Quasi uncharged solvent resistance complex function ball and method for making same

A composite function and solvent-resistant technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems such as instability of electrophoretic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of polystyrene / titanium dioxide nanoparticles: prepared according to Chinese invention patent 200610011885.0;

[0032] (2) Disperse 2g of polystyrene / titanium dioxide nanoparticles obtained in step (1) into 1000mL of deionized water dissolved with 5g of PVP (MW=400000);

[0033] (3) 40g urea and 49mL formaldehyde are mixed to obtain a prepolymer;

[0034] Dilute 200ml of the polystyrene / titanium dioxide nano light sphere solution obtained in step (2) to a certain volume, add 20ml of prepolymer, adjust the pH value to 1 with HCl, polycondense at 15°C, and then solidify at 75°C. Centrifugal washing;

[0035] (4) Stability study: The obtained urea-formaldehyde resin-coated particles were dispersed in non-polar solvents (halogenated alkanes, aromatic compounds, fluorine-containing compounds, alkanes), and they could still be dispersed well after being left for a long time.

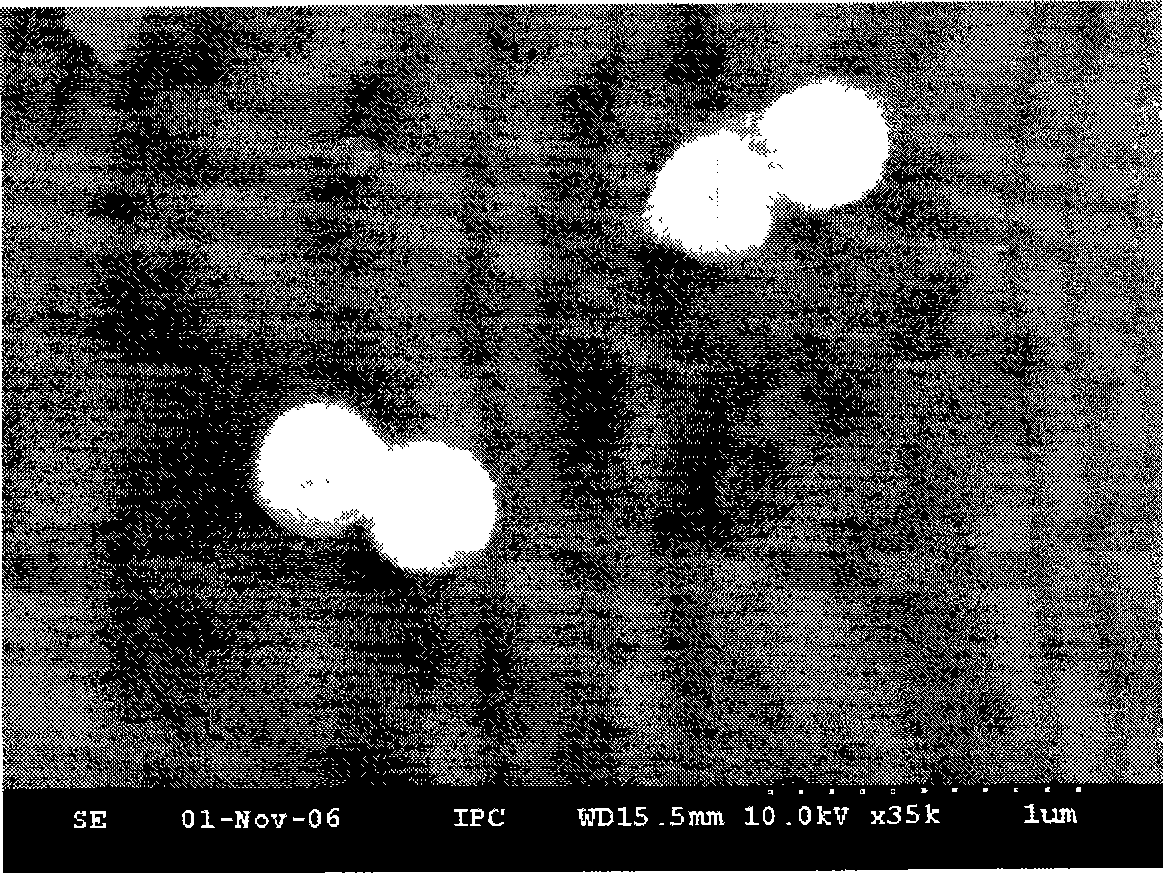

[0036] figure 1 A photo of polystyrene spheres / titanium dioxide nanoparticles / ure...

Embodiment 2

[0038] (1) Preparation of polystyrene / titanium dioxide nanoparticles: prepared according to Chinese invention patent 200610011885.0;

[0039] (2) 2g of polystyrene / titanium dioxide nanoparticles obtained in step (1) were dispersed into 1000mL of deionized water dissolved with 200g of PVP (MW=2000);

[0040] (3) 40g urea is mixed with 147mL formaldehyde to obtain prepolymer;

[0041] Dilute 280mL of the polystyrene / titanium dioxide nano-light sphere solution obtained in step (2) to a certain volume, add 40mL of prepolymer, adjust the pH value to 6 with sulfuric acid, polycondense at 55°C, and then solidify at 80°C. Centrifugal washing;

[0042] (4) Stability study: The obtained urea-formaldehyde resin-coated particles were dispersed in non-polar solvents (halogenated alkanes, aromatic compounds, fluorine-containing compounds, alkanes), and they could still be dispersed well after being left for a long time.

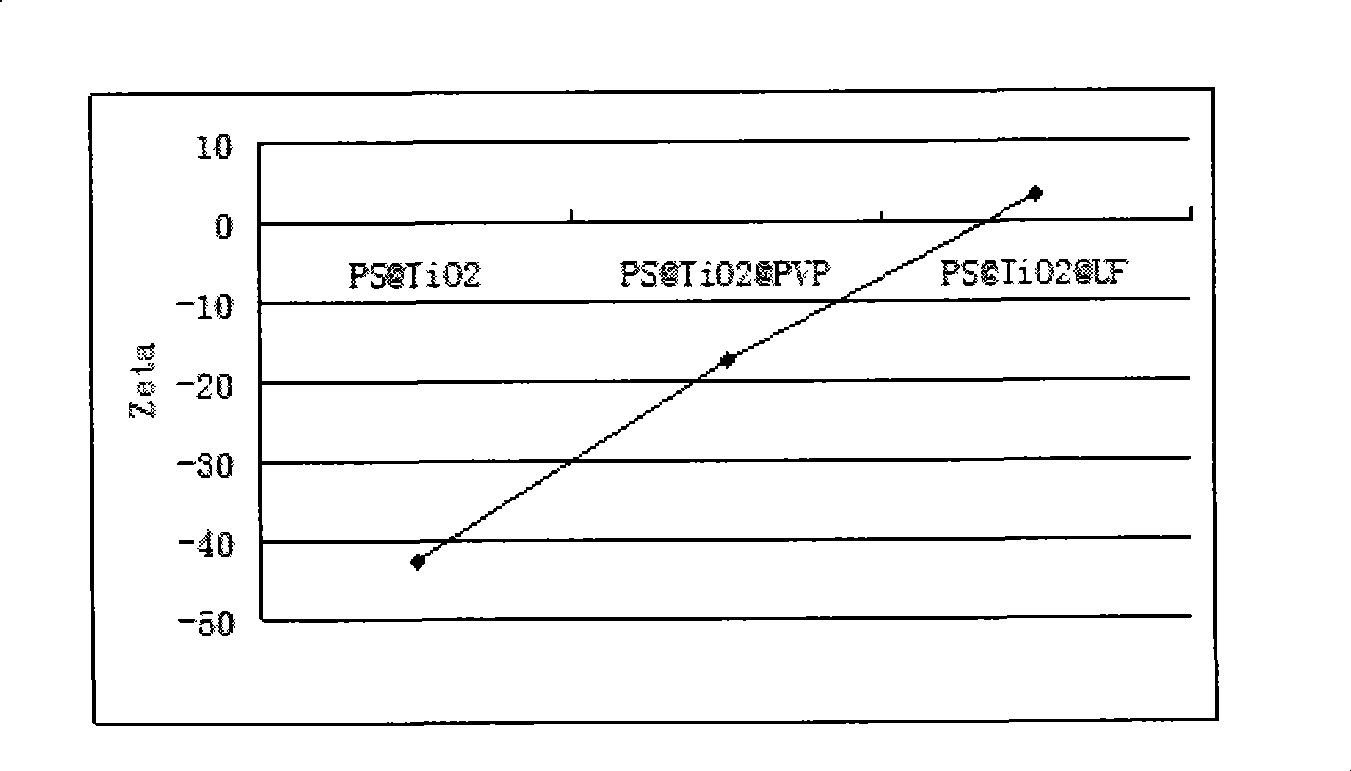

[0043] figure 2 For the Zeta change map.

Embodiment 3

[0045] (1) Preparation of polystyrene / titanium dioxide nanoparticles: prepared according to Chinese invention patent 200610011885.0;

[0046](2) 2g of polystyrene / titanium dioxide nanoparticles obtained in step (1) were dispersed into 1000mL of deionized water dissolved with 50g of PVP (MW=55000);

[0047] (3) 40g urea is mixed with 86mL formaldehyde to obtain prepolymer;

[0048] Dilute 200 mL of the polystyrene / titanium dioxide nano-light sphere solution obtained in step (2) to a certain volume, add 8 mL of prepolymer, adjust the pH value to 3 with HCl, polycondense at 30°C, solidify at 55°C, and centrifuge washing;

[0049] (4) Stability study: The obtained urea-formaldehyde resin-coated particles were dispersed in non-polar solvents (halogenated alkanes, aromatic compounds, fluorine-containing compounds, alkanes), and they could still be dispersed well after being left for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com