Multifunctional water treatment agent used for treating refractory wastewater

A water treatment agent, multi-functional technology, applied in adsorption water/sewage treatment, oxidized water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The effect of reducing COD concentration and biological toxicity, good effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A multifunctional water treatment agent for treating refractory wastewater, which is prepared through the following steps:

[0031] (1) Bentonite modification: Weigh 1 part by weight of bentonite and pour it into 10 parts by weight of 3% cetyltrimethylammonium bromide aqueous solution, stir at room temperature for 2 hours, centrifuge, After washing, place it in a constant temperature drying oven at 50°C to dry, and grind it through a 180-mesh sieve to obtain modified bentonite;

[0032] (2) Potassium ferrate loading: put 1 part by weight of modified bentonite into 10 parts by weight of pH 7.8 and concentration of 10×10 -3 mol / L potassium ferrate aqueous solution for loading, after 48 hours to reach the saturated state, it can be obtained after natural air-drying.

[0033] The water treatment agent prepared by the above method is used for the pretreatment of landfill leachate. Add 5g / L water treatment agent to the landfill leachate to be treated. After stirring for half...

Embodiment 2

[0039] A multifunctional water treatment agent for treating refractory wastewater, which is prepared through the following steps:

[0040] (1) Bentonite modification: Weigh 1 part by weight of bentonite and pour it into 15 parts by weight of cetyltrimethylammonium chloride 10% ethanol aqueous solution with a mass percentage of 4%, and stir at room temperature for 1 hour. After centrifugation and washing, it is dried in a constant temperature oven at 50°C, and ground through a 200-mesh sieve to obtain modified bentonite;

[0041] (2) Potassium ferrate loading: put 1 part by weight of modified bentonite into 15 parts by weight of pH 7 and concentration of 12×10 -3 mol / L potassium ferrate aqueous solution for loading, after 45 hours to reach saturation, it can be obtained after natural air-drying.

[0042] The water treatment agent prepared by the above method is used for the pretreatment of landfill leachate. Add 5g / L water treatment agent to the landfill leachate to be treated. ...

Embodiment 3

[0047] A multifunctional water treatment agent for treating refractory wastewater, which is prepared through the following steps:

[0048] (1) Bentonite modification: Weigh 1 part by weight of bentonite and pour it into 20 parts by weight of 5% cetyltrimethylammonium bromide aqueous solution, stir at room temperature for 3 hours, and centrifuge. After washing, put it in microwave drying, and grind it through a 150 mesh sieve to obtain modified bentonite;

[0049] (2) Potassium ferrate loading: put 1 weight part of modified bentonite into 20 weight parts of pH 8.6 and concentration of 15×10 -3 mol / L potassium ferrate aqueous solution for loading, the loading reached saturation state after 52 hours, and it was obtained after natural air-drying.

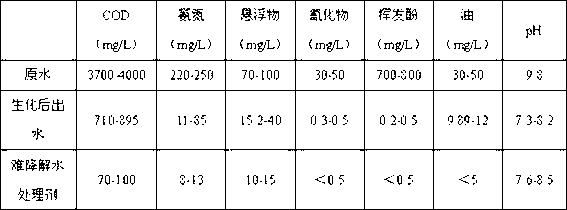

[0050] The water treatment agent prepared by the above method is used for the advanced treatment of coking wastewater, and 2g / L of water treatment agent is added to the coking wastewater to be treated for treatment. After stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com