Patents

Literature

408 results about "Potassium ferrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium ferrate is the chemical compound with the formula K₂FeO₄. This purple salt is paramagnetic, and is a rare example of an iron(VI) compound. In most of its compounds, iron has the oxidation state +2 or +3 (Fe²⁺ or Fe³⁺). Reflecting its high oxidation state, FeO₄²⁻ is a powerful oxidizing agent.

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Ferrous sulfide passivation cleaning agent and preparation method and application thereof

The invention discloses a ferrous sulfide passivation cleaning agent which comprises sodium bicarbonate, sodium hypochlorite, ethylene diamine tetraacetic acid-tetrasodium (EDTA-tetrasodium), potassium ferrate, surfactant and water. The passivation cleaning agent provided by the invention is safe, efficient, environment-friendly and low in price and can absorb harmful gases; the component potassium ferrate is bactericidal and environment-friendly and is a novel efficient multifunctional passivation treating agent integrating oxidation, adsorption, flocculation, coagulant aid, sterilization, insect killing and deodorization; and the component potassium ferrate has the advantages of good sterilization effect, little dosage, fast effect, multiple functions, high safety and the like, and is convenient to use and widely applicable.

Owner:CHINA PETROLEUM & CHEM CORP +1

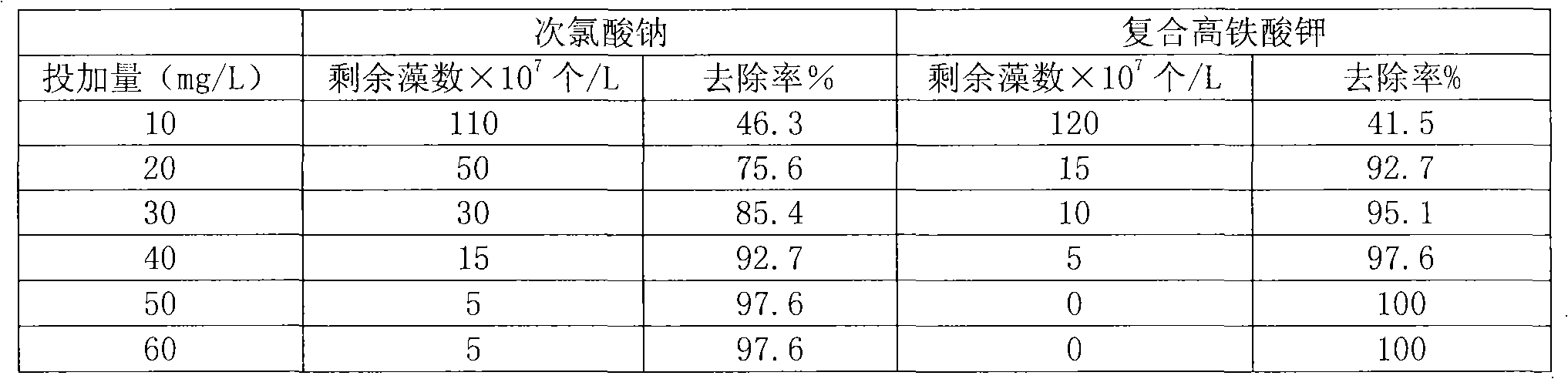

Combination of disinfectors and its applications used in aquiculture

InactiveCN1430896AInhibits and hinders synthesisStunted growthBiocideAnimal repellantsDisinfectantAdhesive

A composite disinfectant for culturing aquatic products contains potassium (or sodium) perferrite, excipient, and / or pH regulator, stabilizer, adhesive, talc powder and magnesium stearate. Its advantages are high effect on disinfecting, enriching oxygen in water, and removing heavy metals, organic substances and harmful suspended substances, and no poison.

Owner:王永东

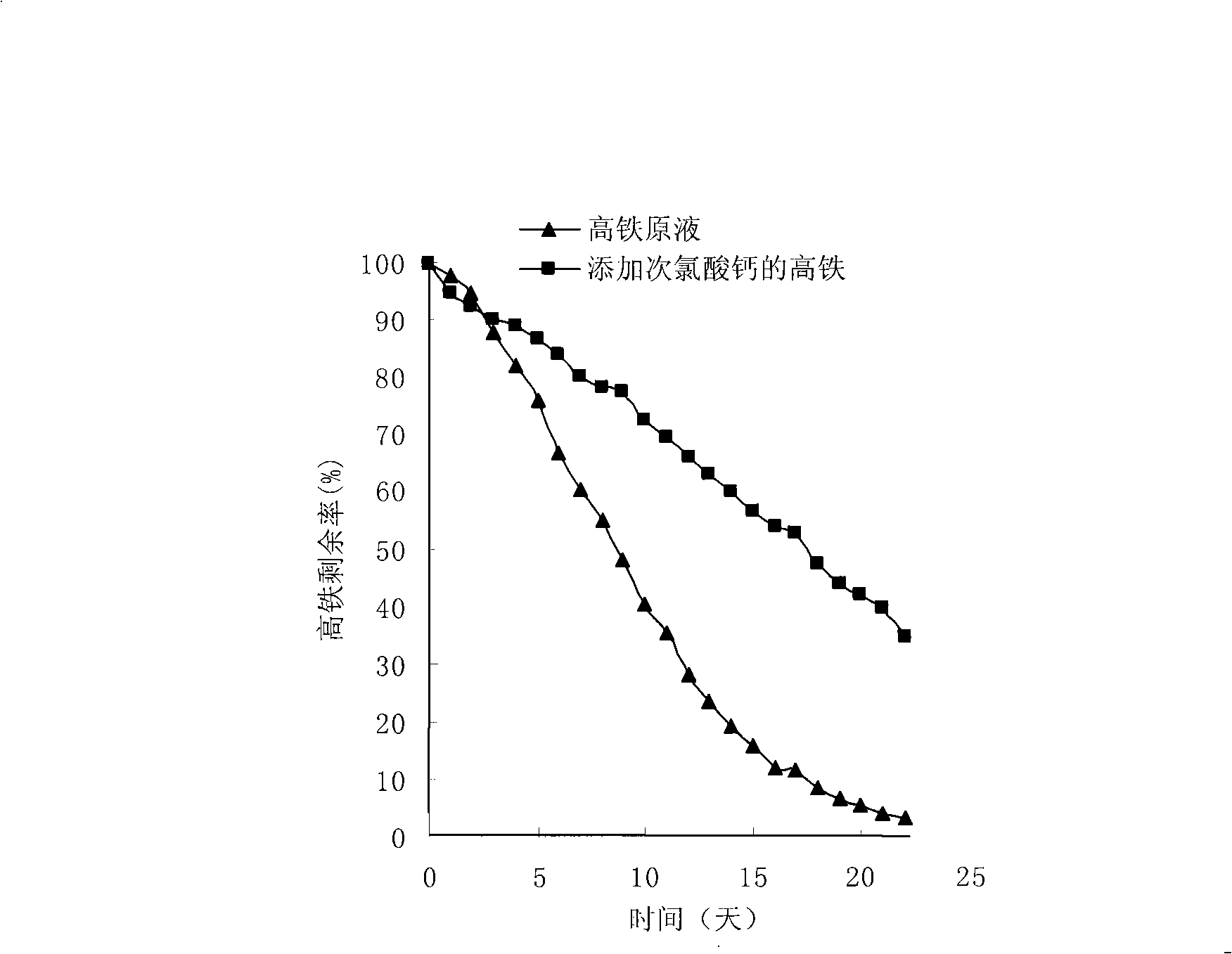

Method for preparing steady composite potassium ferrate solution

InactiveCN101318707AImprove stabilityLong storage timeIron compoundsWater/sewage treatment using germicide/oligodynamic-processChemical industryFiltration

The invention relates to a method for preparing a composite potassium ferrate solution, which belongs to the chemistry and chemical industry and water treatment agent preparation process technical field. The method comprises the following preparation processes that: firstly, a sodium hypochlorite solution reacts with sodium hydroxide, a white salt substance is generated first and is subject to pumping filtration, then ferric nitrate is added according to a molar mass ratio of sodium hypochlorite to ferric nitrate being equal to between 1.5 and 2.0 to 1, the reaction temperature is between 20 and 45 DEG C, and the pumping filtration is performed after 1.5 to 2.0 hours of reaction; and then a filtrate is added with a saturated potassium hydroxide solution to ensure that the filtrate is transformed into a potassium ferrate solution. Then 0.06 to 0.16mol / L of calcium hypochlorite is added, the reaction temperature is controlled to between 10 and 30 DEG C, the reaction time is between 10 and 30 minutes, and finally the composite potassium ferrate solution with good stability is produced. The composite potassium ferrate solution prepared by the method has good stability, long preservation time, difficult decrease of high iron content, and easiness for industrialized production. The product can be widely used for purification treatment of algae-laden water, city domestic sewage and so on.

Owner:SHANGHAI UNIV

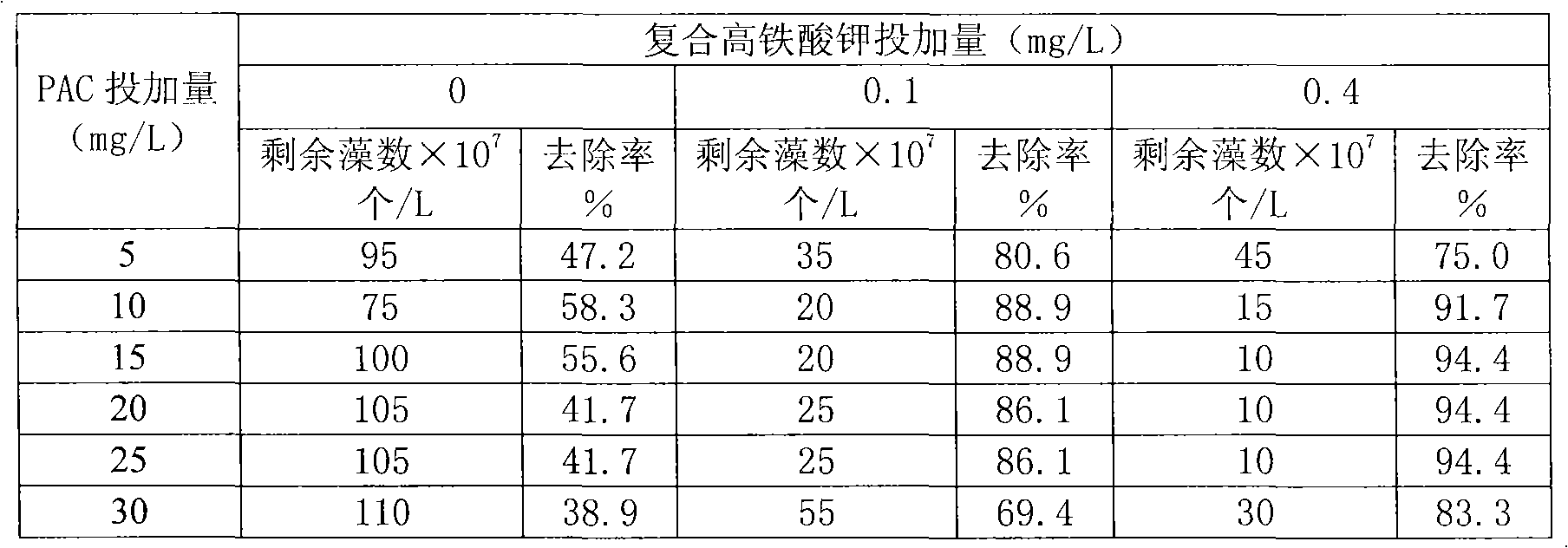

Aquaculture water purification agent and preparation method thereof

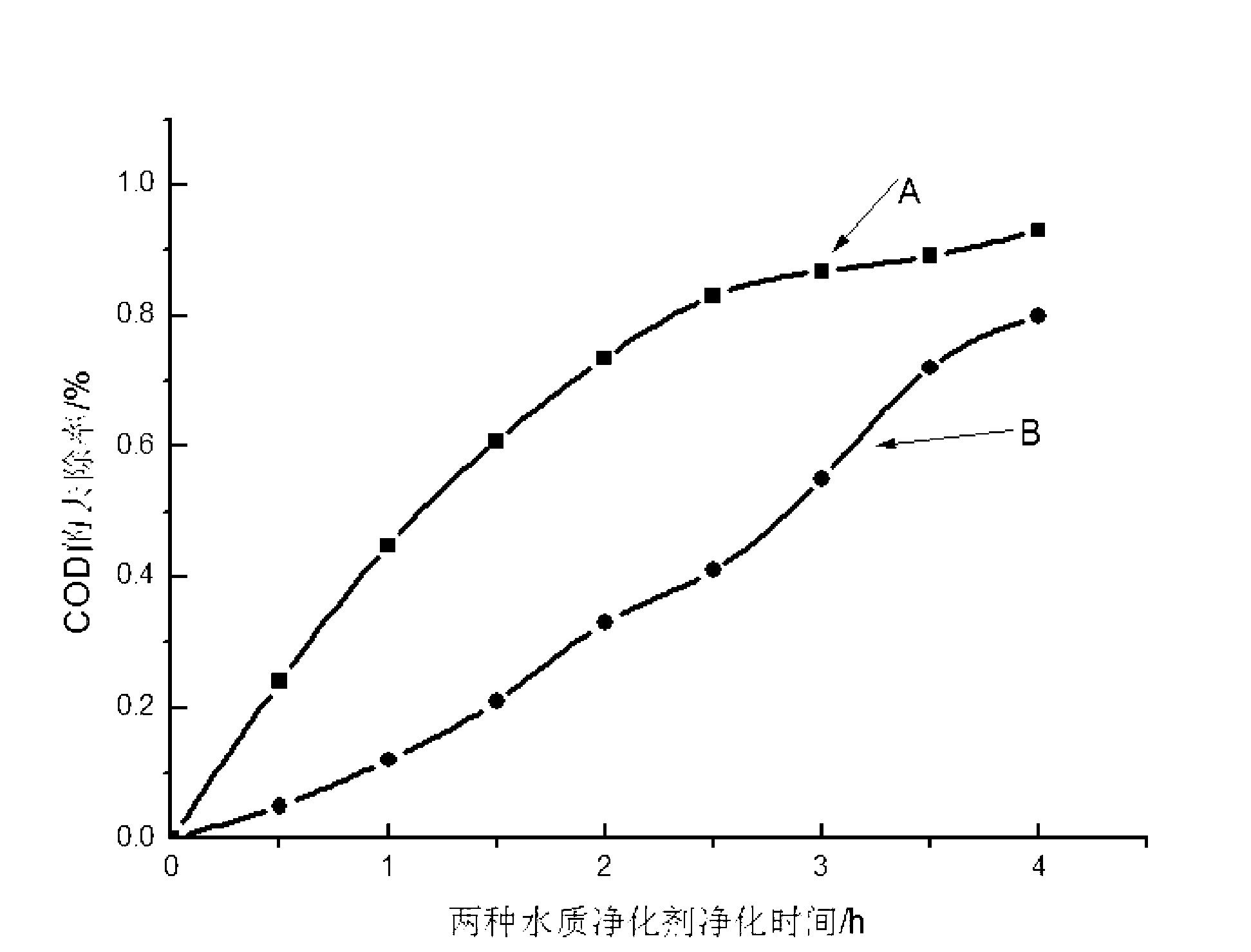

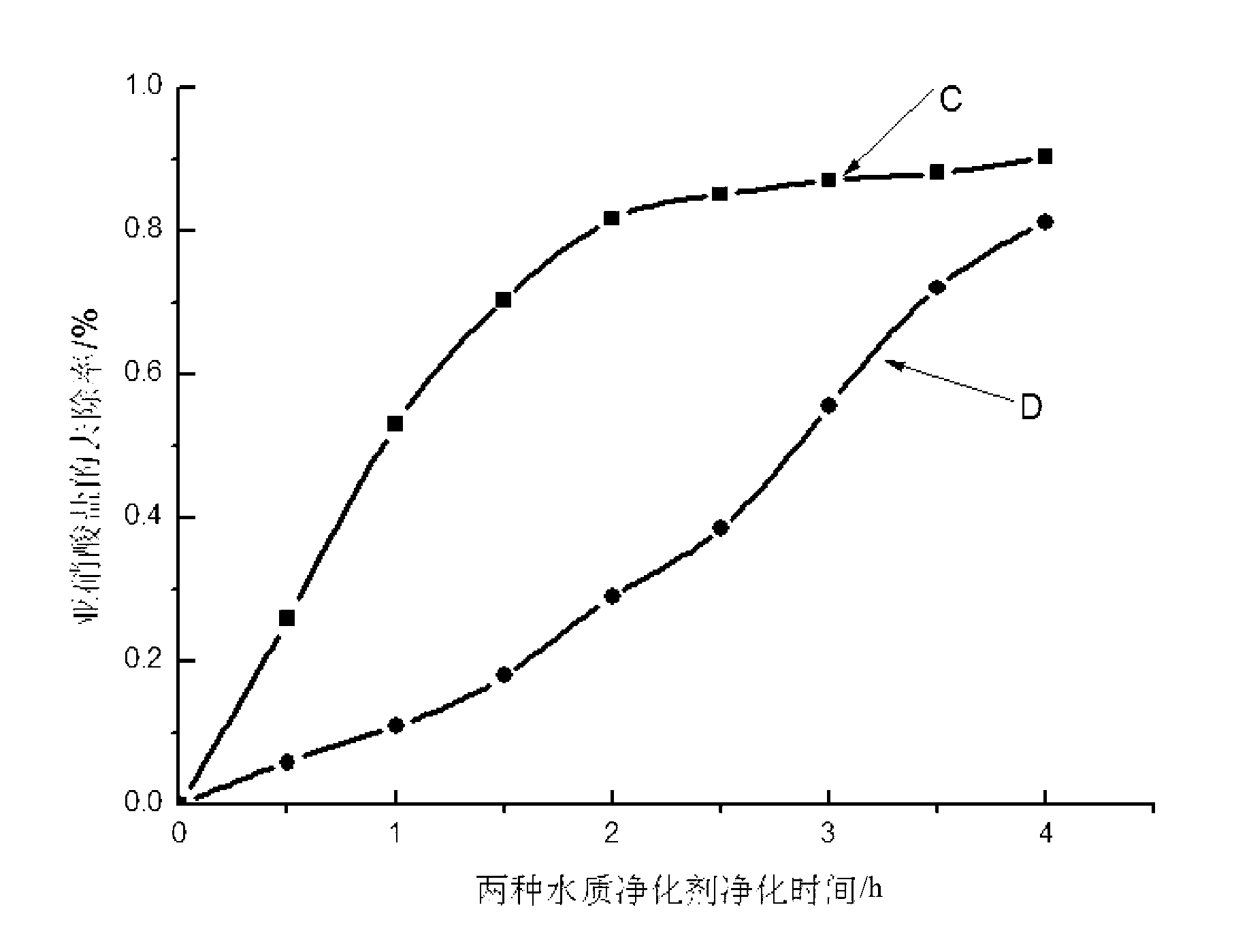

ActiveCN103214074AQuick purificationReduced duration of actionWater/sewage treatment by flocculation/precipitationWater qualityPotassium ferrate

The invention relates to an aquaculture water purification agent. The purification agent comprises the following components in parts by weight: 200-300 parts of polyaluminium chloride, 200-300 parts of potassium ferrate, 0.1-20 parts of cationoid polyacrylamide, 1-20 parts of powdered sulfur, 10-100 parts of activated carbon, 2-40 parts of calcium oxide, 100-300 parts of zeolite powder, 100-300 parts of kieselguhr and 0.1-5 parts of copper sulphate. The invention further relates to a preparation method of the aquaculture water purification agent. The aquaculture water purification agent is ingenious in design, has a physical purification and chemical agent synergistic effect and an obvious coagulation effect, quickly and thoroughly purifies and is suitable for large-scale popularization and application.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

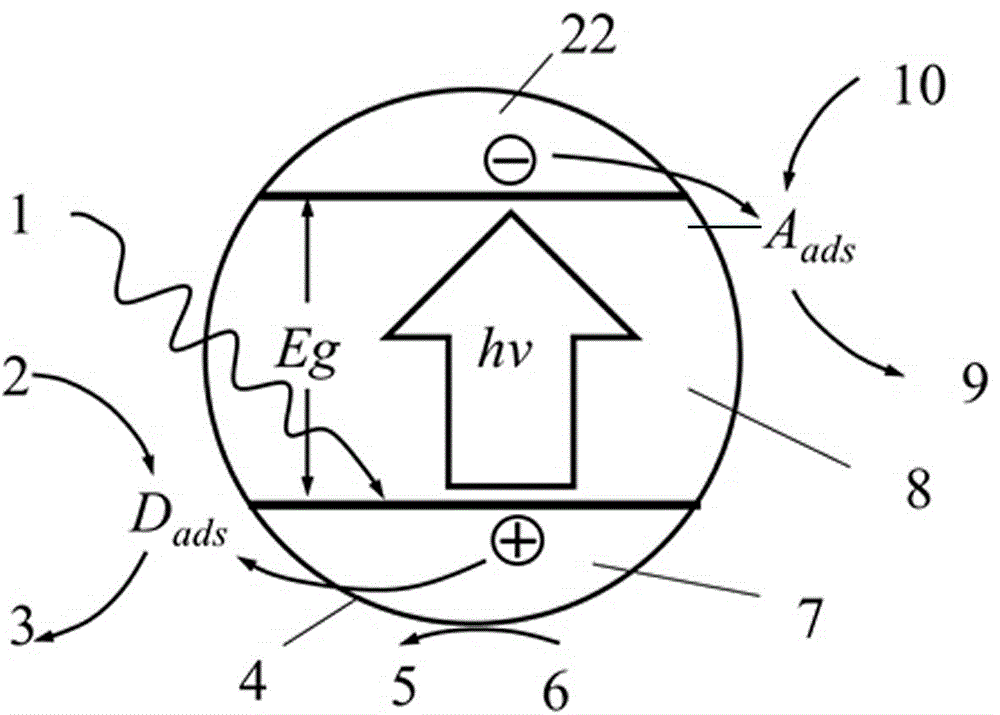

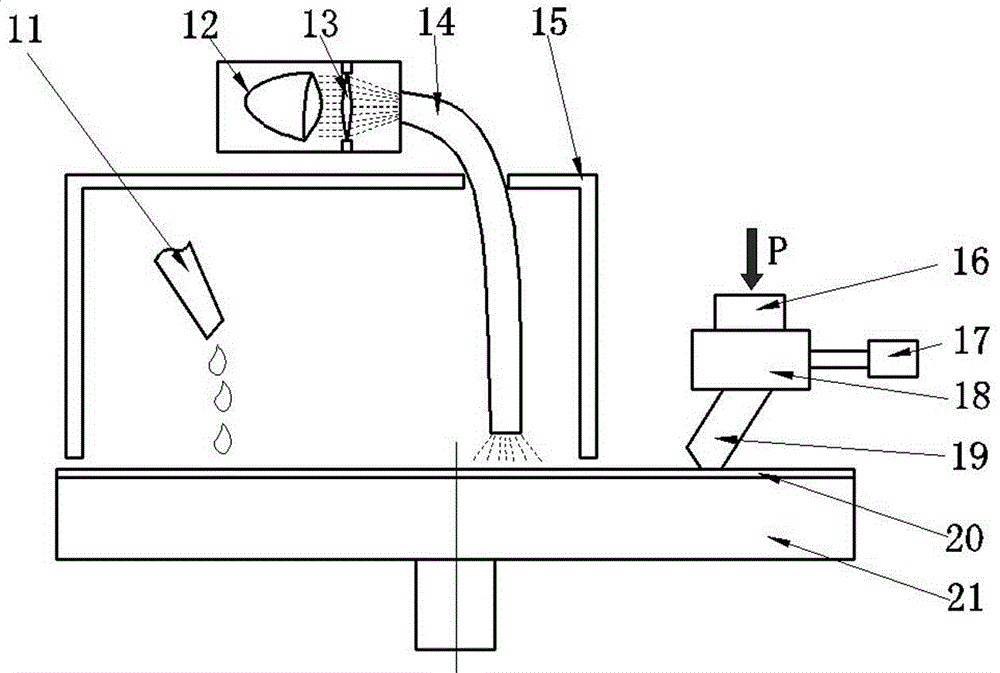

Photocatalytic auxiliary cutter sharpening method and device for diamond cutter

ActiveCN104669075ASimple structureGood sharpening qualityCathode-ray tube indicatorsOther manufacturing equipments/toolsUltravioletSurface roughness

The invention belongs to the field of ultra-precision cutting machining and discloses a photocatalytic auxiliary cutter sharpening method and a photocatalytic auxiliary cutter sharpening device for a diamond cutter. The photocatalytic auxiliary cutter sharpening method and the photocatalytic auxiliary cutter sharpening device for the diamond cutter are characterized in that nano titanium dioxide is used as a main component and right amounts of electron capturer and abrasive particles are added to prepare polishing solution. When ultraviolet rays irradiate the polishing solution on the surface of a polishing disk, hydroxyl free radicals with strong oxidizability are generated on the surfaces of titanium dioxide particles in the polishing solution and under the synergistic action of mechanical friction of the polishing disk, trace removal of materials on the surface of diamond is implemented. by changing an input voltage of an ultraviolet ray generator, the chemical oxidation effect of the polishing solution is regulated. The photocatalytic auxiliary cutter sharpening method and the photocatalytic auxiliary cutter sharpening device for the diamond cutter have the effects and benefits that a rounded edge radius of below 100 nanometers, nanometer and sub-nanometer scale surface roughness and ultralow damage surface quality of a cutter can be realized; the photocatalytic auxiliary cutter sharpening method and the photocatalytic auxiliary cutter sharpening device are helpful for improving the service life of the cutter and workpiece machining quality. Moreover, titanium dioxide and potassium ferrate are used as the main components of the polishing solution, and thus, human bodies and the environment cannot be damaged and the environment pollution can be improved to a certain degree.

Owner:SHENYANG POLYTECHNIC UNIV

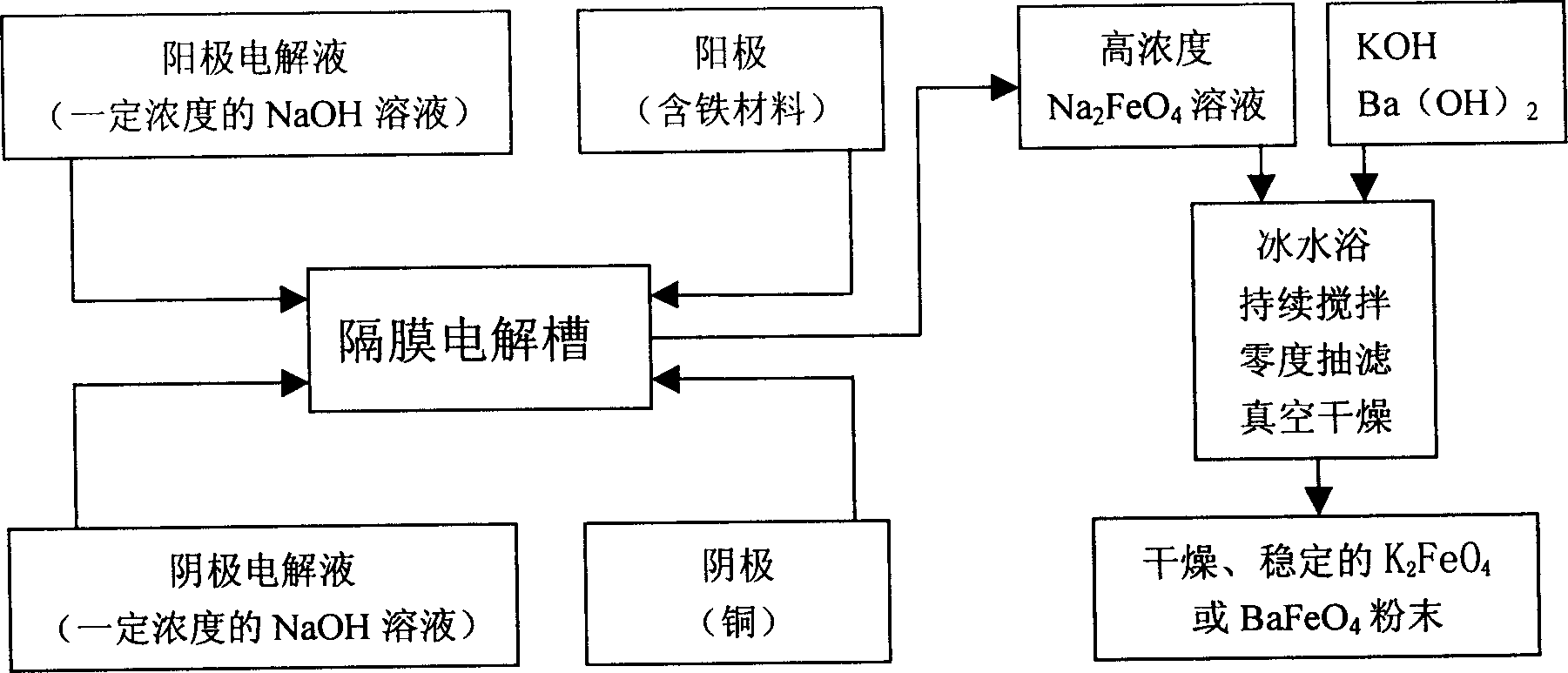

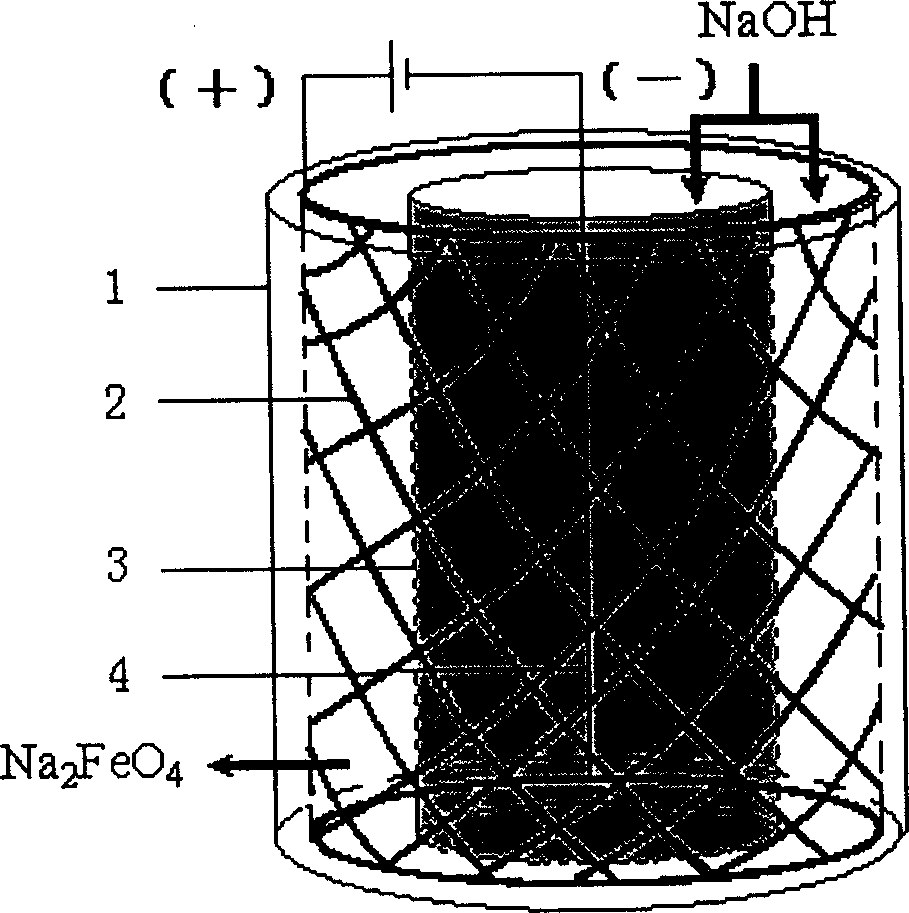

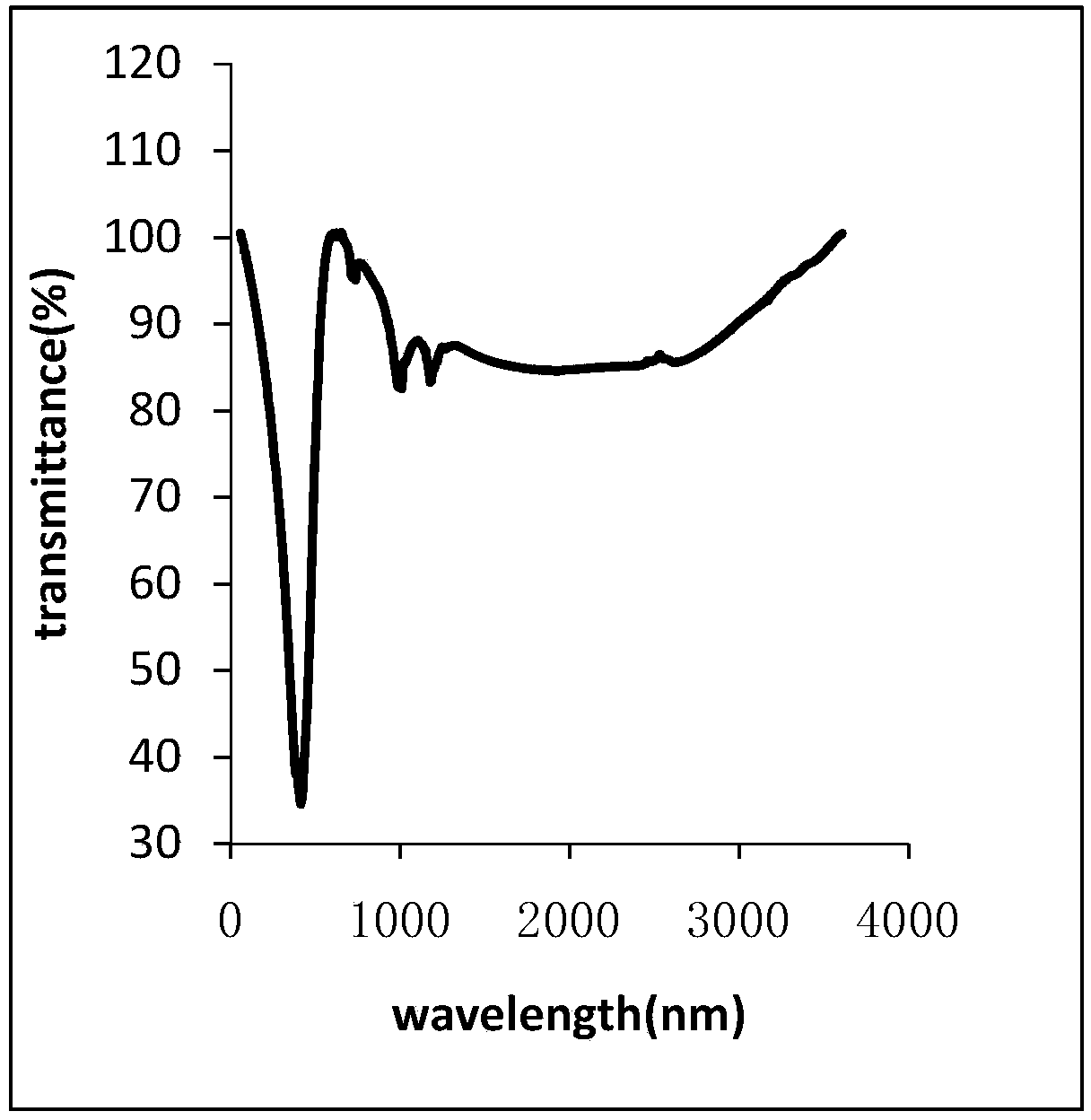

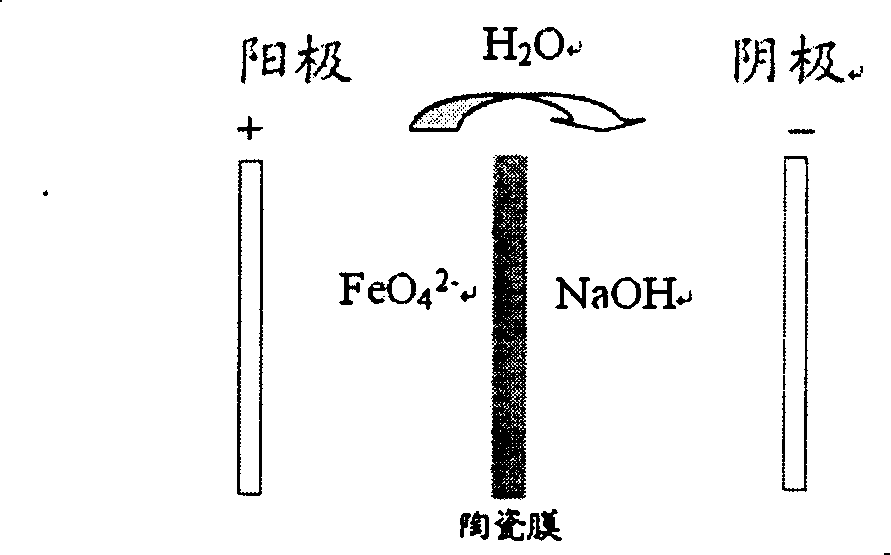

Direct electrochemical process of preparing ferrate

InactiveCN1740398AImprove electrolysis efficiencyReduce manufacturing costElectrolysis componentsHigh concentrationElectrolysis

The present invention belongs to the field of chemical preparing technology, and is especially direct electrochemical process of preparing ferrate. The preparation process prepares ferrate inside one diaphragm type cylindrical electrolytic bath with pure sodium hydroxide as electrolyte. While controlling electrolyte concentration, reaction temperature and applied voltage, high concentration sodium ferrate solution is first prepared, and potassium ferrate or barium ferrate is then prepared via adding potassium ion or barium ion. The present invention has simple technological process and low cost, and is suitable for large scale preparation of ferrate.

Owner:FUDAN UNIV

Combination type efficient sludge dewatering conditioning method

ActiveCN104891779AFully dehydratedHas strong oxidizing propertiesSludge treatment by de-watering/drying/thickeningSulfatePotassium ferrate

The invention relates to a combination type efficient sludge dewatering conditioning method and belongs to the field of sludge dewatering preprocessing. According to the technical scheme, the method includes performing acidification treatment on sludge to be dewatered through concentrated sulfuric, adjusting the pH of a sludge system to range from 3.5 to 5, and stirring for 15 to 30min through a stirring blade; adding strong oxidizing agent, namely potassium ferrate, with the content of 0.2% to 4% of the total solid sludge into acidified sludge after water dissolving, stirring for 2min in the speed of 200 to 300 r / min rapidly, and stirring for 20 to 40min in the speed of 80 to 150 r / min slowly; adjusting the pH to range from 3.5 to 5 through concentrated sulfuric, adding ferrous sulfate with the content of 4% to 8% of the total solid sludge after preparing the ferrous sulfate as solution with the concentration of 20% to 50%, after stirring and scattering, adding H2O2, with the concentration of 30%, with the content of 4% to 8% of the total solid sludge, and reacting for 30 to 50min completely during slow stirring; finally, adding quicklime with the content of 3% to 8% of the total solid sludge into the sludge conditioning system, adjusting the system pH to range from 6 to 8, scattering the quicklime evenly, and dewatering.

Owner:BEIJING UNIV OF TECH

Controlled release type potassium ferrate composite as well as preparation method and application thereof

ActiveCN103896389AIssues Affecting DissolutionGuaranteed DissolutionIron compoundsWater/sewage treatment using germicide/oligodynamic-processFoaming agentControl release

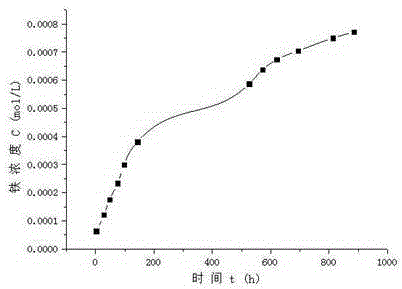

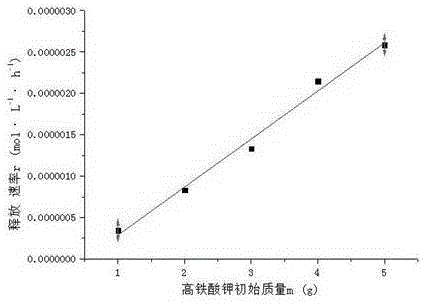

The invention discloses a controlled release type potassium ferrate composite as well as a preparation method and application thereof. The preparation method is as follows: by taking a high polymer which is biodegradable and environment-friendly as a framework material, dissolving the high polymer in a low-boiling point organic solvent, adding a pore-foaming agent, a dispersing agent and high-purity potassium ferrate, adding the mixture into a medium for emulsifying and curing, and filtering and drying the cured product to obtain the controlled release type potassium ferrate composite. The composite is in a water environment, so that a net-shaped duct structure is formed in an inert framework material by virtue of the hydrophilcity of the pore-foaming agent, and therefore, the potassium ferrate is effectively aided to release from the composite, and a problem that dissolution of active ingredients is affected due to texture compaction of the framework material is avoided; the composite is different from the conventional disposable oxidant, controllable in release speed in water, uniform in velocity, long in holding time, good in storage stability, and has wide application prospect on in-situ repairing polluted underground water.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Compound sludge conditioner for sludge dewatering

InactiveCN107686225AReduce interfacial tensionReduce adhesionSludge treatment by de-watering/drying/thickeningFiltrationPulverized fuel ash

The invention discloses a compound sludge conditioner for sludge dewatering, which comprises the following raw materials by mass percentage: 10-20% of oxidant, 30-60% of sludge conditioning bulking agent, 25-55% of inorganic flocculent and 5-10% of cationic polyacrylamide, wherein the wherein is at least one of sodium ferrate, potassium ferrate, sodium percarbonate and sodium hypochlorite; the sludge conditioning bulking agent is at least one of 50-200-mesh pulverized fuel ash, calcined kaoline and magnetite tailing powder; and the inorganic flocculent is at least one of polymeric aluminum ferric chlorine sulfate, polymeric aluminum ferric sulphate and polymeric aluminum ferric silicate. The addition amount of the compound sludge conditioner is small and 5-15% of absolute dry weight of sludge; a dewatering rate is high; a water content of the sludge with a water content of 90-99% can be reduced to 40-60% after pressure filtration dewatering; and the reduction, stabilization, harmlessness and reclamation of the sludge are achieved.

Owner:SHENZHOU HUAMEI BEIJING TECH +1

Method for improving dehydration performance of residual sludge by assisting oxidization of ferrate by utilizing ultrasonic waves

InactiveCN103359908AImprove dehydration effectFilter specific resistance dropsSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPotassiumPotassium ferrate

The invention relates to a method for improving dehydration performance of residual sludge by assisting oxidization of ferrate by utilizing ultrasonic waves and belongs to the technical field of sludge processing. The method comprises the following steps of: introducing concentrated sludge into a conditioning tank, and adding dilute sulfuric acid or dilute nitric acid into the conditioning tank while stirring, so as to enable the pH of the sludge to be 2.5-3.5; adding potassium ferrite under the action of the ultrasonic waves, adding calcium hydroxide into the reacted sludge and carrying out stirring, and regulating the pH to 6-7, wherein the adding amount of the ferrate (namely the mass ratio of the ferrate to the residual sludge) is ((0.5-2)*10<3>):1, the ultrasonic frequency is 20-40 kHz, the energy density of sound of a dry basis is 1000-3000 KJ / kg, and the action time is 60-90 seconds; carrying out mechanical dehydration on the processed sludge by utilizing a belt press-filter or centrifugal dehydration method, so as to obtain the dehydrated sludge with the water content of 70-75%. According to the method disclosed by the invention, the filtering specific resistance of the sludge can be reduced, the solid content of a mud cake can be increased, the reaction efficiency can be improved, the reaction time can be shortened, the processing capacity can be improved, and the sludge treatment cost can be lowered.

Owner:SUN YAT SEN UNIV

Method for removing organic pollutants in water by ferrate reinforced ozone oxidation

ActiveCN105036293AIncrease the effective concentrationImprove removal efficiencyWater contaminantsWater/sewage treatment by oxidationWater sourcePotassium ferrate

The invention relates to a water treatment method, particularly a method for removing organic pollutants in water by ferrate reinforced ozone oxidation, which aims to solve the problem of high ozone addition amount due to great influence by background components and low effective concentrations of ozone and hydroxy free radicals in the existing ozone-oxidation-process exposed water. The treatment method comprises the following steps: adding ferrate into source water containing organic pollutants to perform preoxidation treatment, stirring to react, introducing ozone, and continuing stirring to react, thereby removing the organic pollutants in water by ferrate reinforced ozone oxidation, wherein the ferrate is one or mixture of potassium ferrate and sodium ferrate. The ferrate is used as a strong oxidant, has a co-oxidation action with ozone, and reduces the trapping consumption of the background component for ozone and hydroxy free radicals. Compared with the oxidation by single ozone, the pollutant removal rate is enhanced by 30-50%, and the ozone addition amount is decreased by 20-50%.

Owner:HARBIN INST OF TECH

Preparation method of novel compound wastewater treatment adsorbing agent

ActiveCN103949203AImprove decontamination abilityOther chemical processesWater/sewage treatment by sorptionActive agentSorbent

The invention provides a preparation method of a novel compound wastewater treatment adsorbing agent. The preparation method comprises the following steps: step one, preparing attapulgite clay powder which is subjected to surface modification by adopting a dendritic quaternary ammonium salt tetramerization surface active agent; step two, preparing nanometer manganese oxide suspension liquid ; step three, preparing potassium ferrate; and step four, compounding products prepared in the step one to three so as to prepare the compound wastewater treatment adsorbing agent. The stain removal capacity of the compound wastewater treatment adsorbing agent for industrial wastewater is greatly improved by combined application of respective stain removal characteristics of attapulgite clay, nanometer manganese oxide and potassium ferrate through mutual compensation and synergistic effects of the attapulgite clay, the nanometer manganese oxide and the potassium ferrate.

Owner:浙江东嘉水务有限公司

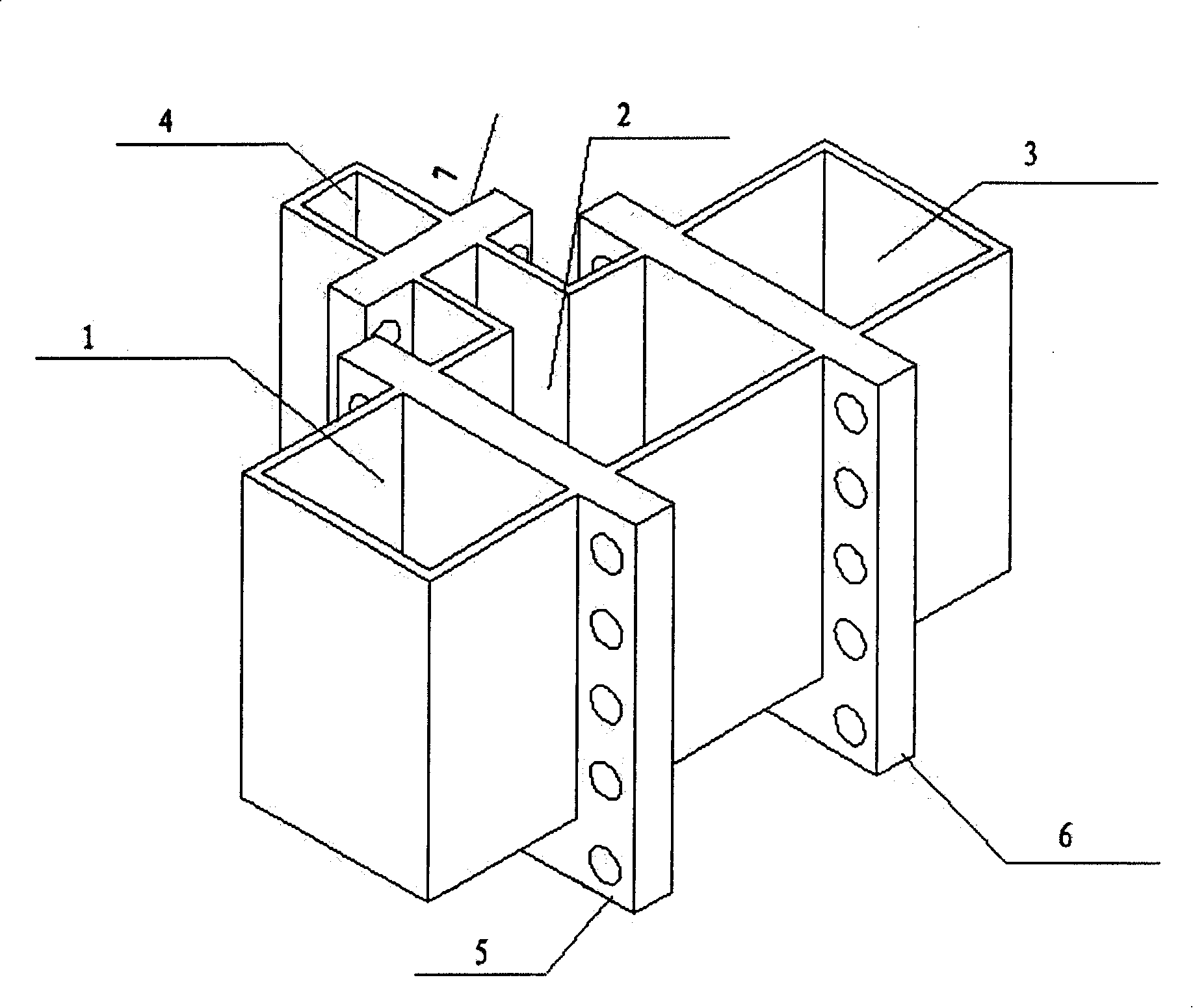

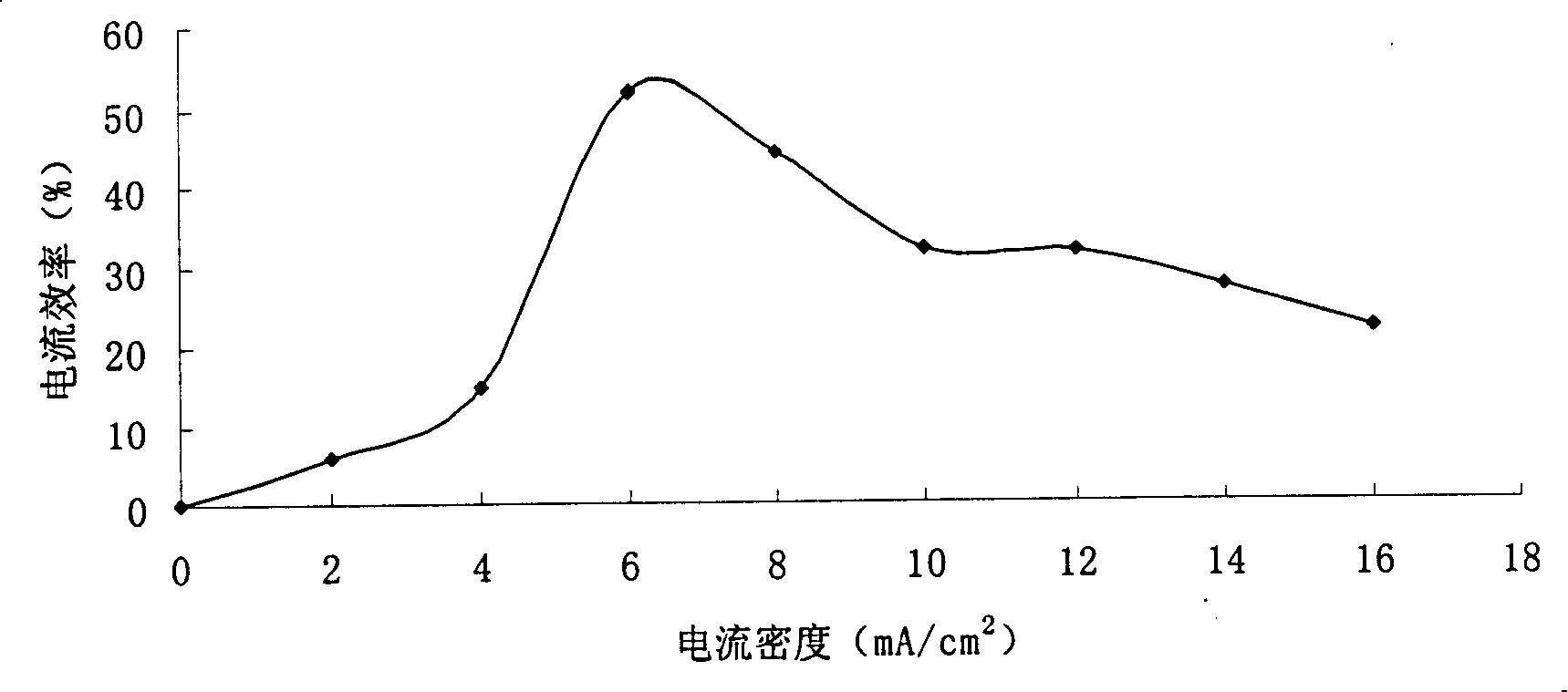

Potassium ferrate preparation method

The invention discloses a process for preparing potassium ferrate. An electrolysis bath is placed inside a water bath kettle with a constant temperature of 15-35DEG C, white cast-iron is placed inside a second groove of an anode chamber of the electrolysis bath, nickel screens as negative electrodes are placed inside a first groove and a third groove, electrolytic solution is NaOH of 14mol per liter, and N2 is sent into the cathode chamber to take off hydrogen. KIO4 of 0.1% and NaCl of 3% are added in the cathode chamber, direct current of 6-7mA per square centimeter is applied for reaction of 2-10 hours, sodium ferrate is prepared via electrolysis, then potassium ferrate solution in the second groove is concentrated via electro-osmosis method between the first groove and the second groove, after 5-10 hours the potassium ferrate solution in the second groove is taken out and added with KOH solid to be stirred for dissolving, after the mixture stands for aging, crude products of the potassium ferrate are obtained via extraction and filtration, and finally the potassium ferrate with high purity is obtained via recrystallization. The invention is simple in preparing process and is pollution-free, and the degree of purity of the prepared potassium ferrate products reaches up to 98%.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

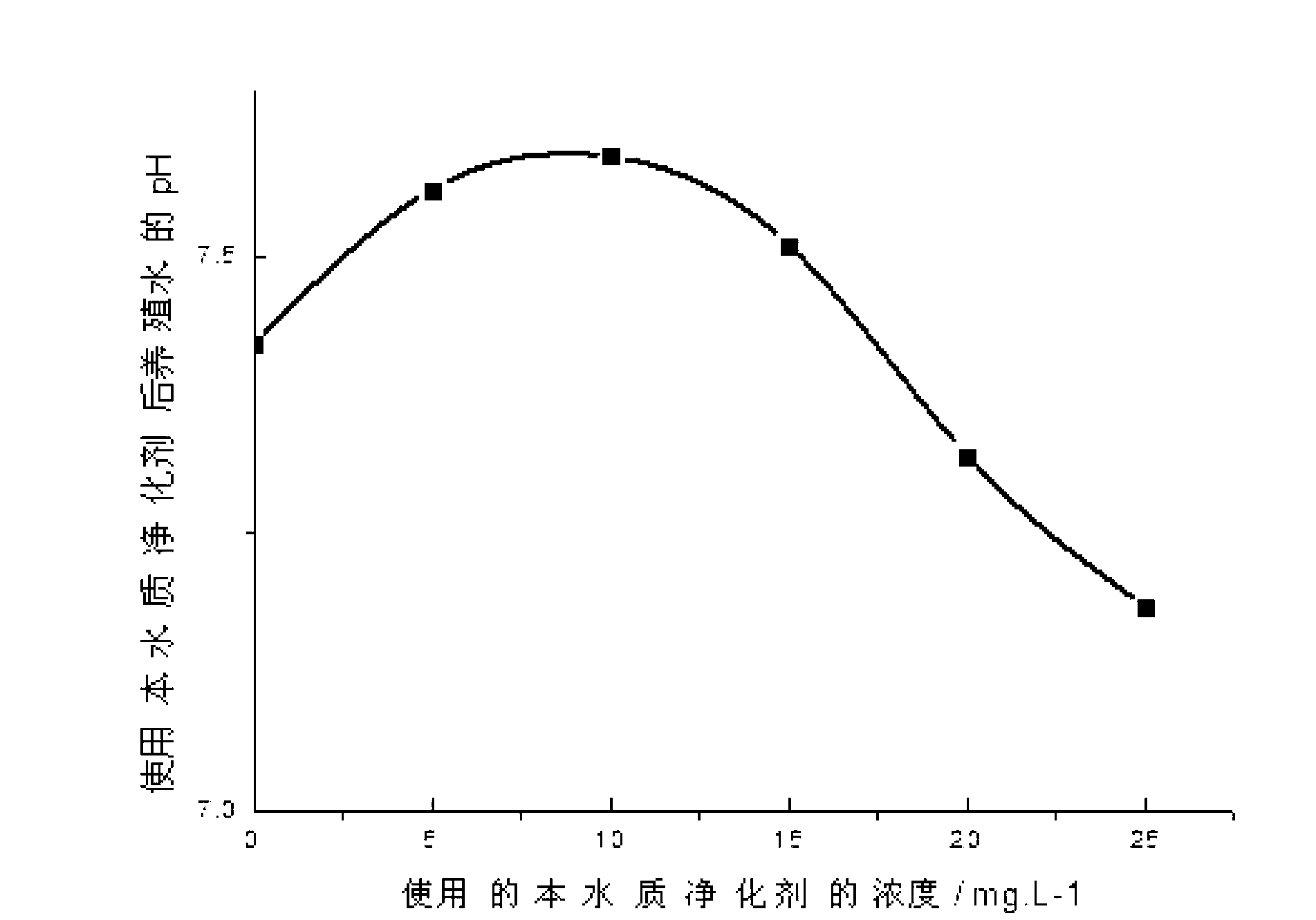

Water purifying agent for aquaculture, and preparation method thereof

InactiveCN107162093AGood coagulation effectPurify thoroughlyWater/sewage treatment by centrifugal separationWater contaminantsFiberWater quality

The invention discloses a water purifying agent for aquaculture, and a preparation method thereof. The water purifying agent comprises, by weight, 50-60 parts of tourmaline particles, 30-50 parts of modified zeolite, 20-30 parts of polyaluminum chloride, 15-25 parts of potassium ferrate, 10-20 parts of copper sulfate, 3-8 parts of carbon black, 10-30 parts of activated carbon fibers, 2-8 parts of diatomaceous earth, 3-8 parts of calcium oxide and 1-5 parts of magnesium oxide. The preparation method comprises the following steps: crushing and uniformly mixing the tourmaline particles, modified zeolite, polyaluminum chloride, potassium ferrate, copper sulfate, carbon black, activated carbon fibers, diatomaceous earth, calcium oxide and magnesium oxide to obtain a powder, and drying the powder to produce the water purifying agent for aquaculture. The water purifying agent for aquaculture has the advantages of physical purification and chemical preparation synergism, obvious coagulation effect, and fastness and thoroughness in purification, and is suitable for large-scale promotion.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Method combining oxidizing composite reagent and activated carbon to remove arsenic in water

InactiveCN102642951AQuick removalWater safetyWater contaminantsMultistage water/sewage treatmentPotassium persulfateChlorine dioxide

The invention provides a method combining an oxidizing composite reagent and activated carbon to remove arsenic in water. The oxidizing composite reagent is added into the water and stirred, and then the activated carbon is utilized to adsorb the arsenic. The oxidizing composite reagent is formed by compositing potassium ferrate, chlorine dioxide, sodium peroxide, potassium persulfate, potassium monopersulfate, ferrous sulfate, ferric sulfate and hydroxylamine hydrochloride, or is formed by compositing potassium peroxide, sodium peroxide, sodium monopersulfate, iron chloride and hydroxylaminehydrochloride, or is formed by compositing calcium peroxide, sodium hypochlorite, calcium monopersulfate, calcium persulfate, cerium chloride, ferric chloride, cerous sulfate and humus, or is formed by compositing cobalt chloride, ammonium monopersulfate, ammonium persulfate, cerous sulfate, sodium peroxide and hydroxylamine hydrochloride. The method can not only remove the arsenic in drinking water, underground water and surface water rapidly, efficiently, conveniently and safely, but also effectively reduce concentration of the arsenic in sewage containing arsenic and effluent of sewage secondary sedimentation tanks, and simultaneously can have good recovery effect on lakes and inland seawater polluted by the arsenic.

Owner:HARBIN ENG UNIV

A cathode material of potassium ferrate battery

InactiveCN101217196AImprove utilization efficiencyAlkaline accumulatorsCell electrodesDischarge efficiencyAluminate

The invention provides a material used for a cathode for a super-iron battery. The material includes 65 to 80wt percent of potassium ferrate, 10 to 25wt percent of conductive material, 1 to 10 wt percent of additive and 4 to 8wt percent of electrolyte according to weight percentage, wherein, the additive consists of 40 to 60 percent of silicon aluminate and 60 to 40 percent of manganese dioxide according to weight percentage, the conductive material is one of graphite and acetylene black with 3000 to 4000 meshes, the electrolyte is the KOH water solution with 10 to 14mol / L, and the discharging efficiency of the super-iron battery which is produced by using the cathode material is obviously improved.

Owner:DAQING GASOLINEEUM INST

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Rapid synthesis method of drinking water treatment agent (i.e. potassium ferrate)

InactiveCN101597087AGreat tasteEfficient killingIron compoundsSodium/potassium compoundsFerric hydroxideSynthesis methods

The invention discloses a rapid synthesis method of a drinking water treatment agent (i.e. potassium ferrate). The method directly utilizes the industrial pure ferric hydroxide Fe(OH)3, the self-prepared potassium hypochlorite (KClO) saturated solution and the deionized water as raw materials for preparing potassium ferrate. The process comprises the following steps: preparing the potassium ferrate by the potassium hypochlorite (KClO) saturated solution and the industrial pure ferric hydroxide Fe(OH)3, adding the CuCl22H2O stabilizer for solid liquid separation, adding the KOH for recrystallization and purification, and washing and removing impurity by the normal pentane and the inorganic ethanol; and performing vacuum drying and sealing. The method has the advantages of simple process, good quality of the products and low production cost.

Owner:张亮

Method for preparing modified biochar through ferrate oxidation under alkaline condition

InactiveCN105289485AImprove adsorption capacityNo harmOther chemical processesEnvironmental engineeringPotassium ferrate

The invention discloses a method for preparing modified biochar through ferrate oxidation under an alkaline condition. The method comprises the steps of dispersing and mixing biochar in an alkaline solution; adding a strong oxidant-potassium ferrate, carrying out ultrasonic processing after uniformly stirring the mixture, continuously stirring, then slowly rising the temperature to be 10 to 70 DEG C and continuously stirring; then adding a proper amount of water in the mixture, standing, removing upper-layer liquid, then cleanly washing by water, drying, and obtaining the modified biochar. The adsorption performance of the modified biochar provided by the invention on heavy metal is greatly increased; the biochar is oxidized by adopting the alkaline condition, modification is carried out by utilizing a chemical method, the content of surface functional groups of the biochar is changed, and equivalent stability is obtained. A preparation method provided by the invention is simple, the condition is mild, the method can be easily used for industrial production, additional environment hazards cannot be caused, the utilization efficiency of biomass resources is increased, the problem that agricultural and forestry biomass wastes are difficult to degrade and reutilize is solved, and the social significance and the economic value are extremely profound.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

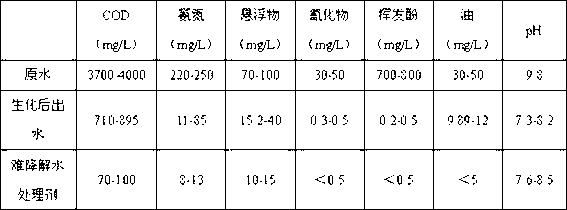

Multifunctional water treatment agent used for treating refractory wastewater

InactiveCN103241793AExtended reaction timeImprove adsorption capacityOther chemical processesWater/sewage treatment using germicide/oligodynamic-processHazardous substanceEmission standard

The invention relates to a multifunctional water treatment agent used for treating refractory wastewater. The multifunctional water treatment agent is prepared through the following steps of: (1) modifying through bentonite, namely weighing bentonite, pouring the bentonite into an organic modifier solution with mass percent of 3-5%, stirring for 1-3 hours at room temperature, centrifuging, washing, drying and grinding the bentonite to powder so as to obtain modified bentonite; and (2) loading through potassium ferrate: pouring the modified bentonite prepared by step (1) into a potassium ferrate aqueous solution with the pH of 7-9 to be loaded, and air-drying the solution after saturating to obtain the multifunctional water treatment agent. The multifunctional water treatment agent provided by the invention integrates multiple functions, such as oxidation, adsorption, flocculation, sterilization, and the like, thereby greatly reducing the COD concentration and biotoxicity in the wastewater, improving the biodegradability of the wastewater, reducing the treatment cost and improving the emission standard-reaching rate of the refractory wastewater; and the multifunctional water treatment agent has the characteristics of being good in refractory wastewater treatment effect, free of toxic and harmful substance, low in treatment cost, environmentally-friendly, and the like, thereby being suitable for large scale industrial production.

Owner:浙江一清环保工程有限公司

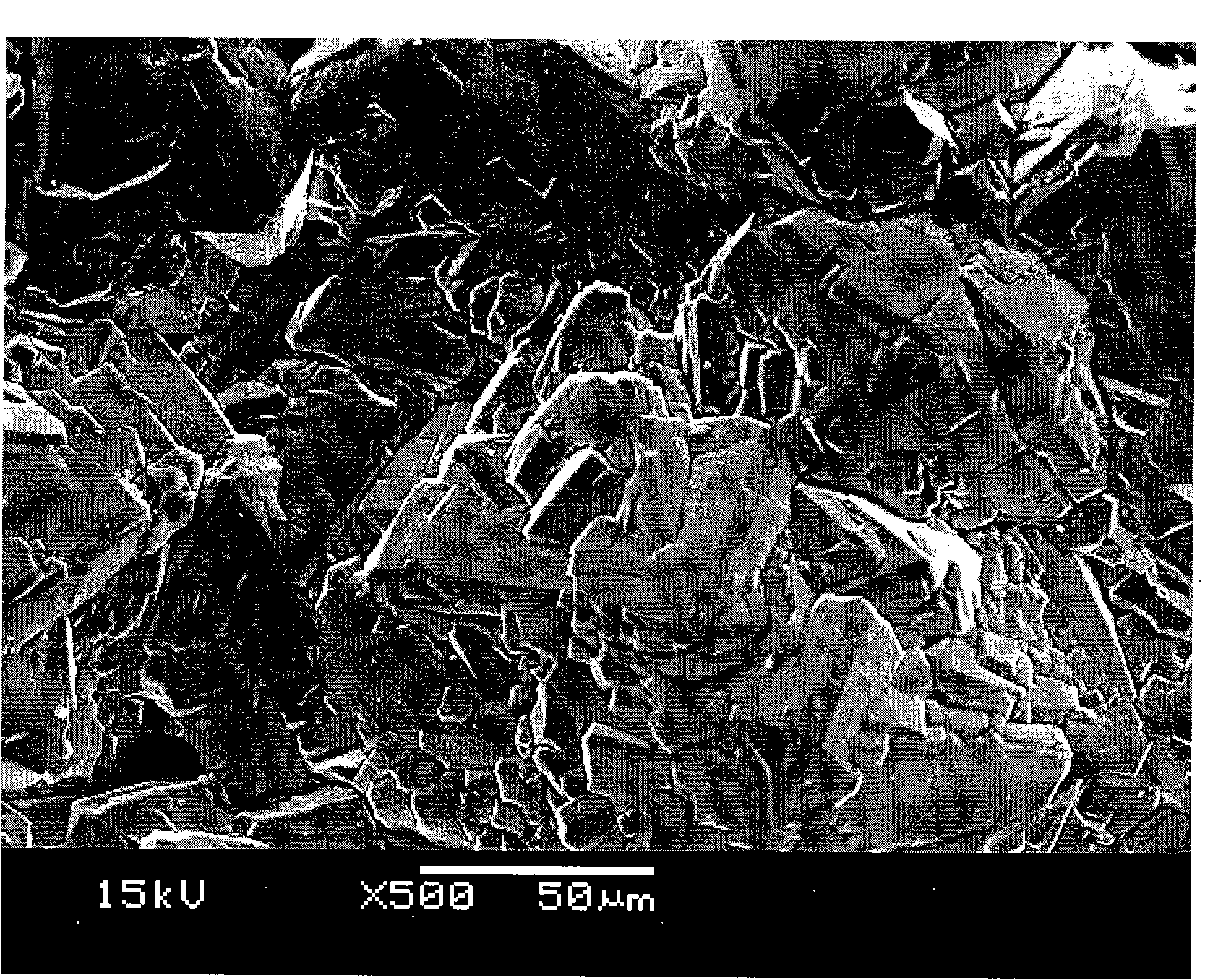

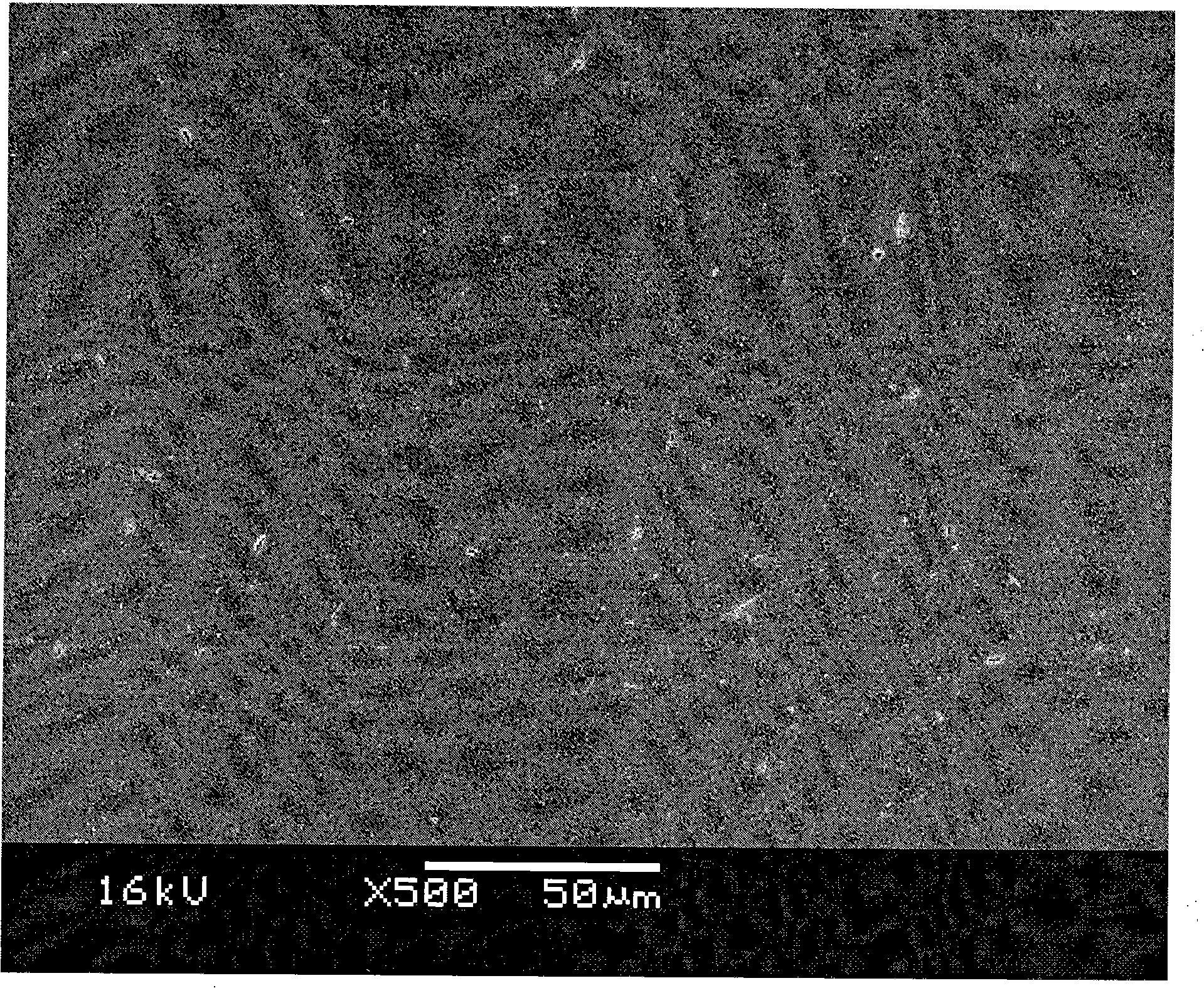

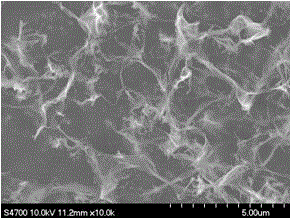

Preparation method of single-layer graphene oxide modified waterborne polyurethane composite material

The invention provides a preparation method of a single-layer graphene oxide modified waterborne polyurethane composite material, belonging to the field of preparation of inorganic nano modified polyurethane materials. The method provided by the invention comprises the following steps: firstly carrying out oxidized stripping on crystalline flake graphite by utilizing a novel strong oxidizer, namely potassium ferrate, and centrifugally washing to obtain single-layer graphene oxide; and ultrasonically dispersing the single-layer graphene oxide into deionized water, adding in the waterborne polyurethane emulsion stage, and stirring at a high speed so as to obtain single-layer graphene oxide modified waterborne polyurethane composite emulsion. Compared with the existing inorganic substance modified high molecular material, the single-layer graphene oxide modified waterborne polyurethane composite material has the advantages that the single-layer graphene oxide can be stably dispersed in a polymer matrix after being subjected to ultrasonic treatment; and because the attributes, such as specific surface area, strength and hardness, of the graphene oxide are superior to those of other nano modified substances, the waterborne polyurethane has great advantages in the aspects of thermal stability, mechanical properties and the like.

Owner:JIANGNAN UNIV

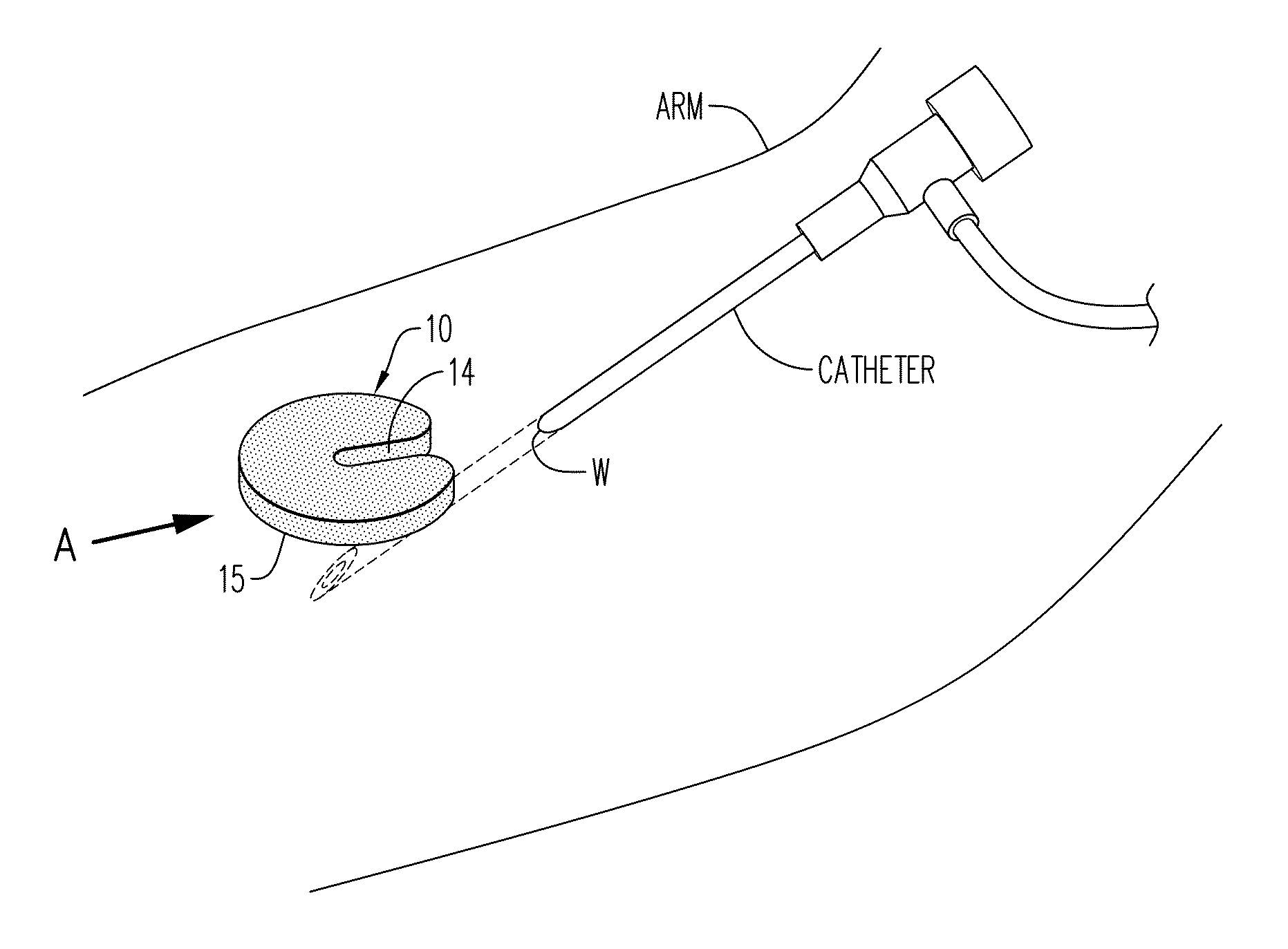

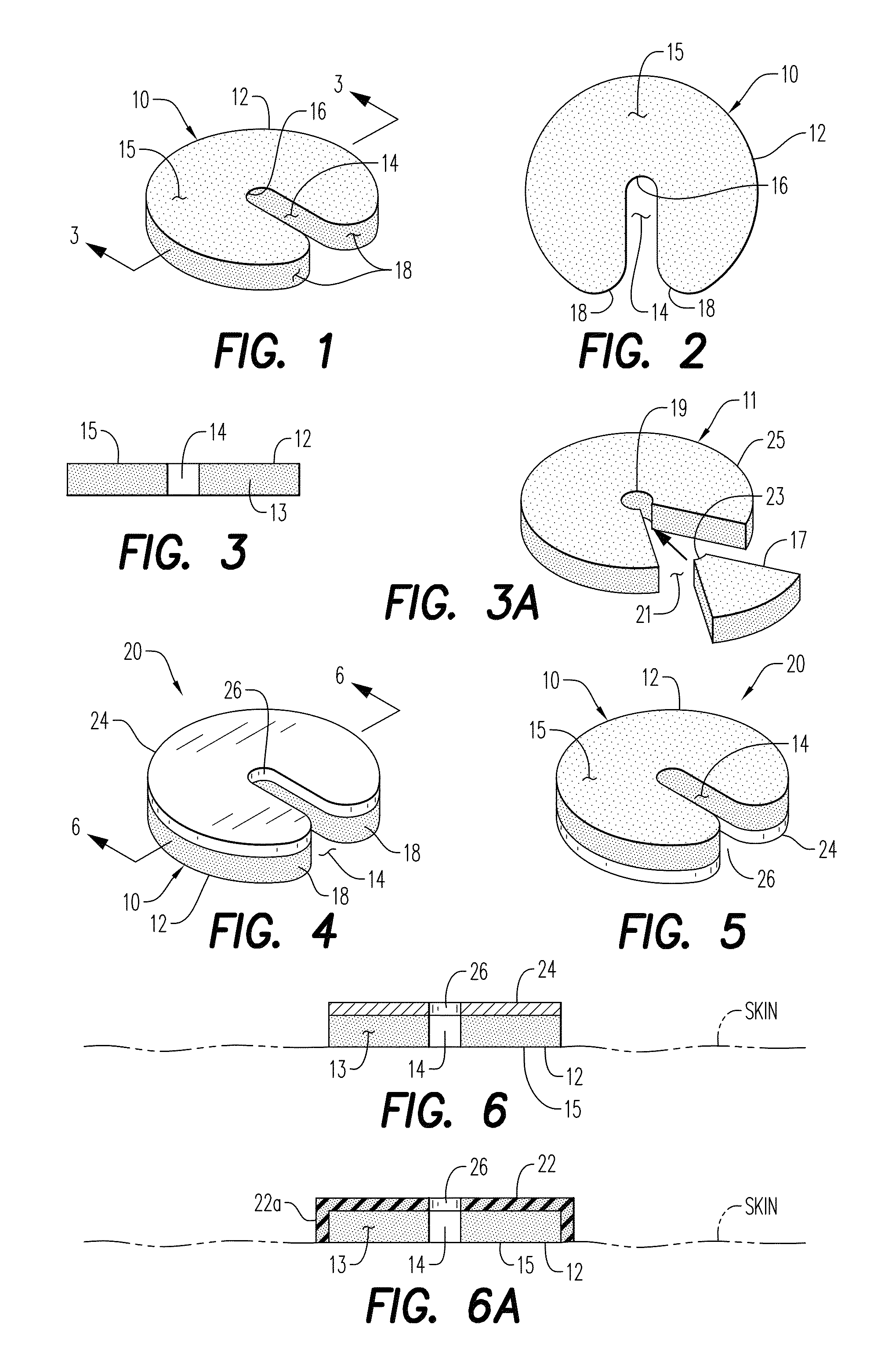

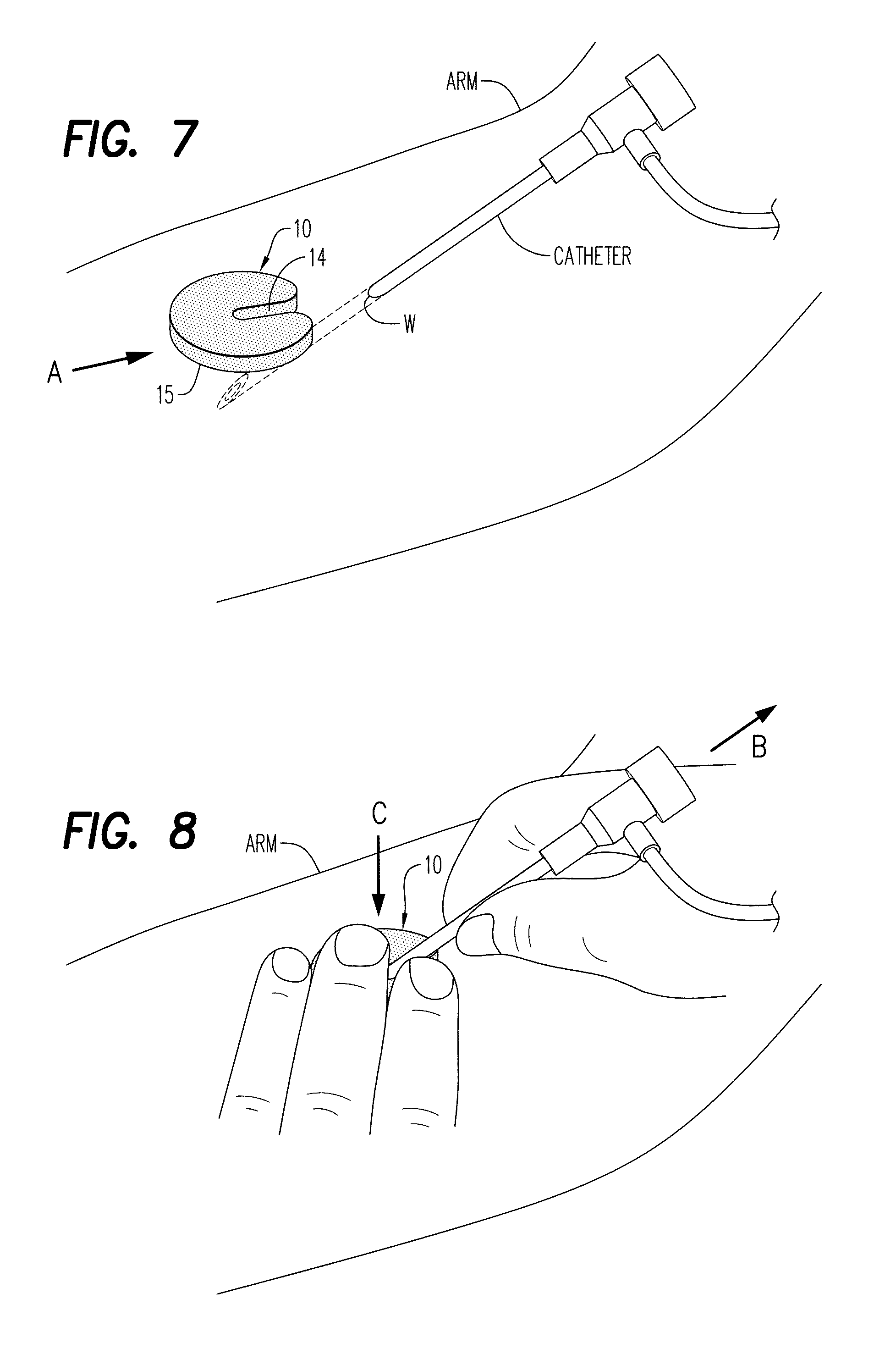

Hemostatic device and method

ActiveUS8961479B2Improved delivery and controlSlow actingSurgical adhesivesSurgical needlesHEMOSTATIC POWDERThin layer

A hemostatic tablet preferably including potassium ferrate and a cation ion exchange resin pressure formed into a tablet for delivery to a bleeding wound. The tablet improves the rate of adhesion to a bleeding wound surface, and allows a significantly greater and more uniform pressure to be exerted by manual compression of the tablet on the wound site, as compared to that of a thin layer of scattered hemostatic powder. After the seal is formed from the interaction of blood or exudates with the immediate contacting surface of the tablet, the bulk of the unused tablet easily delaminates from the seal making clean up facile. If the unused portion of the tablet is not removed from the wound site, a reservoir of hemostatic dressing stops further bleeding and to provide antimicrobial protection and healing. The tablet may be applied to any surface orientation and take any shape and thickness possible.

Owner:BIOLIFE

Combined flocculant

InactiveCN103241817AReduce manufacturing costReduce the amount of feedWater/sewage treatment by flocculation/precipitationMetasilicatePotassium ferrate

The invention discloses a combined flocculant composed of the following components in parts by weight: 5-10 parts of polymeric aluminum calcium chloride, 10-20 parts of aluminum trichloride, 10-20 parts of ferric citrate, 5-8 parts of polysulfide ferric chloride, 6-9 parts of polymeric ferric metasilicate, 2-3 parts of potassium ferrate, 5-10 parts of polyaluminum chloride, 10-15 parts of soluble coatings and 3-5 parts of flocculant activating components, wherein the flocculant activating components are selected from one or a combination of two from porous perlite micro powder and coal ash micro powder, and the particle size of the porous perlite micro powder is 200-300. The combined flocculant is good in humidity resistance, favorable in quality stability, long in quality guarantee period, high in adaptability for the natural environment and convenient to use.

Owner:CHUZHOU YOULIN TECH DEV

Environment-friendly composite ferrous sulfide passivator and preparation method thereof

InactiveCN104263408AStable in natureFast passivationTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateSpontaneous combustion

The invention discloses an environment-friendly composite ferrous sulfide passivator which is composed of the following components in percentage by mass: 5-10% of sodium pyrosulfate, 10-25% of sodium hypochlorite, 1-10% of trisodium phosphate, 0.5-7% of sodium hydrogen carbonate, 20-35% of sodium hydroxide, 1-2% of potassium ferrate and 30-60% of water; and the environment-friendly composite ferrous sulfide passivator is prepared by uniformly mixing the components according to a specific step order. The environment-friendly composite ferrous sulfide passivator disclosed by the invention is efficient, is free of toxicity, corrosive property and secondary pollution and is capable of quickly passivating ferrous sulfide and effectively preventing spontaneous combustion of ferrous sulfide; the passivator has a good cleaning effect on such malodorant as hydrogen sulfide, ferrous sulfide passivation time is 8-10h and more than 98% of ferrous sulfide is removed, and shutdown time of a device is correspondingly shortened; and a protective film is formed on the surface of passivated metal, so as to effectively prevent metal surface from being further corroded.

Owner:JINAN RUIDONG IND

Compound sewage treatment adsorbent

InactiveCN104138740AImprove decontamination abilityOther chemical processesIron compoundsSorbentSewage

Owner:肇庆永信塑料助剂科技有限公司

A method for separating and recovering ammonia in ultra-high concentration ammonia nitrogen wastewater

InactiveCN102259967AEfficient separationEfficient separation and recoveryEnergy inputWater/sewage treatmentHigh concentrationPotassium ferrate

The invention provides a method for separating and recovering ammonia from ultrahigh concentration of ammonia nitrogen wastewater. The method comprises separation and recovery and is characterized in that the separation process comprises: firstly pumping the ultrahigh concentration of ammonia nitrogen wastewater into an aeration tank of a denitrogenation tower, adding a denitrogenation agent, andcarrying out aeration treatment with a blower or compressed air at the pH not smaller than 9.5 and the temperature of 45-55 DEG C until the content of ammonia nitrogen in the wastewater is decreased to below 10 mg / L, wherein the denitrogenation agent is formed by mixing 60-70wt% of sodium carboxymethyl cellulose, 10-20wt% of butanediol transaminase, 5-10wt% of potassium ferrate and 5-10wt% of sodium persulfate and has a concentration of 10-30 ppm; and introducing the separated ammonia gas into a multi-stage absorbing tower from the tower top. Through once treatment of the method provided by the invention, the content of ammonia nitrogen in the ultrahigh concentration of ammonia nitrogen wastewater is decreased to below 5 mg / L, the separated ammonia is recovered, and the waste heat is simultaneously utilized.

Owner:陈平 +2

Potassium ferrate slow-release composite material as well as preparation method and use thereof

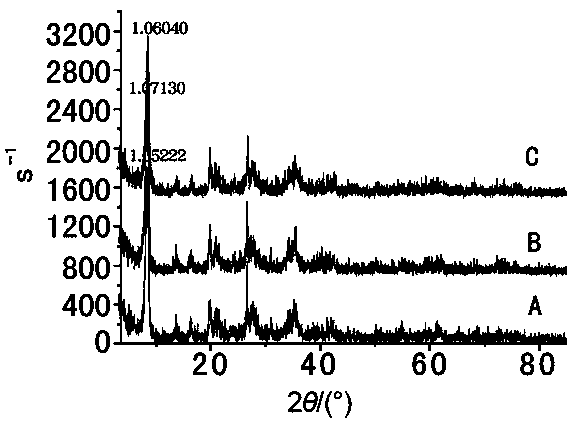

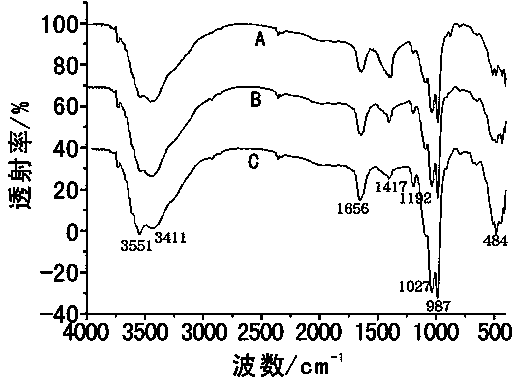

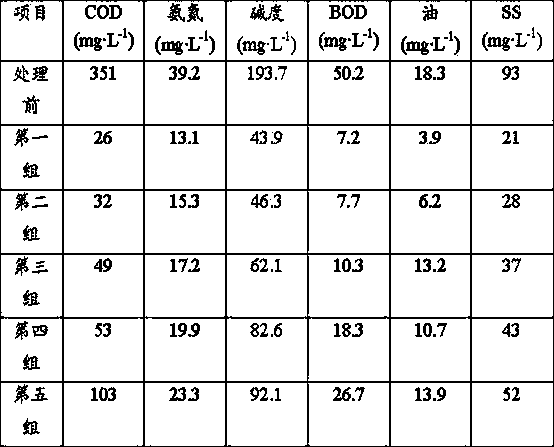

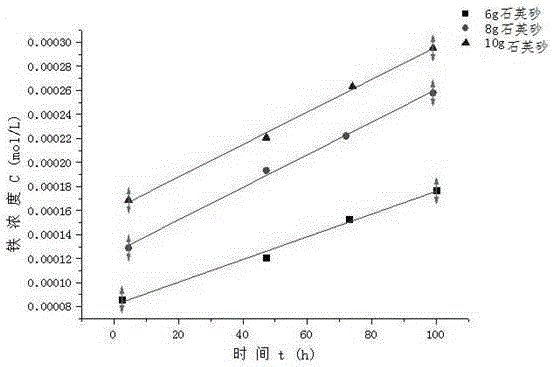

InactiveCN105174677AReduce releaseSustained releaseSludge treatment by oxidationBiological sludge treatmentPotassium ferrateQuartz

The invention discloses a potassium ferrate slow-release composite material as well as a preparation method and use thereof, belonging to the technical field of environment protection. The preparation method of the potassium ferrate slow-release composite material comprises the following steps: firstly, uniformly stirring and mixing quartz sand with potassium ferrate powder, so as to form a quartz sand-potassium ferrate mixture; then adding the quartz sand-potassium ferrate mixture into molten paraffin while heating, rapidly stirring until the mixture is completely infiltrated by the molten paraffin, so as to form a quartz sand-potassium ferrate-paraffin mixture; finally, rapidly pouring the quartz sand-potassium ferrate-paraffin mixture into a mold when the mixture is hot, carrying out compaction, and cooling, so as to obtain the potassium ferrate slow-release composite material. The potassium ferrate slow-release composite material has the advantages of high utilization rate, good processing effect, low cost, long duration time, easiness in acceptation by the public and the like. The preparation method is simple, convenient and rapid, and the raw materials are low in cost and easily available; the potassium ferrate slow-release composite material has the multiple effects in the removal process of organic pollutants in bottom mud and is also nontoxic and harmless to the environment.

Owner:WUHAN UNIV

Preparation method of carbon-manganese dioxide composite material

ActiveCN108217733AWide variety of sourcesLow costMaterial nanotechnologyManganese oxides/hydroxidesPotassium persulfatePhosphoric acid

The invention provides a preparation method of a carbon-manganese dioxide composite material. The preparation method is characterized by comprising the following specific steps: carrying out intercalation-expansion treatment on a raw material graphite to obtain graphene-like expanded graphite, wherein an intercalation agent is prepared from acid and an oxidant, the acid is one or more of sulfuricacid, phosphoric acid and nitric acid and the oxidant is one or more of potassium permanganate, potassium ferrate and potassium dichromate; an expansion agent is prepared from acid and an oxidant, theacid is one or two of the sulfuric acid and the phosphoric and the oxidant is one or more of hydrogen peroxide, ammonium persulfate, potassium persulfate and sodium persulfate; enabling the graphene-like expanded graphite and potassium permanganate to react under a shaking or standing condition; carrying out water washing to obtain the carbon-manganese dioxide composite material. In the compositematerial, a conjugated structure of a carbon material keeps relatively good and manganese dioxide vertically grows on the surface of a carbon nano-sheet. The carbon-manganese dioxide composite material prepared by the preparation method can be widely applied to fields including supercapacitors, lithium-ion batteries, fuel cells, energy conversion and the like.

Owner:ZHEJIANG SHANYU TECH CO LTD

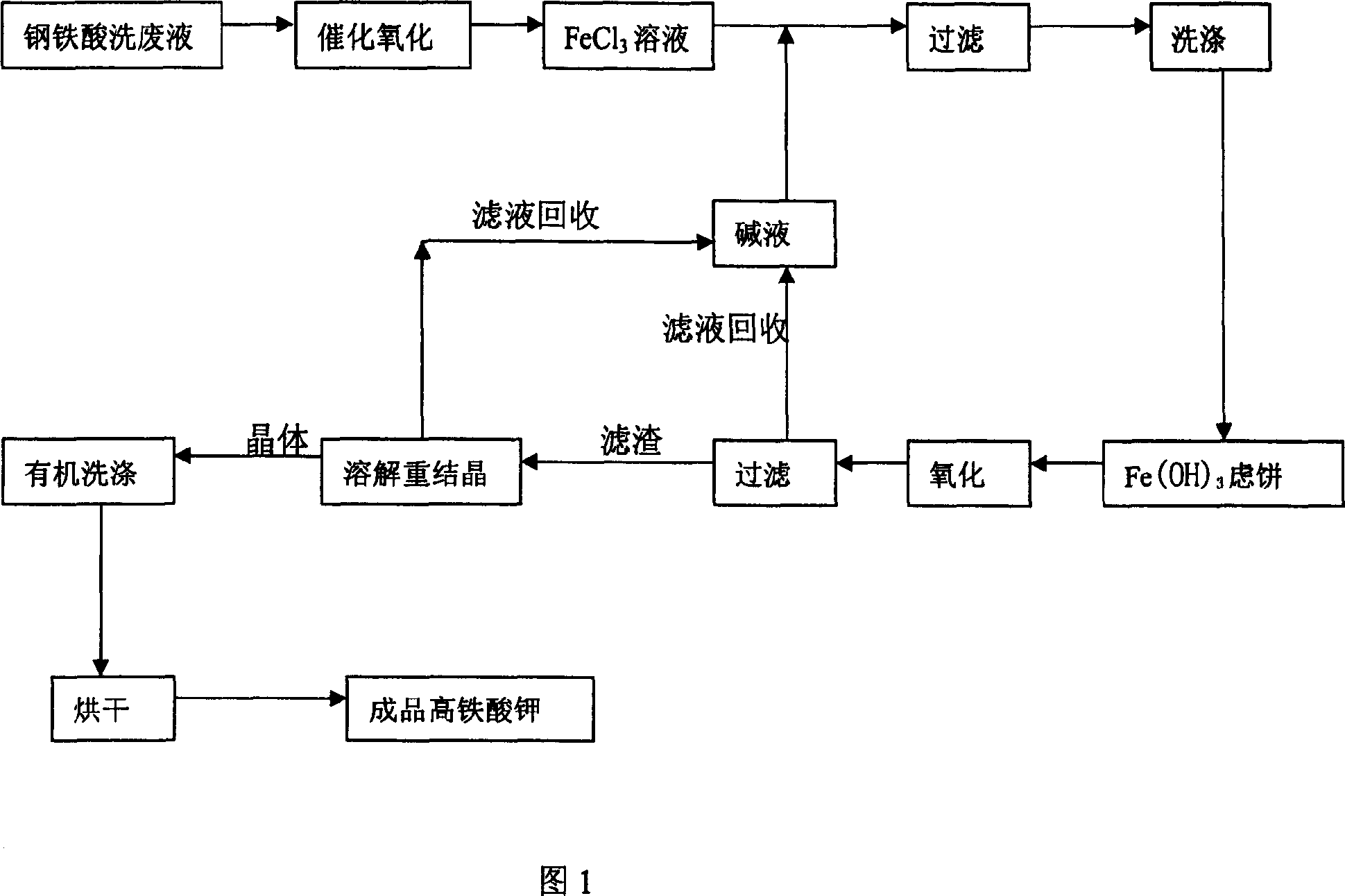

Method for preparing potassium ferrate by using waste liquid from acid washing steel

InactiveCN1958462AAvoid pollutionEasy to operateMultistage water/sewage treatmentIron compoundsOrganic solventAcid washing

This invention relates to a method preparing potassium ferrate from steel acid-washing waste liquid. The method comprises: oxidizing bivalent iron ions in steel acid-washing waste liquid into trivalent iron ions, precipitating trivalent iron ions to obtain Fe (OH) 3, and oxidizing Fe (OH) 3 by KClO in a strong alkaline condition to obtain potassium ferrate. The process mainly comprises: catalytically oxidizing, filtering the precipitate, oxidizing by KClO, recovering the filtrate, recrystallizing for purification, and washing with organic solvent. The method is environmentally friendly.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com