Device for coating a plurality of closest-packed substrates arranged on a susceptor

A technology for substrates and bases, applied in coatings, gaseous chemical plating, metal material coating processes, etc., can solve problems such as gas phase loss and negative impact on the uniformity of deposited layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

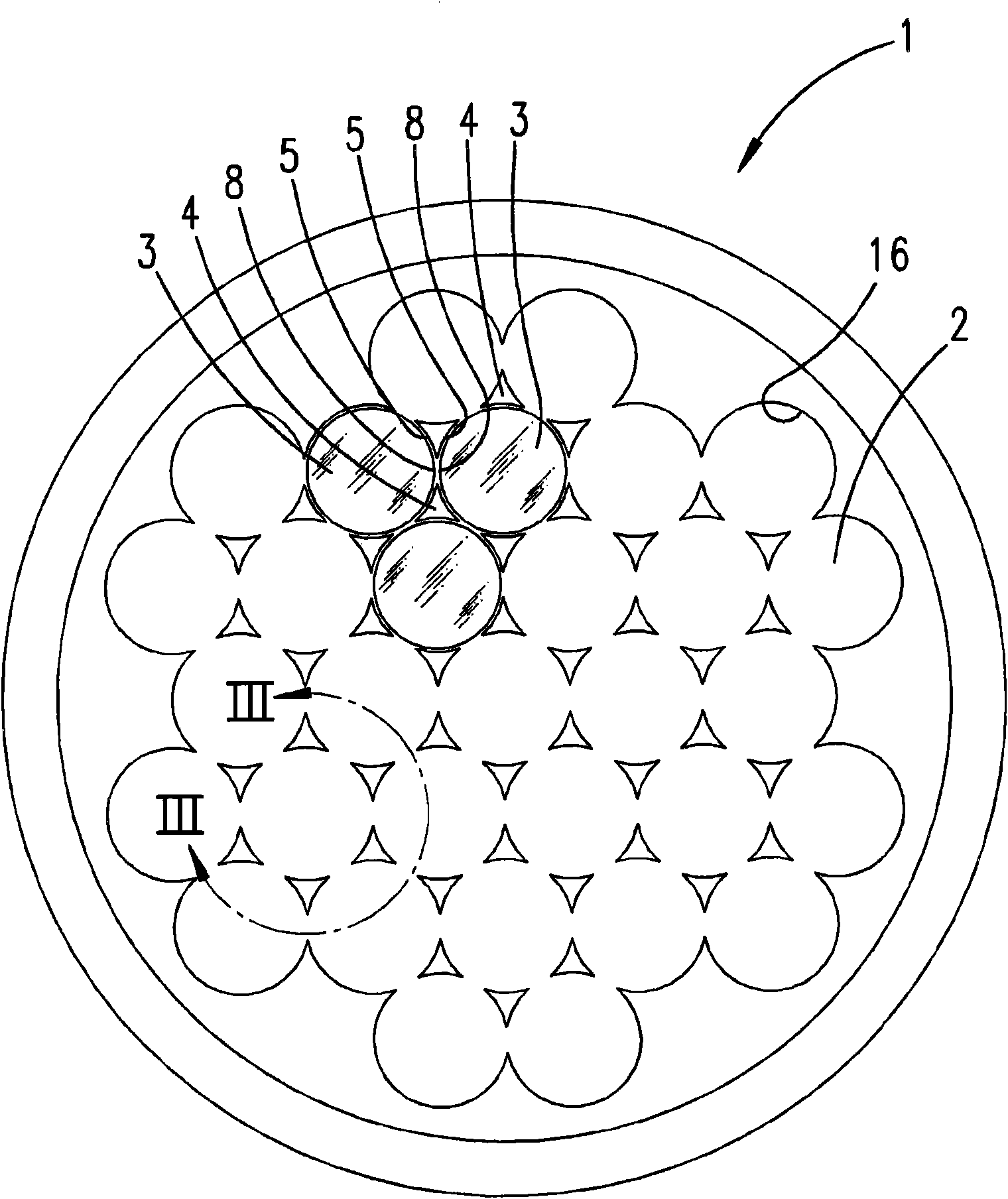

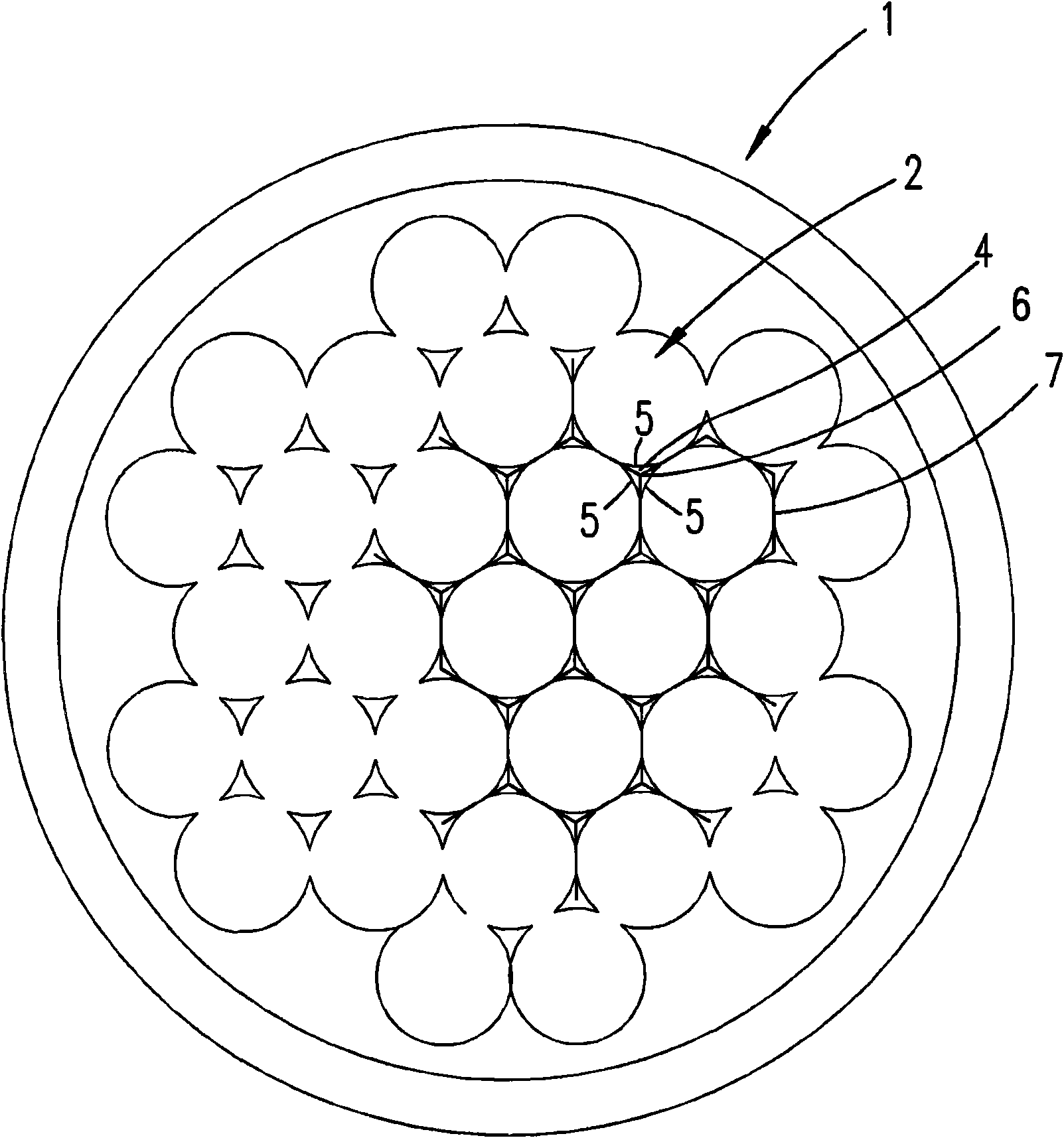

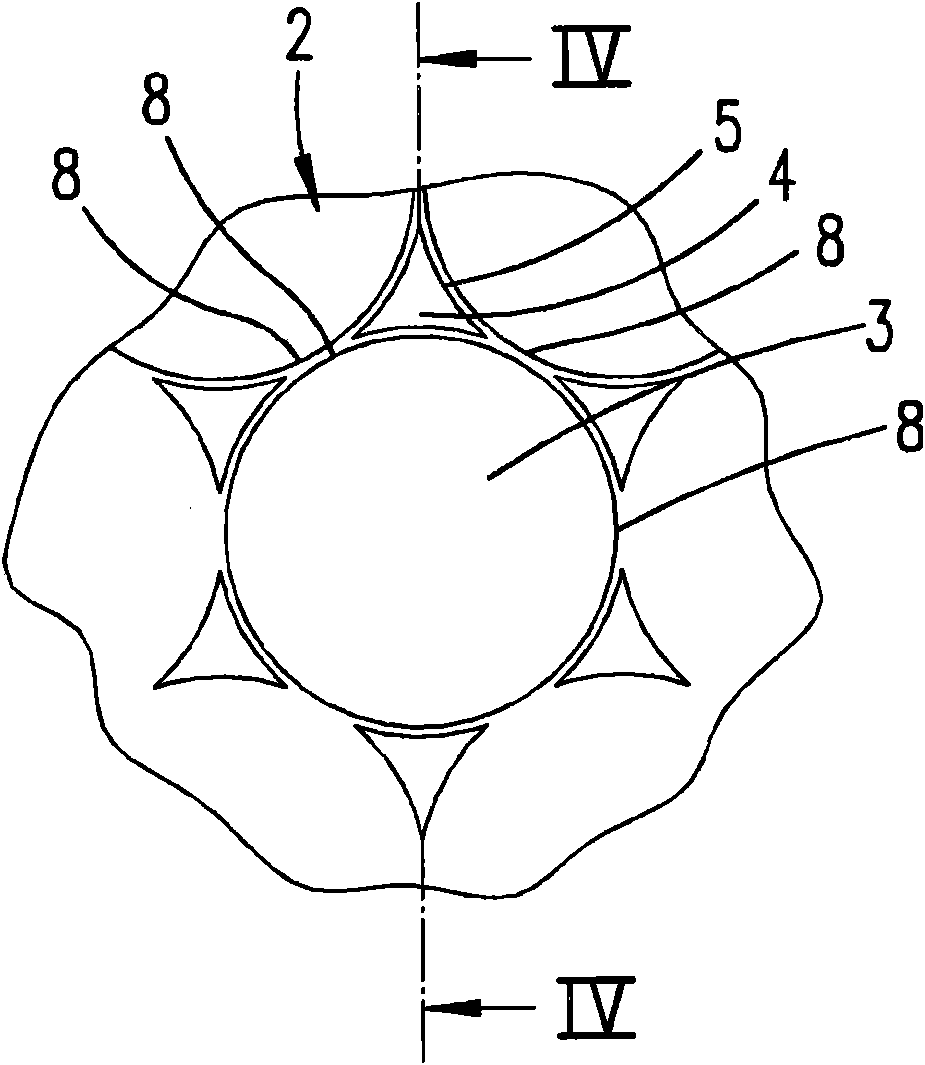

[0020] Figure 7 The interior of a reactor frame of a device for coating a plurality of substrates 3 arranged on a susceptor 1 is described. The susceptor 1 essentially consists of a graphite body with a circular upper surface lying in a horizontal plane, which upper surface forms a support surface 2 for a plurality of substrates. The base 1 has a diameter of up to 40 cm and is rotatable about an axis A of rotation.

[0021] Above the susceptor 1 there is a process chamber 14 delimited upwardly by the underside of a gas inlet member 15 . Openings may be distributed over the entire downwardly facing gas outlet face of the gas inlet member 15 in the manner of showerheads, through which openings one or more process gases enter the process chamber 14, so that the gas phase is formed spontaneously or by The heater disposed under the susceptor 1 reacts thermally active on the upper surface of the substrate. The process gas contains elements of the fourth main group or elements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com