Solar and industrial waste heat cogeneration system

An industrial waste heat and combined power generation technology, applied in the field of Rankine cycle system, can solve the problems such as the equipment capacity is not fully utilized, the unit cannot reach the designed power generation capacity, and the cost of heat storage equipment is high, so as to avoid complexity and large equipment. performance, good matching, and the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

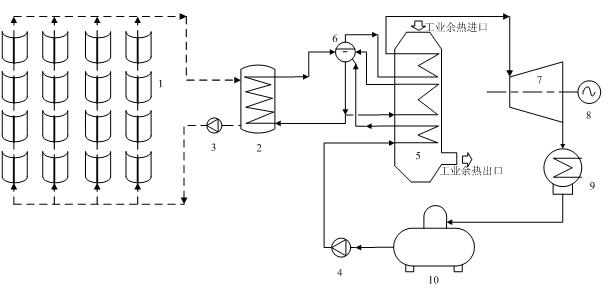

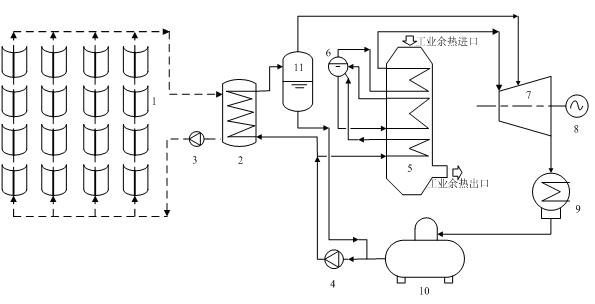

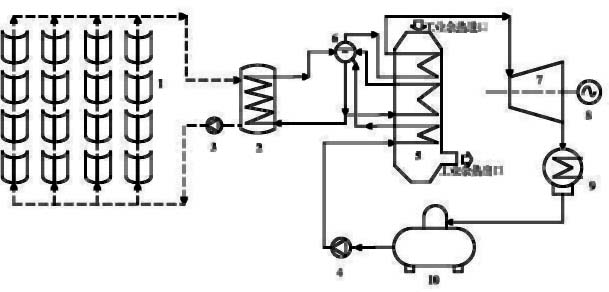

[0012] Further description will be given below with reference to the drawings and embodiments.

[0013] The solar energy and industrial waste heat combined power generation system in the present invention refers to a Rankine cycle power generation system at medium and low temperature.

[0014] As shown in the figure, the solar heat collector 1, the intermediate heat exchanger 2 and the working fluid pump 3 form a cycle. The heat carrier absorbs solar energy in the solar heat collector 1, and the temperature rises to become a high temperature heat carrier. After the heat in the intermediate heat exchanger 2 is transferred to the working medium, its temperature is lowered, and then it is boosted by the working medium pump 3 and then enters the solar heat collector 1 to absorb heat again. Among them, the solar thermal collector 1 can be a trough solar thermal collector or a tower solar thermal field or a combination of the two. The heat carrier can be heat conducting oil or water, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com