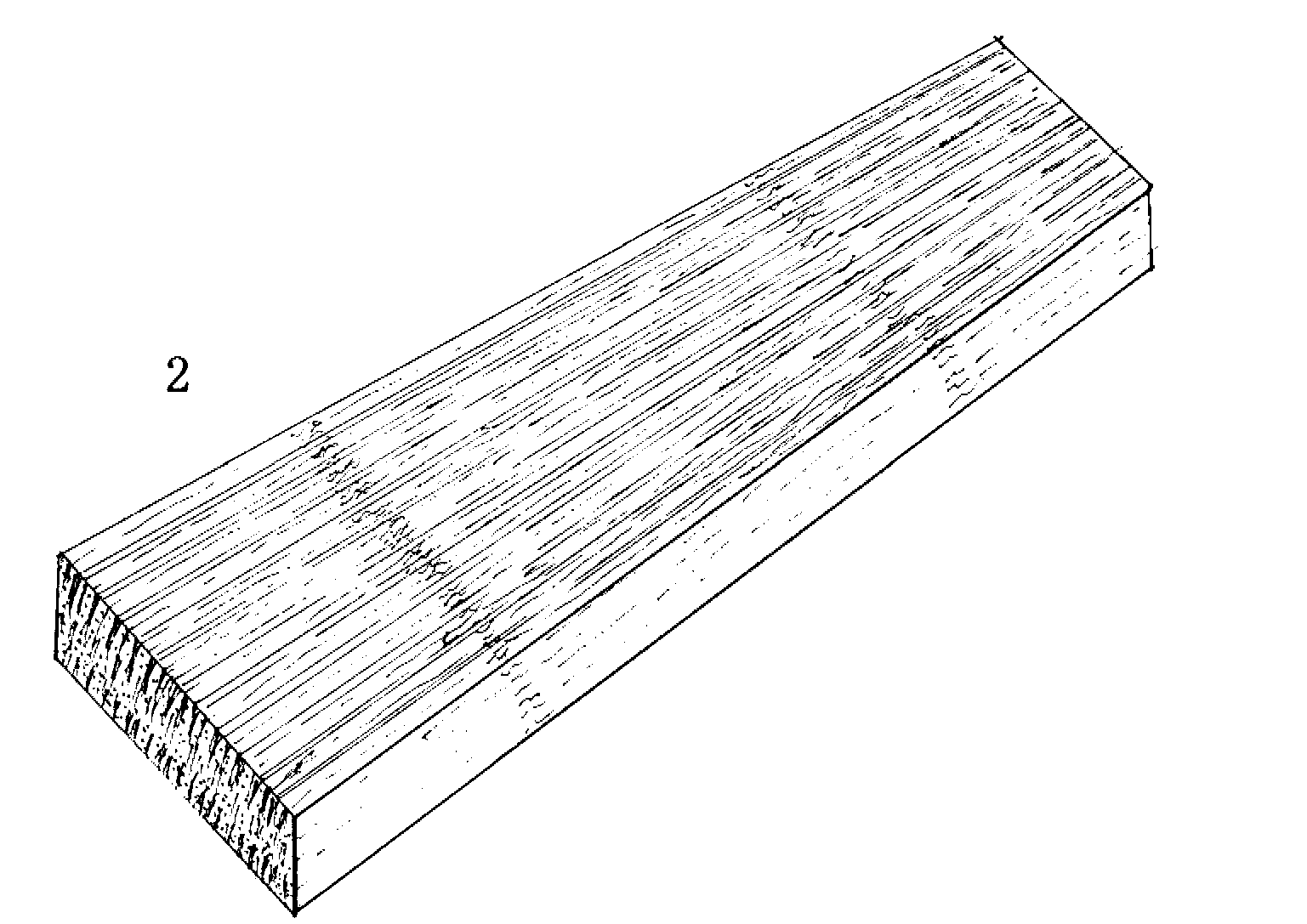

Laminated board formed by fine disintegration and rearrangement of whole raw bamboos and production technical method thereof

InactiveCN103072160AKeep natural widthLow costWood veneer joiningWood layered productsEngineeringMechanical property

The invention discloses a laminated board formed by the fine disintegration and rearrangement of whole raw bamboos and a production technical method thereof. Moso bamboos are used as raw materials. The method comprises the following steps that first, raw arc-shaped bamboo sheets are finely cut, disintegrated, rolled and unfolded by a machine to form longitudinal bamboo filaments, the bamboo filaments are laterally connected into planar trapezoid bamboo blocks of basically identical thickness, and the widths of the planar trapezoid bamboo blocks gradually change from one ends to the other ends; then, the wide ends and the narrow ends of two adjacent bamboo blocks are alternately put according to the width direction of the same end of one planar trapezoid bamboo block, the bamboo green sides or the bamboo yellow sides are arranged on the same upper side or the same lower side, and the bamboo blocks are glued to form a whole board, thereby forming a fine disintegrated bamboo filament block single-layer board; and at least two layers of fine disintegrated bamboo block single-layer boards are layered and laminated in a way that the bamboo green sides of two adjacent layers of single-layer boards are close or the bamboo yellow sides and the bamboo green sides in two adjacent layers are close, and the laminated board formed by the fine disintegration and rearrangement of the whole raw bamboos is obtained after different layers of single-layer boards are glued by an adhesive and hot-pressed into a whole. According to the invention, the bamboo bodies are stored to an utmost extent, a cut quantity is reduced, and the mechanical properties of the raw bamboo materials are exerted.

Owner:HUNAN ACAD OF FORESTRY +1

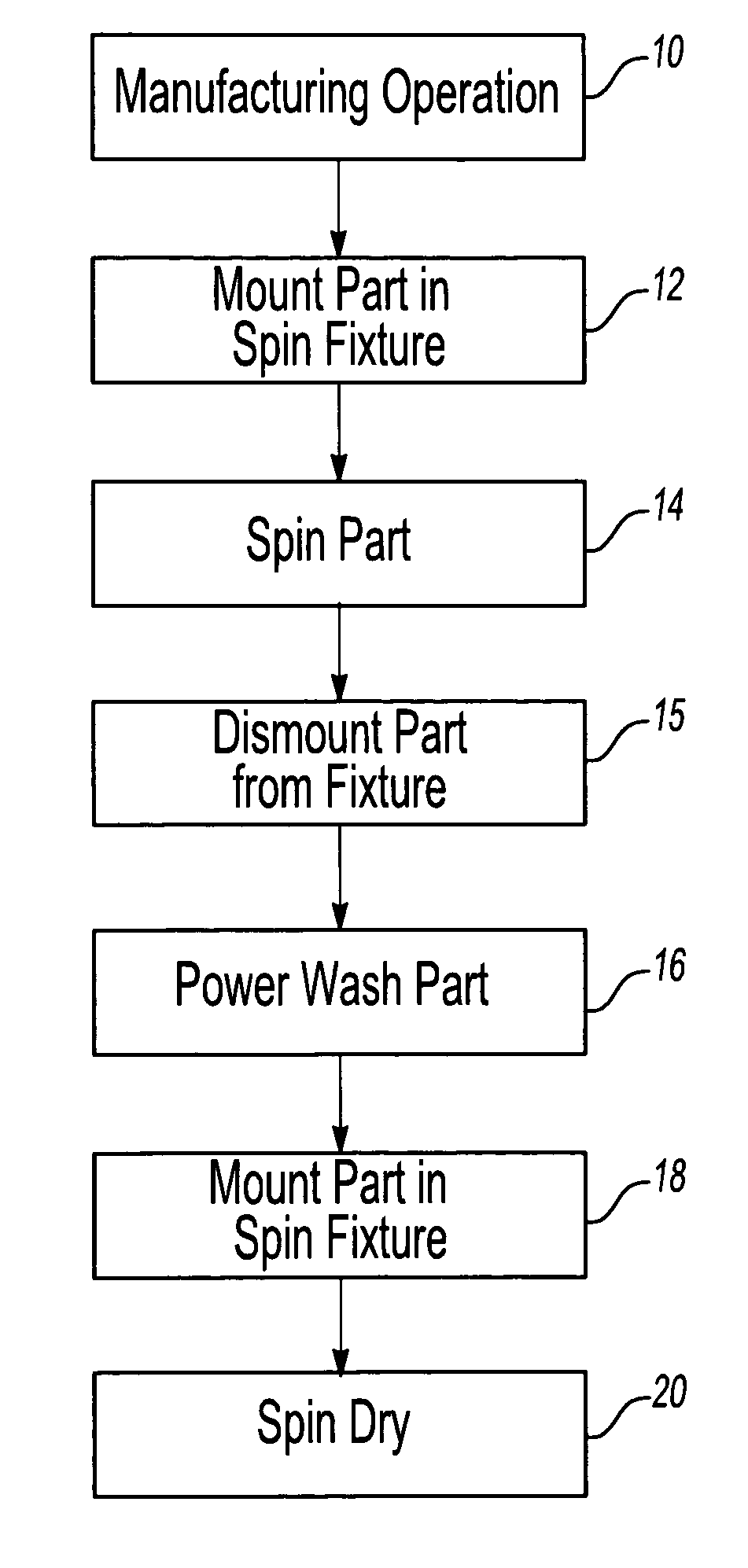

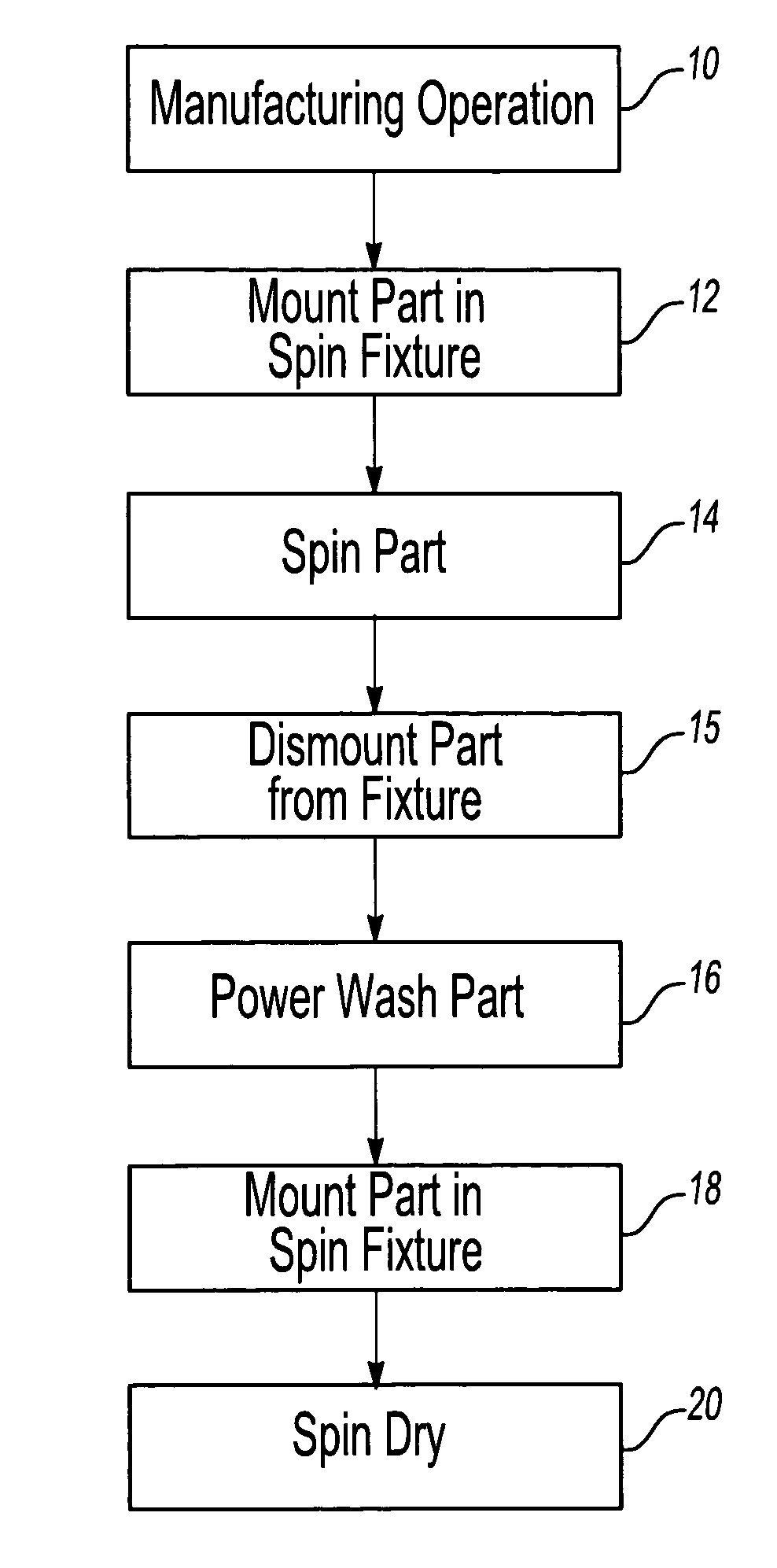

Method for cleaning an industrial part

InactiveUS20060201536A1Avoid pollutionSave energyCleaning using gasesCleaning using liquidsWood shavingsFoundry

A method for cleaning an industrial part, such as crankshafts, engine blocks and the like, following a manufacturing operation after which manufacturing debris, such as oils, shavings, and / or foundry sand, are present on the part. The part is first spun at a speed and for a time period sufficient to eject at least a portion of the debris and oil from the part after the manufacturing operation. Thereafter, the part is washed with a cleaning solution to remove the remaining oil and debris from the part. Optionally, the part is spun dry after being washed with the cleaning solution.

Owner:VALIANT CO LTD

Process and apparatus for the recovery of ethylene glycol in the production of polyethylene terephthalate

ActiveUS20100041925A1Low costSave investmentOrganic compound preparationOxygen compounds purification/separationPolyethylene terephthalatePolymer science

A method and apparatus are disclosed for the recovery of ethylene glycol in a polyethylene terephthalate(PET) production process, in which water accumulating in the esterification reaction is mixed with a process fluid containing 2-methyl-1,3-dioxolane (MDO). The mixing is carried out in a tank arranged upstream of a rectification column. Through the increase in the water content in the fluid, a shift in the reaction equilibrium takes place and consequently a cleavage of the 2-methyl-1,3-dioxolane present into ethylene glycol and acetaldehyde takes place. Following the cleavage reaction, the mixture is fed from the tank into a rectification column, whereby the ethylene glycol produced from the cleavage reaction is returned to the PET production process.

Owner:LURGI ZIMMER GMBH

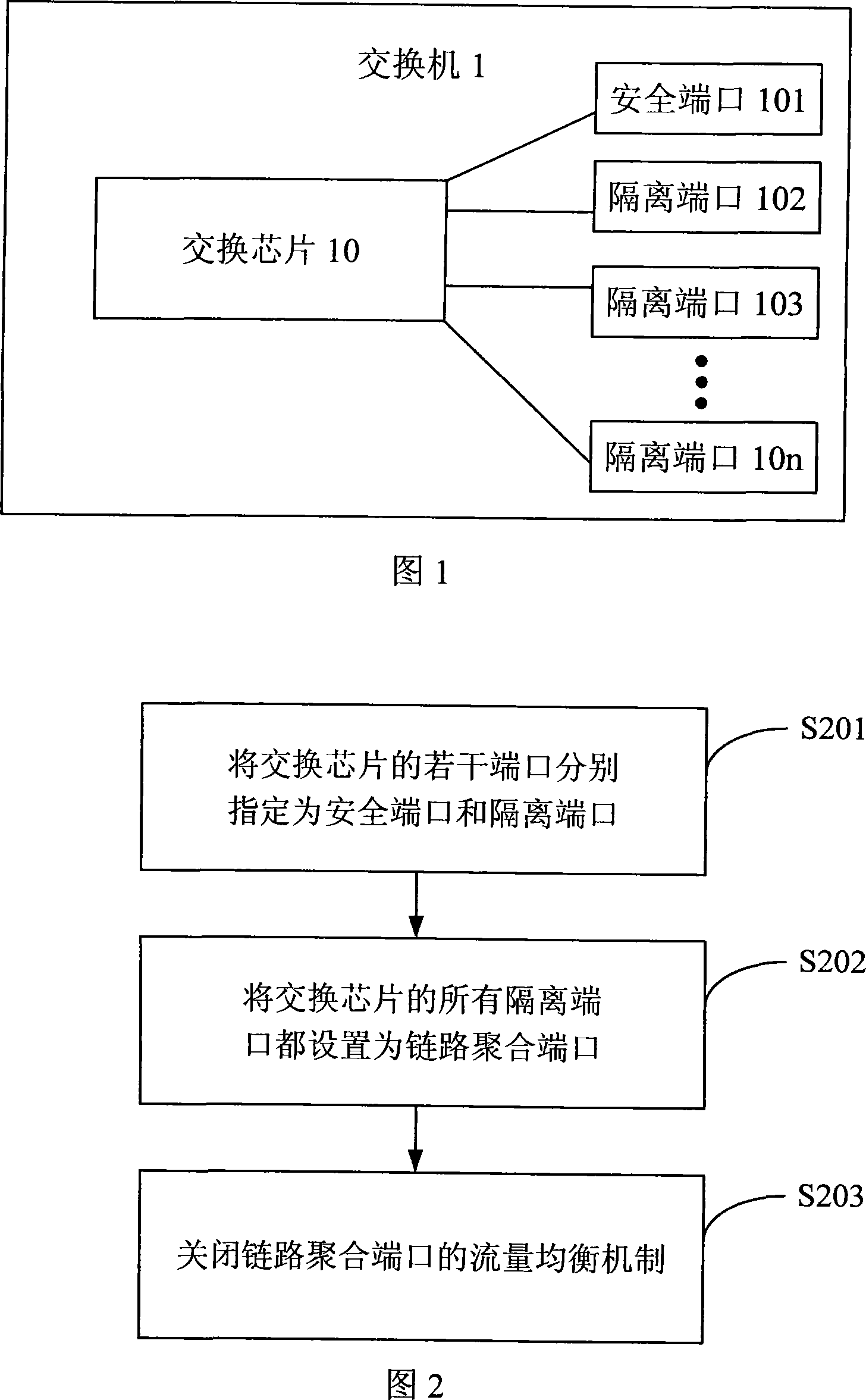

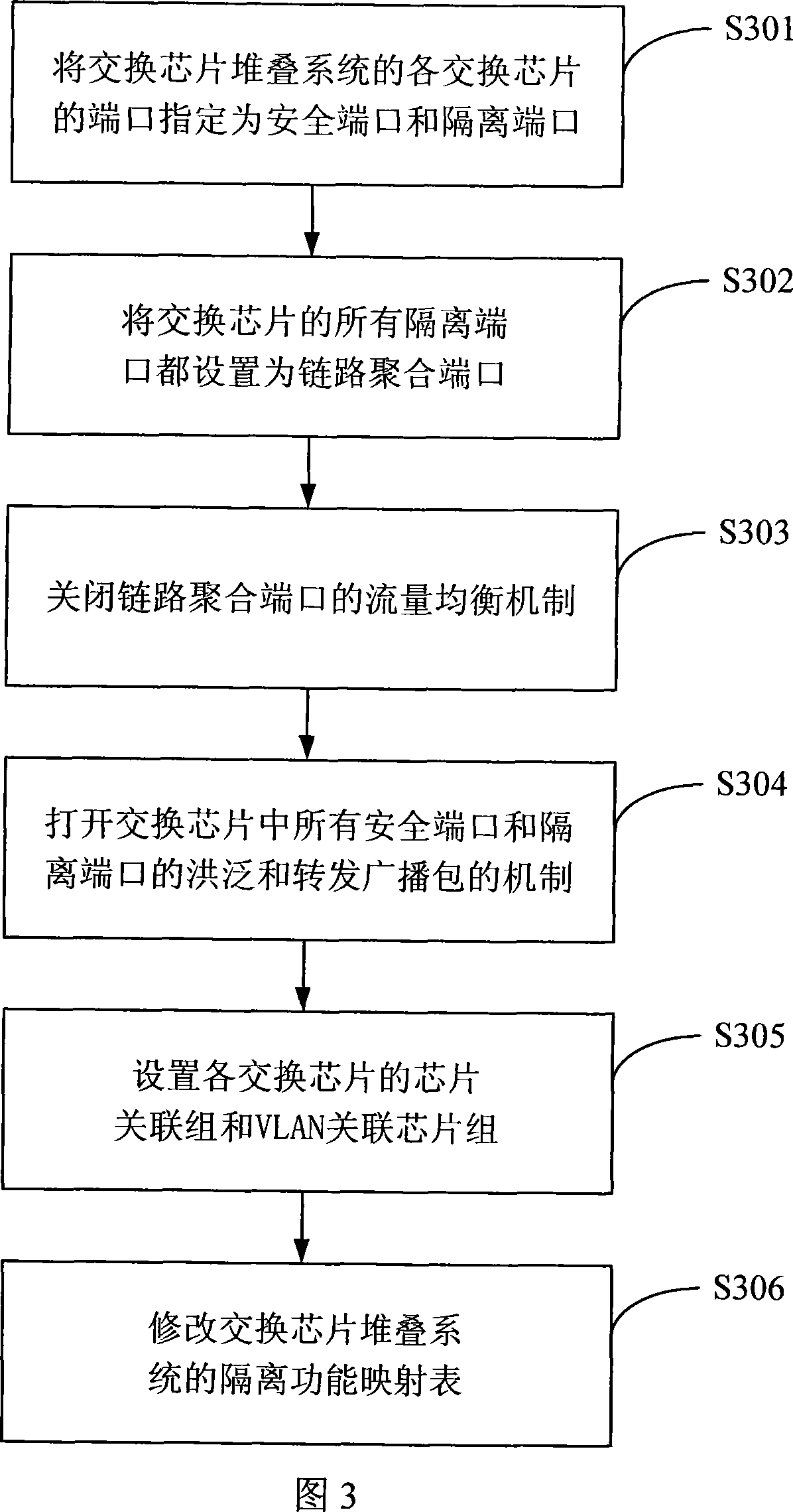

Method, switch and switching chip for port separation of switch

InactiveCN101123510AImprove isolationLarge choiceData switching detailsNetworks interconnectionLink aggregationUsability

The invention discloses a method for realizing switch port isolation. The method comprises the steps of: respectively designating several ports of a switch chip as safe ports and isolated ports; setting all the isolated ports of the switch chip as link aggregation ports; Turn off the traffic balancing mechanism of the link aggregation port to ensure that the Layer 2 forwarding is performed according to the normal mechanism. Correspondingly, the present invention also provides a switch and a switch chip for realizing port isolation. The invention not only achieves a good port isolation effect, but also enables the switch to have a greater choice in using the switching chip, and it can realize port isolation by using a low-end switching chip, thereby saving the investment required for purchasing a high-end switching chip and cost, thereby improving the practicability and stability of the product.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

Nonadjustable focusing type camera module

InactiveUS7555211B2Reduce manufacturing costMinimized volumeTelevision system detailsSolid-state devicesCamera lensOptical axis

A nonadjustable focusing type camera module includes a lens assembly having at least one lens, a lens accommodating part mounted on an upper surface of a substrate, and a barrel having an inner space in which the lens assembly is arranged along an optical axis. An upper cap having an incident hole formed in a front center thereof is fixed to the upper side of the barrel to apply pressure to the lens assembly along the optical axis. The camera module further includes an image sensor having an image forming plane on which a light passed through the lens is focused. The sensor is electrically connected to the substrate to transmit the focused image, and a filter is disposed between the lens assembly and the image sensor.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

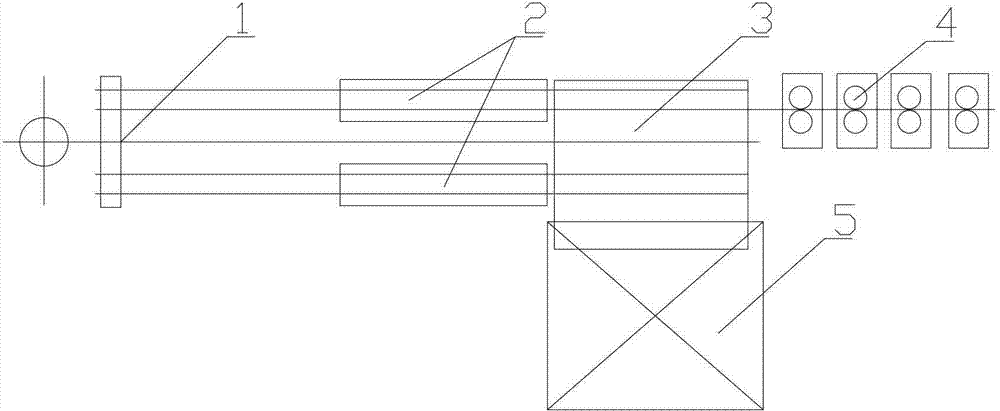

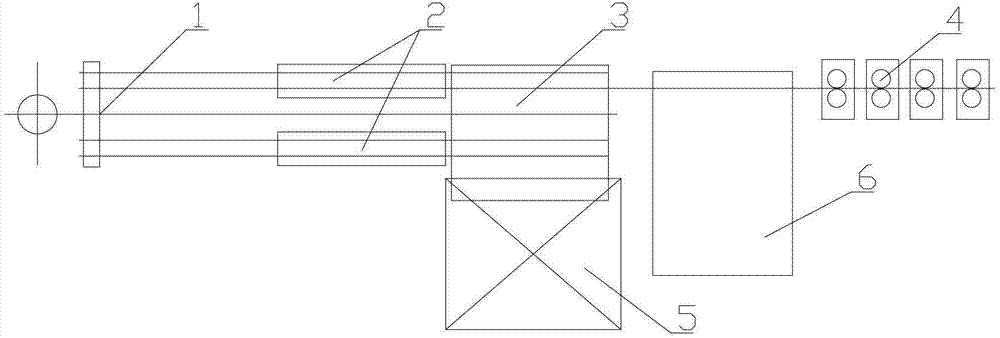

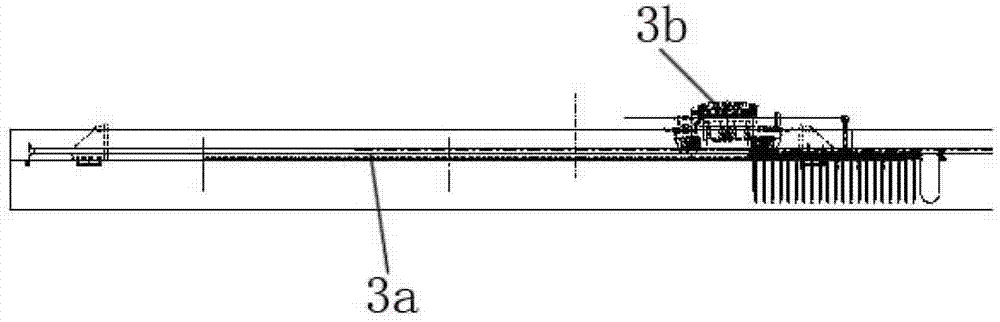

Continuous casting and rolling device and method for producing long profiles

InactiveCN102764762AReduce consumptionReduce energy consumptionMetal rolling arrangementsHeating furnaceRegular Production

The invention discloses a continuous casting and rolling device and method for producing long profiles. The continuous casting and rolling device comprises a continuous casting machine. The rear part of a cutting machine of the continuous casting machine is closely connected with a roller-hearth type heating furnace, a translating device and a rolling machine in sequence, wherein the rolling machine is used for rolling at low temperature. Because the rear part of a cutting machine of the continuous casting machine is closely connected with the roller-hearth type heating furnace, the translating device and the rolling machine 4, and the rolling machine 4 is used for rolling at low temperature, the continuous casting and rolling process of the long profiles can be realized in the embodiment of the invention, the energy consumed for producing the long profiles conventionally can be reduced greatly, the investment of equipment of producing the long profiles conventionally and the floor area can be saved, and the amount of labor and the consumption of metal can be decreased.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

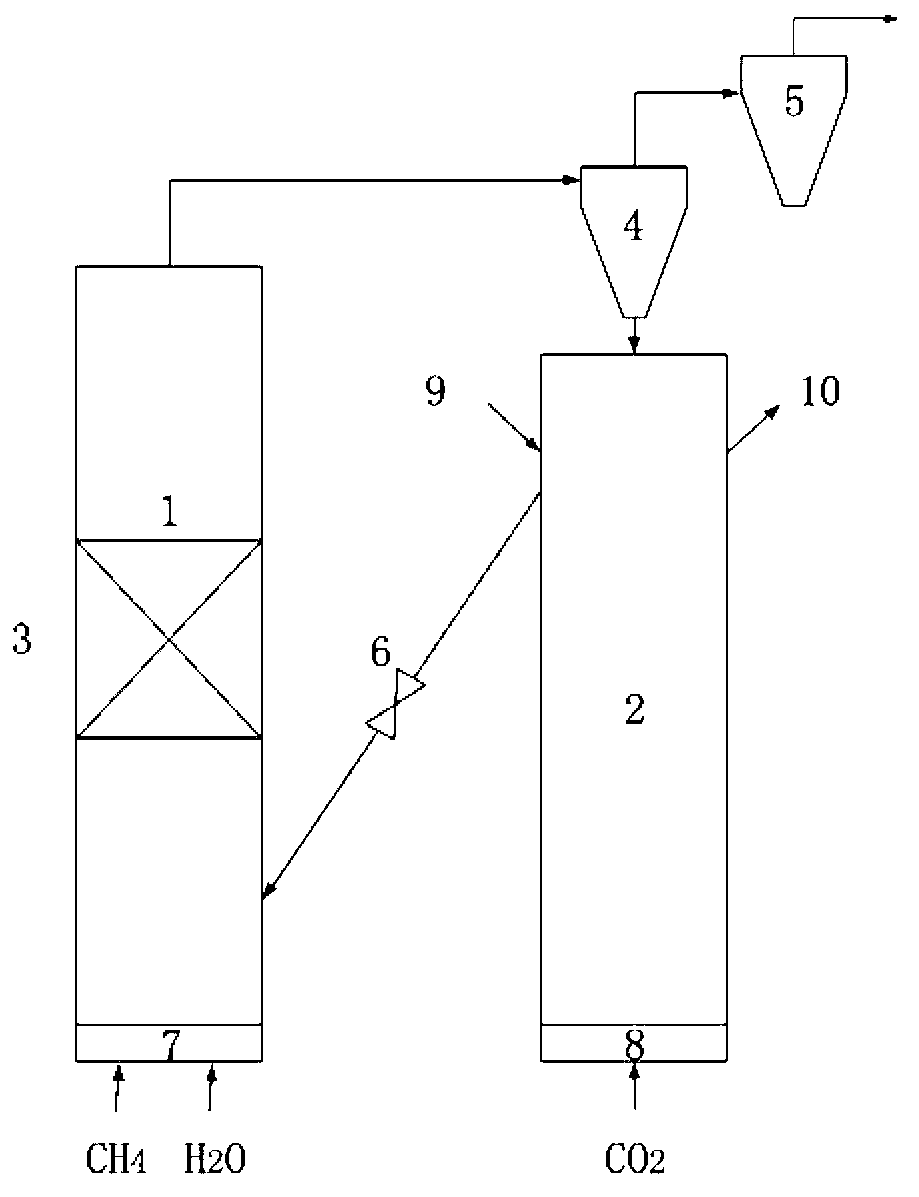

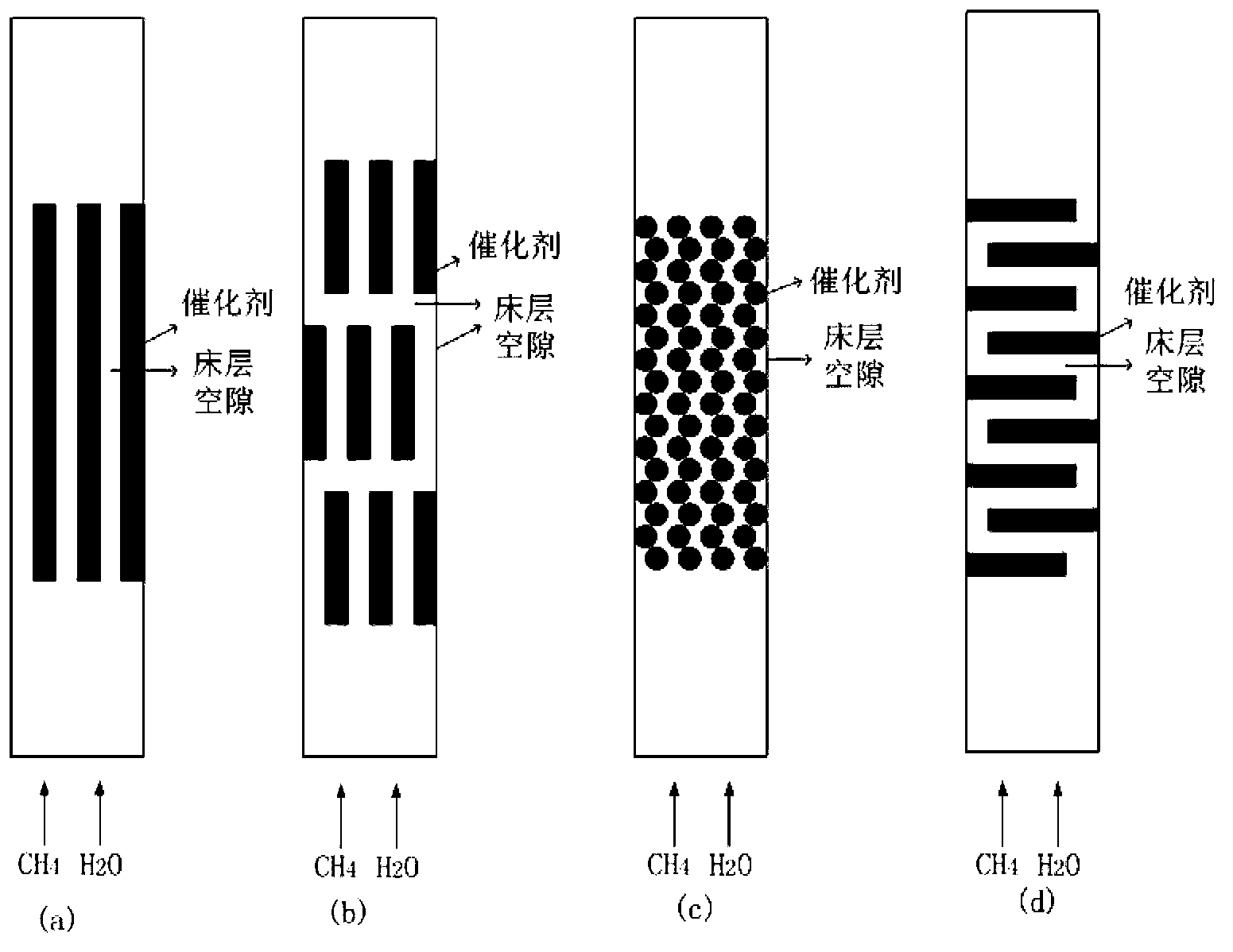

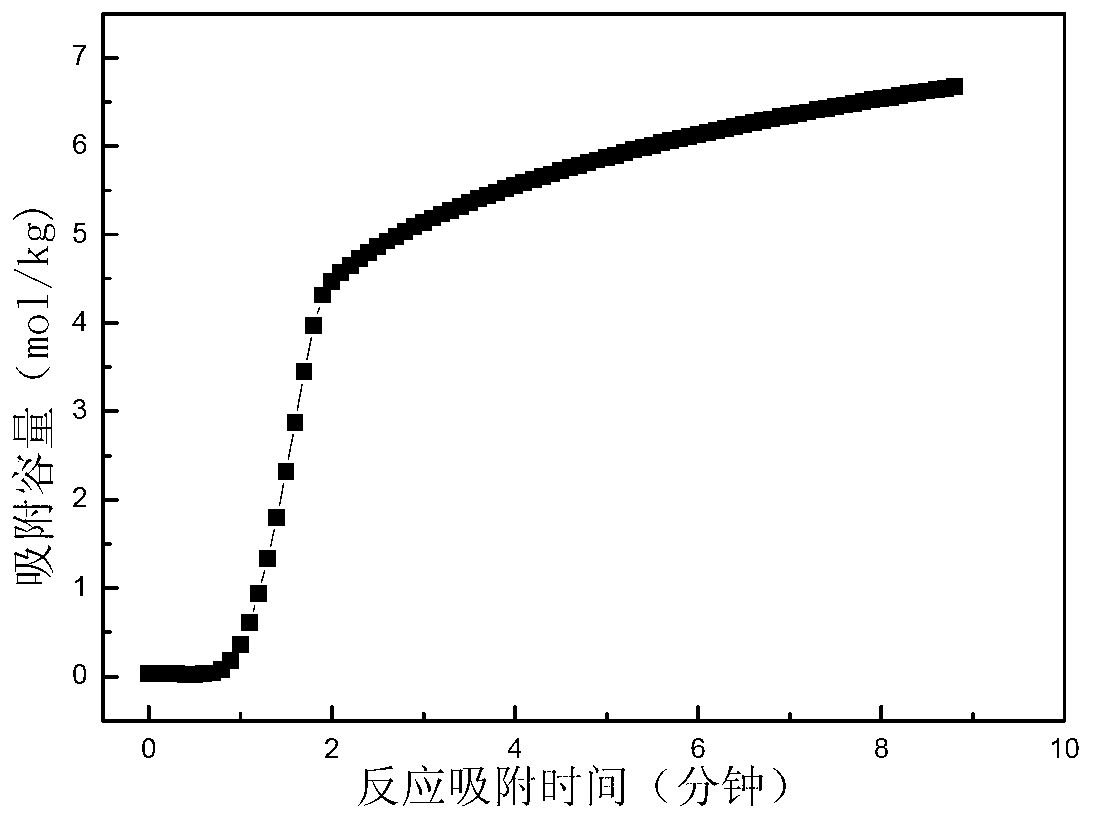

Fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device and method by methane vapor reforming

ActiveCN103288049ASolve the problem of easy deactivation at high temperatureEfficient hydrogen productionHydrogenChemical recyclingCycloneSorbent

The invention discloses a fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device by methane vapor reforming, which mainly comprises a fluidized-fixed composite bed reactor, a primary cyclone separator, a secondary cyclone separator and a regenerator. The invention also discloses a reaction adsorption reinforced hydrogen production method by methane vapor reforming, which comprises steps as follows: a nickel-base reforming catalyst is fixed and filled into the composite reactor in a specific mode; a nano or micro CaO-base CO2 adsorbent in a fluidized state can contact a catalyst bed layer, and the reaction adsorbs CO2 released by the reforming reaction; and the CO2 enters the separators and regenerator through the catalyst bed layer, and enters the fluidized-fixed composite bed reactor to be recycled. The method and device disclosed by the invention avoids the possibility of the catalyst entering the high-temperature regenerator, thereby prolonging the service life of the catalyst; and the invention solves the problem of unmatched service life between the catalyst and adsorbent when a single fixed bed or fluidized bed reactor is used for reaction adsorption to reinforce the methane vapor reforming reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

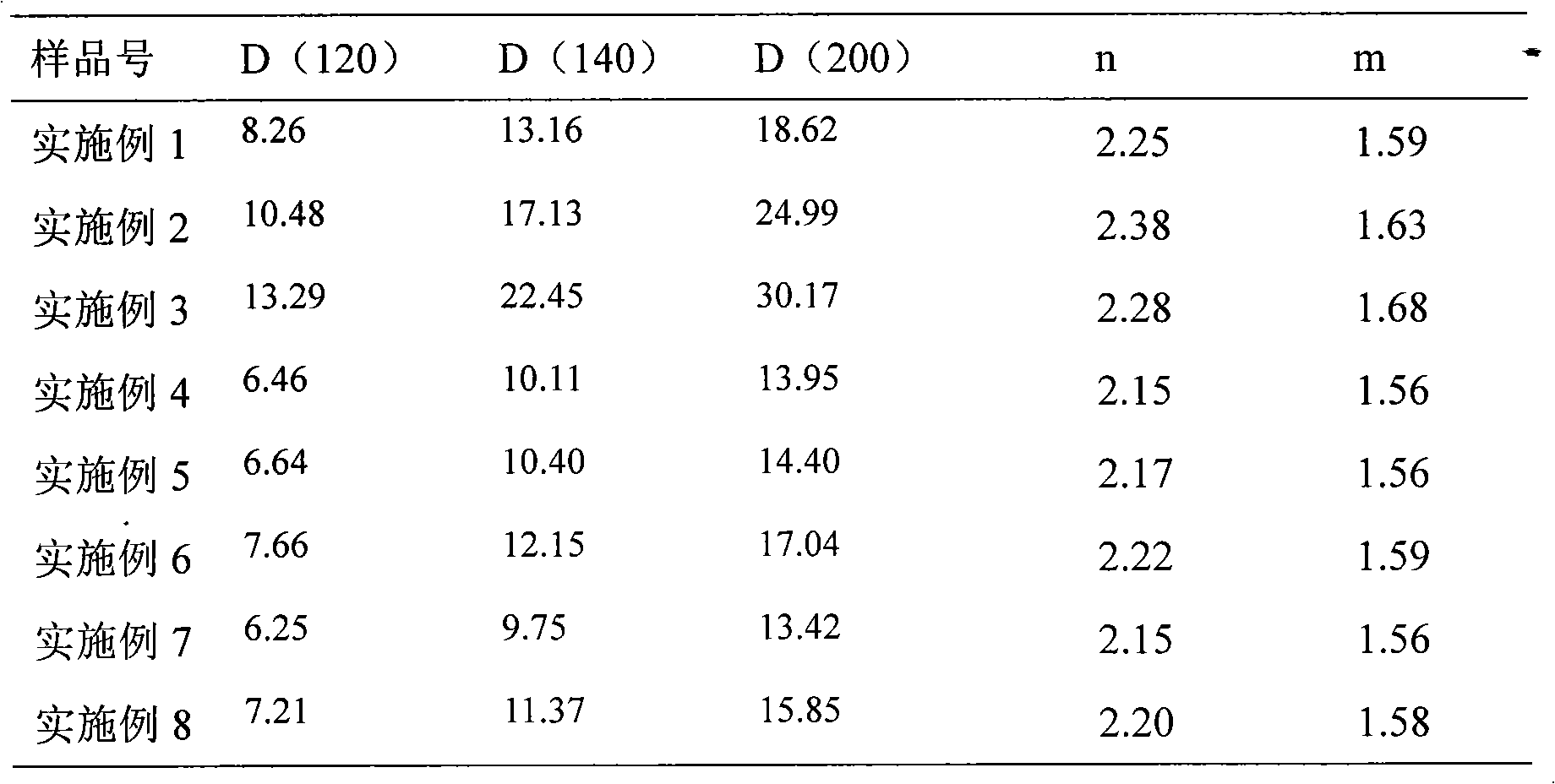

Preparation method of high-purity boehmite

InactiveCN102120597AHigh puritySave investmentAluminium oxide/hydroxide preparationHigh carbonSolvent

The invention provides a preparation method of high-purity boehmite, belonging to the technical field of synthesis of metallic organic compounds. The preparation method comprises the following steps of: preparing alkoxyl aluminum by adopting metallic aluminum with the purity more than 99.5 percent and mixed alcohol of C5-C8 and n-butyl alcohol under the existence of aluminum choride and alkylbenzene solvents; and hydrolyzing, aging and drying the alkylbenzene to obtain the high-purity boehmite. The invention overcomes the defects that the purification is difficult when the alkoxyl aluminum is prepared with low-carbon alcohol and the reaction efficiency is low when the alkoxyl aluminum is prepared with high-carbon alcohol and can obtain the boehmite with the purity up to 99.9 percent by controlling the proportion of the mixed alcohol and the metallic aluminum and the hydrolysis condition. The method provided by the invention ensures that the preparation process of the high-purity boehmite is simplified, the preparation efficiency is high, and the preparation cost is low.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

Preparation method of palladium-platinum bimetallic catalyst

InactiveCN103071486AHigh activityExtend your lifeOrganic compound preparationAmino compound preparationActivated carbonPlatinum

The invention relates to a preparation method of a palladium-platinum bimetallic catalyst. The preparation method is characterized by using active carbon as a carrier, pretreating the active carbon respectively by hydrochloric acid and nitric acid before preparation, then simultaneously loading palladium and platinum on the pretreated active carbon, and adding an activating agent into the active carbon with palladium and platinum for reduction to finally obtain the palladium-platinum bimetallic catalyst. According to the invention, the preparation method is simple; and the obtained palladium-platinum bimetallic catalyst disclosed herein has the advantages of high activity, long life, etc, and is especially suitable for preparing o-phenylenediamine by solvent-free hydrogenation.

Owner:JIANGSU YANGNONG CHEM GROUP +1

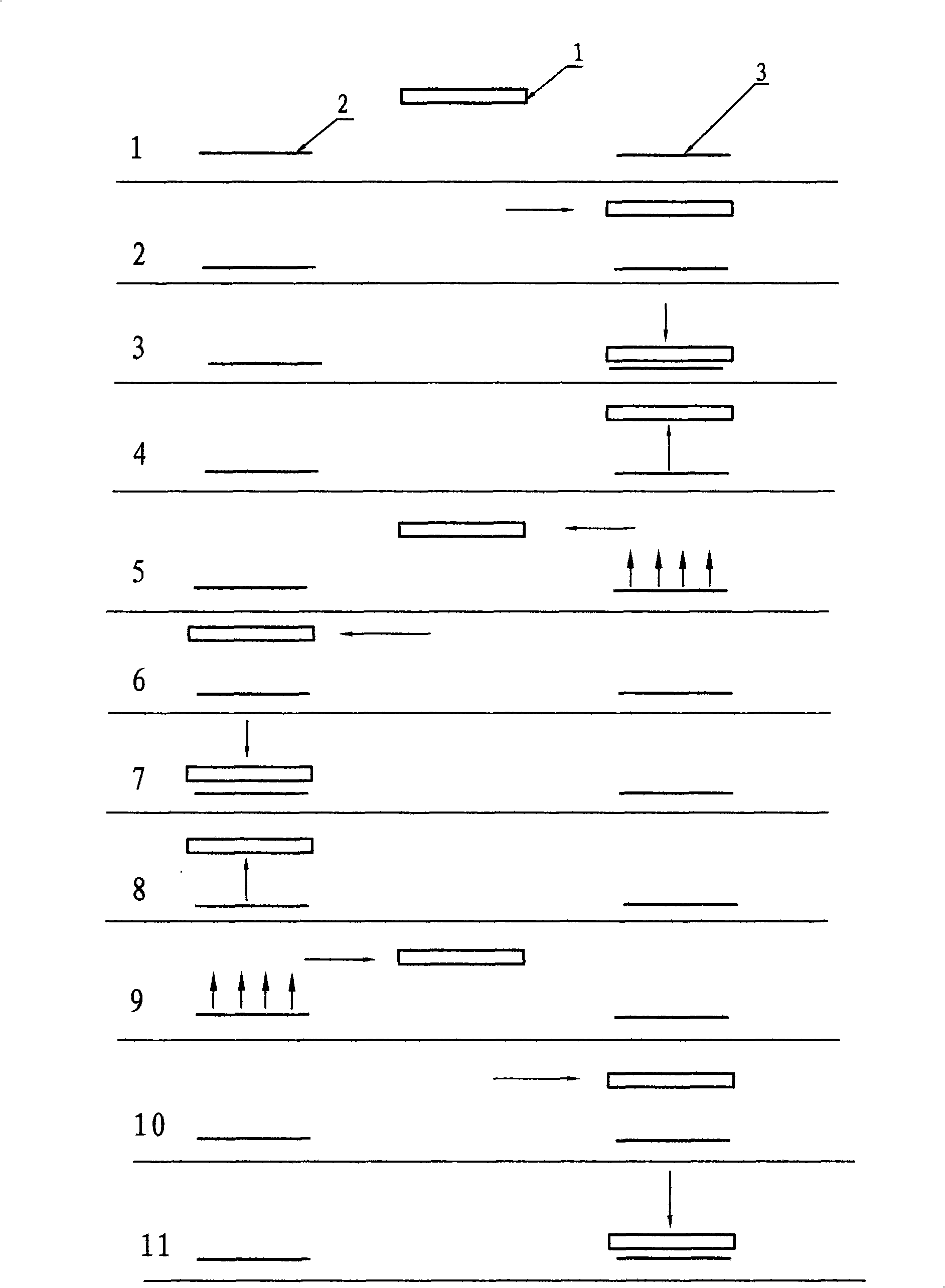

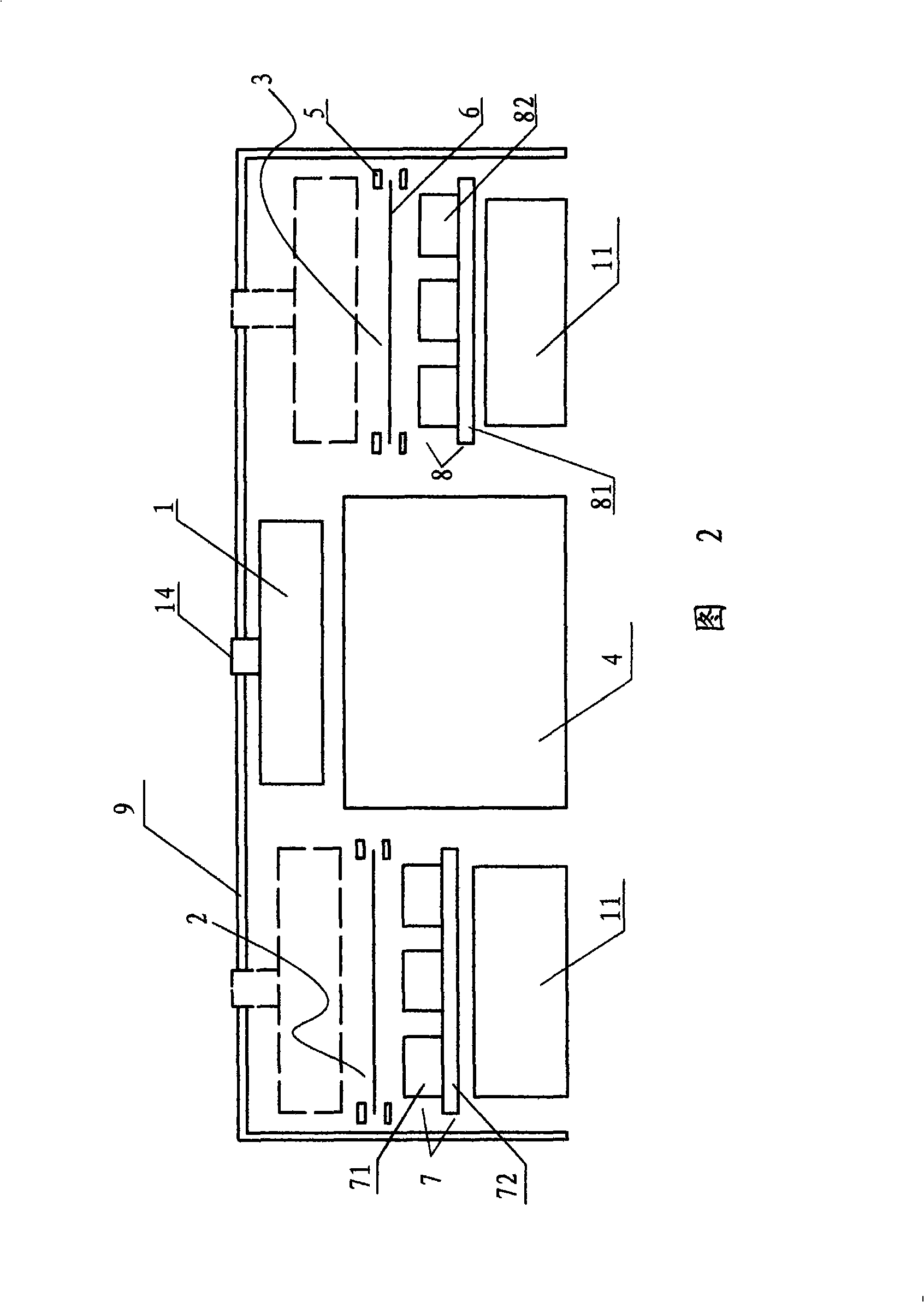

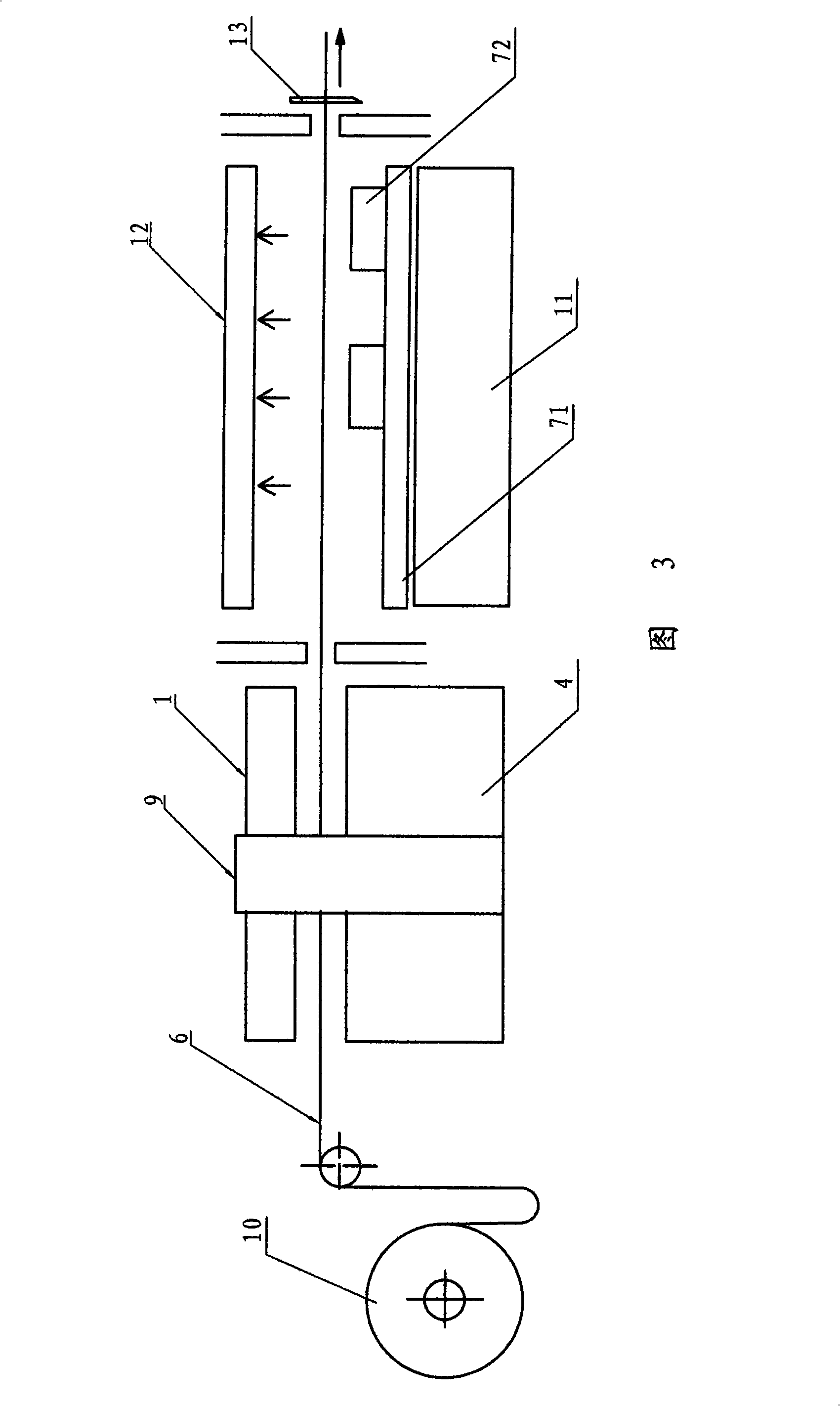

Efficient double-line suction plastic production method and device

The invention provides a high-efficiency dual-line plastic suction production method, comprising the steps as follows: 1) a bidirectional movable plastic suction heating furnace is arranged; the left side and the right side right below the plastic suction heating furnace are respectively provided with a set of vacuum forming processing line; 2) the plastic suction heating furnace is moved to the initial position and electrified to a given temperature, and the temperature is kept; 3) after the plastic suction heating furnace is transversely moved to one side right above the hot forming working position of the vacuum forming processing line, the plastic suction heating furnace vertically runs downwards to a given height H1 and remained for the time t1 so as to heat the material on the side of the processing line hot forming working position; 4) after the prearranged heating time t1 is reached, the plastic suction heating furnace runs upwards vertically and recovers transversely, and stops for a time t3; 5) the plastic suction heating furnace is moved to another processing line, runs downwards vertically by a height H2 and stops for a time t2; 6) the plastic suction heating furnace runs upwards vertically, transversely recovers and stops for a time t4; 7) the step 3) to step 6) are repeated. The invention also discloses a device which realizes the method of the invention.

Owner:DONGGUAN FUCAI PACKAGING PROD

Synthesizing process of fatty diglycollic amide

InactiveCN100999482ASimple processLess side effectsOrganic compound preparationCarboxylic acid amides preparationPotassium fluorideFiltration

This invention relates to a synthesis method of fatty acids diethanolamine. It takes fatty acid and diethanolamine as raw materials. The method includes follow steps: first fatty acids and a certain amount of diethanolamine for dehydration and condensation reaction, then adding the remaining diethanolamine and alkaline catalyst for aminolysis reaction, the final using activated clay for adsorption treatment, and through filtration to obtain fatty acid diethanolamine. The weight proportion between fatty acids and diethanolamine is 1:0.5 ~ 0.6; account for weight, 30 ~ 70% diethanolamine add in dehydration and condensation reaction, and the remaining add in aminolysis reaction; its alkaline catalyst is one of the alkali metal hydroxide, potassium fluoride and sodium borohydride, account for 0.3 to 2.0% of total weight of fatty and diethanolamine.

Owner:王伟松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com