Patents

Literature

272 results about "Polystyrene spheres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Characterization of highly scattering media by measurement of diffusely backscattered polarized light

InactiveUS6011626APolarisation-affecting propertiesScattering properties measurementsBiological cellOptical property

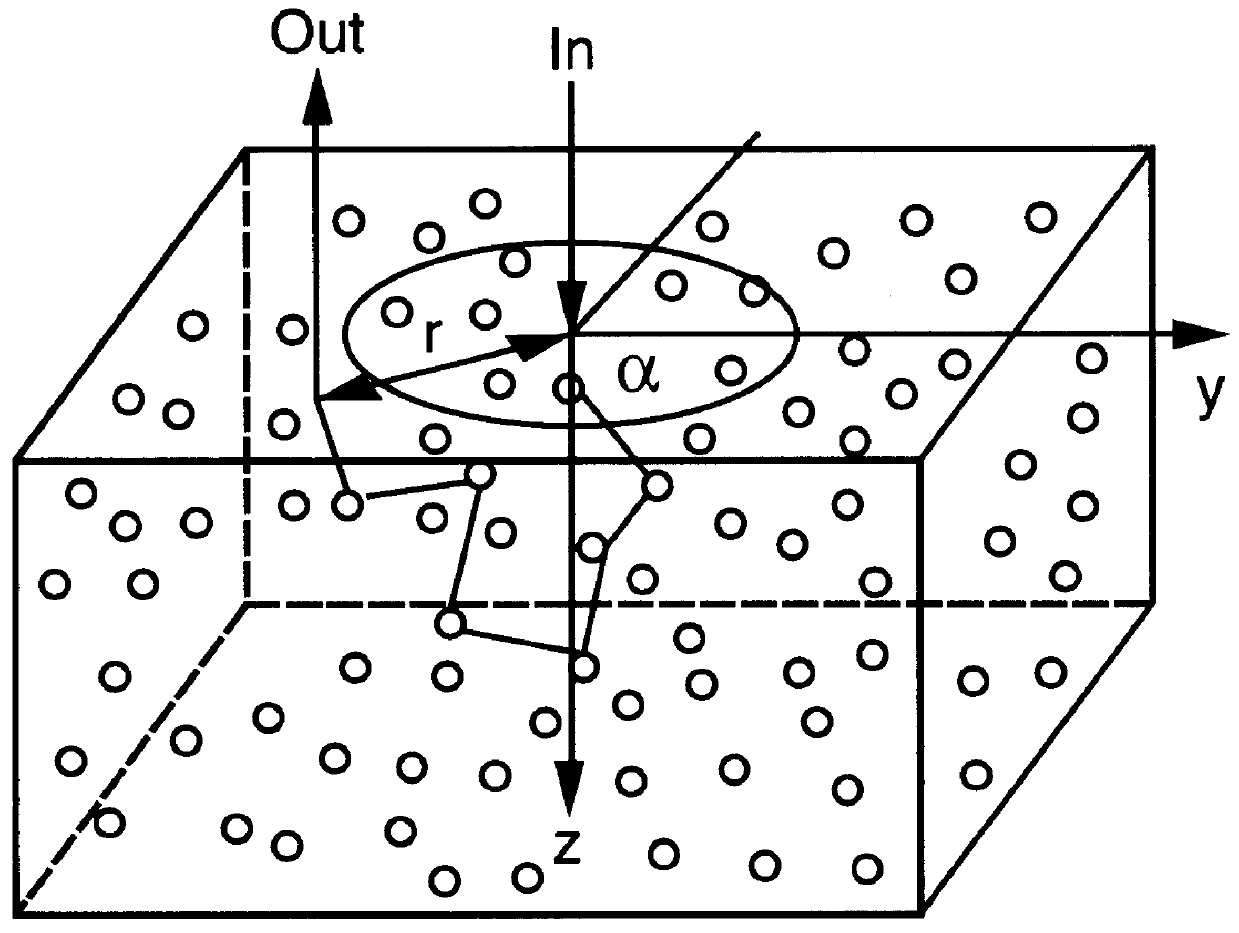

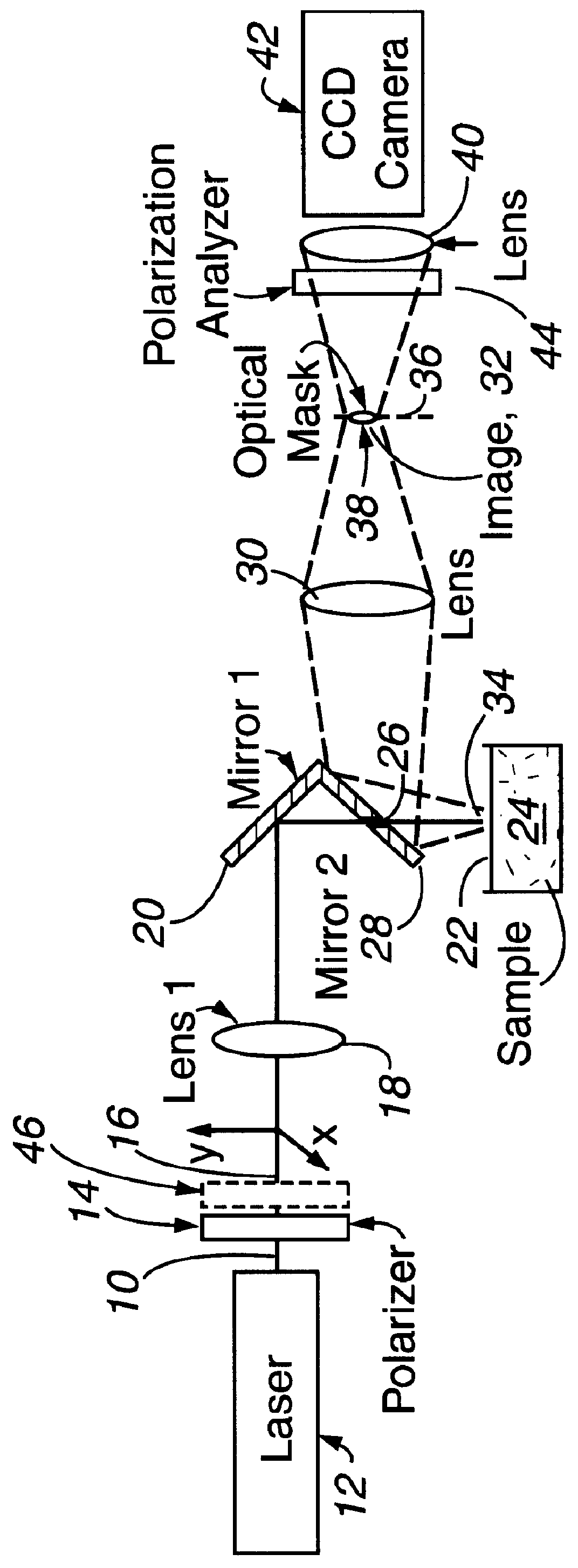

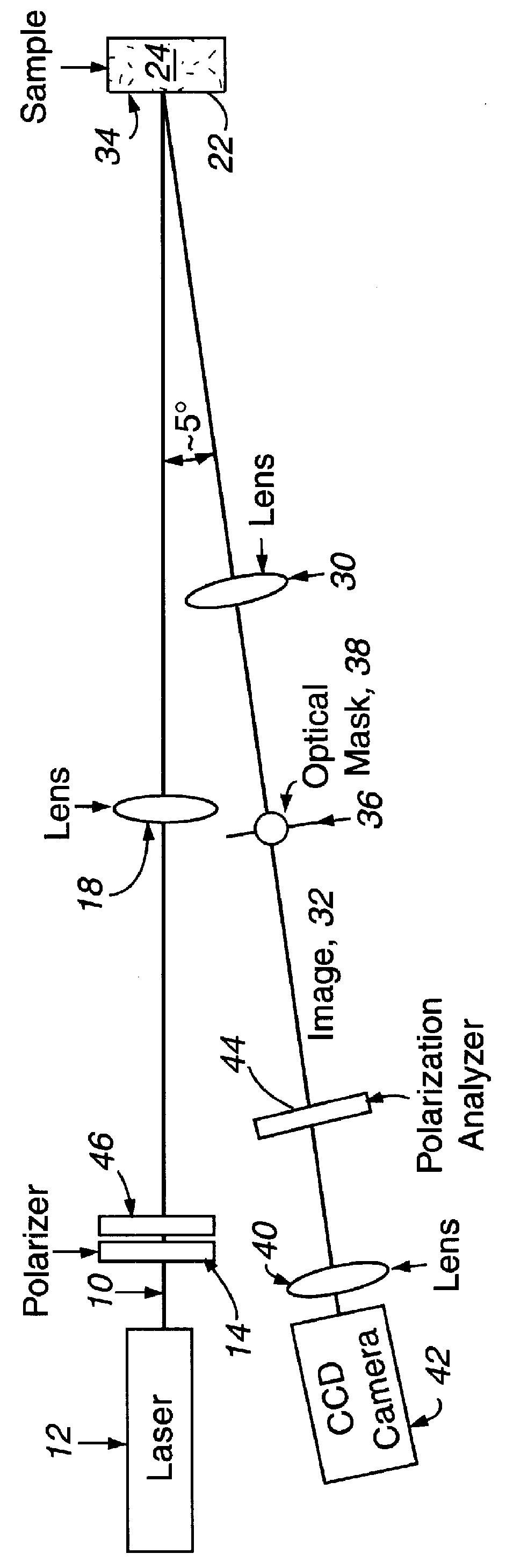

An apparatus and method for recording spatially dependent intensity patterns of polarized light that is diffusely backscattered from highly scattering media are described. These intensity patterns can be used to differentiate different turbid media, such as polystyrene-sphere and biological-cell suspensions. Polarized light from a He-Ne laser ( lambda =543 nm) is focused onto the surface of the scattering medium, and a surface area of approximately 4x4 cm centered on the light input point is imaged through polarization analysis optics onto a CCD camera. A variety of intensity patterns may be observed by varying the polarization state of the incident laser light and changing the analyzer configuration to detect different polarization components of the backscattered light. Experimental results for polystyrene-sphere and Intralipid suspensions demonstrate that the radial and azimuthal variations of the observed pattern depend on the concentration, size, and anisotropy factor, g, of the particles constituting the scattering medium. Measurements performed on biological cell suspensions show that intensity patterns can be used to differentiate between suspensions of cancerous and non-cancerous cells. Introduction of the Mueller-matrix for diffusely backscattered light, permits the selection of a subset of measurements which comprehensively describes the optical properties of backscattering media.

Owner:LOS ALAMOS NATIONAL SECURITY

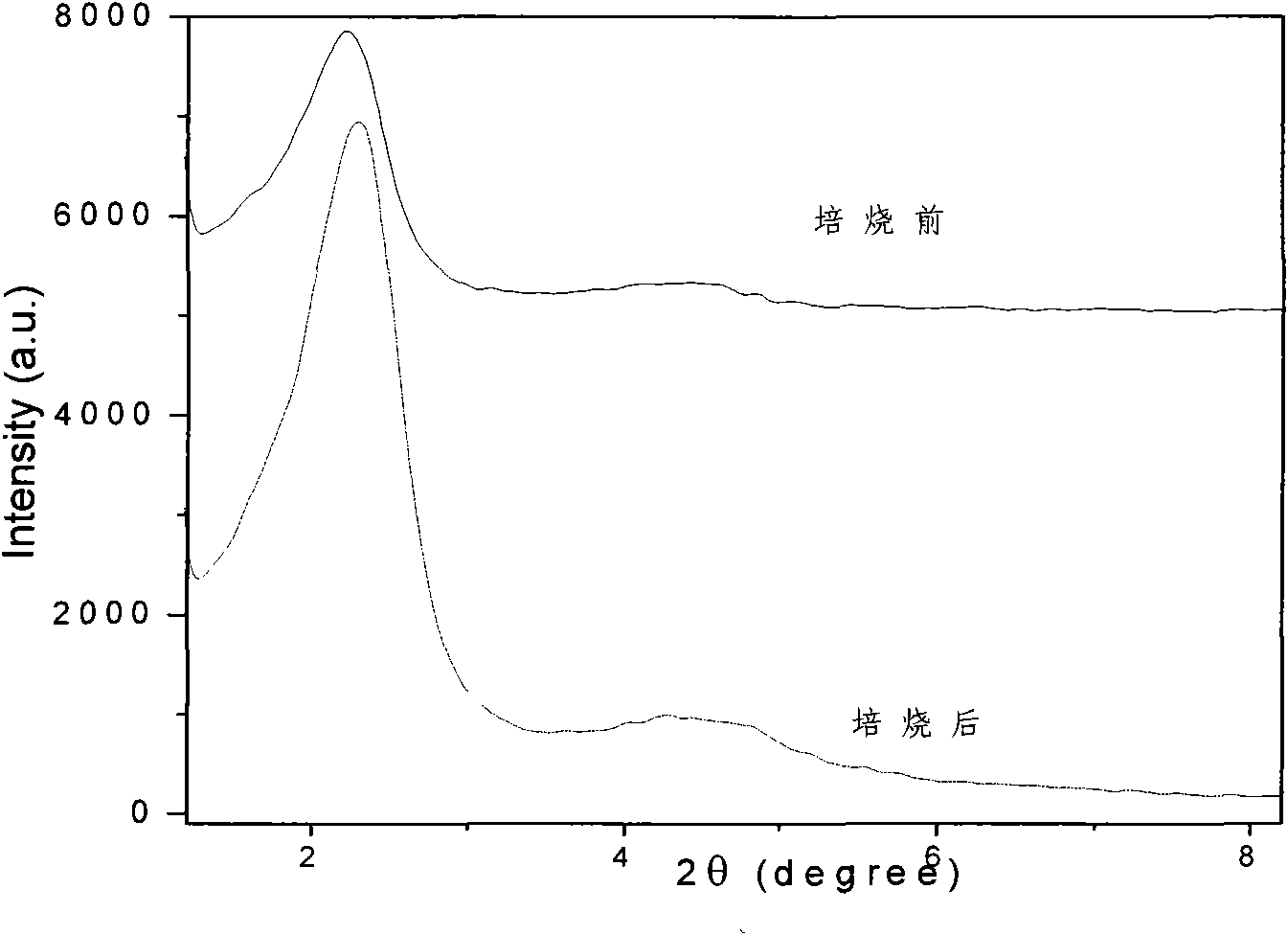

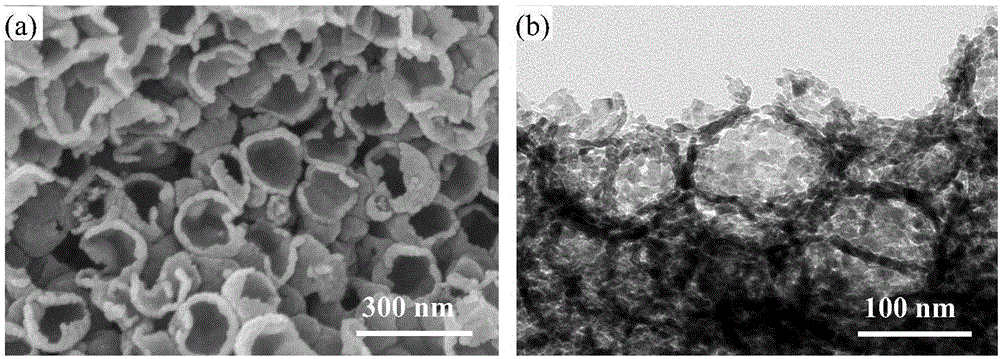

Method for preparing hollow mesoporous lamella spherical silica material

The invention relates to an inorganic porous material synthesis technology field, and concretely relates to a method for preparing hollow mesoporous lamella spherical silica material. In a mixed solvent of alcohol and water, under the catalytic action of ammonia, using a cationic surface active agent of cetyl trimethyl ammonium bromide as a mesoporous template, the inorganic silicon material self-assembles to be mesoporous uniform spheres on the polyphenylacetylene sphere surface, the surface active agent and the polyphenylacetylene sphere are deprived in high temperature environment, the hollow silica spheres with uniform size from micron to millimeter and mesoporous lamella are obtained. The specific surface area of the obtained hollow silica sphere is 800-2000m<2> / g, the bore diameter is 1.8-3.5nm, and the bore volume is 0.5-0.8 ml / g.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

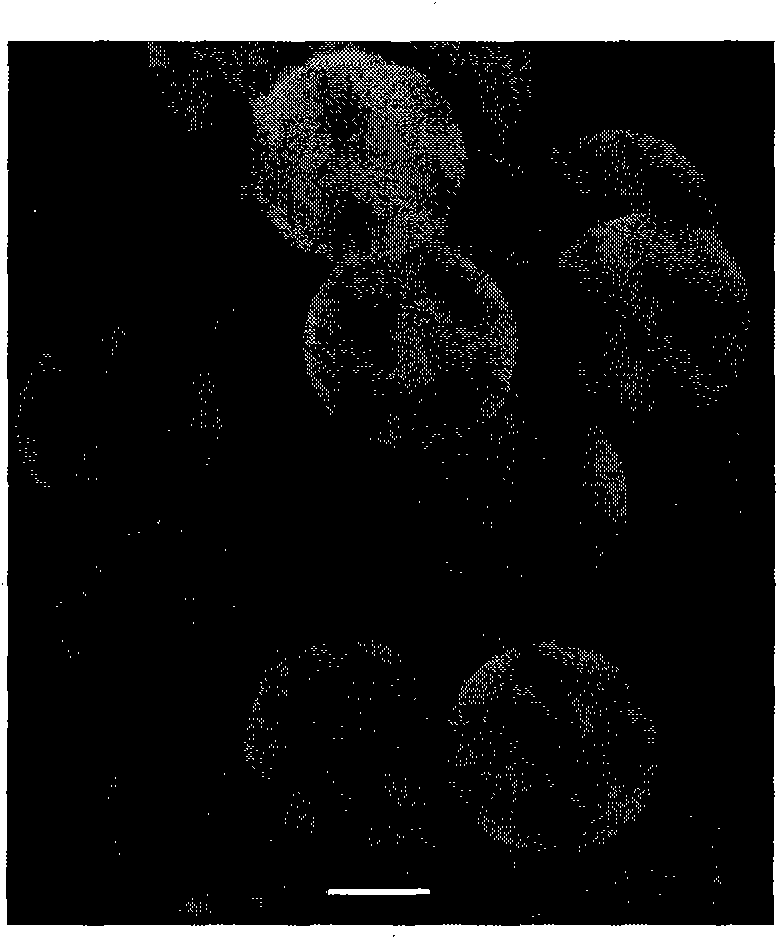

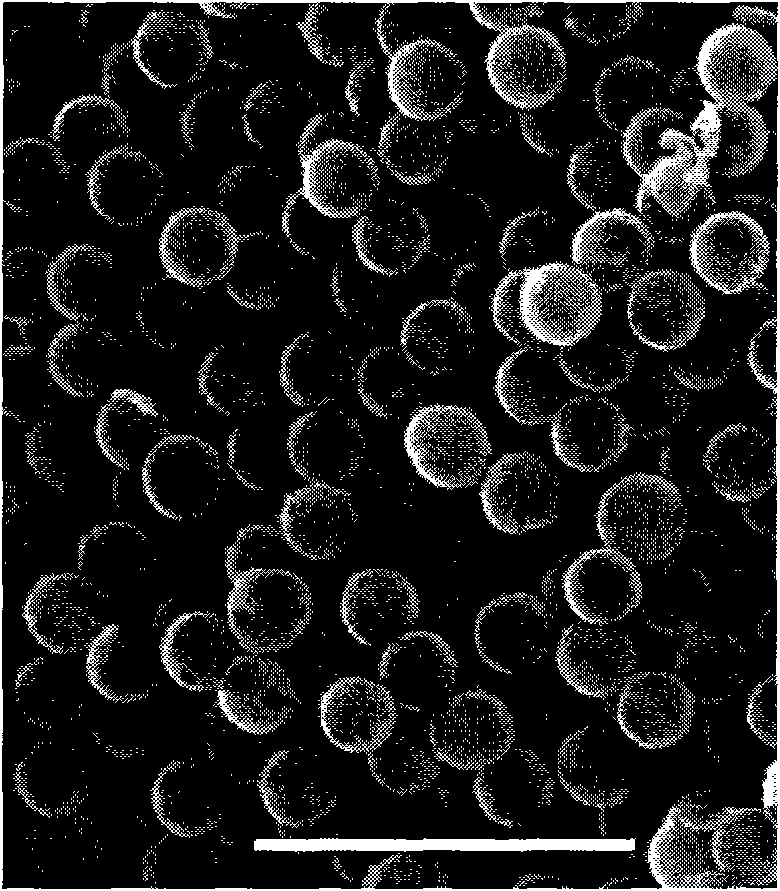

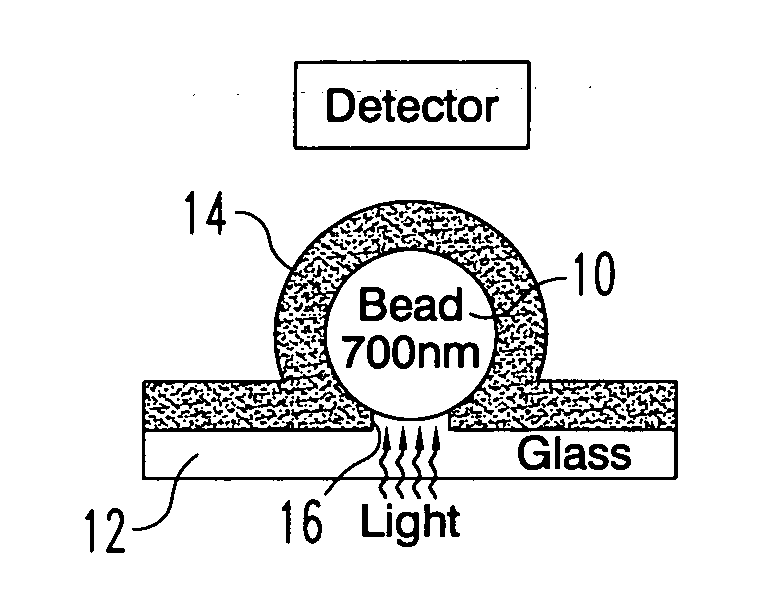

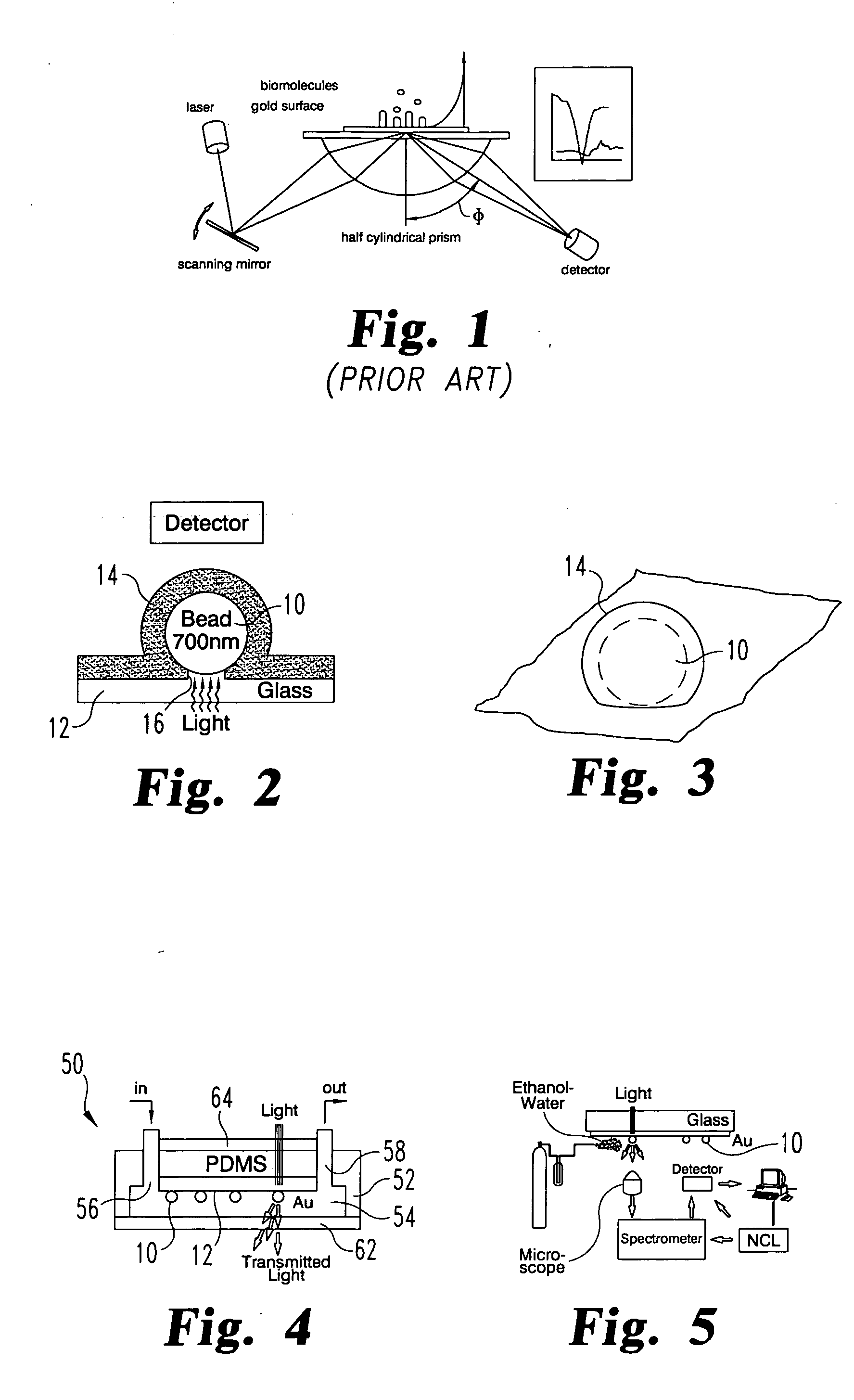

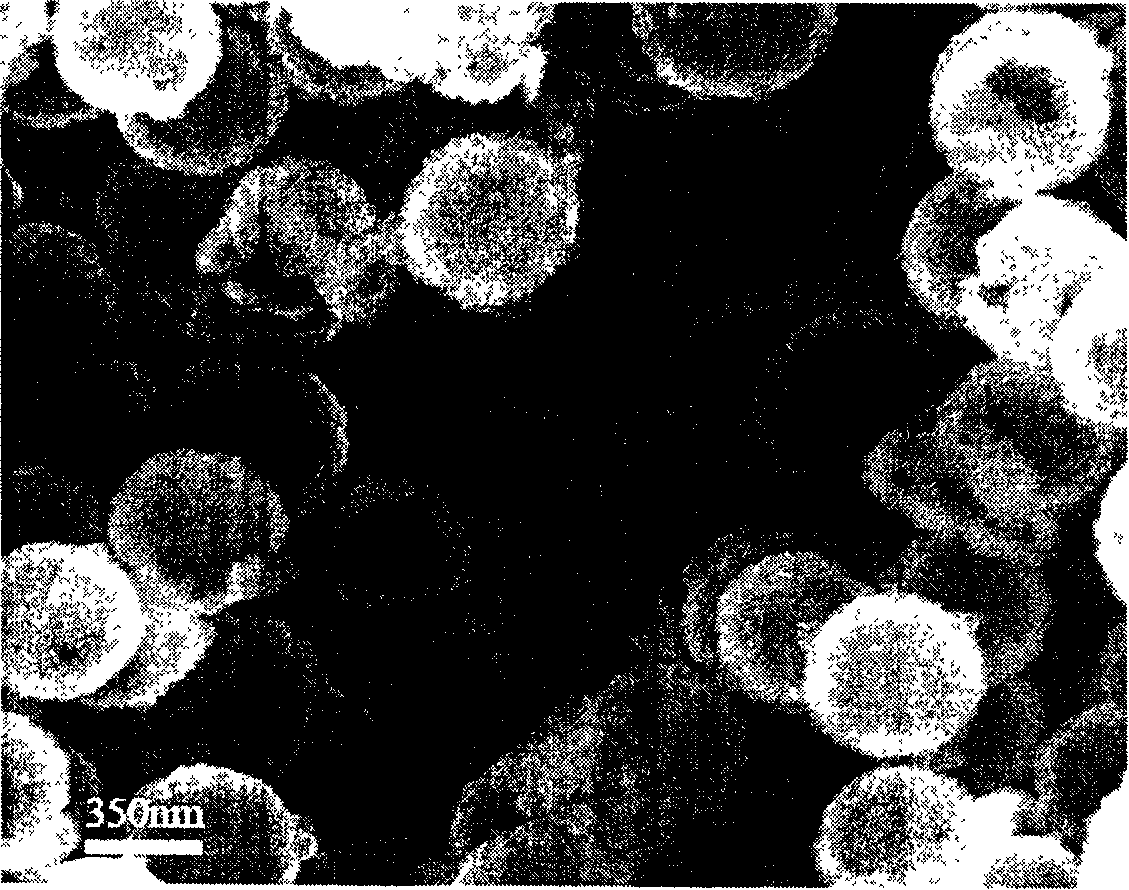

Sub-Micron Surface Plasmon Resonance Sensor Systems

InactiveUS20070153284A1High sensitivitySmall sensor sizeMaterial nanotechnologyScattering properties measurementsVALVE PORTLight source

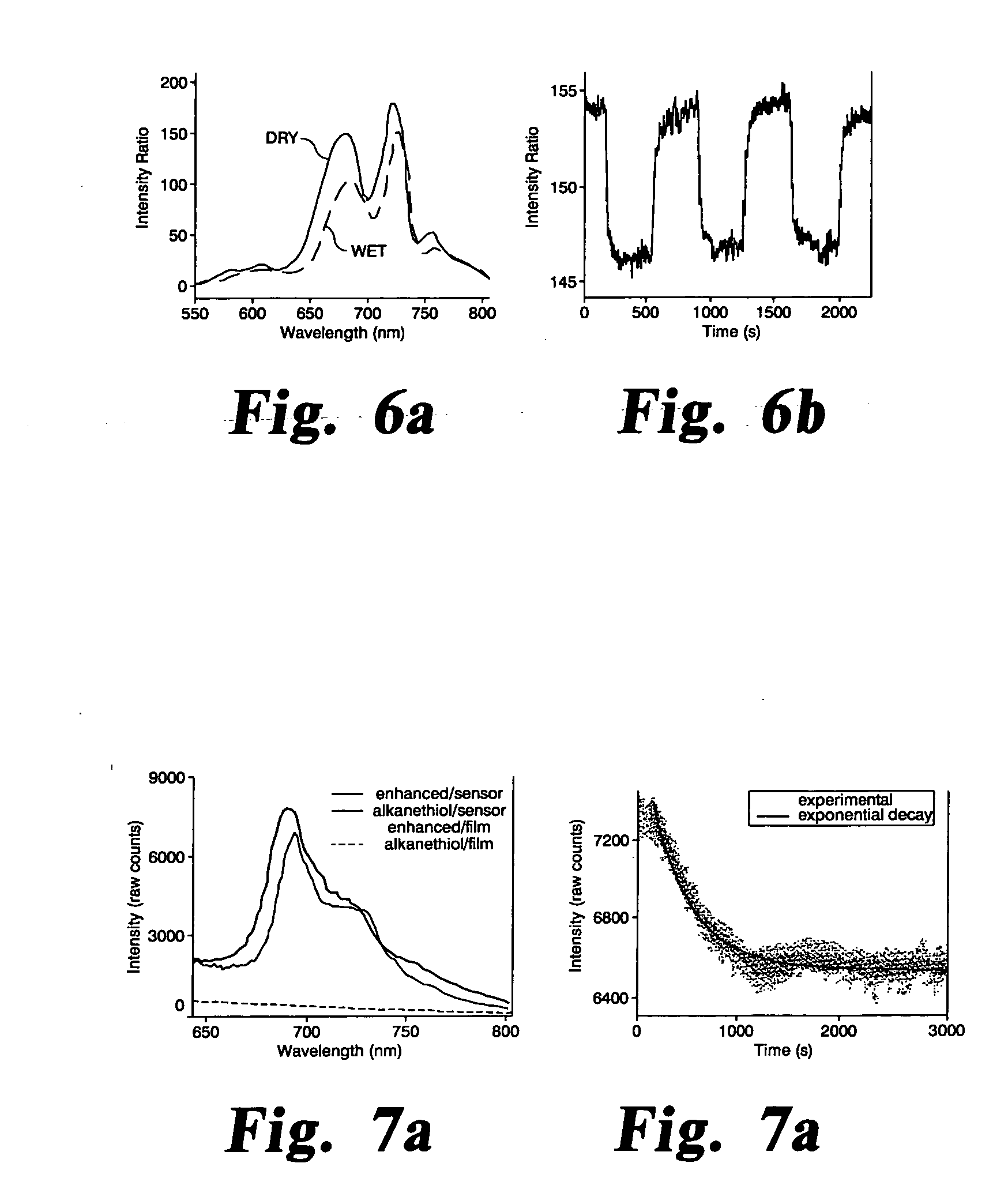

A sensor for detecting the presence of a target analyte, ligand or molecule in a test fluid, comprises a light transmissive substrate, an array of surface plasmon resonant (SPR) elements mounted thereon, a light source arranged to direct light into the SPR elements, and a detector arranged to detect light transmitted through the SPR elements. The SPR elements may include a dielectric polystyrene sphere having a spherical diameter of about 770 nm with a gold coating layer about 150 nm thick. The interface between the SPR elements and the substrate forms a pinhole with a diameter less than the wavelength of the light directed into the elements to produce a near-field coupling mode within the micro-sized SPR elements. In specific embodiments, the pinhole diameter ranges between 150-200 nm. The SPR elements are contained within a molded PDMS chip that may incorporate micro-fluidic components, such as a pump and valves, to control flow of the test fluid across the SPR elements. A multi-channel sensor may be provided for detecting the presence of several targets with a single micro-chip sensor. In the multi-channel sensor collections of SPR elements are commonly functionalized to one of the several targets. The detectors sense changes in the resonant response of the SPR elements indicative of binding with the targets.

Owner:THE TRUSTEES OF INDIANA UNIV

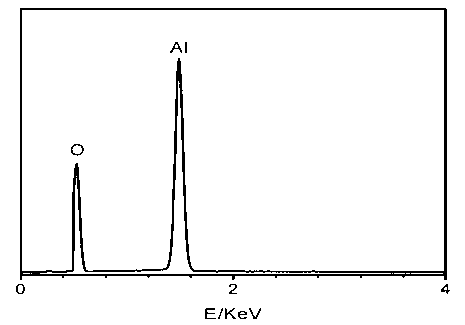

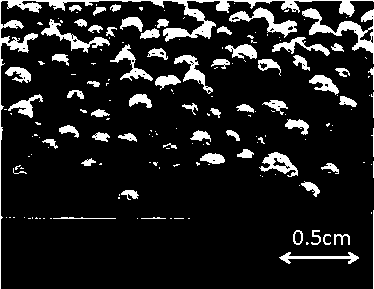

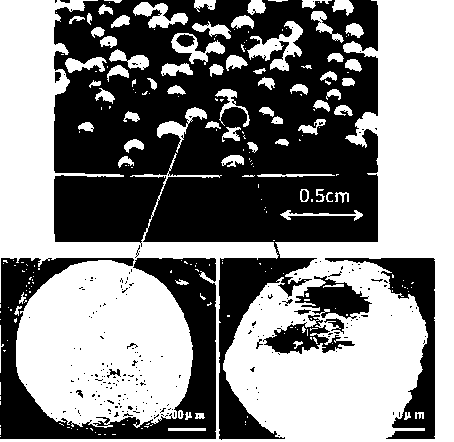

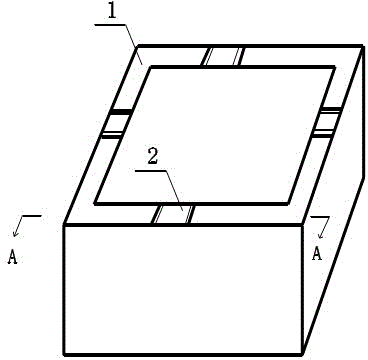

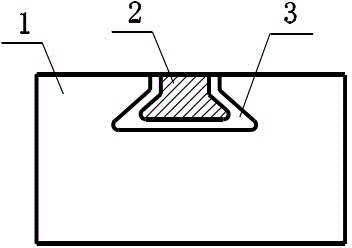

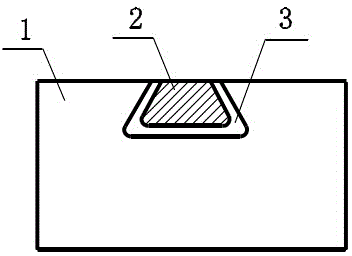

Preparation method for alumina hollow spheres

The invention discloses a preparation method for alumina hollow spheres. The preparation method comprises the steps of preparing a chitosan-acetic acid-water solution; weighing raw materials according to a mass ratio of polystyrene spheres to the chitosan-acetic acid-water solution 5:1 to 10:1 and a mass ratio of the polystyrene spheres to alpha-alumina powder of 1:5 to 1:15; mixing and stirring the polystyrene spheres and the chitosan-acetic acid-water solution to make the surfaces of the polystyrene spheres uniformly coated by a layer of the chitosan-acetic acid-water solution; putting the polystyrene spheres coated by the chitosan-acetic acid-water solution and the alpha-alumina powder in a ball-milling device, rotating at a rotation speed of 5-30 r / s to coat for 2-24 h so as to prepare core-shell spheres; and sintering the core-shell spheres to obtain the alumina hollow spheres with the diameter of 0.2-2 mm and wall thickness of 20-100 [mu]m. The preparation method is low in cost of the raw materials, simple in process and safe and simple in operations, and can realize industrial production easily.

Owner:SOUTHWEAT UNIV OF SCI & TECH

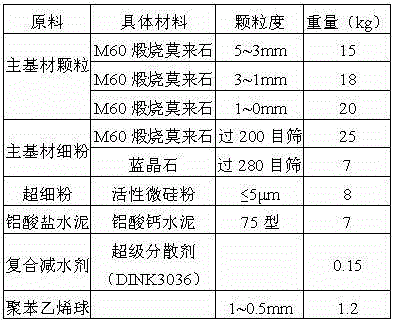

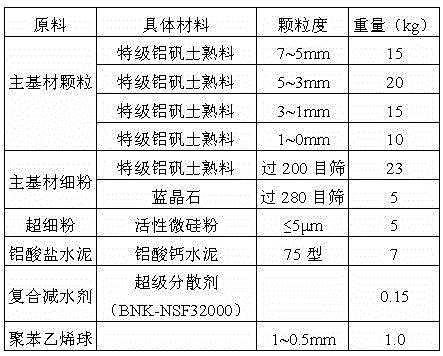

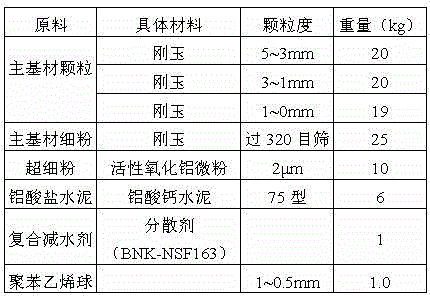

High temperature resistant lightweight heat insulation castables

Disclosed is high temperature resistant lightweight heat insulation castables. Substrate raw materials and the weight percentage are as follows: 53-60% of main substrate particles with the average particle size less than or equal to 7 millimeters, 25-32% of main substrate fine powder which can pass through a target screen mesh not less than 200, 5-10% of ultrafine powder with the average particle size less than or equal to 10 microns, and 6-7% of aluminate cement. The sum of the weight of the substrate raw materials is an entirety, compound water-reducing agents need to be added besides the substrate raw materials, and the weight of the compound water-reducing agents is 0.1-1% of that of the entirety. Besides the substrate raw materials, polystyrene spheres need to be added, the average particle size of the polystyrene spheres is 1-0.5 millimeter, and the weight of the polystyrene spheres is 1-3% of that of the entirety. The high temperature resistant lightweight heat insulation castables can be used as working lining of a thermal furnace which does not contact with molten liquid, the use temperature is from 1250-1650 DEG C according to different main substrates, and the volume density of the high temperature resistant lightweight heat insulation castables can be 1.2-1.7g / cm<3> by adding burning articles with different quantities.

Owner:宜兴天霸非金属材料有限公司

Method for preparing controllable ordered porous tin dioxide nano structures

InactiveCN102153133AStable chemical propertiesImprove thermal stabilityTin oxidesNano structuringPolystyrene spheres

Owner:YANGZHOU UNIV

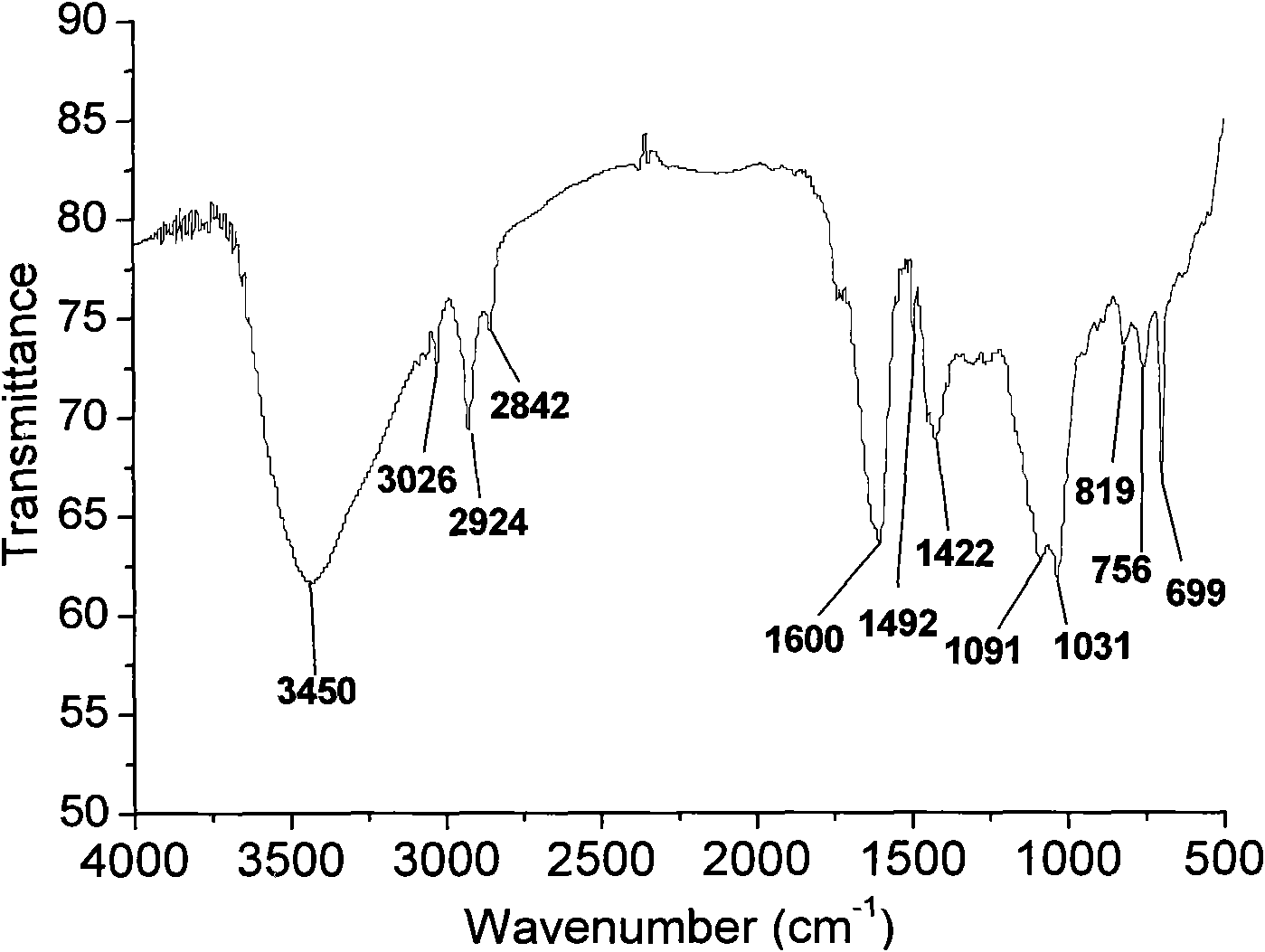

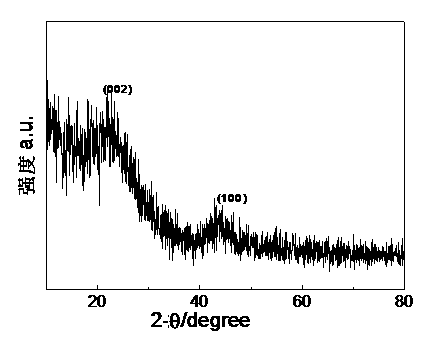

Preparation method of positive electrode material LiFePO4/C of lithium ion battery

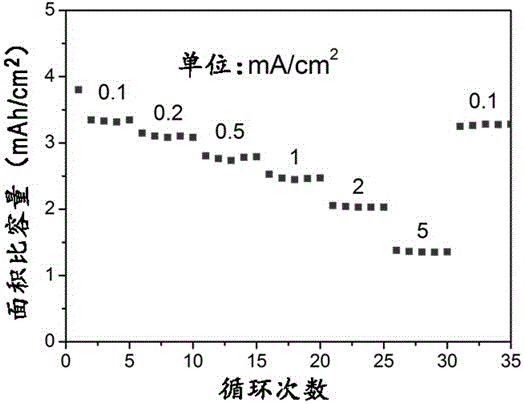

The invention discloses a method for preparing the positive electrode material LiFePO4 / C of a lithium ion battery by adopting carbon sources of the polystyrene sphere series. A carbon thermal reduction and solid phase sintering method is adopted in the preparation process. The method comprises the following concrete steps: firstly, uniformly mixing a lithium source, an iron source and a phosphorus source, and then, mixing the mixture with a carbon source; then, adding a solvent for ball milling, and drying to obtain a precursor; and pretreating and calcining the precursor in the protective atmosphere, and then, cooling the precursor in a furnace to synthesize the LiFePO4 / C of which the particle size distribution is uniform and the particle diameter is 200-500nm. The invention has the advantages of wide sources of raw materials, simple preparation method, convenient control and operation, good carbon coating effect, excellent electrochemical performance and the like.

Owner:XINJIANG JINSHENGDA NONFERROUS METAL MATERIALS CO LTD +1

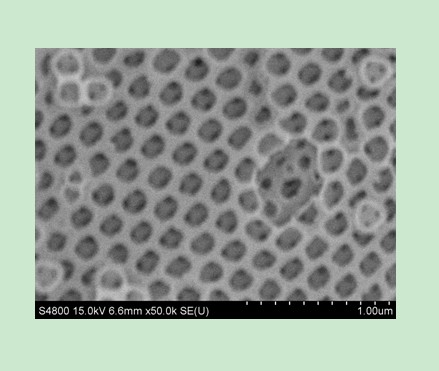

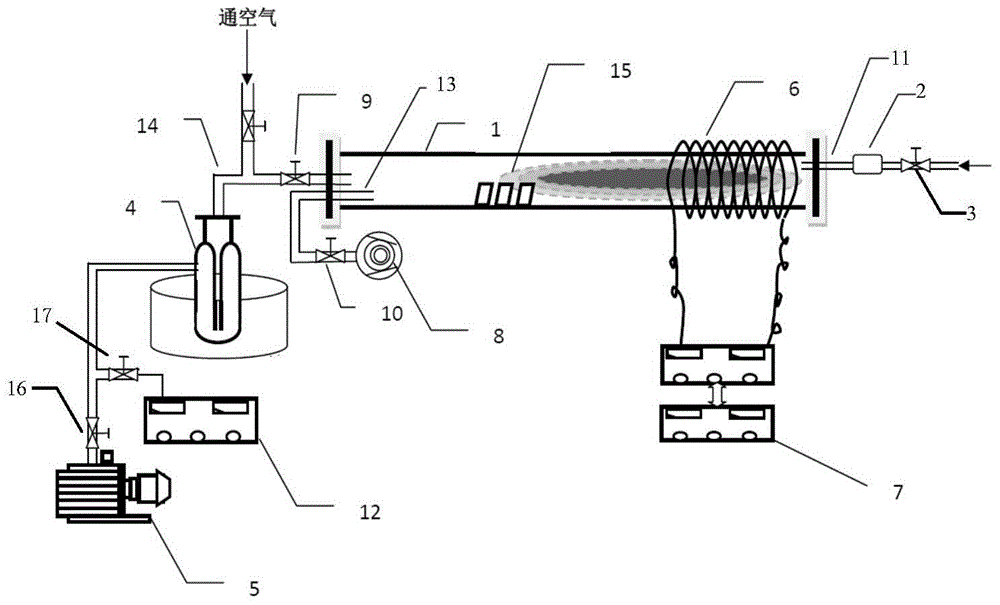

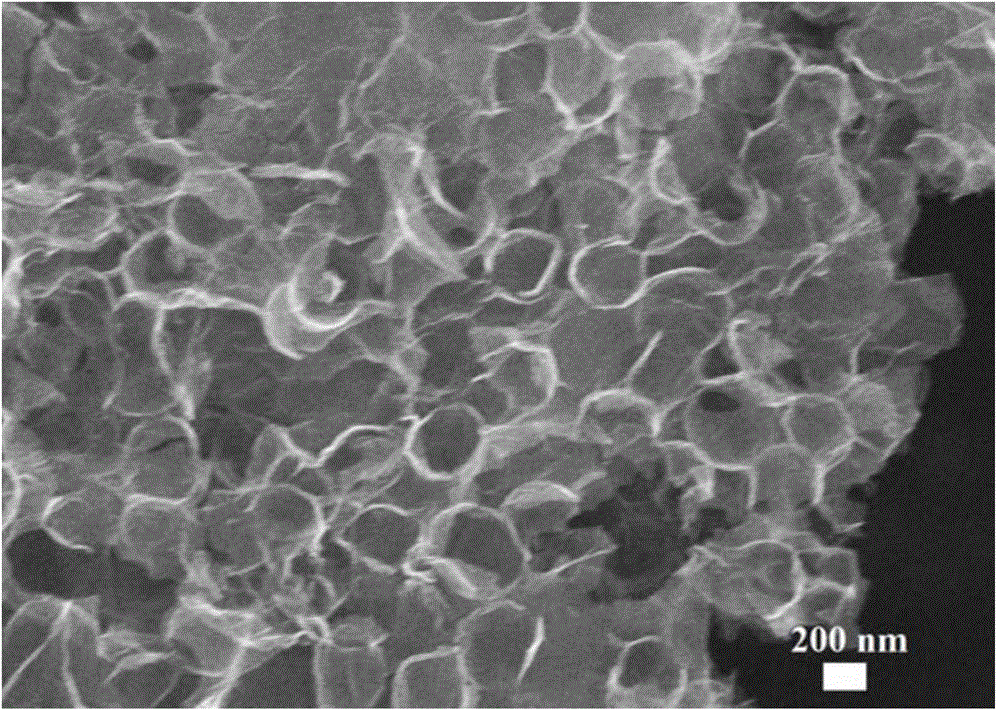

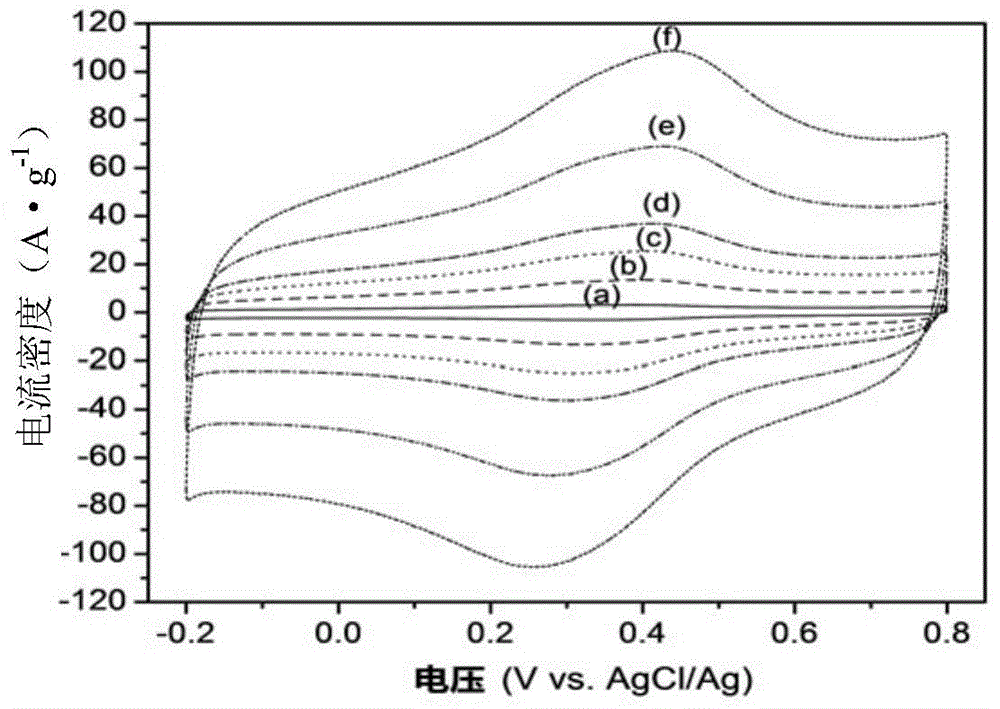

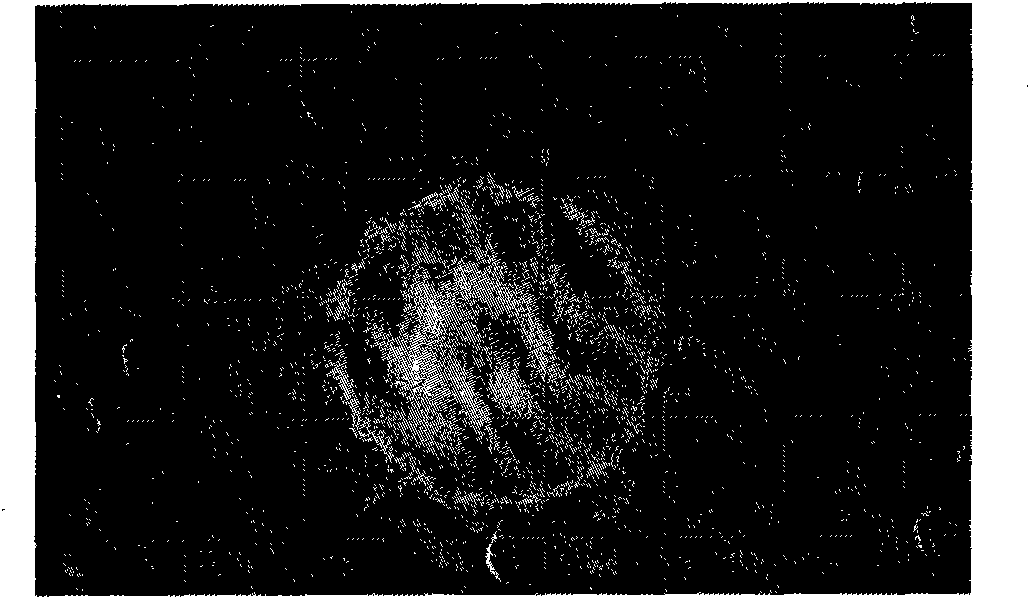

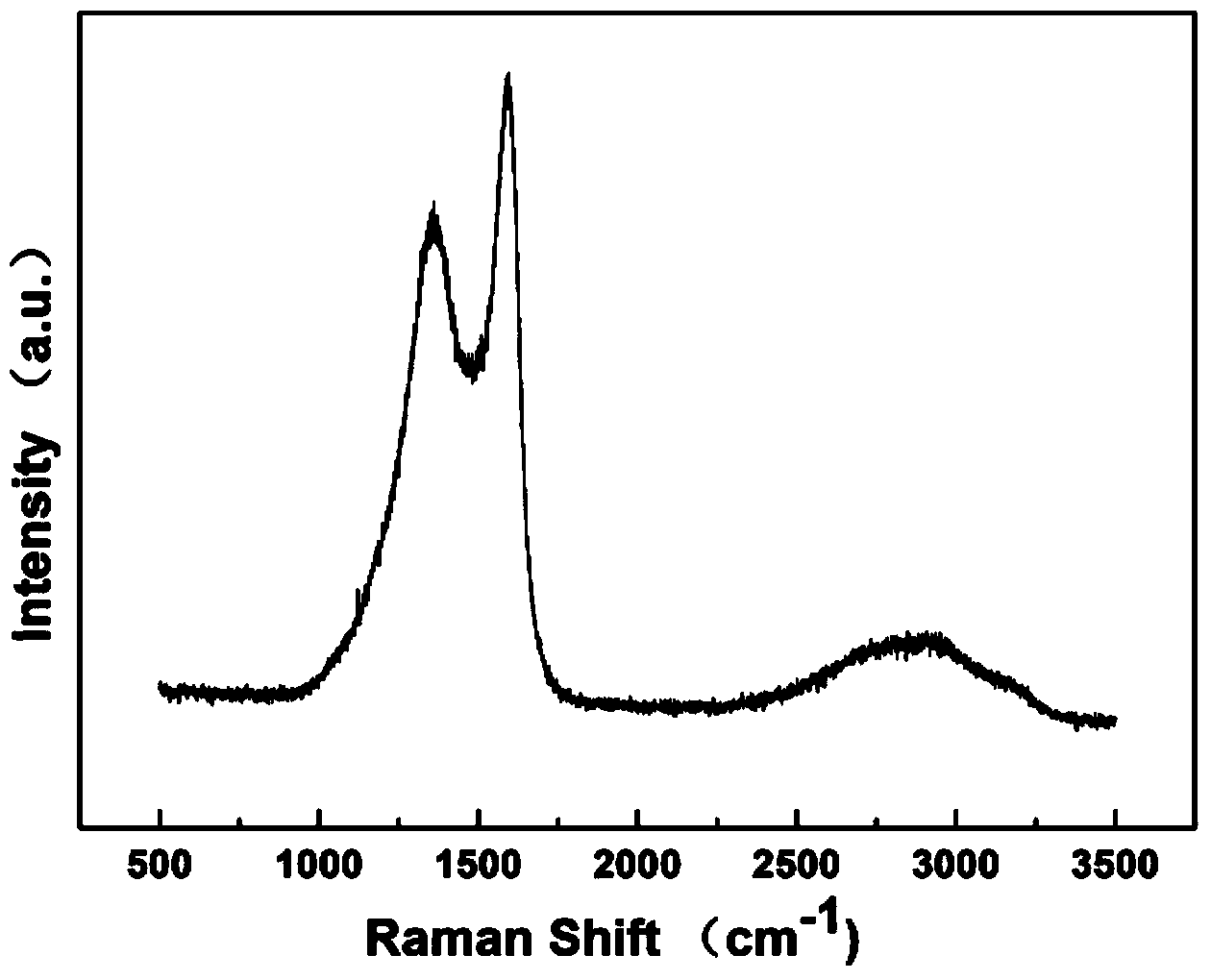

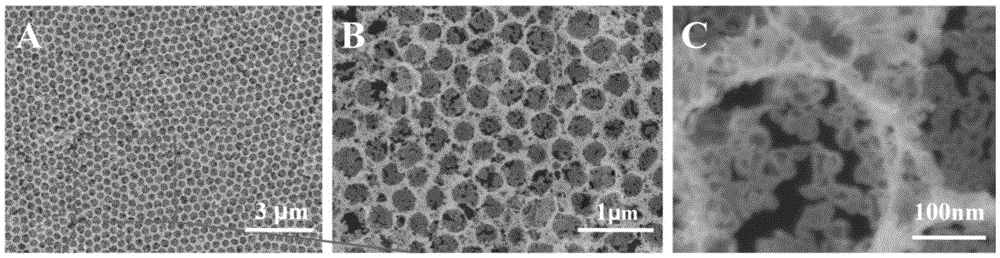

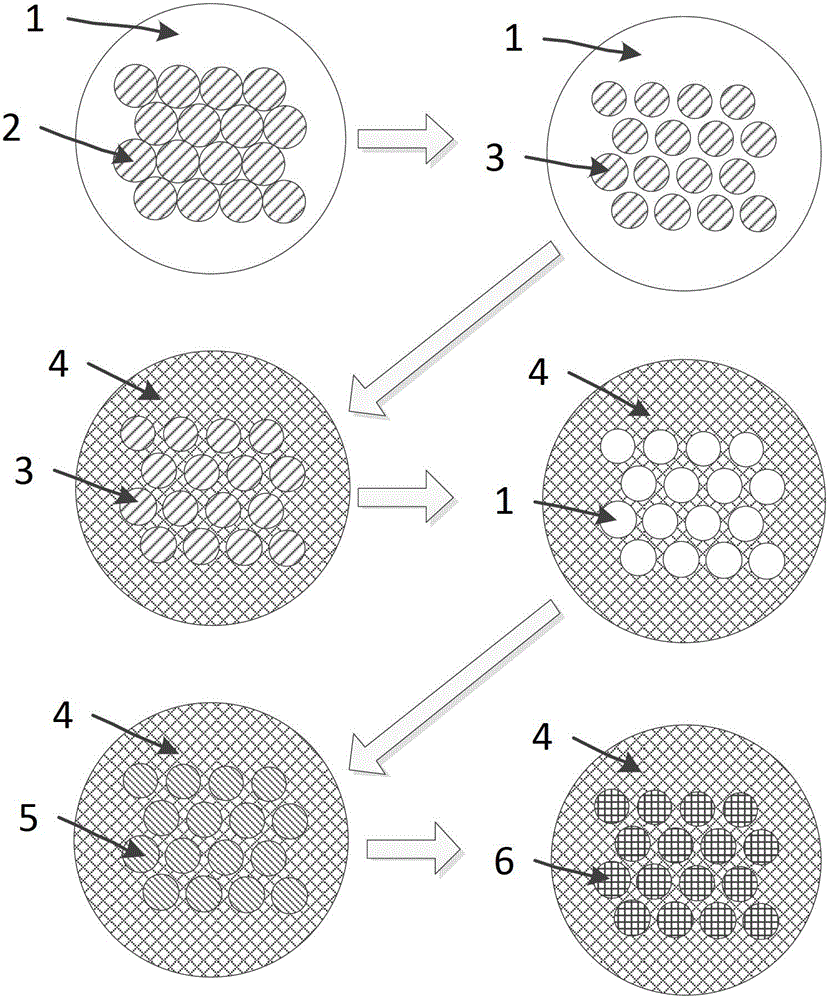

Hetero atom-doped hollow spherical grapheme composite material, and preparation method and applications thereof

The invention belongs to the technical field of carbon material and electrochemistry, and discloses a hetero atom-doped hollow spherical grapheme composite material, and a preparation method and applications thereof. The preparation method comprises following steps: styrene, polyvinyl pyrrolidone, and 2,2'-azobis(2-methylpropionamidine) dihydrochloride are mixed with water, and positively charged polystyrene spheres are prepared under certain conditions; a graphene oxide aqueous dispersion and a positively charged polystyrene sphere aqueous dispersion are stirred for reaction so as to prepare a graphene oxide@polystyrene sphere compound; a hetero atom-doped sourced compound and a solvent are added into the graphene oxide@polystyrene sphere compound, and an obtained mixture is subjected to mixing, coating, and freeze drying so as to obtain solid thin films; a substrate loaded with the solid thin films is delivered into a plasma high-temperature tubular reactor for reaction so as to obtain the hetero atom-doped hollow spherical grapheme composite material. The hetero atom-doped hollow spherical grapheme composite material possesses relatively high specific surface area and relatively excellent electrical properties, and can be applied to the field of supercapacitor.

Owner:SOUTH CHINA UNIV OF TECH

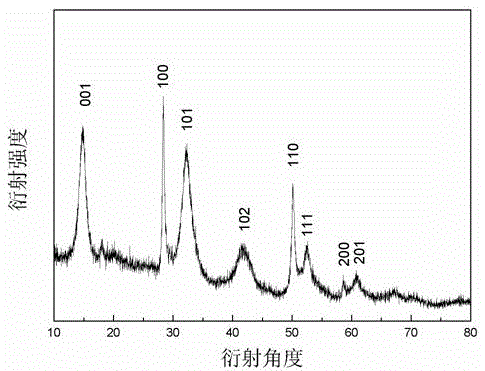

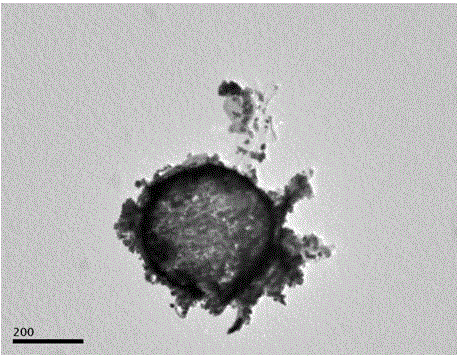

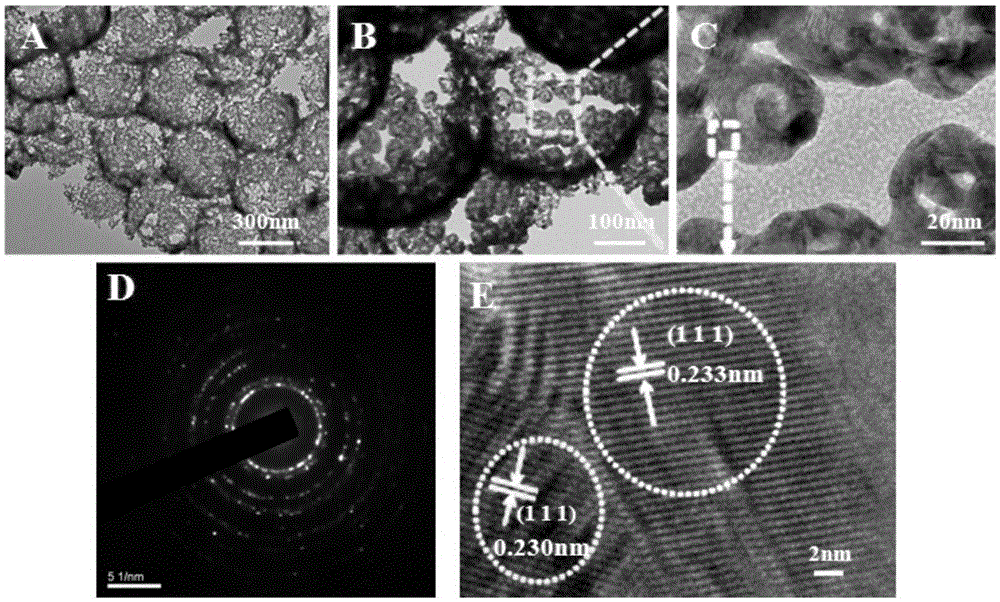

Composite material with hollow graphene spheres loaded with nanometer tin disulfide and method for preparing composite material

ActiveCN105621355ALow costSimple preparation processMaterial nanotechnologyCell electrodesPorous grapheneLithium

The invention discloses a composite material with hollow graphene spheres loaded with nanometer tin disulfide. The composite material is characterized in that the hollow graphene spheres with sub-micron sizes are used as carriers, tin disulfide nanometer particles are loaded on the inner walls and the outer walls of the hollow graphene spheres, and the sizes of the tin disulfide nanometer particles grown on the surfaces of the hollow graphene spheres range from 10 nm to 40 nm. A method for preparing the composite material includes steps of a, synthesizing cationic polystyrene spheres; b, synthesizing the hollow graphene spheres; c, loading the tin disulfide to obtain the composite material with the hollow graphene spheres loaded with the nanometer tin disulfide. The composite material and the method have the advantages that the composite material is a carbon material with a two-dimensional structure, the tin disulfide with an expanded volume can be accommodated in charging and discharging procedures, and the electric conductivity and the structural stability of electrode materials can be improved; the electric conductivity and the ion transport performance of the materials can be improved by porous graphene structures, and the composite material is favorable for embedding lithium ions in the materials and releasing the lithium ions from the materials.

Owner:SHANGHAI UNIV

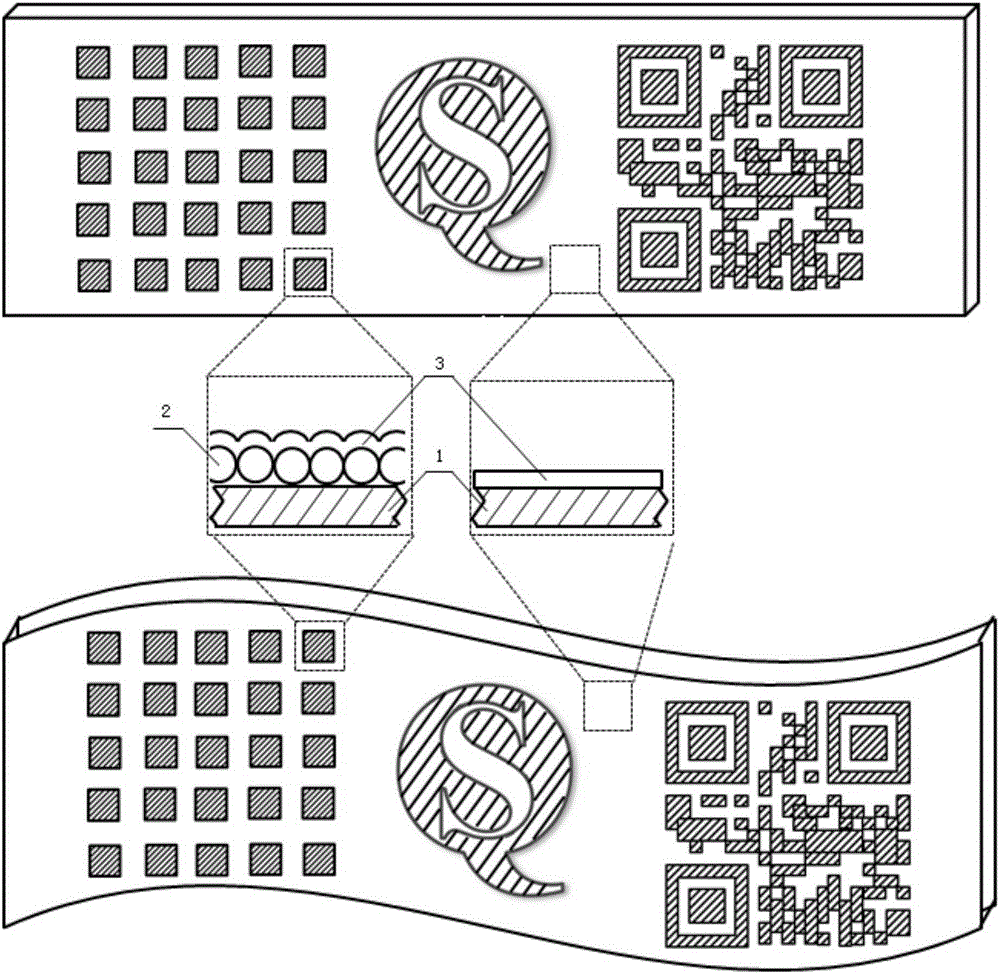

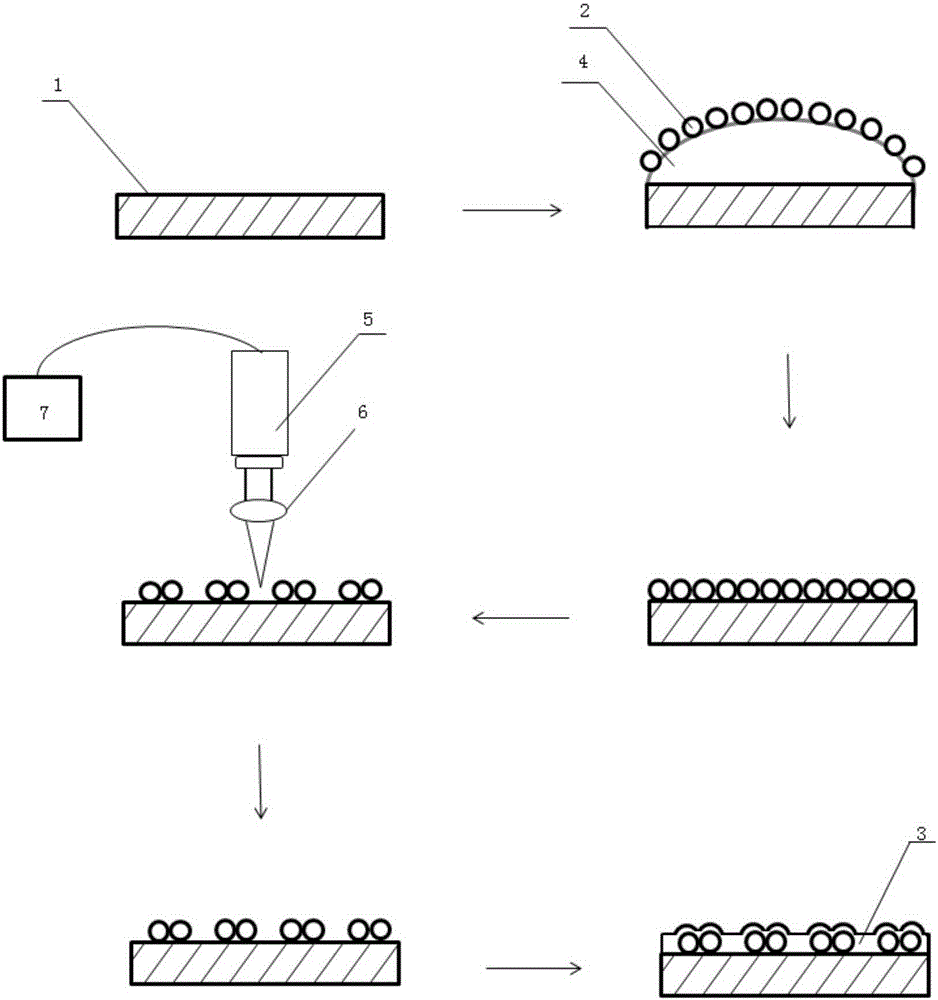

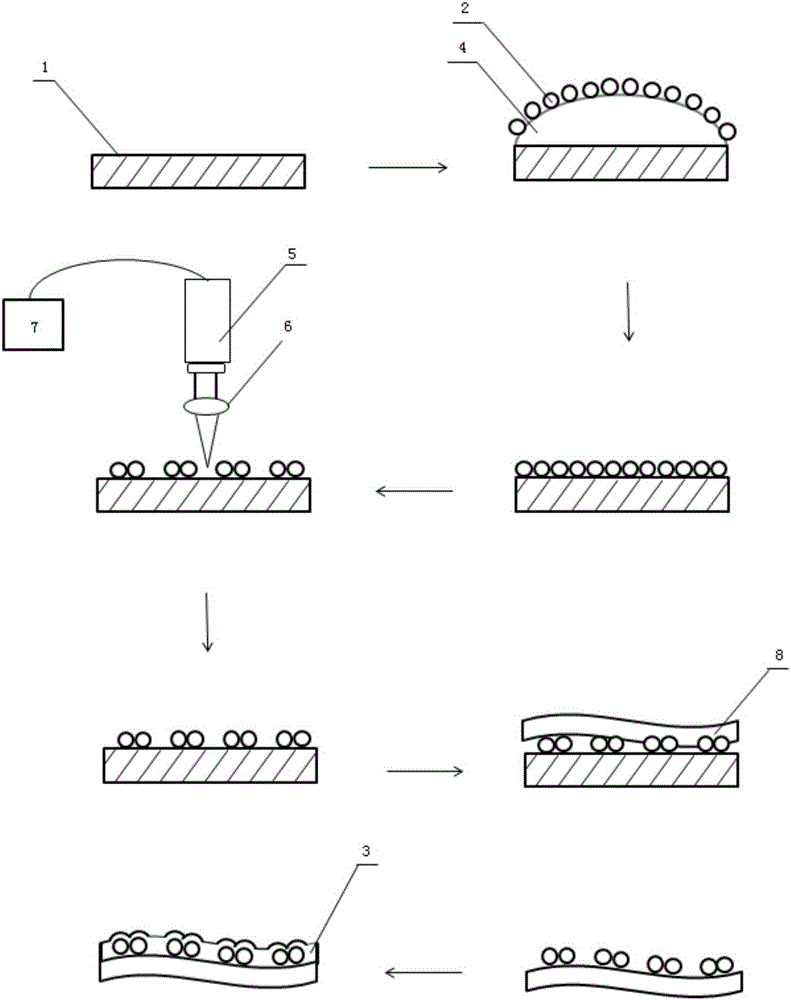

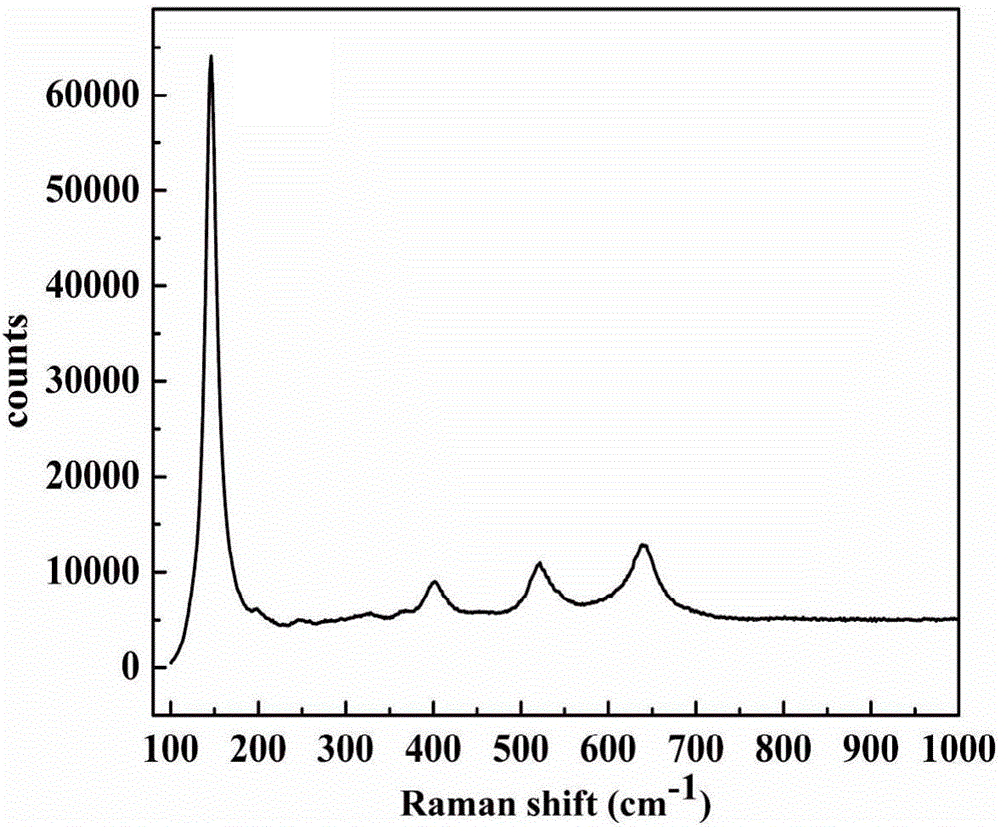

Anti-counterfeit label based on patterned metal nanocomposite and production method of anti-counterfeit label

ActiveCN105206175AEasy to identifyEnhanced Raman scattering activityStampsIdentification meansMicrosphereSurface plasmonic resonance

The invention discloses an anti-counterfeit label based on a patterned metal nanocomposite and a production method of the anti-counterfeit label. The anti-counterfeit label comprises a base material adopting a hard or flexible material and a patterned metal and polystyrene sphere composite nanostructure which is formed on the base material, wherein the patterned metal and polystyrene sphere composite nanostructure comprises a polystyrene microphere array coating the surface of the base material and a metal layer plated on the polystyrene microsphere array. The anti-counterfeit label is characterized in that colorful structured lights can be generated through a surface plasma resonance phenomenon, so as to form clear and recognizable pattern labels; a specific organic matter combination with Raman scattering activity is further added to be used for hiding or reading encrypted information at higher anti-counterfeit grades. As an anti-counterfeit label material, the anti-counterfeit label achieves multiple anti-counterfeit characteristics, has the characteristics of being high in anti-counterfeit grade, convenient to use, and the like, and can be widely applied to the industries of pharmacy, food, aircraft parts, automobile parts, brand-name clothes, luxuries, artworks, and the like.

Owner:ZHEJIANG UNIV

Method for preparing electric polypyrrole nano hollow sphere

The process of preparing composite particle of hollow nanometer conductive polypyrrole-silica ball includes the following successive steps: adding pyrrole monomer and nanometer silica ball into deionized water and dispersing ultrasonically; and introducing initiator to react at 100-180 deg.c to obtain the composite particle. Compared with available technology, the process of the present invention has the advantages of less intermediate steps, low cost, capacity of obtaining product with high size homogeneity and controllability, and other advantages.

Owner:CENT SOUTH UNIV

Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

InactiveCN101857698AAchieve adsorptionSynthetic conditions are mildPharmaceutical non-active ingredientsOn/in organic carrierUltrasonic emulsificationFiltration

The invention provides a polystyrene / calcium alginate composite gel microsphere in a nuclear shell structure and a preparation method thereof, relating to biopolymer materials. The polystyrene / calcium alginate composite gel microsphere in the nuclear shell structure takes a polystyrene microsphere as a core and calcium alginate gel as a shell, wherein the grain size of the core is 1-100 microns, and the thickness of the shell layer is 50-800 nm. The preparation method comprises the following steps of: mixing polystyrene microsphere with aqueous solution containing a surface active agent I, and carrying out ultrasonic emulsification to obtain mixed solution A; adding sodium alga acid solution in the mixed solution A, and stirring to obtain mixed solution B; adding organic solution containing a surface active agent II into the mixed solution B, and stirring to obtain mixed solution C; adding calcium chloride solution which has the same volume with the sodium alga acid solution into the mixed solution C under stirring to react, and carrying out vacuum filtration, washing the solution until no calcium ion residue exists on the surface and drying to obtain a product D; and dispersing the product D into water, centrifuging the mixture, pouring out supernate and taking out precipitate to obtain the product.

Owner:XIAMEN UNIV

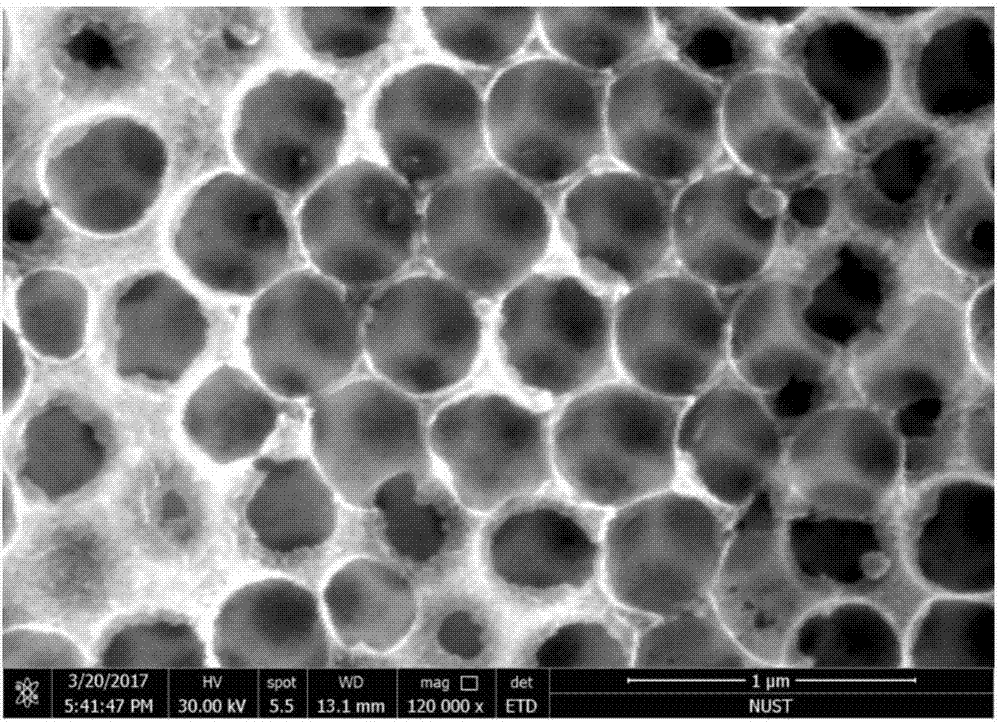

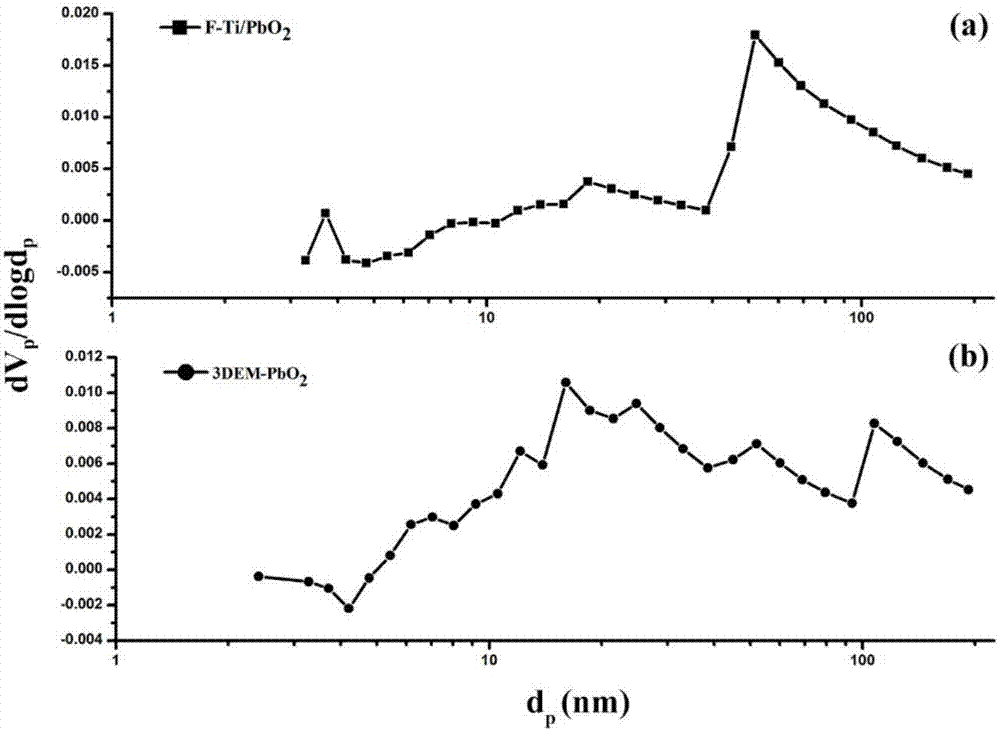

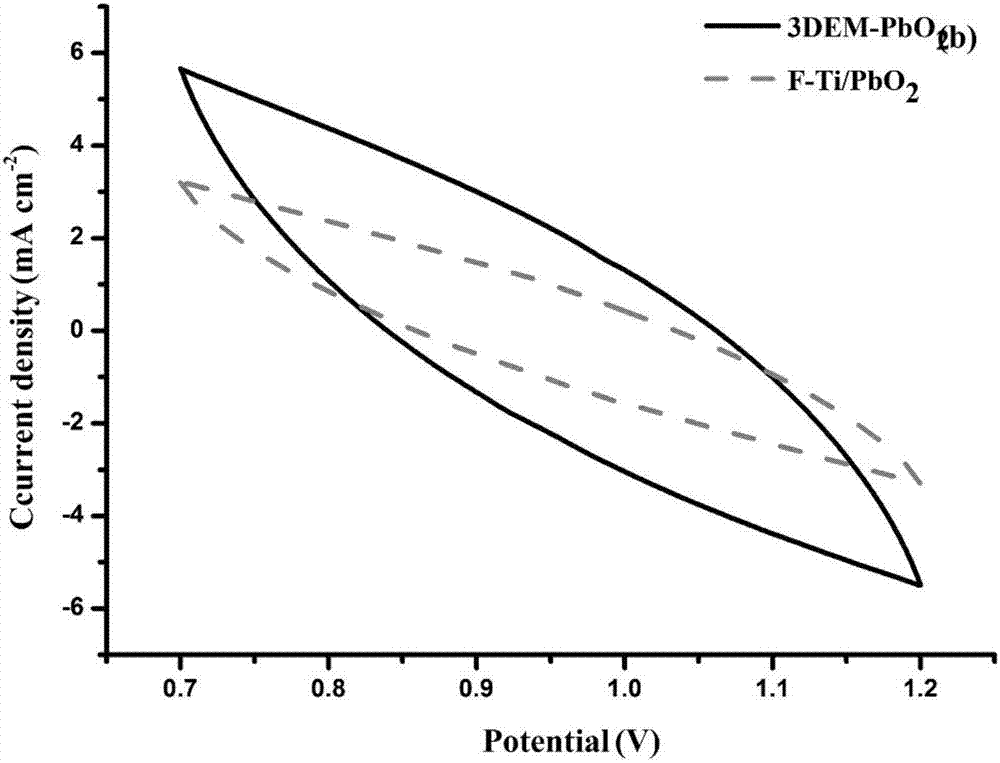

Three-dimensional ordered porous lead dioxide membrane electrode and preparation method thereof

InactiveCN107302102AImprove electrocatalytic efficiencyEnhanced mass transferFuel cellsTin dioxideLead dioxide

The invention discloses a method for preparing a three-dimensional ordered porous lead dioxide membrane electrode by a template electro-deposition method. The method comprises the steps of preparing an antimony-doped tin dioxide intermediate layer on a porous titanium matrix via a sol-gel method, assembling a polystyrene sphere mono-dispersion serving a template agent to the intermediate layer via natural settlement, then preparing a lead dioxide active layer in the gap of the template agent via an electro-deposition method, and finally dissolving the template agent to obtain the lead dioxide membrane electrode with a porous structure. The lead dioxide membrane electrode has three-dimensional ordered porous structure, large specific surface area, many electrochemical active sites and large filtration flux, overcomes the defects that the traditional lead dioxide electrode has a compact structure and cannot be applied to a filtering electrochemical system, and has great application value in the electrochemical catalysis field.

Owner:NANJING UNIV OF SCI & TECH

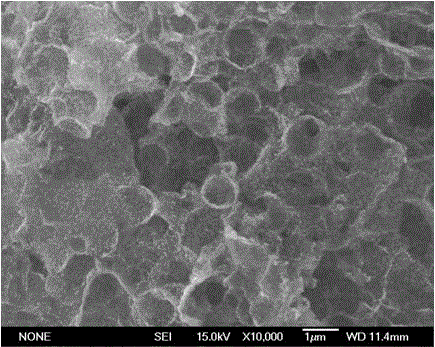

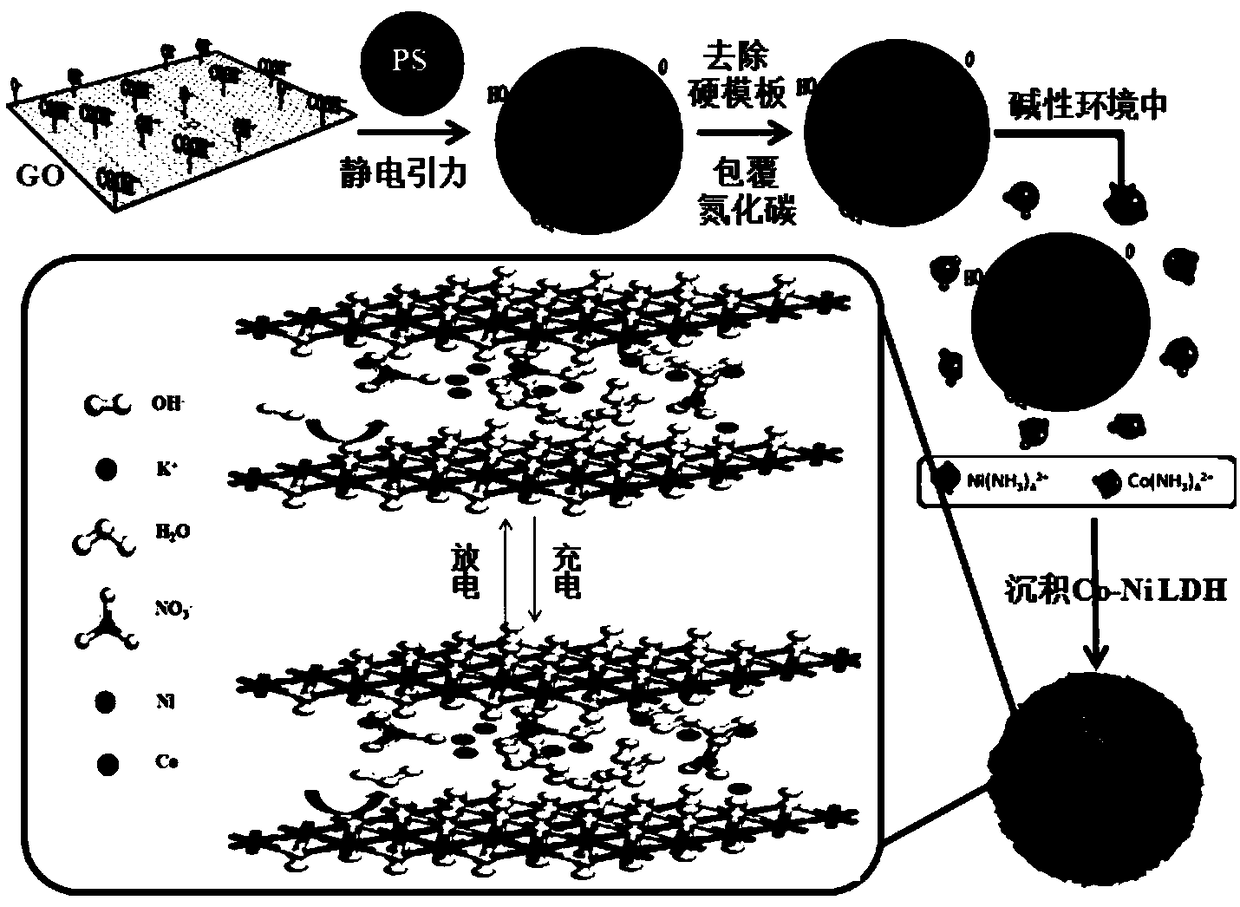

Cobalt-nickel-double-metal-hydroxide-nanosheet/carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and preparation method thereof and application

InactiveCN109300703AImprove stabilityAvoid deformationHybrid capacitor electrodesElectric capacityUnit structure

The invention discloses a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and a preparation method thereof, and application as a supercapacitor electrode material. The composite material comprises a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere has a 3D spherical appearance; and the specific surface area is 100 to 1000m<2> / g and the average pore diameter of 1 to 200mm. In addition, the preparation method includes the following steps: preparing a small polystyrene sphere; preparing a polyaniline-coated graphene sphere; preparing a carbon-nitride-coated nitrogen-doped hollow graphene sphere; and preparing a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material. Therefore, a problem of series agglomeration of the cobalt-nickel double-metal hydroxide unit structure during the traditional preparation technology process is solved effectively; and a novel method is provided for preparing an electrode material with advantages of large specific surface area, high flexibility, high electric capacity, and high stability.

Owner:ZHEJIANG SCI-TECH UNIV

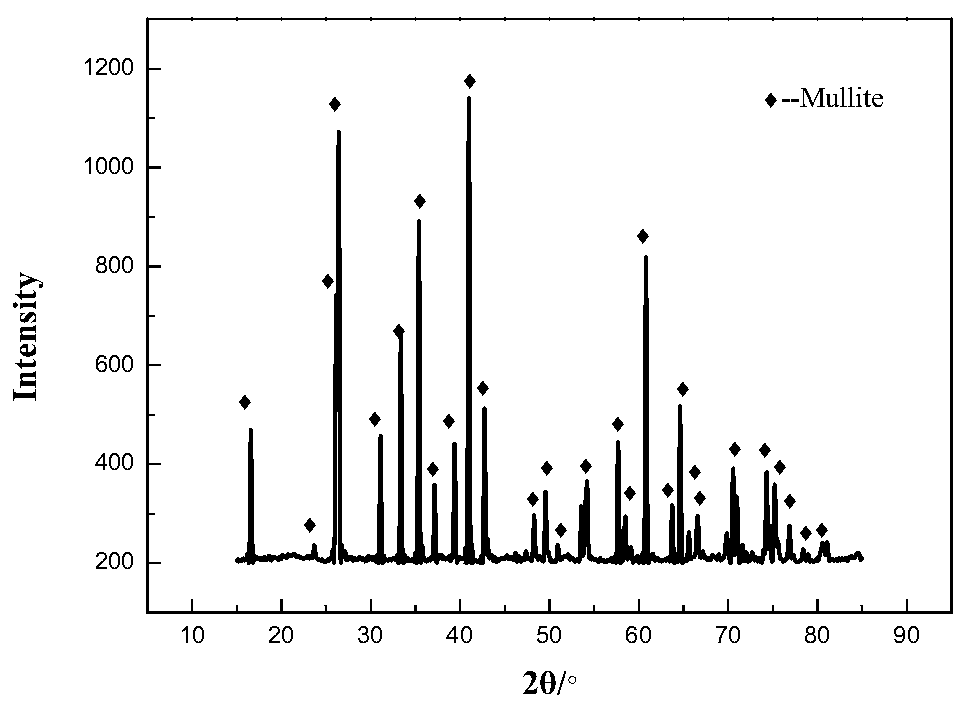

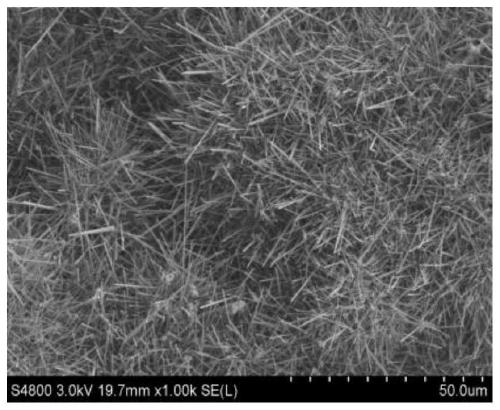

Hollow spheroidal mullite material and preparation method thereof

The invention provides a hollow spheroidal mullite whisker material and a preparation method thereof. The preparation method comprises steps as follows: silica sol, water and ethanol are added to a container and stirred uniformly, the pH value is regulated to 2, and silica sol is formed; alumina powder, aluminum fluoride trihydrate and ethanol are mixed and subjected to ball milling, and mixed slurry is obtained; the silica sol and the mixed slurry are mixed uniformly in a volume ratio of 1:(0.5-1.4), the pH value is regulated to 7-9, gelatinization is performed, and precursor powder is obtained; a polyvinyl alcohol solution is uniformly sprayed to the surfaces of polystyrene spheres, starch spheres, phenol-formaldehyde resin spheres or urea spheres, then the spheres are put in the precursor powder to adhere to the precursor powder, the operation is repeated multiple times, then ball milling, drying and calcining are performed in sequence, and the hollow spheroidal mullite whisker material is obtained. According to the hollow spheroidal mullite whisker material, the volume density is 0.34-0.85 g / cm<3>, the room-temperature thermal conductivity is 0.184-0.485 W / (m<-1>.K<-1>), and the open porosity is 62.33%-81.86%.

Owner:CHANGAN UNIV

Preparation method of three-dimensional flocculent graphene substrate material and application

A preparation method of a three-dimensional flocculent graphene substrate material and an application belong to the field of preparation of a functional nanometer material. The preparation method comprises the following steps: 1, graphite oxide is placed in a crucible to prepare expanded graphite; 2, 10-20mg of expanded graphite is dispersed in 10-30mL of water, 200-800 microliters of an aqueous dispersion liquid of polystyrene spheres is added and an ultrasonic treatment is carried out for 1h-4h; 3, suction filtration of a dispersion liquid of an expanded graphite-polystyrene compound system is carried out directly on foamed nickel, drying at 40-60 DEG C for 12-18h, the foamed nickel loaded with expanded graphite-polystyrene is placed in a mixed solution of hydrazine hydrate and ammonia with the volume ratio of hydrazine hydrate to ammonia being 1:5-1:10 so as to react at 90-95 DEG C for 1-3h, deionized water is used for immersion and washing, and drying is carried out; and 4, the temperature rises to 450-500 DEG C at the heating rate of 1-2 DEG C / min under a vacuum condition, and thermal insulation is carried out for 1-2h, and a finished product is taken out finally. The prepared material has a three-dimensional flocculent structure similar to a pore structure, has excellent conductivity and can be used to greatly reduce internal resistance of a capacitor and improve capacitive performance of an electrode active material. The preparation method is suitable for large-scale production of graphene.

Owner:安徽省泰达创投科技有限公司

Preparation method for hollow hemispherical titanium dioxide

ActiveCN106082317ALarge specific surface areaImprove photocatalytic performancePhysical/chemical process catalystsTitanium dioxideMicrosphereEmulsion polymerization

The invention provides a preparation method for hollow hemispherical titanium dioxide. The preparation method comprises the following steps: with a nanometer polystyrene sphere synthesized by using a soap-free emulsion polymerization method as a template, coating the surface of the polystyrene microsphere with a titanium dioxide shell layer by using a mixed solvent method; carrying out centrifugal cleaning and drying so as to obtain a titanium dioxide-coated polystyrene core-shell microsphere; subjecting the titanium dioxide-coated polystyrene core-shell microsphere to high-temperature calcination so as to allow polystyrene to be fused and decomposed, wherein the shell part of titanium dioxide collapses to form a semispherical structure and the hollow hemispherical titanium dioxide with excellent photocatalysis performance is obtained. The method provided by the invention can realize controllable adjustment of the size and thickness of titanium dioxide hemispheres, and is simple to operate and easy to realize large-scale production; and the prepared hollow hemispherical titanium dioxide has the characteristics of a large specific surface area, low density and excellent photocatalysis performance.

Owner:SHAANXI UNIV OF SCI & TECH

High-strength and high-aluminum light heat-insulation and fire-resistant brick and production method thereof

The invention relates to a high-strength and high-aluminum light heat-insulation and fire-resistant brick, which is used in a heat-insulation layer in thermal equipment, and a production method thereof. The fire-resistant brick includes following basic raw materials: 30-35% of a high-aluminum alumina clinker, 10-20% of an expansion agent and 45-55% of a bonding agent and additionally includes 0.1-0.15% of engineering fibers and 0.15-0.2% of a water reducer on the basis of the total amount of the basic raw materials above. In addition, each ton of the basic raw materials is added with 0.7-2.0 m<3> of expandable polystyrene spheres. The bonding agent is kaolin or high-aluminum alumina cement and is 200-320 meshes in granularity. The production method includes the steps of stirring the raw materials to form a sludge material, preparing the sludge material into green bricks, drying the green bricks, and sintering the green bricks at 1350-1400 DEG C with heat insulation. The fire-resistant brick is high in pressure resistance strength, is low in heat conductivity and is low in change rate of a high temperature reburning curve. The normal-temperature pressure resistance strength of the fire-resistant brick is higher than that of a common fire-resistant brick by more than two times. The fire-resistant brick can be used in a heat insulation layer and a fireproof layer in all thermal equipment, achieves both energy-saving and fireproofing effects and is beneficial to popularization.

Owner:郑州东方炉衬材料有限公司

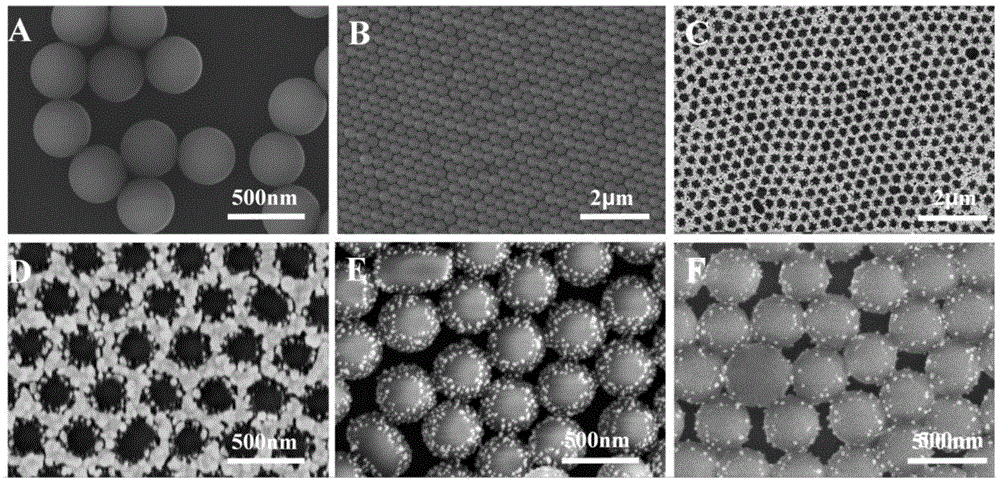

Gold-sliver alloy two-dimensional ordered nano film prepared by in-situ interface transformation and method for preparing gold-sliver alloy two-dimensional ordered nano film

InactiveCN105543817ALarge specific surface areaImprove permeabilityTransportation and packagingMetal-working apparatusAlloyTwo step

The invention relates to a gold-sliver alloy two-dimensional ordered nano film prepared by in-situ interface transformation and a method for preparing the gold-sliver alloy two-dimensional ordered nano film. The method adopting a two-step transformation process comprises the following steps: by taking a single-layer polystyrene sphere self-assembled film as a template, preparing a polystyrene-silver nano net film with a controllable thickness by a gas slow release method; transferring the polystyrene-silver nano net film to a solution surface of a chloroauric acid and disodium hydrogen phosphate solution, and obtaining the gold-sliver alloy two-dimensional ordered nano film by carrying out in-situ replacement reaction; and finally, soaking the gold-sliver alloy two-dimensional ordered nano film to remove the polystyrene template. The synthetic method has the advantages of being simple, quick, gentle and low in energy consumption, and meets the requirements of green chemistry; the smallest constitutional unit of the prepared gold-sliver alloy two-dimensional ordered nano net film is a hollow gold-sliver alloy nano particle; and the film has the advantages of being great in specific surface area, good in permeability, low in density and the like, can be loaded on substrates of different types, has the advantages of being convenient to recycle, and easy to enlarge a product, and can be widely applied to the fields of photoelectrocatalysis, biosensing, biological medicine carrying and the like.

Owner:TONGJI UNIV

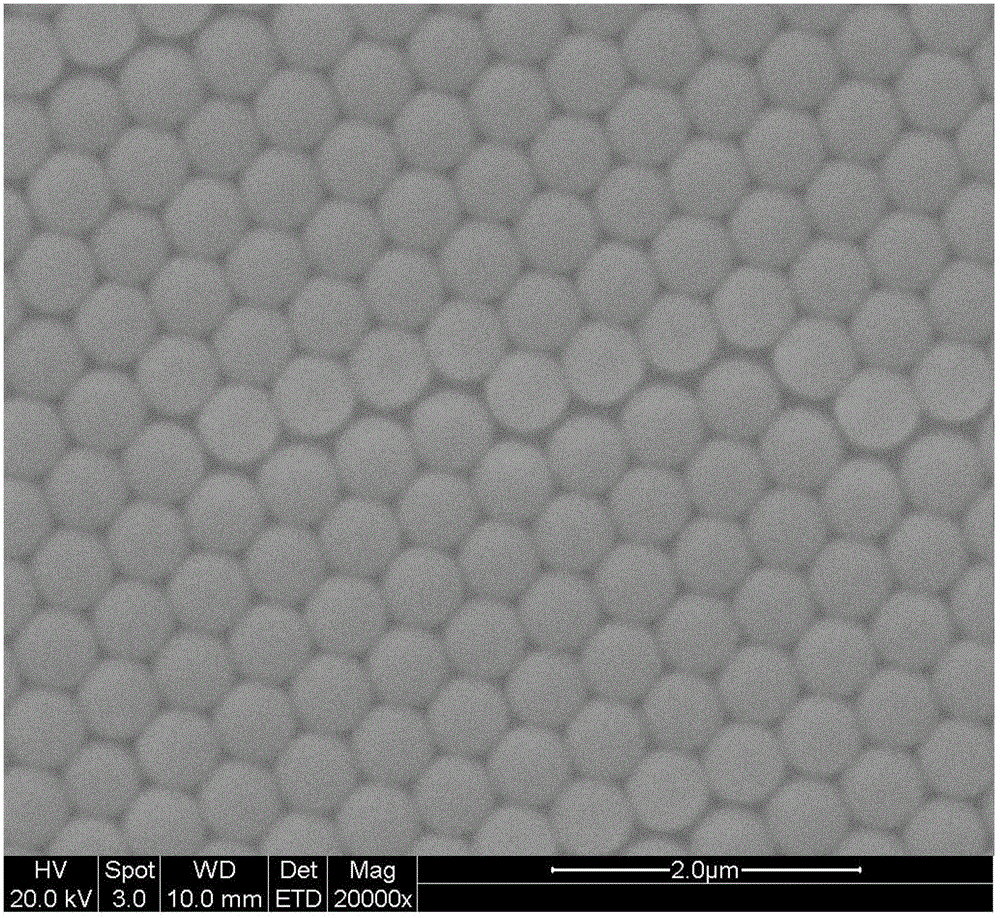

Process for manufacturing bionic gecko structure material

InactiveCN102718181ASimple equipment requirementsEasy to operateDecorative surface effectsChemical vapor deposition coatingMicro nanoPhotoresist

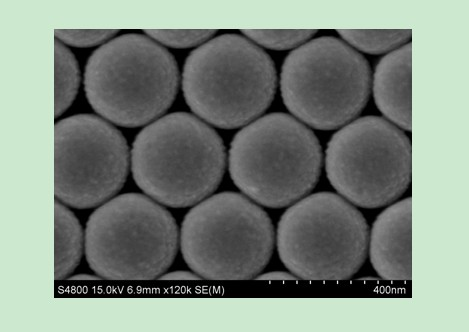

The invention belongs to a process for manufacturing a micro-nano bionic structure, and particularly relates to a process for manufacturing a bionic gecko foot structure material. The process comprises steps of (1) self-assembling polystyrene spheres with a diameter from 100 nanometers to 1 micrometer; (2) performing plasma etching on the polystyrene spheres; (3) plating a protective layer; (4) removing the polystyrene spheres; (5) plating a catalyst layer; (6) performing wet etching; (7) performing spin coating of photoresist and performing photoetching development; and (8) casting a mould and demoulding, pouring polydimethylsiloxane (PDMS) on a compound die, baking, and peeling off the PDMS from the compound die to obtain the nano-micro layered bionic gecko foot structure material. The process can be used for manufacturing a bionic gecko foot layered structure which has quite high absorbability, can be easily separated from an absorbed surface, and has super-hydrophobicity and self-cleaning ability.

Owner:HUAZHONG UNIV OF SCI & TECH

Prepn of silica with great specific surface area

The present invention relates to method of preparing silicon oxide material having high degree of order, large pore-mosopore dual pore and high specific surface area. Surfactant is used as structure guide agent combine with inorganic silicon material to assemble into ordered structure, and under the guide of new large pore template agent polystyrene ball, through sol-gel process to form into shape. Surfactant and polystyrene ball are rmoved under high temperature, thereby multigrade silicon oxide material with high degree of order and large pore mesopole is obtd. The invented multi grade porematerial can be extensively used in adsorption, separation, sensor, optical material etc.

Owner:FUDAN UNIV

Preparation method of zirconium oxide hollow spheres

The invention relates to the preparation technology of fire resistant materials and discloses a preparation method of zirconium oxide hollow spheres. The preparation method comprises the steps of: mixing a solid ceramic powder material with a solvent according to a certain proportion to prepare uniform and stable ceramic slurry; with polystyrene spheres as templates, fully soaking a plurality of the polystyrene spheres in the ceramic slurry; and enabling the ceramic slurry mixed with the polystyrene spheres to pass through a screen, filtering out excessive slurry, repeatedly covering the surfaces of the polystyrene spheres with the ceramic slurry, then drying the polystyrene spheres with the ceramic slurry of a certain thickness, removing plastics and sintering at a high temperature, wherein in the process of sintering at a high temperature, the polystyrene spheres are fully volatilized through high temperature combustion and hollow structures are left, so that the zirconium oxide ceramic hollow spheres are obtained. According to the preparation method of zirconium oxide hollow spheres, the problem of easy breakage of hollow spheres in the prior art is solved, and the sizes of the polystyrene spheres can be selected according to the sizes of the required hollow spheres; and the preparation method is simple in process and easy for industrial popularization.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Mullite light heat-insulation fire-resistant brick and production method thereof

ActiveCN104973869AReasonable ratioGood compatibilityCeramic shaping apparatusInsulation layerAluminium hydroxide

The invention relates to a mullite light heat-insulation fire-resistant brick and production method thereof. The fire-resistant brick includes following raw materials: 25-35% of aluminium hydroxide, 10-30% of flint clay clinker, 10-30% of kyanite, 35-50% of a bonding agent. With the raw materials, 1.0-2.0 m<3> of expandable polystyrene and 0.3-0.5 m<3> of sawdust are added. The bonding agent is kaolin or aluminum oxide cement. The fire-resistant brick is high in pressure resistance strength, is low in heat conductive coefficient, is low in change rate of a high-temperature re-burning curve and is good in thermal shock resistance, is excellent in performance and can reach the requirement of the standard of related products in American ASTM. By means of aluminium hydroxide for replacing aluminum oxide, the production method is low in energy consumption and cost, can generate more mullite crystal phases, can effectively reduce the content of a corundum phase in the product, and can increase the thermal shock resistance. The fire-resistant brick can be used in a heat insulation layer and a fireproof layer in all thermal equipment, achieves both energy-saving and fireproofing effects and is beneficial to popularization.

Owner:郑州东方炉衬材料有限公司

Preparation method of mesoporous carbon sphere material

InactiveCN103848413ASimple manufacturing methodLow costCarbon preparation/purificationCarbon sourcePolystyrene spheres

The invention provides a preparation method of a mesoporous carbon sphere material. The preparation method comprises the following steps: dissolving polystyrene spheres in water or an organic solvent; under an ultrasonic condition, adding a carbon source into suspension liquid obtained in the step, and continuously carrying out ultrasonic treatment for at least 0.5 hour-6 hours; separating solids; and preparing the mesoporous carbon sphere material by a high-temperature roasting method under an inert atmosphere, wherein a weight ratio of the polystyrene spheres to the carbon source is 1:(50-100), and a volume ratio of the polystyrene spheres to water or the organic solvent is 1:(500-1000). The preparation method is simple and easy to carry out and low in cost, realizes dispersion of a template and polymerization of a carbon source under an ultrasonic condition, is free of heating and stirring, free of an oxidant or a catalyst, time-saving and labor-saving; under protection of inert gases, a carbon precursor is carbonized to obtain hollow mesoporous carbon spheres while the template is removed by high temperature; the template is removed without extra steps, and therefore, the preparation method is simple and easy to carry out, and avoids pollution at the same time.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

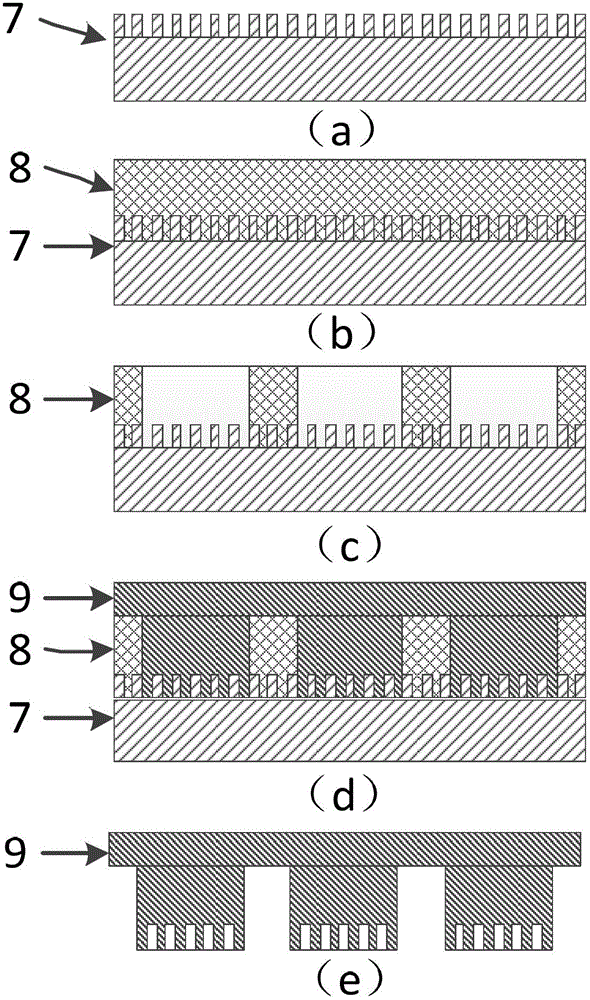

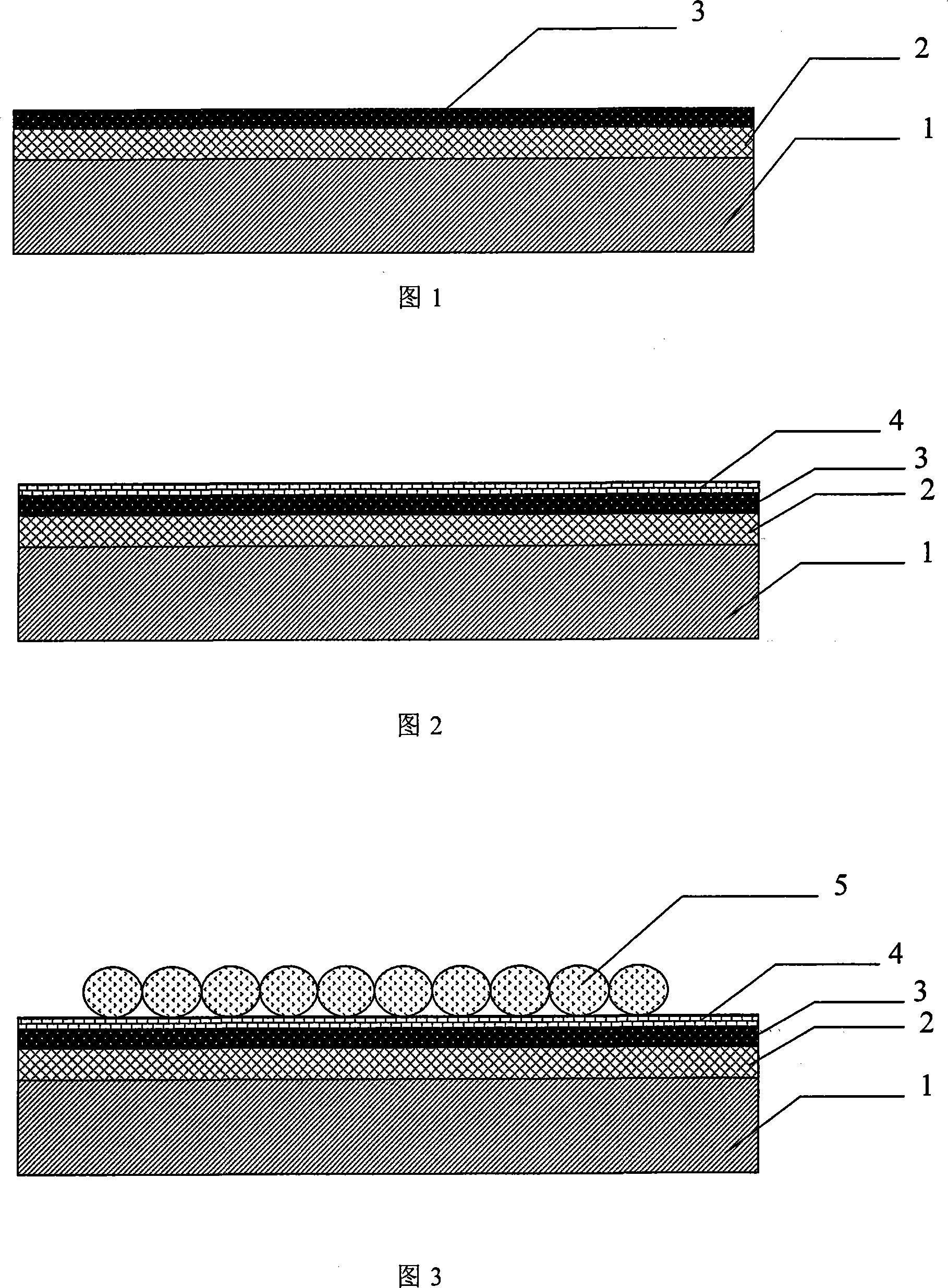

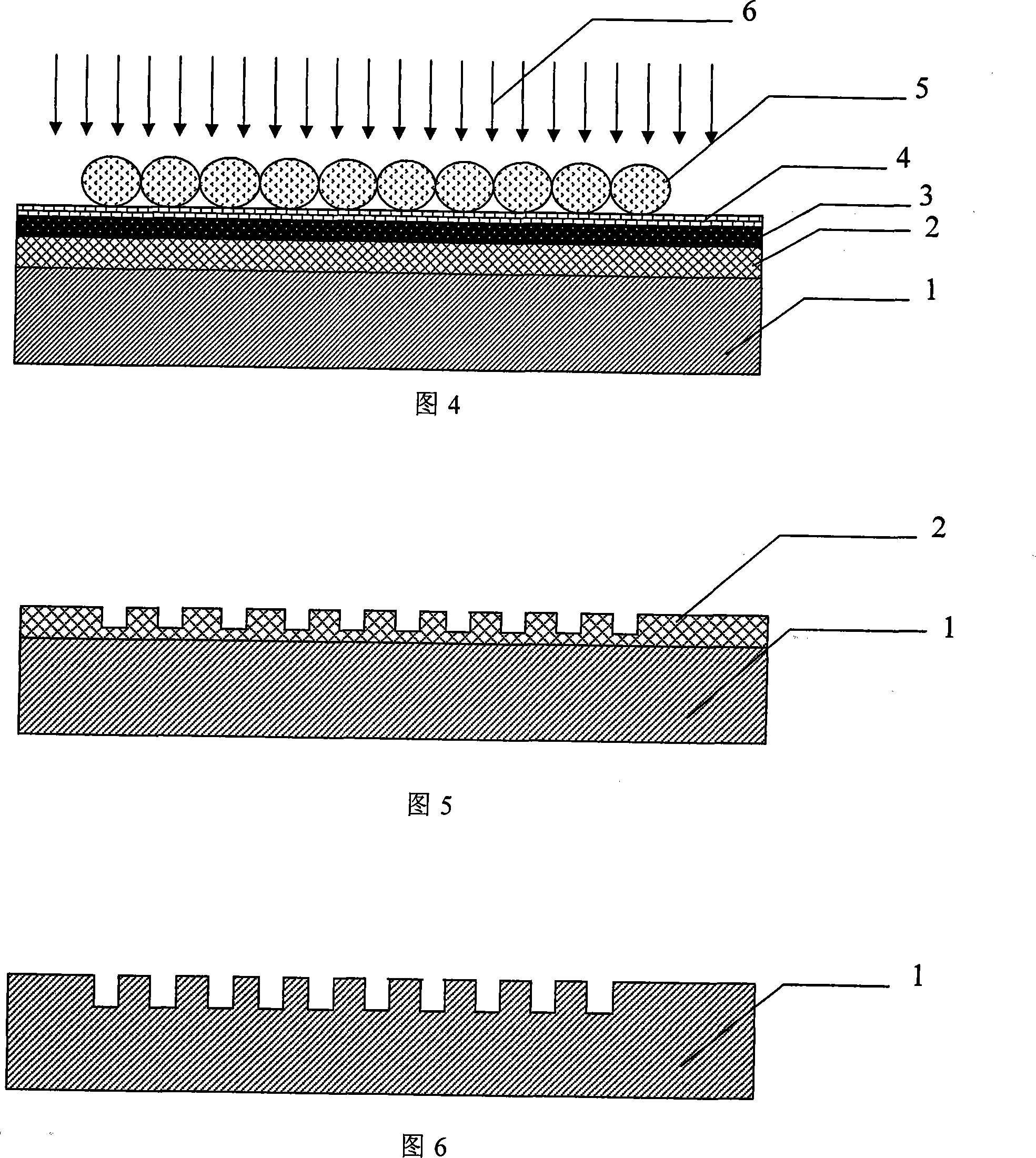

Sub-wavelength micro-nano structure using polystyrol ball to focused photoetching form

InactiveCN101158809AOvercome the problems of large caliber and small numerical apertureShorten the overall cycleDecorative surface effectsPhotomechanical apparatusResistMicro nano

The present invention provides a production method used for focusing lithography forming sub-wavelength micro-nanostructure of polystyrene sphere, and is characterized in that: surface of substrate material firstly selected is sequentially in a spinning manner coated with a layer of anti-corrosion agent, evaporated with a layer of metal structure, then in a spinning manner coated with a layer of interval layer, and finally assembled with a layer of the polystyrene sphere. The structure is exposed in exposure system, then the polystyrene sphere, the interval layer and the metal layer structure are removed, the substrate is positioned into developing agent for development and obtainment of target structure, and finally the structure is transmitted to the substrate by etch of the target structure. The present invention adopts the polystyrene sphere as a focusing lens, further reduces the cycle and dimension of the lens, has stimulation of surface plasma inside the metal in the focusing and exposure as the metal structure is evaporated on the surface of the exposed anti-corrosion agent, improves resolution of a focusing focal spot, reduces the characteristic size of the forming targeted structure, and provides an effective method for the production of the sub-wavelength micro-nanostructure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

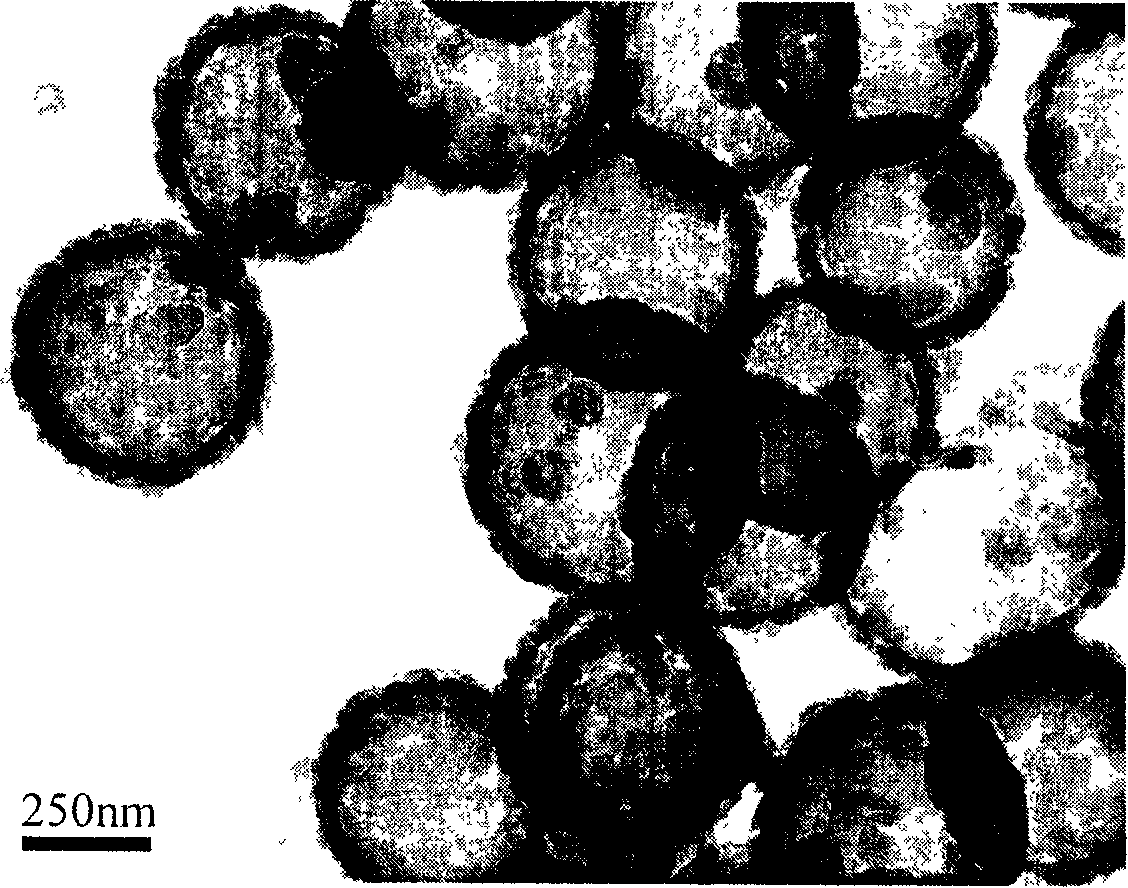

Method for producing size-controllable magnetic hollow spheres

InactiveCN101444712AReduce usageSimple stepsMicroballoon preparationMicrocapsule preparationDrug targetSodium hydroxide

A method for producing size-controllable magnetic hollow spheres belongs to the technical field of magnetic materials. The method is characterized in that a monodisperse polystyrene sphere prepared by adopting the emulsion-polymerization method and dispersion-polymerization method is used as a template; inorganic metallic salts conduct coprecipitation under the action of a precipitating agent, namely sodium hydroxide, in a water solution; a ferrite precursor for coating the polystyrene sphere is formed by the deposition on the surface of the template sphere; and during the calcining process at the high-temperature, the ferrite precursor conducts the crystal transformation when the macromolecular spherical template decomposes, so that the polystyrene sphere coated with the ferrite precursor is converted into a corresponding magnetic hollow sphere. The method has the advantages of simple and convenient operation, favorable popularization and environmental friendliness. The magnetic hollow sphere prepared by adopting the method possesses a regulated and monodispersed hollow spherical structure and different magnetic properties, meets the requirement of different practical applications, and illustrates a good prospect of application in the fields, such as the separation science, the drug targeting preparation, the material science, the coating industry, and the like.

Owner:BEIJING UNIV OF CHEM TECH

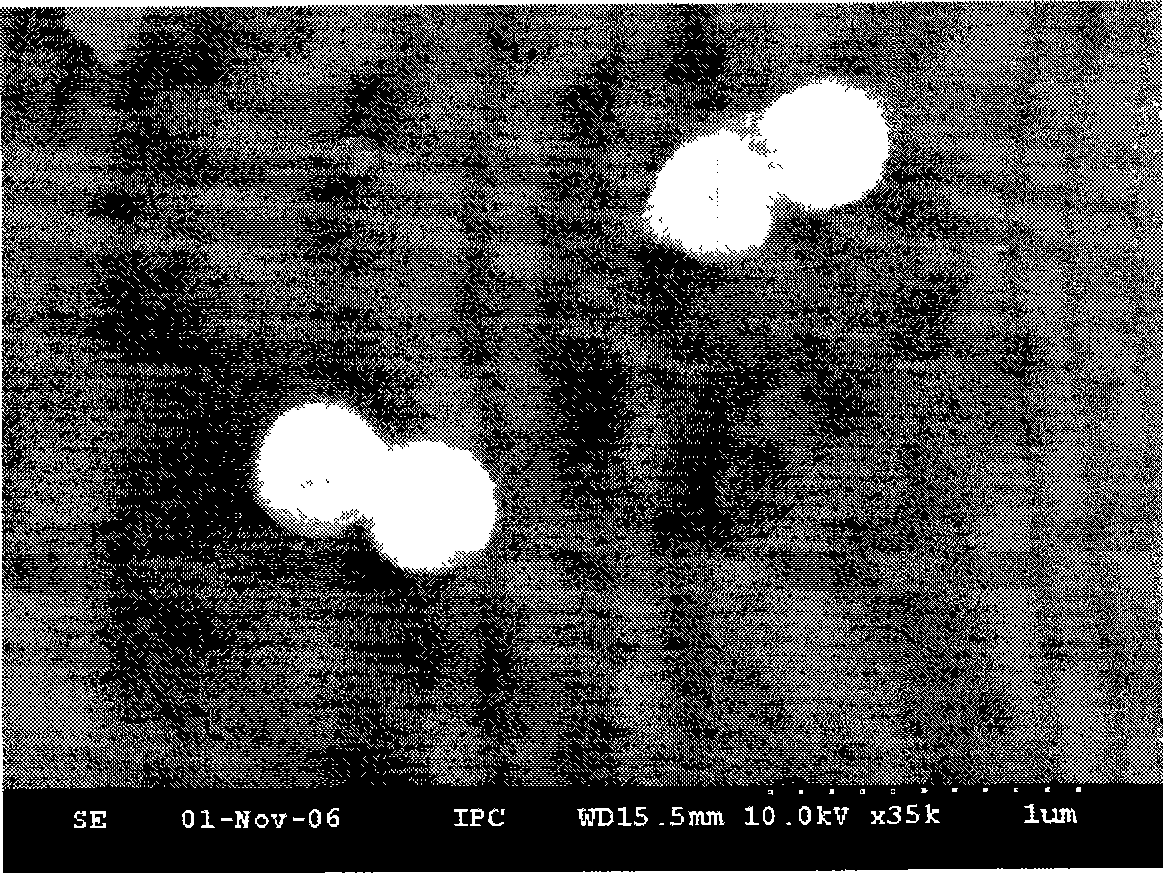

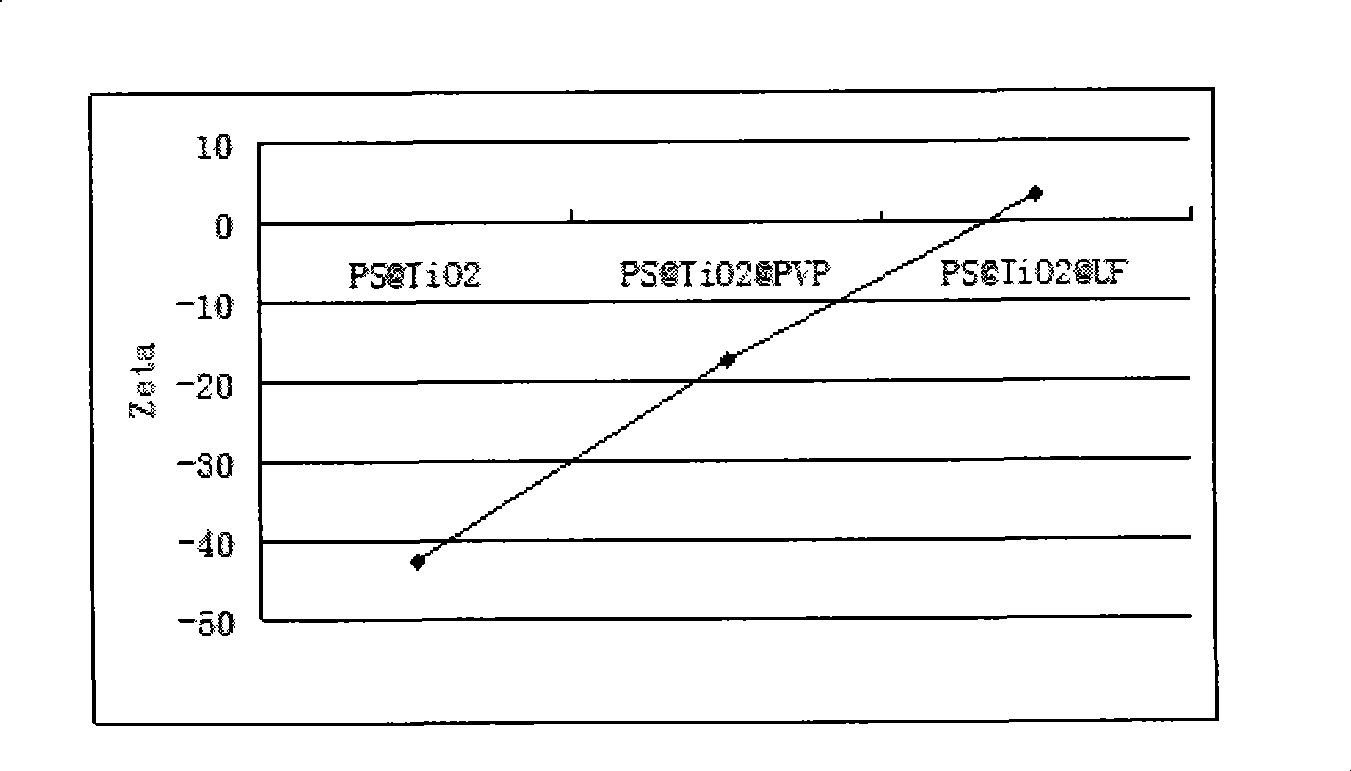

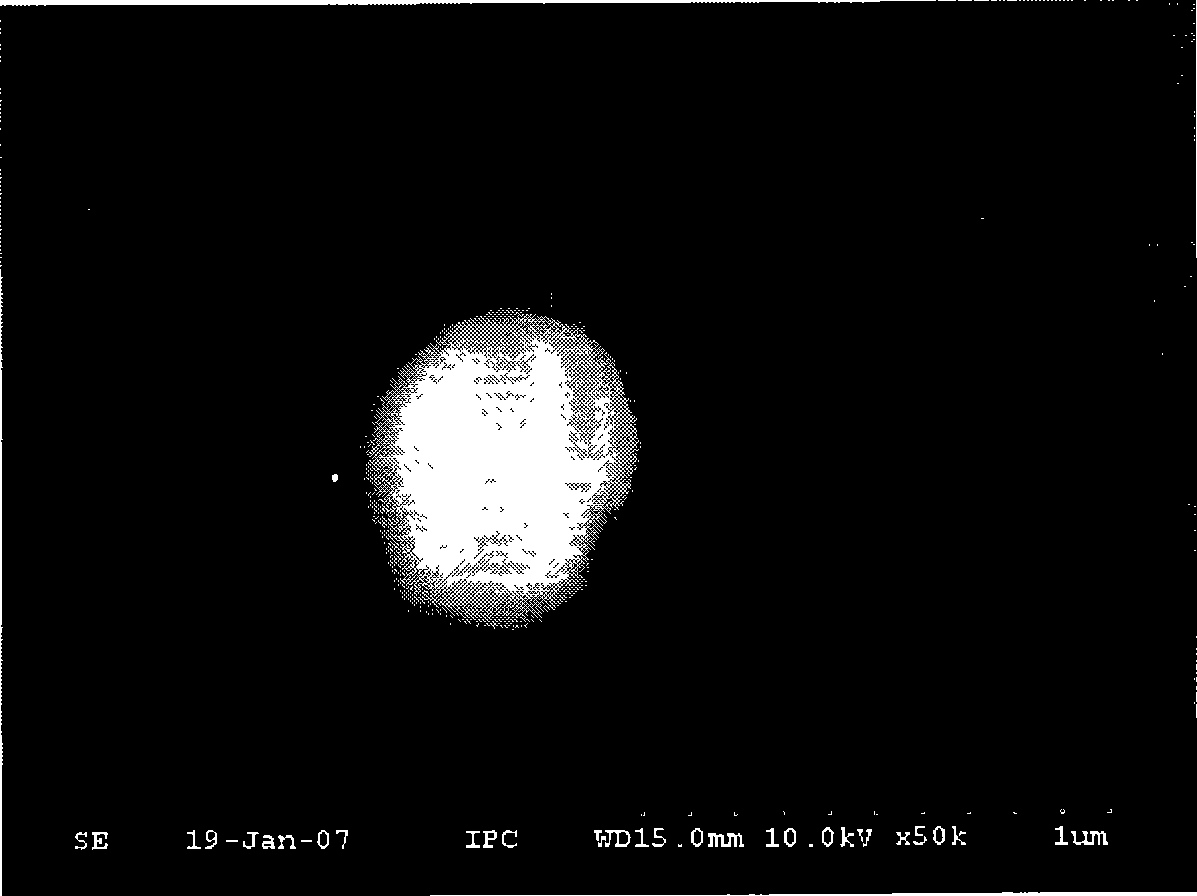

Quasi uncharged solvent resistance complex function ball and method for making same

InactiveCN101387808ASolve instabilitySynthetic resin layered productsCoatingsIn situ polymerizationResin coating

The invention relates to a similar no-electric solvent resistance composite functional ball, in particular to a urea-formaldehyde resin coating polystyrene ball / titanium dioxide nanometer particle. The similar no-electric solvent resistance composite functional ball is urea-formaldehyde resin coating polystyrene ball / titanium dioxide nanometer particle. The preparation method comprises: using polyvinylpyrrolidone or silane coupler to modify polystyrene ball / titanium dioxide nanometer particle; using in-situ polymerization to condensate urea-formaldehyde prepolymer on the surface of the nanometer particle to form dense and transparent similar no-electric urea-formaldehyde resin coat, to obtain solvent resistance particles. The similar no-electric solvent resistance composite functional ball is matched with disperse mediums and can resist the corrosion of non-polar solvent, to stabilize the particles in the solvent and overcome the defects caused by using dyes, thereby providing a base for stabilizing two dyes of different colors in electrophoretic liquid to realize bistability display.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing lightweight mullite refractory by high-alumina fly ash

The invention relates to a method for preparing a lightweight mullite refractory by high-alumina fly ash and relates to the technical fields of solid waste comprehensive utilization and refractories. According to the method, waste from a power plant, namely high-alumina fly ash, is used as a raw material; commercial alumina is added according to the composition design; the mixture is fired and crushed to prepare lightweight mullite aggregate and lightweight fine powder, with different granularities; then silicon dioxide fine powder is additionally added; polystyrene spheres or sawdust is used as a pore-forming agent, aluminate cement is used as a gelling agent, and sodium hexametaphosphate is used as a water reducer; the lightweight mullite refractory is prepared through the processes such as forming by vibration pouring, curing, drying and sintering. The main high-temperature-resistant phase of the lightweight refractory is mullite phase and corundum phase; the lightweight mullite refractory comprises the main chemical constituents: 55.0-70.0 wt% of Al2O3, 25.0-40.0 wt% of SiO2 and 0-5.0 wt% of other impurities. Compared with the prior art, the method has the characteristics of wide raw material source, low production cost, low energy consumption, high mullite content, high performance, long service life, and simple operation in the preparation process; significant economic and environmental benefits can be generated.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

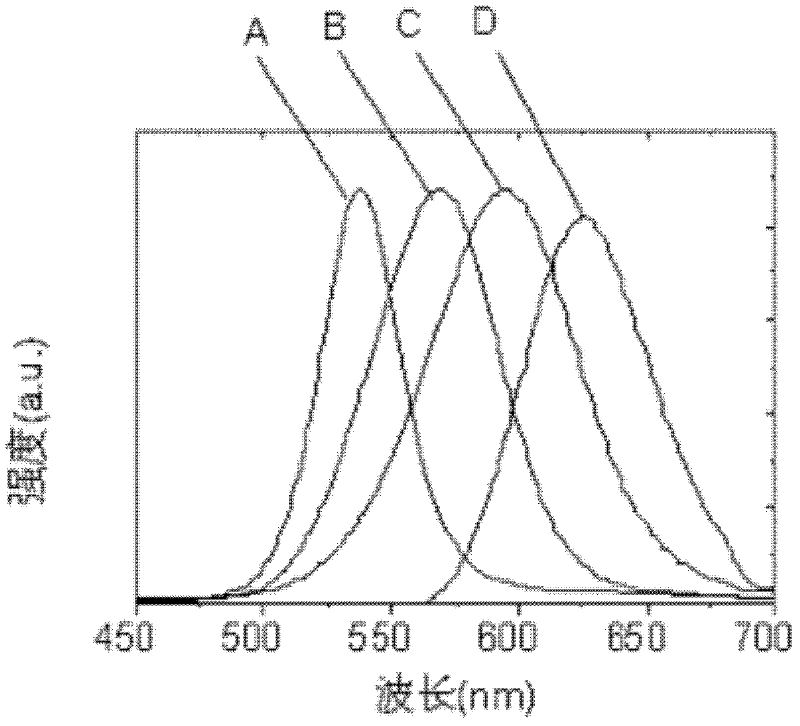

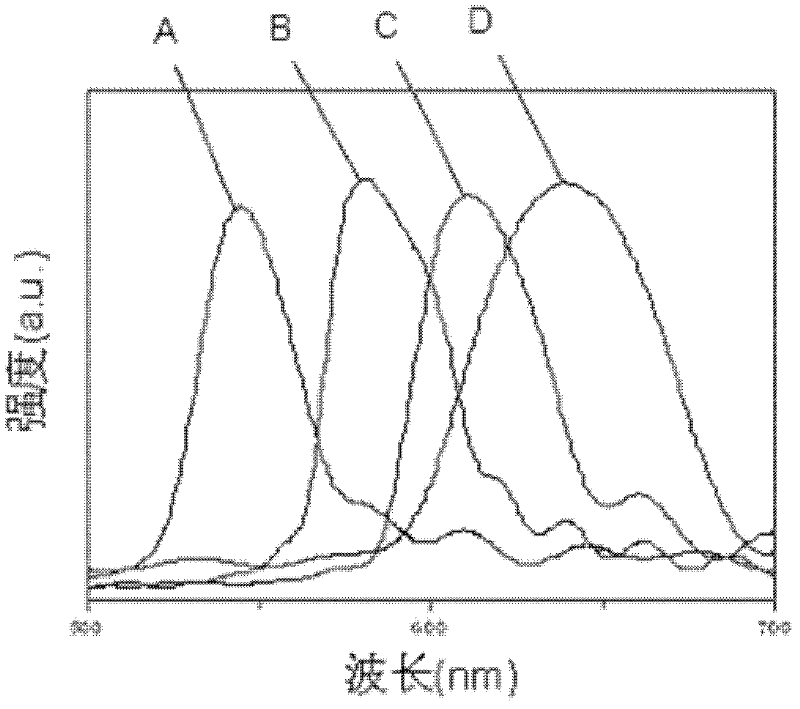

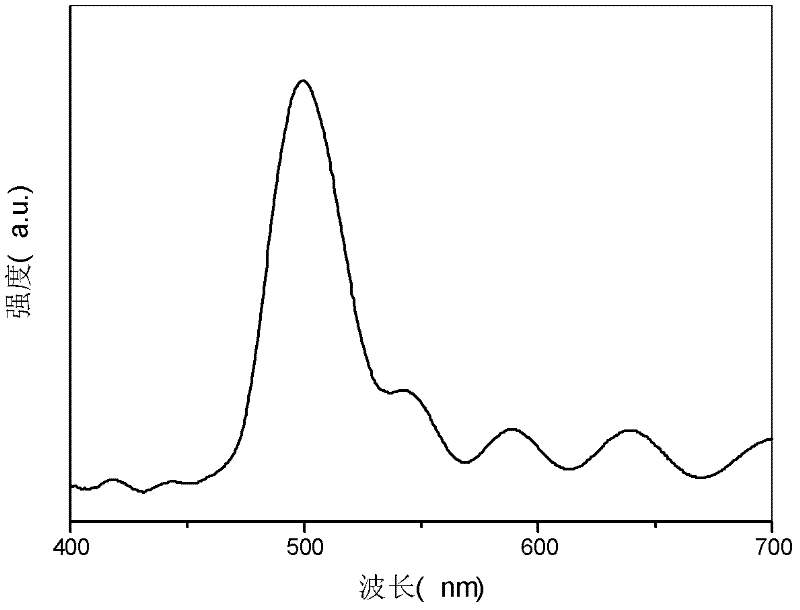

Method for preparing shell fluorescent microsphere

InactiveCN102600773ASmall particle sizeControl thicknessLuminescent compositionsMicroballoon preparationEmulsionPhotonic crystal

The invention relates to a method for preparing a shell fluorescent microsphere, relates to the preparation method of a fluorescent microsphere, and mainly aims to solve the problems that the diameter of a photonic crystal microsphere of the existing silicon dioxide shell is not uniform, and the size of the photonic crystal microsphere of the existing silicon dioxide shell is difficult to regulate. The method for preparing the shell fluorescent microsphere comprises the following steps of: firstly synthesizing CdTe quantum dots with different diameters through an aqueous phase method, preparing polystyrene spheres with different diameters by utilizing a soap-free emulsion method, coating the quantum dots with the different diameters in a SiO2 grain by taking the polystyrene spheres with the different diameters as seeds, finally dissolving SiO2 microspheres coated with the quantum points by taking the polystyrene spheres as seeds or calcining to remove the polystyrene spheres, namely obtaining PS@SiO2&CdTe fluorescent microspheres. According to the method for preparing the shell fluorescent microsphere, disclosed by the invention, the condition is simple and easily controlled, and the prepared fluorescent microsphere has excellent chemical stability and stronger fluorescence characteristic, controllable size and uniform diameter. The method for preparing the shell fluorescent microsphere is applied to the field of preparation of the shell fluorescent microsphere.

Owner:HEILONGJIANG UNIV

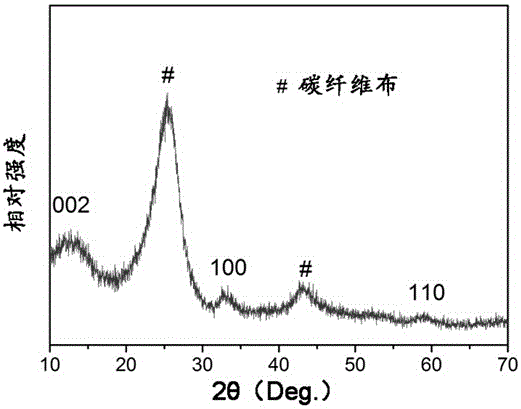

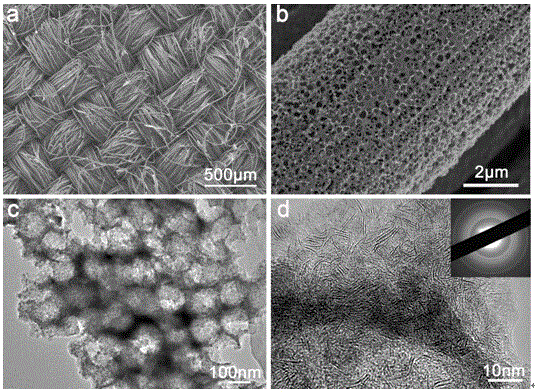

Three-dimensional ordered macroporous molybdenum disulfide/carbon composite flexible electrode material and preparation method and application thereof

ActiveCN106684386AImprove electrochemical performanceRelieve redepositionCell electrodesCarbon compositesCarbonization

The invention discloses a preparation method and application of a three-dimensional ordered macroporous molybdenum disulfide / carbon composite flexible electrode. Through an amine compound solution for processing carbon cloth, the carbon cloth has positive charges and then is impregnated in an aqueous solution composed of polystyrene spheres with negative charges, a molybdenum source and a carbon source precursor; and during the subsequent calcining process, through matching generating rate of molybdenum disulfide and carbonization rate of the precursor, assembling of a three-dimensional ordered macroporous molybdenum disulfide / carbon embedded structure composite material on the carbon cloth is realized. The prepared electrodes combines high-performance electrode material, flexibility and integrated design without the need of using inactive substances such as a binder, a conductive agent, etc., remarkably enhances utilization rate of active substances, shows excellent electrochemical lithium storage capacity, and is expected to be applied in the field of flexible electronics, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com