Grouting reinforcement device and method for shallow clay

A technology of grouting reinforcement and clay, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as poor stabilization effect and troublesome operation, achieve good grouting pressure and solve unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

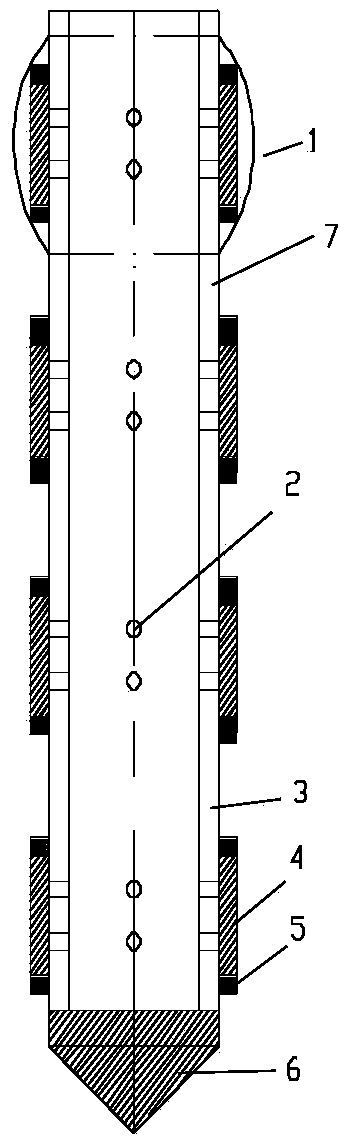

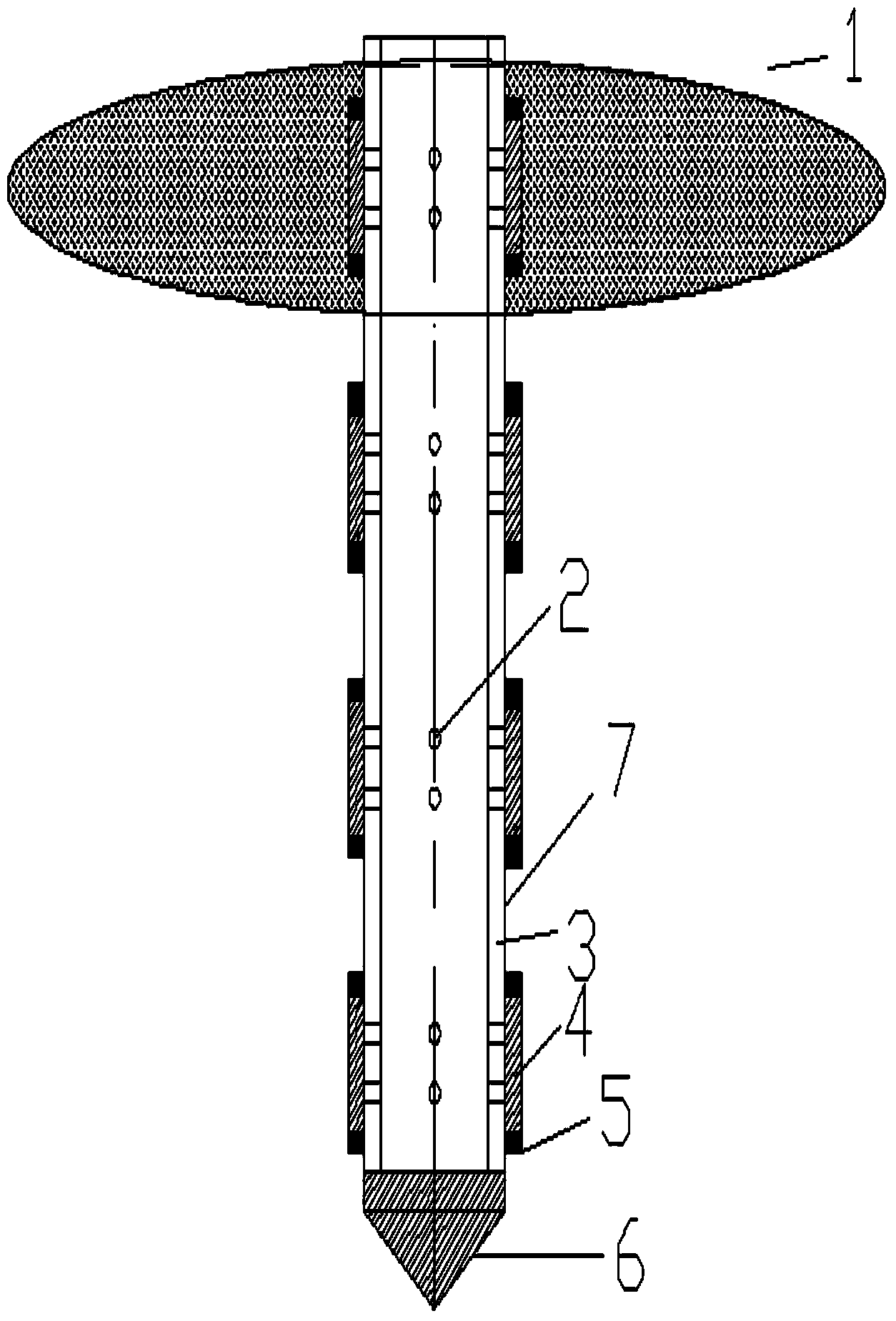

[0024] Such as figure 1 As shown, a shallow clay grouting reinforcement device includes two parts, a mold bag 1 and a sleeve valve tube. The sleeve valve tube consists of a galvanized grouting inner tube 3, a PVC outer tube 7, a grout hole 2, a rubber sleeve 4, The positioning ring 5 and the lower cover 6 are composed of the galvanized grouting inner pipe 3 and the PVC outer pipe 7, and the galvanized grouting inner pipe 3 is provided with a grout overflow hole 2. The outer ring suit of pipe 7 is provided with some rubber sheaths 4, and the upper and lower sides of rubber sheaths 4 are provided with positioning rings 5, and the bottom of galvanized pipe 3 is provided with a lower boring cover 6.

[0025] The PVC outer pipe collects the grout from the grouting inner pipe, so that the grout flows out from the set position, realizing segmental grouting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Suture strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com