Thermal process soft sensor modeling method based on least squares and support vector machine ensemble

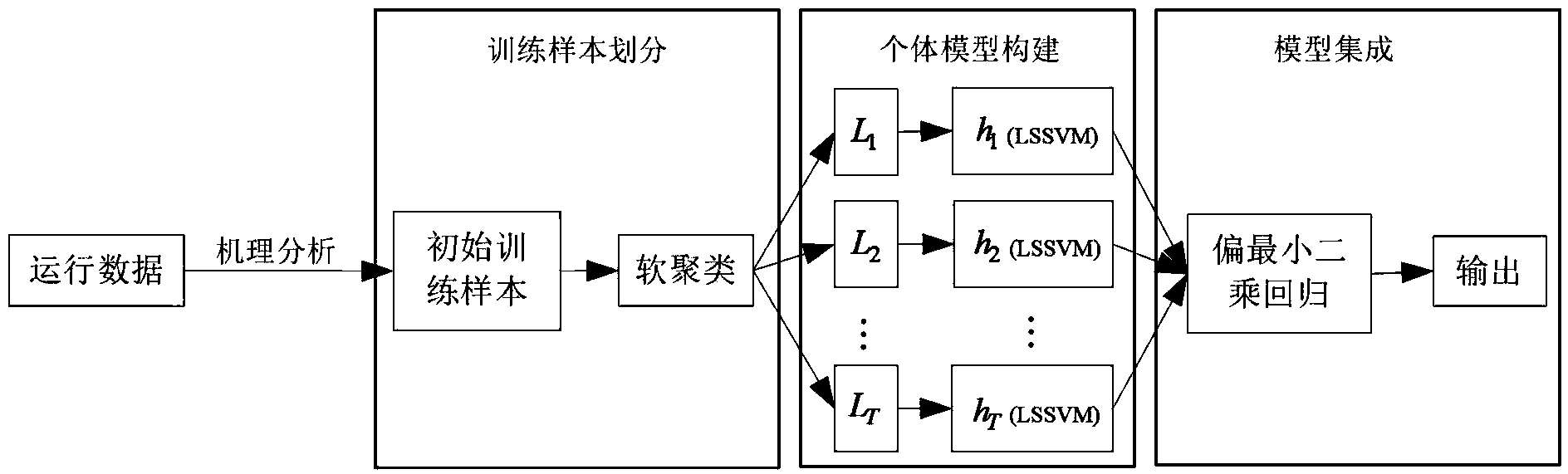

A technology of support vector machine and least squares, which is applied in the intersection of thermal technology and artificial intelligence, and can solve the problems of low prediction accuracy and time-consuming calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

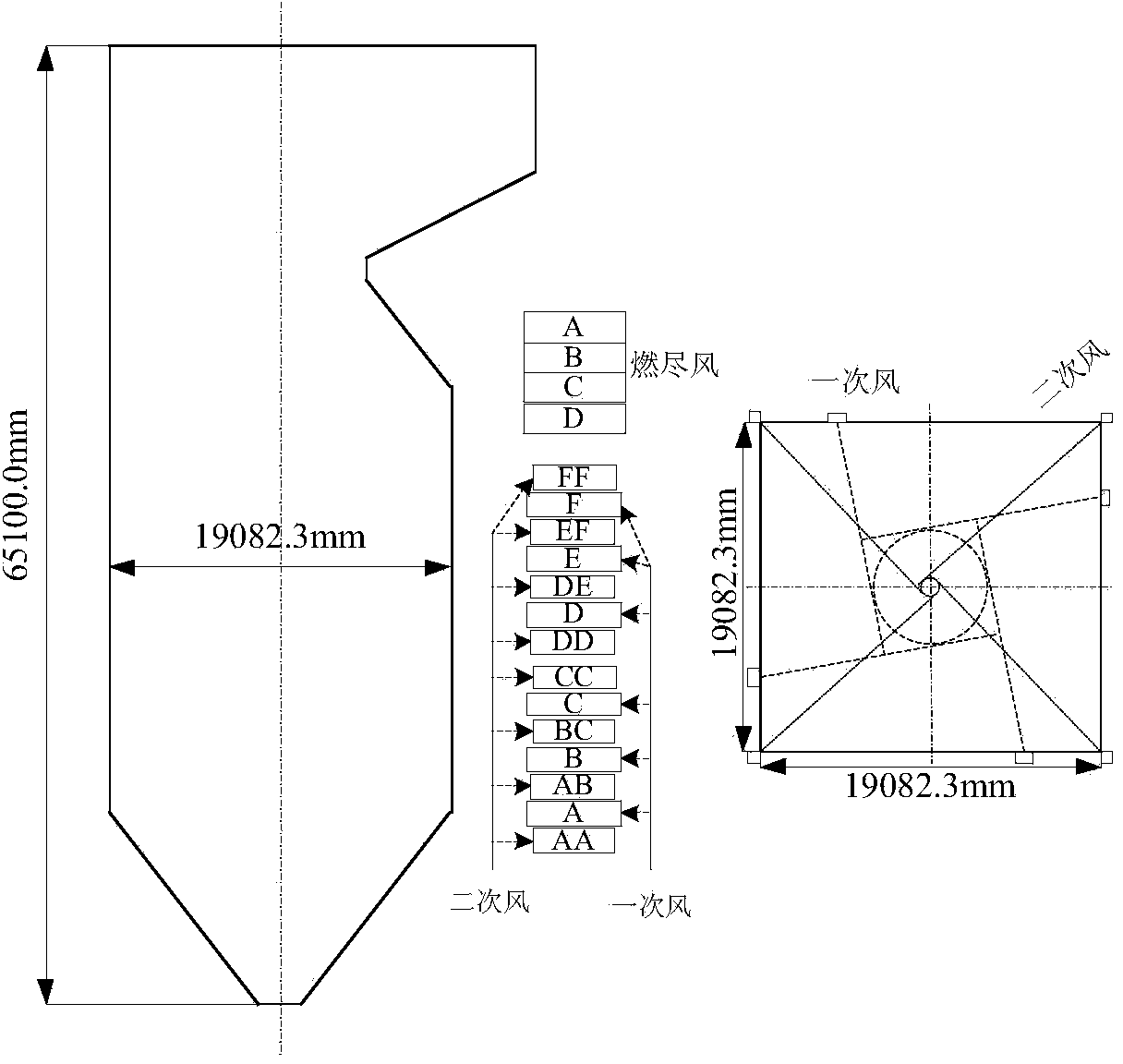

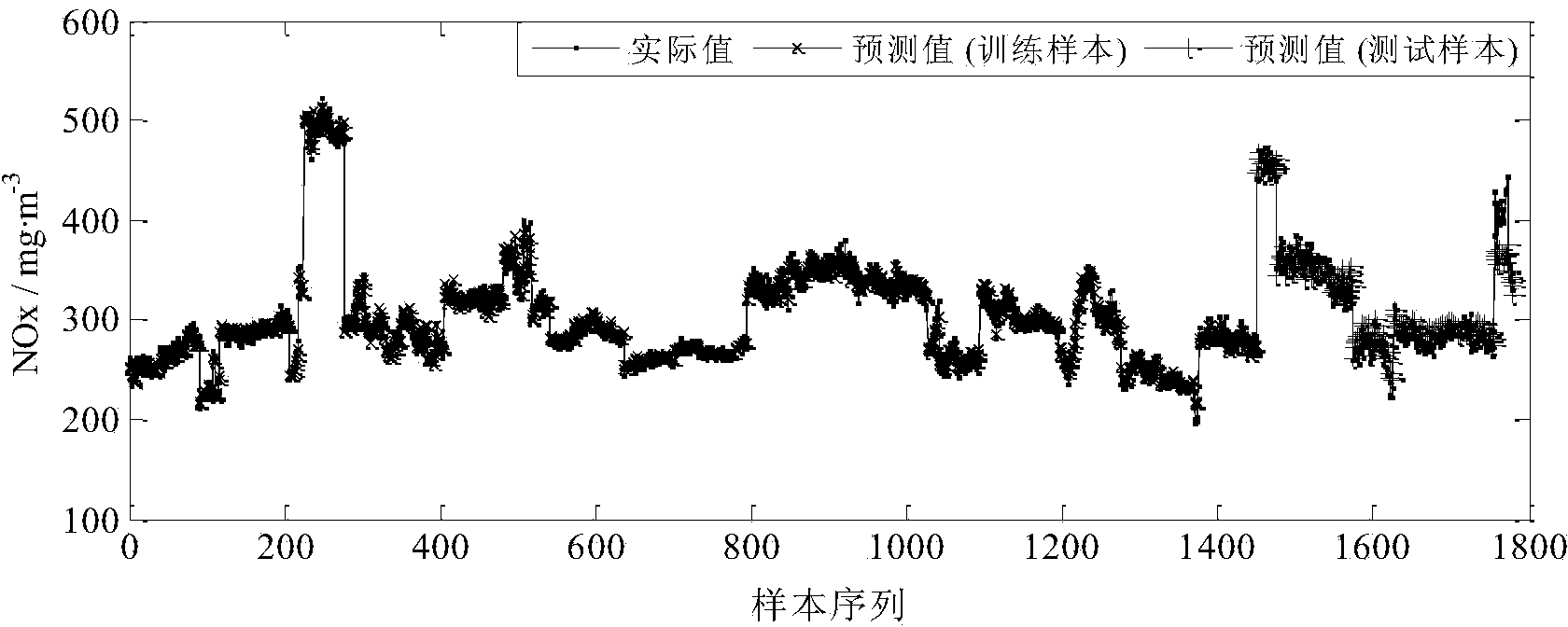

[0046] In this embodiment, soft sensor modeling is performed on NOx emission in a 660MW utility boiler. figure 1 It is a schematic diagram of the structure of a coal-fired boiler. like figure 1 As shown, the boiler is a single furnace Π-type boiler, and adopts a new type of tangential combustion method to form a large-diameter single tangential circle to obtain a relatively uniform aerodynamic field along the horizontal section of the furnace. The main burners are arranged in upper and lower groups, and they are separated by a certain distance to reduce the heat load of the burner area and effectively reduce the coking of the furnace. Four layers of separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com