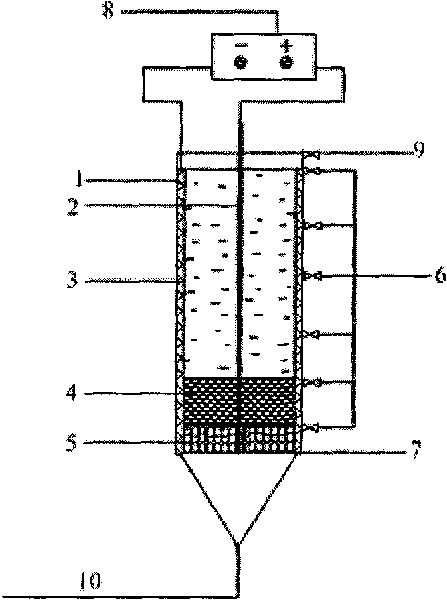

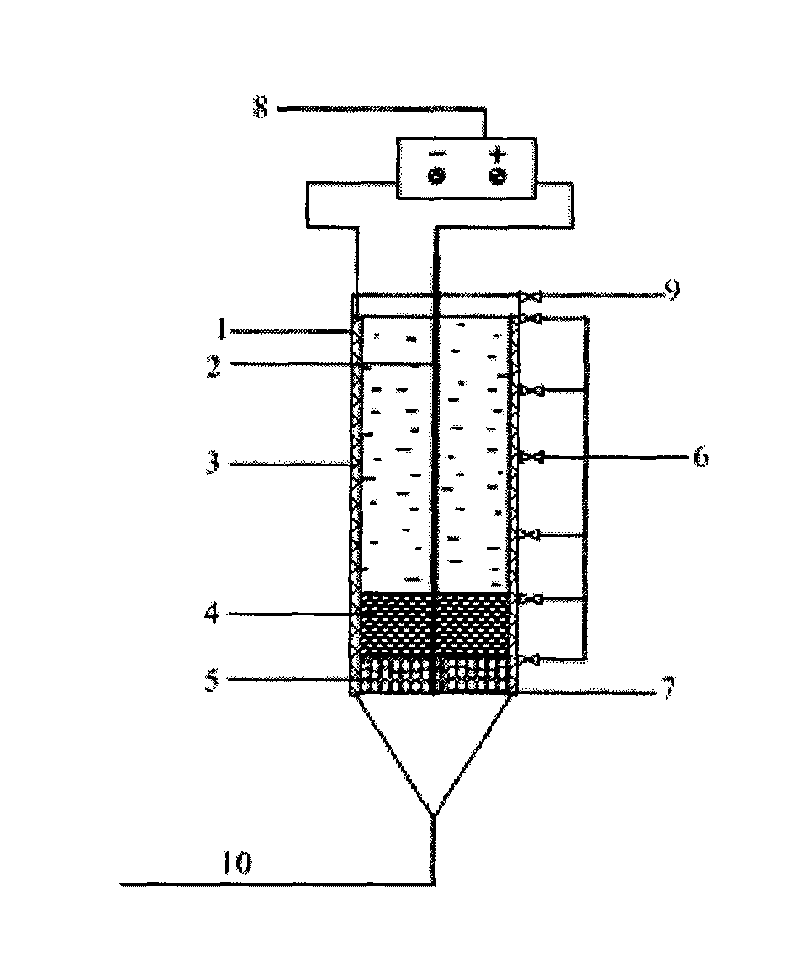

Solidoid heterotrophy and electrochemical autotrophy integrated denitrification reactor for removing nitrate out of water

A reactor and nitrate technology, applied in the field of groundwater and surface water treatment, can solve the problems of secondary pollution, high management requirements, not suitable for small-scale or decentralized water supply treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

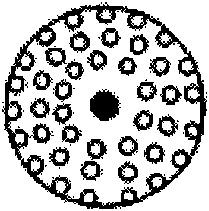

Image

Examples

Embodiment 1

[0025] Example 1: When the pH is 7.5, the temperature is 30°C, the current is 40mA, ORP3 - Under the condition of ion concentration of 70mg / L, microorganisms enriched in the foamed nickel cathode can convert NO 3 - quickly reduced to N 2 , to achieve NO 3 - removal of ions. The removal efficiency is above 98%.

Embodiment 2

[0026] Example 2: When pH is 7.5, temperature is 30°C, current is 40mA, ORP3 -Under the condition of ion concentration of 100mg / L, microorganisms enriched in the foamed nickel cathode can convert NO 3 - quickly reduced to N 2 , to achieve NO 3 - removal of ions. The removal efficiency is above 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com