Anode horizontal height-finding system with radio comparing base as platform

An anode and platform technology, applied in signal transmission systems, measuring devices, instruments, etc., can solve problems such as large errors and low anode efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

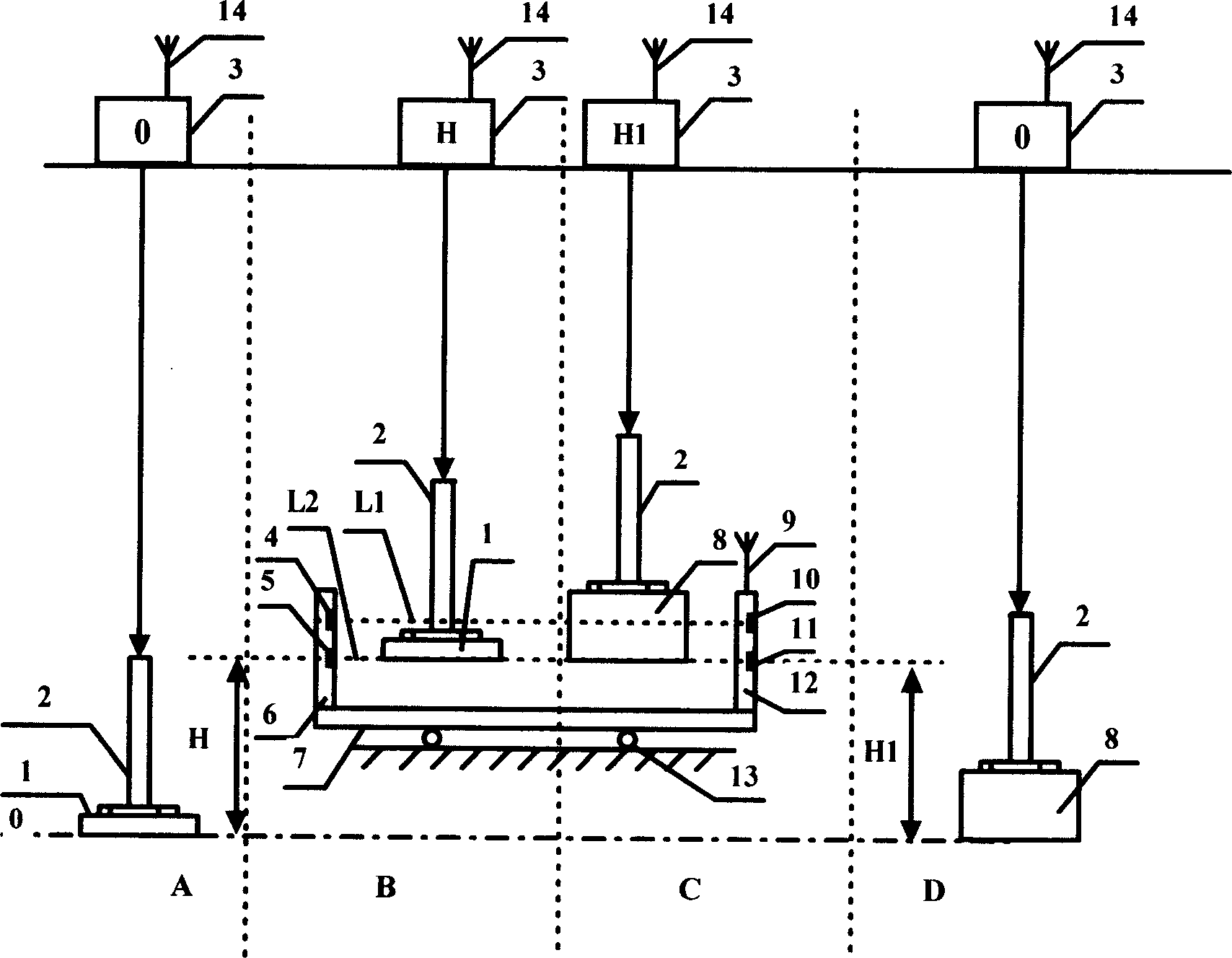

[0012] Depend on figure 1 It can be seen from the schematic diagram of the system structure of the present invention that in the replacement of the old and new anodes, the system has to go through four stages of initialization A, preset B, comparison C and update insertion D, and each stage is separated by a vertical dotted line in the figure. exist figure 1 , the horizontal line 0 is the position of the palm plane of the bottom of the anode butt 1 in the electrolytic cell, and the anode butt 1 is also called the old anode, which is an anode that needs to be replaced. Regardless of the old anode 1 or the new anode 8, it must be conducted and hoisted through the same guide rod 2. The aluminum electrolysis multifunctional overhead traveling crane 3 performs operations of raising, lowering or translating the anodes 1 and 8 through the anode frame and fixtures. On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com