Soft sensing method for load parameter of ball mill

A load parameter, ball mill technology, applied in measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve problems such as affecting the processing capacity and product quality of the ball mill, difficult to measure the internal parameters of the ball mill load, and inability to produce economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0214] Take the small ball mill system in the laboratory as an example. The cylinder size of the ball mill is Φ460mm×460mm, the inner wall is equipped with a manganese steel liner, and the middle part of the ball mill is open, so that the ball mill can be stopped at any time and the amount of minerals and steel balls in the ball mill can be changed. The maximum weight of steel balls installed in this ball mill is 80kg, and the mineral processing capacity is 10kg / h. The rotational speed of the ball mill was 53 rpm. During the experiment, three kinds of manganese steel balls of Φ30mm, Φ20mm and Φ15mm were used. The ore processed in the experiment was crushed copper ore with particle size less than 6mm.

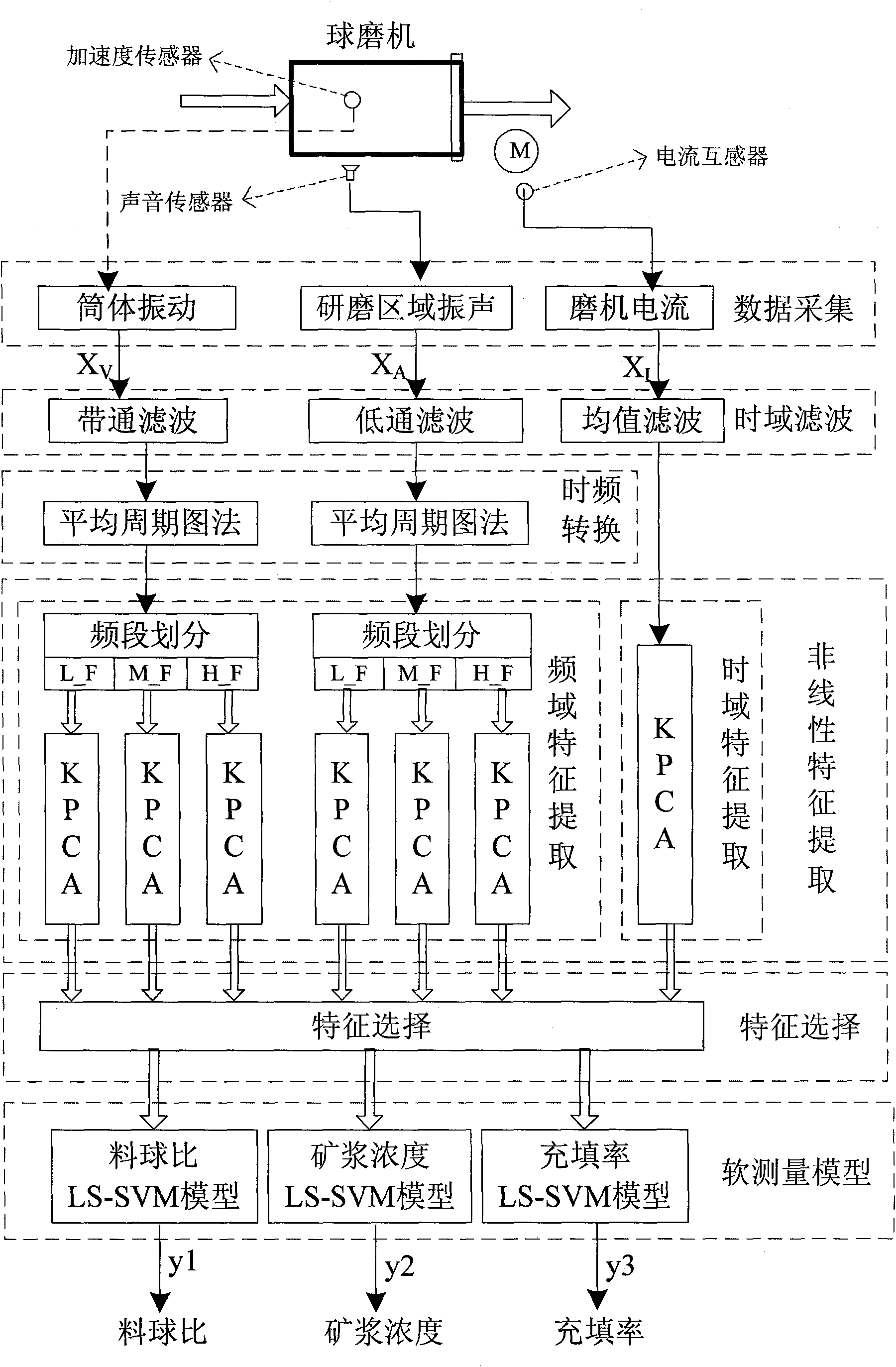

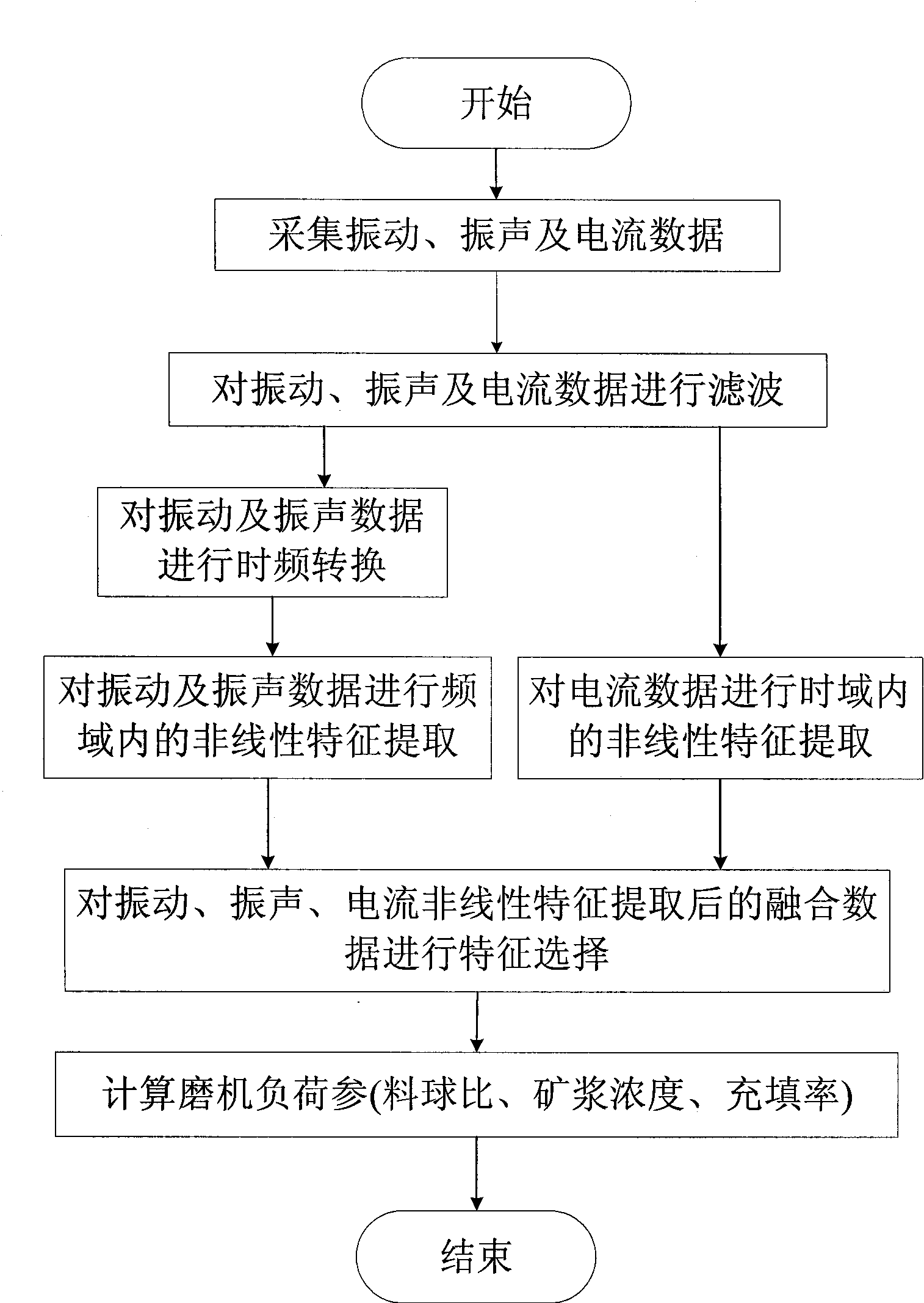

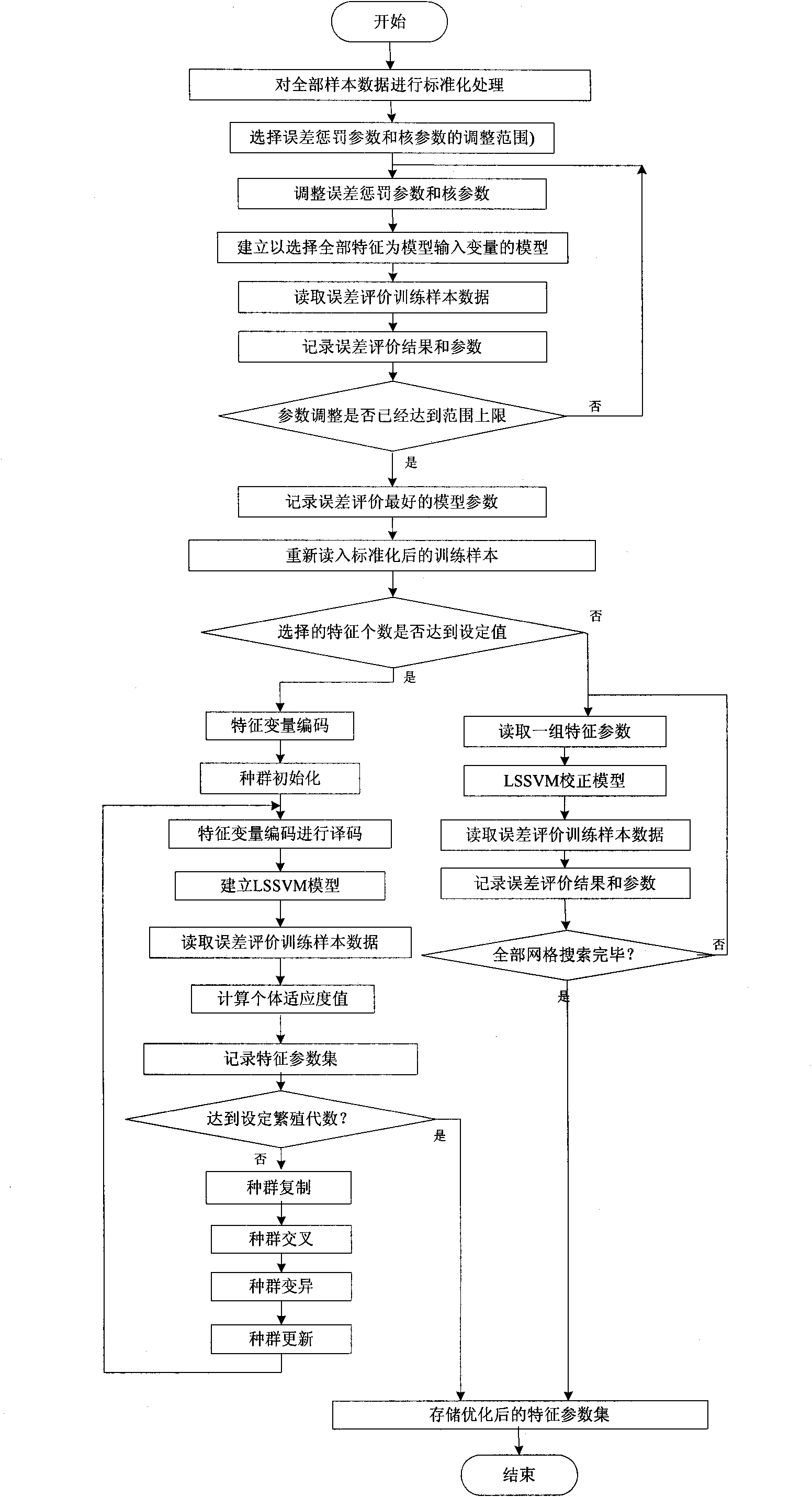

[0215] Such as figure 1 and 2 As shown, a ball mill load parameter soft measurement method is based on the KPCA-LSSVM method, including the following steps:

[0216] Step 1: Data Collection

[0217] According to the experimental design plan, add a certain quality of steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com