Silica matrix chemically bonded phase packing

A silica gel matrix, chemical bonding technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of low bonding amount of surface functional groups, uneven surface reaction, inconvenient operation, etc. The effect of short reaction time, improved selectivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

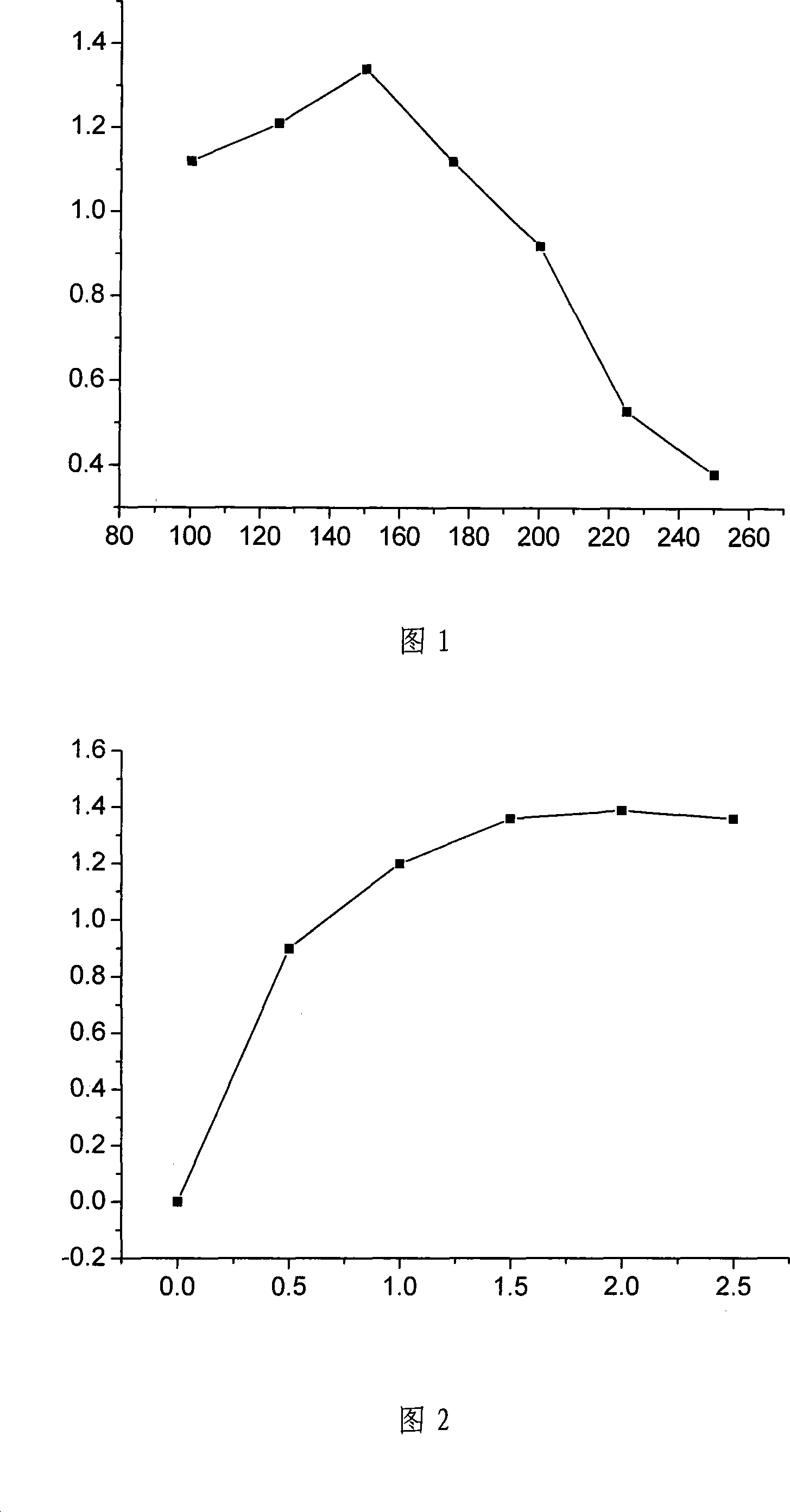

Image

Examples

Embodiment 1

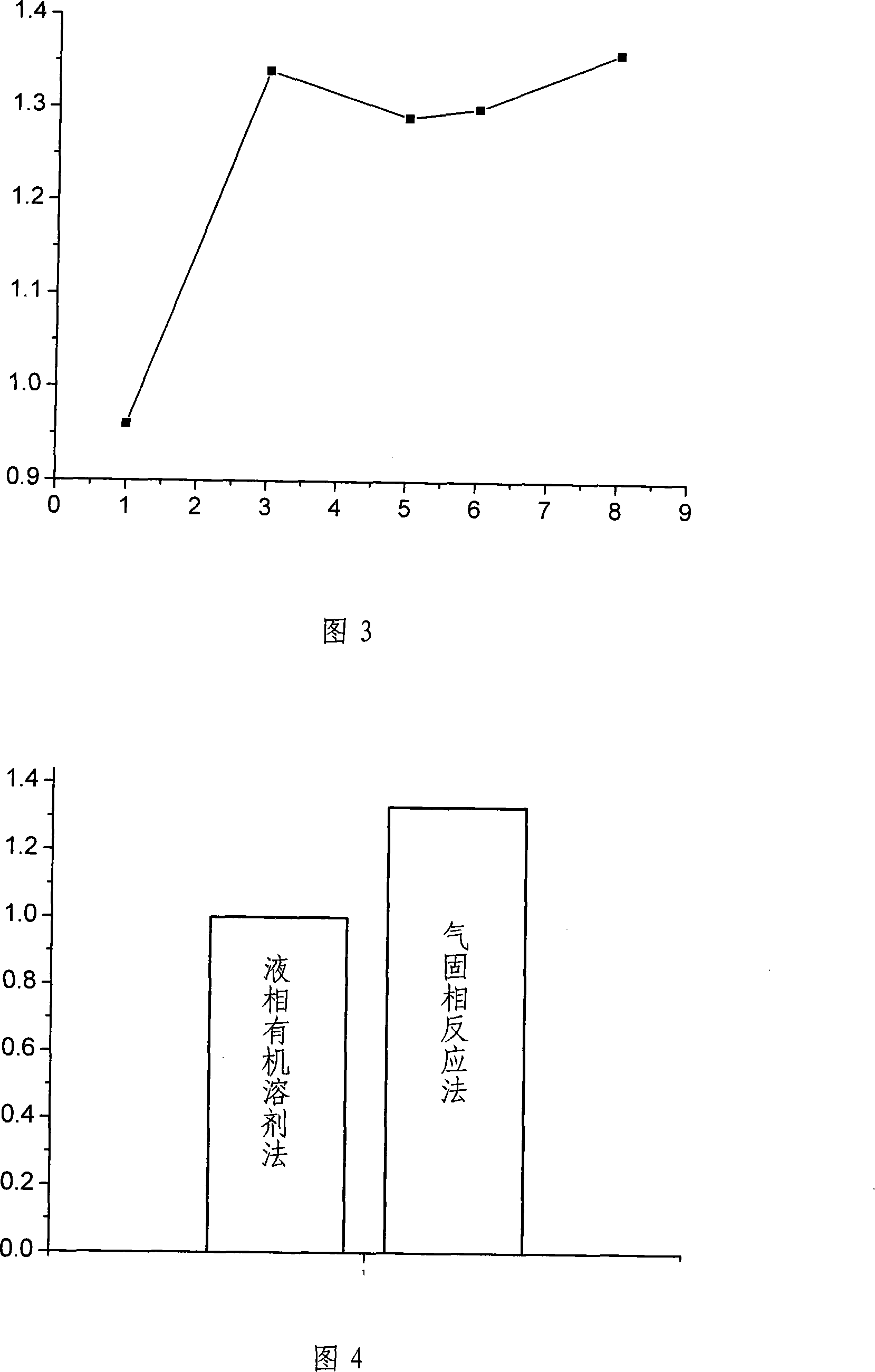

[0019] The silica-based chemically bonded phase filler was synthesized by the traditional liquid-phase organic solvent reaction method.

[0020]Weigh 20.0g of column chromatography silica gel (Qingdao Ocean Chemical Factory branch, particle size: 200-300 mesh), put it into a three-necked flask, install a condenser tube, add 200ml of 10% hydrochloric acid aqueous solution, and mechanically stir and reflux at 105°C for 12h. Wash with deionized water repeatedly until the filtrate is neutral, and dry in vacuum at 90°C for 12h.

[0021] Weigh 6.0 g of acidified pretreated silica gel, dry it in vacuum at 90°C for 12 hours, put it into a three-necked flask after cooling, and install a condenser tube and a drying tube. Add 60ml of dehydrated toluene (activated molecular sieve treatment for more than 12h), 0.6ml of triethylamine, and 3ml of γ-mercaptopropyltrimethoxysilane. Stir mechanically, blow dry nitrogen and heat to toluene reflux. 110 ℃ constant temperature reaction for 12h. ...

Embodiment 2

[0023] The silica-based chemically bonded phase packing was synthesized by gas-solid phase reaction.

[0024] Weigh 3.0g of dry and acidified pretreated column chromatography silica gel, put it into a 250ml autoclave, then add 1.5ml of γ-mercaptopropyltrimethoxysilane and 0.3ml of triethylamine, stir evenly, and seal the autoclave The reactor was passed with a dry inert gas, and then the temperature of the reactor was raised to 250°C, and the reaction was carried out for 3 hours. Heating was stopped, and the reaction system was cooled to room temperature. The obtained silica-based chemically bonded phase filler was washed with methanol-water and acetone in sequence, and dried at 60° C. in vacuum for 12 hours.

[0025] Take by weighing 3.0g of dry mercapto chemically bonded phase packing, put in the autoclave of 250ml, add 3.0ml hexamethyldisilazane (HMDS), stir evenly, seal the autoclave, pass into inert gas, the reaction kettle is heated up to React at 250°C for 3 hours, sto...

Embodiment 3

[0027] Determination of Surface Bonding Rate of Mercapto Silica Filler

[0028] 1. Accurately weigh about 0.1g of silica gel filler bonded with mercapto groups

[0029] 2. Precisely prepare 1mol / L H 2 SO 4 Standard solution: Accurately measure 14.21ml of concentrated H 2 SO 4 , dissolved in deionized water, 250ml volumetric flask to volume

[0030] 3. Precisely prepare 0.2mol / L KMnO 4 -1mol / L H 2 SO 4 Standard solution: Accurately weigh 8.3158g KMnO 4 , accurately measure 14.21ml concentrated H 2 SO 4 Dissolve in deionized water, 250ml volumetric flask to volume

[0031] 4. Disperse about 0.1g of silica gel filler bonded with mercapto groups accurately weighed in 20ml of 1mol / L H 2 SO 4 In the standard solution, sonicate for 1-5min, with precisely prepared 0.2mol / L KMnO 4 -1mol / L H 2 SO 4 Standard solution for titration, titration until the solution is pink is the end point, and the 0.2mol / LKMnO used for accurate determination 4 -1mol / L H 2 SO 4 Amount of sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com