Packing guide tool and sheet packing method

A technology for packaging and guiding tools, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, and can solve problems such as long time and manpower, difficult packaging, and distortion of the glass substrate 20

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

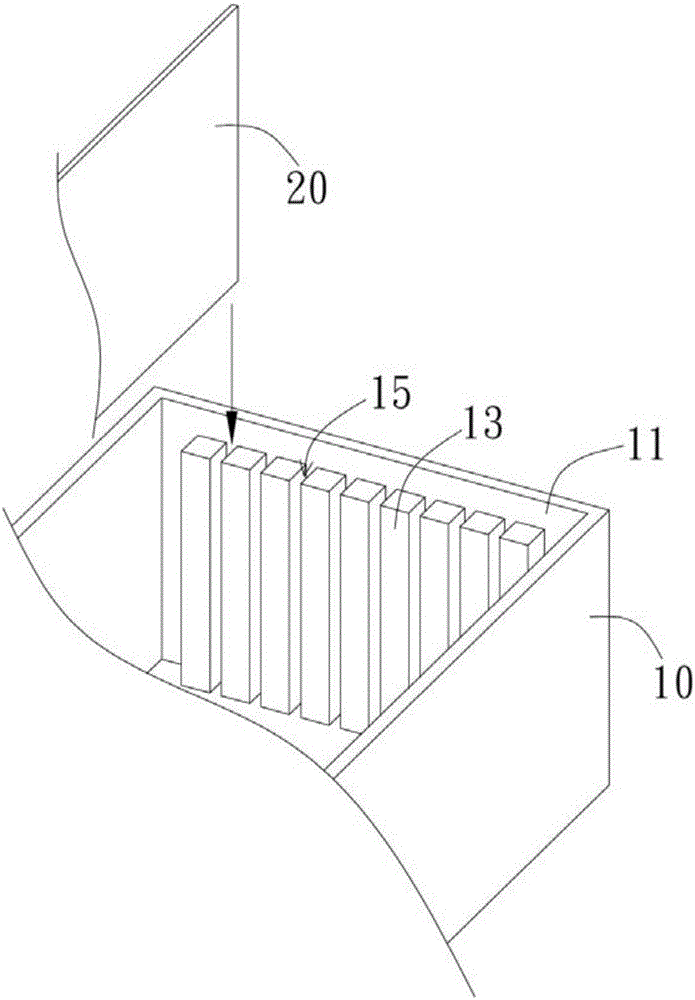

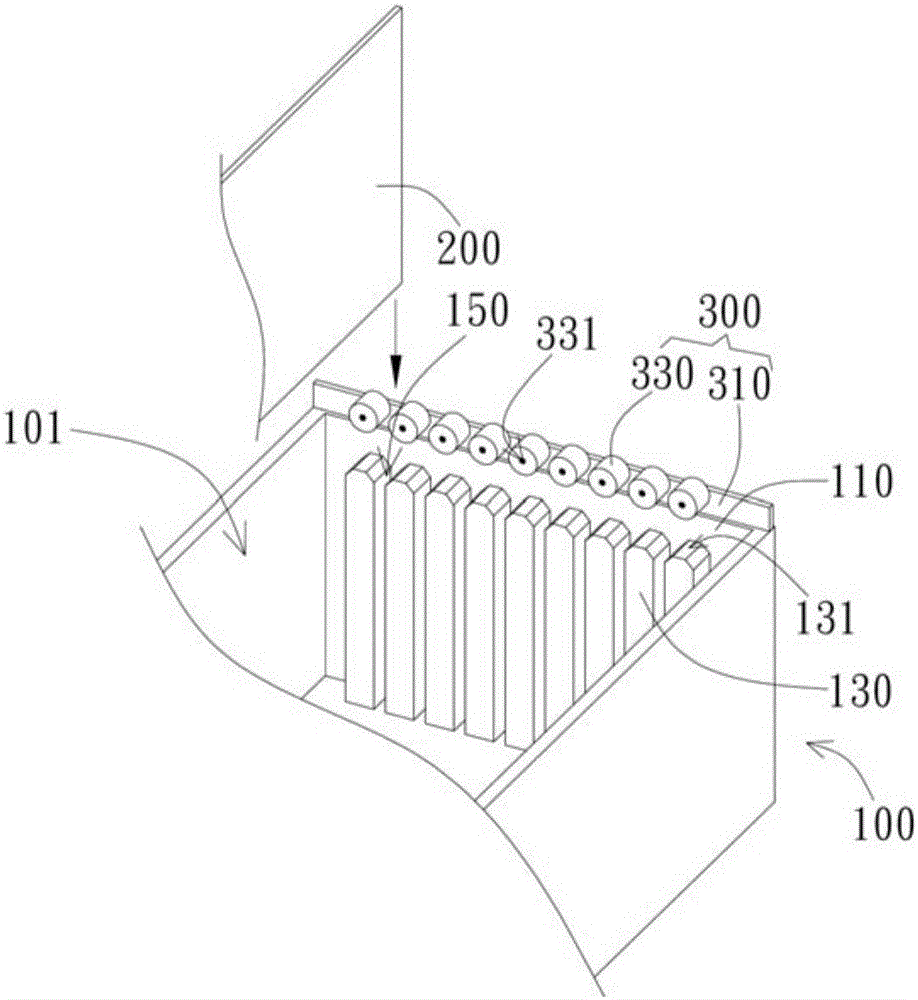

[0064] The invention provides a guide for use when introducing sheets into packing boxes. In this embodiment, the sheet may include various sheet or plate elements such as a display panel, a glass substrate, and an optical film. In addition, the present invention also provides a packaging method using the above guide.

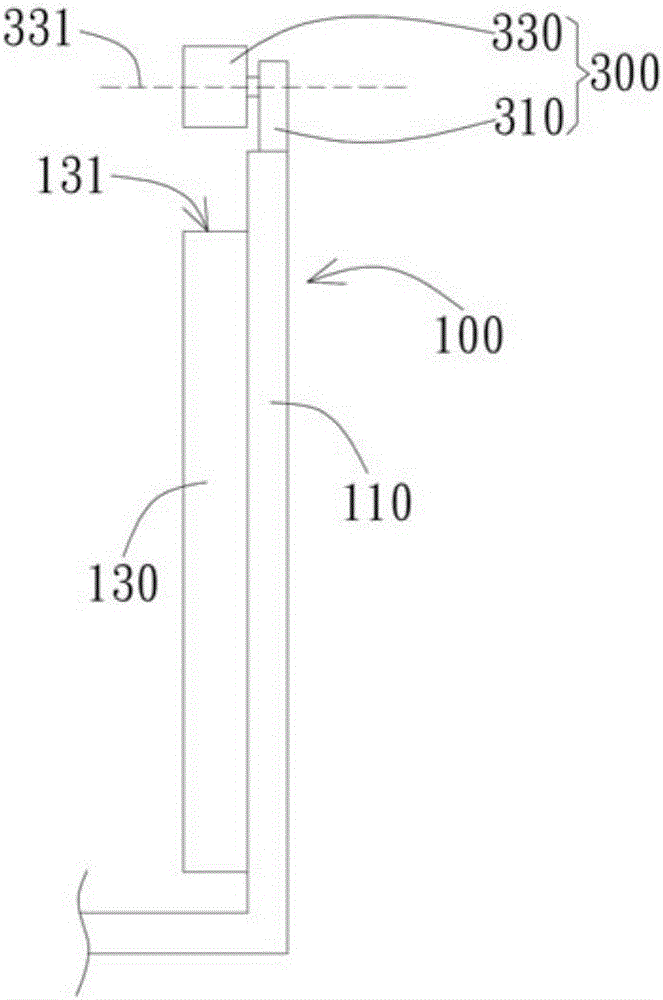

[0065] Such as figure 2 As shown, the packaging box 100 matched with the guide includes a plurality of side walls 110 to enclose the accommodating space 101 inside the packaging box 100 . The opposite side walls 110 are respectively provided with a plurality of longitudinal spacer bars 130 , and the spacer bars 130 extend from the opening of the accommodating space 101 to the bottom. A groove 150 is sandwiched between adjacent spacer bars 130 for guiding the side edge of the sheet 200 to enter when the sheet 200 is inserted into the accommodating space 101, and to align the sheet 200 after the sheet 200 is inserted into the position. The side edges of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com