Patents

Literature

41 results about "Sphere packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a sphere packing is an arrangement of non-overlapping spheres within a containing space. The spheres considered are usually all of identical size, and the space is usually three-dimensional Euclidean space. However, sphere packing problems can be generalised to consider unequal spheres, spaces of other dimensions (where the problem becomes circle packing in two dimensions, or hypersphere packing in higher dimensions) or to non-Euclidean spaces such as hyperbolic space.

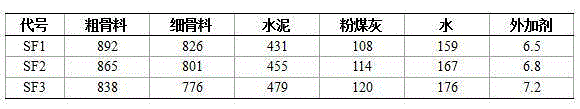

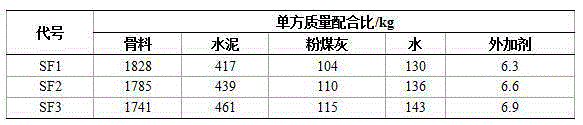

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

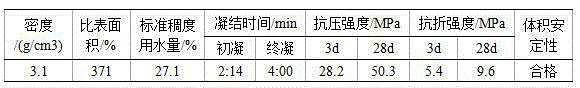

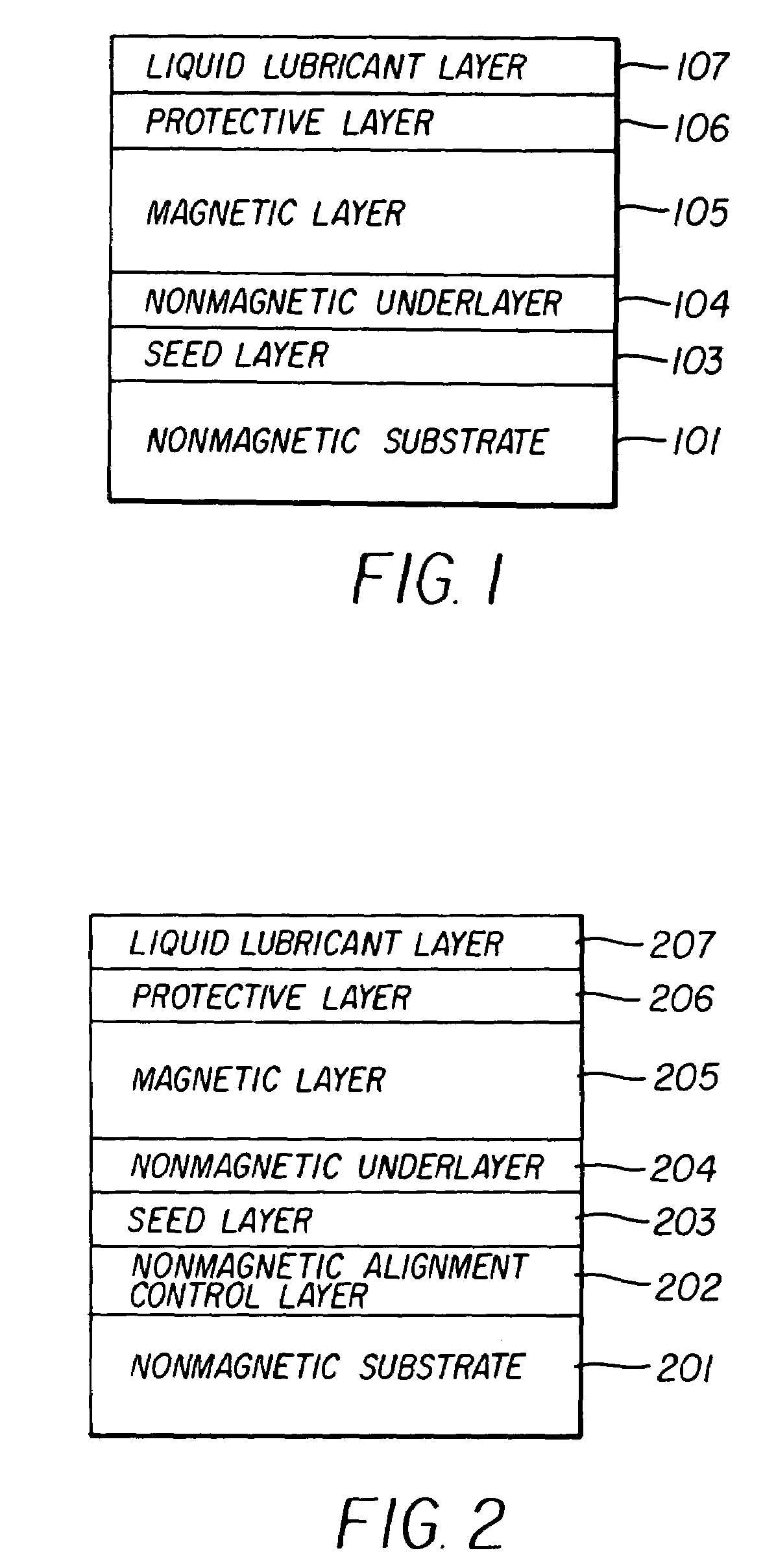

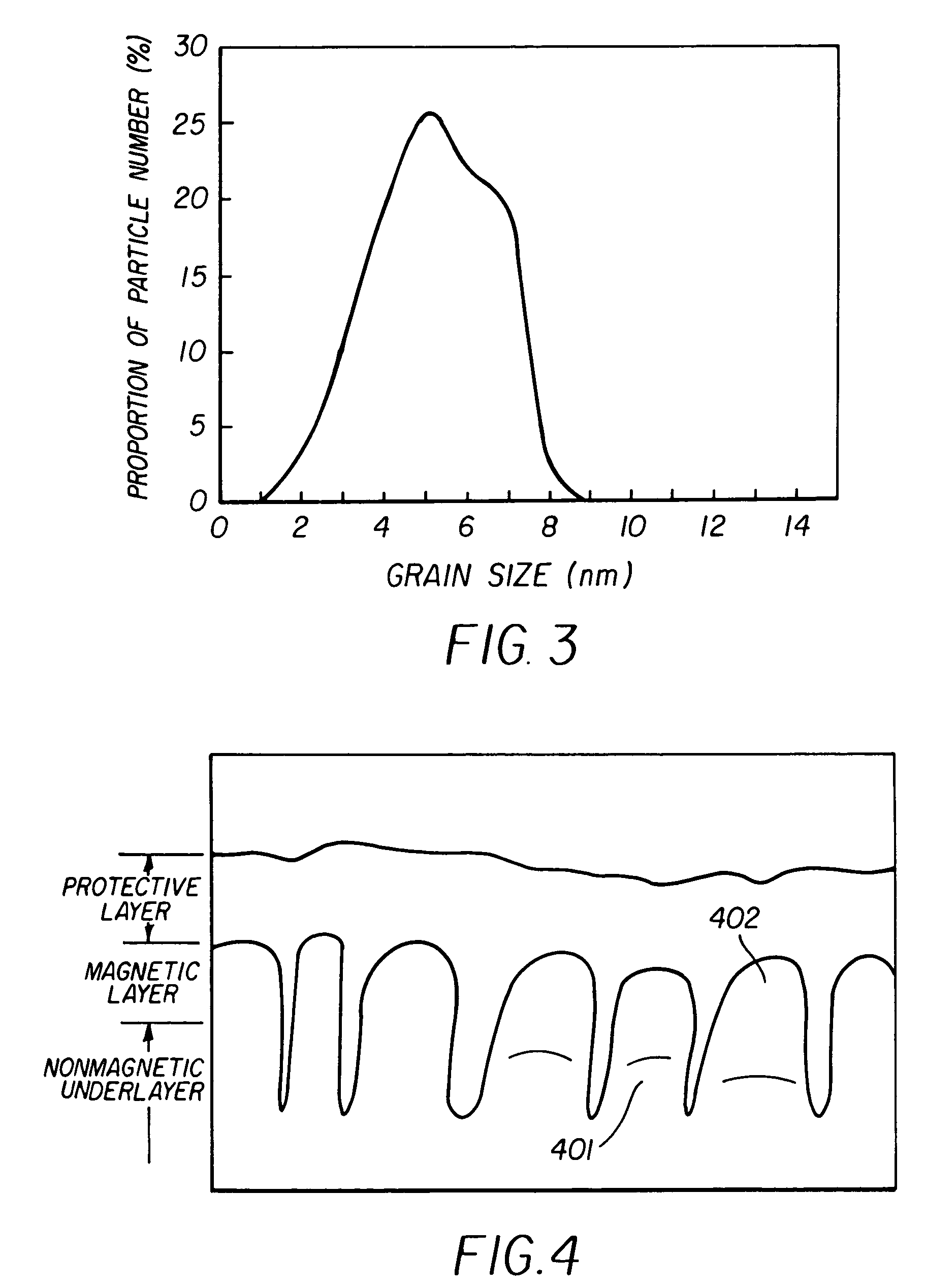

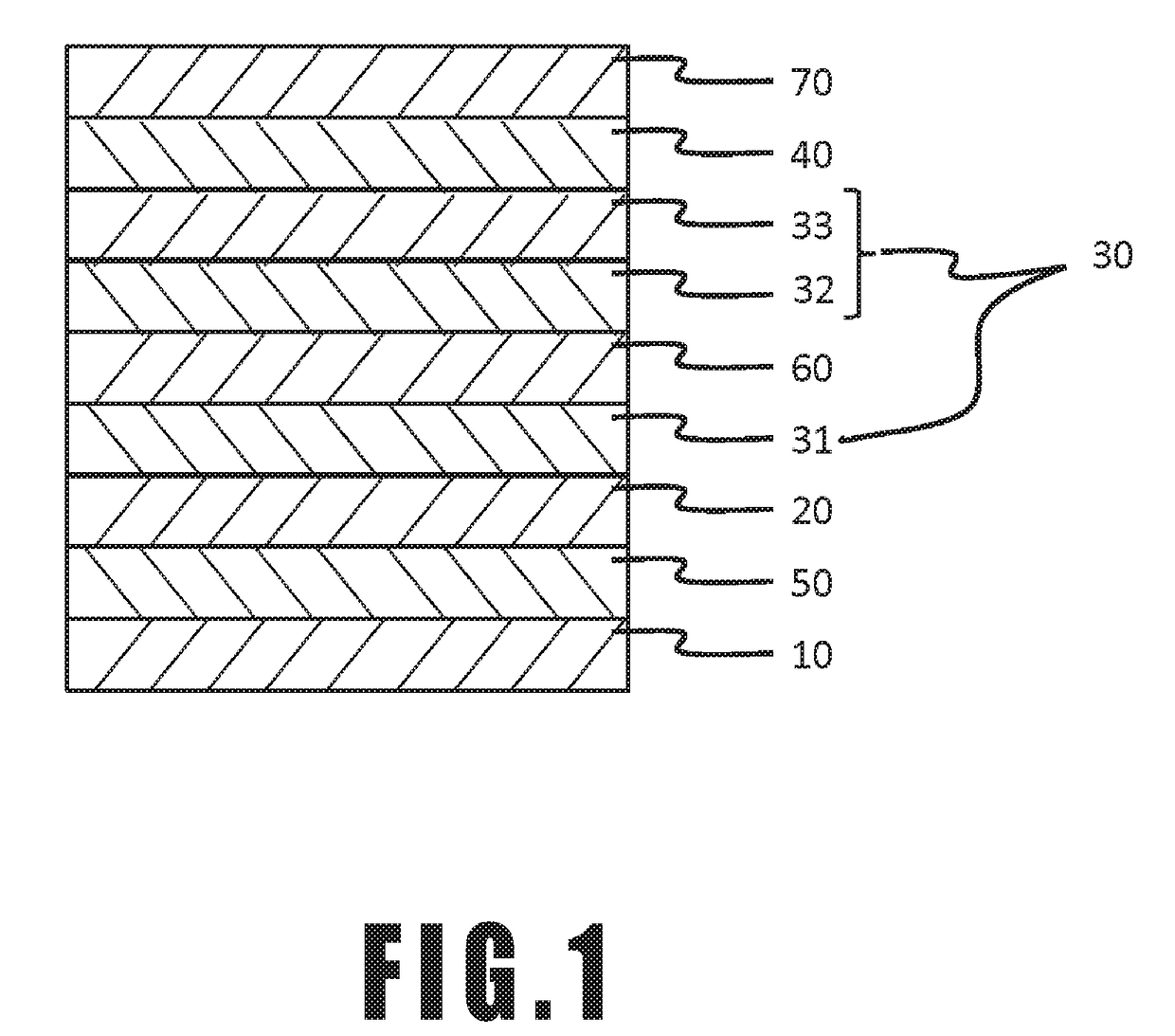

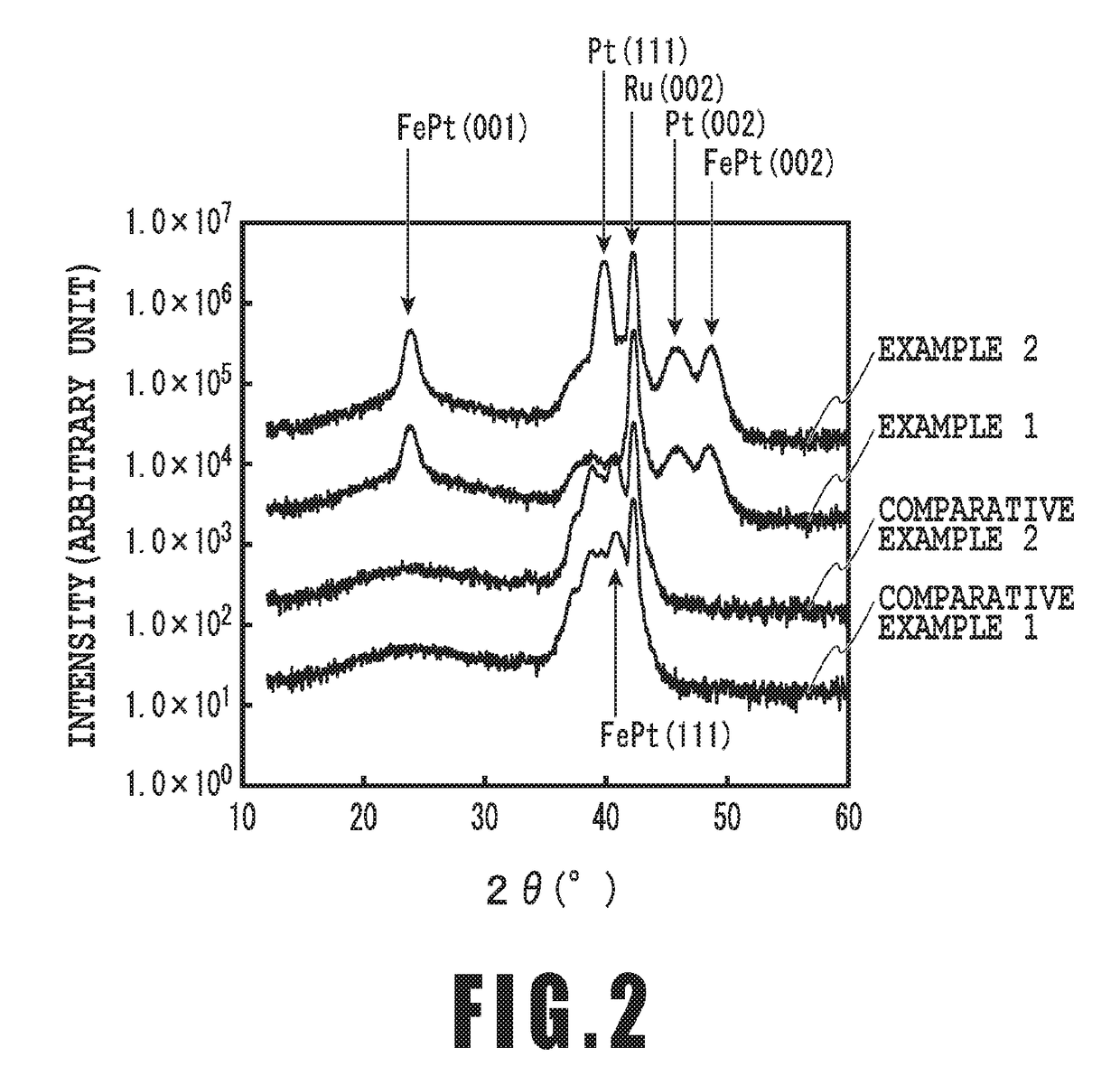

Magnetic recording medium

A magnetic recording medium for perpendicular magnetic recording system includes a nonmagnetic substrate and layers sequentially laminated on the substrate. The layers include a seed layer comprised of a metal or an alloy with a face centered cubic crystal structure, a nonmagnetic underlayer of a metal or an alloy with a hexagonal closest packed crystal structure, a magnetic layer having a granular structure including ferromagnetic crystalline grains with a hexagonal closest packed structure and nonmagnetic grain boundary region of mainly oxide surrounding the crystalline grains, a protective layer, and a liquid lubricant layer.

Owner:FUJI ELECTRIC CO LTD

Manufacture method for staining resistant artificial quartz stone

The invention particularly relates to a manufacture method for a staining resistant artificial quartz stone, which includes the steps of quartz stone powder sand surface modification, mixed pressing, sizing and solidifying and the like to generate a transparent film on the surface of the artificial quartz stone. The manufacture method has the advantages that by means of mechanical activation and modification of quartz stone powder sand serving as raw materials of the artificial quartz stone, flowability of the quartz stone powder sand during pressing is enhanced so that the quartz stone powder sand tends to be accumulated orderly and most densely, and binding of the quartz stone powder sand and resin during solidification is enhanced; the proportion and the grain distribution range are strictly controlled in an artificial quartz stone formula so that micron-sized pore quantity on the surface of the artificial quartz stone is decreased maximally; the surface of the artificial quartz stone is filled to form chemical adsorption so as to improve glossiness of the surface of the artificial quartz stone; and the micron-sized film formed on the surface of the artificial quartz stone has the hydrophobic feature, oil stains within 24 hours can be cleaned by wet cotton cloth, and hidden dirt and bleeding are effectively prevented, therefore, the artificial quartz stone is high in staining resistance. The manufacture method is simple in process, easy in operation and short in consumed time.

Owner:BENYEE NEW MATERIAL CO

Silica matrix chemically bonded phase packing

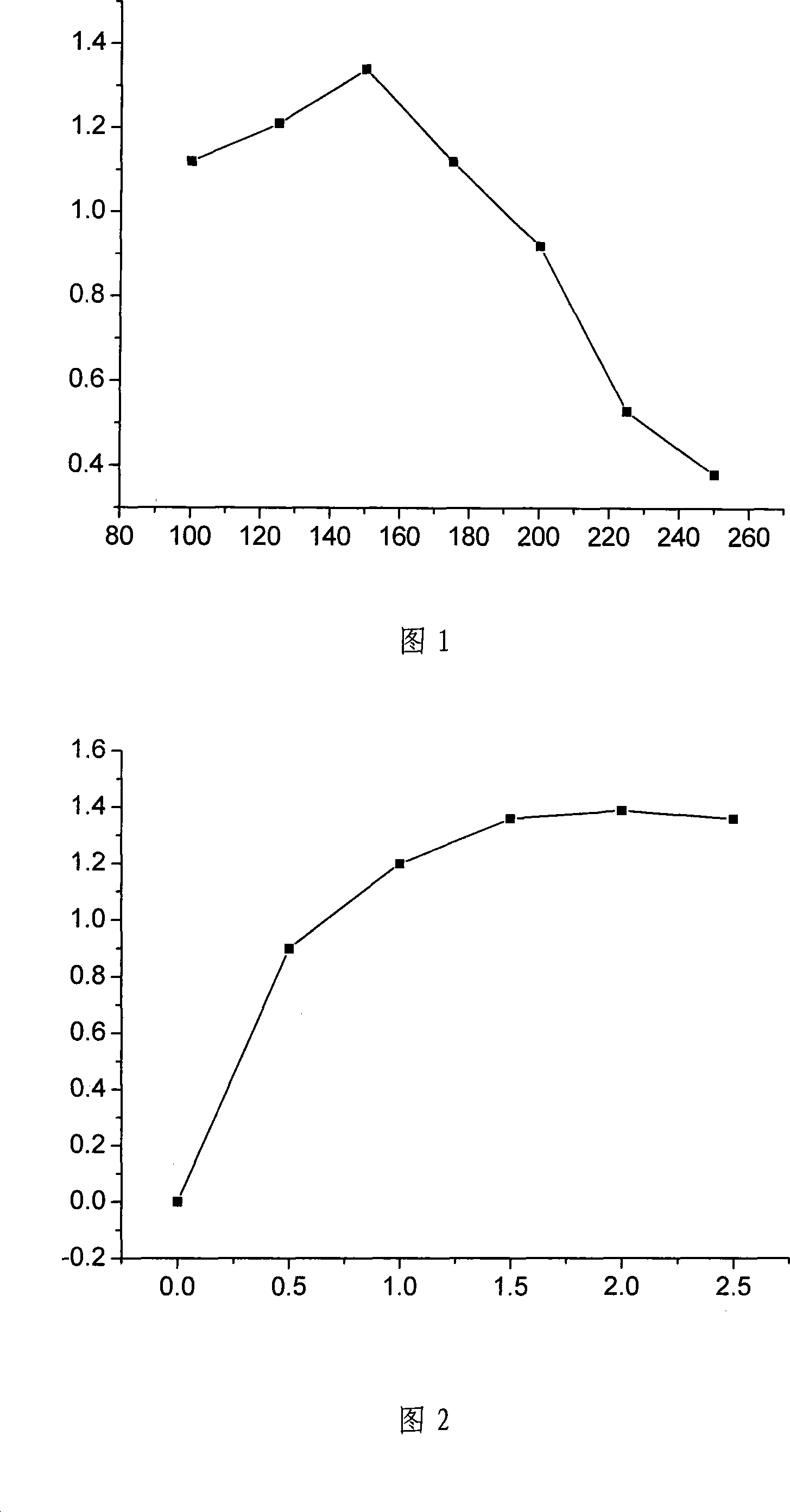

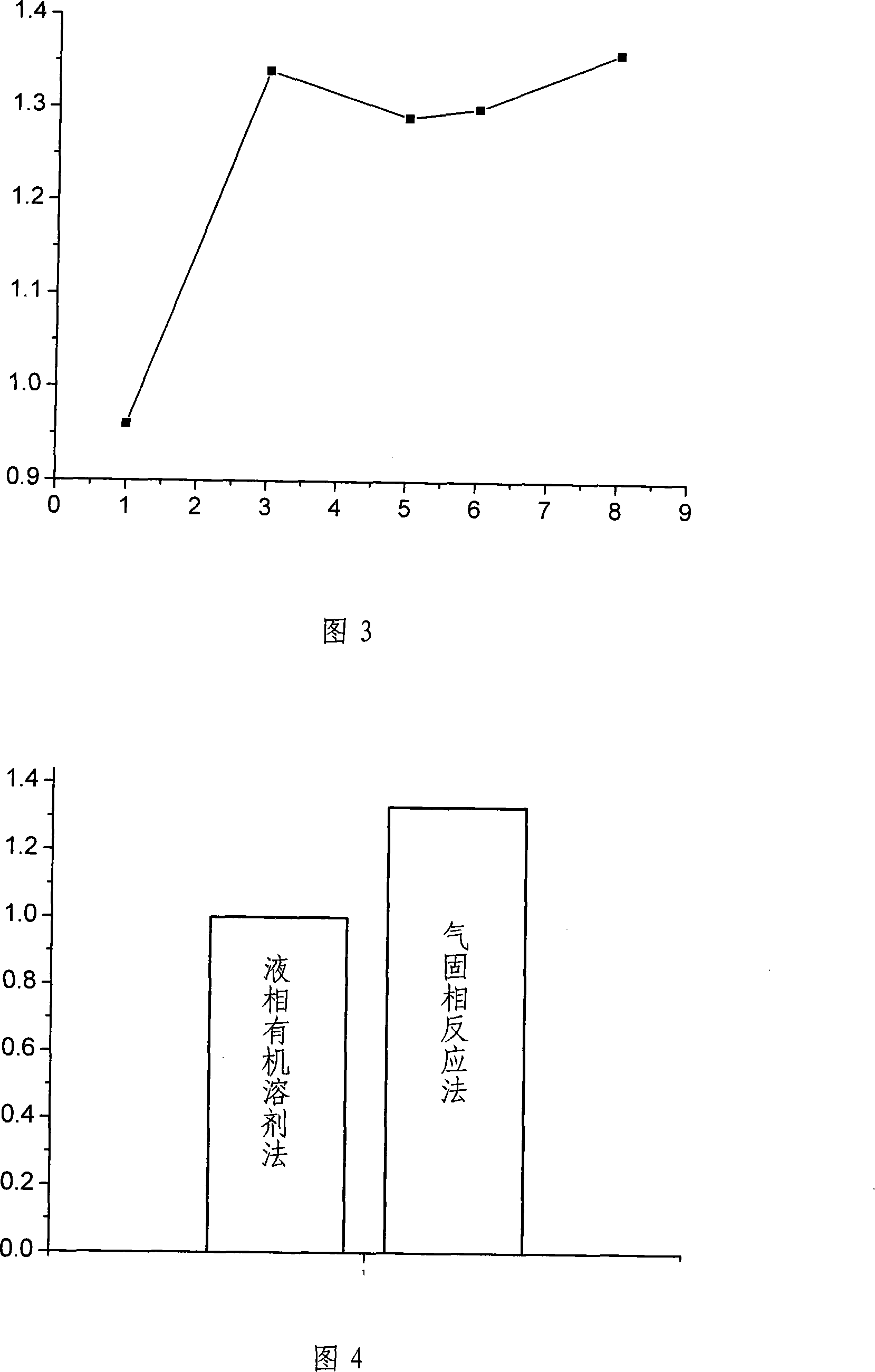

InactiveCN101234339AIncrease throughputShort response timeOther chemical processesChemical LinkageOrganic solvent

The invention relates to a preparation method of silica matrix chemically bonded phase stuffing, which belongs to the technical field of high efficiency liquid phase chromatography. The method comprises the following procedures: firstly, the acidification pretreatment of silica matrix stuffing produces silica matrix particles rich in hydroxide radical; secondly, the bonding of silica matrix stuffing; thirdly, the deactivation processing of silica matrix chemically bonded phase stuffing. Compared with the traditional organic solvent method, the stuffing prepared by the method has higher surface functional group bond rate, thus raising the selectivity and the separating size of the compartment analysis of samples.

Owner:TIANJIN UNIV

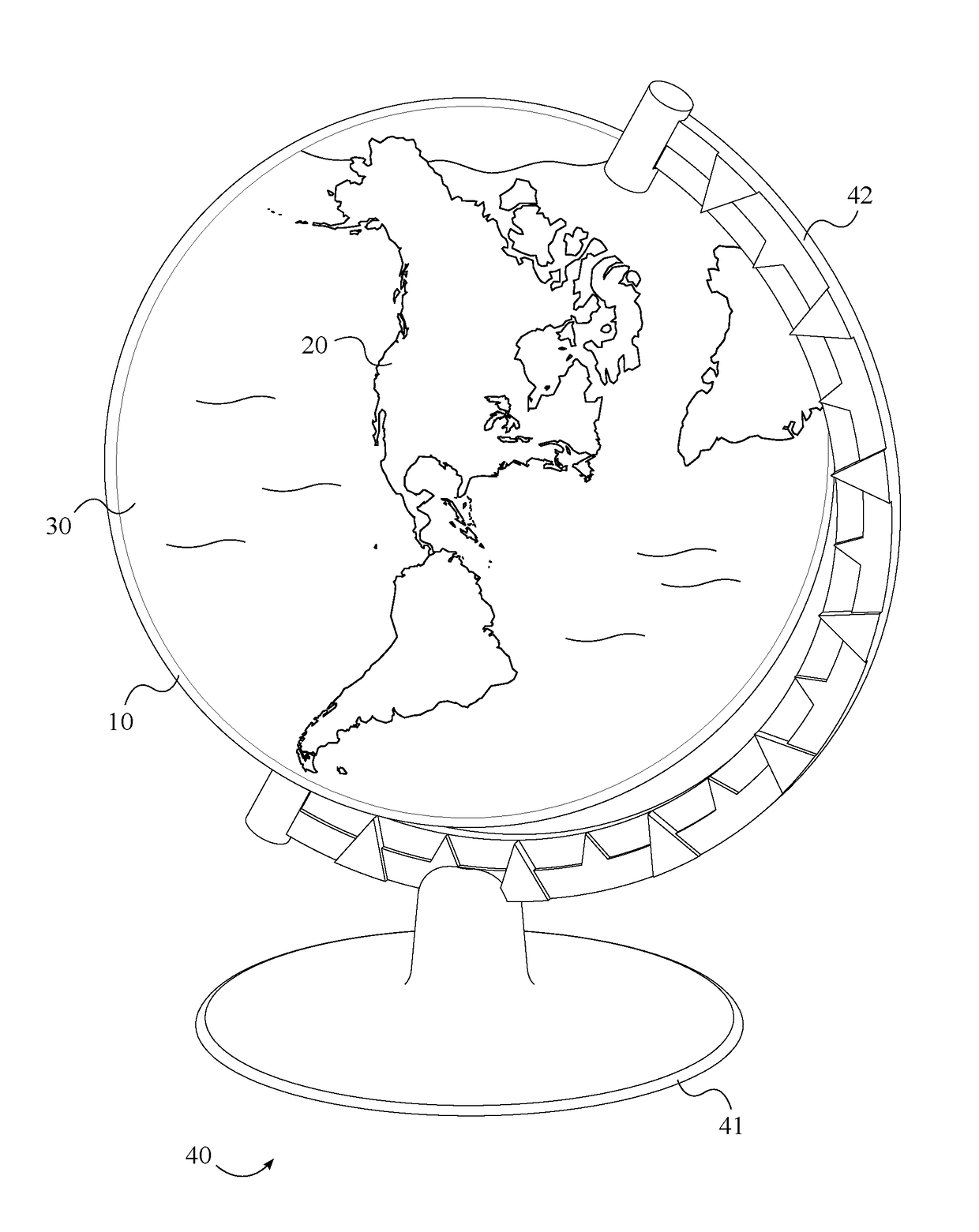

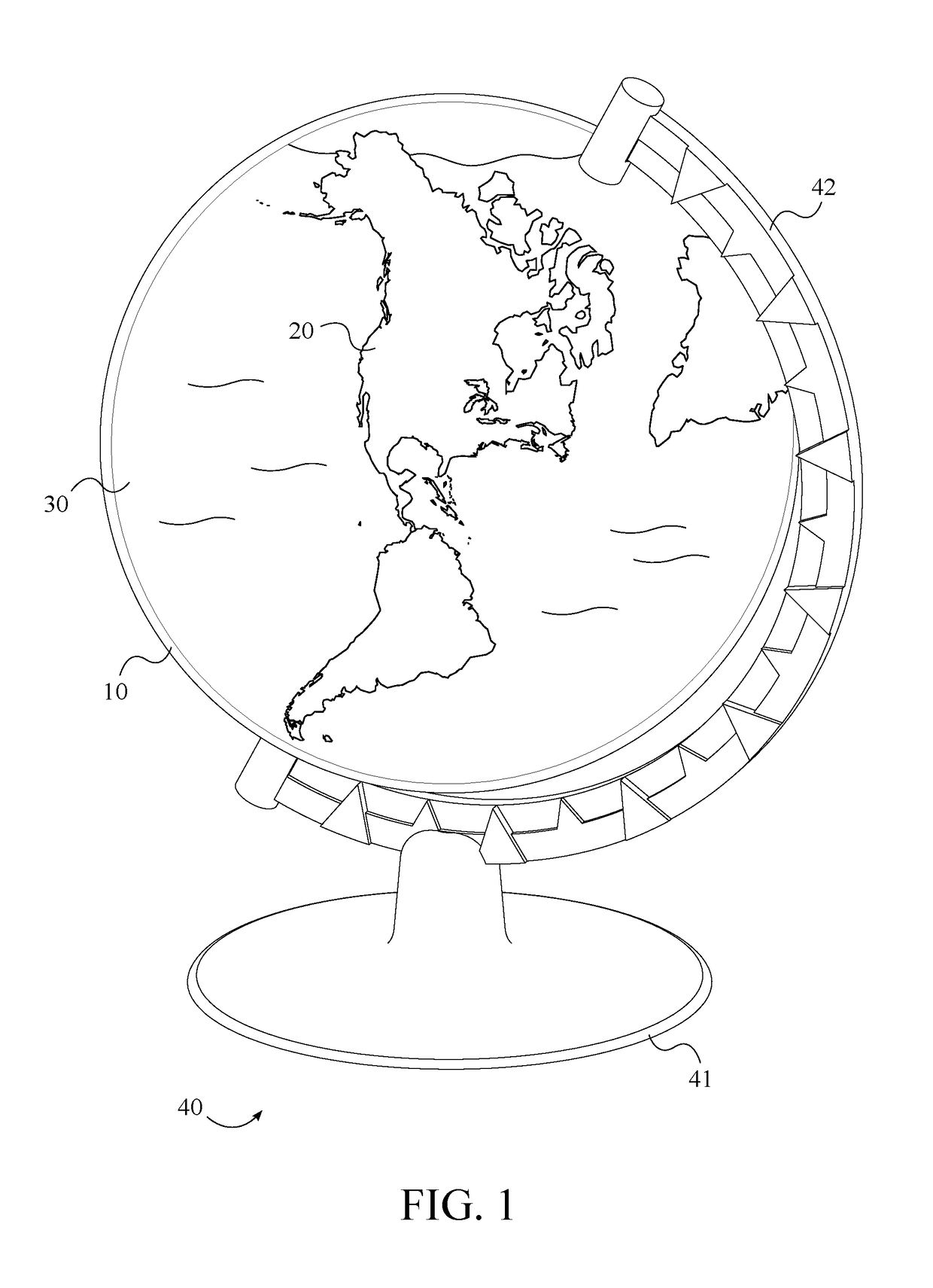

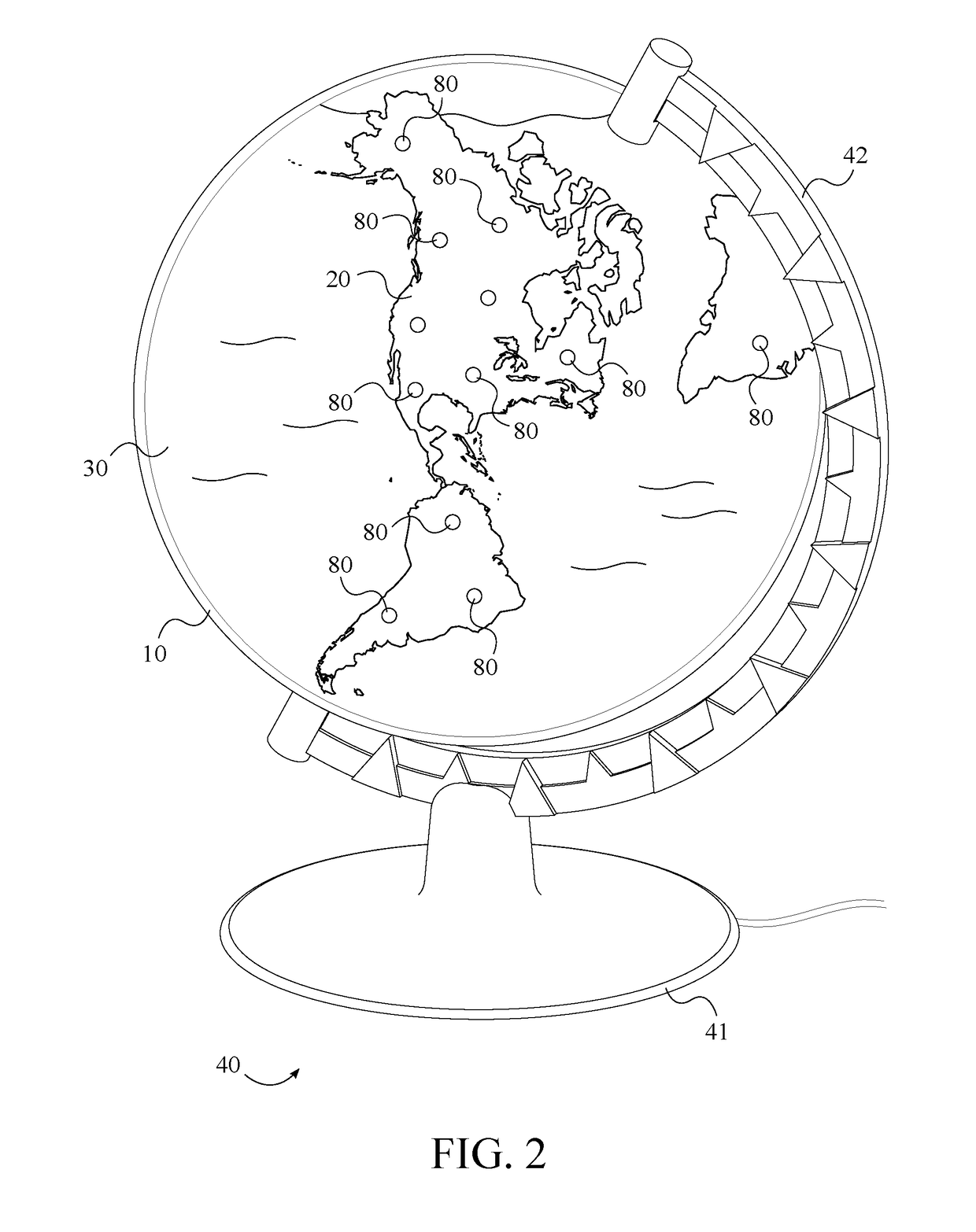

Nifty Globe

An intuitive globe that provides an ornamental display piece and / or an interactive learning tool has a sphere casing, a geographical demarcation, a liquid, and a support stand. The support stand holds the sphere casing, wherein the sphere casing is rotatably connected to a sphere mount. The sphere casing is a hollow body that is filled with the liquid and is transparent such that movement of the liquid is visible when the sphere casing is rotated. The geographical demarcation is disposed about the sphere casing, representing a body of land. The geographical demarcation is a first color, while the liquid is a second color; the second color contrasting the first color, such that the geographical demarcation is readily discernable from the liquid. A plurality of touch sensors can be utilized in conjunction with a plurality of lights to illuminate selected regions of the geographical demarcation.

Owner:SIGELAGELANI MENZI

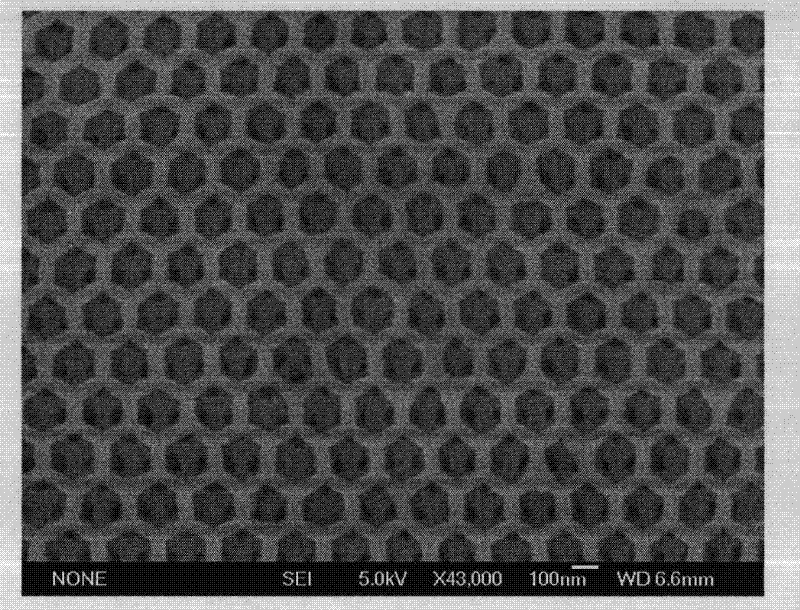

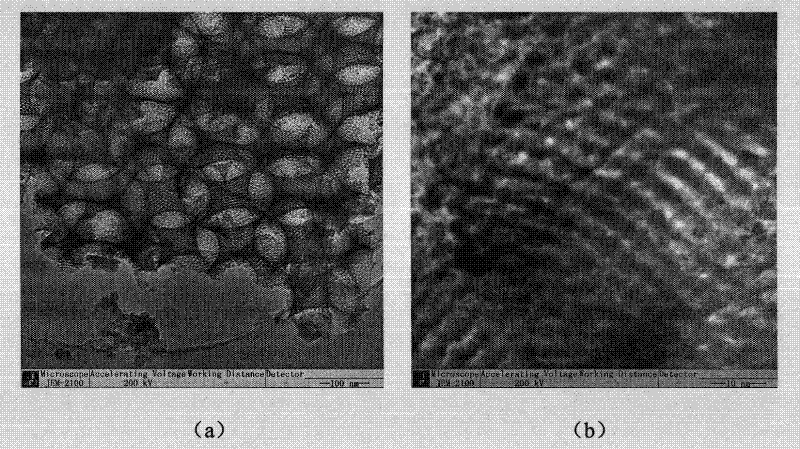

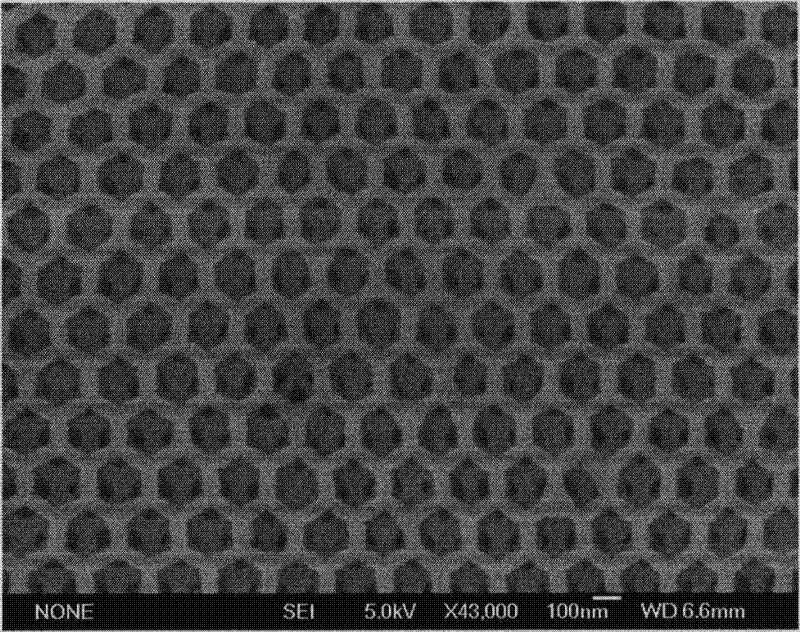

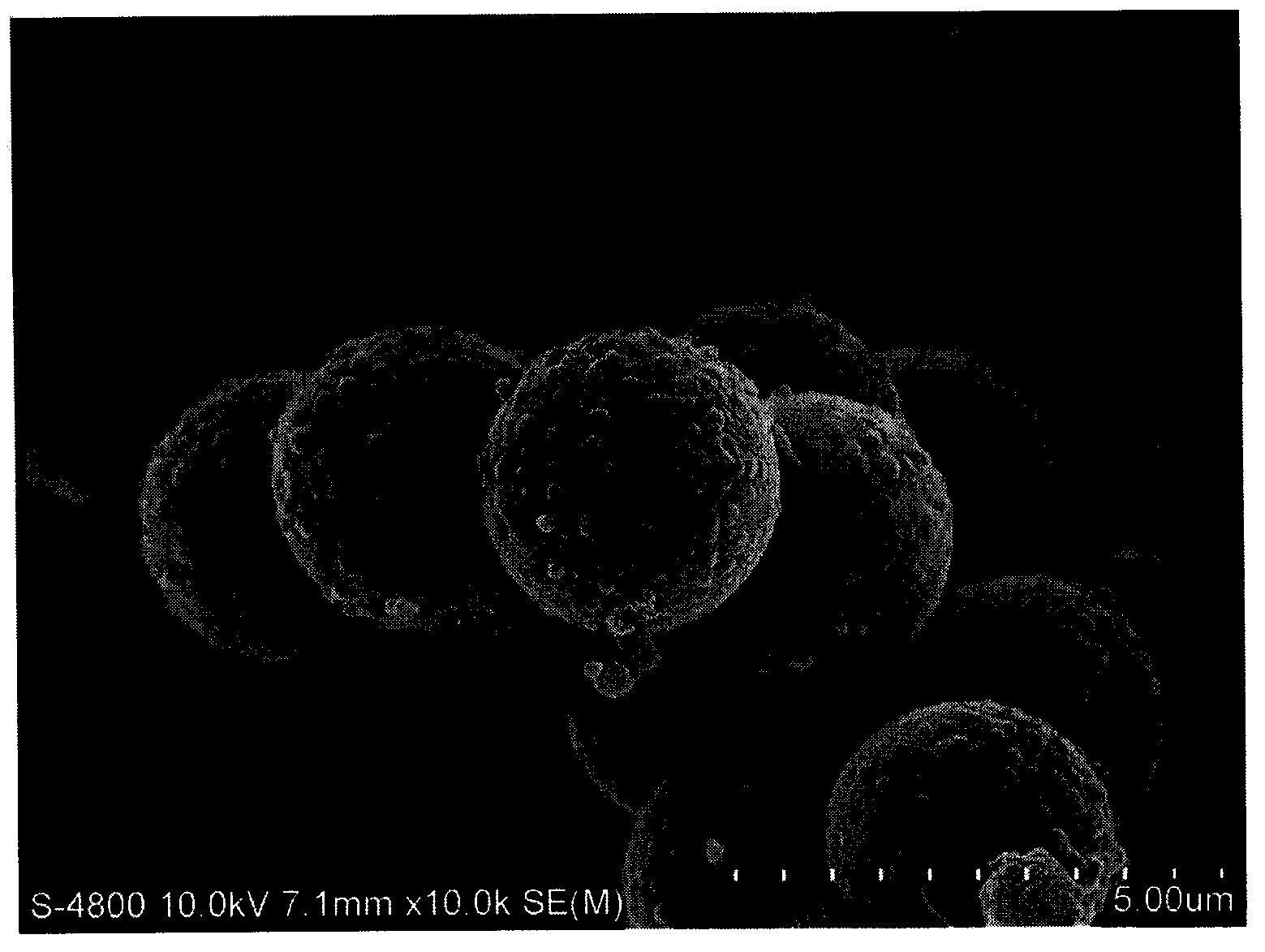

Macro pore/meso pore TiO2 film with high double ordered structure and preparation method thereof

ActiveCN102531051ARealize regulationAvoid excessive local concentrationTitanium dioxideComposite filmEvaporation

The invention provides a macro pore / meso pore TiO2 film with high double ordered structure and a preparation method thereof. The method comprises the following steps: preparing monodispersed polystyrene spheres; then arranging the polystyrene spheres on a glass slide to form a close-packed opal structure through evaporation, induction and self assembly, thus preparing a polystyrene sphere colloidal crystal template; placing the template in a Ti precursor sol and preparing a composite film by a soaking-pulling method; and finally removing organic matters through thermal treatment, thus obtaining the macro pore / meso pore TiO2 film. The macro pore / meso pore TiO2 film provided by the method has high double orderliness; by virtue of the control on the grain diameter and uniformity of the polystyrene spheres, the selection of surfactants and the control over soaking-pulling and thermal treatment conditions, the regulation and control over the size and orderliness of the macro pores and meso pores of the film are realized; and by virtue of the synergetic effect of the macro pores and the meso pores, the photocatalysis efficiency of materials is greatly improved. The method provided by the invention has the advantages of simplicity and convenience in operation, high controllability and wide application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

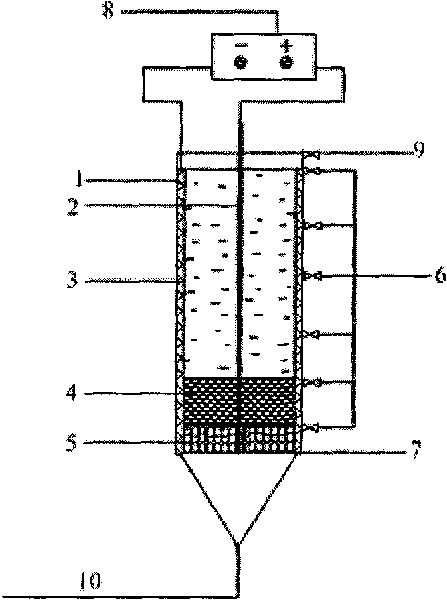

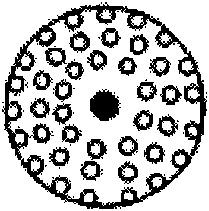

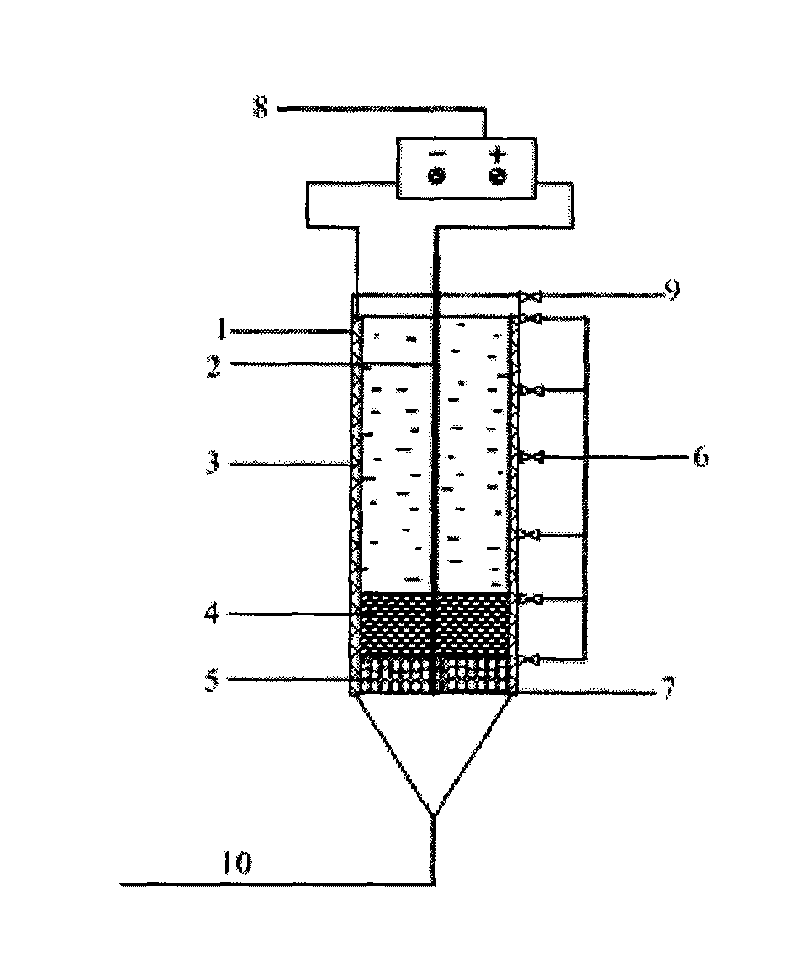

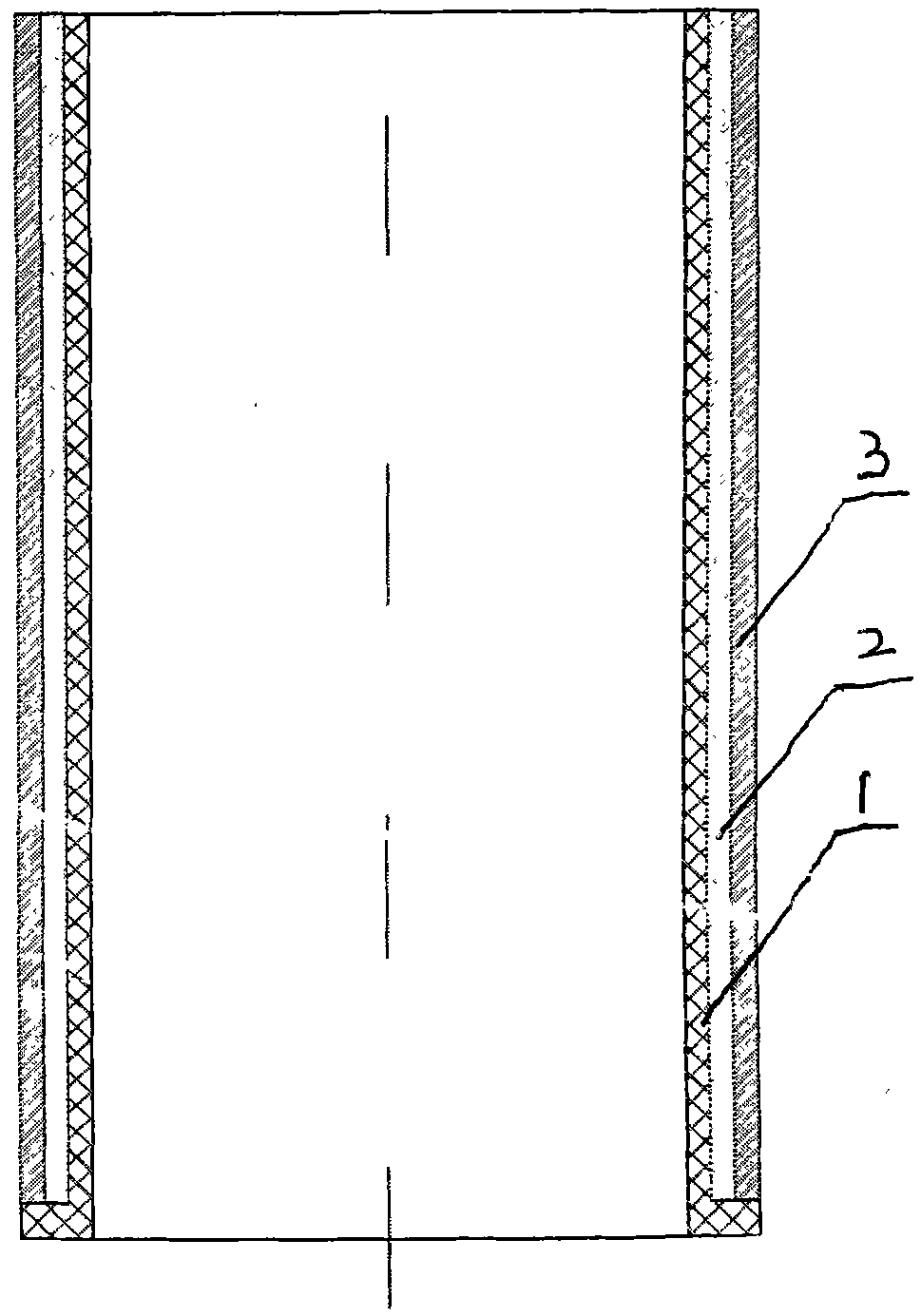

Solidoid heterotrophy and electrochemical autotrophy integrated denitrification reactor for removing nitrate out of water

InactiveCN101693578ATake advantage ofImprove anaerobic environmentWater/sewage treatmentTreatment with anaerobic digestion processesNitriteSphere packing

The invention discloses a solidoid heterotrophy and electrochemical autotrophy integrated denitrification reactor for removing nitrate out of water. The denitrification reactor comprises a reactor body, a graphite anode, a foamed nickel cathode, a solidoid denitrification matrix packing layer, a plastic polyhedral hollow sphere packing layer, sample connections, a perforated baffle plate, a direct current supply, a water outlet and a water inlet. Solidoid denitrification matrixes, plastic polyhedral hollow spheres and the perforated baffle plate are arranged at the inner lower part of the reactor body from top to bottom; the water inlet is arranged at the bottom of the reactor body; a plurality of sample connections are arranged on the side wall of the reactor body; the water outlet is arranged at the top of the reactor body; the graphite anode is arranged in the middle of the reactor body; the foamed nickel cathode is arranged on the inner side wall of the reactor body; and the graphite anode and the foamed nickel cathode are respectively connected with the anode and the cathode of the direct current supply. The denitrification reactor can effectively remove nitrate pollutant out of water, the nitrate removal rate can be more than 80 percent, and the content of nitrite is below 0.01mg / l.

Owner:ZHEJIANG UNIV

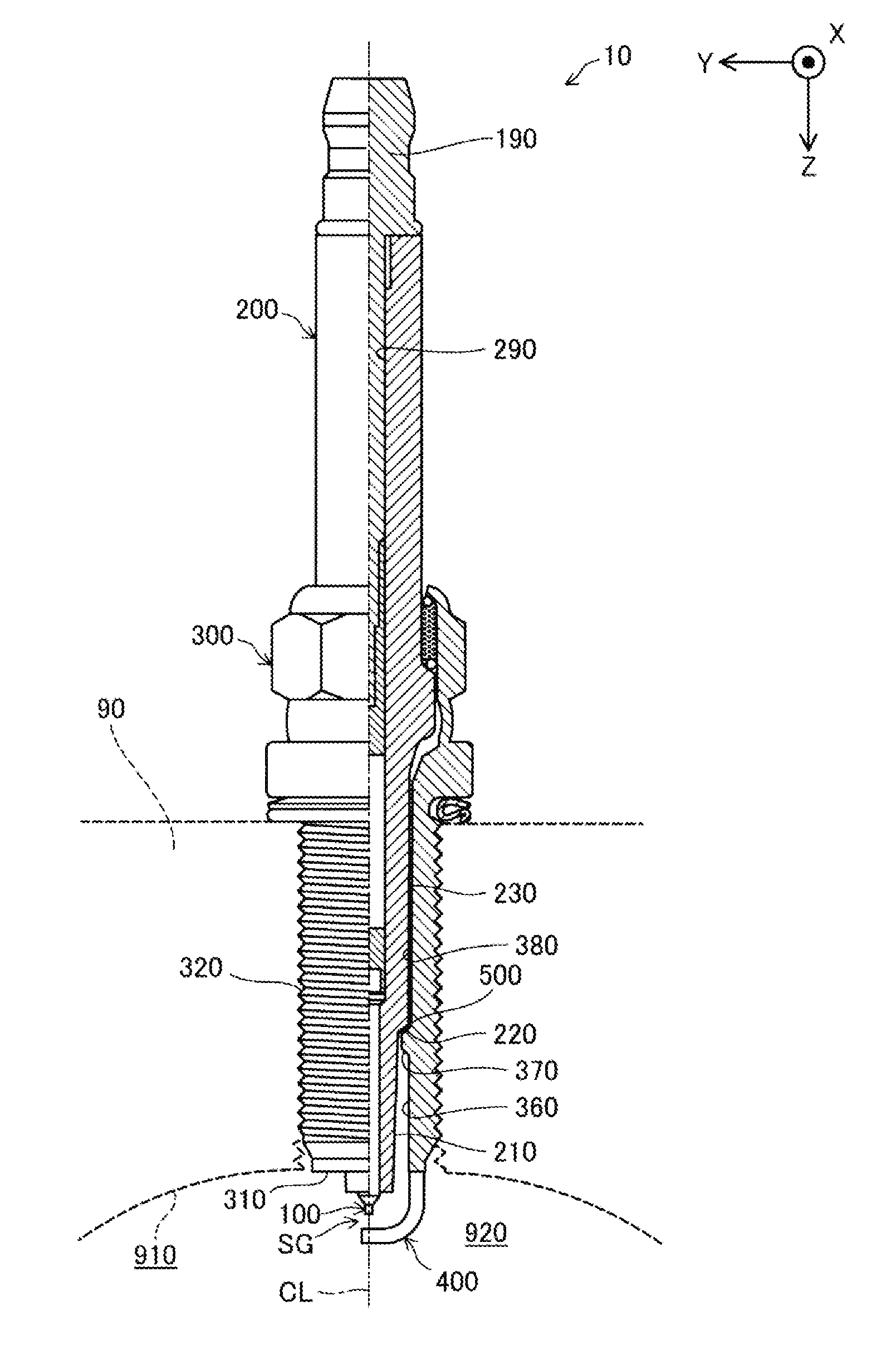

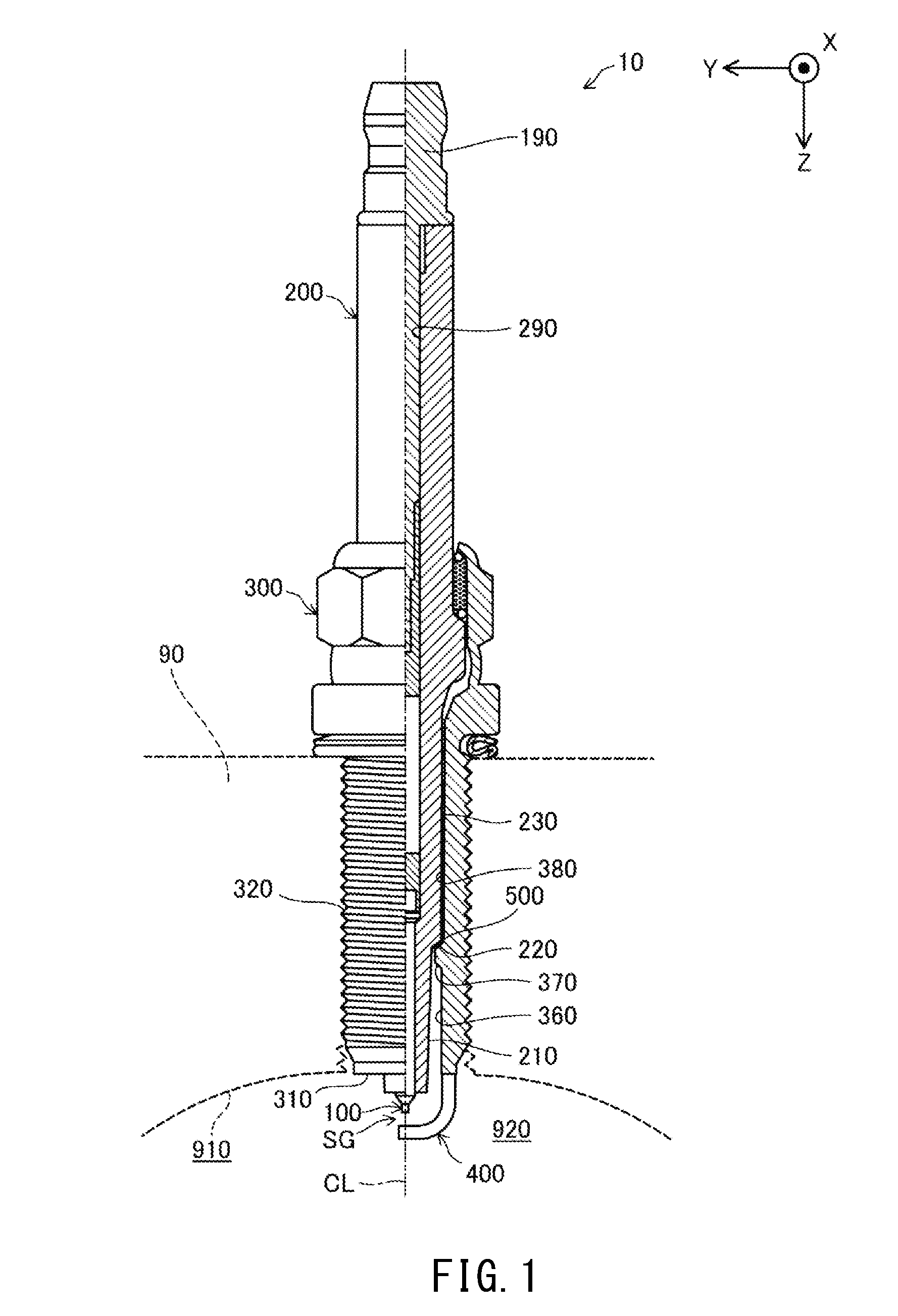

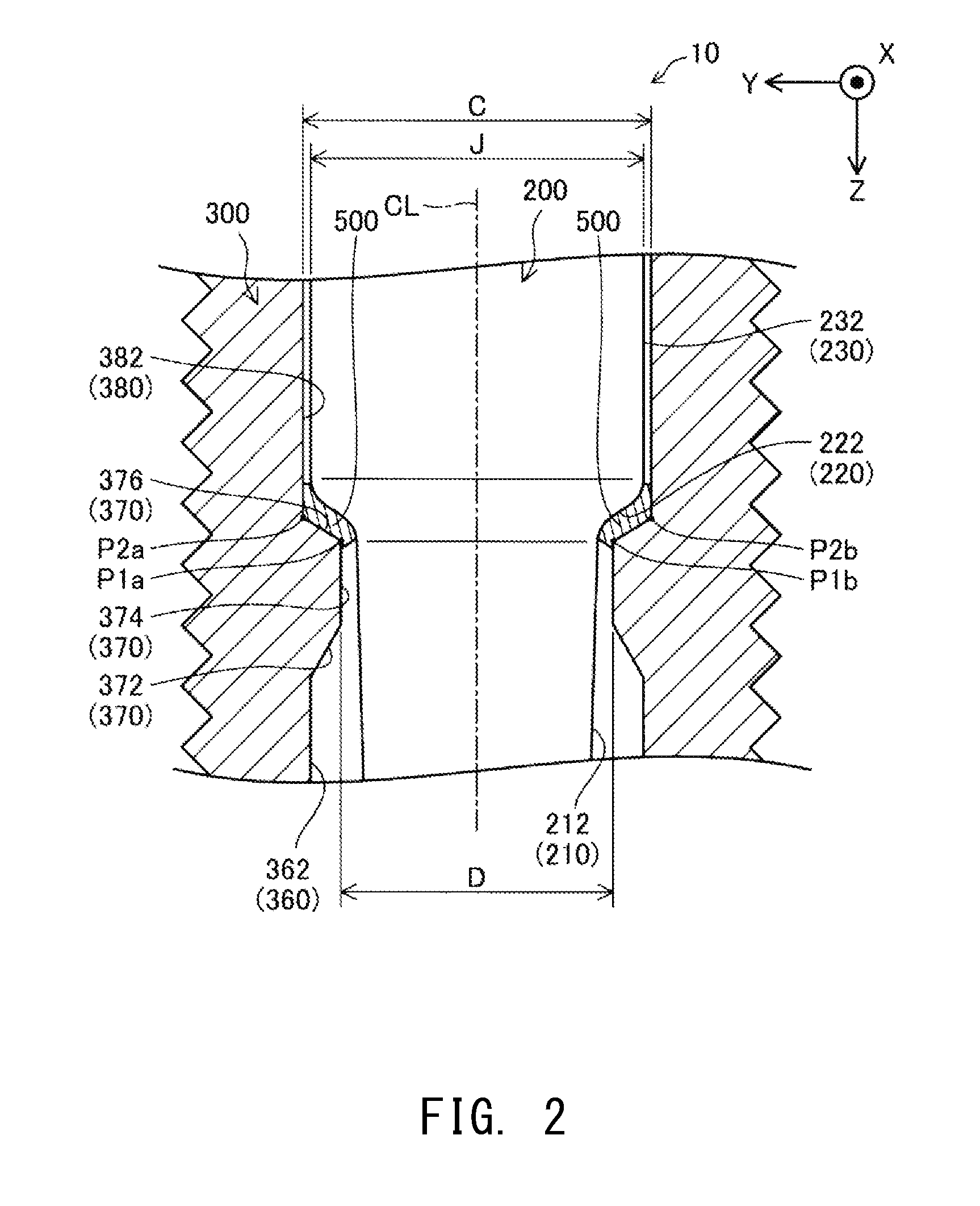

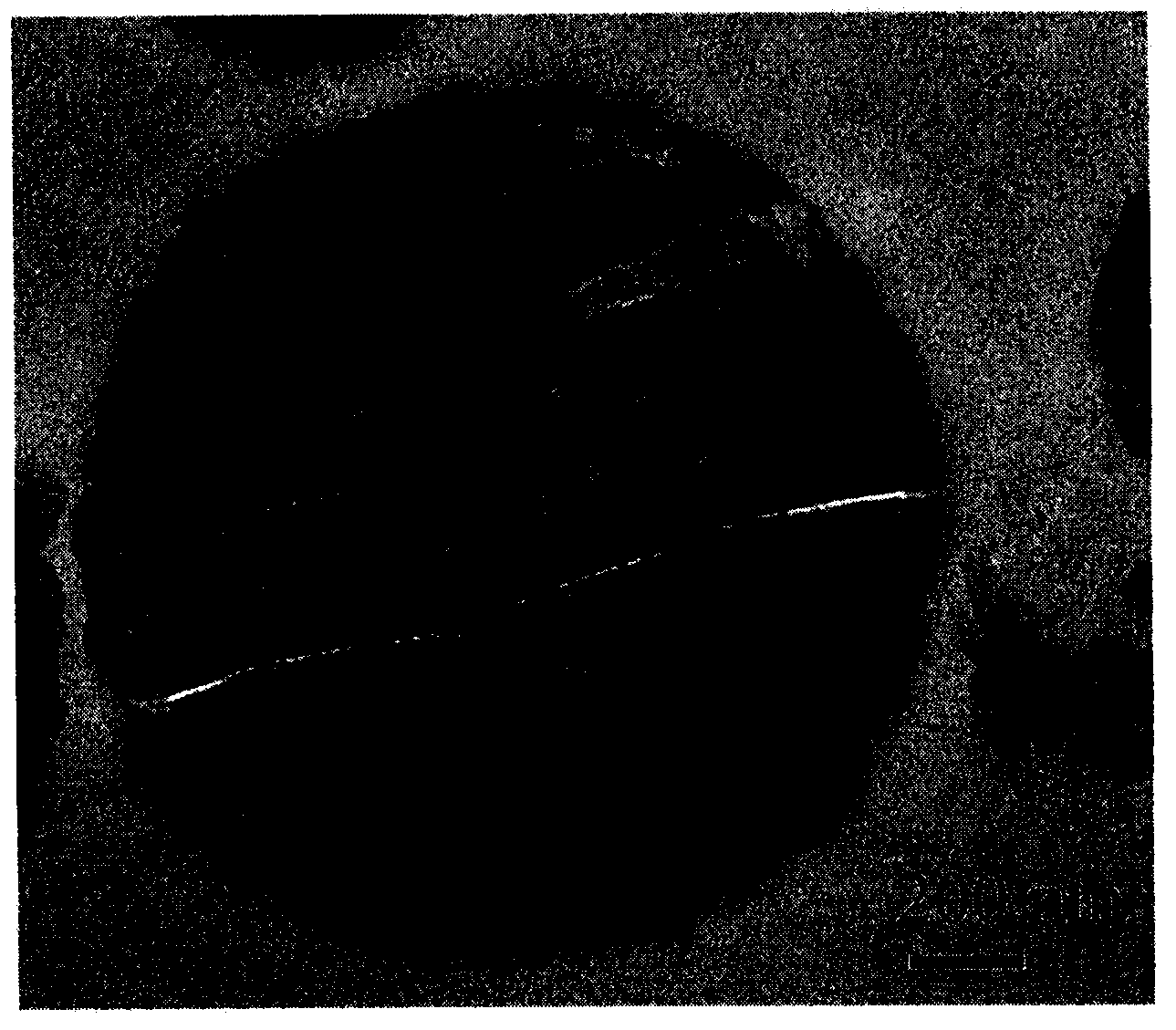

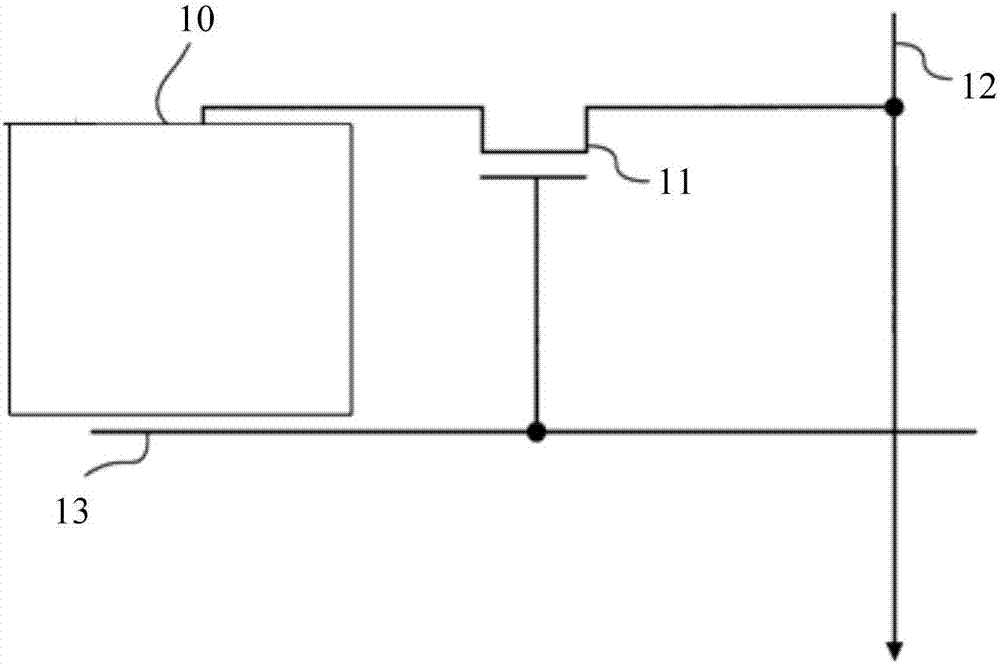

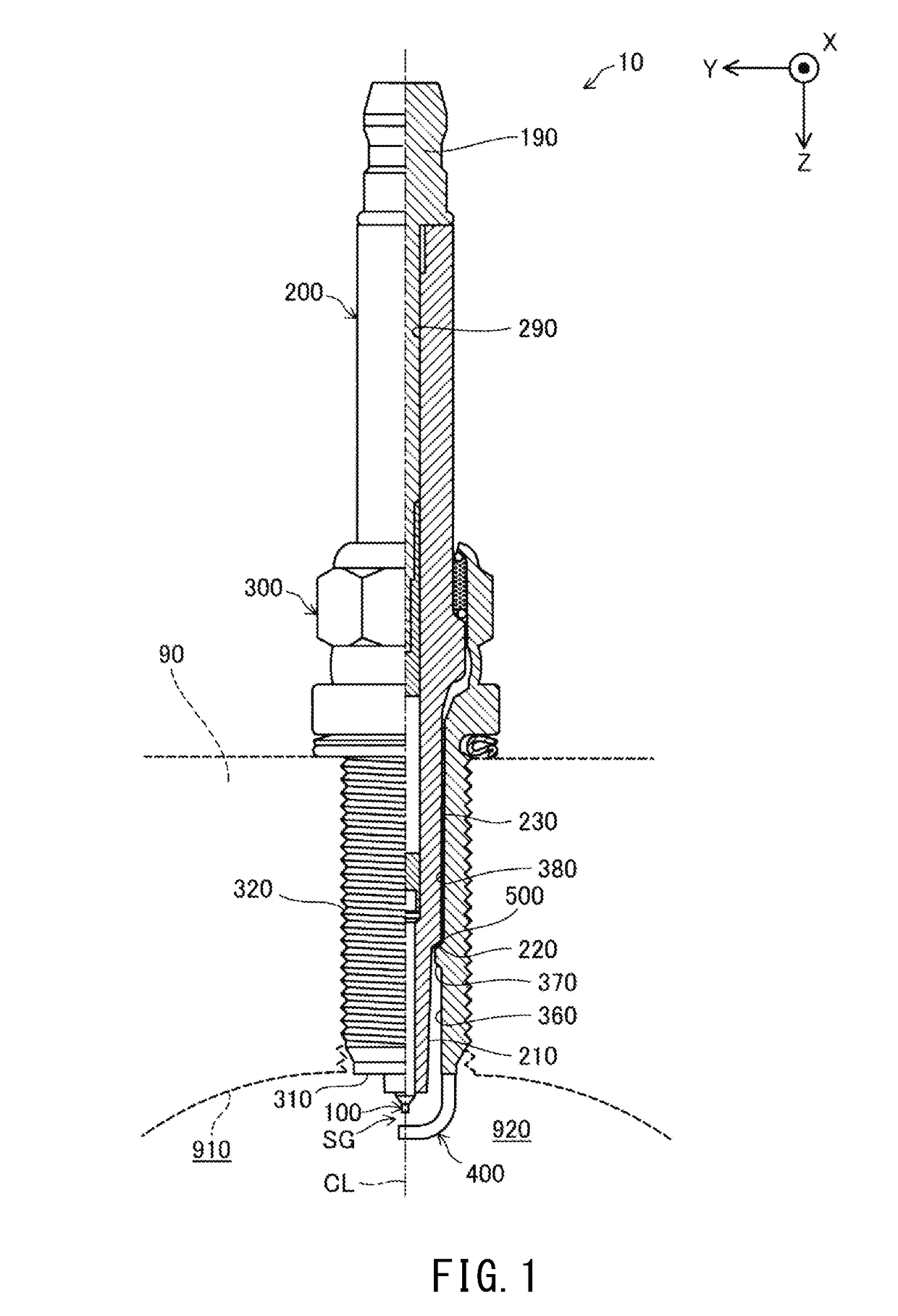

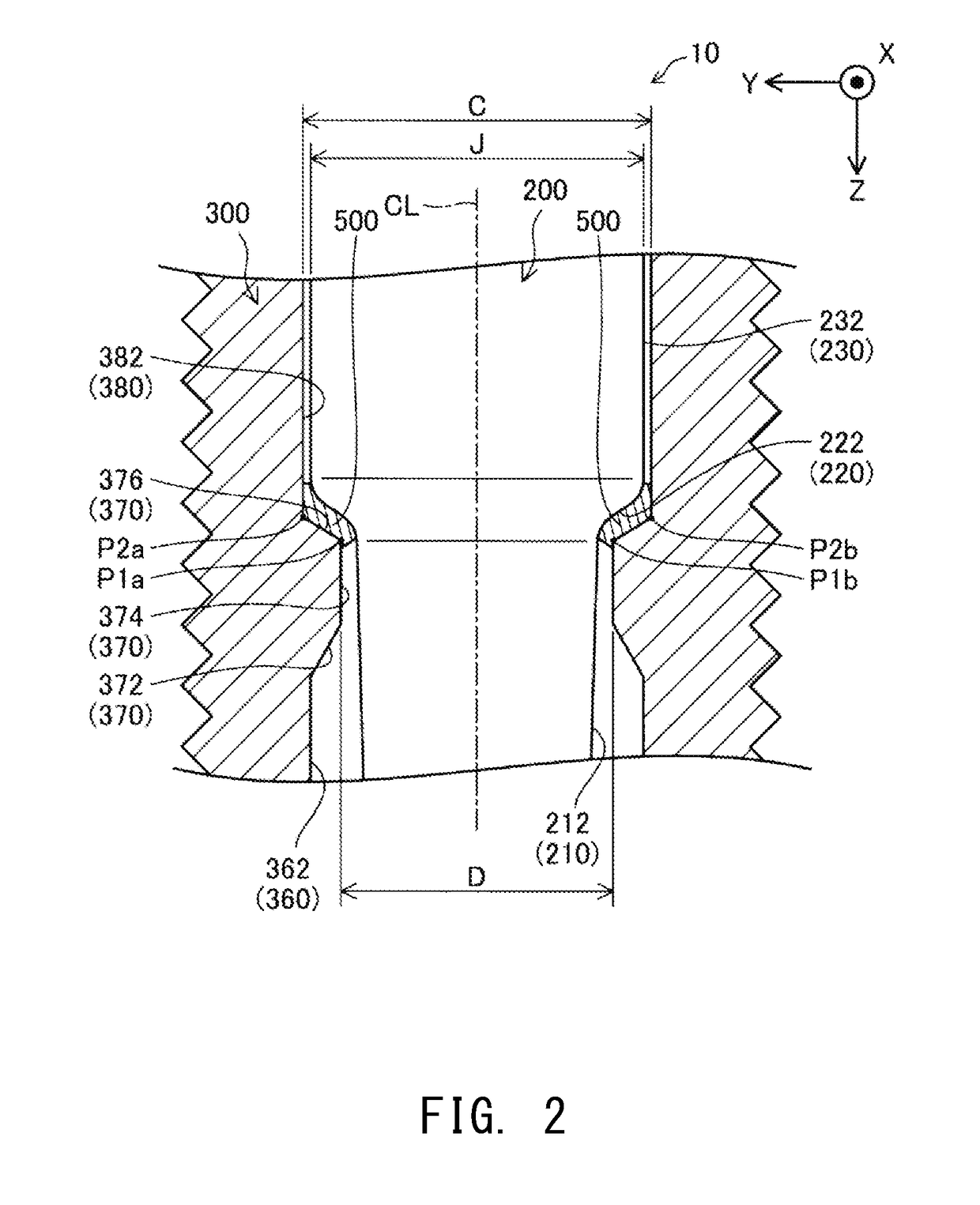

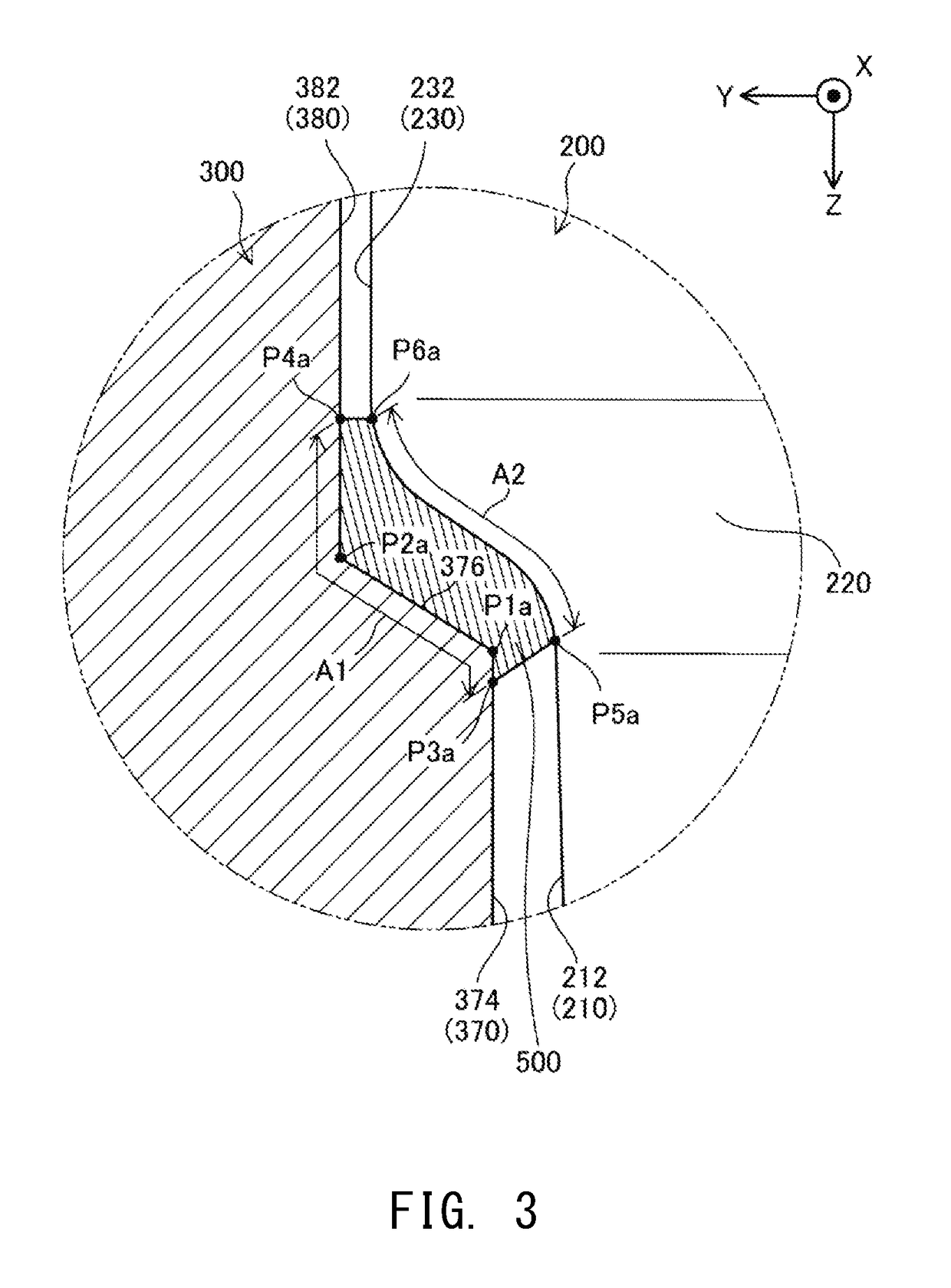

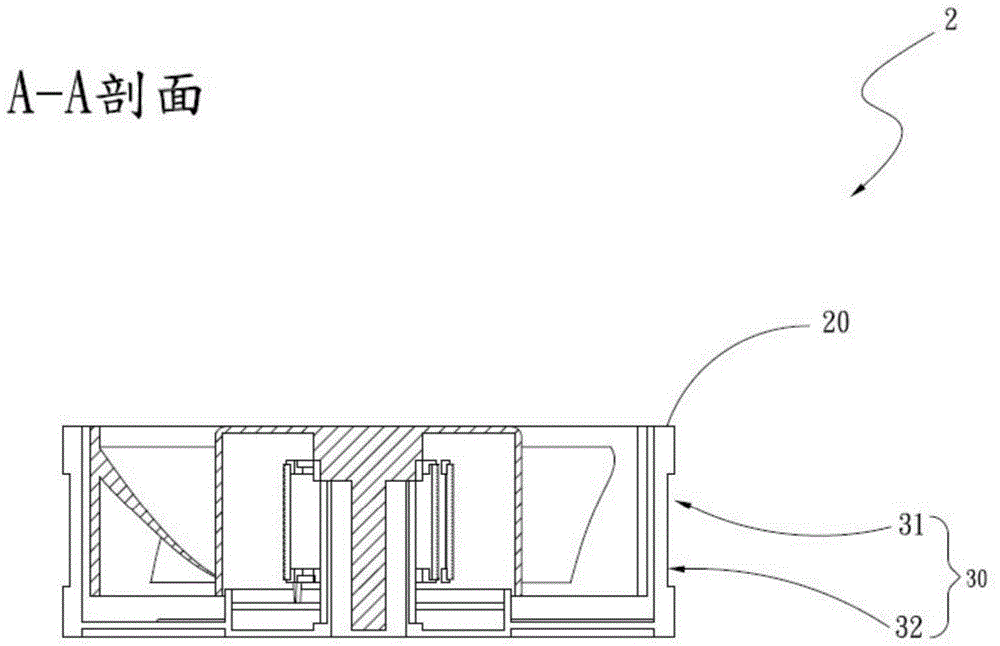

Spark plug

ActiveUS20170033538A1Improve cooling effectSufficient allowance for deformationSparking plugsSphere packingSpark plug

A spark plug that satisfies the relation 2.8≦(A+B) / M, where A is the sum of a length A1 of contact between a sheet packing and a metallic shell of a spark plug in one half section and a length A2 of contact between the sheet packing and the insulator in the one half section, and B is the sum of a length B1 of contact between the sheet packing and the metallic shell in the other half section and a length B2 of contact between the sheet packing and the insulator in the other half section. M is the difference obtained by subtracting the inner diameter D of a ledge from the inner diameter C of a middle hole portion.

Owner:NGK SPARK PLUG CO LTD

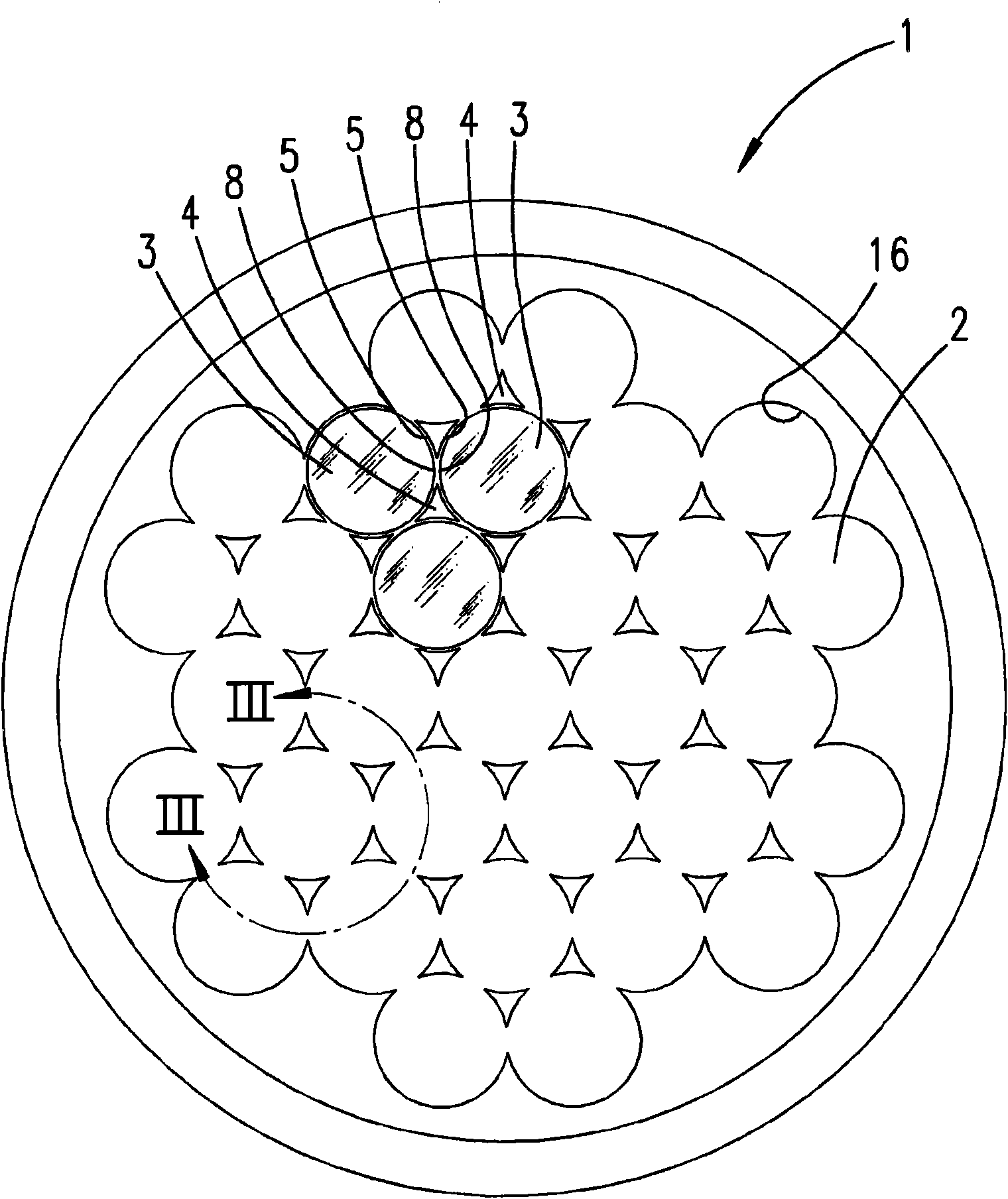

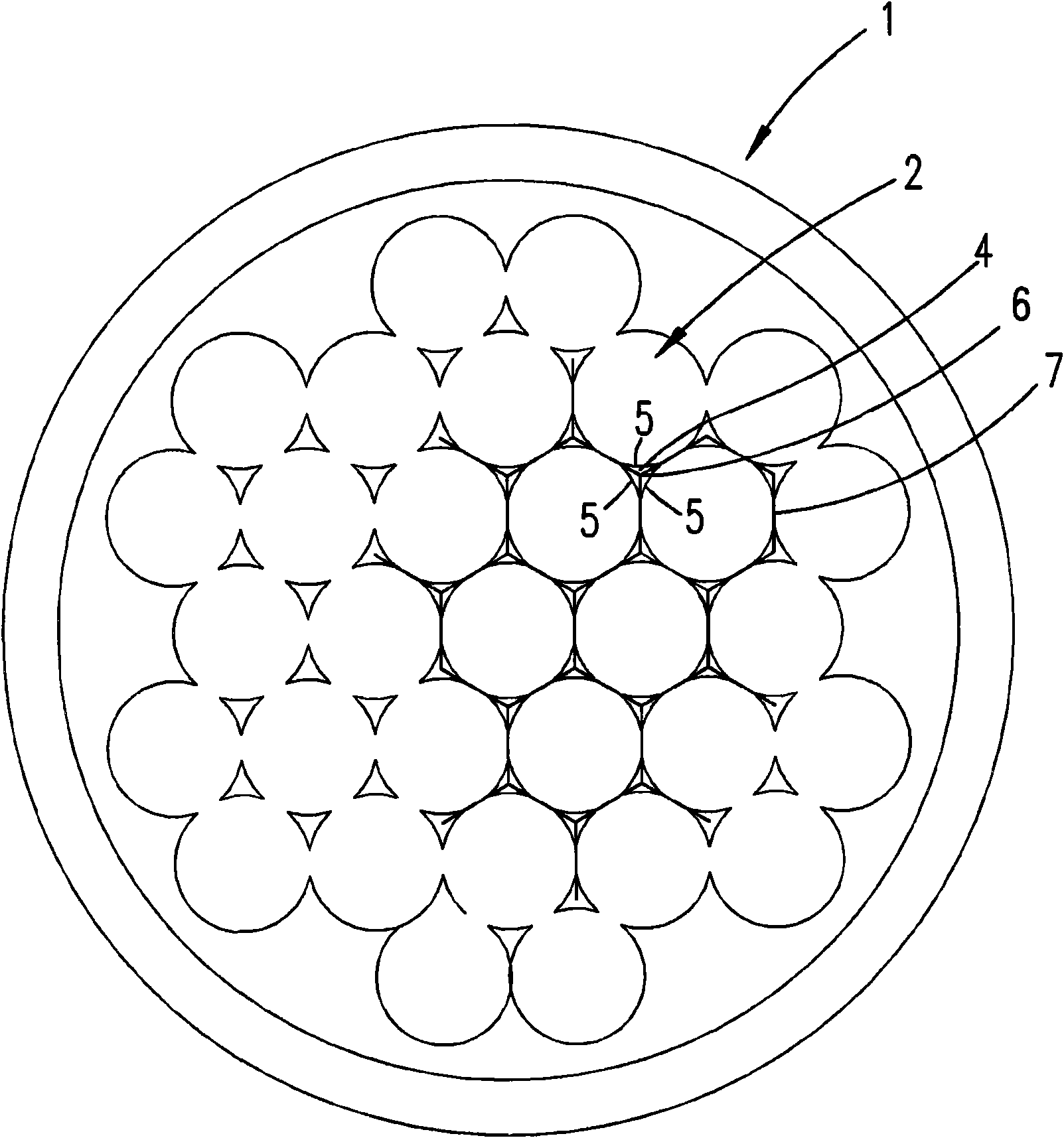

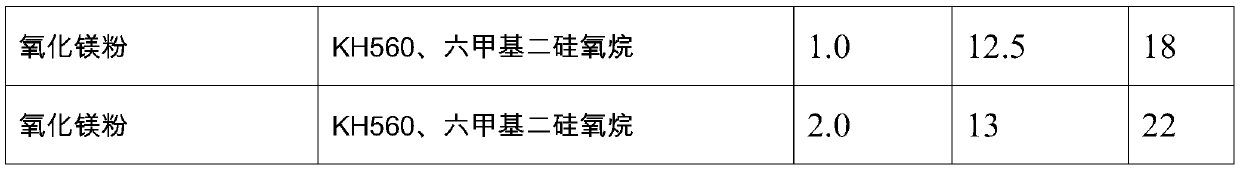

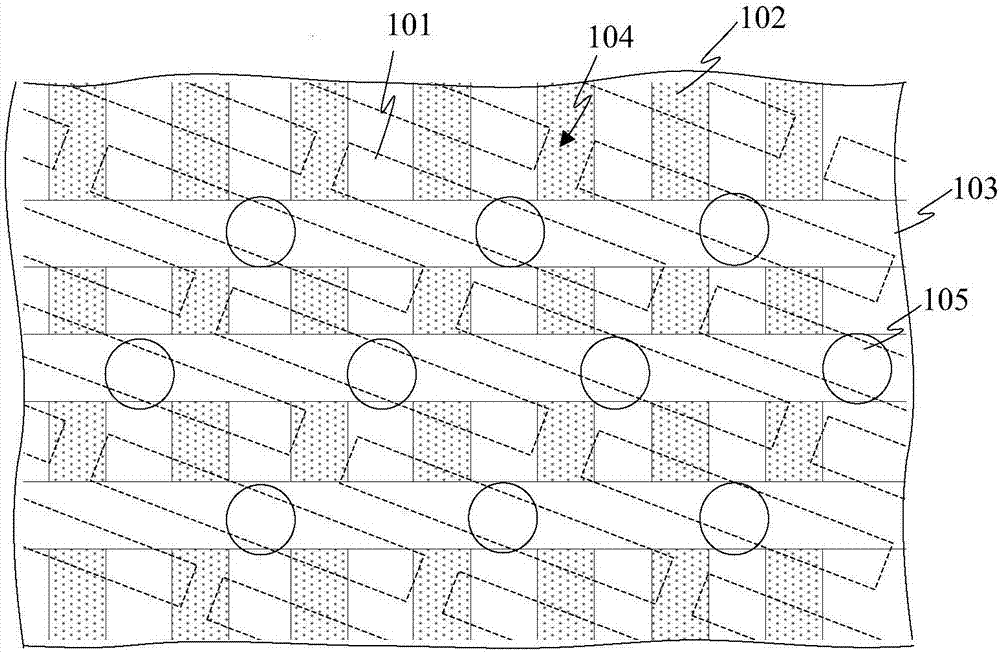

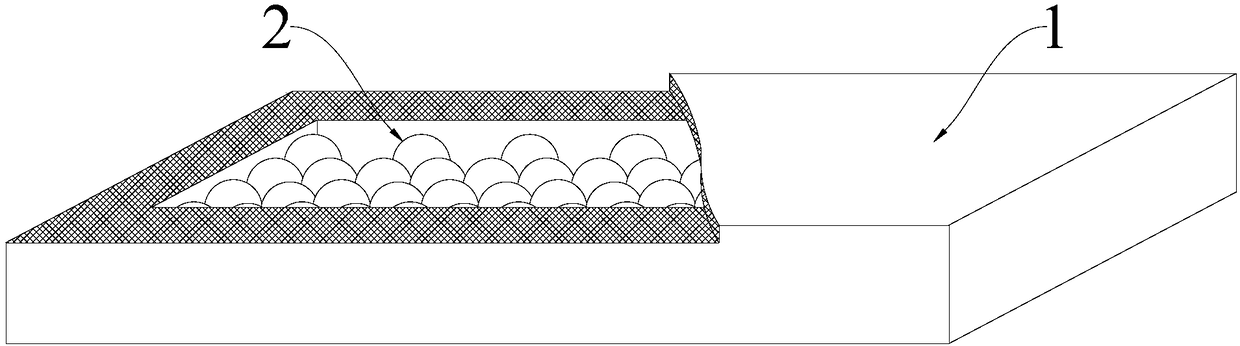

Device for coating a plurality of closest-packed substrates arranged on a susceptor

ActiveCN101681871AImprove uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorIsoetes triquetra

The invention relates to a device for coating a plurality of substrates (3) which are regularly arranged on a bearing surface (2) of a susceptor (1) associated to a process chamber (14), wherein the bearing surface (2) forms abutment flanks (5) for the edge mounting of each substrate (3). In order to reduce the free susceptor surface to a minimum, it is proposed that the abutment flanks of the lateral walls (5) are formed by bases (4) which project from the bearing surface (2) and are separated at a distance from one another. Said bases are arranged on the corner points (10) of a honeycomb structure and have an outline essentially corresponding to an equilateral triangle with inwardly curved sides (5).

Owner:AIXTRON AG

Manufacture method for staining resistant artificial quartz stone

Owner:BENYEE NEW MATERIAL CO

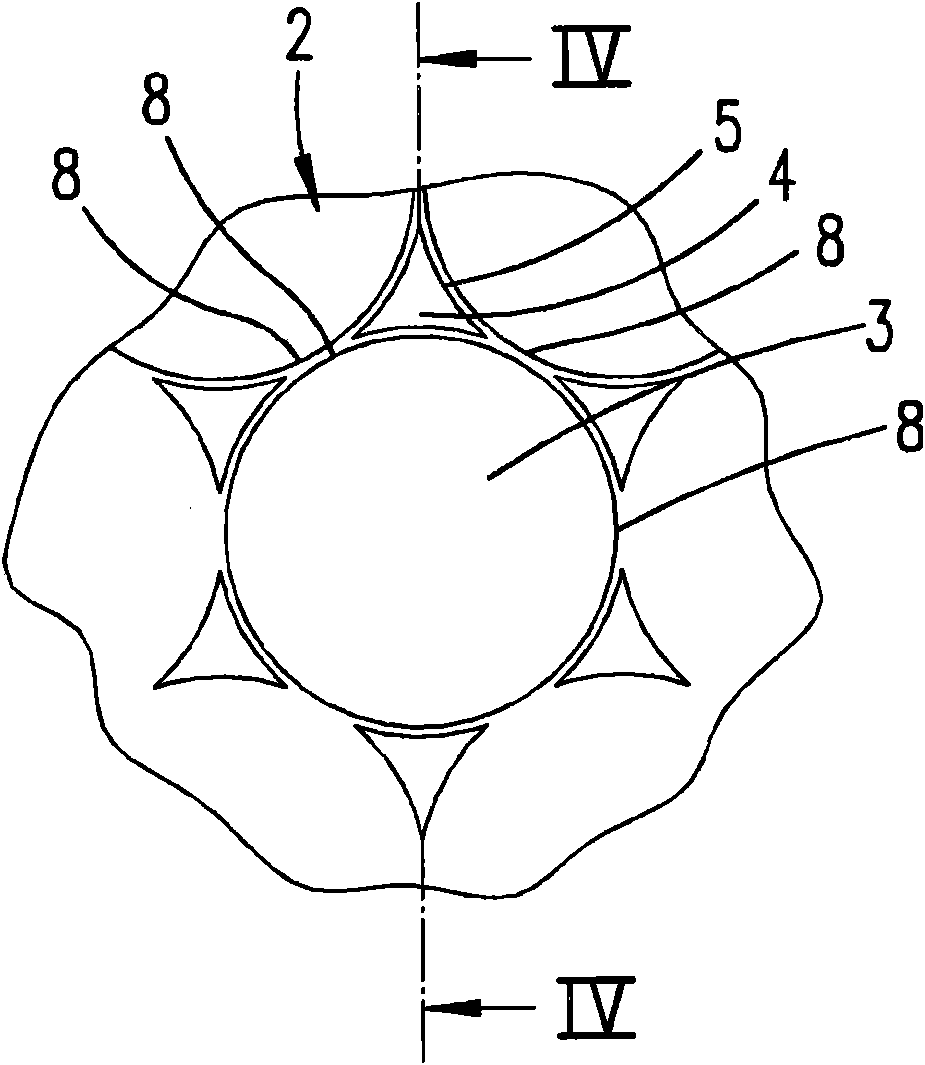

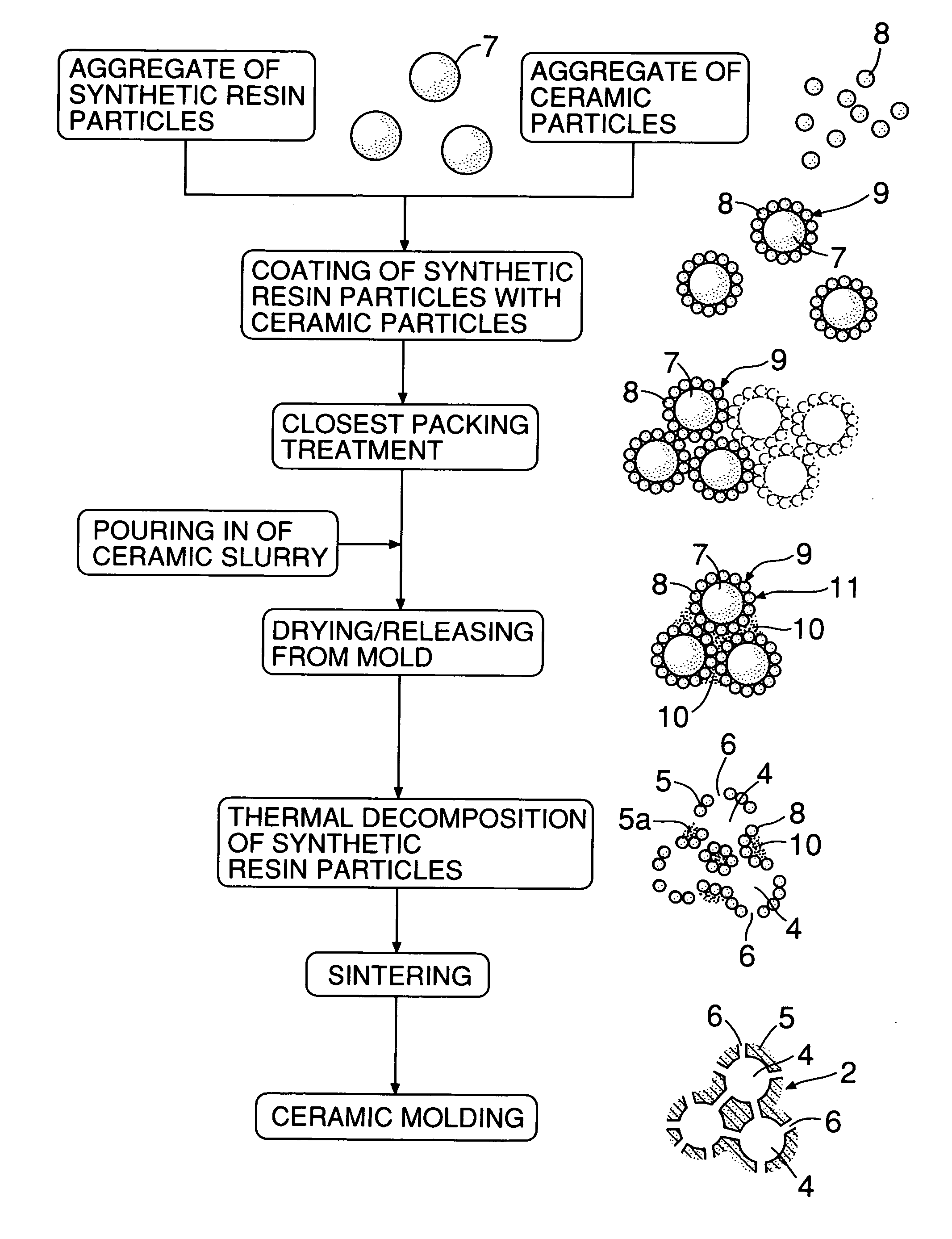

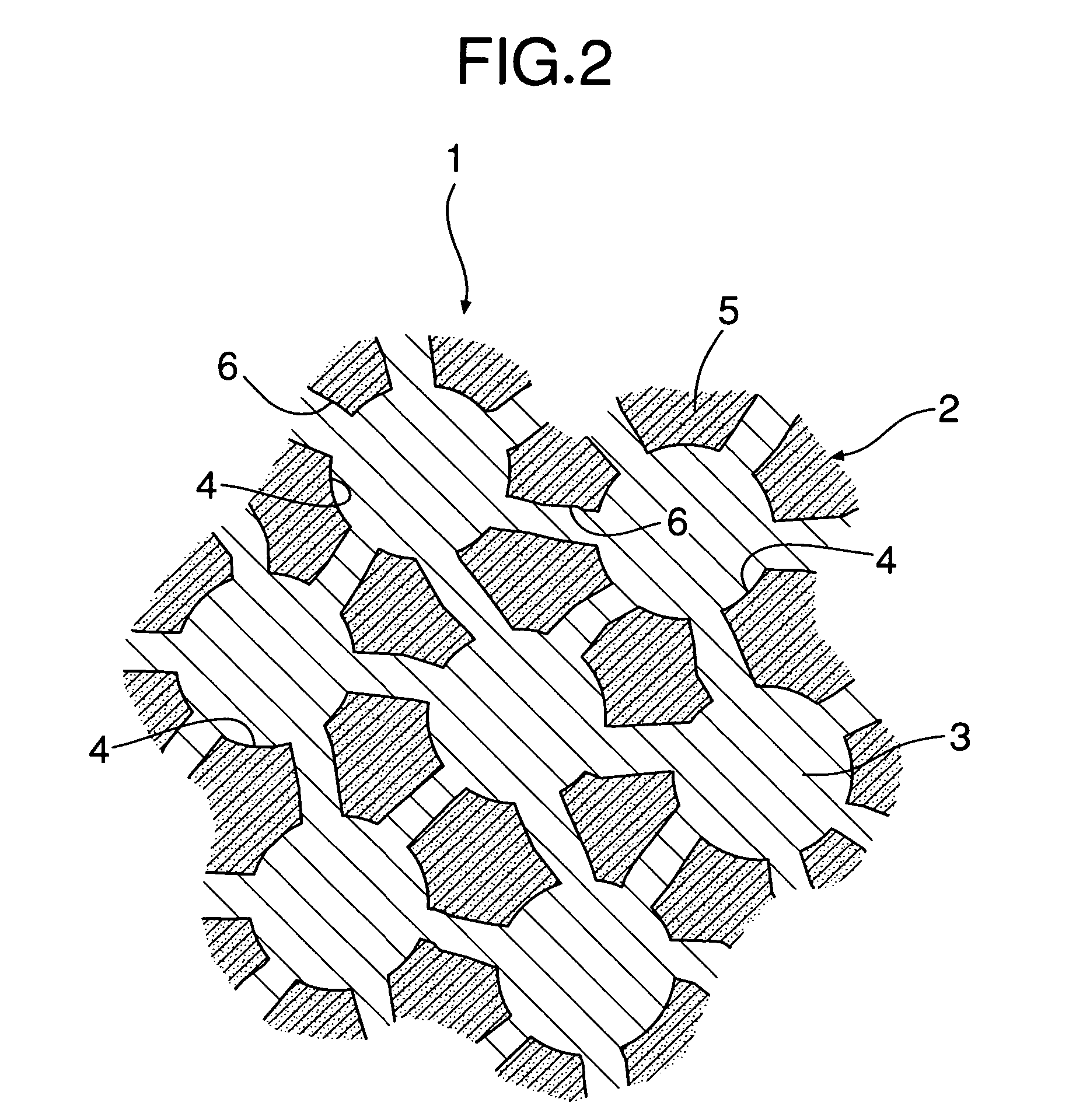

Process for producing ceramic molding having three-dimensional network structure

InactiveUS20050121816A1Improve uniformityEasy to adjustCeramic shaping apparatusCeramicwareCeramic moldingNetwork structure

A process for producing a ceramic molding having a three-dimensional network structure with a plurality of spherical cells and a plurality of through holes present in dividing walls between the spherical cells, includes: a step of obtaining an aggregate of coated particles in which a plurality of ceramic particles are attached to the surface of spherical synthetic resin particles; a step of arranging the aggregate of coated particles in closest packed form within a mold; a step of filling gaps in the aggregate of coated particles with a ceramic so as to give a shaped product; a step of releasing the shaped product from the mold; a step of thermally decomposing the spherical synthetic resin particles of the shaped product so as to form the spherical cells and form the plurality of through holes in dividing wall-forming sections that are present between adjacent spherical cells; and a step of sintering the ceramic particles and the ceramic so as to form the dividing walls.

Owner:HONDA MOTOR CO LTD

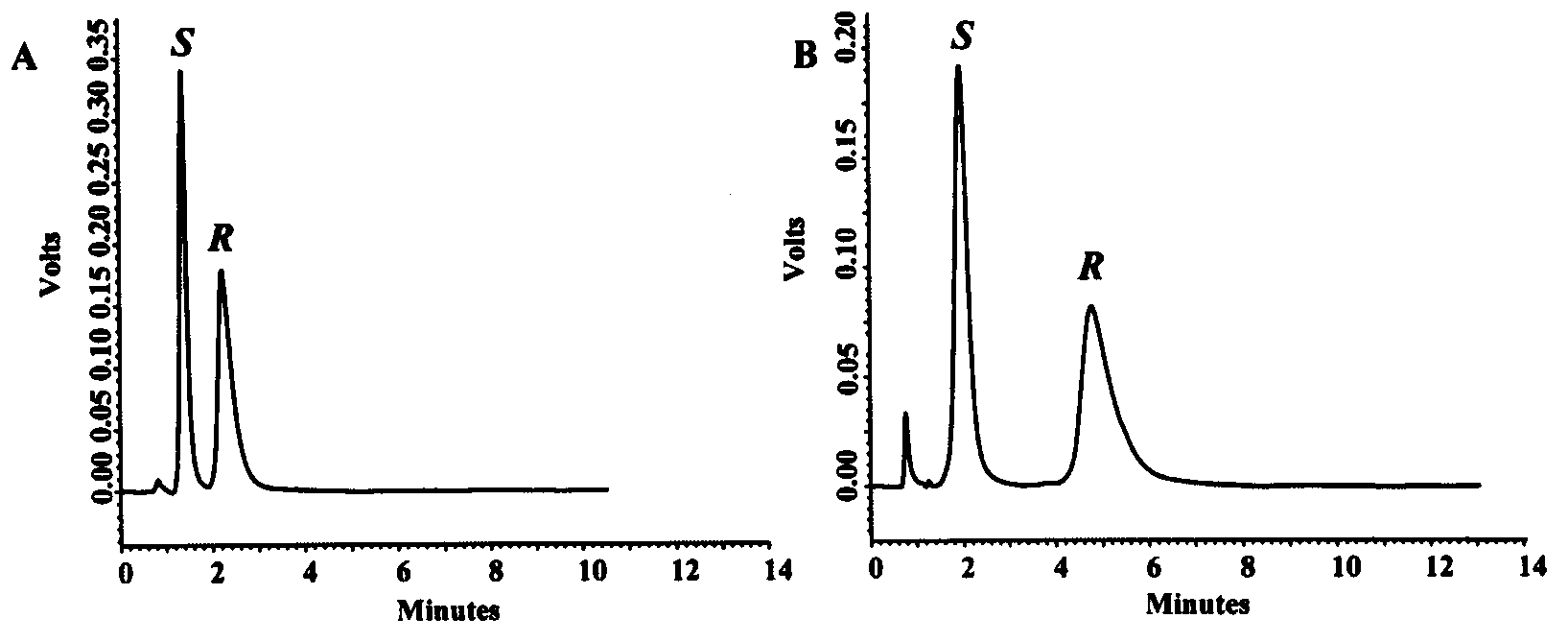

Chiral core-shell chromatography stationary phase and preparation method

InactiveCN104138751AHigh column efficiencyFast analysisOther chemical processesStationary phaseMesoporous silica

The invention discloses a chiral core-shell chromatography stationary phase. The inner layer is nonporous silica gel which is coated with a hybrid mesoporous silica gel shell layer containing a chiral diaminocyclohexane group. Meanwhile, the invention also discloses a preparation method of the above chiral core-shell liquid chromatography packing. The hybrid mesoporous silica gel has characteristics of high permeability and uniform distribution of organo-functional groups, and the core-shell packing has advantages of high column efficiency and fast analysis speed. By combining the characteristics of the hybrid mesoporous silica gel and the advantages of the core-shell packing, a novel chromatography stationary phase packing is formed.

Owner:CHINA PHARM UNIV

Method for preparing vertical intermediate-frequency furnace by integrally casting and compounding furnace pipe and thermal insulation layer

InactiveCN102419094AReduce energy consumptionEasy to repair and replaceMonolithic liningsFurnace temperatureIntermediate frequency

The invention belongs to the technical field of tungsten powder carbonized and cemented carbide sintered furnaces, and in particular relates to a method for preparing a vertical intermediate-frequency carbonized and cemented carbide sintered furnace by integrally casting and compounding a furnace pipe and a thermal insulation layer. The vertical intermediate-frequency carbonized and cemented carbide sintered furnace is produced by compounding and casting the fire-resistant furnace pipe in which zirconium oxide hollow spheres and alumina hollow spheres are taken as aggregate, a crude corundum hollow sphere packing layer in which crude corundum hollow spheres are as the aggregate, and a zirconium oxide hollow sphere thermal insulation layer in which the zirconium oxide hollow spheres are taken as the aggregate sequentially and integrally. As the compound furnace pipe and thermal insulation layer are integrally cast by using different fire-resistant materials, the working temperature of the vertical intermediate-frequency carbonized furnace is raised from 1,600 DEG C to 2,300 DEG C, the energy consumption of thermal equipment can be reduced greatly, and the vertical intermediate-frequency furnace is convenient to maintain and replace and saves cost.

Owner:江西耀升钨业股份有限公司

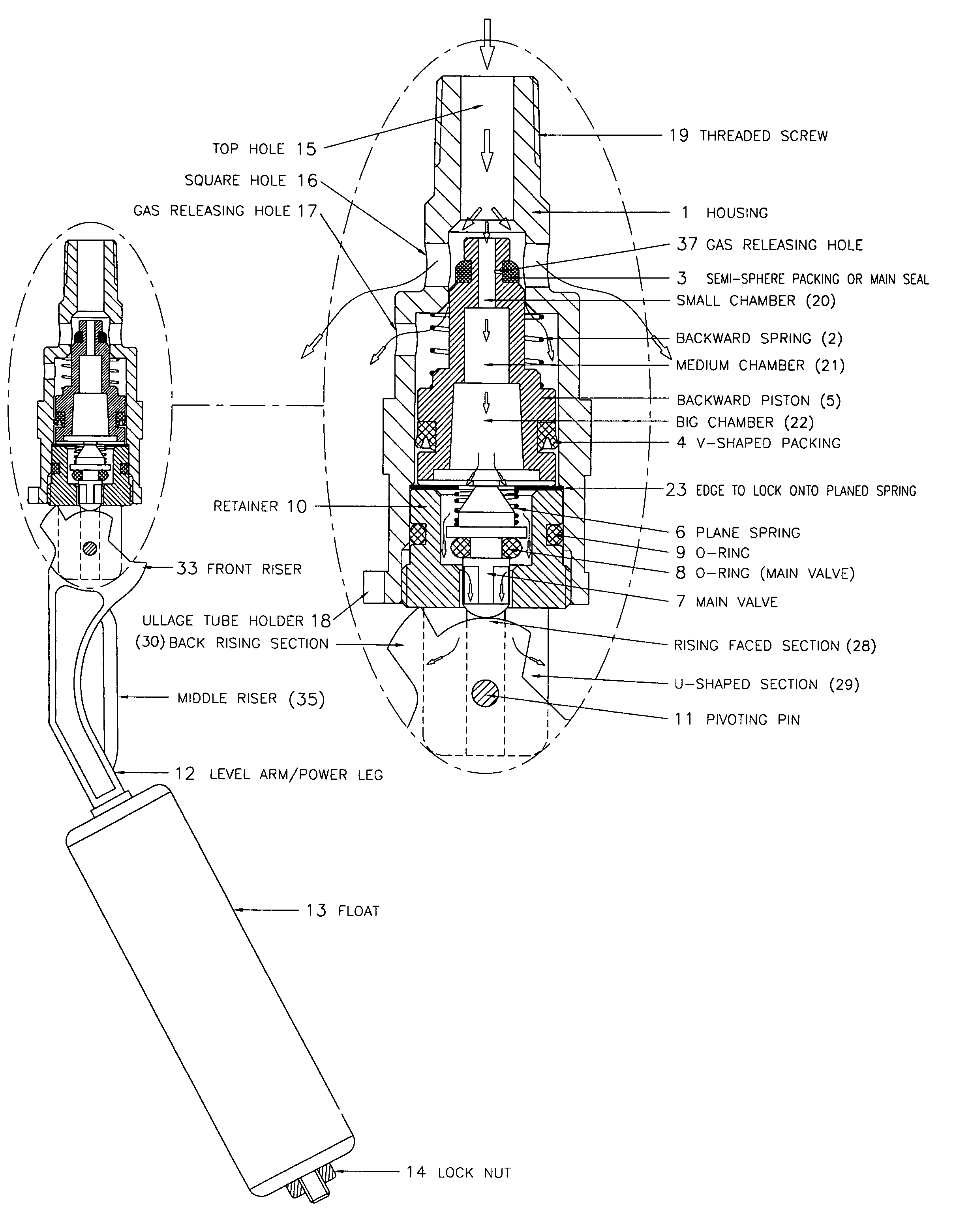

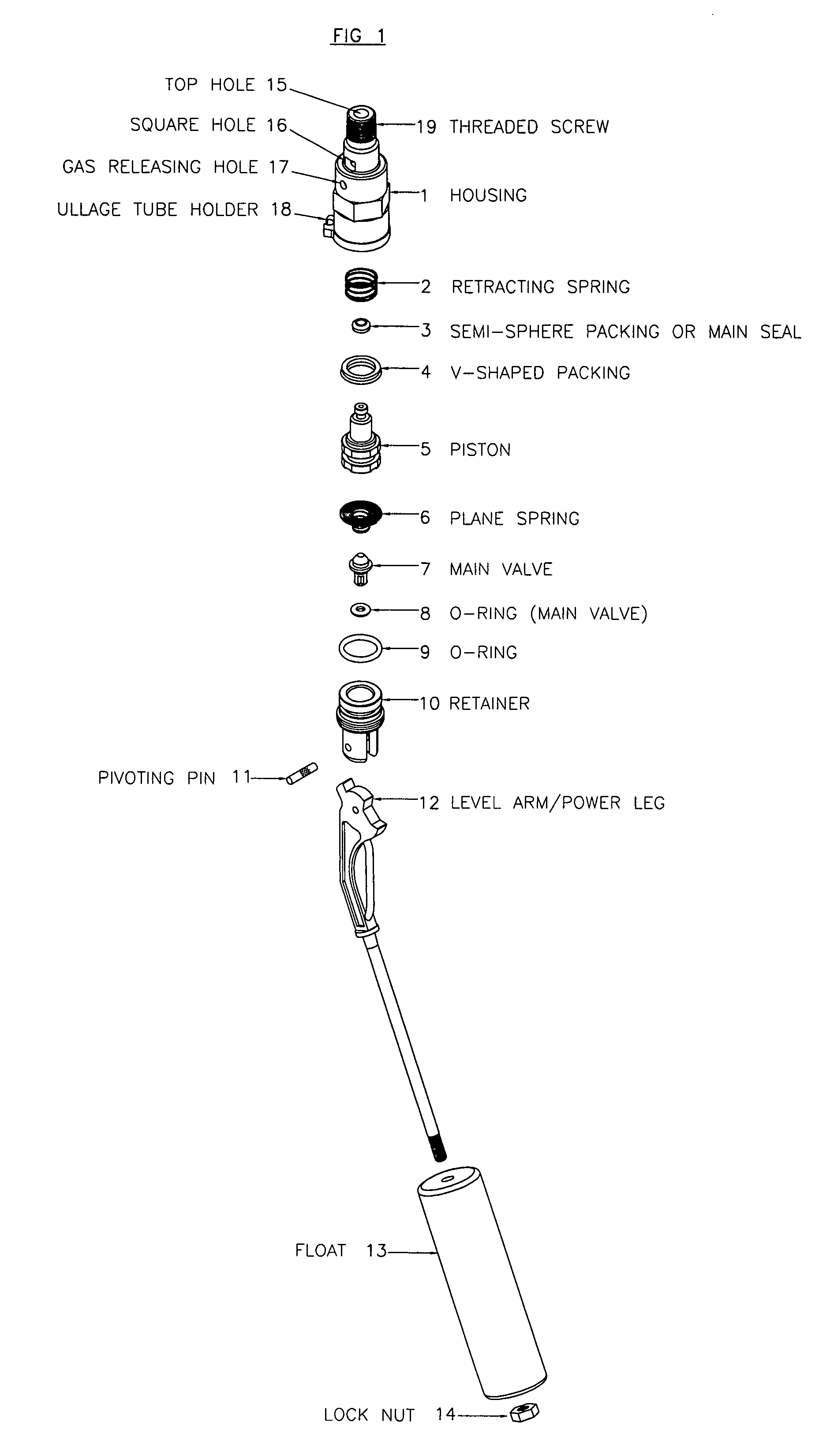

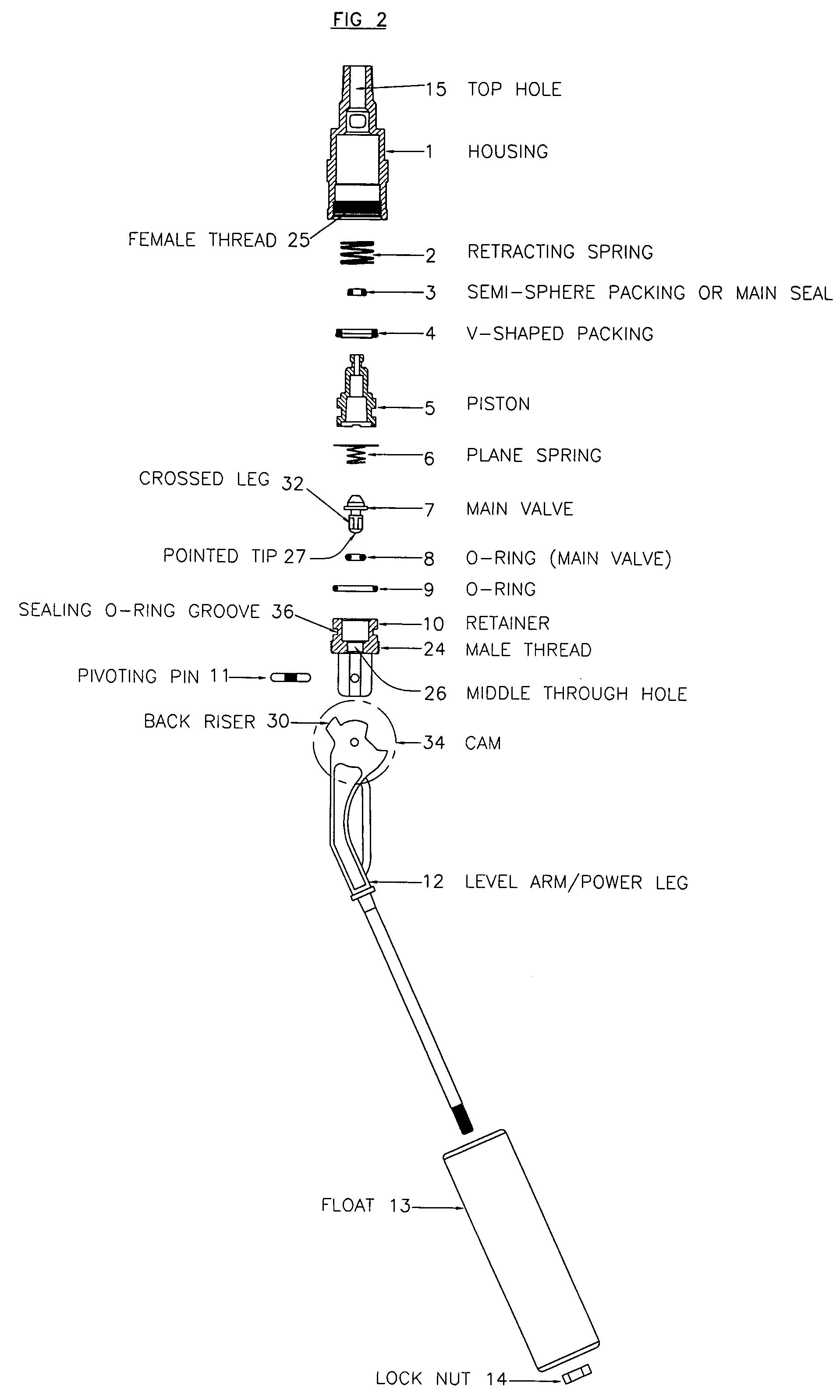

Overfill protection device (OPD)

ActiveUS7967025B2Easy to useGuaranteed safe operationOperating means/releasing devices for valvesFluid handling accessoriesEngineeringSphere packing

An overfill protection device includes a piston (5) comprising a main seal or semi-sphere packing (3) on its tip and a V-shaped packing (4) on its side, a retracting spring (2) for pushing the piston back to its original position, a main valve (7) with an o-ring that drops into the inner hole of the retainer (10) to block off the gas flow, a level arm consisting of a rising faced section (28) and a U-shaped section (29), whereby no gas will be allowed to flow through the overfill protection device when the gas reaches the predetermined 80 percent level.

Owner:SCG (THAILAND) CO LTD

High-effect cross flow washing pool

InactiveCN103055638AReduce humidityEfficient use ofUsing liquid separation agentEngineeringProduct gas

The invention discloses a high-effect cross flow washing pool which comprises a box body, wherein a purification cavity penetrating through the inside of the box body from front to back is arranged in the box body; the front end and rear end of the purification cavity in the box body are respectively provided with a gas inlet and a gas outlet; a cross flow type waste gas processing system is arranged in the purification cavity; the cross flow type waste gas processing system is composed of polypropylene polyhedral hollow sphere packing, a front spraying system and an upper spraying system; the polypropylene polyhedral hollow sphere packing is filled in the purification cavity; and the front spraying system and the upper spraying system are used for spraying purifying liquid to the polypropylene polyhedral hollow sphere packing, the front spraying system is arranged at the front side of the polypropylene polyhedral hollow sphere packing, the upper spraying system is arranged above the polypropylene polyhedral hollow sphere packing, and a pool is arranged below the purification cavity of the box body. The high-effect cross flow washing pool disclosed by the invention realizes the complete automation of running and control of the waste gas processing system, and has the advantages of high temperature resistance, corrosion resistance, small pressure loss of equipment, long service life and high waste gas treatment efficiency, is easy to install, and is safe and reliable to operate.

Owner:上海慧丰环境工程有限公司

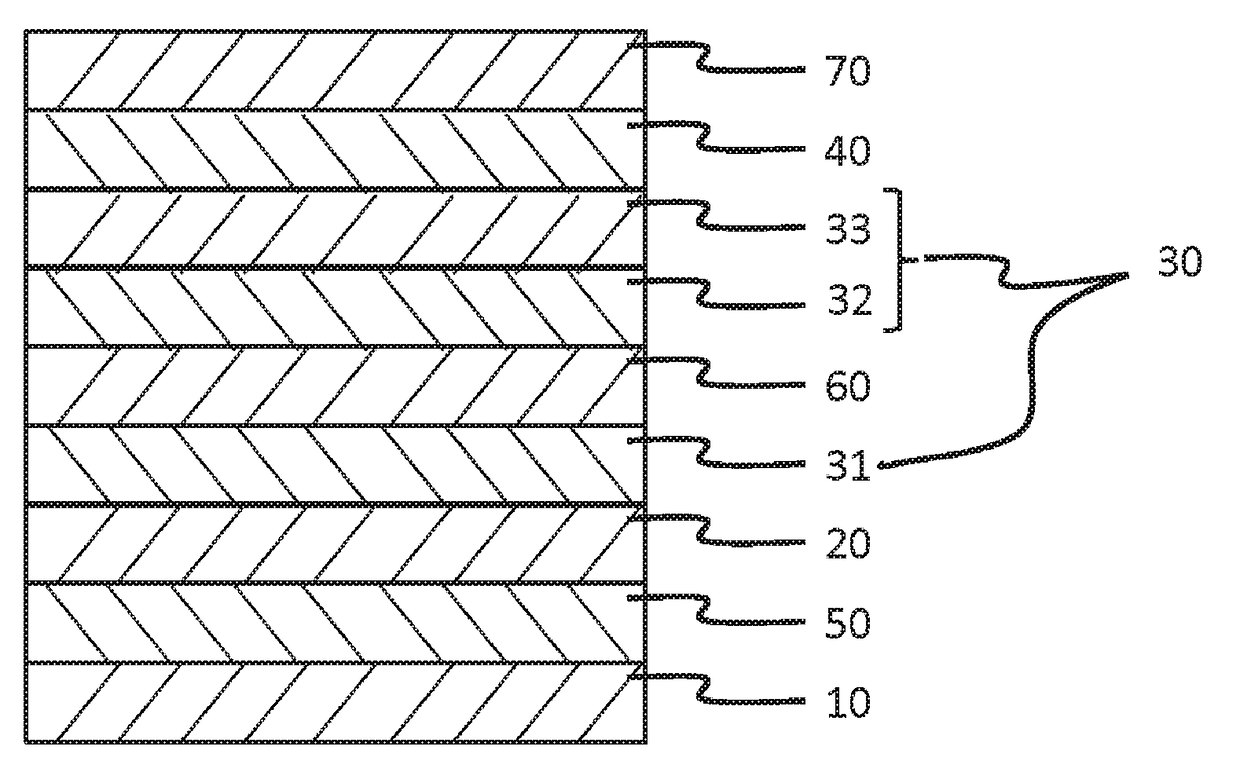

Magnetic recording medium

The purpose of the present invention is to provide a perpendicular magnetic recording medium which uses an Ru seed layer having a (002)-oriented hcp structure, and has a magnetic recording layer including a (001)-oriented L10 ordered alloy suitable to perpendicular magnetic recording. The magnetic recording medium of the present invention includes a substrate, a first seed layer containing Ru, a second seed layer containing ZnO, a third seed layer containing MgO, and a magnetic recording layer containing an ordered alloy, in this order, the first seed layer having the (002)-oriented hexagonal closest packed structure.

Owner:FUJI ELECTRIC CO LTD

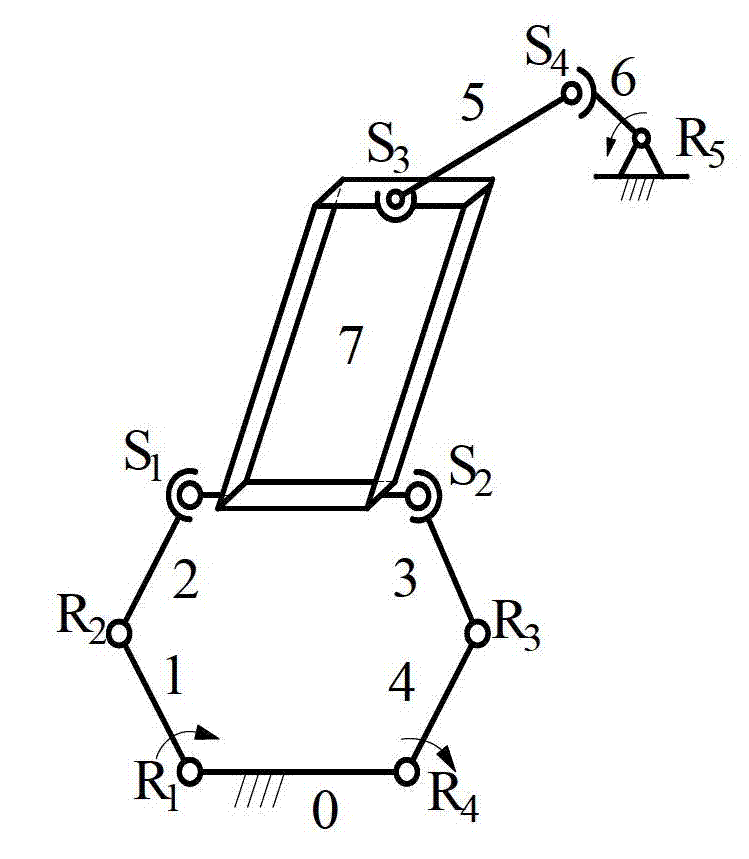

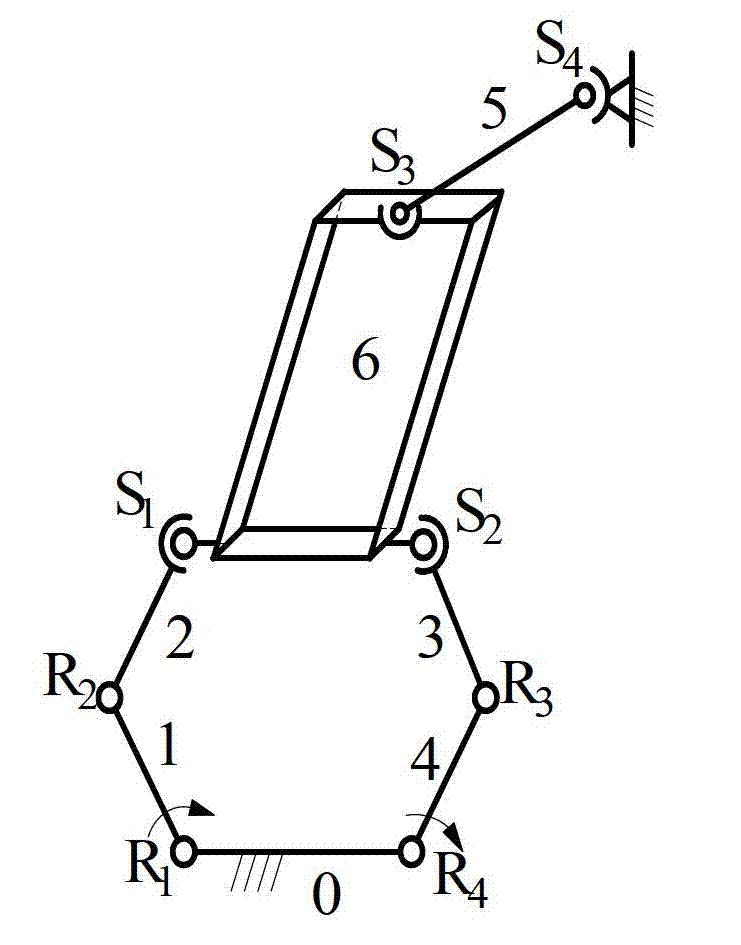

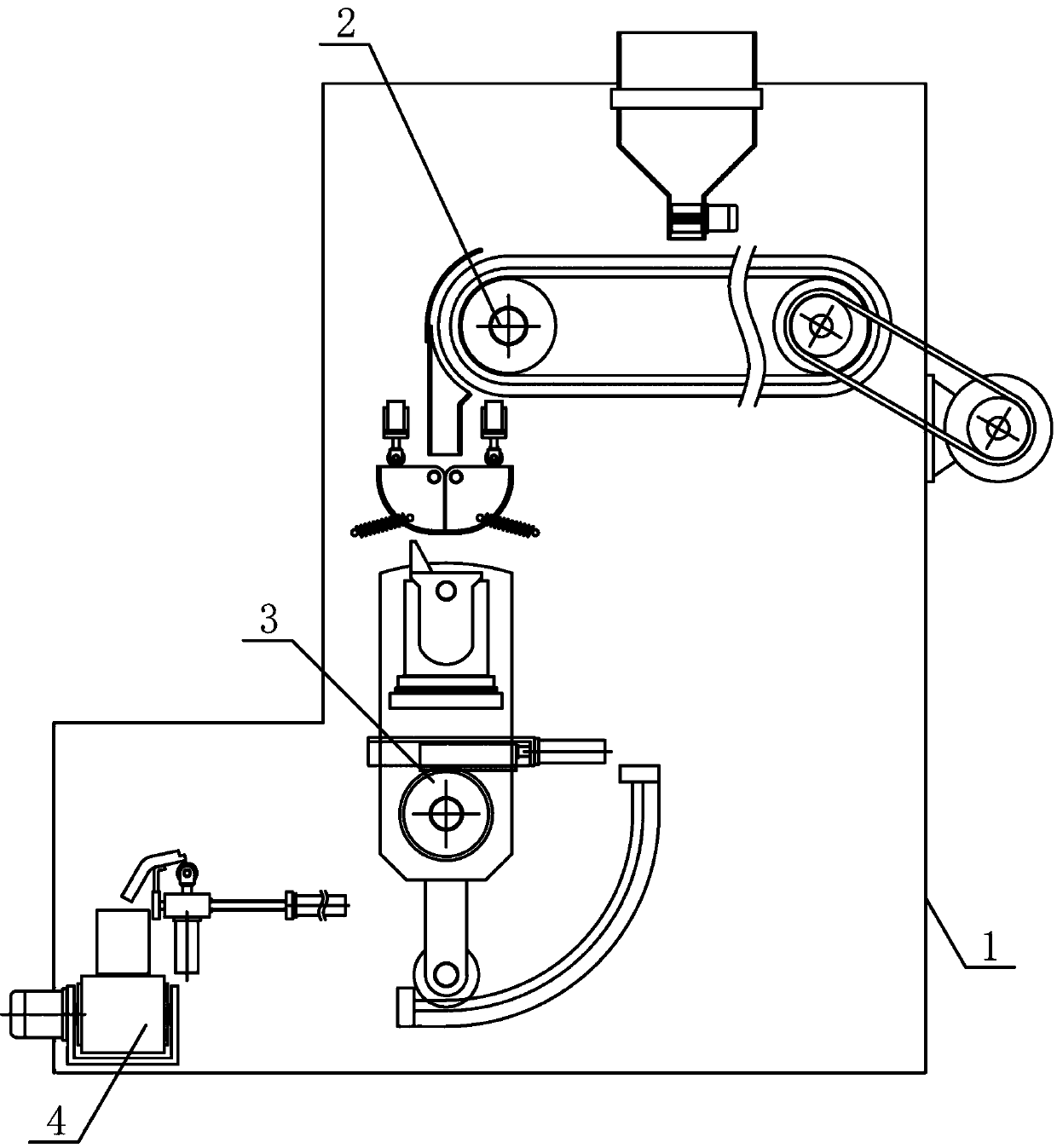

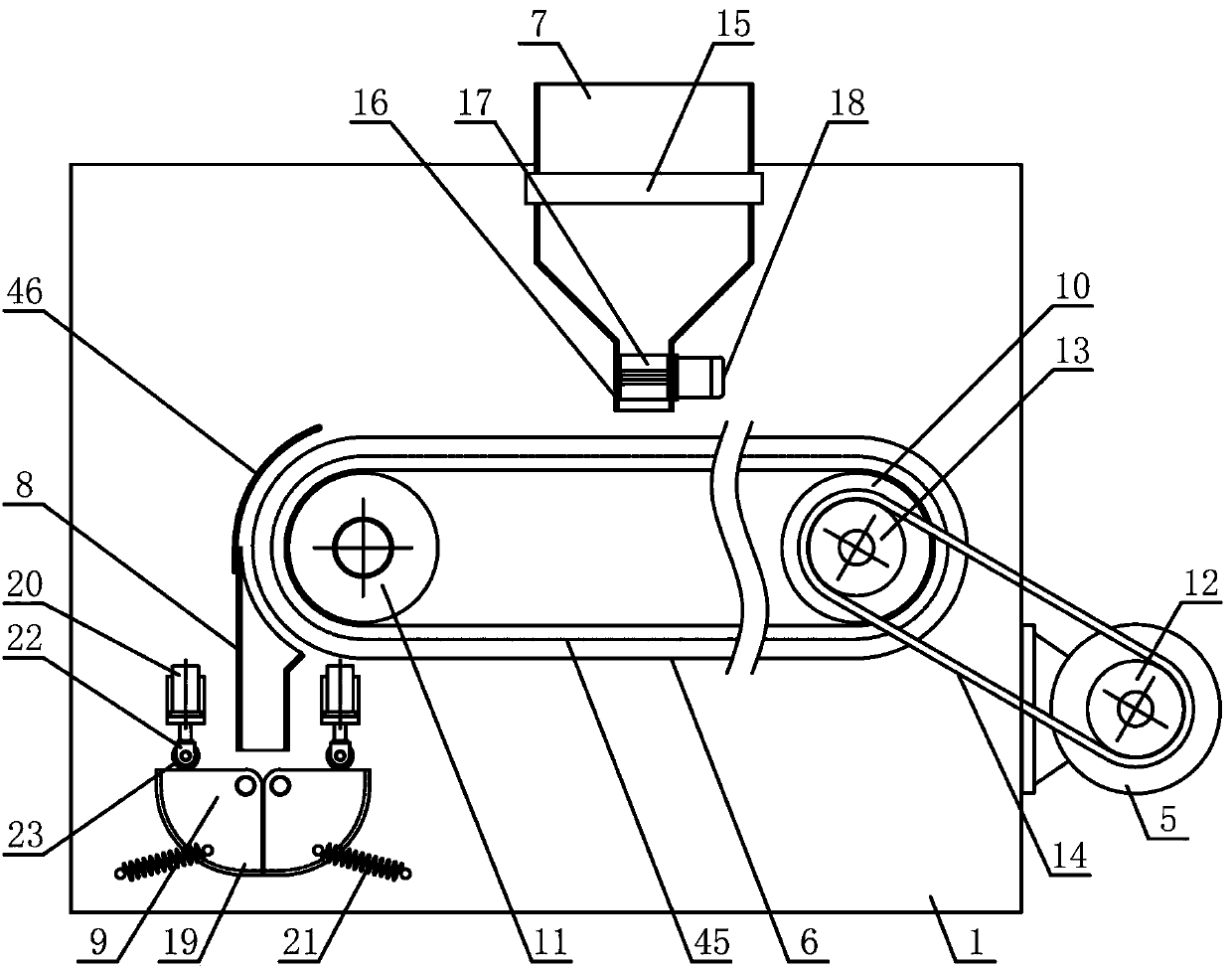

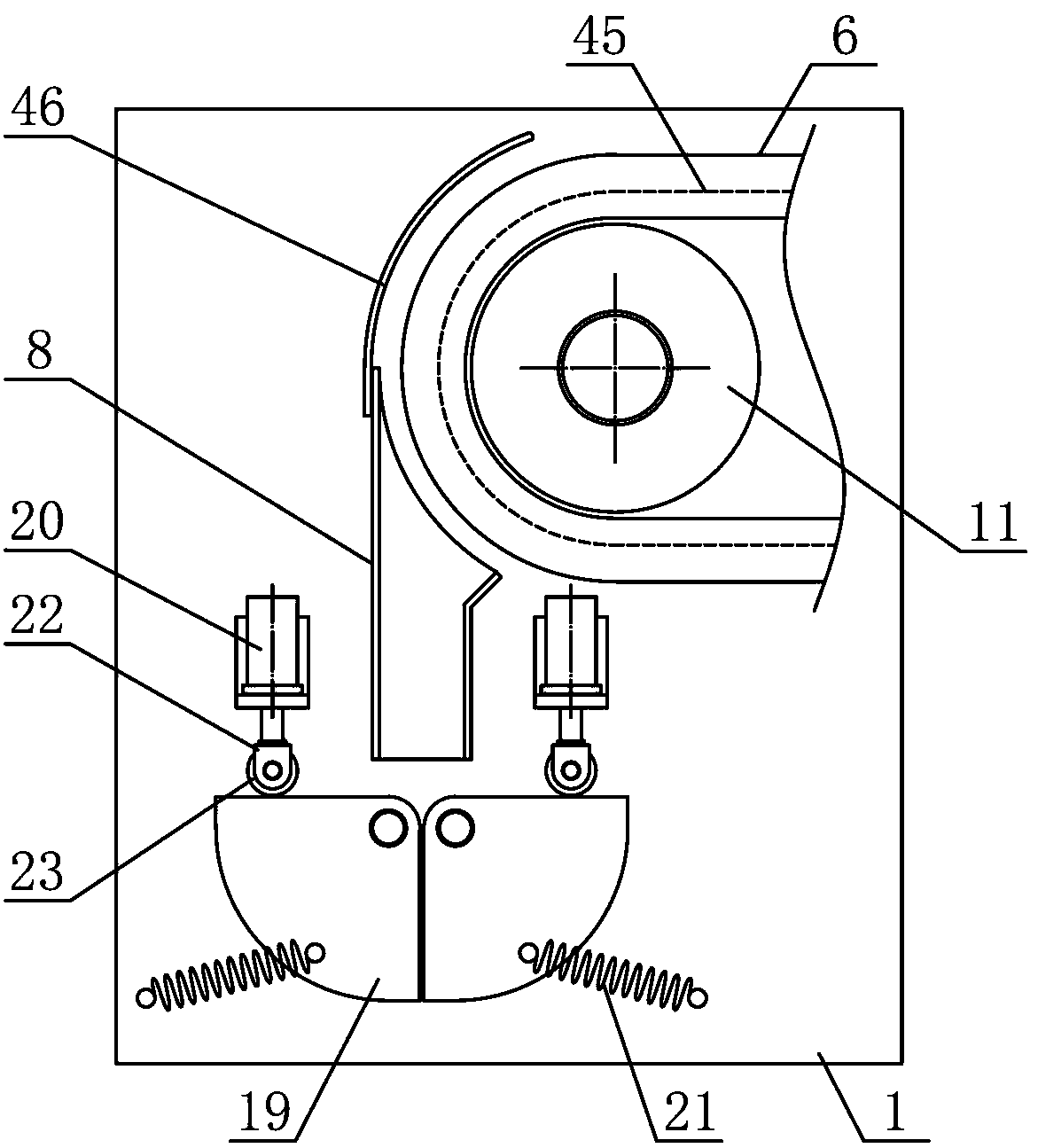

Metering guide mechanism for seed packing

ActiveCN109533470ASmooth and smooth pouringReasonable structural designSolid materialMechanical equipmentEngineering

The invention discloses a metering guide mechanism for seed packing, and belongs to the field of seed conveying and packing mechanical equipment. A seed conveying mechanism and a metering transfer mechanism are fixedly arranged on one side of a guide bracket in sequence from top to bottom; a pouring and packing mechanism is horizontally fixed on the guide bracket on one side of the metering guidemechanism; a seed storage hopper is vertically fixed on the guide bracket on the upper side of a conveying belt; a baffle mechanism is fixedly arranged on the guide bracket on the lower side of a collecting pipe; the end part of one side of a transfer connecting plate is fixedly connected with the end part of a reciprocating rotating shaft; a metering hopper is connected on a hopper connecting plate on the outer side of a metering weigher on the transfer connecting plate; an output end of a lifting cylinder is vertically and rotationally connected with a hopper push wheel; and a tank conveyingbelt is horizontally arranged on the upper side of a tank conveying bracket. The metering guide mechanism for seed packing is reasonable in structural design, can accurately and efficiently meter andtransfer seeds, can realize automatic packing and conveying of the seeds, and meets the seed packing use demands.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

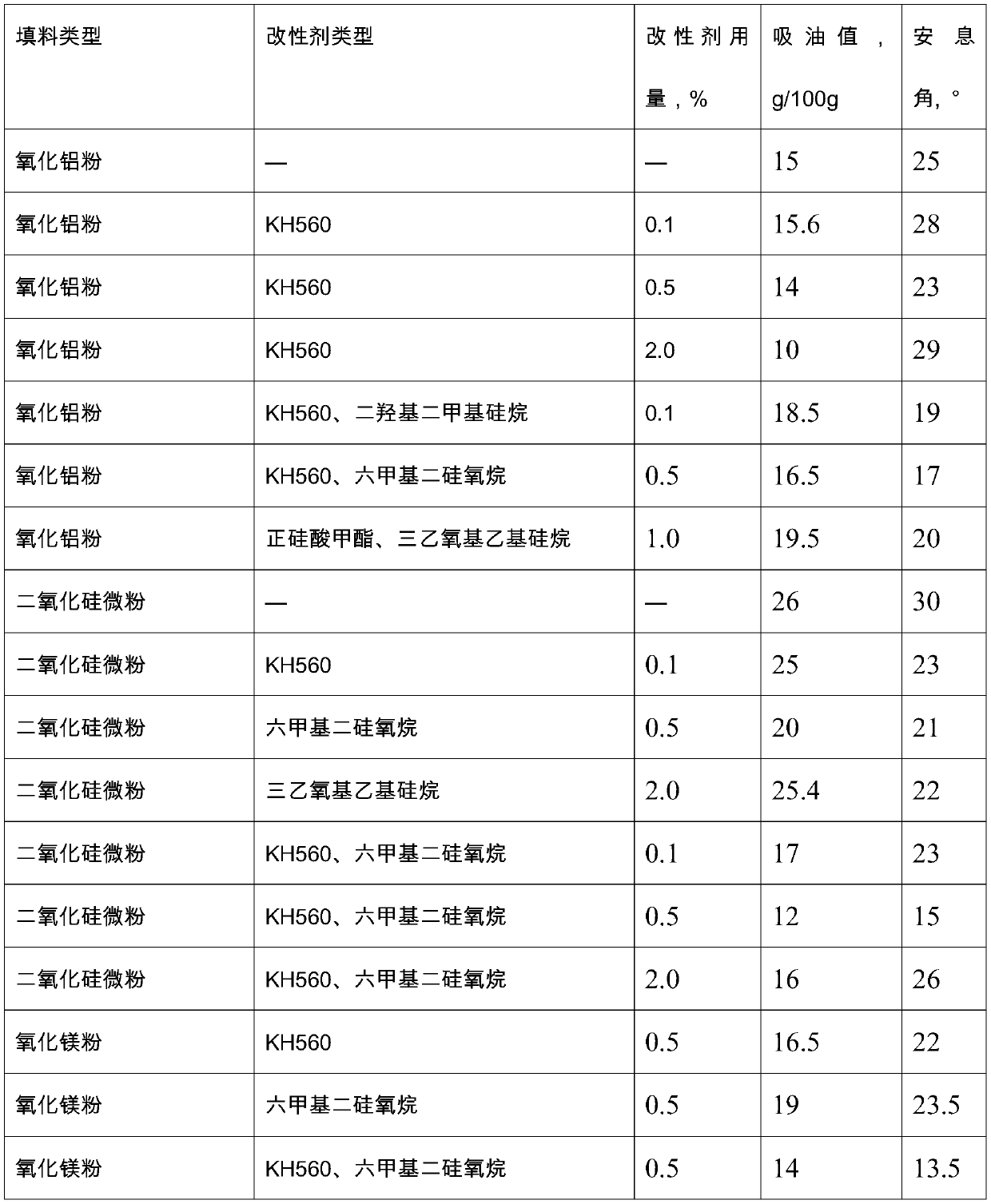

In situ modification method of electronic grade spherical packing

The invention discloses an in situ modification method of electronic grade spherical packing. The in situ modification method comprises the steps that spherical packing with the average particle sizeD50 between 0.01 [mu]m and 60 [mu]m is selected, the spherical packing is led into a reaction vessel, igniting and spheroidization are conducted, cooling is conducted after spheroidization, when the temperature is cooled to 80 DEG C to 150 DEG C, a coupling agent is added into the spherical packing after spheroidization, the additive amount of the coupling agent accounts for 0.1% to 2% of the total weight of the spherical packing, and thus the spherical packing after modified in situ is prepared; and the coupling agent is one or more of hexamethyldisiloxane, polysiloxane, dihydroxydimethylsilane and a silane coupling agent. According to the in situ modification method, in the spheroidization and cooling processes of the spherical packing, the coupling agent is adopted to modify the spherical packing in situ by using residual heat, and thus the spherical inorganic packing modified in situ has excellent hydrophobic performance, good particle dispersion and excellent compatibility and binding force with organic resin.

Owner:JIANGSU NOVORAY NEW MATERIAL CO LTD

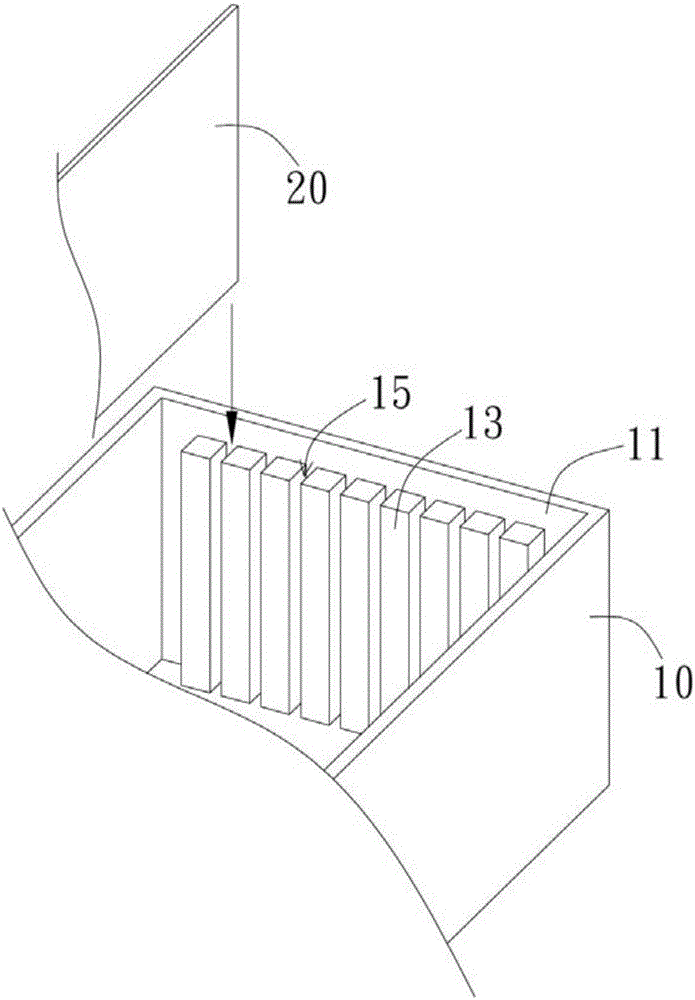

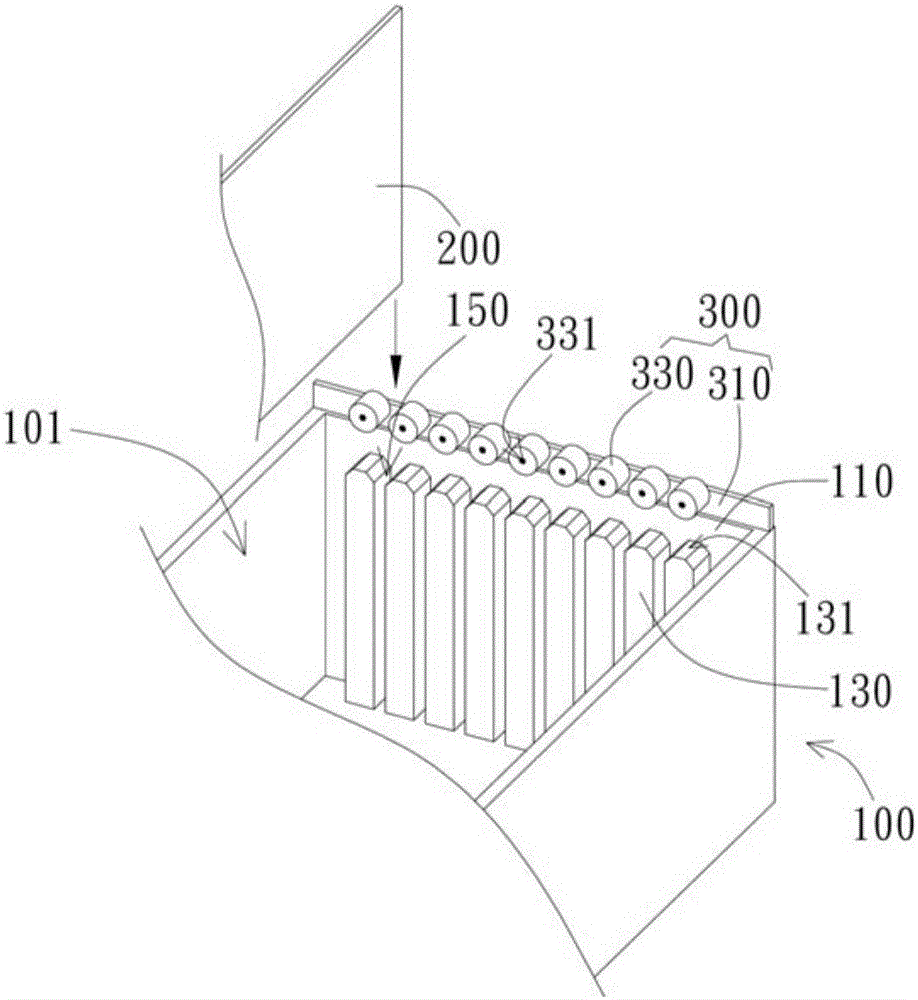

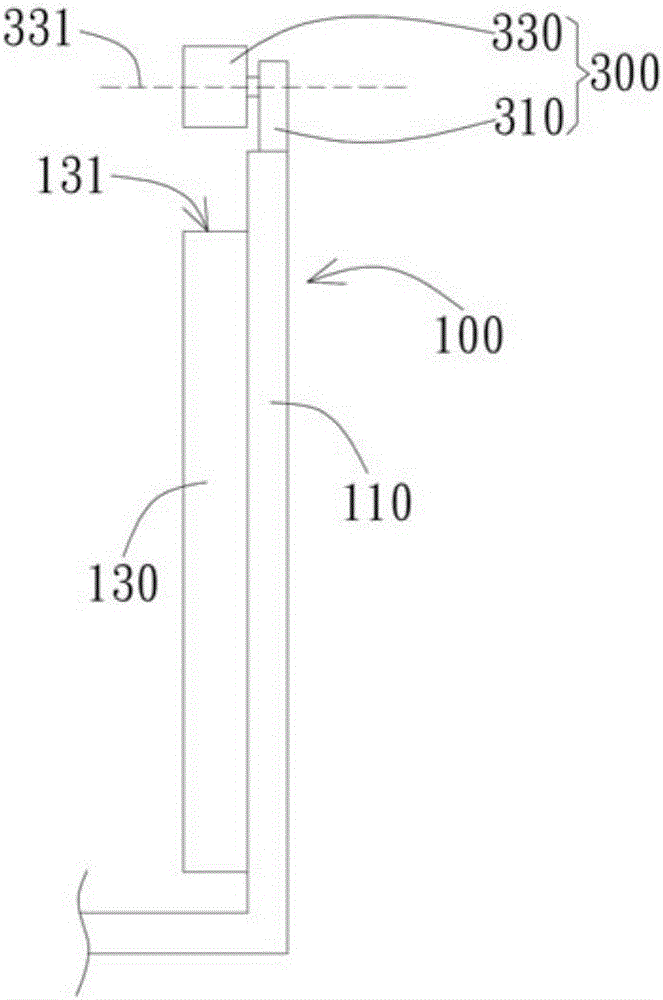

Packing guide tool and sheet packing method

InactiveCN105775208AImprove convenienceReduce difficultyShock-sensitive articlesIndividual articlesSphere packingPlane parallel

The invention provides a packing guide tool and sheet packing method. A guide tool is arranged on a packing casing, and comprises substrate and a plurality of guide wheels. The packing casing comprises a plurality of sidewalls, on which a plurality of spacing bars are arranged; grooves are formed between adjacent spacing bars. The substrate extends along the top rim of the packing casing sidewalls; the guide wheels are separately arranged on the substrate, and can rotate around an axis vertical with the substrate, and extend in the packing casing along an axis direction to arrive above the top surface of the spacing bars. Each guide wheel is provided with a wheel surface which has a tangent plane parallel with the extending direction of a corresponding spacing bar, and the tangent plane corresponds to the top surface rim outer side of a spacing bar through the guide wheel. The wheel surface of the guide wheel is in contact with a sheet, the guide wheel rotates to guide the sheet to a groove, and the sheet completely extends into the packing casing along the groove, thereby completing sheet packing. Two adjacent guide wheels form a guiding gate therebetween. Before the side rim of a sheet enters the grooves, the sheet first passes through the gate, and is then guided to a corresponding groove.

Owner:AU OPTRONICS CORP

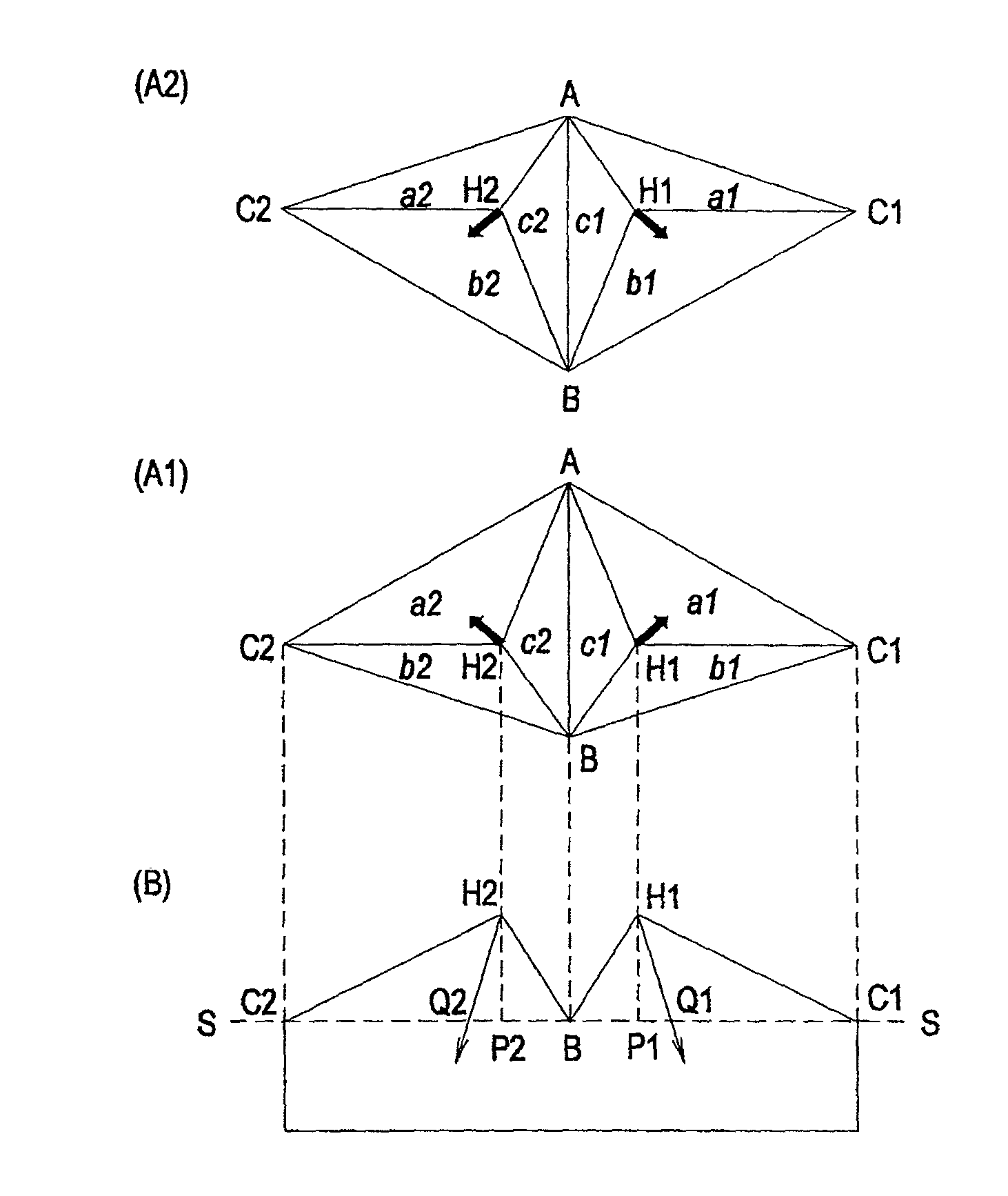

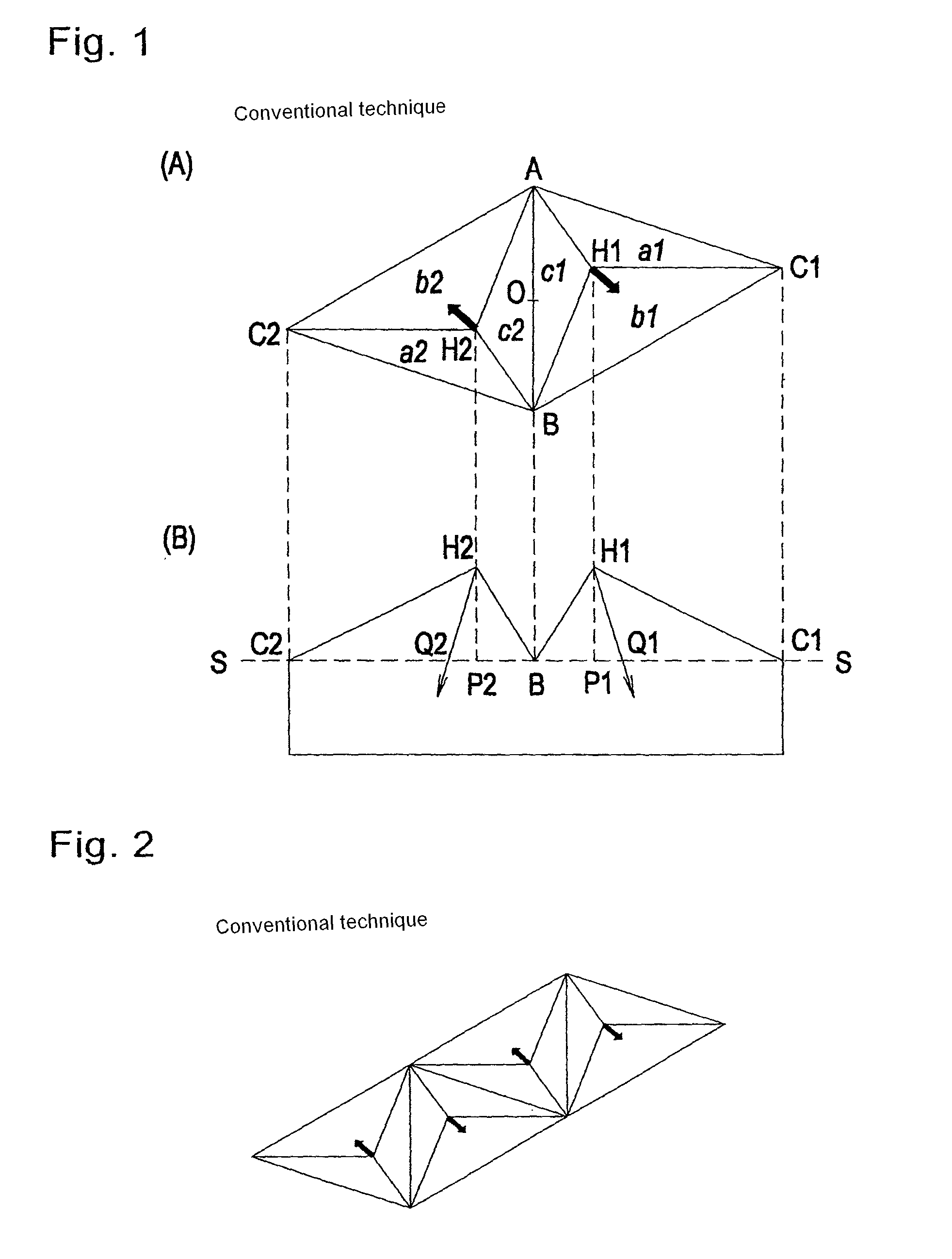

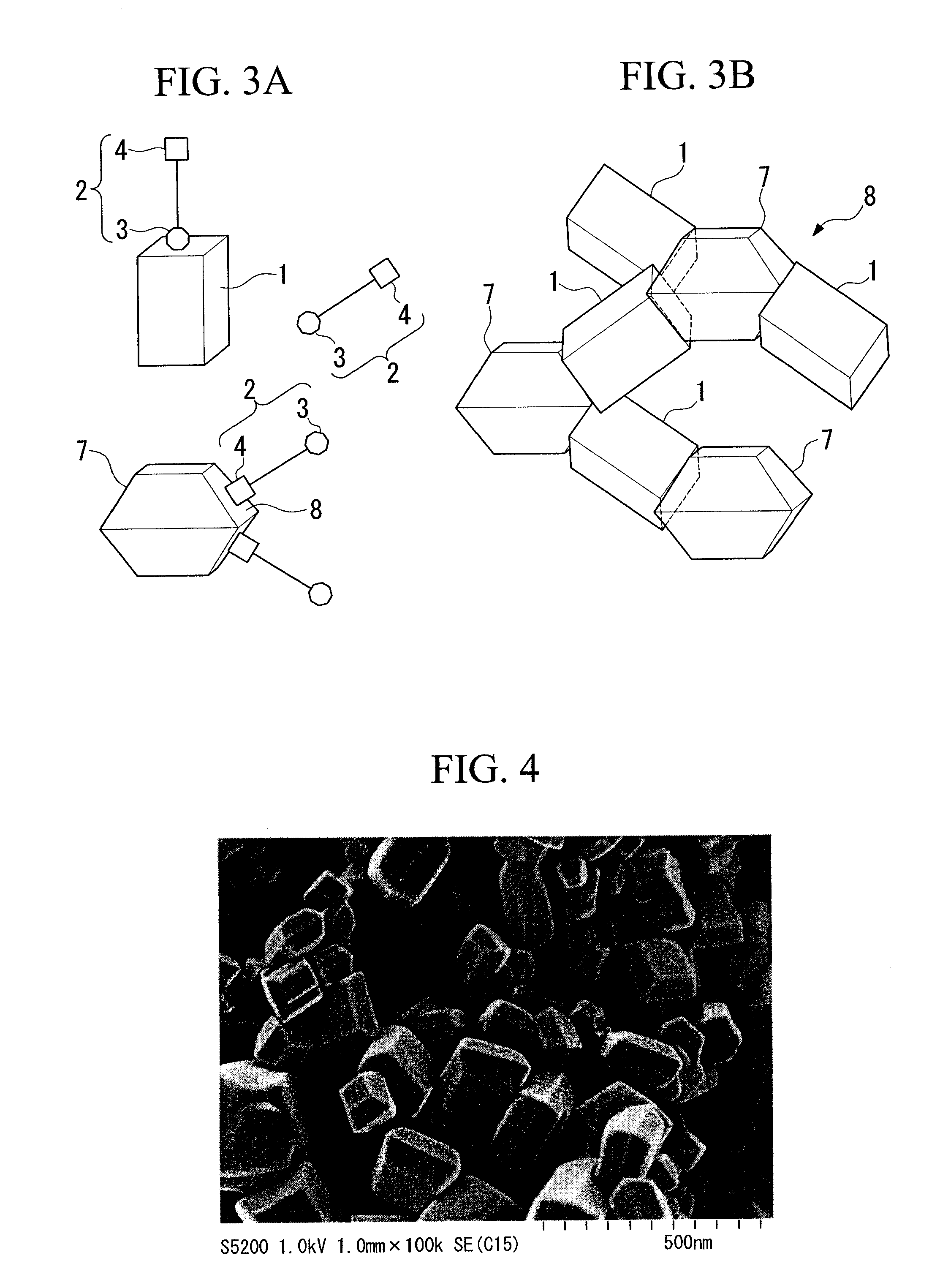

Triangular pyramid type cube corner retroreflection article, and its manufacturing method

ActiveUS8459806B2Improve angularity angularity angularityGood for observationLamination ancillary operationsLaminationEngineeringTrigonal crystal system

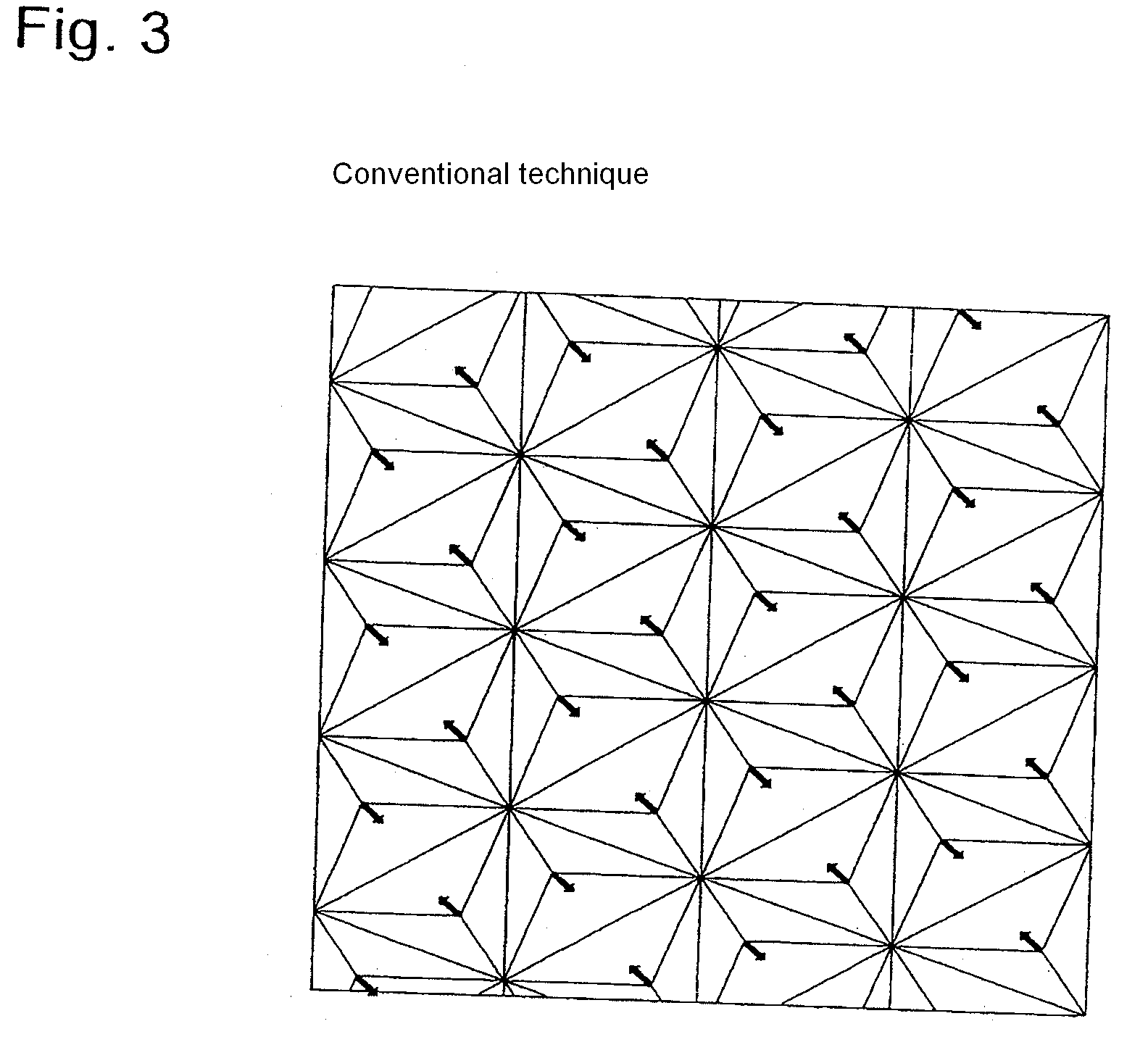

The present invention relates to a triangular pyramidal cube corner retroreflective article and a producing method thereof. In the triangular pyramidal cube corner retroreflective article, a triangular pyramidal cube corner retroreflective element pair group is disposed in a closest-packed fashion on a common plane defined by three base lines, and the each of retroreflective elements in a pair having one base line (A-B) shared by the retroreflective elements in the pair. The triangular pyramidal cube corner retroreflective article includes a first element pair group, in which two interior angles (α=∠BAC and β=∠ABC) formed by the shared base line of the element pair and two other base lines are different from each other and the element pair is line-symmetrically disposed in relation to the shared base line (A-B); and a second element pair group, in which the element pair is congruent to a line-symmetrical shape to the first element pair in relation to a line segment connecting vertexes of the base planes.

Owner:NIPPON CARBIDE KOGYO KK

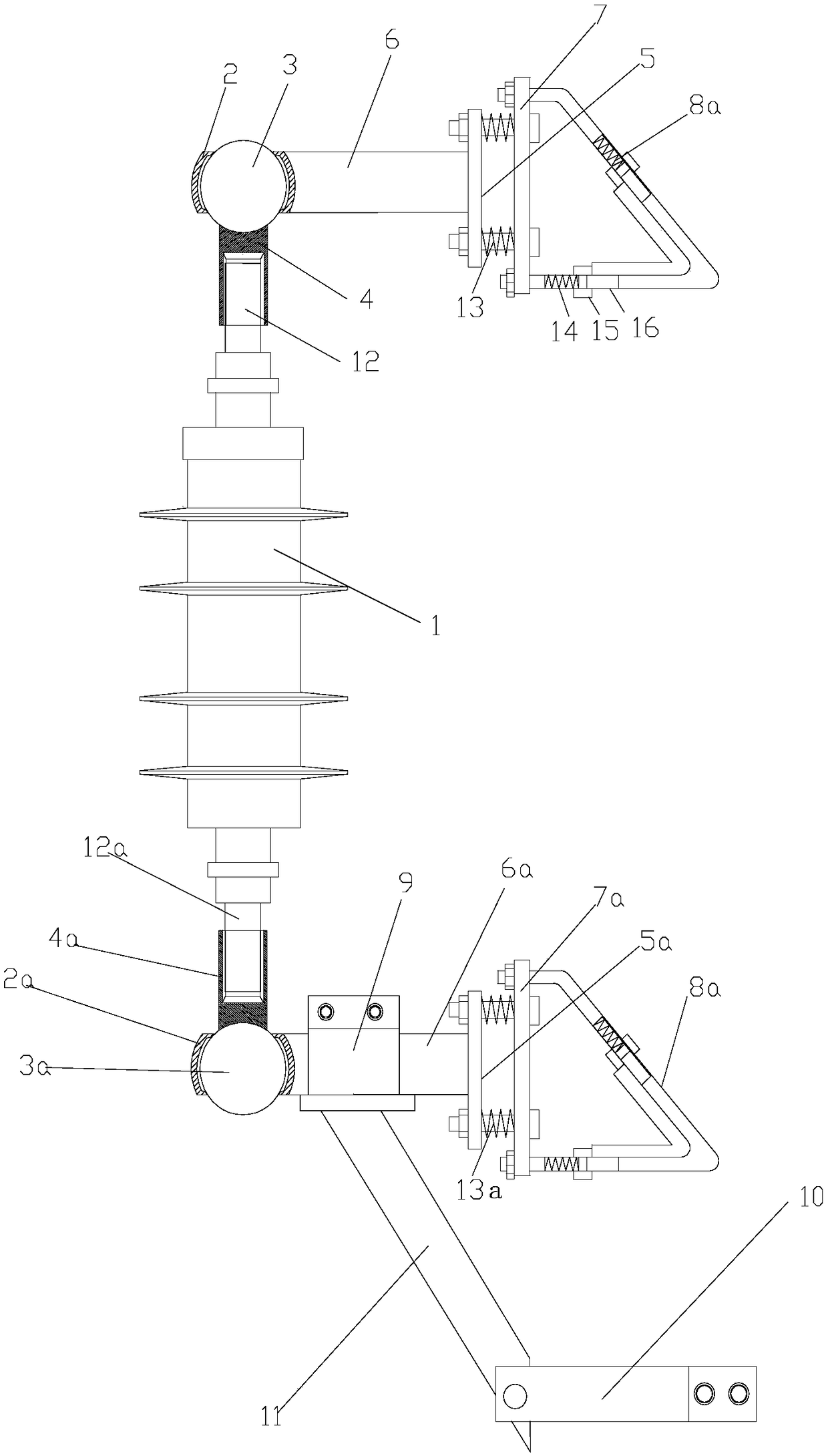

Intelligent lightning protection system of power transmission line

The invention discloses an intelligent lightning protection system of a power transmission line. The intelligent lightning protection system comprises a lightning arrestor body, and an upper connecting assembly and a lower connecting assembly used for being connected with the upper end and lower ends of the lightning arrestor body and a wire rod cross arm respectively; the upper connecting assembly and the lower connecting assembly are the same in structures, and each of the upper connecting assembly and the lower connecting assembly at least comprises an outer sphere pack, a sphere body movably connected with the outer sphere pack, and a vertical connecting arm in threaded connection with the end part of the lightning arrestor body; the vertical connecting arm is fixedly connected with the sphere body; by virtue of setting of the sphere pack structure, the upper and lower ends of the lightning arrester body can be connected with a tower or cross arm angle iron through sphere hinged structures, so that whether there is an inclination angle or not in the connecting position of the tower or the cross arm angle iron, the connected and mounted lightning arrester body can be naturally kept in a vertical state, without needing manual adjustment or locking; and therefore, the intelligent lightning protection system is convenient to use, high in practicability and high in reliability.

Owner:海南智弘智能信息化工程有限公司

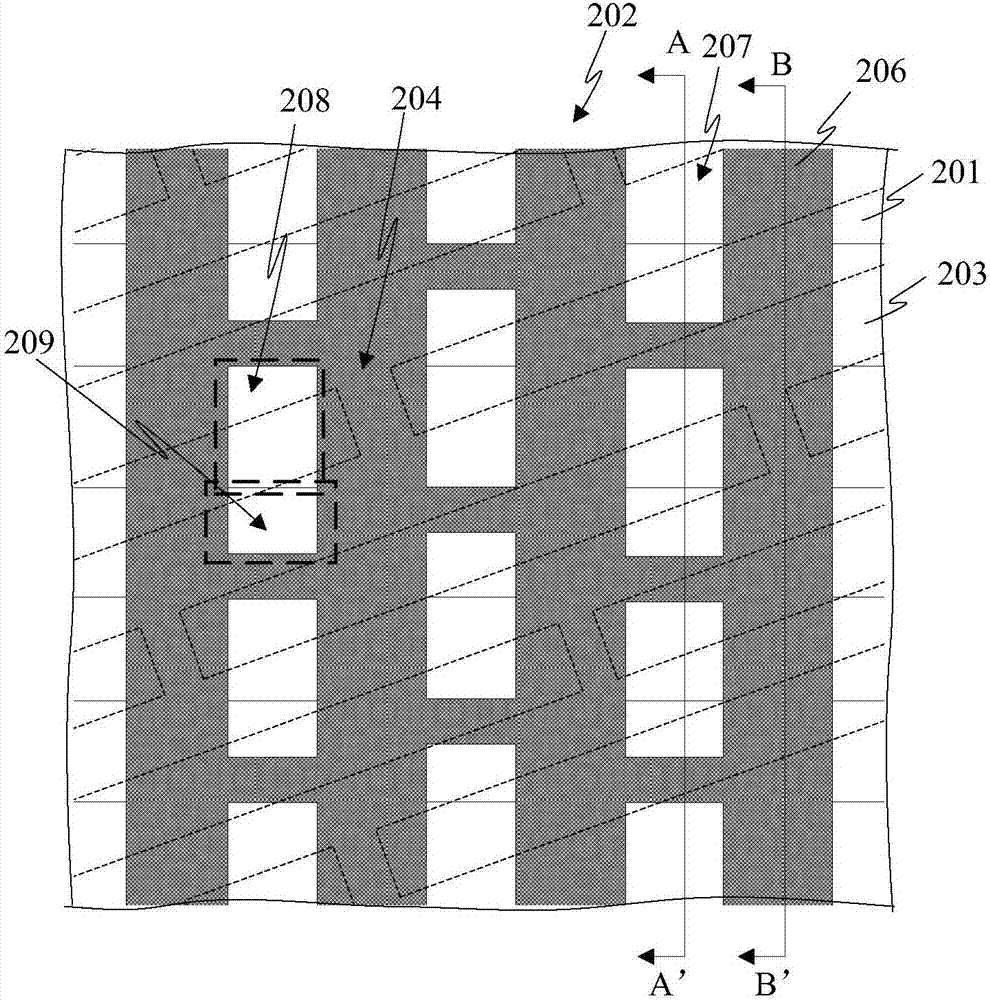

Semiconductor memory device and manufacturing method thereof

ActiveCN106992175AReduce manufacturing costImprove insulation performanceTransistorSemiconductor/solid-state device manufacturingArray data structureContact pad

The invention provides a semiconductor memory device and a manufacturing method thereof. The manufacturing method of the semiconductor memory device includes the steps: forming an active region, vertically interlaced word lines and bit lines, and first and second insulating layers on a semiconductor substrate, wherein isolation materials are filled among the bit lines; forming a contact window and gaps in the first and second insulating layers through etching; filling the contact window and the gaps with conductive materials, and etching back the conductive materials to enable the conductive materials to be lower than the first insulating layer; and depositing the insulating materials and etching to remove the insulating materials at the middle part totally so as to form a contact pad window for a capacitor and maintain part of the insulating materials at two sides to form a contact pad side wall insulating layer. The manufacturing method of the semiconductor memory device manufactures a self-aligning three dimensional contact pad structure through photoetching and plasma etching technology, enables the word line and bit line array to joint with the capacitor array, and can realize connecting contact between hexagonal closest packing capacitor array and a tetragonal word line and bit line array, without increasing a rewiring layer, and can manufacturing the contact pad side wall insulating layer to improve the insulating effect.

Owner:CHANGXIN MEMORY TECH INC

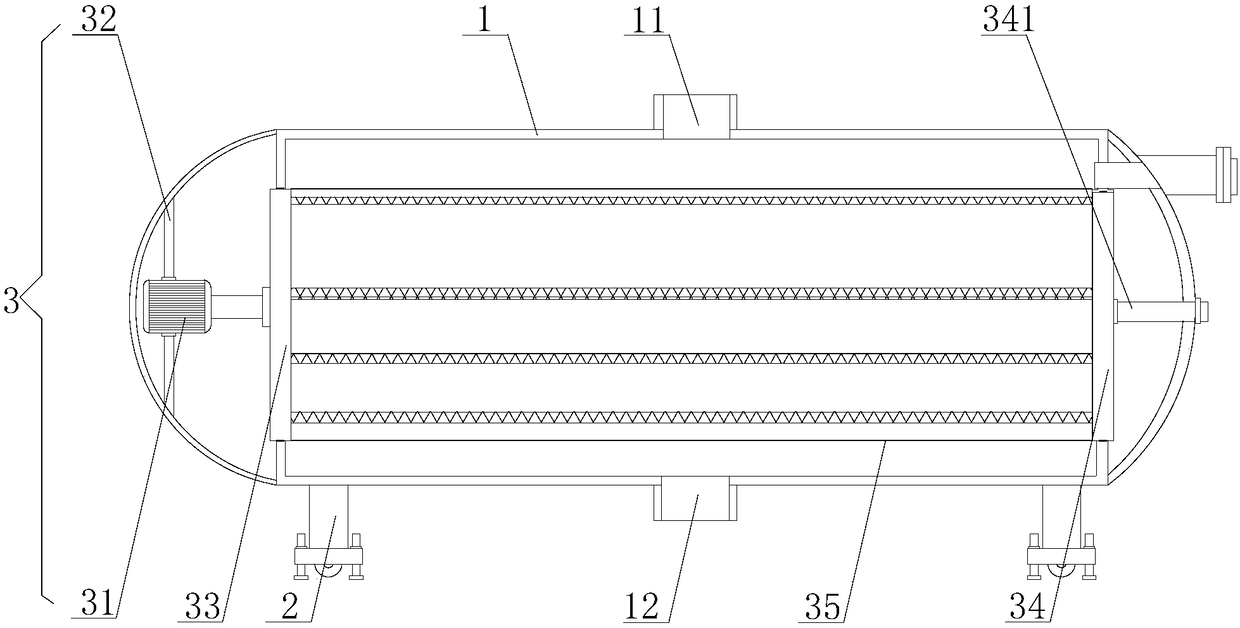

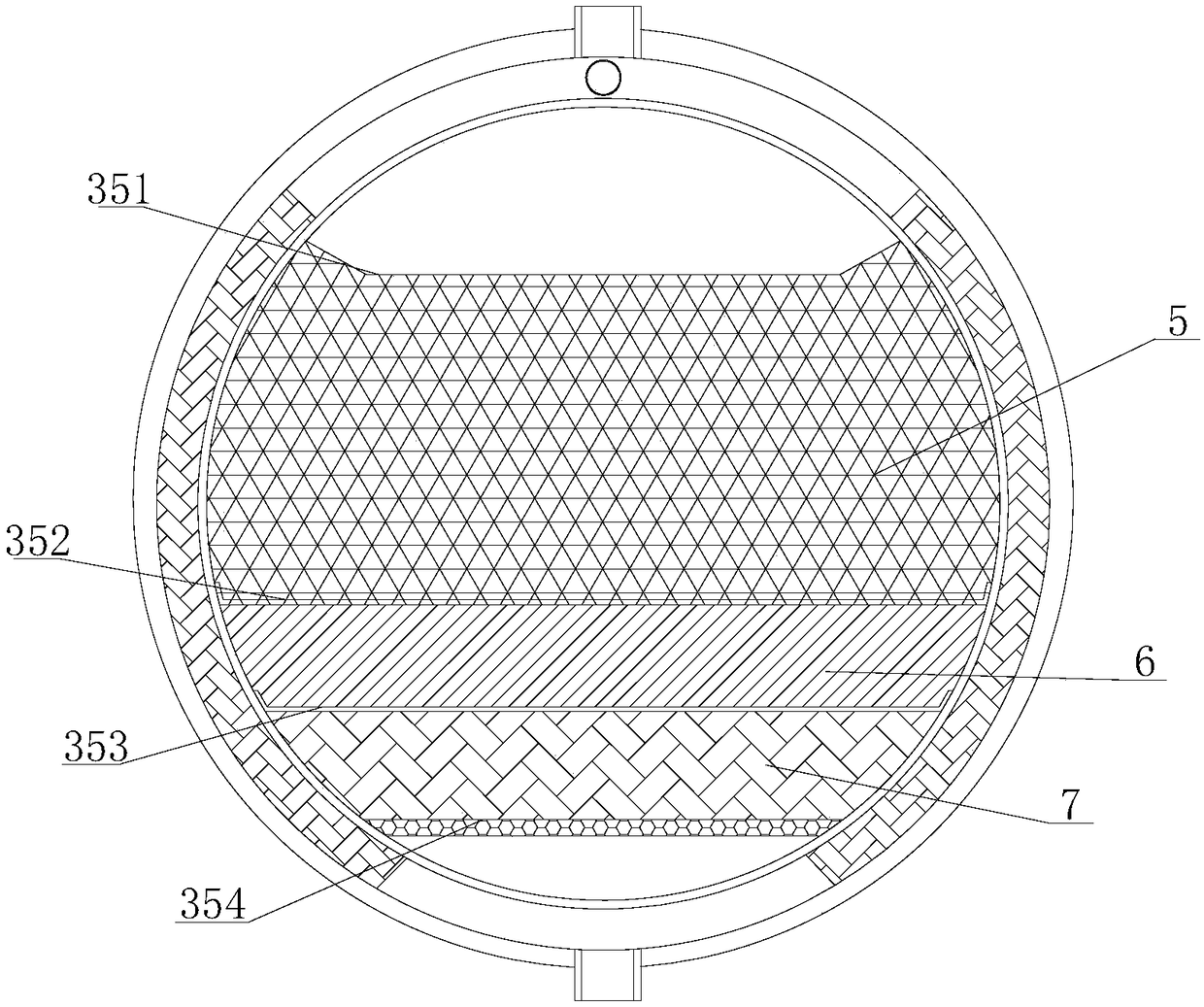

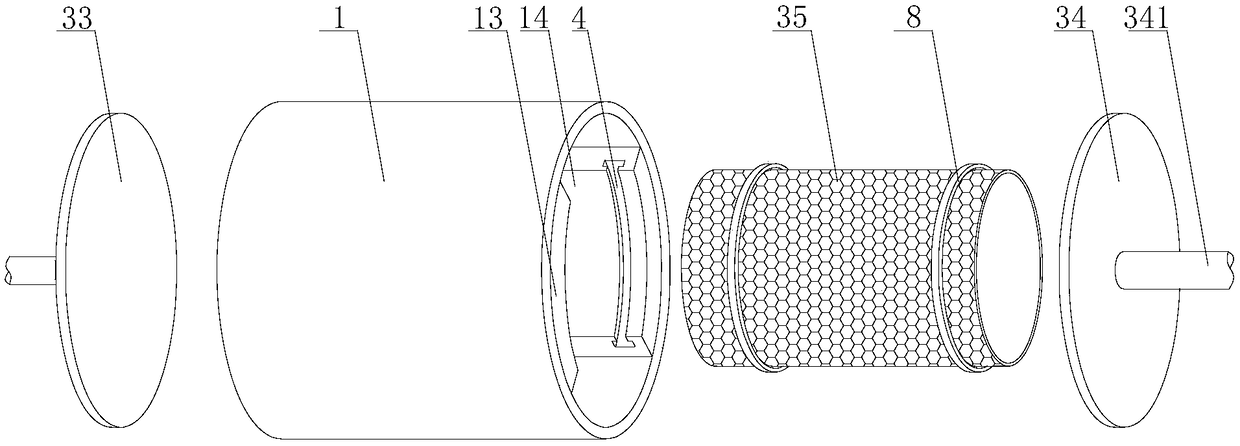

Molecular sieve adsorber for air

InactiveCN109157947AImprove completenessSpeed up regenerationGas treatmentDispersed particle separationEngineeringNitrogen gas

The invention discloses a molecular sieve adsorber for air. The molecular sieve adsorber comprises a horizontal type cylindrical tank; an upper pipe for entering of gas and a lower pipe for exiting ofthe gas are respectively connected with the top and the bottom of the tank; pulley bottom frames for movement and supporting are mounted on the bottom surface, beside the lower pipe, of the tank; a rotating mechanism is further mounted in the tank; an arc block A and an arc block B which are connected with the rotating mechanism are respectively connected with the inner wall of the tank; slidingchutes are formed in the arc block A and the arc block B; a multi-surface hollow sphere packing layer, a carbon dioxide removal layer and a hydrocarbon removal layer are put in the molecular sieve adsorber to adsorb moisture, carbon dioxide and most of the hydrocarbon in the air; hot and dry impure nitrogen gas flows enter the molecular sieve adsorber through the upper pipe and the lower pipe in adirection opposite to a negative flow so as to carry out regeneration; the internal part of the adsorber is continuously rotated; and centrifugal force generated in a rotation process is matched withmovement of the nitrogen to improve the regeneration speed.

Owner:马鞍山马钢林德气体有限责任公司

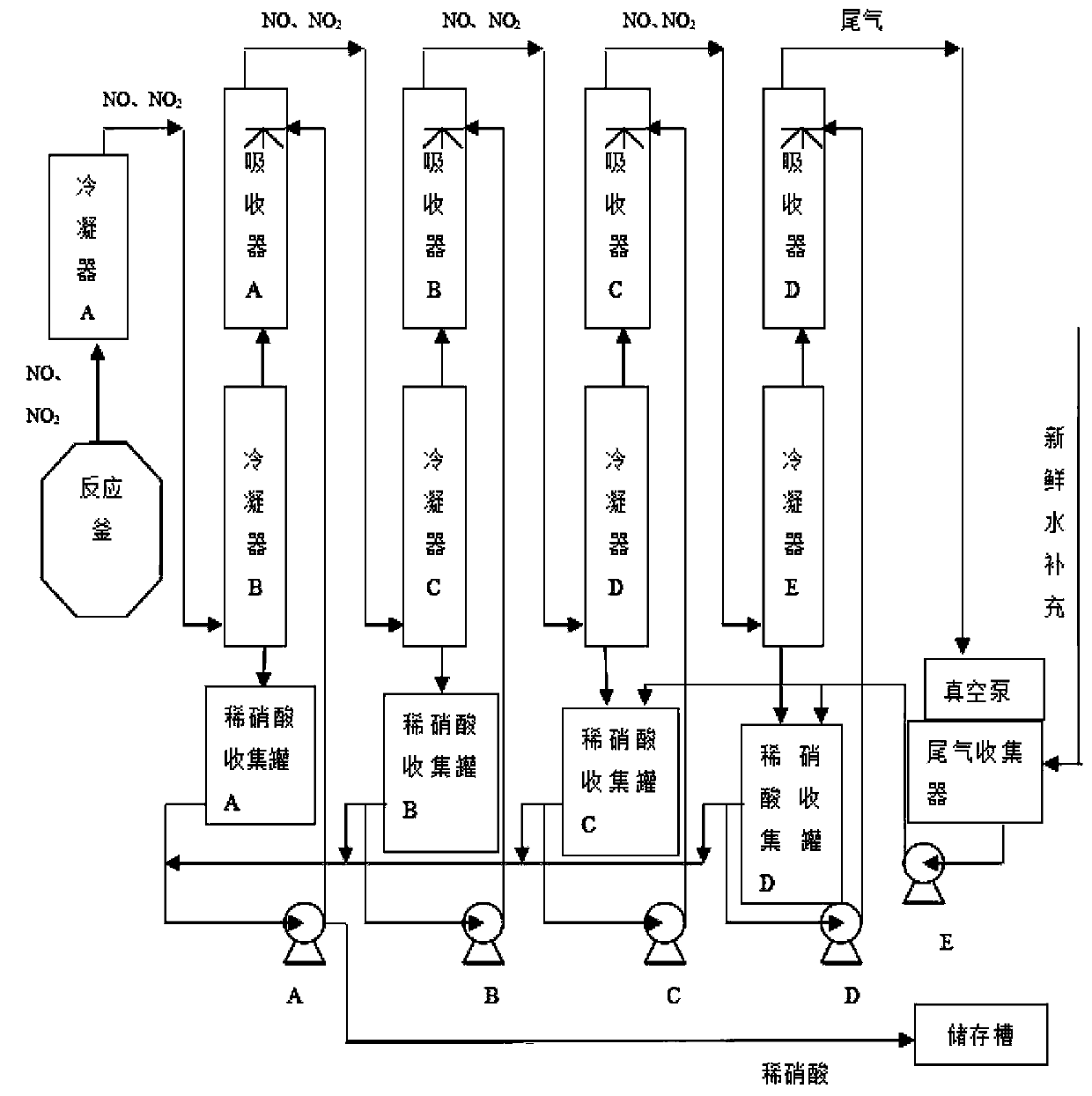

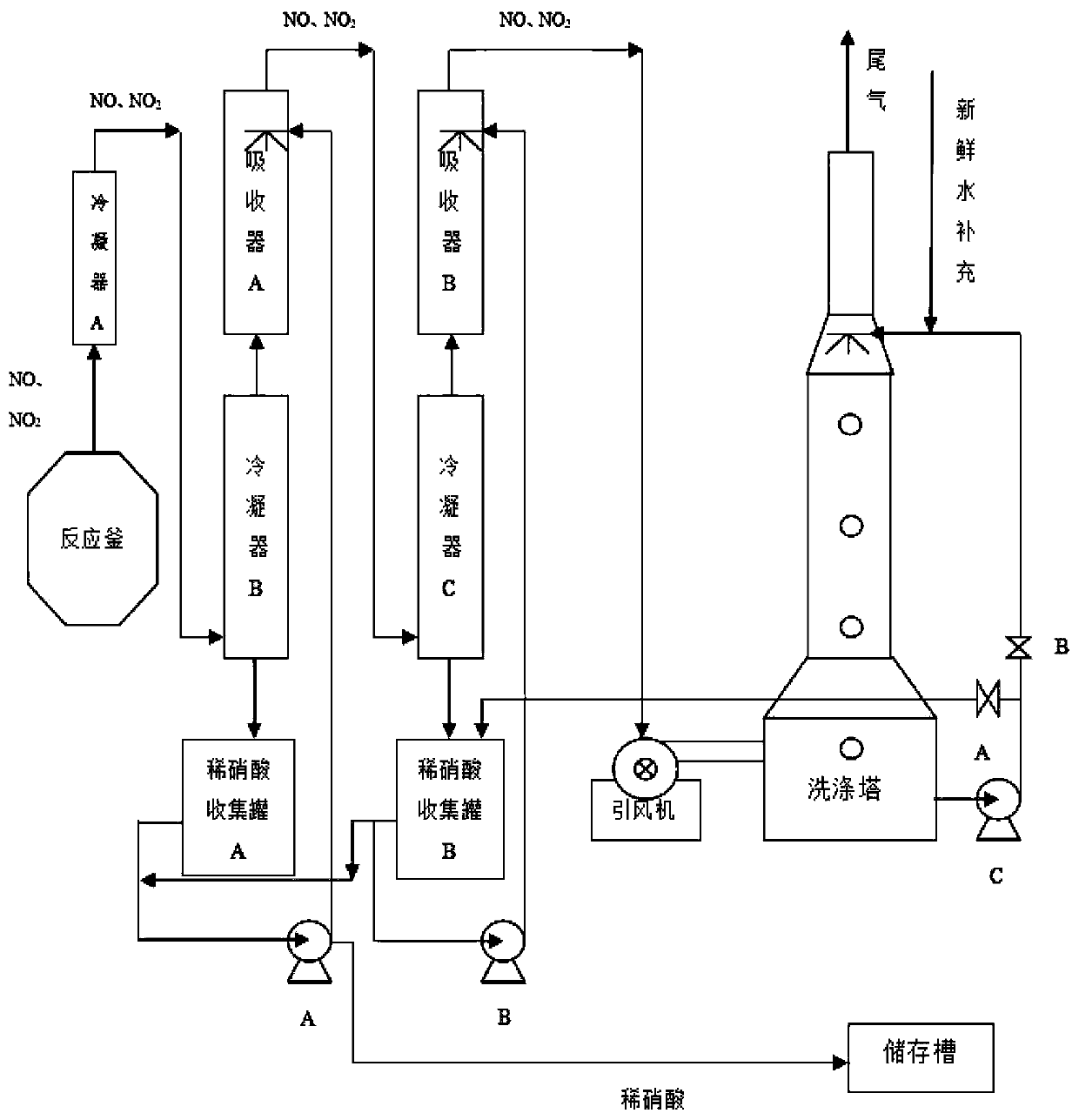

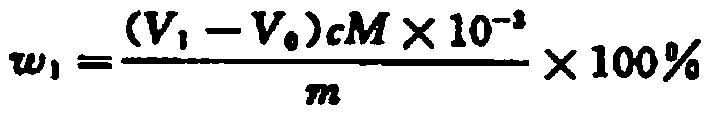

Nitration reaction tail gas converting and recycling device and process

InactiveCN109821365AImprove conversion rateReflect the value of circular economyDispersed particle separationNitroimidazoleNitration

The invention discloses a nitration reaction tail gas converting and recycling device and process and belongs to the technical field of nitration reaction tail gas treatment. A combined process of lowtemperature, oxidization and multi-stage water absorption is adopted, and anti-corrosion packing formed by PVDF plastic polyhedral hollow sphere packing, ceramic Pall ring packing and 2507 duplex stainless steel metal cascade ring packing is placed in an absorber; aiming at the serious problem that NO and NO2 waste gas exhaust emissions generated in a 2-methyl-5-nitroimidazole synthesis process exceeds the standard, NO and NO2 waste gas can be converted into nitric acid available in production, a multi-stage condensation cooling and circulating spraying absorption mode is adopted, the conversion rate of NO and NO2 is greatly increased, and therefore the dual purposes of reducing pollutant discharge and increasing economic benefits are achieved.

Owner:河池市金兴生物科技有限公司

Spark plug

A spark plug that satisfies the relation 2.8≤(A+B) / M, where A is the sum of a length A1 of contact between a sheet packing and a metallic shell of a spark plug in one half section and a length A2 of contact between the sheet packing and the insulator in the one half section, and B is the sum of a length B1 of contact between the sheet packing and the metallic shell in the other half section and a length B2 of contact between the sheet packing and the insulator in the other half section. M is the difference obtained by subtracting the inner diameter D of a ledge from the inner diameter C of a middle hole portion.

Owner:NGK SPARK PLUG CO LTD

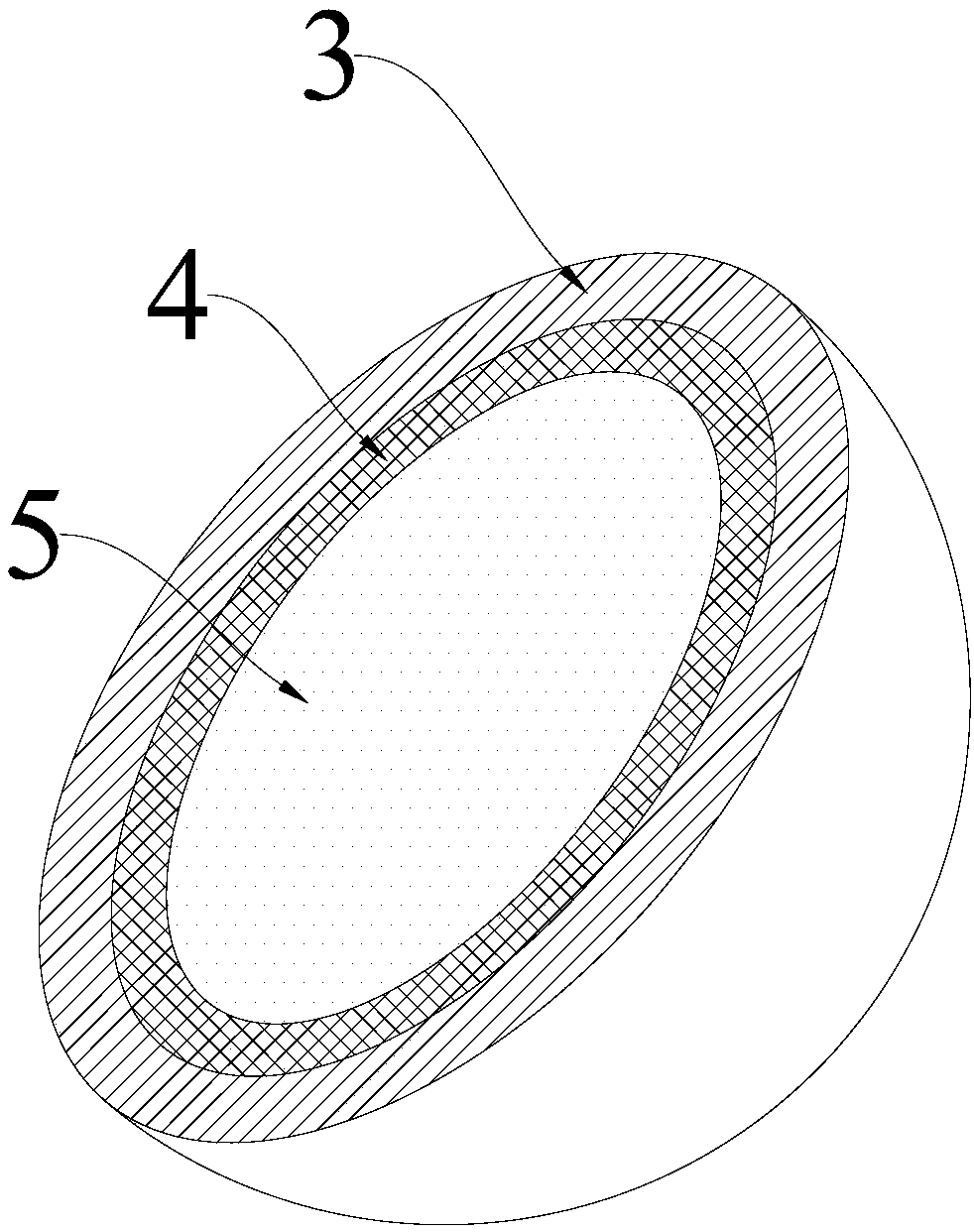

Assembling type vacuum foam wall body and preparation method thereof

InactiveCN108532779AImprove insulation effectImprove sound insulationClimate change adaptationInsulation improvementSurface layerThermal insulation

The invention discloses an assembling type vacuum foam wall body and a preparation method thereof. The wall body comprises a wall surface layer and vacuum balls, wherein a first containing cavity is surrounded by the wall surface layer; the vacuum balls are arranged in a first containing cavity and are in a closest accumulation arrangement way; the first containing cavity is filled with foamed filler which is distributed in a gap between each vacuum ball and the wall surface layer and in a gap between vacuum walls; each vacuum ball comprises an external protection layer, a vacuum diaphragm andfoam, wherein the external protection layer, the vacuum diaphragm and the foam are arranged in sequence from the outside of the ball body to the inner side of the ball body; a second containing cavity is surrounded by the vacuum diaphragm and is filled with foam. The preparation method is used for manufacturing the assembling type vacuum foam wall body. The assembling type vacuum foam wall body provided by the invention not only can perform a relatively good thermal insulation and heat insulation function but also can perform a relatively good sound insulation effect. In addition, the invention can provide a thinner wall body so as to realize a purpose that indoor use space is increased to a maximum degree under a situation that wall body strength is not influenced.

Owner:HEBEI ZHUOQIU IND CO LTD

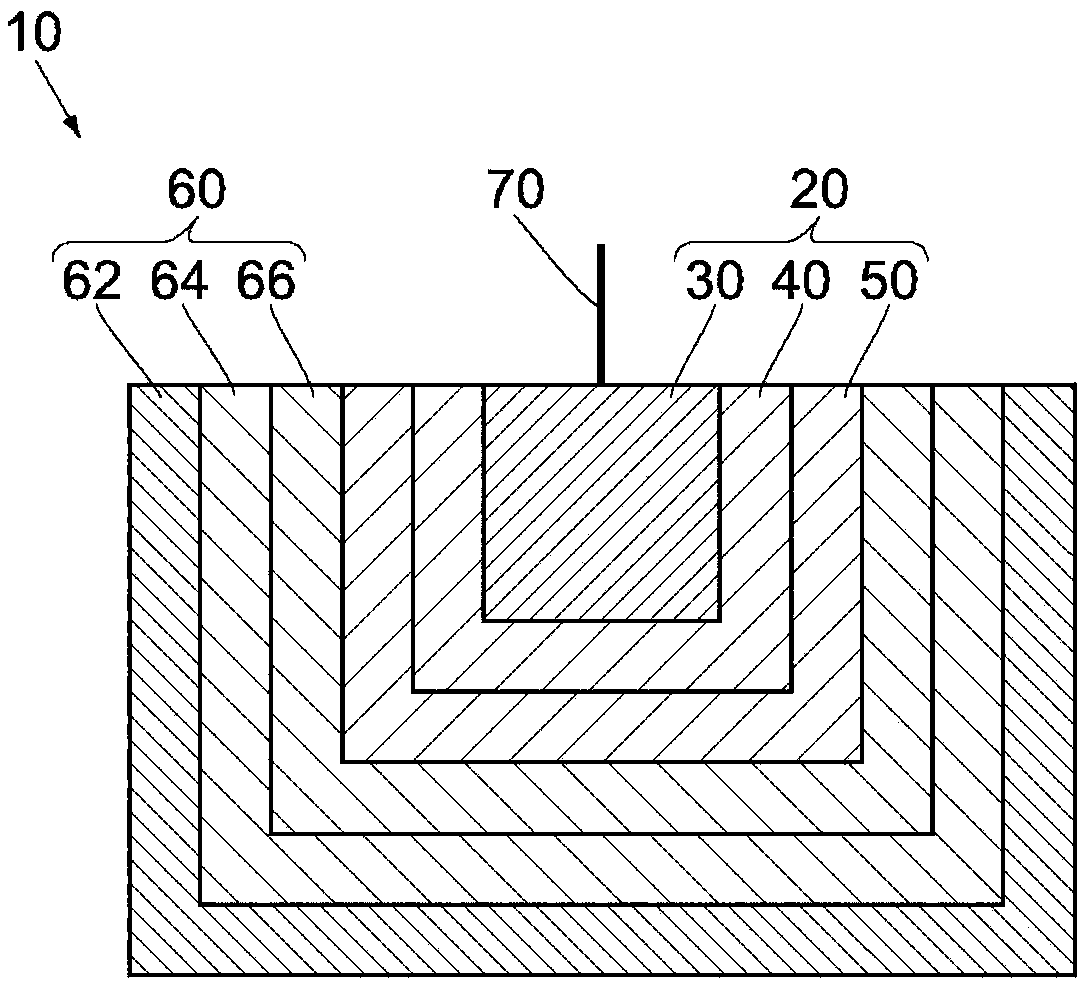

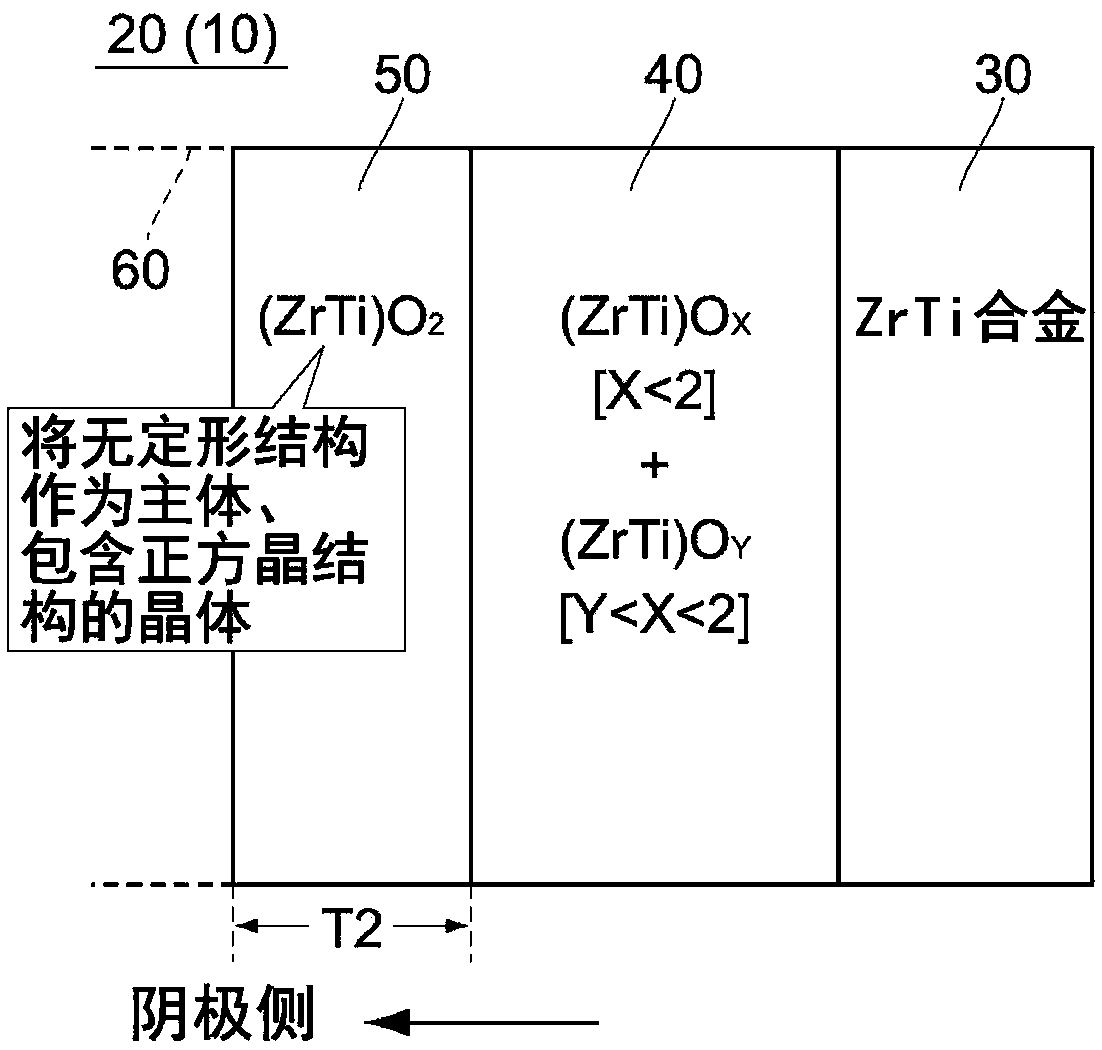

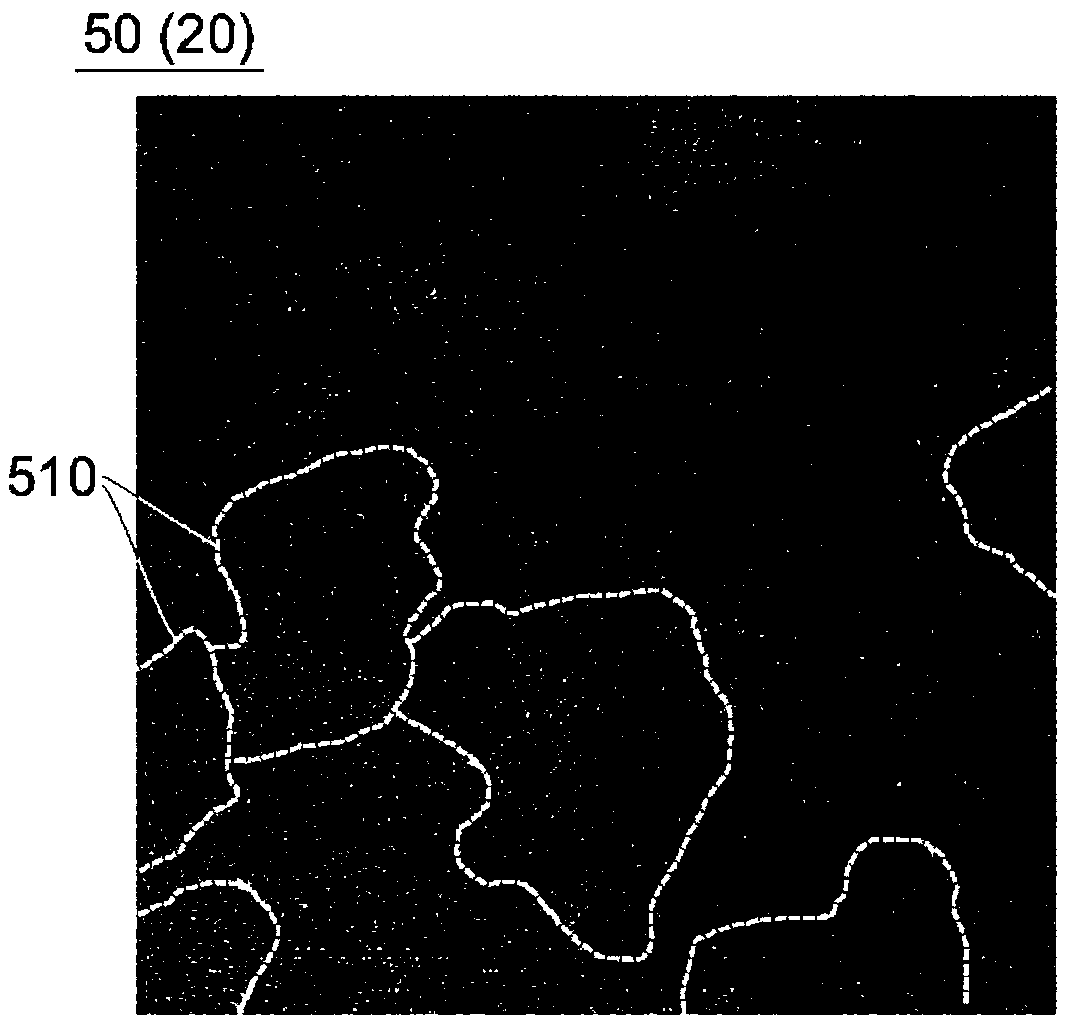

Capacitor and method for manufacturing capacitor

InactiveCN109155200APrevent proliferationInhibit deteriorationSolid electrolytic capacitorsElectrolytic inorganic material coatingOptoelectronicsSphere packing

This capacitor is provided with: a positive electrode; an oxide layer; a dielectric layer; and a negative electrode. The oxide layer is positioned between the positive electrode and the dielectric layer. The positive electrode comprises a Zr alloy (ZrM, where M is a metallic element that can form an oxide film in an electrolytic solution). The oxide layer includes a ZrM composite oxide ((ZrM)OY, wherein Y<2) that has a hexagonal closest packing structure. The dielectric layer includes a ZrM composite oxide ((ZrM)O2).

Owner:TOKIN CORP +1

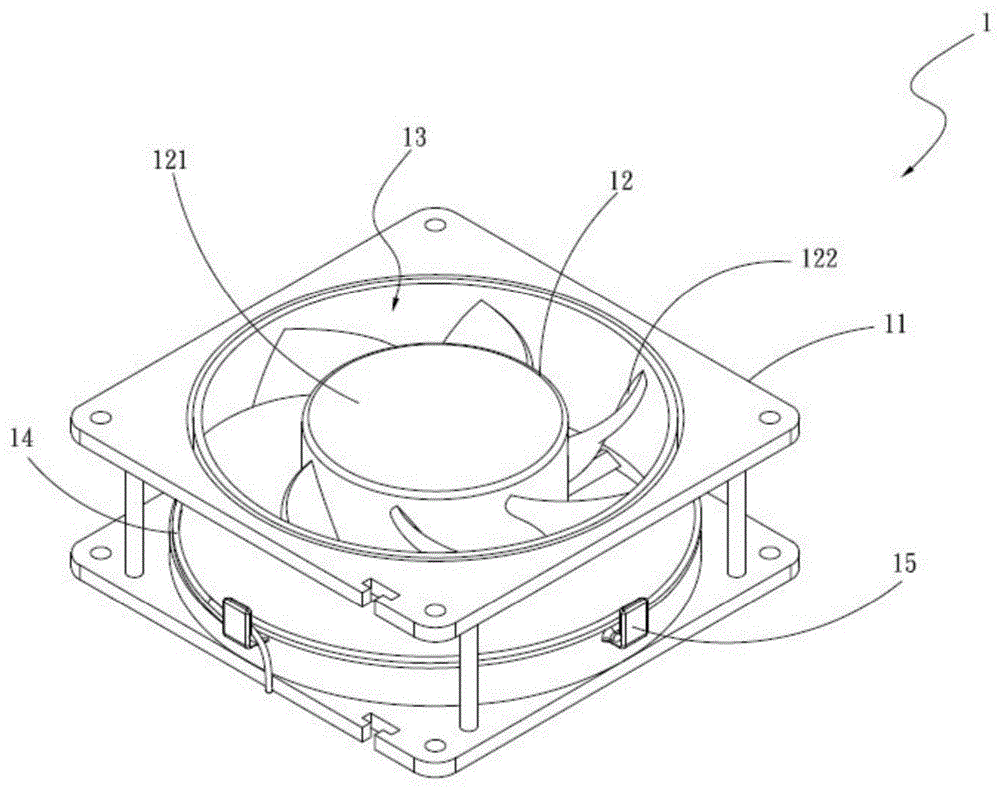

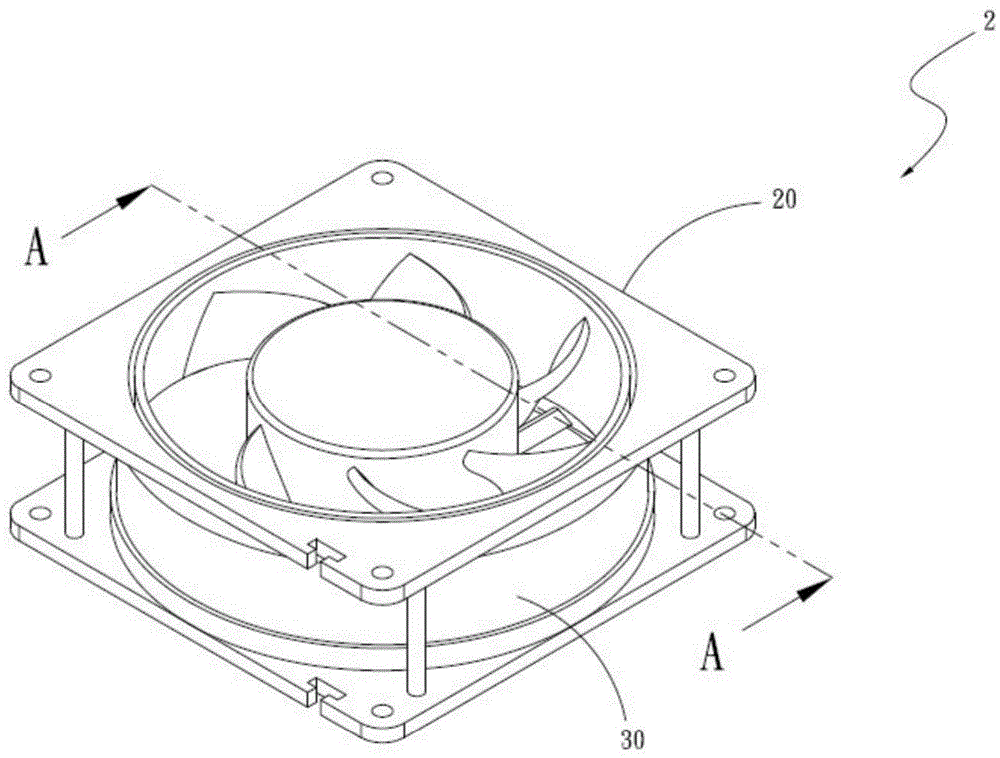

Annular fan line neatening structure

The invention relates to an annular fan line neatening structure which comprises a frame body and at least one groove, wherein the groove is annularly disposed on the peripheral side of the frame body and equipped with an opened end and a sealed end opposite to the opened end, and the opened end is horizontally tangent to the peripheral side of the frame body. By the structural design provided by the invention, effective conductor group stabilization and convenient storage and line neatening are realized. When the structure is applied in an annular fan module, closest packing and cost reduction can be realized more effectively.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

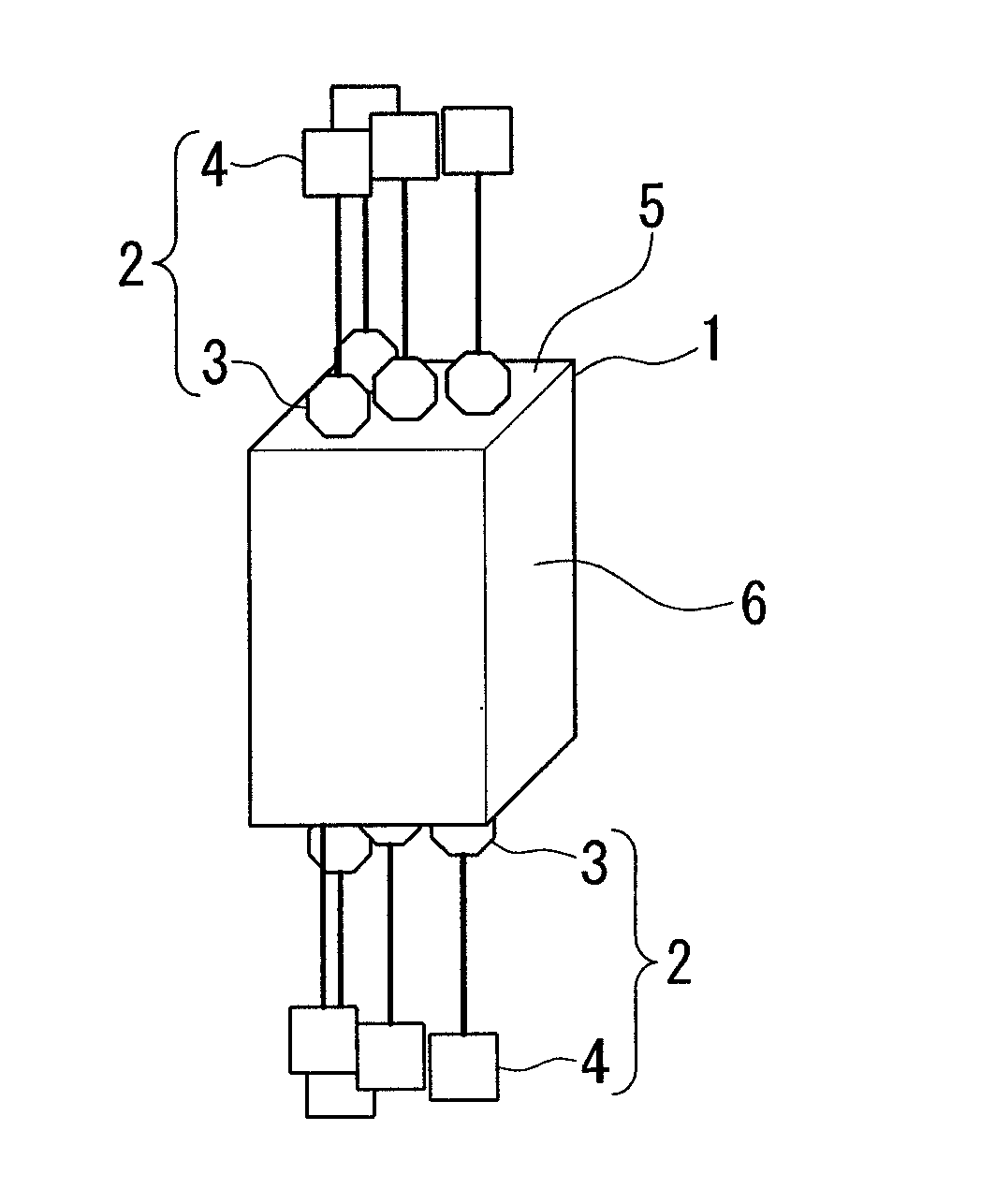

Nanostructure and manufacturing method for same

InactiveUS20080075889A1Low costPolycrystalline material growthFrom normal temperature solutionsEngineeringNanostructure

The invention relates to nanostructure and its manufacturing method. In the manufacturing method of a nanostructure, first anisotropic crystalline particles, connectors having end to be connected to a specific crystal face of each of said crystalline particles, and second particles to be connected to the other end of each of said connectors are prepared. First ends of the connectors are connected to specific crystal faces of the first crystalline particles, and simultaneously or before or after the connection, the second ends of the connectors are connected to the second particles. A nanostructure formed by this method has a three-dimensional structure which does not have a closest packing structure.

Owner:THE FUJIKURA CABLE WORKS LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com