Direct electrochemical process of preparing ferrate

A ferrate, electrochemical technology, applied in the electrolysis process, electrolysis components, etc., can solve problems affecting product costs and market potential, and achieve the effects of improving electrolysis efficiency, reducing preparation costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

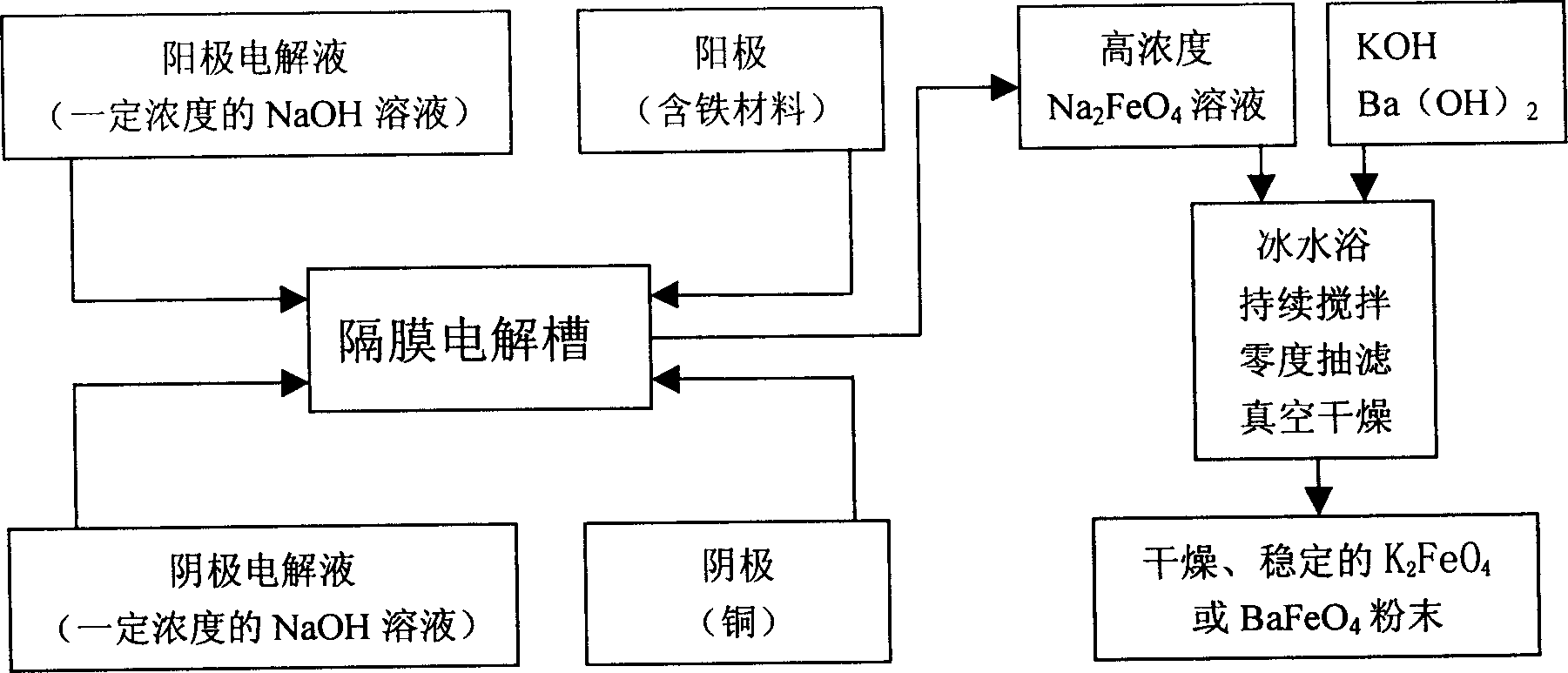

AI Technical Summary

Problems solved by technology

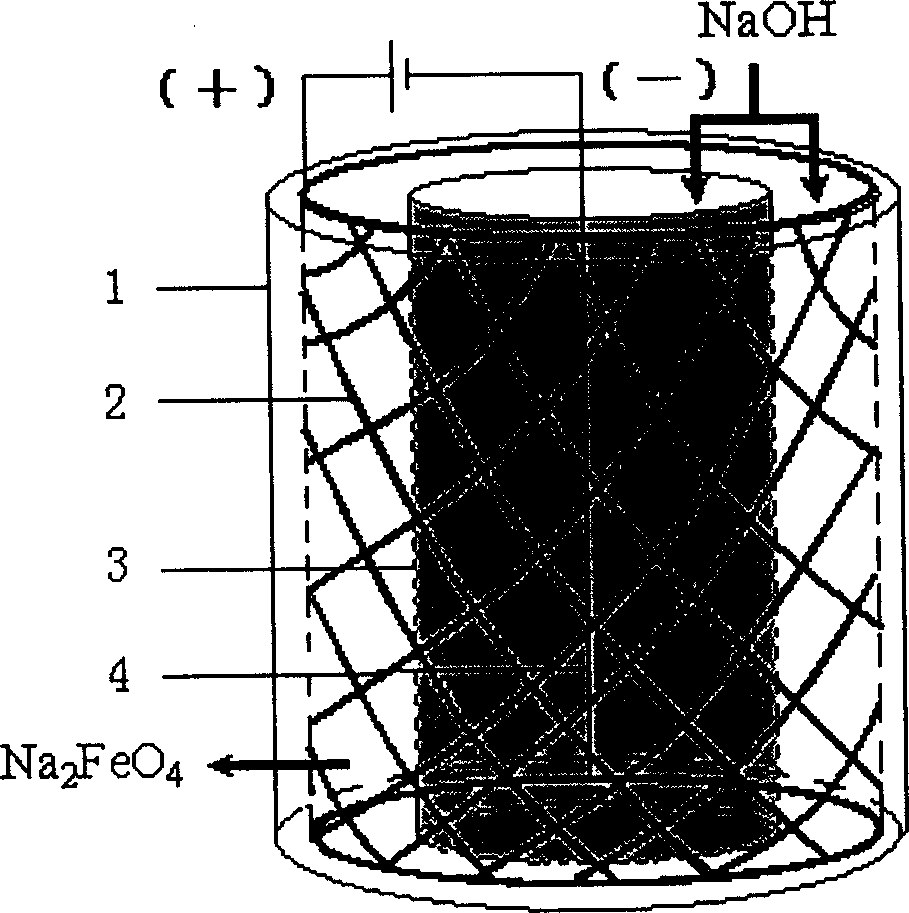

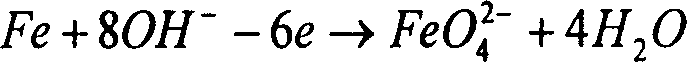

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the NaOH solution of preparation 16mol / L is anolyte, and the NaOH solution of 2mol / L is catholyte, and control electrolyte temperature is at 40 ℃, and applied voltage is 8.5V, obtains sodium ferrate concentration after electrolysis 69min is 22.14g / L.

Embodiment 2

[0026] Embodiment 2, the NaOH solution of preparation 15mol / L is anolyte, and the NaOH solution of 2mol / L is catholyte, and control electrolyte temperature is at 40 ℃, and applied voltage is 10.8V, obtains sodium ferrate concentration after electrolysis 60min is 22.99g / L.

Embodiment 3

[0027] Embodiment 3, the NaOH solution of preparation 15mol / L is anolyte, the NaOH solution of 2mol / L is catholyte, controls electrolyte temperature at 35 ℃, and applied voltage is 8.5V, obtains sodium ferrate concentration after electrolysis 70min is 18.66g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com