Nitration reaction tail gas converting and recycling device and process

A nitrification reaction and recovery device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as incomplete absorption, tail gas emission not meeting environmental protection requirements, etc., and achieve huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

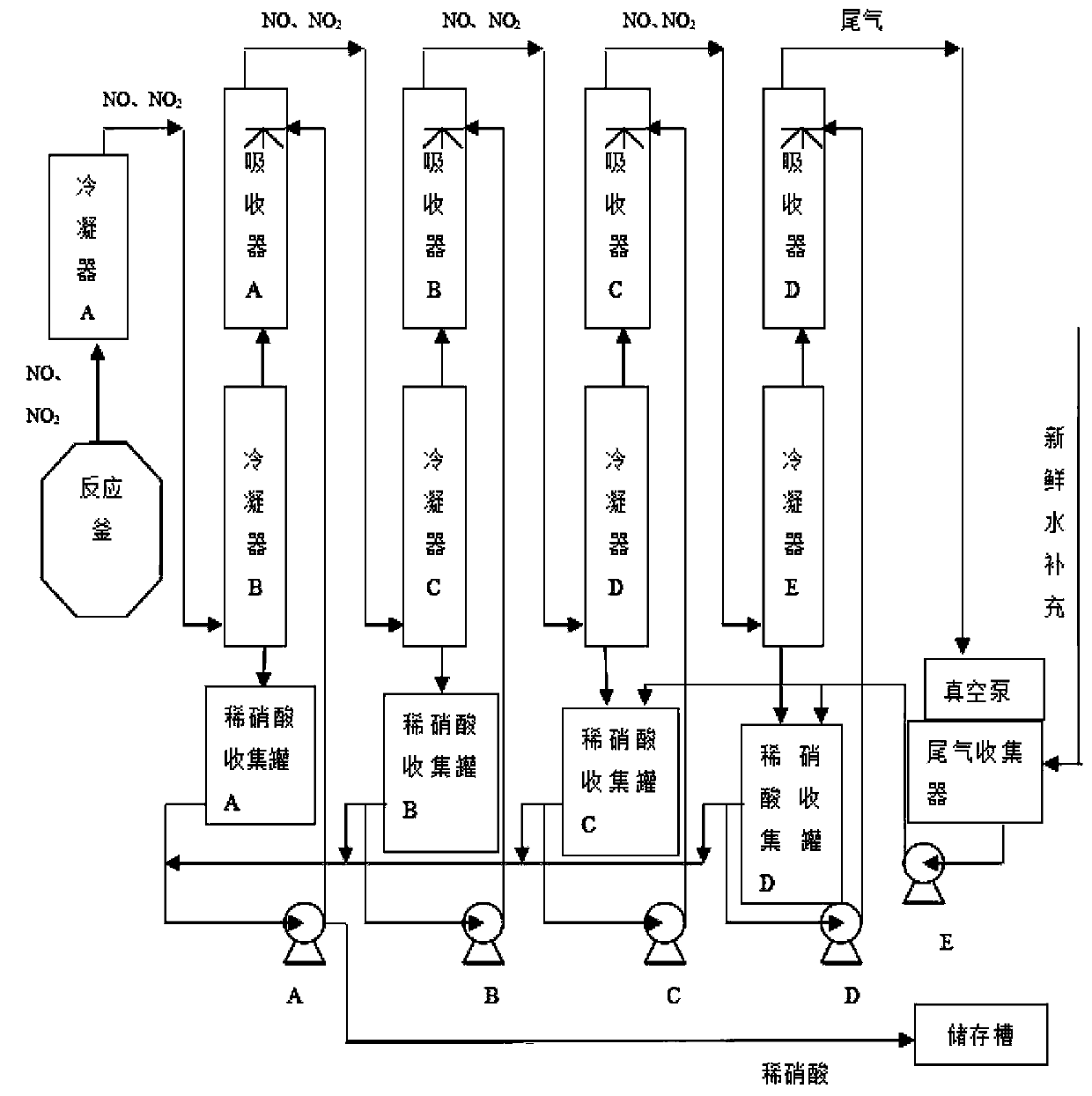

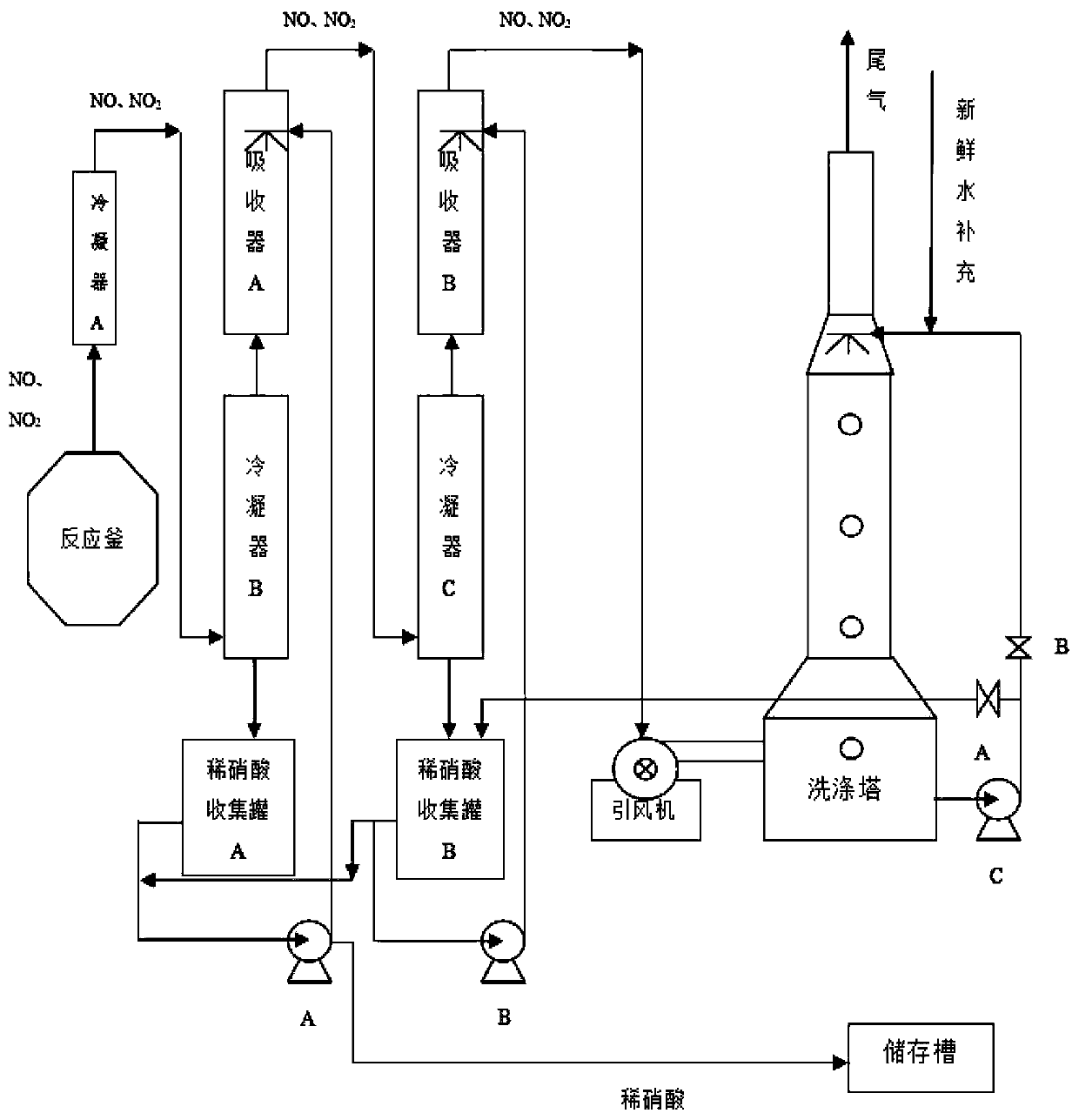

[0027] Such as figure 1 Shown, a kind of nitrification tail gas conversion recovery process is characterized in that, the process steps are as follows:

[0028] S1: Use vacuum system to decompose NO, NO 2 、H 2 O and O 2 Draw out from the 2-methyl-5-nitroimidazole reaction kettle and enter the condenser; at 30°C, some NO 2 and evaporatively condensed H 2 O reaction is converted into dilute nitric acid, which is recycled to the dilute nitric acid collection tank, part of NO and O 2 NO 2 and unconverted NO, NO 2 Continue to enter the absorber, the absorber is equipped with corrosion-resistant packing, and the space of the packing has O 2 Fully contact with NO to generate NO 2 ; Then the nitric acid in the dilute nitric acid collection tank is pumped into the absorber with a circulation pump, and the NO in the absorber is removed by circulation. 2 into nitric acid;

[0029]S2: A small part of the tail gas that has not been completely converted is put into the tail gas co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com